Abstract

Conserving the world’s cultural and natural heritage is considered a key contributor to achieving the targets set out in the United Nation’s Sustainable Development Goals, yet how much attention do we pay to the methods we use to conserve and protect this heritage? With a specific focus on wooden objects of cultural heritage, this review discusses the current state-of-the-art in heritage conservation in terms of sustainability, sustainable alternatives to currently used consolidants, and new research directions that could lead to more sustainable consolidants in the future. Within each stage a thorough discussion of the synthesis mechanisms and/or extraction protocols, particularly for bio-based resources is provided, evaluating resource usage and environmental impact. This is intended to give the reader a better understanding of the overall sustainability of each different approach and better evaluate consolidant choices for a more sustainable approach. The challenges facing the development of sustainable consolidants and recent research that is likely to lead to highly sustainable new consolidant strategies in the future are also discussed. This review aims to contribute to the ongoing discussion of sustainable conservation and highlight the role that consolidants play in truly sustainable heritage conservation.

1. Introduction

Wood is an anisotropic, hierarchical material with a three-dimensional fibrous structure composed primarily of cellulose and hemicelluloses, that self-assemble on the nanoscale and are bound into the macroscale structure of wood tissue by lignin [1,2,3]. It is a widely available natural resource that has been used for centuries to create everything from kitchen utensils to dwellings and transportation. As such, wooden artefacts are common objects in the historical record [3].

Depending on where a wooden artefact is found it will have been subjected to a variety of biotic and abiotic stresses that exert significant influence on the extent and the speed of its degradation [4,5,6,7]. All wooden objects will have been exposed to a greater or lesser extent to abiotic factors such as temperature, light, and moisture. Degradation as a function of normal abiotic stress is generally rather slow and such objects can often be displayed or stored with minimal or no active consolidation, although storage in a controlled environment would be recommended to maintain the slow rate of natural degradation [8,9]. At extremes of abiotic stress, particularly moisture, accelerated biotic degradation is often encountered, primarily in the form of wood-decaying fungi and bacteria, although insects and marine borers are also common in certain environments [4]. The action of these organisms can significantly speed up the degradation of wood, through the decomposition of the cellulosic or lignin components, which is highly dependent on the organism. Their action requires mitigation through the use of biocides and/or consolidant treatments to hinder biological activity and maintain the mechanical stability of the artefact. In the majority of cases, the consolidants employed are polymers derived from petrochemical refining.

The Sustainable Development Goals, which form part of the United Nations Agenda for 2030, list strengthening “efforts to protect and safeguard the worlds’ cultural and natural heritage” as a key target to achieving safe, resilient, inclusive and sustainable cities and human settlements (Goal 11) [10]. However, the methods we use to achieve this conservation are not always sustainable themselves. While some natural resins and inorganic minerals are used in wood conservation, many consolidants are petroleum-based. Poly(ethylene glycol) (PEG) [11,12,13,14,15], epoxy-based glues [16], melamine-formaldehyde (MF) resins [17,18,19] and acrylate or methacrylate copolymers [20,21] are all regularly employed in conservation of wooden objects of cultural importance. As these treatments are by-products of the petroleum industry, their production is inherently unsustainable [22]. The result is that we regularly use highly unsustainable materials, often in large quantities, to ‘sustain’ our cultural heritage.

Currently, only 5–20% of extracted crude oil is refined into chemicals at most refineries [22], with the remainder being used for energy and transportation. This includes the raw materials to produce PEG, MF resins, epoxy, alkoxide (alkoxysilane), methacrylate and acrylate consolidants. With the signing of the Paris Agreement in 2015 [23,24,25,26,27,28], many countries and institutions pledged to phase out the use of fossil fuels by 2050. What does this mean for the polymers used regularly in the conservation laboratory? One would think that phasing out fossil fuels in the energy sector would reduce the attraction of oil refining and force a switch to more renewable chemical consolidants. Unfortunately, this may not be the case [29]. The reduction in demand for oil for energy and transport means refineries and oil companies are changing their business models and refocusing on petrochemical production [30]. In the coming two decades, petrochemicals will likely make up almost 80% of the products of oil refineries [22]. This significant increase in the availability of non-renewable raw materials for polymers will drive the cost of virgin polymers and plastics down, to the point that it may be more cost-effective to continue using non-renewable consolidants than recyclable or bio-based alternatives [31]. Knowing that cultural institutions often run on very lean budgets [32], the barrier to creating more sustainable conservation methods will increase significantly.

Despite this significant economic driver towards less sustainable conservation practices, the continuation of unsustainable practices across all fields will eventually lead to significant and irreversible damage to our environment with extraordinary economic costs [33], that no amount of cheap petroleum-based products will stem. Thus, there are two strategies we need to enact to ensure a more sustainable conservation practice and do our part to reduce the impact of petroleum-based products on the environment. In the short term, we need to choose sustainable alternatives to current consolidants. This is not a perfect solution, as bio-based alternatives to petroleum-based chemicals are often just as environmentally unfriendly and difficult to dispose of as their fossil-based counterparts [34]. However, their bio-based sourcing does reduce the environmental impact of their production. Unfortunately, commercially available, sustainably sourced alternatives do not exist for all commonly used consolidants. Thus, the longer-term strategy is to explore new bio-inspired alternatives to our current consolidants. This not only requires advances in materials science research but also a mindset shift across all levels of the museum and conservation hierarchy. We must move away from the unsustainable state-of-the-art and embrace sustainable consolidants as a key aspect of the future conservation toolkit, alongside environmentally friendly conservation practices (i.e., use and disposal of gloves and other consumables) and replacement of lighting and ventilation systems with low energy alternatives [35]. Over the following sections, the current state-of-the-art in conservation treatments will be discussed with a specific focus on sustainable alternatives to petroleum-based consolidants and new directions in sustainable consolidant design.

2. Consolidants for Wooden Heritage Objects: The Current State-of-the-Art

In the context of wooden objects of cultural importance, there are several commonly used consolidants. These treatments can be broken down into three principal categories: synthetic, inorganic and bio-based. In the following sections, an overview of the various aspects of consolidant production is given to heighten awareness of the sustainability and environmental impact of the processes involved in their production. This is not a thorough life cycle analysis of each material, which would be outside the scope of this review. However, if we are to increase sustainability in wood conservation, we must be aware of the processes involved in the production of consolidants, to understand whether treatments marked as sustainable alternatives are really an improvement on the state-of-the-art.

Inorganic treatments are the least commonly used in wood conservation, being more heavily exploited in stone and masonry conservation. Those that are used can be divided into two categories-inorganic nanoparticles (INPs) and inorganic polymers. INPs are primarily mined rather than synthesised, thus, their discussion requires a detailed look at the sustainability and practices of the mining industry, which is also too broad a discussion for this review. As such, the discussion of inorganic consolidants will be limited to inorganic polymers that include a petroleum-based component, such as alkoxymethylsilanes. These inorganic polymers are included under the synthetic consolidant section.

2.1. Bio-Based Consolidants

Interestingly, the origins of wood consolidation are rather sustainable, insofar as the consolidants have been obtained from renewable resources. Natural resins, oils, and waxes have long been used to preserve and treat wood [36,37,38,39]. Waxes (e.g., beeswax obtained from the hives of honey bees (Apis mellifera Linneaus, 1758)), resins (e.g., colophony (rosin) obtained from the sap of various pine (Pinus spp.) species) and oils (specifically linseed (from Linum ussitatissimum L.) and Tung (from Vernicia fordii (Hemsl.) Airy Shaw), have been used to fill cracks, stabilise mechanical properties and enhance the aesthetic qualities of wooden objects for centuries [3]. Their hydrophobicity is also used to improve the water-repellency of wood, reducing susceptibility to bacterial degradation. With the advent of industrial-scale extraction of sucrose for the food industry, sugar conservation also became popular, due to the increased mechanical stability of sugar-conserved wood and its realistic wood-like appearance. Non-reducing sugars and sugar alcohols have also been introduced to the conservation toolkit over the years.

A common misconception is that bio-based consolidants, being obtained from nature, are more sustainable than petroleum-based chemicals. While this is generally true with respect to the renewability of the resource, the methods of cultivation and the processes used to extract and refine these bio-based consolidants into a useable form are often highly damaging to the environment and this must also be taken into consideration. These aspects are discussed in more detail in the following sections.

2.1.1. Oils

Within this class, oils from linseed and tung are the most commonly used. Their relatively low viscosity means that they are used both to enhance the surface aesthetics of the wood by creating a varnished look, as well as penetrate deeper into wooden objects, enhancing the hydrophobicity within their structure [3].

Linseed oil is obtained from flax (L. ussitatissimum), an annual crop that exists in two forms, fibre flax and linseed [40]. The former produces high-quality fibres used in the textile industry as linen, while the latter produces lower quality fibres but large quantities of oilseed, from which linseed oil is extracted. With its popularity in the food, textile and automotive industries, it is widely cultivated across North America and large parts of Europe, in areas with cooler temperatures and high rainfall that mean little demand for additional water to maintain crop growth [40]. Otherwise, the cultivation of flax is highly resource-intensive and damaging to the environment. Both flax cultivars have poorly developed root systems and low nutrient uptake, with a low resistance to pests, weeds and disease. Thus, they rely heavily on the use of agrochemicals, derived from petroleum, to sustain high outputs matching demand. High use of agrochemicals combined with soil runoff due to the poor structure of flax roots contributes to eutrophication and degradation of soil quality. Crop rotations with potatoes and beets, known for their excellent soil structuring and cleaning properties, as well as employing organic manure and natural pest control systems can help reduce the environmental impact of flax leading to more sustainable cultivation and a lower environmental impact [41], however, this is not yet the state-of-the-art. In terms of oil extraction, while cold mechanical pressing is used to obtain food-grade linseed oil [42], warm pressing or solvent extraction is used to retrieve linseed oil for conservation purposes [43]. These techniques lead to greater oil expression but require more input energy or the use of toxic (petroleum-based) solvents, which then require incineration further impacting the environmental footprint of linseed oil. More recently, supercritical and green solvent extraction methods have been explored to extract comparable quantities of oil from oilseeds as their less environmentally friendly counterparts [43,44]. This will hopefully lead to a further reduction of the environmental impact of linseed oil production on the environment. On a positive note, despite their lower fibre quality, fibres from linseed are used as reinforcements in the automotive industry, valorising the waste from oil production and improving the sustainability of crop cultivation, with less material going to waste [40]. A disadvantage of linseed oil as a consolidant is its slow-drying nature, which can lead to softening of the wood during the drying period. This affects the stability of the artefact and has led to much research on improving the drying properties of linseed oil through chemical modifications of the triglyceride structure. An example of this is the epoxidation of linseed oil to create linseed oil-based epoxy resins [45,46], which are discussed in more detail in Section 3.2. While these modifications have significantly enhanced their application in wood conservation, they have impacted the sustainability of linseed oil by reducing the resource efficiency of the consolidant production. Interestingly, while these modifications reduce the sustainability of linseed oil as a consolidant, epoxidised linseed oil is seen as a major improvement to the sustainability of epoxy consolidants, removing a significant amount of the non-renewable component of these adhesives.

Tung oil is obtained from the fruit of the tung tree (V. fordii) native to southern China. Tung oil has been used for centuries in China as a wood consolidant and for waterproofing of wooden ships and boats [47]. Its fast-drying nature is an enhancement over the slow-drying properties of linseed oil [48]. This can, however, lead to issues with heterogeneous film formation and incomplete protection of heritage wood, when used alone as a wood consolidant. Thus, combination with thinners is generally recommended to enhance the overall protection of the wood. Interestingly, this fast-drying property led to increased demand for tung oil in the paint industry in the early part of the 20th century to create fast-drying paints with a lower environmental footprint [49,50]. Thus, tung trees were cultivated on an industrial scale to match this new demand. Unlike, the industrial-scale cultivation of linseed, tung trees created a much lower environmental impact. Firstly, tung is a perennial crop, and while it cannot be said that perennials are always more environmentally benign than annual crops due to various dependencies on agrochemicals, the continual growth cycle in comparison to the fragile seedling stage that must be revisited each year does generally reduce overall environmental burden [51]. Perennial crops, combined with low reliance on agrochemicals, are seen as an integral component of sustainable agriculture [52]. Moreover, tung trees have a highly efficient photosynthesis mechanism that leads to initial fruiting, and thus initial oil production, within three years, one of the fastest of all commercial oil crops [53]. The hardy nature of the tung tree reduces the need for extensive agrochemicals, as such, the overall cultivation of tung oil is relatively environmentally friendly. With respect to oil extraction, the same methods are employed with equal environmental concerns as for other oilseeds. However, the advent of green extraction processes, as detailed previously, will likely contribute to further improvement of the overall environmental impact of tung oil, making it one of the most sustainable wood consolidants currently available.

2.1.2. Waxes and Resins

In contrast to linseed and tung oil, colophony, and beeswax, due to their high viscosity, have generally been confined to surface treatment [37]. Their major advantages are the ability to fill gaps in the wood surface and bind fragile fragments of the surface, preventing loss and increasing mechanical stability. Their high viscosity, however, means that they often must be heated to penetrate the surface of the wood. Depending on the state of degradation of the wood, the high temperature of the melted treatment can cause darkening of the wood or weakening of the structure if the glass transition temperature of the remaining wood components is exceeded [3].

Looking first at beeswax, produced from the wax secreting glands of the honeybee (A. mellifera) [54,55]. The primary function of the wax is to template the formation of the honeycomb that will eventually breed larvae and store pollen and the resulting honey [56]. On a small scale, beeswax is extracted by first warming (35–40 °C) and liquefying the honey. As beeswax melts between 60–65 °C, the wax remains solid and can be filtered from the surface of the liquid honey and then cleaned. This can be melted to form wax cakes that are used for a variety of applications. Bees are not physically harmed by the extraction of the wax from the hive and can continue to thrive after extraction by ‘re-combing’ the hive, thus, it is generally thought that beeswax is a sustainable natural product. However, very little wax is extracted from small apiaries, thus, beeswax is often obtained from industrial beekeeping. The link between industrial beekeeping and monocultures, specifically almond and avocado crops, with respect to the high use of agrochemicals and their environmental impact raises questions about the sustainability of beeswax [57]. The environmental impact of monocultures means we must reconsider the environmental sustainability of beeswax [58,59,60]. This wax is more commonly extracted using solvent heavy extraction processes involving petroleum-derived dimethylformamide and hexane, to ensure removal of pesticides from the final wax product [61]. Moreover, industrial hives are often sacrificed after the harvest to reduce the cost of sustaining colonies over winter [57], thus, increasing the negative environmental and, for many, the ethical impact of the use of beeswax.

Resin tapping, the process by which colophony is obtained from many species of pine (Pinus spp.), is a simple process in which a section of bark is removed, and an incision is made in the outer layers of the tree to encourage resin secretion [62]. A vessel is attached to the tree to collect the expressed resin, a process which is often repeated exhaustively until the tree is felled. Resin tapping is often an integral part of sustainable forestry management for a number of reasons, including the increase in production of resin within the tree as a function of tapping, making it a renewable bio-resource [63]. Moreover, resin tapping increases the profitability of pine stands, creating a sustainable source of income in economically depressed and rural areas [64]. Resin tapping activities also promote increased forest management, often resulting in a lower incidence of forest fires. Many studies have also examined the impact of pine tapping on the wood quality and sensitivity of the trees to climatic and environmental stress [65,66,67,68]. While there is often mechanical damage to the wood at the site of tapping, overall, the impact on the quality of the felled wood has been negligible. In fact, some studies have shown that tapped wood is more elastically deformable and less rigid and brittle than untapped wood, contributing to the increased value of the felled wood [69]. Furthermore, it has been observed that tapped trees are no more sensitive to climatic changes and environmental stress than untapped trees, meaning no reduction in stability of forest stands due to resin extraction. Thus, colophony, at least from a sourcing point of view, is an extremely sustainable, environmentally responsible consolidant. Obtaining rosin, and its more valuable counterpart, turpentine, from the tapped resin is a more energy-intensive process known as destructive distillation [70]. Here, the resin is heated to just over 200 °C to distil off phenols and terpenes and degrade unnecessary biological components of the tar (wood shards, insects, etc.), the remaining gum is the rosin, which is then washed and recrystallised several times using ether and 1% solutions of NaOH to give a pure rosin cake. In comparison to its highly sustainable and environmentally friendly sourcing, extraction of pure rosin is more energy and resource-intensive. However, advances in green solvent extraction, already discussed with respect to linseed oil extraction could certainly be employed to reduce the environmental impact of the extraction process, increasing the overall sustainability of the final consolidant.

2.1.3. Sugars and Sugar Alcohol

Sugars, particularly sucrose obtained from sugarcane (Saccharum spp.) and sugar beet (Beta vulgaris L.), have also long been employed in the conservation of wooden objects [71]. For conservation, objects are immersed in high concentration solutions that penetrate the wood structure. Controlled drying of the artefact leads to the formation of crystals within the structure that stabilise the wood and enhance mechanical stability [71]. While sucrose is widely available at low cost, due to its use in the food industry, care must be taken during impregnation to avoid bacterial infestations of the wood due to the affinity of bacteria for the sugar solutions and during drying to prevent the formation of excessively large crystals that could rupture the wood cells.

Both sugarcane and beet are cultivated extensively for use in the food industry. In 2020, sugar production reached 187 million tonnes and is set to increase by 3%, to 193 million tonnes, by the end of 2021 [72]. Sugar production has not historically been an environmentally friendly crop, with the tendency to grow sugarcane in extensive monocultures that are highly detrimental to biodiversity and soil quality [73,74]. Monocultures generally require extensive use of agrochemicals to ensure resistance to pests, further damaging soil quality. However, since the mid-2000s, efforts have been made by some of the world’s largest sugar producers, particularly in the UK (beet) and Brazil (cane), to improve the environmental impact of both sugar crops. With respect to beet, there is a tendency to grow crops in rotation rather than in monocultures [75] and the advent of green biotechnology has allowed the cultivation of new varieties with greater pest resistance, contributing to a 65% reduction in the use of agrochemicals from 2.0 kg/tonne of beet crop in 1975–80 to 0.7 kg/tonne in 2006 and 2007 [76]. In the UK, this has been reduced even further to total agrochemical usage of 414.5 tonnes in 2018 for a beet production of 6.94 million tonnes, equating to 0.06 kg/tonne [77], a reduction of 97% from 1980s levels. In Brazil, where sugarcane is the primary sugar source, the enhancement of biodiversity on sugar plantations has considerably improved the impact of cane cultivation on the environment. Growing specifically selected complementary crops alongside sugarcane attracts a variety of wildlife and insects that are natural predators of sugarcane pests, thus functioning as natural pest control, reducing or eliminating the need for agrochemicals [78]. One of the best examples of this is the sugarcane plantations of the Balbo group, which alone produces 34% of the worlds exported sugar [79]. Their plantation is now exclusively maintained by organic and sustainable agriculture practices improving the environmental impact of sugar cultivation.

Despite significant advances in the enhancement of the sustainability of sugar crops, extraction of sucrose from cane or beet is an energy-intensive process [80], in which the cane is crushed and milled and beet is sliced and diffused to extract the raw juice. This is then followed by heating, liming and clarification (in a different order depending on the starting material), and finally, filtration in the case of beets, to produce the thin juice that is then evaporated and crystallised to give raw sugar. Further refining is carried out to give the white sugar we recognise as table sugar or sucrose [76]. To offset the energy demands of extraction, many sugar refineries are switching to renewable energy to drive these processes, reducing CO2 emissions in the process. In some cases, this renewable energy is even produced from the by-products of the pulping process, specifically bioethanol and biogas from the fermentation of the beet pulp or sugarcane bagasse, creating a circular system for the extraction of sugar and the valorisation of waste products. Further valorisation of waste products from sugar production includes renewable energy, animal feed, soil enhancers and bio-fertilisers and bioethanol. As such, at many refineries very little of the by-products of the sugar extraction go to waste, creating a more sustainable and circular system with reduced environmental impact. One of these waste products, sugarcane bagasse [81], is the starting material for bio-glycerol production and will be discussed in more detail in Section 3. Thus, in terms of sustainable consolidants, sucrose is certainly an increasingly environmentally friendly option.

Some alternatives to sucrose have also been explored, specifically lactitol, a sugar alcohol obtained from lactose, and trehalose, a non-reducing sugar found in prokaryotes. While their chemical and environmental stability is much greater than that of sucrose, particularly with respect to bacterial infestation, the dimensional stability of artefacts treated with these alternatives has been observed to be rather inhomogeneous [71]. As such, lactitol and trehalose conservation are rather labour-intensive consolidants in terms of maintaining homogeneity of treated wood, but what of their sustainability?

In the last decade, whey protein has become increasingly interesting as a food additive, improving the texture and nutritional value of a variety of food products [82]. A by-product of whey protein isolate is the milk sugar lactose. The extent of whey protein isolate is such that demand for lactose, a sparsely soluble, low-sweetness sugar, is far outstripped by supply, resulting in large amounts of wastage [82]. Thus, strategies to increase the profitability of lactose by converting it into other high-value products have gained considerable traction. One of these products is lactitol, produced from the catalytic hydrogenation of lactose [82,83]. Lactitol is valued for numerous applications, from low-calorie sweetener to emulsifying agents for polymer and surfactant formulations and, of course, bulking agent and cryo-protective [82], for which it is employed in wood conservation. It is difficult to fully assess the sustainability of lactitol being a by-product of the dairy industry, which can range from very environmentally friendly to highly unsustainable. However, as lactose is a low-value by-product of whey protein isolate, the production of lactitol prevents significant amounts of lactose from being destroyed. As such, it can be considered a positive impact. The catalytic hydrogenation of lactose, or the introduction of hydrogen to the carbonyl group of lactose, currently relies on the use of transition metal catalysts, a finite resource, along with high temperatures (110–200 °C, catalyst dependent), high pressures (10–60 bar) and up to 6 h reaction times. This makes it highly energy and resource-intensive. Moreover, only Ru and Ni catalysts have been shown to produce highly selective hydrogenations (>90%), while Cu (68%) and Pd (30%) have much poorer outcomes [82]. Current manufacturing protocols, thus, impact the overall sustainability of lactitol as a wood consolidant. While not widely used for the hydrogenation of lactose, organocatalytic methods need to be introduced more widely in manufacturing protocols to improve the environmental impact of such waste product valorisation. Organocatalysis relies on the use of small-molecule organic catalysts to promote efficient, low energy and low-temperature transformation, and has revolutionised and improved the environmental impact of catalytic processes in the pharmaceutical and fine chemical industries [84]. Hopefully the recent awarding of the 2021 Nobel prize in Chemistry for organocatalysis [85] will further the uptake of this green methodology in more industrial applications, contributing to lower overall emissions, lower finite resource use and lower energy requirements.

Trehalose, another alternative to sucrose, is a disaccharide consisting of two glucose units with a 1,1-α,α-glycosidic linkage widely found in several prokaryotes, unicellular organisms, of which bacteria are the best-known members. Its role as a bio-protectant, specifically its ability to protect organisms from the effects of desiccation, as well as its resistance to acidic degradation [86], are the principal reasons for its use in wood conservation. Initial attempts to synthesise trehalose focused on chemical glycosylation pathways, however, the unusual 1,1-α,α-glycosidic linkage between the two units of trehalose makes this reaction hard to achieve with high selectivity. A large number of efficient chemoenzymatic trehalose synthesis pathways are known in nature [86], and these have been exploited to make large scale enzymatic synthesis of trehalose a more efficient option for commercial production. In contrast to sucrose, which is extracted, the production of trehalose focuses on enzymatic biotransformation of starch, sucrose, maltose, and maltodextrins. Starch is obtained from the grinding, washing, sieving, and drying of high starch seeds, tubers and roots like potatoes, corn, wheat, rice and tapioca, in another energy-intensive process, similar to the extraction of sucrose as described previously. Maltose and maltodextrin are obtained from either the acidic or enzymatic degradation of starch, enzymatic methods being the most resource-efficient. Enzymatic pathways to produce trehalose from starch, sucrose, maltose and maltodextrins stemming from fungi and yeasts (phosphorylase), from mesophilic bacteria (glycosyltransferase-hydrolase) and thermophilic bacteria (trehalose synthase) have been reported in the literature [87]. Two of these methods are used to commercially produce trehalose, the glycosyltransferase-hydrolase and the trehalose synthase route. The two-step nature of the phosphorylase route and the low yields of trehalose have made this route commercially non-viable. The one-step trehalose synthase route, relying on extremophilic bacteria, requires a temperature of 75–85 °C and the final yields are up to 85%, thus resulting in a more resource-intensive production route. The glycosyltransferase-hydrolase route is the most environmentally benign, despite the two-step procedure, primarily due to the low temperatures required throughout the procedure (35–45 °C). Furthermore, employing enzymes derived from Arthrobacter spp. with corn starch as the substrate, yields of up to 92% have been reported [87]. Despite the energy-efficient final synthesis step, thought must also be given to the cultivation and extraction of the substrates, as in many of the previous cases.

2.2. Synthetic Consoldants

Inhomogeneity, or the difficulty in obtaining reproducible treatment standards, has long plagued the use of natural substances as effective consolidants. Thus, when innovations in petroleum refinement and commercial chemical synthesis ushered in the reproducible, large scale, low-cost synthesis of a variety of polymers and polymer precursors in the 1940s, this was seen as a significant benefit to the conservation of heritage wood. While the use of sugars, and oils to a lesser extent, are still popular, the first demonstration of archaeological wood stabilisation using low molecular weight PEG in the late 1950s ushered in a new state-of-the-art for wood conservation. This remains the top choice today, particularly for large artefact conservation. However, methacrylate/acrylate copolymers (e.g., Paraloid B72), melamine-formaldehyde resins (e.g., Kauramin), epoxy resins (e.g., EPO155), and, more recently alkoxysilanes, are also popular. Their various methods of production and their primary applications are discussed below. In comparison to the bio-based consolidants discussed previously, in this section all starting materials are obtained from the petrochemical refining of non-renewable resources and further transformed through synthetic processes to wood consolidants as we are familiar with them.

2.2.1. Poly(ethylene glycol), PEG

Poly(ethylene glycol) or PEG is a polyether, a class of polymers in which the repeating unit contains a C-O bond, and by far, the most widely used wood consolidant currently available. Although it was first synthesised in the 1850s, its commercialisation in the 1940s under the name Carbowax was the main driver for its widespread use in applications from cosmetics and personal care products, to medicine and wood conservation [12,88,89,90], among others. The high solubility of low molecular weight PEG derivatives (under 4000 g/mol) in water means that PEG can effectively penetrate wood cells without precipitation of the chains in the wood cell wall, leading to complete replacement of water with non-volatile PEG retaining the wood structure during drying [13]. Moreover, the high monodispersity associated with the production of PEG means that conservation treatment can consist of several different PEGs penetrating different depths of the wood, offering varying degrees of stabilisation. For example, a low viscosity PEG (200–600 g/mol) is generally used to penetrate deep into a wooden object where degradation is generally lower, but water must still be replaced. Whereas higher molecular weight PEGs (1500–4000 g/mol) with higher viscosity and greater mechanical stability are generally used to conserve the more degraded surface wood.

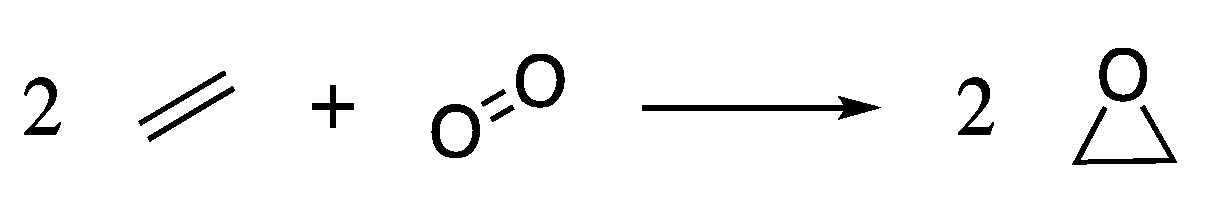

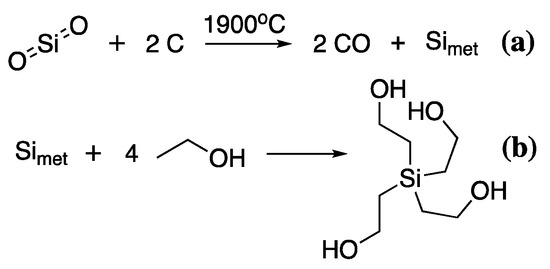

Synthesis of PEG is carried out on a commercial scale by the ring-opening polymerisation of ethylene oxide (EtO) under cationic or anionic conditions. EtO is industrially produced by the direct oxidation of the petroleum-derived ethylene [91], Scheme 1.

Scheme 1.

The direct oxidation of ethylene gives ethylene oxide, the starting material for PEG.

The reaction is carried out using high purity O2 (air is also used in some cases) over a silver catalyst at high temperatures (220–280 °C) and pressures (1–3 MPa) to increase the purity of the yield. On an industrial scale, anionic polymerisations are exploited in which Na, K or Cs alkoxide, hydroxide or carbonates are used to initiate ring-opening of EtO and chain propagation in polar, aprotic solvents (e.g., THF, dioxane and DMSO) [92]. This is a living polymerisation in which no quenching of the reaction occurs. Living polymerisations are characterised by a fast rate of chain initiation with a low rate of chain propagation and no chain termination or chain transfer, meaning a more controlled growth of polymer chains and a less polydisperse chain length distribution [93]. Using this methodology, PEG chains of specific molecule weights can be synthesised. While no external heat is required to start the reaction, the use of toxic, petrochemically obtained starting materials and solvents like THF and dioxane, and the need to dispose of these waste solvents after PEG synthesis, contribute to the negative environmental impact of PEG production.

2.2.2. Methacrylate and Acrylate Copolymers

Acrylates and methacrylates are also a variety of polyether known primarily for their use in cosmetics and adhesives. Copolymers of methyl acrylate and ethyl methacrylate are used in wood conservation under the trade name Paraloid B-72 [20]. A range of additional Paraloid variants exist in which the ethyl methacrylate is replaced by methyl methacrylate (B-82), butyl methacrylate (B-66) or isobutyl methacrylate (B-67) [94,95]. These low molecular weight copolymers with high photo and thermal stability are used to improve the dimensional stability of wood and the aesthetic quality of wooden artefacts. Their insolubility in water means they must be applied to wood in organic solvents, most commonly acetone or toluene.

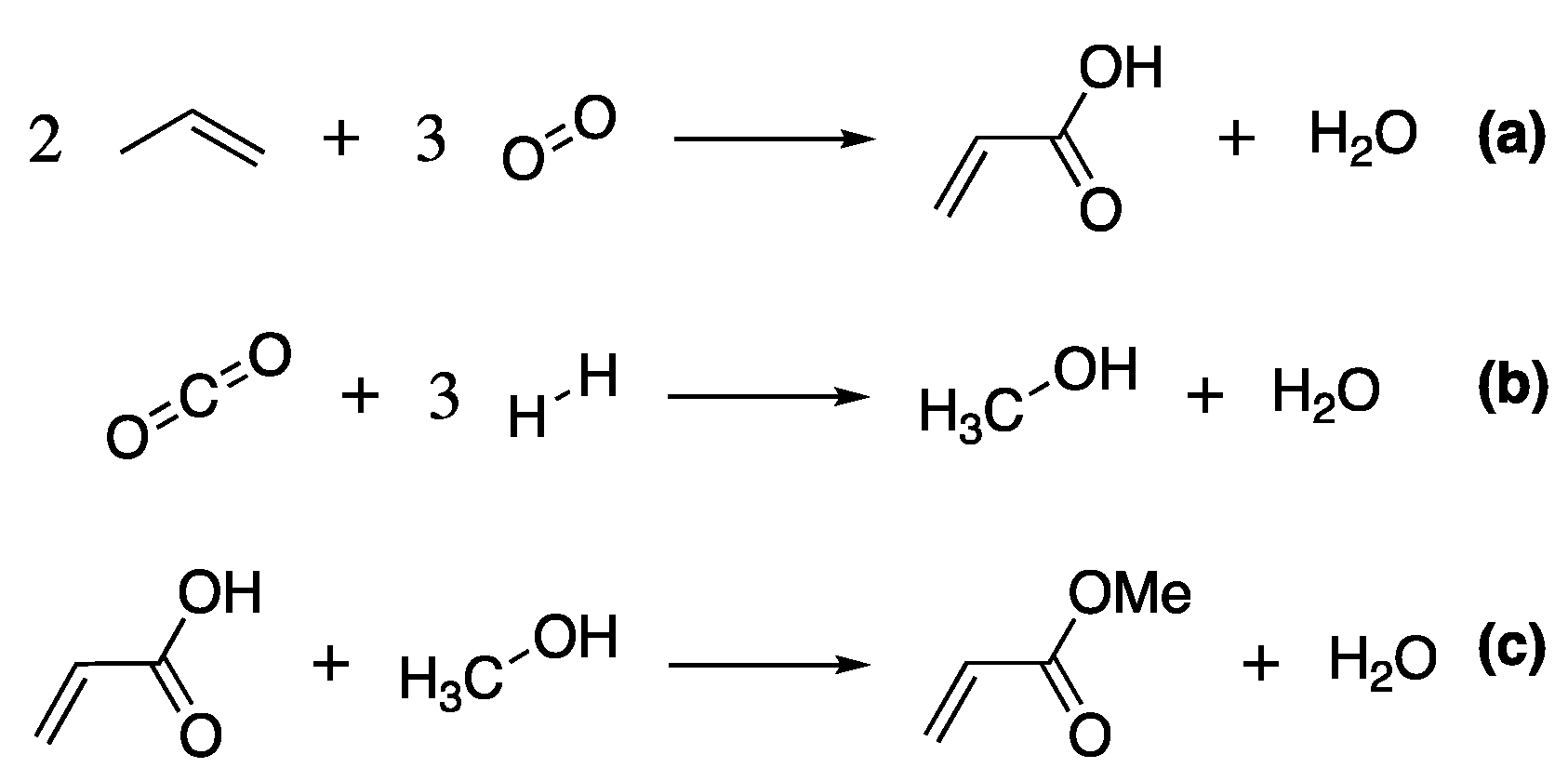

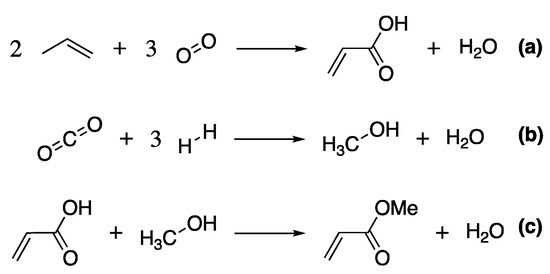

Standard commercial production of methyl acrylate uses acrylic acid as a feedstock, obtained from the oxidation of propylene from petroleum refining, Scheme 2a. This is then esterified with methanol, produced from the energy-intensive catalytic reduction of syngas (Scheme 2b, [96]), under acid conditions (e.g., sulfuric or para-toluenesulfonic acid) at elevated temperatures (Scheme 2c) [96].

Scheme 2.

The main reactions resulting in the production of methyl acrylate, (a) the synthesis of acrylic acid, (b) the production of methanol and (c) the esterification of acrylic acid.

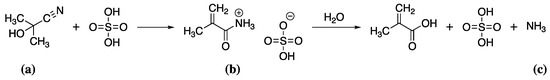

Methacrylates are prepared from methacrylic acid (MAA) [97]. MAA is produced in a multi-step process involving the reaction of acetone with sodium cyanide at 40 °C to give acetone cyanohydrin (Scheme 3a), which is converted to methacrylamide sulfate (Scheme 3b) by reaction with sulfuric acid at 180 °C and finally hydrolysed to give MAA (Scheme 3c).

Scheme 3.

The reaction of acetone cyanohydrin (a) with sulfuric acid to give methacrylamide sulfate (b) as an intermediate which is then hydrolysed to methacrylic acid (c).

This last step can be replaced with an esterification reaction to directly give methyl methacrylate. The production of ethyl, butyl or isobutyl methacrylate requires the further reaction of methacrylic acid with the corresponding alcohol. The preparation of the copolymers that make up the Paraloid B family of consolidants is carried out by free-radical polymerization in a polar solvent using an initiator that generates free radicals upon heating or irradiation with UV light, such as azobisisobutyronitrile (AIBN) or benzoyl peroxide [98]. This initiator generates radicals on the acrylate and methacrylate units by charge transfer allowing chain propagation. This continues until the desired molecular weight has been reached, at which point copolymers are precipitated in a polar solvent terminating the chains. The multi-step nature of the methacrylate production, the high energy input required, as well as the use of large quantities of acid and polar solvents that are produced from finite resources and must be incinerated to dispose of safely makes the production of acrylate-methacrylate copolymers highly resource inefficient. The further requirement to introduce these consolidants into the wood in organic solvents, generally derived from fossil-based resources further increases the negative environmental impact of the use of these consolidants

2.2.3. Aminoplasts

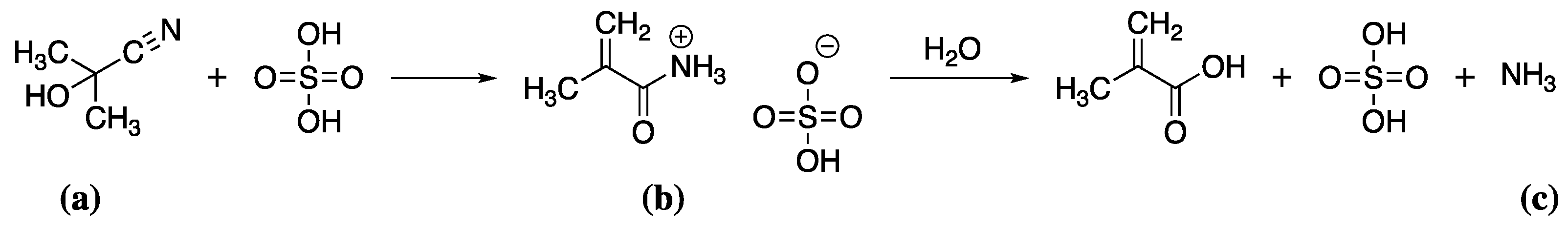

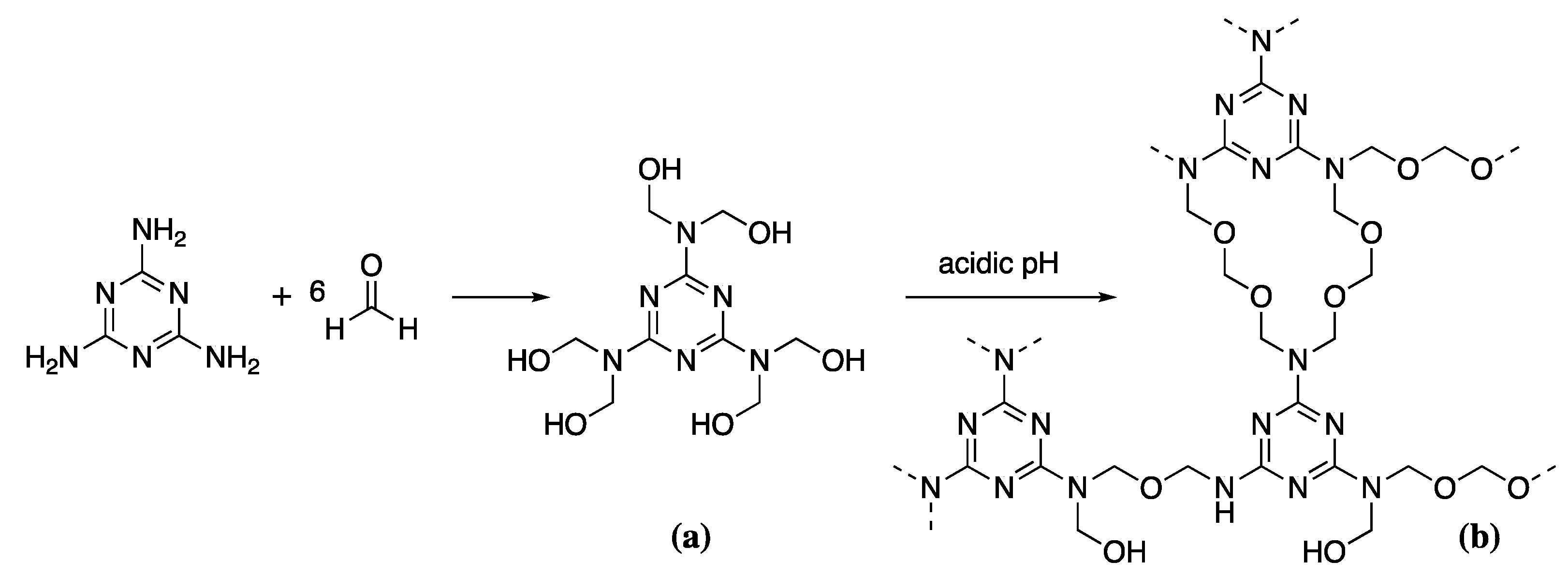

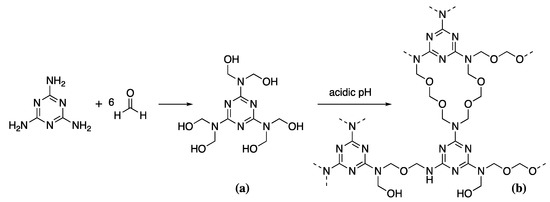

Aminoplasts are thermosetting polymers formed by condensation reactions, of which there are two main types-urea-formaldehyde and melamine-formaldehyde resins. Both resins have been used in wood conservation in the past. However, issues with the toxicity of urea-formaldehyde have led to its replacement with the less toxic melamine-formaldehyde, marketed under the name Kauramin [3]. This is one of few commonly used non-reversible wood consolidants. As such it is generally reserved for the most significantly degraded wood requiring consolidants of greater mechanically stability than is provided with standard PEG or bio-based consolidants. The low molecular weight of the monomers means MF consolidants can penetrate deeply into the wood leaving a rigid 3D polymer network after polymerisation. MF resin synthesis requires the pre-synthesis of both melamine and formaldehyde [99]. Commercial melamine production requires urea as a feedstock. Urea is produced by the high temperature (180–210 °C), high pressure (150 bar) reaction of ammonia (NH3) and carbon dioxide (CO2) forming ammonium carbamate, which is then dehydrated to urea [100]. Urea is then heated to cause decomposition to cyanic acid and ammonia [101]. Cyanuric acid is formed from the polymerisation of cyanic acid, which condenses with the evolved ammonia to form melamine. The off-gas from the melamine production contains such large quantities of ammonia that it is often funnelled off to create feedstock for the further production of urea, helping to reduce the environmental impact of the production cycle, even if only to a small degree. Formaldehyde is produced by the catalytic oxidation of methanol over a silver metal catalyst at 650 °C [102]. Methylolation or the formation of MF pre-polymer is carried out by mixing melamine with formaldehyde in a 1:6 ratio at approximately 60 °C (Scheme 4a) [99].

Scheme 4.

The condensation of melamine and formaldehyde to give the prepolymer (a), followed by polymerisation at acidic pH to give the network structure (b).

This pre-polymer is then infiltrated into the wood over several days/weeks with pH maintained at 8.5 to ensure no unwanted polymerisation of the pre-polymer occurs. This is generally done with triethanolamine. Once the wood has been completely infiltrated, the pH is allowed to drop to acidic pH starting the condensation reaction that produces the MF resin in situ (Scheme 4b). In industrial settings, this would be done by thermal polymerisation to increase reaction efficiency. The entire production process is resource, energy, and labour intensive from the initial preparation of urea to the final MF polymerisation within the wood.

2.2.4. Epoxy Resins

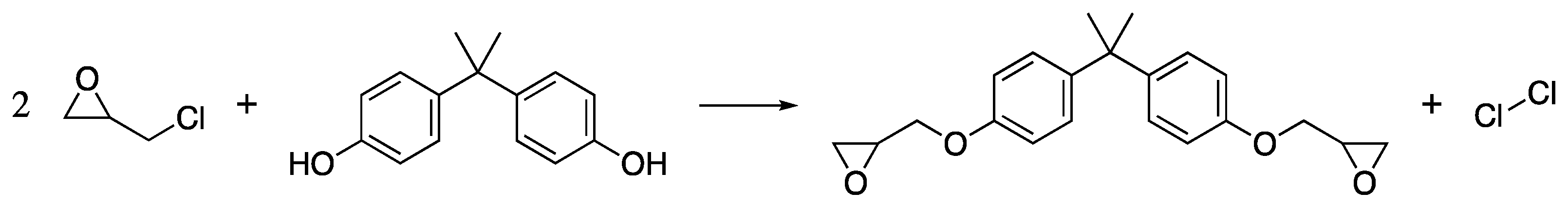

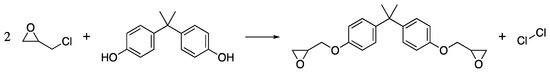

Epoxy resins are another non-reversible treatment, that have primarily been used to repair fragile wood surfaces. Their high viscosity makes infiltration of the wood structure impossible, as such epoxy resins are generally confined to surface work. They are also thermosetting polymers that can be homopolymerised to create pure epoxy resins or cross-linked with a range of curing agents, including polyfunctional amines, acids, acid anhydrides, alcohols, phenols and thiols [103]. The most common system, and the one found in most epoxy resins used in wood conservation, are polyfunctional amines. Thus, heteropolymers of epoxies cross-linked by amine curing agents will be the focus of this discussion. Like MF, epoxy resins are a two-part system containing an epoxy pre-polymer and, typically an amine cross-linking unit. The most commonly used epoxy prepolymer is bisphenol A diglycidyl ether (DGEBA) formed from the reaction of bisphenol A (BPA) and epichlorohydrin (Scheme 5).

Scheme 5.

The reaction of bisphenol A with epichlorohydrin to give DGEBA.

Traditionally, allyl chloride is reacted with hypochlorous acid to give two isomeric dichloropropanols, which are treated with NaOH to give epichlorohydrin, salt and water [104]. Allyl chloride is produced from the high-temperature chlorination of propylene from petroleum refining [105]. The reaction must be carried out over 500 °C to produce allyl chloride, lower temperature reactions result in 1,2-dichloropropane as the main reaction product. Hypochlorous acid is produced by the electrolysis of saline solutions [106]. Thus, just to reach the stage of epichlorohydrin production requires a significant amount of inputted energy, in the form of both electricity and heat. The production of BPA involves the condensation of acetone with 2 equivalents of phenol in the presence of a strong acid. Both acetone and phenol are produced by the cumene process [107], also known as the Hock rearrangement, where benzene is alkylated by propylene, both from petroleum refining, to form isopropylbenzene (cumene) which is then oxidized by air to give acetone and phenol. These are often directly further reacted with a strong acid to produce BPA without further purification. To create the epoxidized DGEBA, BPA is alkylated by epichlorohydrin, this results in the epoxy component of the standard two-barrel resin syringe. In addition to the heavy usage of hazardous chemicals that require specific disposal protocols, and a large energy and resource input, there are significant concerns about the use of BPA. Since the 1990s, BPA has been suspected to be an endocrine disruptor [108,109]. These chemicals disrupt natural hormone production leading to cancers and birth defects, among others. As such, BPA is often replaced by BPS or bisphenol sulfone, in which the starting material for the BP production is a sulfone instead of acetone. However, the process is equally resource-intensive and there are additional health concerns related to the use of BPS which does not significantly improve the impact of the process.

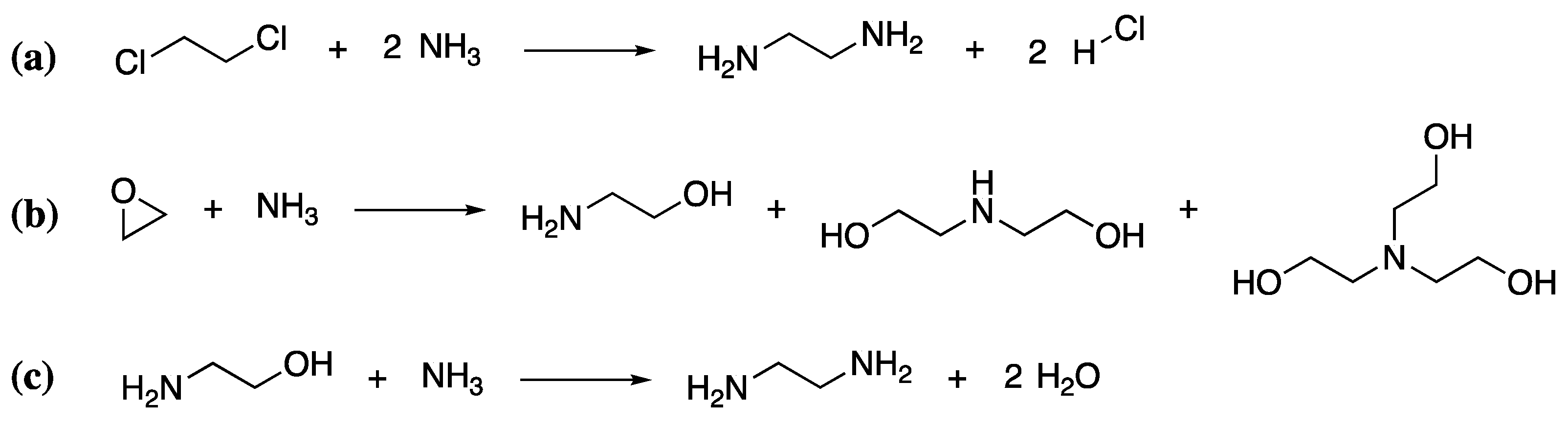

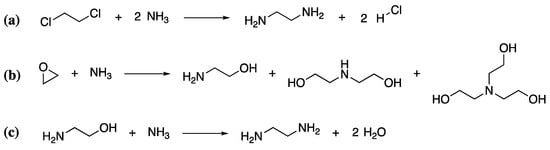

As mentioned previously, polyamines are the most common curing agents for epoxy resins. This family of compounds is extremely large, comprising both aliphatic and aromatic polyamines, of which there are at least 25 commercially available products. Thus, a detailed discussion of their synthesis is not feasible within the context of this review. However, a summary of the basic protocol for some of the simpler aliphatic polyamines will be given to illustrate the process. One common polyamine hardener is triethylenetetramine (TETA), with a curing time of approximately 30 min. It is produced from heating ethylene diamine or mixtures of ethanolamine and ammonia (which react when heated to form ethylene diamine) over a metal oxide catalyst [110]. If the ethylene diamine route is followed, ethylene diamine must be produced by the chlorination of ethylene to produce 1,2-dichloroethane, followed by reaction of the 1,2-dichloroethane with ammonia at 180 °C under pressure in aqueous media (Scheme 6a). Within the second route, ethanolamine must first be formed by the reaction of ethylene oxide with ammonia (Scheme 6b), which is then further reacted with aqueous ammonia to give ethylene diamine (Scheme 6c). Both routes are not completely selective and give a variety of polyfunctional amines. Like that of the epoxidized component, their production also requires significant heat, energy and resources, leaving a significant environmental impact.

Scheme 6.

The synthesis of ethylenediamine from 1,2-dichloroethane (a) and the ethanolamine (b,c).

2.2.5. Alkoxysilanes

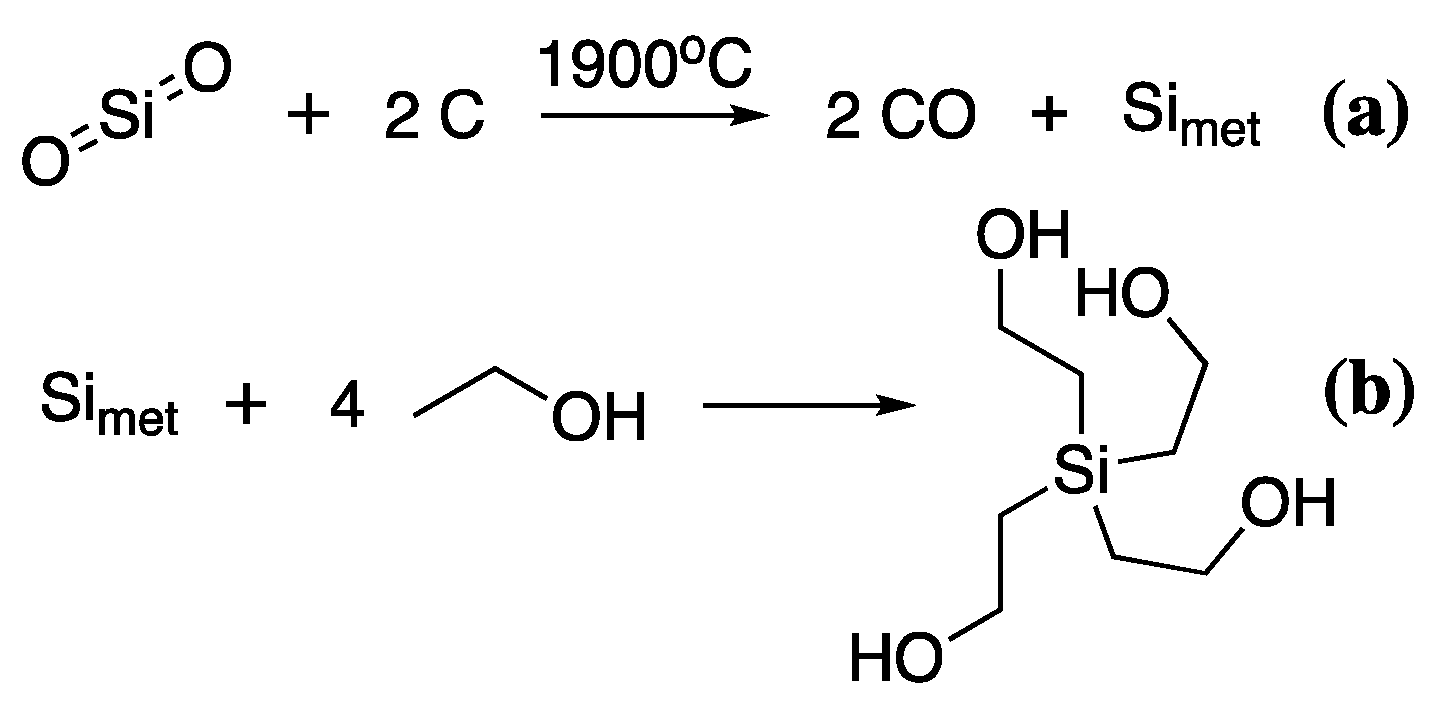

Lastly, alkoxysilanes are a relatively new addition to the wood conservation toolkit but have gained increasing popularity in recent years [111,112,113,114]. Alkoxysilanes have already been heavily used in the waterproofing and fire retardancy of construction wood, particularly for external applications, so their transfer into the conservation field is not surprising [115,116,117]. Moreover, they are a major component of almost all commercially available silicon products, thus the synthesis of these polymers is on an industrial scale [118]. The production of alkoxysilanes is one of the most energy-intensive of all the production processes described so far. Mined sand (SiO2) is carbothermally reduced at 1900 °C to give pure silicon (Simet), which is then reacted with the corresponding alcohol to give the desired alkoxysilane [118], Scheme 7.

Scheme 7.

The synthesis of TEOS from the carbothermal reduction of SiO2 (a), followed by reaction of Simet with EtOH (b).

Thus, to produce the commonly used tetraethoxysilane (TEOS), ethanol or ethylene glycol is reacted with Simet with an acidic catalyst. Alcohols for this reaction are either produced from petroleum sources or, in the case of ethylene glycol and ethanol, they can also be produced by fermentation. Alcohols from petroleum refining are produced by acid-catalysed hydration of the corresponding alkene to give the desired alcohol, thus hydration of ethylene produces ethanol. Ethanol can also be produced by fermentation of biomass [119], primarily with the yeast Saccharomyces cerevisiae, which breaks down polysaccharides at 35–40 °C releasing ethanol and CO2. The disadvantage of this process is the toxicity of ethanol to yeasts meaning that the overall ethanol content of the fermentation broth cannot exceed 18% by volume. Concentration and distillation must be used to increase overall volume concentrations. Thus, initial savings in energy due to low-temperature fermentations are used to refine the overall product. Currently, the industrial method of choice for ethanol production is country-specific with the US and Brazil favouring biomass-derived ethanol [120], while many other countries favour petroleum refined ethanol. The choice is heavily dependent on the regional costs of oil and grain stocks.

3. Sustainable Alternatives to Conventional Treatments

Despite much research in the past decade into new consolidant treatments to replace several state-of-the-art techniques, in particular PEG, there is little uptake of these newer consolidants among heritage institutions. This resistance is, while perhaps frustrating on the part of the conservation scientist, entirely understandable given the one-of-a-kind nature of the wooden objects of interest. New consolidants are often only considered viable alternatives once a large body of data has been collected over many years on the stability, toxicity, and by-products of the process, or when a particular treatment must be replaced due to legislations against its current use.

Due to the long timescale of the transition process, switching to completely new technologies overnight, despite their evident sustainability or other attractive features, is not feasible. As such, the first step in the transition to sustainability is not to switch treatments completely but to search out sustainable alternatives to the treatments currently in use. Thankfully, with more and more interest in the production of bio-based chemicals, there has been a significant increase in the number of commonly used consolidants for which sustainable alternatives exist.

3.1. Poly(ethylene glycol)

One of the most relevant sustainable alternatives is the recent increase in production of PEG from bio-based glycerol, produced from the fermentation of the fibrous waste that remains after the extraction of edible crops (e.g., corn, sugarcane). The ability of various species of yeast (e.g., S. cerevisiae) to break down polysaccharides from biomass to produce alcohols has been known for over 150 years [121]. However, in the period after World War II the cost of petroleum refining dropped significantly [122], making the production of alcohols from fermentation a less cost-effective process. Environmental concerns, alongside the desire to valorise the vast amounts of waste from the harvesting of food crops and enhanced yeast variants, have made this approach more attractive in recent decades and has driven a boom in bio-based chemicals, primarily in petroleum poor/agriculturally rich nations, such as Brazil [123].

Glycerol, the feedstock required for bio-based PEG, is produced within yeast cells as a reaction to osmotic stress from the environment during fermentation as the concentration of ethanol in the fermentation broth increases. Its production over that of ethanol can be promoted through one of three ways: (1) using more osmotolerant yeast strains that can produce higher quantities of glycerol intercellularly, (2) fermenting at neutral or slightly alkaline pH enhancing the osmotolerance of the yeast or (3) forming complexes that limit ethanol formation. The primary route to option (3) is by promoting reoxidation of nicotinamide adenine dinucleotide (NADH), a coenzyme necessary for metabolism, whose production consumes glycerol as a cytosolic mechanism to maintain redox balance in the yeast cell [124]. As with the production of ethanol described previously, fermentation is carried out around physiological temperature to maintain the best environment for yeast growth. The glycerol can then be used as the raw material to produce any number of bio-based chemicals, including ethylene glycol (EG). Glycerol undergoes a catalytic dehydrogenation over a transition or noble metal catalyst to give ethylene glycol. The polymerisation of EG to give PEG follows the same process as described in Section 2.2.1 [125]. This bio-derived PEG is already commercially available through several suppliers, marketed as sustainable or green or bio-based PEG (bPEG). While the production of the starting material is inherently more environmentally friendly and sustainable than the derivation of PEG from petroleum refining, the catalytic dehydrogenation step that produces the EG is hugely resource-intensive requiring high temperatures, high pressure, and expensive finite catalysts. However, recent publications on the use of enzymatic cascades to produce ethylene glycol through a multi-step process from monosaccharide feedstocks give hope that the environmental footprint of the bPEG production will reduce further in years to come [126]. It must, however, be kept in mind that while the environmental footprint of the production of the PEG is significantly reduced, the disadvantages associated with the use of conventional PEG (non-recyclable, partially biodegradable at low molecular weights, solid-state ion transport and degradation to acidic by-products over time within the wood structure) will continue to be a feature of the bio-based PEG. However, at the very least choosing to employ bio-based PEG (bPEG) over petroleum-based PEG (pPEG) will contribute to improving sustainability in the conservation laboratory.

3.2. Epoxies

The widespread use of epoxies in many fields has also led to a significant increase in research in the production of bio-based epoxy resins (bio-epoxies) and resulted in several commercially available products. However, to date, researchers have struggled to produce bio-based epoxies with similar or better mechanical properties than traditional epoxies. Thus, most epoxies marketed as ‘bio-based’ are a mixture of renewable and non-renewable epoxies up to a total of 70% renewably sourced materials, to maintain the desired mechanical properties of the final product. While the creation of bPEG is almost completely focused on production from bio-glycerol, bio-based epoxies have been derived from bio-glycerol, plant oils and wood biomass. The multi-step nature of the epoxy generation process means that different parts of resin production have been reproduced from different bio-resources.

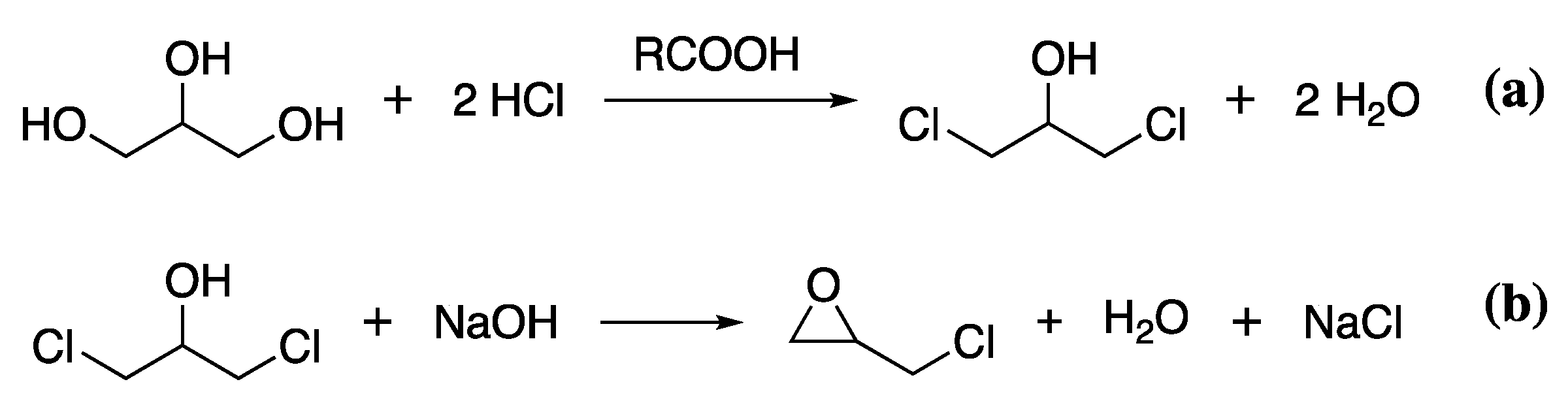

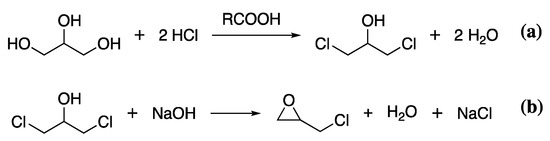

The most common sustainably produced component of epoxy resins is epichlorohydrin. The widespread availability of biomass feedstock for glycerol production means many chemical companies have transitioned to producing epichlorohydrin from bio-glycerol obtained through the same fermentation process as described for bPEG. To obtain epichlorohydrin, bio-glycerol is treated with hydrochloric acid in the presence of a carboxylic acid catalyst to give 1,3-dichlor-2-propanol, releasing water, Scheme 8a. The 1,3-dichlor-2-propanol is then reacted with NaOH to give epichlorohydrin, Scheme 8b.

Scheme 8.

The reaction of bio-glycerol with HCl to give 1,3-dichlor-2-propanol (a), which is further reacted with NaOH to give epichlorohydrin (b).

The use of bio-glycerol feedstock improves the sustainability of the epichlorohydrin production, however, the further synthesis of the DGEBA generally follows the traditional route described above. Thus, the overall improvement in the sustainability of the process is limited. Moreover, methods to reduce the use of chlorine in the process need to be advanced.

Environmental concerns relating to the use of BPA have resulted in various biomass-derived units being explored to replace BPA and any of its derivatives. The most common of these are lignins and tannins. Both lignins and tannins are macromolecules with multiple phenol residues obtained from the valorisation of woody biomass. The presence of the phenol groups means that they can be reacted with (bio)epichlorohydrin in the presence of NaOH in a polar solvent at approx. 50 °C (lignin) [127] or 80 °C (tannin) [128] to give polyfunctional epoxidised monomers. While this eliminates the hazardous BPA component, and the epichlorohydrin can be derived from bio-glycerol, it does not eliminate the use of chlorine and chlorinated intermediates in the epoxide formation.

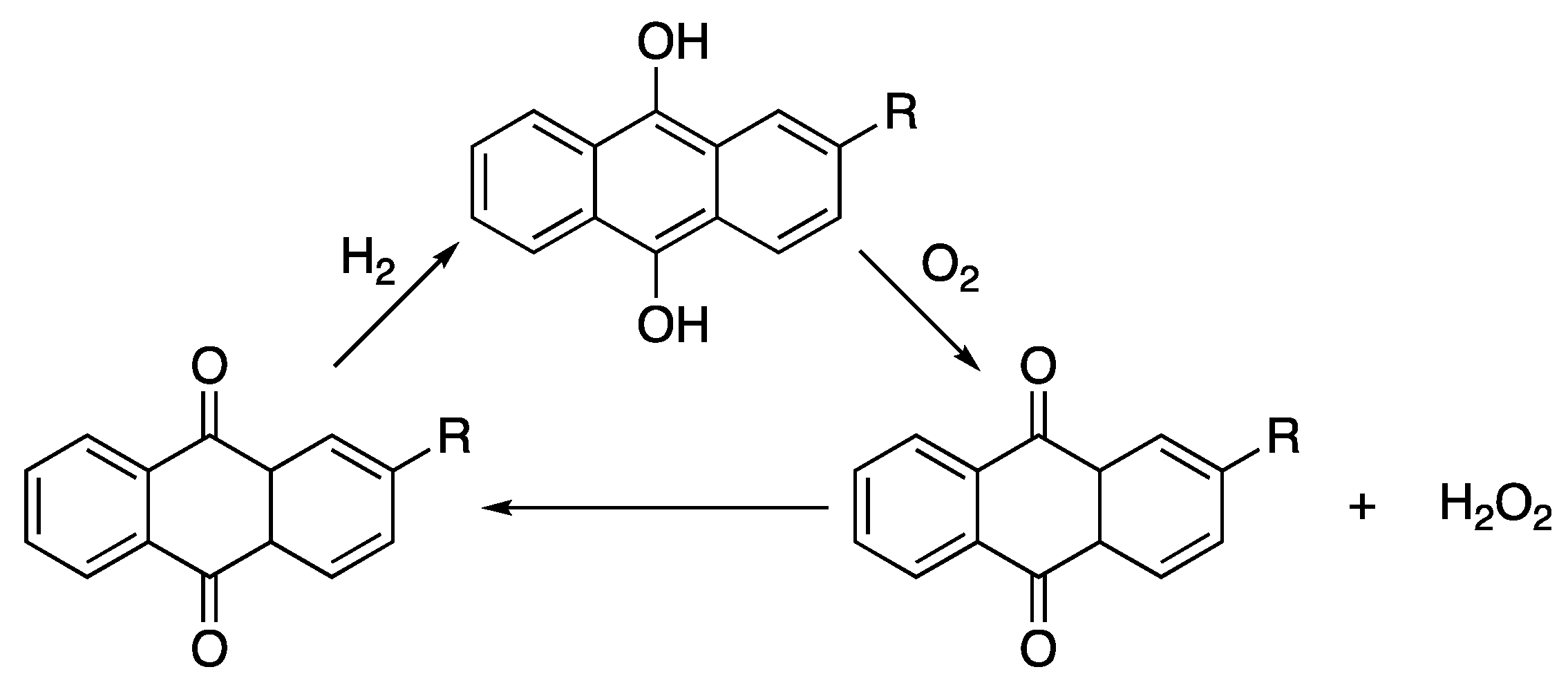

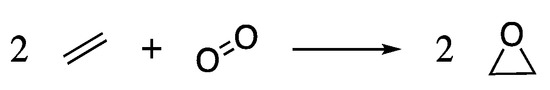

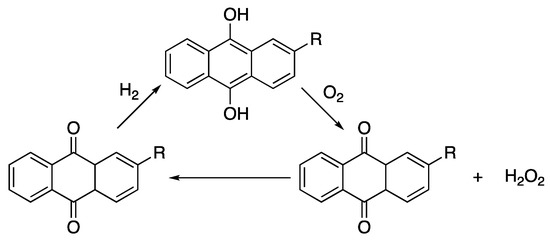

Epoxidising plant and vegetable oils to create polyfunctional epoxide monomers are one of the most explored methods of replacing the entire DGEBA component, removing the need for chlorine gas and chlorinated intermediates [45,129,130,131]. Suitable candidates for epoxidation require the presence of unsaturated fatty acids, i.e., C=C bonds where the epoxide ring can be formed. Linseed (75–90% oleic, 1 C=C, and linolenic acid, 3 C=C) and soybean oil (~85% oleic, 1 C=C, linoleic, 2 C=C, and linolenic acid, 3 C=C) have significantly high concentrations of fatty acids with multiple C=C bonds to allow cross-linking of epoxidised oils [132,133]. As such, epoxidised linseed oil (ELO) and epoxidised soybean oil (ESBO) are the most explored and commercially available epoxidised oils used in a variety of paints, coatings and resins. Epoxidation of the oils is generally carried out by reacting hydrogen peroxide with the oil, resulting in the addition of an oxygen atom across the C=C creating the epoxide ring. While the renewable sourcing of the oil and the advances in green oil extraction are an improvement on the synthetic DGEBA protocol, the major downside to this process is the production of hydrogen peroxide. H2O2 is prepared by the anthraquinone process [134], Scheme 9.

Scheme 9.

The anthraquinone process.

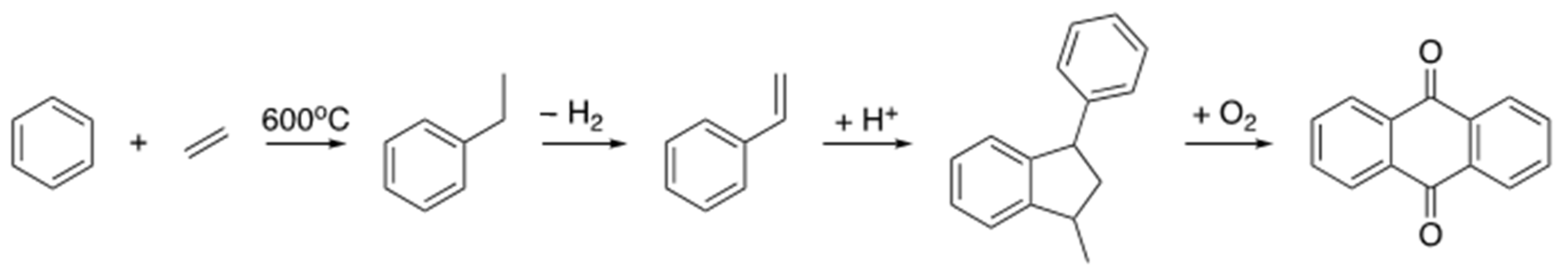

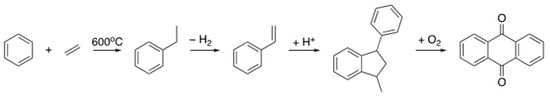

This involves the high-temperature reduction of anthraquinone to anthrahydroquinone by hydrogenation over a palladium catalyst. The anthrahydroquinone autoxidizes in the presence of oxygen to regenerate the anthraquinone and transfer the H2 to the O2 giving H2O2. Production of anthraquinone involves the reaction of benzene and ethylene from petroleum refining to produce ethylbenzene in a Freidel–Craft reaction over a zeolite catalyst. The ethylbenzene is then dehydrogenated using superheated steam (>600 °C) over an iron catalyst to give styrene. This then undergoes acid catalysed dimerization to 1-methyl-3-phenylindane, which is oxidized to anthraquinone [135], Scheme 10. Thus, once again a large amount of resource and energy-intensive processes are used to produce sustainable alternatives to common consolidants.

Scheme 10.

The multi-step production of anthraquinone from benzene and ethylene.

The final component is the polyamine hardener. This is one of the easiest problems to address given that polyamines are widely found in nature, although they are not yet widely commercialised from bioresources. Until roughly a decade ago little was known about the biosynthetic pathways related to polyamine production, and their low natural abundance made extraction from biomass non-viable from an economic standpoint. However, a better understanding of the biosynthesis of polyamines by bacteria and yeast has led to advances in industrial fermentation of these highly useful molecules and brought their use in bio-based epoxies closer to reality [136]. Several different routes have been explored to engineer the metabolism of bacteria (Escherichia coli and Corynebacterium glutamicum) and yeast (S. cerevisiae) strains that are known to overproduce polyamine precursors (L-arginine, L-lysine and L-ornithine) to directly produce polyamines such as putrescine and cadaverine. These can then be further modified either through biotechnological or chemical means to create a variety of polyamine cross-linkers [137,138,139,140,141]. While the fermentation conditions may differ slightly from bacteria to yeast and depending on the initial feedstock, the clear advantage of this method over the synthetic route is the use of bio-based feedstock and physiological conditions to produce polyamines resulting in a significantly reduced environmental footprint for the process. Although discussed in the literature these advances have not yet made it to the industrial scale for epoxy resin production.

3.3. Acrylates and Methacrylates

While no commercially available acrylates or methacrylate currently exist, much research is being carried out to find alternatives to current synthetic procedures. Some of the most promising routes to acrylic acid involve the fermentation of corn starch and vegetable oil to produce glycerol, which is further fermented to lactic acid or 3-hydroxypropionic acid and then dehydrated to give acrylic acid (AA). The disadvantage of this route is the requirement for high-temperature dehydration with heterogeneous or metal oxide catalysts at temperatures approaching 300 °C. Another route to the preparation of bioAA is from poly(3-hydroxybutyrate), which is synthesised bacterially from wastewater and constitutes a waste valorisation route. P3HB can then be pyrolysed to crotinic acid and then metathesised, a reaction in which two hydrocarbons exchange carbon-carbon bonds in the presence of a metal catalyst [142], with (bio-based) ethylene from bio-glycerol to give propene and acrylic acid [143,144].

With respect to bio-based alternatives to MAA production, which can also then be reacted with the appropriate alcohol to give the desired ester, two main commercially viable routes have been described in the literature, although others exist [143]. The first is the decarboxylation of citric acid (CA), found in large quantities in citrus fruits. It is obtained commercially from the fermentation of sugar cane and beet molasses by Aspergillus niger. CaOH is added to precipitate the citric acid from the fermentation broth, which must then be neutralised with excess sulfuric acid. The citric acid is then pyrolysed to itaconic anhydride and hydrolysed to itaconic acid. The itaconic acid is then decarboxylated to methacrylic acid using various supported transition metal catalysts (although some reports also discuss cheaper solid base catalysts) at temperatures ranging from 200–250 °C, and often high pressure. The disadvantages of this protocol are the multiple steps involved, many of which involve high temperature and pressure reactions, as well as the production of large amounts of gypsum waste from the neutralisation of the CaOH precipitant. A less energy-intensive approach is the direct production of itaconic acid from the fermentation of glucose with Aspergillus terreus [145]. The itaconic acid is purified by filtration, evaporation, and crystallisation. The drawbacks to this approach are the cost of the substrate and the low yields of itaconic acid compared to the CA approach. However, research is being conducted to investigate cheaper substrates to produce itaconic acid and higher yield, resource-efficient purification techniques. For example, investigations on the use of Aspergillus orzyae with lignin biomass as a substrate detailed the highest yield from solid-state fermentation of IA reported to date [146]. This highlights that as interest increases in bio-based methacrylic acid, and of course acrylics, better and more efficient production will be found.

3.4. Aminoplasts and Related Consoldants

Limited options exist in the literature for the sustainable production of MF resins, primarily limited by the sustainable production of melamine. One recent publication discusses the replacement of up to 30% of the melamine content with bark extractives (i.e., polyphenols from tannins) in an MF resin to give a mixed phenol-melamine-formaldehyde resin [147]. However, when the total weight % of tannin exceeded 30 wt.% the mechanical properties of the adhesives deteriorated significantly. More promising routes appear to focus on the sustainable production of formaldehyde to improve the overall sustainability of the resins. This generally focuses on the electrolytic production of formaldehyde from seawater and CO2 [148]. Furthermore, several authors report the replacement of formaldehyde with furfural, which can be obtained from renewable resources and reduces the toxic emissions related to formaldehyde over time. Furfural is a furan-based aldehyde produced from the acid-catalysed hydrolysis and dehydration of pentoses obtained from agricultural waste [149,150]. This has only been reported for urea-formaldehyde (UF) resins to date, however one could envisage the same potential to replace formaldehyde in MF resins. Up to 50% of the formaldehyde could reportedly be replaced before the deterioration in the properties of the materials was observed.

The most promising sustainable alternatives to the use of MF resins in conservation are not actually aminoplasts, but phenol-formaldehyde resins. They were previously investigated in wood conservation but were found to have less desirable properties than MF resins. The wide range of polyphenols that can be obtained from wood biomass, specifically from lignins, tannins and suberins, coupled with the ability to sustainably produce, or replace formaldehyde with bio-derived aldehydes means that there is extraordinary potential for a wide variety of new sustainable alternatives to MF resins. The recent hike in prices on MF by the main producer BASF in response to increasing restrictions on chemicals with a high environmental footprint and no viable sustainable sources will certainly drive research further in this direction [151]. The forerunner in this new category is lignin-formaldehyde resins and several commercially available products exist. A recent study compared the life cycle analysis of three PF resins (with 100% phenol, 40% lignin: 60% phenol and 100% lignin) and both lignin-containing resins showed significantly improved environmental impacts over the traditionally obtained phenol [152], meaning that even the impact of non-sustainable formaldehyde production is balanced by the renewable sourcing of the lignin component. This highlights the fact that even partially sustainably-sourced consolidants show an improved environmental impact compared to the unsustainable consolidants currently in use. Thanks to the sourcing of lignin, tannin and suberin-based resins from woody biomass, compatibility with wooden artefacts would likely not be a significant issue. The major disadvantage here is that, unlike the other proposed alternatives, switching to lignin-phenol-formaldehyde (LPF) resins is not a simple switch from petroleum sourced to a bio-sourced version of the same chemical. Phenol-formaldehyde resins are not extensively used in wood conservation and LPF resins consist of a completely different phenol structure, as such extensive testing would be necessary before the widespread use of lignin-aldehyde resins could be considered. However, it is certainly a development to monitor in coming years with possible further restrictions, and increased costs, in the manufacture of MF resins.

3.5. Alkoxysilanes

While alkoxysilanes are a relatively new addition to the wood conservation toolkit, they are a major component in almost all silicon-based commercial products currently available, as such, they are widely synthesised at industrial levels. Despite their widespread usage and the almost century-long search for an alternative to the standard carbothermal process, few match the yields of the current standard [118]. Recently a bio-based alternative has been found that could match the demand for silicon products. Harvesting of rice for food produces a vast amount of waste in the form of rice husks, this is then generally combusted for energy and the residue remaining after pyrolysis is known as rice husk ash (RHA) [153]. Interestingly RHA contains up to 98% amorphous silica depending on location, rice variety and fertilisers used [154]. This RHA can be depolymerised in a base-catalysed reaction, using 10% NaOH, in the presence of various diols to give distillable spirocyclic alkoxysilanes [118]. Of particular interest is the ability to react RHA with (bio-based) ethylene glycol to produce a bio-based alternative to the most common alkoxysilane TEOS [118].

A report from 2019 states that Indonesia alone, the world’s third-biggest rice producer after China and India, can produce 3.2 million tonnes of silica from RHA per year [154]. The global demand for speciality silicas, i.e., SiO2 used to produce silicon-based polymers, was reported to be 3.9 million tonnes in the same year [155]. Thus, Indonesia alone could satisfy over 80% of the global demand. Assuming the same conversion from rice production to silica for both China and India for the same year [156], results in approximately 28 million tonnes of silica, 7 times the global demand. Thus, bio-based sources of silica can well match global demand for silicon polymers, meaning a sustainable future for the commercial production of alkoxysilanes may soon become a reality.

3.6. General Comments

While interest in developing alternatives to petroleum-based polymers for a variety of applications exists, the number of commercially available products is still rather low. Cost-effectiveness over petroleum-based consolidants may still hinder the switch to bio-based consolidants for many institutions. However, the strategy of replacing unsustainable chemicals with sustainable alternatives does not work for all consolidants. It is only possible when considering relatively simple syntheses with easily scalable processes, e.g., the production of PEG, or where the demand across many different fields is so high as to make sustainable synthesis methods a viable commercial option, e.g., bio-based epoxies. For many wood consolidants, this may remain a niche area with a high cost available only to institutions with research laboratories that can create these speciality chemicals on demand for use in limited quantities. Thus, instead of relying on the production of sustainable alternatives to common consolidants that come with the same disposal concerns as their petroleum-based counterparts, we need to start reimagining the entire future of wood consolidation.

4. Designing the Sustainable Consolidants of the Future

As mentioned above, simply switching to sustainable alternatives of currently employed consolidants is only part of the solution. While the overall environmental footprint of these bio-derived chemicals is reduced compared to petroleum-based consolidants in terms of production, once produced the bio-based alternatives are just as non-recyclable, toxic and/or non-reparable as the original. Thus, in the long-term, we need to think about the development of more responsible, and circular consolidant solutions, in which none of the material becomes waste. This translates to the need for consolidants that can be so well-tailored to the specific degradation issues of the wooden object as to adapt to the changing conservation needs of the wood over time negating the need for repetitive treatment and reducing overall consolidant consumption. Furthermore, unused consolidants within the conservation laboratory should be able to be biodegraded under specific conditions or used to create other materials when they are no longer of use, to reduce the quantities of chemicals going to waste. Development of such materials requires us not only to examine the provenance of the consolidant but its compatibility with the wood matrix, the modification strategies used to create the tailored consolidant behaviour, and the impact these modifications have on the environment. Moreover, the energy use and resource efficiency of the abovementioned strategies are also due to their effect on the overall environmental impact and sustainability of the final consolidant.

Moving away from the current state-of-the-art in consolidants is a much longer-term process and requires a significant amount of development. However, there is already plenty of research underway, particularly around responsive consolidants that could adapt to the changing environment within wooden objects overtime reducing or eliminating the need for repetitive conservation. Several ‘new generation’ technologies have appeared in the literature in recent years for the treatment of either archaeological or fresh wood with the potential to significantly impact the future of sustainable consolidants. These fall into one of four different categories; (1) bio-based polymers, (2) bio-based capsules with the sustained or triggered release of cargo, (3) bio-based polymer/inorganic NP composites and (4) bio-based polymers with responsive or targeted bulking of wood structure. Many of these new generations of consolidants are based on polysaccharides, although lignin (and lignin-derived polymers), proteins and waxes are also examined.

4.1. Polymers Extracted from Biomass

4.1.1. Proteinaceous Consolidants

Proteinaceous consolidants, particularly collagen, gelatine, and casein, have been extensively used in the conservation of painted works of art. Their ability to form thin, varnish-like films on drying has been exploited in the cleaning and restoration of painted surfaces. Proteinaceous wood consolidants are rarer, apart from keratin, which has recently been extensively investigated for the conservation of waterlogged wood. Keratin is a structural protein that exists in two forms, α-keratin (soft keratin) which is found in the hair, skin, claws (nails), horns and hooves of all vertebrates and β-keratin (hard keratin) which is found in the feathers and shells of birds and reptiles [157]. Keratin is the third most abundant biopolymer, after cellulose and chitin. Keratin is a significant waste product of the meat-processing industry, with pigskin, for example, containing almost 80% keratin. Thus, the use of keratin as a wood consolidant represents a valorisation of this waste product and an increase in the sustainability of the meat-processing industry. Despite the use of keratin in wood consolidation and other applications reducing waste from the meat processing industry, the methods used for the extraction of keratin are very resource-intensive, with the potential for significant negative impact when considering the quantities of keratin to be processed. The extraction involves three steps, generally performed at 60 °C: (1) urea is commonly used to break the covalent bonds in keratin and allow it to be solubilised, (2) a surfactant like sodium dodecyl sulfate is used to disrupt the intermolecular interactions and (3) followed by treatment with thioglycolic acid or mercaptoethanol to cleave the disulphide bond [158]. Sodium dodecyl sulfate (SDS) is produced from the reaction of the petroleum-derived dodecanol, through the procedures previously mentioned in Section 2.2.1 and reacted with sulfur trioxide (SO3), produced by the burning of sulfur or pyrite at 400–600 °C over a silica-supported V2O5 catalyst activated with K2O [159]. Reaction with SO3, or related derivatives of sulfuric acid, adds a sulfonate group (hydrogen lauryl sulfate), which is then neutralised using NaOH or sodium carbonate [160]. Bio-based SDS can also be produced by hydrolysing plant oils with a high content of C12 fatty acids, e.g., palm or coconut oil, and then hydrogenating to add the sulfonate group, as described previously [161]. The only disadvantage to this approach is that there is a mixture of fatty acids in all plant oils, thus the resulting SDS is a mixture of various sulfonated fatty acids. The final stage in the extraction of keratin involves the use of mercaptoethanol, produced from the reaction of ethylene oxide (described previously) with hydrogen sulphide in the presence of thiodiglycol. H2S, a highly toxic gas, is most commonly obtained from the ‘sweetening’ or refining of natural gas to remove H2S and other organosulfurs [162]. This is generally done by amine scrubbing, an acid-base reaction by which solutions of alkylamines (monoethanolamine, diethanolamine or methyldiethanolamine) are used to solubilise H2S and CO2 and remove them from natural gas, due to the higher solubility of dissociated species. The process is carried out using two linked vessels, an absorber to remove the sour gases and release the sweet gas, and a regenerator to collect the sour gases for further use. The absorber uses temperatures of 30–50 °C and pressures of ~200 atm, while the regenerator uses much higher temperatures (115–126 °C) and low pressures of 1.4–1.7 atm, resulting in an energy-intensive process. Thiodiglycol on the other hand is produced from the hydrolysis of bis(2-chloroethyl) sulphide, also known as Mustard gas [163]. Mustard gas is produced by reacting sulphur dichloride, obtained from the high-temperature chlorination of elemental sulphur, with ethylene from petroleum refining. Thus, while the use of keratin is a sustainable method of reducing waste from meat processing, the methods required to extract the keratin have a very high environmental impact. Recent literature reports detail new, more sustainable methods to extract keratin that give hope for less damaging production in the future. This method involves the use of a highly basic industrial degreaser (containing non-ionic surfactants and NaOH) to dissolve the keratin at room temperature within 6 h with constant stirring, followed by filtration to remove larger particles then two rounds of centrifugation, the second with ultrafiltration to give the pure keratin solution. This was also scaled up to an industrial level and required microfiltration in place of the first round of centrifugation and a final reverse osmosis step to ensure pure keratin was obtained at the end. While these processes are still energy-intensive, there are short (20 min) and can be potentially powered by renewable energy. Moreover, they use significantly less toxic chemicals derived from petroleum sources, thus constituting an improvement over current methodologies [164].

4.1.2. Polysaccharides