Assessing the Technical Efficiency of Timber Production during the Transition from a Production-Oriented Management Model to a Multifunctional One: A Case from Poland 1990–2019

Abstract

1. Introduction

2. Multifunctional Forest Management in Poland

3. Data and Methods

3.1. Theoretical Background for Efficiency Measurement

3.2. Characteristics of the DEA Model

3.3. Material

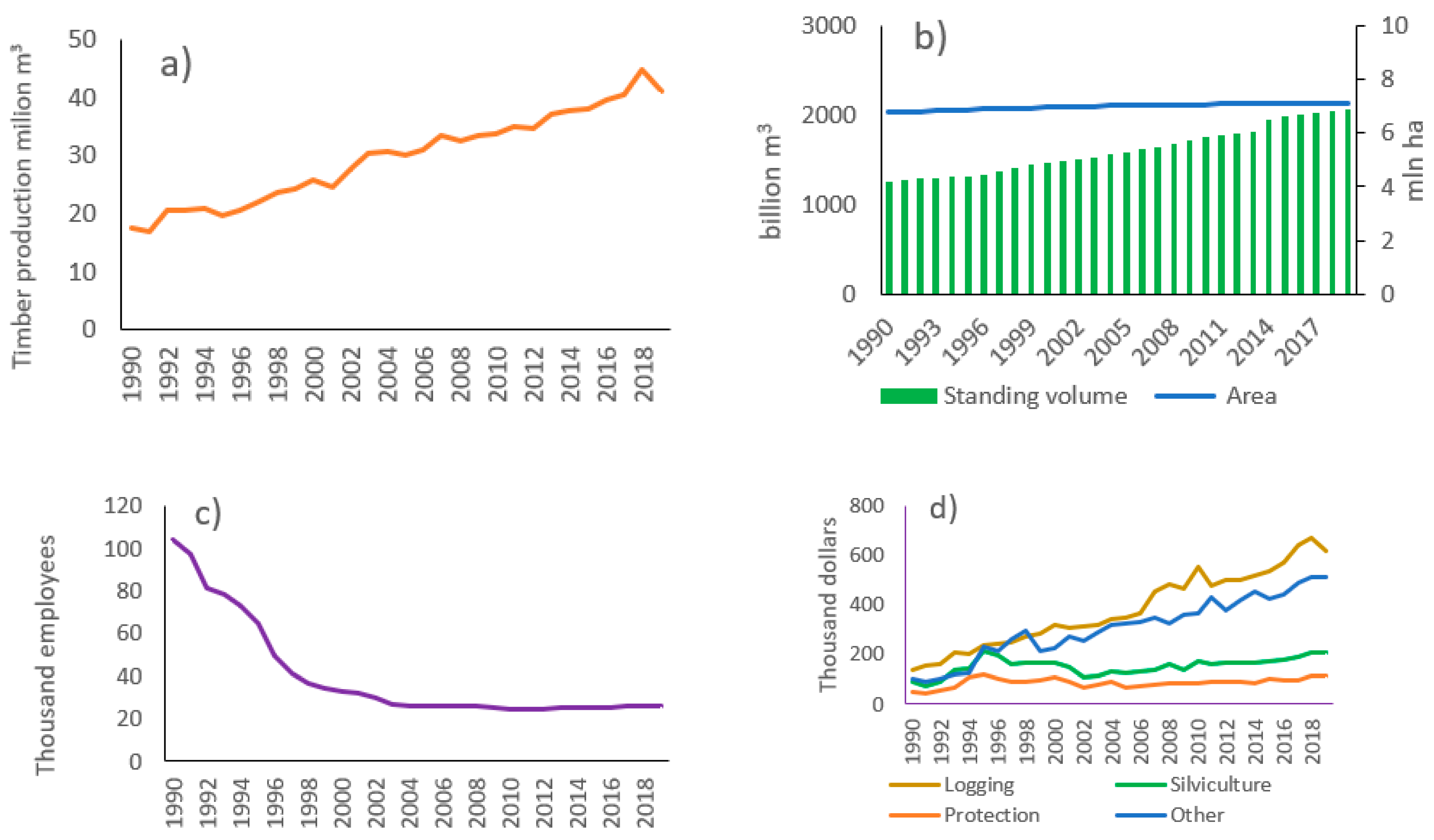

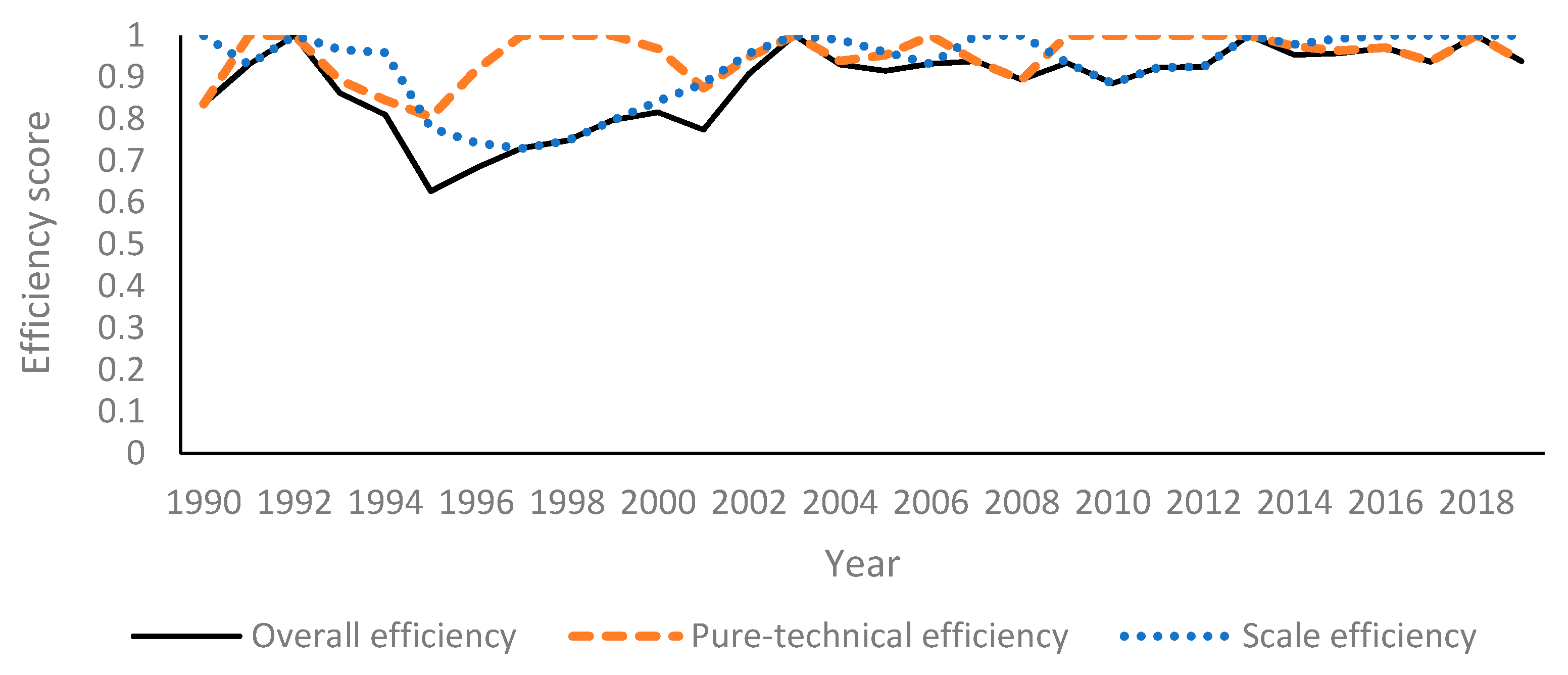

4. Results

4.1. Changes in Technical Efficiency

4.2. Productivity of Inputs

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Hundeshagen, J. Die Forstabschätzung auf Neuen Wissenschaftlihen Grundlagen; Laupp: Tübingen, Germany, 1826. [Google Scholar]

- Sikora, A.T. The effect of natural disasters on the timber market. For. Res. Pap. 2017, 78, 277–284. [Google Scholar] [CrossRef][Green Version]

- Yin, R.; Newman, D.H. The effect of catastrophic risk on forest investment decisions. J. Environ. Econ. Manag. 1996, 31, 186–197. [Google Scholar] [CrossRef]

- Ustawa z Dnia 28 Wrzesnia 1991 r. o Lasach (The 1991 Forest Act). Dziennik Ustaw Nr 101: 444, Poland; -Type - Parliamentary Act. Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU19911010444 (accessed on 10 September 2021).

- Battese, G.E.; Coelli, T.J. Frontier production functions, technical efficiency and panel data: With application to paddy farmers in India. J. Prod. Anal. 1992, 3, 153–169. [Google Scholar] [CrossRef]

- Aigner, D.; Lovell, K.; Schmidt, P. Formulation and estimation of stochastic frontier poduction function models. J. Econom. 1977, 6, 21–37. [Google Scholar] [CrossRef]

- Battese, G.E.; Coelli, T.J. A model for technical inefficiency effects in a stochastic frontier production function for panel data. Empir. Econ. 1995, 20, 325–332. [Google Scholar] [CrossRef]

- Utnik-Banaś, K.; Żmija, J.; Krawczyk, J.; Połtowicz, K. Changes in technical efficiency of the broiler production in Poland, 1994–2013. Br. Poult. Sci. 2018, 59, 245–249. [Google Scholar] [CrossRef]

- Battese, G.E.; Coelli, T.J. Prediction of firm-level technical efficiencies with a generalized frontier production function and panel data. J. Econom. 1988, 38, 387–399. [Google Scholar] [CrossRef]

- Helvoigt, T.L.; Adams, D.M. A stochastic frontier analysis of technical progress, efficiency change and productivity growth in the Pacific Northwest sawmill industry. For. Policy Econ. 2009, 11, 280–287. [Google Scholar] [CrossRef]

- Sowlati, T. Efficiency studies in forestry using data envelopment analysis. For. Prod. J. 2005, 55, 49–57. [Google Scholar]

- Yin, R. DEA: A new methodology for evaluating the performance of forest products producers. For. Prod. J. 1998, 48, 29–34. [Google Scholar]

- Kao, C.; Yang, Y.C. Measuring efficiency of forest management. For. Sci. 1991, 37, 1239–1252. [Google Scholar]

- Kao, C. Measuring the performance improvement of Taiwan forests after reorganization. For. Sci. 2000, 46, 577–584. [Google Scholar]

- Kao, C.; Chang, P.; Hwang, S.N. Data envelopment analysis in measuring efficieny of forest management. J. Environ. Manag. 1993, 38, 73–83. [Google Scholar] [CrossRef]

- Kao, C. Congestion measurement and elimination under the framework of data envelopment analysis. Int. J. Prod. Econ. 2010, 123, 257–265. [Google Scholar] [CrossRef]

- Shiba, M. Measuring the efficiency of managerial and technical performances in forestry activities by means of data envelopment analysis (DEA). J. For. Eng. 1997, 8, 7–19. [Google Scholar]

- Helminen, R. Developing tangible measures for eco-efficiency: The case of the Finnish and Swedish pulp and paper industry. Bus. Strat. Env. 2000, 9, 196–210. [Google Scholar] [CrossRef]

- Kortelainen, M. Dynamic environmental performance analysis: A Malmquist index approach. Ecol. Econ. 2008, 64, 701–715. [Google Scholar] [CrossRef]

- Chen, K.; Li, X.T.; Piao, H.L. Analysis on forestry eco-efficiency and ecological productivity measure in China. Issues For. Econ. 2016, 36, 115–120. [Google Scholar]

- Chen, S.; Yao, S. Evaluation of forestry ecological efficiency: A spatiotemporal empirical study based on China’s Provinces. Forests 2021, 12, 142. [Google Scholar] [CrossRef]

- Shashi, S.K.; Dia, M. Efficiency measurement of Ontario’s sawmills using bootstrap data envelopment analysis. J. Multi-Crit. Decis. Anal. 2019, 26, 272–295. [Google Scholar] [CrossRef]

- Diaz-Balteiro, L.; Herruzo, C.A.; Martinez, M.; González-Pachón, J. An analysis of productive efficiency and innovation activity using DEA: An application to Spain’s wood-based industry. For. Policy Econ. 2006, 8, 762–773. [Google Scholar] [CrossRef]

- Yin, R. Alternative measurements of productive efficiency in the global bleached softwood pulp sector. For. Sci. 2000, 46, 558–569. [Google Scholar]

- Kovalčík, M. Efficiency of the Slovak forestry in comparison to other European countries: An application of data envelopment analysis. Cent. Eur. For. J. 2018, 64, 46–54. [Google Scholar] [CrossRef]

- Kovalčík, M. Profitability and Efficiency of Forest Contractors in Slovakia—Comparison of Mountain and Lowland Regions. Forests 2020, 11, 370. [Google Scholar] [CrossRef]

- Obi, O.; Visser, R. Including exogenous factors in the evaluation of harvesting crew technical efficiency using a multi-step data envelopment analysis procedure. Croat. J. Eng. 2018, 39, 153–162. [Google Scholar]

- Lundmark, R.; Lundgren, T.; Olofsson, E.; Zhou, W. Meeting Challenges in Forestry: Improving Performance and Competitiveness. Forests 2021, 12, 208. [Google Scholar] [CrossRef]

- Neykov, N.; Krišťáková, S.; Hajdúchová, I.; Sedliačiková, M.; Antov, P.; Giertliová, B. Economic Efficiency of Forest Enterprises—Empirical Study Based on Data Envelopment Analysis. Forests 2021, 12, 462. [Google Scholar] [CrossRef]

- Krišťáková, S.; Neykov, N.; Antov, P.; Sedliačiková, M.; Reh, R.; Halalisan, A.-F.; Hajdúchová, I. Efficiency of Wood-Processing Enterprises—Evaluation Based on DEA and MPI: A Comparison between Slovakia and Bulgaria for the Period 2014–2018. Forests 2021, 12, 1026. [Google Scholar] [CrossRef]

- Młynarski, W.; Prędki, A.; Kaliszewski, A. Efficiency and factors influencing it in forest districts in southern Poland: Application of Data Envelopment Analysis. For. Policy Econ. 2021, 130, 102530. [Google Scholar] [CrossRef]

- Młynarski, W.; Prędki, A. Metoda DEA w badaniu efektywności nadleśnictw (Data Envelopment Analysis in evaluation of the forest districts). Sylwan 2017, 161, 1018–1025. [Google Scholar]

- Siry, J.P.; Newman, D.H. A stochastic production frontier analysis of Polish State Forests. For. Sci. 2001, 47, 526–533. [Google Scholar]

- Yin, R. An alternative approach to forest investment assessment. Can. J. For. Res. 1997, 27, 2072–2078. [Google Scholar] [CrossRef]

- Yin, R.; Pienaar, L.V.; Aronow, M.E. The productivity and profitability of fiber farming. J. For. 1998, 96, 13–18. [Google Scholar]

- Newman, D.H.; Wear, D.N. Production economics of private forestry: A comparison of industrial and nonindustrial forest owners. Am. J. Agric. Econ. 1993, 75, 674–684. [Google Scholar] [CrossRef]

- Han, X.; Frey, G.; Geng, Y.; Cubbage, F.; Zhang, Z. Reform and efficiency of state-owned forest enterprises in Northeast China as “social firms”. J. For. Econ. 2018, 32, 18–33. [Google Scholar] [CrossRef]

- Ning, Y.; Liu, Z.; Ning, Z.; Zhang, H. Measuring eco-efficiency of state-owned forestry enterprises in Northeast China. Forests 2018, 9, 455. [Google Scholar] [CrossRef]

- Xiong, L.; Wang, F.; Cheng, B.; Yu, C. Identifying factors influencing the forestry production efficiency in Northwest China. Resour. Conserv. Recycl. 2018, 130, 12–19. [Google Scholar] [CrossRef]

- Yang, H.; Yuan, T.; Zhang, X.; Li, S. A decade trend of total factor productivity of key state-owned forestry enterprises in China. Forests 2016, 7, 97. [Google Scholar] [CrossRef]

- Campos, P.; Caparrós, A.; Cerdá, E.; Díaz-Balteiro, L.; Herruzo, C.; Huntsinger, L.; Martín-Barroso, D.; Martínez-Jauregui, M.; Ovando, P.; Oviedo, J.L.; et al. Multifunctional natural forest silviculture economics revised: Challenges in meeting landowners’ and society’s wants. A review. For. Syst. 2017, 26, eR01S. [Google Scholar] [CrossRef]

- Dieterich, V. Forst-Wirtschaftspolitik—Eine Einführung; Verlag Paul Parey: Hamburg, Germany; Berlin, Germany, 1953. [Google Scholar]

- Diaz-Balteiro, L.; González-Pachón, J.; Romero, C. Sustainability as a Multi-Criteria Concept: New Developments and Applications. Sustainability 2020, 12, 7527. [Google Scholar] [CrossRef]

- Ortiz-Urbina, E.; González-Pachón, J.; Diaz-Balteiro, L. Decision-Making in Forestry: A Review of the Hybridisation of Multiple Criteria and Group Decision-Making Methods. Forests 2019, 10, 375. [Google Scholar] [CrossRef]

- Diaz-Balteiro, L.; Romero, C. Making forestry decisions with multiple criteria: A review and an assessment. For. Ecol. Manag. 2008, 255, 3222–3241. [Google Scholar] [CrossRef]

- Diaz-Balteiro, L.; González-Pachón, J.; Romero, C. Measuring systems sustainability with multi-criteria methods: A critical review. Eur. J. Oper. Res. 2017, 258, 607–616. [Google Scholar] [CrossRef]

- Diaz-Balteiro, L.; Alfranca, O.; Bertomeu, M.; Ezquerro, M.; Giménez, J.C.; González-Pachón, J.; Romero, C. Using quantitative techniques to evaluate and explain the sustainability of forest plantations. Can. J. For. Res. 2016, 46, 1157–1166. [Google Scholar] [CrossRef]

- DGLP. Raport o stanie lasów w Polsce 2019. 2020. Available online: https://www.bdl.lasy.gov.pl/portal/raporty-o-stanie-lasow (accessed on 11 May 2021).

- DGLP. Zarządzenie nr 30 Dyrektora Generalnego Lasów Państwowych z Dnia 19 Grudnia 1994 r. w Sprawie Leśnych Kompleksów Promocyjnych (LKP); Dyrekcja Generalna Lasów Państwowych: Warsaw, Poland, 1994. [Google Scholar]

- Blicharska, M.; Angelstam, P.; Elbakidze, M.; Axelsson, R.; Skorupski, M.; Węgiel, A. The Polish Promotional Forest Complexes. Objectives, implementation and outcomes towards sustainable forest management? For. Policy Econ. 2012, 23, 28–39. [Google Scholar] [CrossRef]

- Rykowski, K. The basics of sustainable forest management in Forest Promotional Complexes. Geogr. Pol. 2012, 85, 47–55. [Google Scholar] [CrossRef]

- Directive 2009/147/EC of the European Parliament and of the Council of 30 November 2009 on the Conservation of Wild Birds; EC: Brussels, Belgium, 2009.

- Council Directive 92/43/EEC of 21 May 1992 on the Conservation of Natural Habitats and of Wild Fauna and Flora; EC: Brussels, Belgium, 1992.

- PGL LP. Raport o Stanie Lasów w Polsce 2019; Państwowe Gospodarstwo Leśne Lasy Państwowe: Warsaw, Poland, 2020. [Google Scholar]

- Niedziałkowski, K.; Shkaruba, A. Governance and legitimacy of the Forest Stewardship Council certification in the national contexts—A comparative study of Belarus and Poland. For. Policy Econ. 2018, 97, 180–188. [Google Scholar] [CrossRef]

- Paschalis-Jakubowicz, P. Forest Certification in Poland. In Confronting Sustainability: Forest Certification in Developing and Transtioning Countries; Cashore, B., Gale, F., Meidinger, E., Neewsom, D., Eds.; Yale School of Forestry Environmental Studies: New Haven, CT, USA, 2006; pp. 235–260. [Google Scholar]

- Certyfikacja Jednostek Lasów Państwowych w PEFC™ I FSC®. Available online: https://www.bureauveritas.pl/magazine/certyfikacja-jednostek-lasow-panstwowych-w-pefctm-i-fscr (accessed on 27 August 2021).

- Koopmans, T.C. An analysis of production as an efficient combination of activities. In Activity Analysis of Production and Allocation; Koopmans, T.C., Ed.; John Wiley and Sons, Inc.: New York, NY, USA, 1951. [Google Scholar]

- Lovell, K. Production frointers and productive efficiency: In Measurement of Productive Efficiency: Techniques and Applications; Fried, H.O., Schmidt, S.S., Lovell, C.K., Eds.; Oxford University Press: Oxford, UK, 1993. [Google Scholar]

- Debreu, G. The coefficient of resource utilisation. J. Econom. Soc. 1951, 19, 273–292. [Google Scholar] [CrossRef]

- Farrell, M.J. The measurement of productive efficiency. J. R. Stat. Soc. 1957, 120, 253–290. [Google Scholar] [CrossRef]

- Wen, M. Uncertain Data Envelopment Analysis; Springer: Berlin/Heidelberg, Germany, 2015; ISBN 978-3-662-43801-5. [Google Scholar]

- Charnes, A.; Cooper, W.W.; Golany, B.; Seiford, L.; Stutz, J. Foundations of data envelopment analysis for Pareto-Koopmans efficient empirical production functions. J. Econ. 1985, 30, 91–107. [Google Scholar] [CrossRef]

- Cooper, W.W.; Seiford, L.M.; Tone, K. Data envelopment analysis: A comprehensive text with models, applications, references, and DEA-Solver software. In Data Envelopment Analysis; Springer: Berlin/Heidelberg, Germany, 2000. [Google Scholar]

- Färe, R.; Lovell, C. Measuring the technical effciency of production. J. Econ. Theory 1978, 19, 150–162. [Google Scholar] [CrossRef]

- Petersen, N.C. Data envelopment analysis on a relaxed set of assumptions. Manag. Sci. 1990, 36, 305–313. [Google Scholar] [CrossRef]

- Coelli, T. A Guide to DEAP Version 2.1: A Data Envelopment Analysis (Computer) Program; CEPA Working Paper 96/08; Centre for Efficiency and Productivity Analysis, University of New England: New England, Australia, 1996. [Google Scholar]

- Charnes, A.; Cooper, W.W.; Rhodes, E. Measuring the efficiency of decision making units. Eur. J. Oper. Res. 1978, 2, 429–444. [Google Scholar] [CrossRef]

- Banker, R.D.; Charnes, A.; Cooper, W.W. Some models for estimating technical and scale inefficiencies in data envelopment analysis. Manag. Sci. 1984, 30, 1078–1092. [Google Scholar] [CrossRef]

- Tone, K. A slacks-based measure of efficiency in data envelopment analysis. Eur. J. Oper. Res. 2001, 130, 498–509. [Google Scholar] [CrossRef]

- Coelli, T. A multi-stage methodology for the solution of orientated DEA models. Oper. Res. Lett. 1998, 23, 143–147. [Google Scholar] [CrossRef]

- Coelli, T.; Rao, P.; Battese, G.E. An Introduction to Efficiency and Productivity Analysis; Springer: Berlin/Heidelberg, Germany, 1998. [Google Scholar] [CrossRef]

- Balk, B.M. Scale efficiency and productivity change. J. Prod. Anal. 2001, 15, 159–183. [Google Scholar] [CrossRef]

- Spława-Neyman, A. Handel drewnem-obraz rynku drzewnego w dobie przemian polityczno-gospodarczych kraju (Timber trade—the picture of the timber market during political and social transformations in the country). Sylwan 1993, 137, 5–20. [Google Scholar]

- Zarządzenie Nr 51 Dyrektora Generalnego Lasów Państwowych z Dnia 16 Sierpnia 2005 r. w Sprawie Prowadzenia Sprzedaży Drewna w Państwowym Gospodarstwie Leśnym Lasy Państwowe: (OM-906-1-107/05); State Forest Information Center: Warszawa, Poland, 2005.

| Forest Category | 1990 | 1995 | 2000 | 2005 | 2010 | 2015 | 2019 |

|---|---|---|---|---|---|---|---|

| Total area (ha) | 6815 | 6868 | 6953 | 7042 | 7072 | 7100 | 7115 |

| Production (%) | 60.8 | 52.7 | 51.1 | 53.6 | 52.5 | 47.8 | 46.2 |

| Protection (%) | 39.2 | 47.3 | 48.9 | 46.4 | 47.5 | 52.2 | 53.8 |

| Promotional forest complexes (%) | 4.9 | 6.4 | 14.1 | 14.2 | 17.9 | 17.9 | |

| Nature reserves (%) | 0.5 | 0.6 | 0.9 | 1.1 | 1.2 | 1.4 | 1.5 |

| Natura 2000 | 39.0 | 45.4 |

| Inputs | 1990 | 1995 | 2000 | 2005 | 2010 | 2015 | 2019 |

|---|---|---|---|---|---|---|---|

| Land (ha) | 0.39 | 0.35 | 0.27 | 0.23 | 0.21 | 0.19 | 0.17 |

| Standing volume m3 103 | 72.2 | 67.40 | 56.70 | 52.84 | 51.82 | 52.09 | 50.30 |

| Labor (103 employees) | 5.97 | 3.30 | 1.28 | 0.87 | 0.73 | 0.67 | 0.64 |

| Logging costs (USD) | 7.90 | 12.13 | 12.34 | 11.59 | 16.37 | 14.15 | 15.05 |

| Silviculture costs (USD) | 5.02 | 10.94 | 6.37 | 4.19 | 5.08 | 4.56 | 5.06 |

| Protection costs (USD) | 2.75 | 6.17 | 4.19 | 2.30 | 2.57 | 2.76 | 2.73 |

| Other costs (USD) | 5.98 | 11.76 | 8.68 | 10.88 | 10.74 | 11.09 | 12.46 |

| Input | Overall Efficiency | Pure Technical Efficiency | Scale Efficiency | Returns to Scale * |

|---|---|---|---|---|

| Land | 0.671 (0.168) | 0.833 | 0.803 | irs |

| Standing volume | 0.829 (0.099) | 0.940 | 0.883 | irs |

| Labor | 0.584 (0.295) | 0.712 | 0.763 | drs/irs |

| Logging costs | 0.659 (0.133) | 0.921 | 0.718 | drs |

| Silviculture costs | 0.792 (0.174) | 0.840 | 0.941 | drs |

| Forest protection | 0.795 (0.184) | 0.823 | 0.962 | drs |

| Others costs | 0.548 (0.173) | 0.911 | 0.601 | drs |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Banaś, J.; Utnik-Banaś, K.; Zięba, S.; Janeczko, K. Assessing the Technical Efficiency of Timber Production during the Transition from a Production-Oriented Management Model to a Multifunctional One: A Case from Poland 1990–2019. Forests 2021, 12, 1287. https://doi.org/10.3390/f12091287

Banaś J, Utnik-Banaś K, Zięba S, Janeczko K. Assessing the Technical Efficiency of Timber Production during the Transition from a Production-Oriented Management Model to a Multifunctional One: A Case from Poland 1990–2019. Forests. 2021; 12(9):1287. https://doi.org/10.3390/f12091287

Chicago/Turabian StyleBanaś, Jan, Katarzyna Utnik-Banaś, Stanisław Zięba, and Krzysztof Janeczko. 2021. "Assessing the Technical Efficiency of Timber Production during the Transition from a Production-Oriented Management Model to a Multifunctional One: A Case from Poland 1990–2019" Forests 12, no. 9: 1287. https://doi.org/10.3390/f12091287

APA StyleBanaś, J., Utnik-Banaś, K., Zięba, S., & Janeczko, K. (2021). Assessing the Technical Efficiency of Timber Production during the Transition from a Production-Oriented Management Model to a Multifunctional One: A Case from Poland 1990–2019. Forests, 12(9), 1287. https://doi.org/10.3390/f12091287