Alteration of Bending Properties of Wood Due to Ammonia Treatment and Additional Densification

Abstract

:1. Introduction

2. Materials and Methods

3. Results

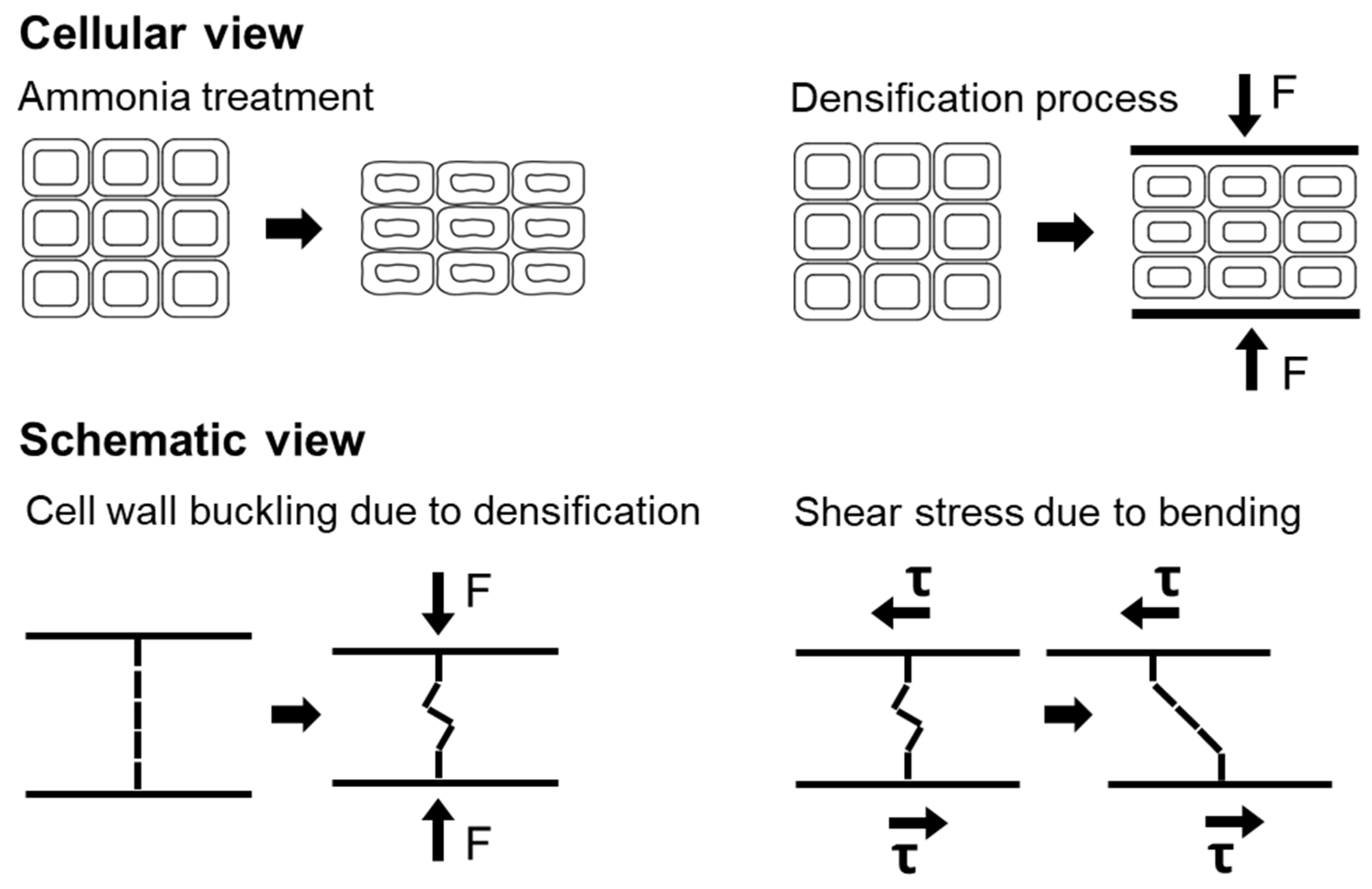

4. Discussion

5. Conclusions

- Treatment with anhydrous gaseous ammonia lowers the equilibrium moisture content of beech, oak and black locust wood.

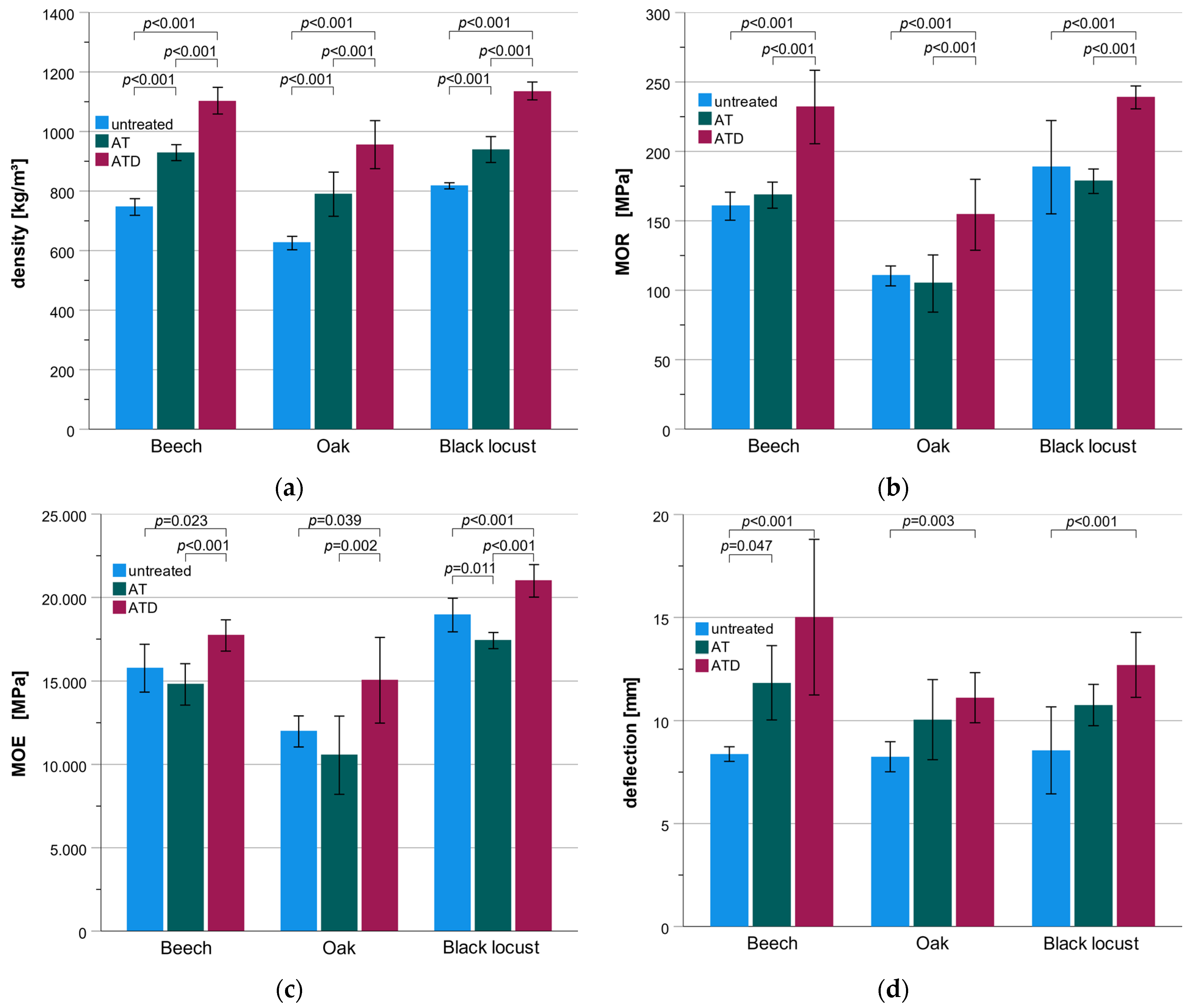

- Bulk density is increased by both ammonia treatment and mechanical densification.

- Ammonia treatment has a lowering effect on MOE. Additional mechanical densification raises MOE above reference level.

- MOR is not significantly affected by ammonia treatment. Mechanical densification leads to a strong increase in MOR.

- Deflection is increased by the ammonia treatment. The additional mechanical densification leads to a further increase in the deflection. The modified wood has a higher bending strength compared to the reference wood and shows a more ductile material behavior.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Báder, M.; Bak, M.; Németh, R.; Rademacher, P.; Rousek, R.; Horníček, S.; Dömény, J.; Klímek, P.; Kudela, J.; Sandberg, D.; et al. Wood densification processing for newly engineered materials. In Proceedings of the 5th PTF BPI, Munich, Germany, 20–21 September 2018; pp. 255–263. [Google Scholar]

- Wolcott, M.P.; Kamke, F.A.; Dillard, D.A. Fundamental Aspects of Wood Deformation Pertaining to Manufacture of Wood-Based Composites. Wood Fiber Sci. 1994, 26, 496–511. [Google Scholar]

- Sandberg, D.; Navi, P. Introduction to Thermo-Hydro-Mechanical (THM) Wood Processing; School of Technology and Design, Växjö University: Växjö, Sweden, 2007. [Google Scholar]

- Bariska, M. Plastifizierung des Holzes mit Ammoniak in Theorie und Praxis. Holz-Zentralblatt 1969, 84, 1309–1311. [Google Scholar]

- Schuerch, C. Plasticizing wood with liquid ammonia. Ind. Eng. Chem. 1963, 55, 39. [Google Scholar] [CrossRef]

- Schuerch, C. Method of Forming Wood and Formed Wood Product. U.S. Patent No.US 3282,313A, 1 November 1966. [Google Scholar]

- Rousek, R.; Rademacher, P.; Brabec, M.; Dejmal, A.; Horníček, S.; Baar, J.; Šprdlík, V. Beech wood modification with ammonia gas—Improved properties. Pro Ligno 2015, 11, 230–238. [Google Scholar]

- Yamashita, D.; Kimura, S.; Wada, M.; Samejima, M.; Takabe, K. Effect of ammonia treatment on white birch wood. Holzforschung 2018, 72, 31–36. [Google Scholar] [CrossRef]

- Schuerch, C. Wood Plasticization. For. Prod. J. 1964, 14, 377–381. [Google Scholar]

- Zauer, M.; Dietrich, T.; Oberer, I.; Hackenberg, H.; Wagenführ, A. Strukturelle Untersuchungen an nativer und behandelter Fichte, Rotbuche und Eiche: Ammoniakbegasung und mechanische Verdichtung. Holztechnologie 2019, 60, 39–47. [Google Scholar]

- Berzin’š, G.; Wagenführ, R.; Steiger, A. Strukturveränderungen des Holzes beim Plastifizierungsvorgang. Holztechnologie 1970, 11, 233–236. [Google Scholar]

- DIN EN 310:1993-08: Wood-Based Panels; Determination of Modulus of Elasticity in Bending and of Bending strength; German Version EN 310:1993. Available online: https://www.beuth.de/en/help/citing-din-standards (accessed on 6 July 2021).

- Krüger, R.; Zauer, M.; Wagenführ, A. Physical properties of native and thermally treated European woods as potential alternative to Indian rosewood for the use in classical guitars. Eur. J. Wood Wood Prod. 2018, 76, 1663–1668. [Google Scholar] [CrossRef]

- Bariska, M. Physikalische und Physikalisch-Chemische Änderungen im Holz Während und nach NH3—Behandlung. Ph.D. Thesis, Habilitation, ETH Zürich, Zürich, Switzerland, 1974. [Google Scholar]

- Bariska, M. Collapse phenomena in beechwood during and after NH3-impregnation. Wood Sci. Technol. 1975, 9, 293–306. [Google Scholar] [CrossRef]

- Coles, R.W.; Walker, J.C.F. Induced shrinkage and structural reorganisation in ammonia-treated wood of corsican pine. Wood Fiber 1978, 10, 39–57. [Google Scholar]

- Parham, R.A.; Davidson, R.W.; De Zeeuw, C.H. Radial-tangential shrinkage of ammonia-treated loblolly pine wood. Wood Sci. 1972, 4, 129–136. [Google Scholar]

- Pollisco, F.S.; Skaar, C.; Davidson, R.W. Some physical properties of maple treated with ammonia vapor. Wood Sci. 1971, 4, 65–70. [Google Scholar]

- Chundawat, S.P.S.; Sousa, L.; Roy, S.; Yang, Z.; Gupta, S.; Pal, R.; Zhao, C.; Liu, S.; Petridis, L.; O’Neill, H.; et al. Ammonia-salt solvent promotes cellulosic biomass deconstruction under ambient pretreatment conditions to enable rapid soluble sugar production at ultra-low enzyme loadings. Green Chem. 2020, 22, 204–218. [Google Scholar] [CrossRef]

- Kalnin’š, A.; Berzin’š, G.; Skrupskis, W.; Rumba, A. Chemisch plastifiziertes Holz anstelle von Buntmetallen und importiertem Hartholz. Holztechnologie 1969, 10, 17–23. [Google Scholar]

- Niemz, P.; Sonderegger, W. Holzphysik: Physik des Holzes und der Holzwerkstoffe; Carl Hanser Verlag: Munich, Germany, 2017; ISBN 978-3-446-44526-0. [Google Scholar]

- Oriez, V.; Peydecastaing, J.; Pontalier, P. Lignocellulosic Biomass Mild Alkaline Fractionation and Resulting Extract Purification Processes: Conditions, Yields, and Purities. Clean Technol. 2020, 2, 91–115. [Google Scholar] [CrossRef] [Green Version]

- Yu, Y.; Zhang, F.; Zhu, S.; Li, H. Effects of high-pressure treatment on poplar wood: Density profile, mechanical properties, strength potential index, and microstructure. Bioresources 2017, 12, 6283–6297. [Google Scholar] [CrossRef] [Green Version]

- Hackenberg, H. Alteration of mechanical properties of ammonia treated and densified beech (Fagus sylvatica L.). In Proceedings of the Hardwood Conference, Sopron, Hungary, 7–8 November 2018; pp. 101–102. [Google Scholar]

- Tabarsa, T.; Chui, Y.H. Characterizing Microscopic Behavior of Wood under Transverse Compression Part II. Effect of Species and Loading Direction. Wood Fiber Sci. 2001, 33, 223–232. [Google Scholar]

| Series | EMC 1 | Change in Mass 2 | |||||||

|---|---|---|---|---|---|---|---|---|---|

| (%) | p-Value | (%) | p-Value | ||||||

| Beech | untreated | 8.7 | (±0.1) | ref | −0.20 | (±0.06) | ref | ||

| AT | 6.7 | (±0.2) | p < 0.001 | ref | −0.21 | (±0.15) | n.s. | ref | |

| ATD | 5.8 | (±0.3) | p < 0.001 | p < 0.001 | 0.17 | (±0.15) | p < 0.001 | p < 0.001 | |

| Oak | untreated | 10.8 | (±0.1) | ref | −0.10 | (±0.31) | ref | ||

| AT | 10.1 | (±0.3) | p < 0.001 | ref | −0.28 | (±0.11) | n.s. | ref | |

| ATD | 9.8 | (±0.3) | p < 0.001 | n.s. | −0.36 | (±0.56) | n.s. | n.s. | |

| Black locust | untreated | 7.9 | (±0.4) | ref | −0.21 | (±0.06) | ref | ||

| AT | 6.6 | (±0.3) | p < 0.001 | ref | 0.88 | (±0.13) | p < 0.001 | ref | |

| ATD | 5.8 | (±0.2) | p < 0.001 | p < 0.001 | 0.83 | (±0.19) | p < 0.001 | n.s. | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hackenberg, H.; Zauer, M.; Dietrich, T.; Hackenberg, K.A.M.; Wagenführ, A. Alteration of Bending Properties of Wood Due to Ammonia Treatment and Additional Densification. Forests 2021, 12, 1110. https://doi.org/10.3390/f12081110

Hackenberg H, Zauer M, Dietrich T, Hackenberg KAM, Wagenführ A. Alteration of Bending Properties of Wood Due to Ammonia Treatment and Additional Densification. Forests. 2021; 12(8):1110. https://doi.org/10.3390/f12081110

Chicago/Turabian StyleHackenberg, Herwig, Mario Zauer, Tobias Dietrich, Katharina A. M. Hackenberg, and André Wagenführ. 2021. "Alteration of Bending Properties of Wood Due to Ammonia Treatment and Additional Densification" Forests 12, no. 8: 1110. https://doi.org/10.3390/f12081110

APA StyleHackenberg, H., Zauer, M., Dietrich, T., Hackenberg, K. A. M., & Wagenführ, A. (2021). Alteration of Bending Properties of Wood Due to Ammonia Treatment and Additional Densification. Forests, 12(8), 1110. https://doi.org/10.3390/f12081110