Haptic and Aesthetic Properties of Heat-Treated Modified Birch Wood

Abstract

1. Introduction

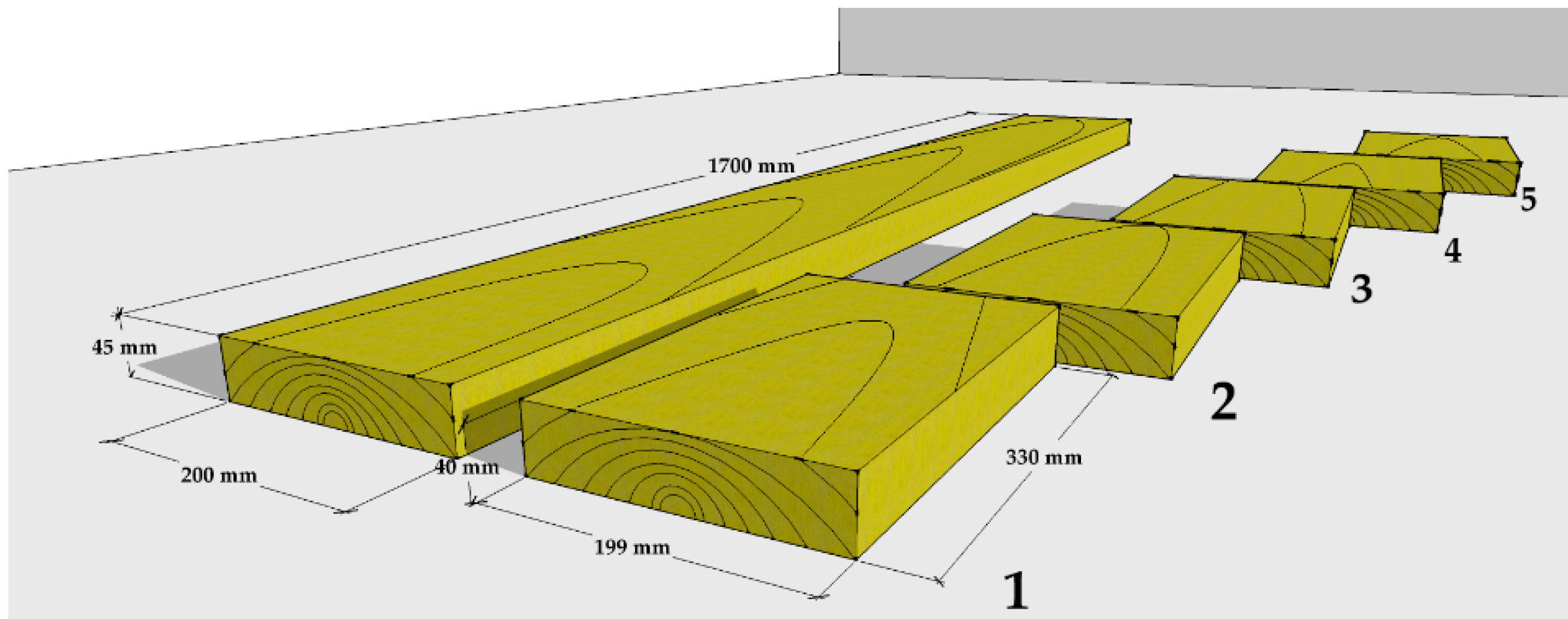

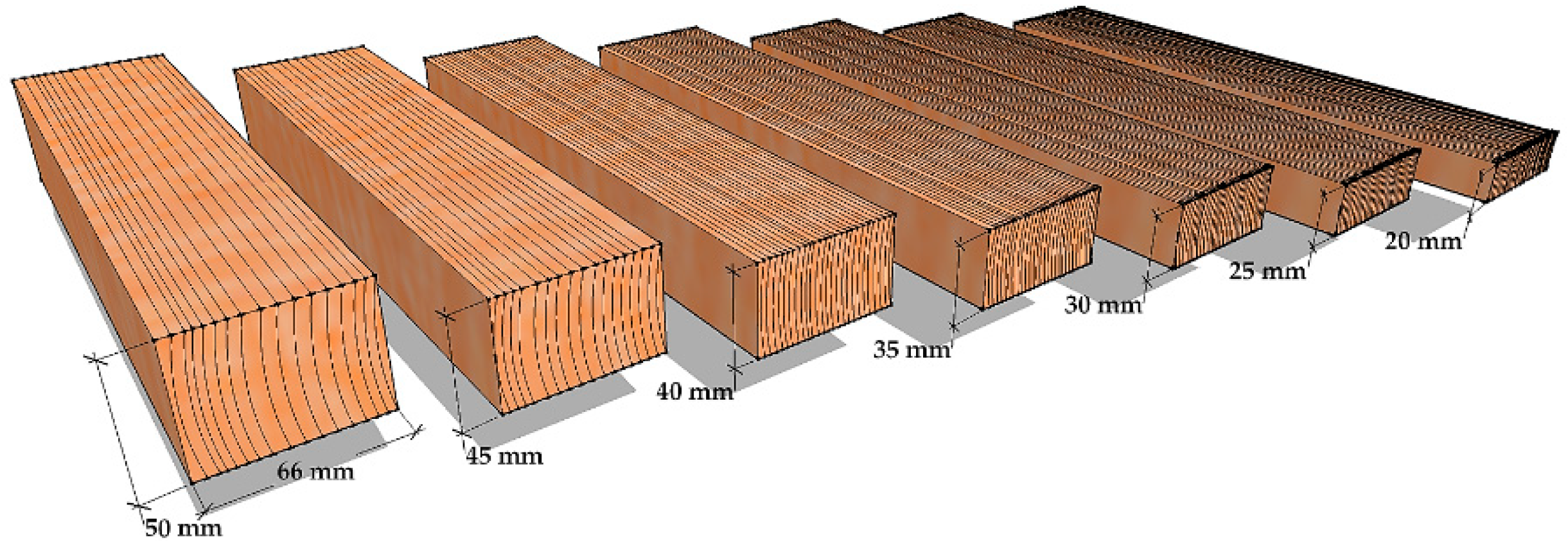

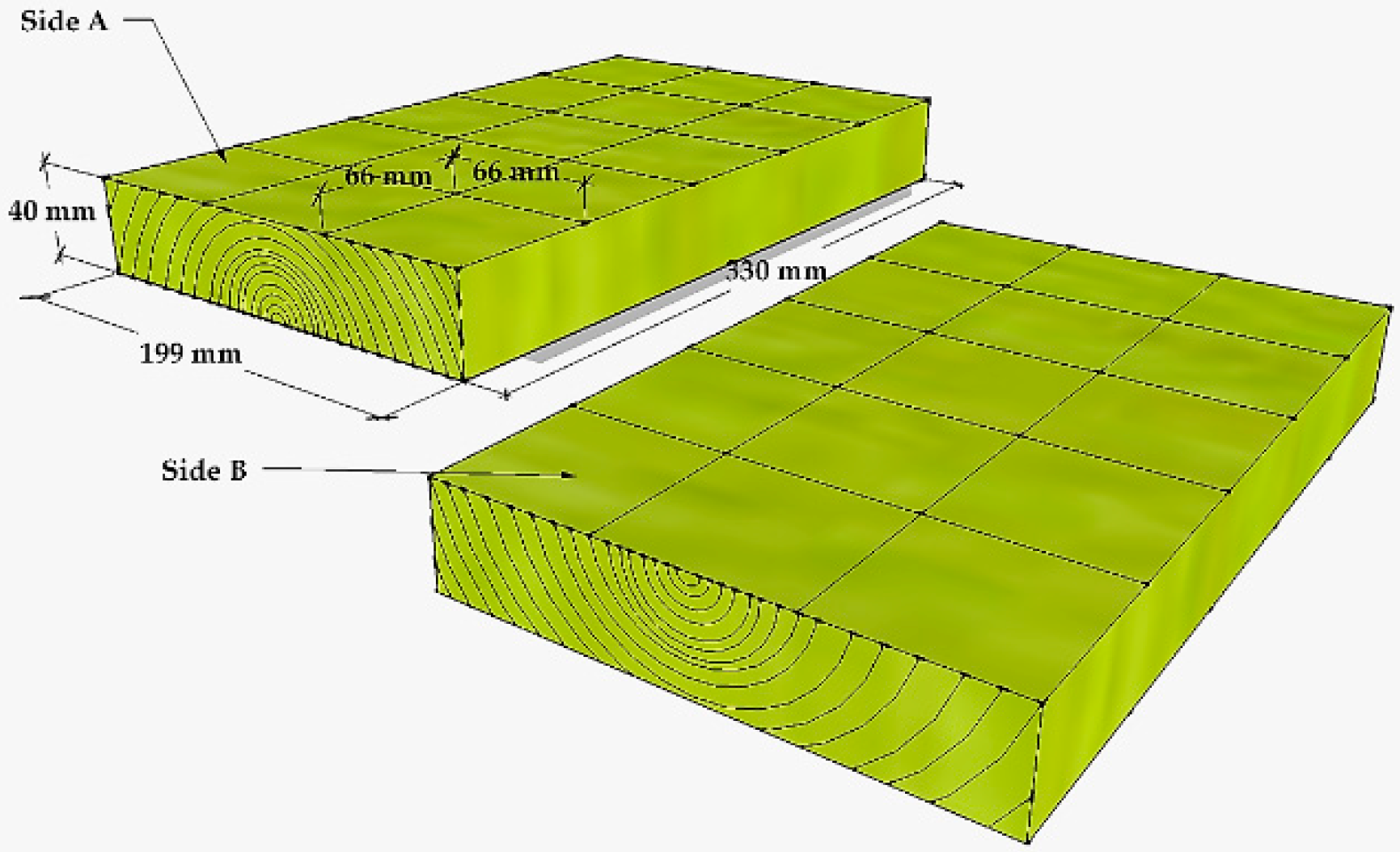

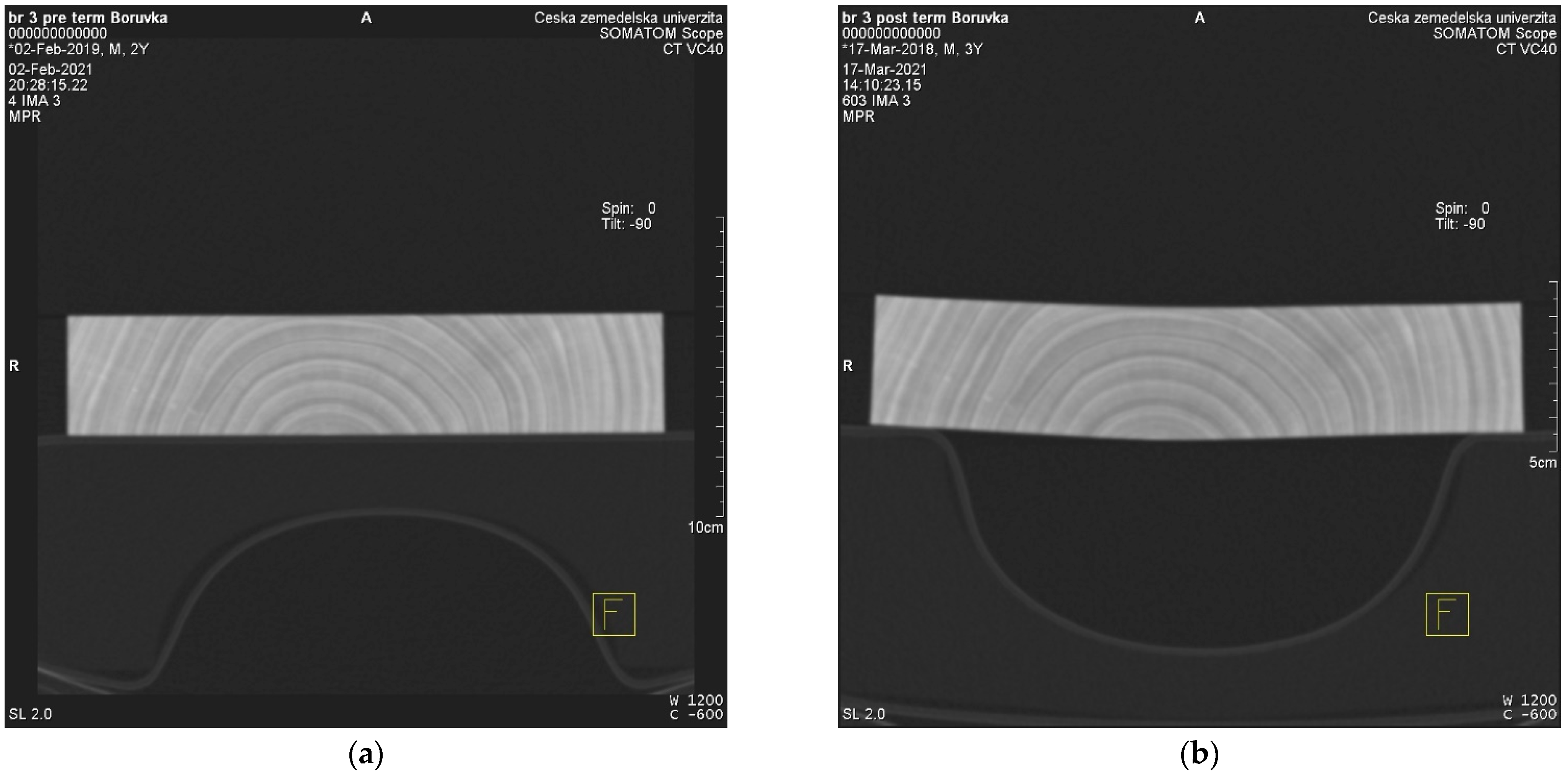

2. Materials and Methods

3. Results and Discussion

4. Conclusions

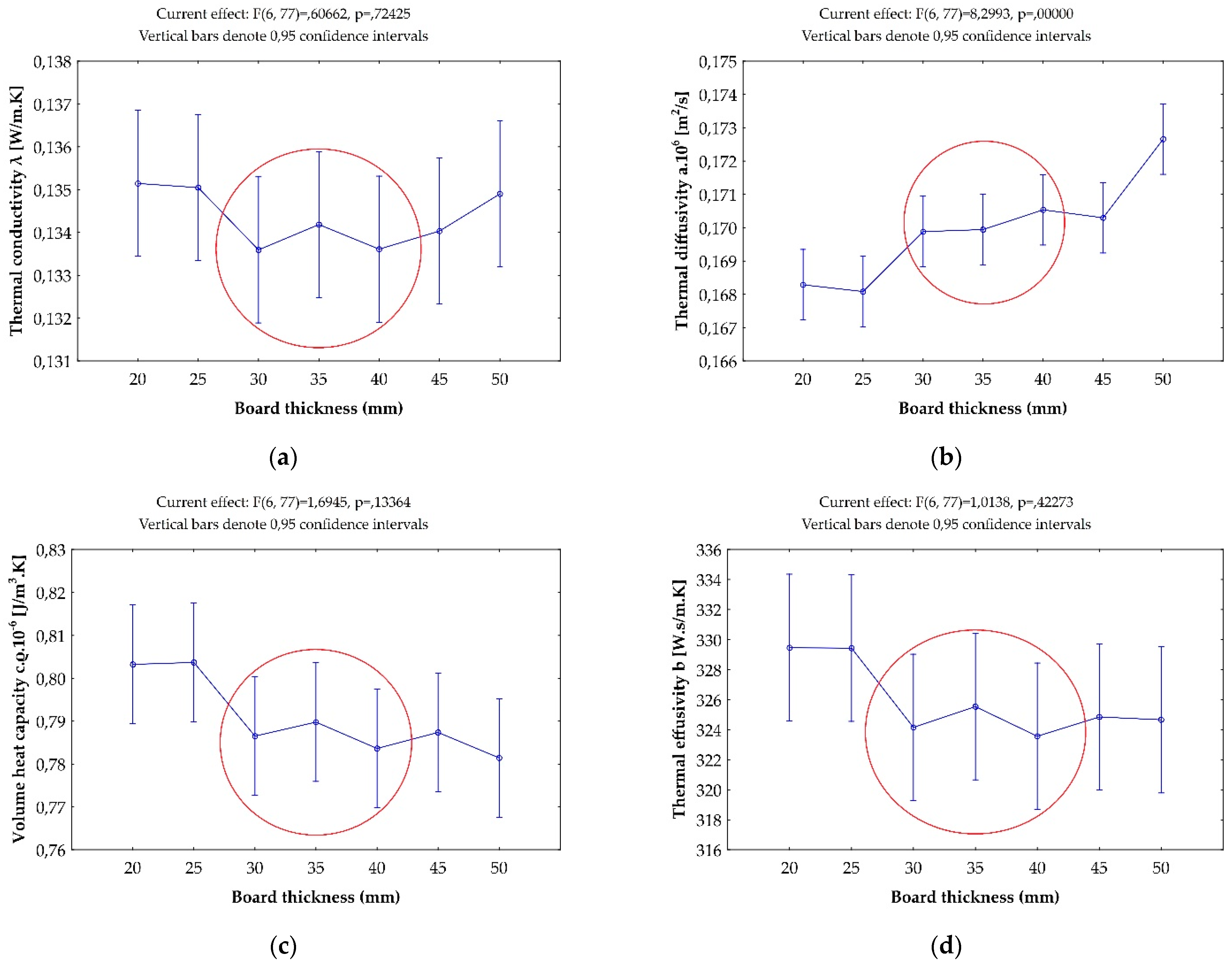

- As the treatment temperature increases, the thermal characteristics gradually decrease. At the highest treatment temperature of 200 °C, there is a decrease in conductivity by 20.2%, a decrease in diffusivity by 6.0%, a decrease in volume heat capacity by 15.0%, and a decrease in effusivity by 17.7%. The decrease in diffusivity is almost constant at all treatment levels, or the differences are statistically insignificant.

- As the treatment temperature increases, the selected colour and gloss parameters gradually decrease. At the highest treatment temperature of 200 °C, there is a decrease in brightness by 44.0%, a decrease in total colour difference by 38.4%, and a decrease in gloss (at an angle of 60°) by 18.2%.

- From the correlation dependencies between the observed quantities, it can be seen that they are statistically significant, regardless of the level of heat treatment. Highly heavy dependencies have been shown between effusivity and volume heat capacity, conductivity and volume heat capacity, effusivity and conductivity, total colour difference and brightness, and gloss and brightness. No dependence between diffusivity and volume heat capacity has been demonstrated.

- Wood defects or anomalies, which are usually a reality in practical wood usage, significantly affect the thermal characteristics of wood, and this issue will need to be given considerable attention in the case of heat-treated wood.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| With Defects | 160/REF | 170/REF | 180/REF | 190/REF | 200/REF |

|---|---|---|---|---|---|

| Without Defects | |||||

| Thermal conductivity | –8.2 | –9.7 | –11.9 | –15.5 | –20.2 |

| –8.5 | –9.5 | –12.1 | –15.7 | –19.9 | |

| Thermal diffusivity | –5.7 | –3.9 | –5.9 | –5.8 | –6.0 |

| –3.3 | –1.8 | –5.7 | –5.0 | –5.5 | |

| Volume heat capacity | –1.4 | –4.3 | –6.3 | –9.8 | –15.0 |

| –5.3 | –7.6 | –6.7 | –10.6 | –15.1 | |

| Thermal effusivity | –5.0 | –7.2 | –9.2 | –12.8 | –17.7 |

| –6.9 | –8.6 | –9.5 | –13.3 | –17.6 |

| 160/REF | 170/REF | 180/REF | 190/REF | 200/REF | |

|---|---|---|---|---|---|

| Brightness | –7.4 | –14.1 | –19.3 | –37.8 | –44.0 |

| Colour parameter a | –11.2 | –2.7 | 11.2 | 36.8 | 17.5 |

| Colour parameter b | –14.8 | –11.7 | –7.9 | –2.3 | –13.1 |

| Total colour difference | –8.4 | –13.7 | –17.6 | –31.6 | –38.4 |

| Degree of gloss at 20° | –10.0 | –19.6 | –36.1 | –57.1 | –52.2 |

| Degree of gloss at 60° | 1.3 | –5.1 | –21.4 | –35.7 | –18.2 |

| Degree of gloss at 85° | 68.0 | 118.7 | 66.7 | 75.5 | 140.9 |

| MS = 7.7787 DF = 445 | 160/REF | 170/REF | 180/REF | 190/REF | 200/REF |

|---|---|---|---|---|---|

| 160/REF | |||||

| 170/REF | 0.000 * | ||||

| 180/REF | 0.000 * | 0.000 * | |||

| 190/REF | 0.000 * | 0.000 * | 0.000 * | ||

| 200/REF | 0.000 * | 0.000 * | 0.000 * | 0.000 * |

| MS = 49.928 DF = 445 | 160/REF | 170/REF | 180/REF | 190/REF | 200/REF |

|---|---|---|---|---|---|

| 160/REF | |||||

| 170/REF | 0.103 | ||||

| 180/REF | 0.847 | 0.094 | |||

| 190/REF | 0.894 | 0.095 | 0.942 | ||

| 200/REF | 0.758 | 0.078 | 0.889 | 0.843 |

| MS = 118.98 DF = 445 | 160/REF | 170/REF | 180/REF | 190/REF | 200/REF |

|---|---|---|---|---|---|

| 160/REF | |||||

| 170/REF | 0.072 | ||||

| 180/REF | 0.004 * | 0.225 | |||

| 190/REF | 0.000 * | 0.001 * | 0.031 * | ||

| 200/REF | 0.000 * | 0.000 * | 0.000 * | 0.001 * |

| MS = 33.456 DF = 445 | 160/REF | 170/REF | 180/REF | 190/REF | 200/REF |

|---|---|---|---|---|---|

| 160/REF | |||||

| 170/REF | 0.011 * | ||||

| 180/REF | 0.000 * | 0.026 * | |||

| 190/REF | 0.000 * | 0.000 * | 0.000 * | ||

| 200/REF | 0.000 * | 0.000 * | 0.000 * | 0.000 * |

| MS = 24.650 DF = 145 | 160/REF | 170/REF | 180/REF | 190/REF | 200/REF |

|---|---|---|---|---|---|

| 160/REF | |||||

| 170/REF | 0.000 * | ||||

| 180/REF | 0.000 * | 0.000 * | |||

| 190/REF | 0.000 * | 0.000 * | 0.000 * | ||

| 200/REF | 0.000 * | 0.000 * | 0.000 * | 0.000 * |

| MS = 160.94 DF = 145 | 160/REF | 170/REF | 180/REF | 190/REF | 200/REF |

|---|---|---|---|---|---|

| 160/REF | |||||

| 170/REF | 0.000 * | ||||

| 180/REF | 0.000 * | 0.000 * | |||

| 190/REF | 0.000 * | 0.000 * | 0.000 * | ||

| 200/REF | 0.000 * | 0.000 * | 0.055 | 0.000 * |

| MS = 58.741 DF = 145 | 160/REF | 170/REF | 180/REF | 190/REF | 200/REF |

|---|---|---|---|---|---|

| 160/REF | |||||

| 170/REF | 0.140 | ||||

| 180/REF | 0.001 * | 0.059 | |||

| 190/REF | 0.000 * | 0.000 * | 0.004 * | ||

| 200/REF | 0.401 | 0.467 | 0.012 * | 0.000 * |

| MS = 19.419 DF = 145 | 160/REF | 170/REF | 180/REF | 190/REF | 200/REF |

|---|---|---|---|---|---|

| 160/REF | |||||

| 170/REF | 0.000 * | ||||

| 180/REF | 0.000 * | 0.001 * | |||

| 190/REF | 0.000 * | 0.000 * | 0.000 * | ||

| 200/REF | 0.000 * | 0.000 * | 0.000 * | 0.000 * |

| MS = 204.76 DF = 145 | 160/REF | 170/REF | 180/REF | 190/REF | 200/REF |

|---|---|---|---|---|---|

| 160/REF | |||||

| 170/REF | 0.010 * | ||||

| 180/REF | 0.000 * | 0.000 * | |||

| 190/REF | 0.000 * | 0.000 * | 0.000 * | ||

| 200/REF | 0.000 * | 0.000 * | 0.000 * | 0.187 |

| MS = 685.97 DF = 145 | 160/REF | 170/REF | 180/REF | 190/REF | 200/REF |

|---|---|---|---|---|---|

| 160/REF | |||||

| 170/REF | 0.343 | ||||

| 180/REF | 0.001 * | 0.021 * | |||

| 190/REF | 0.000 * | 0.000 * | 0.034 * | ||

| 200/REF | 0.005 * | 0.052 | 0.639 | 0.013 * |

| MS = 30963 DF = 145 | 160/REF | 170/REF | 180/REF | 190/REF | 200/REF |

|---|---|---|---|---|---|

| 160/REF | |||||

| 170/REF | 0.296 | ||||

| 180/REF | 0.979 | 0.304 | |||

| 190/REF | 0.868 | 0.342 | 0.857 | ||

| 200/REF | 0.145 | 0.624 | 0.149 | 0.176 |

References

- Dudík, R.; Šišák, L.; Riedl, M. Regeneration of declining spruce stands in the Czech Republic—Economic view of an alternative species composition. In Book of Abstracts, Proceedings of the Sustainable Forest Management for the Future—The Role of Managerial Economics and Accounting, Zagreb, Croatia, 10–12 May 2018; Posavec, S., Ed.; Faculty of Forestry University of Zagreb: Zagreb, Croatia, 2018; pp. 25–26. [Google Scholar]

- Borůvka, V.; Zeidler, A.; Holeček, T.; Dudík, R. Elastic and Strength Properties of Heat-Treated Beech and Birch Wood. Forests 2018, 9, 197. [Google Scholar] [CrossRef]

- Borůvka, V.; Dudík, R.; Zeidler, A.; Holeček, T. Influence of Site Conditions and Quality of Birch Wood on Its Properties and Utilization after Heat Treatment. Part I—Elastic and Strength Properties, Relationship to Water and Dimensional Stability. Forests 2019, 10, 189. [Google Scholar] [CrossRef]

- Dudík, R.; Borůvka, V.; Zeidler, A.; Holeček, T.; Riedl, M. Influence of Site Conditions and Quality of Birch Wood on Its Properties and Utilization after Heat Treatment. Part II—Surface Properties and Marketing Evaluation of the Effect of the Treatment on Final Usage of Such Wood. Forests 2020, 12, 556. [Google Scholar] [CrossRef]

- Esteves, B.M.; Pereira, H.M. Wood modification by heat treatment: A review. BioResources 2009, 4, 370–404. [Google Scholar] [CrossRef]

- Hill, C.A.S. Wood Modification: Chemical, Thermal and Other Processes; John Wiley & Sons: London, UK, 2006; p. 260. ISBN 978-0-470-02172-9. [Google Scholar]

- ITA (International Thermowood Association). Thermowood Handbook; International Thermowood Association: Helsinki, Finland, 2003; Available online: https://asiakas.kotisivukone.com/files/en.thermowood.palvelee.fi/downloads/tw_handbook_080813.pdf (accessed on 15 March 2021).

- Reinprecht, L. Wood Deterioration, Protection and Maintenance, 1st ed.; John Wiley & Sons: Oxford, UK, 2016; p. 376. ISBN 978-1119106531. [Google Scholar]

- Sandberg, D.; Kutnar, A.; Mantanis, G. Wood modification technologies—A review. iForest 2017, 10, 895–908. [Google Scholar] [CrossRef]

- Haviarová, E.; Babiak, M.; Nemec, Ľ.; Joščák, P. Teplotný vnem človeka a tepelné vlastnosti vybraných materiálov a drevín používaných k tvorbe komplexného interiéru (Temperature sense of a person and thermal properties of selected materials and wood species used at the complex interior formation). Acta Fac. Xylologiae Zvolen 1996, 38, 7–14. [Google Scholar]

- Sadoh, T.; Nakato, K. Surface properties of wood in physical and sensory aspects. Wood Sci. Technol. 1987, 21, 111–120. [Google Scholar] [CrossRef]

- Tsoumis, G.T. Science and Technology of Wood—Structure, Properties, Utilization, 1st ed.; Van Nostrand Reinhold: New York, NY, USA, 1991; p. 494. ISBN 9780442239855. [Google Scholar]

- ČSN EN 12664. Tepelné Chování Stavebních Materiálů a Výrobků—Stanovení Tepelného Odporu Metodami Chráněné Topné Desky a Měřidla Tepelného Toku—Suché a Vlhké Výrobky o Středním a Nízkém Tepelném Odporu (Thermal Performance of Building Materials and Products—Determination of Thermal Resistance by Means of Guarded Hot Plate and Heat Flow Meter Methods—Dry and Moist Products with Medium and Low Thermal Resistence); Czech Office for Standards, Metrology and Testing: Prague, Czech Republic, 2001. [Google Scholar]

- ČSN EN 12667. Tepelné Chování Stavebních Materiálů a Výrobků—Stanovení Tepelného Odporu Metodami Chráněné Topné Desky a Měřidla Tepelného Toku—Výrobky o Vysokém a Středním Tepelném Odporu (Thermal Performance of Building Materials and Products—Determination of Thermal Resistance by Means of Guarded Hot Plate and Heat Flow Meter Methods—Products of High and Medium Thermal Resistence); Czech Office for Standards, Metrology and Testing: Prague, Czech Republic, 2001. [Google Scholar]

- Bouguerra, A.; Ledhem, A.; Laurent, J.P.; Diop, M.B.; Queneudec, M. Thermal effusivity of two-phase wood cement-based composites. J. Phys. D Appl. Phys. 1998, 31, 2184–2190. [Google Scholar] [CrossRef]

- Bouguerra, A.; Diop, M.B.; Laurent, J.P.; Benmalek, M.L.; Queneudec, M. Effect of moisture content on the thermal effusivity of wood cement-based composites. J. Phys. D Appl. Phys. 1998, 31, 3457–3462. [Google Scholar] [CrossRef]

- Gustafsson, S.E.; Karawacki, E.; Chohan, M.A. Thermal transport studies of electrically conducting materials using the transient hot-strip technique. J. Phys. D Appl. Phys. 1986, 19, 727–735. [Google Scholar] [CrossRef]

- Harada, T.; Hata, T.; Ishihara, S. Thermal constants of wood during the heating process measured with the laser flash method. J. Wood Sci. 1998, 44, 425–431. [Google Scholar] [CrossRef]

- He, Y. Rapid thermal conductivity measurement with a hot disk sensor. Thermochim. Acta 2005, 436, 130–134. [Google Scholar] [CrossRef]

- Hrčka, R.; Babiak, M. Wood Thermal Properties. In Wood in Civil Engineering, 2nd ed.; Concu, G., Ed.; IntechOpen: Rijeka, Croatia, 2017; pp. 25–43. [Google Scholar] [CrossRef]

- Hrčka, R.; Babiak, M. Some non-traditional factors influencing thermal properties of wood. Wood Res. 2012, 57, 367–374. [Google Scholar]

- Cha, J.; Seo, J.; Kim, S. Building materials thermal conductivity measurement and correlation with heat flow meter, laser flash analysis and TCi. J. Therm. Anal. Calorim. 2012, 109, 295–300. [Google Scholar] [CrossRef]

- Kadem, S.; Lachemet, A.; Younsi, R.; Kocaefe, D. 3d-Transient modeling of heat and mass transfer during heat treatment of wood. Int. Commun. Heat Mass Transf. 2011, 38, 717–722. [Google Scholar] [CrossRef]

- Kotlarewski, N.J.; Ozarska, B.; Gusamo, B.K. Thermal conductivity of Papua New Guinea balsa wood measured using the needle probe procedure. BioResources 2014, 9, 5784–5793. [Google Scholar] [CrossRef]

- Lagüela, S.; Bison, P.; Peron, F.; Romagnoni, P. Thermal conductivity measurements on wood materials with transient plane source technique. Thermochim. Acta 2015, 600, 45–51. [Google Scholar] [CrossRef]

- Maeda, K.; Tsunetsugu, Y.; Miyamoto, K.; Shibusawa, T. Thermal properties of wood measured by the hot-disk method: Comparison with thermal properties measured by the steady-state method. J. Wood Sci. 2021, 67, 20. [Google Scholar] [CrossRef]

- Olek, W.; Weres, J.; Guzenda, R. Effects of thermal conductivity data on accuracy of modeling heat transfer in wood. Holzforschung 2003, 57, 317–325. [Google Scholar] [CrossRef]

- Suleiman, B.; Larfeldt, J.; Leckner, B.; Gustavsson, M. Thermal conductivity and diffusivity of wood. Wood Sci. Technol. 1999, 33, 465–473. [Google Scholar] [CrossRef]

- Vay, O.; De Borst, K.; Hansmann, C.; Teischinger, A.; Müller, U. Thermal conductivity of wood at angles to the principal anatomical directions. Wood Sci. Technol. 2015, 49, 577–589. [Google Scholar] [CrossRef]

- Weres, J.; Olek, W.; Guzenda, R. Identification of mathematical model coefficients in the analysis of the heat and mass transport in wood. Dry. Technol. 2000, 18, 1697–1708. [Google Scholar] [CrossRef]

- Weres, J.; Olek, W. Inverse Finite Element Analysis of Technological Processes of Heat and Mass Transport in Agricultural and Forest Products. Dry. Technol. 2005, 23, 1737–1750. [Google Scholar] [CrossRef]

- Yapici, F.; Ozcifci, A.; Esen, R.; Kurt, S. The effect of grain angle and species on thermal conductivity of some selected wood species. BioResources 2011, 6, 2757–2762. [Google Scholar] [CrossRef]

- Bottomley, J.T. On the thermal conductivity of water. Proc. R. Soc. A Philospohical Trans. 1881, 172, 537–545. [Google Scholar] [CrossRef][Green Version]

- Griffiths, E.; Kaye, G.W.C. The measurement of thermal conductivity. Proc. R. Soc. A Math. Phys. Eng. Sci. 1923, 104, 71–98. [Google Scholar] [CrossRef]

- Hercus, E.O.; Laby, T.H. The thermal conductivity of air. Proc. R. Soc. A Math. Phys. Eng. Sci. 1919, 95, 190–210. [Google Scholar] [CrossRef]

- Rohsenow, W.M.; Hartnett, J.P.; Cho, Y.I. Handbook of Heat Transfer, 3rd ed.; McGraw-Hill: New York, NY, USA, 1998; p. 1520. ISBN 9780070535558. [Google Scholar]

- Schroeder, D.V. An Introduction to Thermal Physics, 1st ed.; Pearson: London, UK, 1999; p. 432. ISBN 0-201-38027-7. [Google Scholar]

- Tritt, T.M. Thermal Conductivity—Theory, Properties, and Applications; Springer: New York, NY, USA, 2004; p. 290. ISBN 0-306-48327-0. [Google Scholar]

- Siau, J.F. Transport. Processes in Wood; Springer: Berlin/Heidelberg, Germany, 1984; p. 248. ISBN 978-3-642-69213-0. [Google Scholar]

- Zobel, B.J.; Buijtenen, J.P. Wood Variation: Its Causes and Control, 1st ed.; Springer: Berlin/Heidelberg, Germany, 1989; p. 363. ISBN 978-3-642-74071-8. [Google Scholar]

- Kollmann, F.F.P.; Côté, W.A. Principles of Wood Science and Technology—I Solid Wood; Springer: Berlin/Heidelberg, Germany, 1968; p. 592. ISBN 978-3-642-87930-2. [Google Scholar]

- Niemz, P. Physik des Holzes und der Holzwerkstoffe; DRW-Verlag: Leinfelden-Echterdingen, Germany, 1993; p. 243. ISBN 3-87181-324-9. [Google Scholar]

- ČSN 49 0101. Drevo. Všeobecné Požiadavky na Fyzikálne a Mechanické Skúšky (Wood. General Requirements for Physical and Mechanical Testing); Office for Standardization and Measurement: Prague, Czech Republic, 1980. [Google Scholar]

- Viitaniemi, P.; Ranta-Maunus, A.; Jämsä, S.; Ek, P. Method for Processing of Wood at Elevated Temperatures. Patent EP-0759137 VTT, 11 May 1995. [Google Scholar]

- ČSN EN ISO 11664-4. Kolorimetrie—Část 4: Kolorimetrický Prostor CIE 1976 L*a*b* (Colorimetry—Part 4: CIE 1976 L*a*b* Colour Space); Czech Office for Standards, Metrology and Testing: Prague, Czech Republic, 2011. [Google Scholar]

- ČSN EN ISO 11664-6. Kolorimetrie—Část 6: CIEDE2000 Vzorce Výpočtu Barevného Rozdílu (Colorimetry—Part 6: CIEDE2000 Colour-Difference Formula); Czech Office for Standards, Metrology and Testing: Prague, Czech Republic, 2017. [Google Scholar]

- ČSN EN ISO 2813. Nátěrové Hmoty—Stanovení Čísla Lesku při Úhlu 20°, 60° a 85° (Paints and Varnishes—Determination of Gloss Value at 20 Degrees, 60 Degrees and 85 Degrees); Czech Office for Standards, Metrology and Testing: Prague, Czech Republic, 2016. [Google Scholar]

- ČSN 49 0108. Drevo. Zisťovanie Hustoty (Wood. Determination of the Density); Czech Standards Institute: Prague, Czech Republic, 1993. [Google Scholar]

- ČSN 49 0103. Drevo. Zisťovanie Vlhkosti pri Fyzikálnych a Mechanických Skúškach (Wood. Determination of Moisture Content at Physical and Mechanical Testing); Office for Standardization and Measurement: Prague, Czech Republic, 1979. [Google Scholar]

- Bucur, V. Nondestructive Characterization and Imaging of Wood, 1st ed.; Springer: Berlin/Heidelberg, Germany, 2003; p. 354. ISBN 978-3-540-43840-3. [Google Scholar]

- Dubois, H.; Verkasalo, E.; Claessens, H. Potential of Birch (Betula pendula Roth and B. pubescens Ehrh.) for Forestry and Forest-Based Industry Sector within the Changing Climatic and Socio-Economic Context of Western Europe. Forests 2020, 11, 336. [Google Scholar] [CrossRef]

| REF * | 160 | 170 | 180 | 190 | 200 | |

|---|---|---|---|---|---|---|

| Thermal conductivity | 0.135 | 0.125 | 0.129 | 0.112 | 0.114 | 0.104 |

| (W/m.K) | 0.013 | 0.013 | 0.014 | 0.005 | 0.007 | 0.006 |

| Thermal diffusivity | 0.179 | 0.171 | 0.173 | 0.165 | 0.167 | 0.166 |

| .106 (m2/s) | 0.018 | 0.010 | 0.017 | 0.006 | 0.005 | 0.005 |

| Volume heat capacity | 0.754 | 0.733 | 0.747 | 0.682 | 0.683 | 0.631 |

| .10−6 (J/m3.K) | 0.062 | 0.072 | 0.072 | 0.040 | 0.045 | 0.041 |

| Thermal effusivity | 318.2 | 302.6 | 309.9 | 276.9 | 278.9 | 256.5 |

| (W.s/m.K) | 24.3 | 28.8 | 27.5 | 13.0 | 17.5 | 15.2 |

| REF * | 160 | 170 | 180 | 190 | 200 | |

|---|---|---|---|---|---|---|

| Brightness | 72.08 | 66.53 | 61.41 | 58.12 | 45.20 | 40.44 |

| 2.80 | 3.00 | 5.60 | 2.22 | 3.11 | 4.52 | |

| Colour parameter a | 8.93 | 7.98 | 8.75 | 9.79 | 11.78 | 10.28 |

| 1.08 | 0.61 | 0.79 | 0.51 | 0.49 | 0.40 | |

| Colour parameter b | 25.96 | 21.39 | 23.44 | 23.50 | 25.06 | 23.02 |

| 1.74 | 1.30 | 1.03 | 1.25 | 1.11 | 1.89 | |

| Total colour difference | 77.17 | 70.36 | 66.37 | 63.48 | 53.04 | 47.68 |

| 2.44 | 2.87 | 5.06 | 1.99 | 2.87 | 4.68 | |

| Degree of gloss at 20° | 1.0 | 0.8 | 0.7 | 0.7 | 0.5 | 0.5 |

| (GU) | 0.2 | 0.2 | 0.2 | 0.1 | 0.1 | 0.1 |

| Degree of gloss at 60° | 4.5 | 4.2 | 3.7 | 3.8 | 3.1 | 3.5 |

| (GU) | 0.9 | 0.7 | 1.2 | 0.6 | 0.5 | 0.5 |

| Degree of gloss at 85° | 2.3 | 3.1 | 3.2 | 3.5 | 4.2 | 4.6 |

| (GU) | 0.8 | 1.2 | 1.2 | 0.6 | 1.1 | 1.4 |

| REF | 160 | 170 | 180 | 190 | 200 | ||

|---|---|---|---|---|---|---|---|

| Density (kg/m3) | before modification | - | 629 | 640 | 609 | 623 | 613 |

| after modification | - | 617 | 625 | 592 | 601 | 567 | |

| Moisture content (%) | - | 13.4 | 10.0 | 9.5 | 8.1 | 7.4 | 6.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Borůvka, V.; Šedivka, P.; Novák, D.; Holeček, T.; Turek, J. Haptic and Aesthetic Properties of Heat-Treated Modified Birch Wood. Forests 2021, 12, 1081. https://doi.org/10.3390/f12081081

Borůvka V, Šedivka P, Novák D, Holeček T, Turek J. Haptic and Aesthetic Properties of Heat-Treated Modified Birch Wood. Forests. 2021; 12(8):1081. https://doi.org/10.3390/f12081081

Chicago/Turabian StyleBorůvka, Vlastimil, Přemysl Šedivka, David Novák, Tomáš Holeček, and Jiří Turek. 2021. "Haptic and Aesthetic Properties of Heat-Treated Modified Birch Wood" Forests 12, no. 8: 1081. https://doi.org/10.3390/f12081081

APA StyleBorůvka, V., Šedivka, P., Novák, D., Holeček, T., & Turek, J. (2021). Haptic and Aesthetic Properties of Heat-Treated Modified Birch Wood. Forests, 12(8), 1081. https://doi.org/10.3390/f12081081