Correlation of Studies between Colour, Structure and Mechanical Properties of Commercially Produced ThermoWood® Treated Norway Spruce and Scots Pine

Abstract

1. Introduction

2. Materials and Methods

- Phase 1—Warming up the wood and kiln (90 to 100 °C);

- Phase 2—High–temperature kiln drying (100 to 130 °C) and mild thermal modification (130 to 190 °C);

- Phase 3—Intensive thermal modification for 2 to 3 h at a temperature dependent on the treatment class (Thermo–S = 190 ± 3 °C, Thermo–D = 212 ± 3 °C);

- Phase 4—Cooling to a temperature between approximately 80 and 90 °C and reconditioning to a final moisture content between 4 and 7%; and

- Phase 5—Final cooling down to ambient temperature.

2.1. Infrared (FT–IR) Spectroscopy and Principal Component Analysis (PCA)

2.2. Colour Measurements

2.3. Bending Strength

2.4. Hardness

3. Results and Discussion

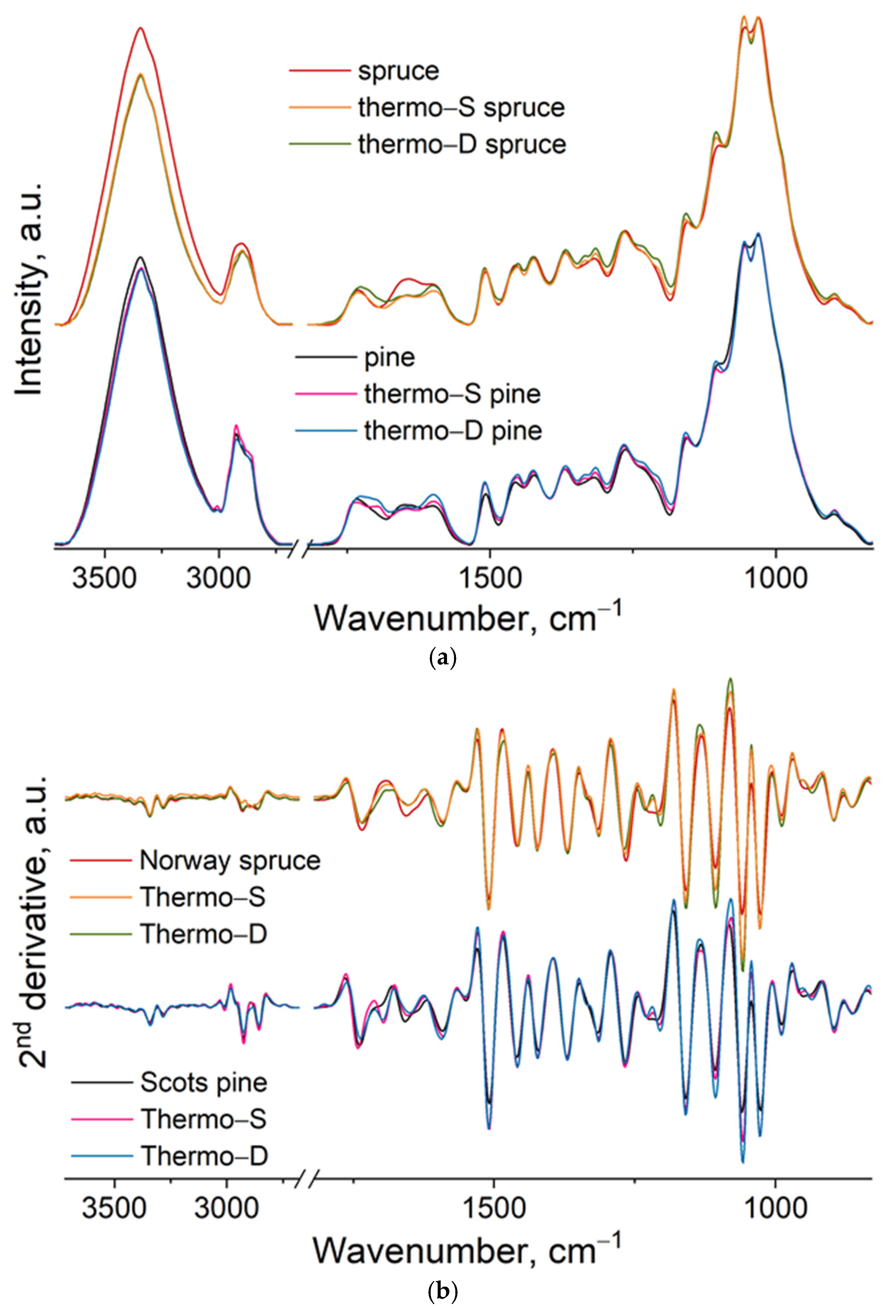

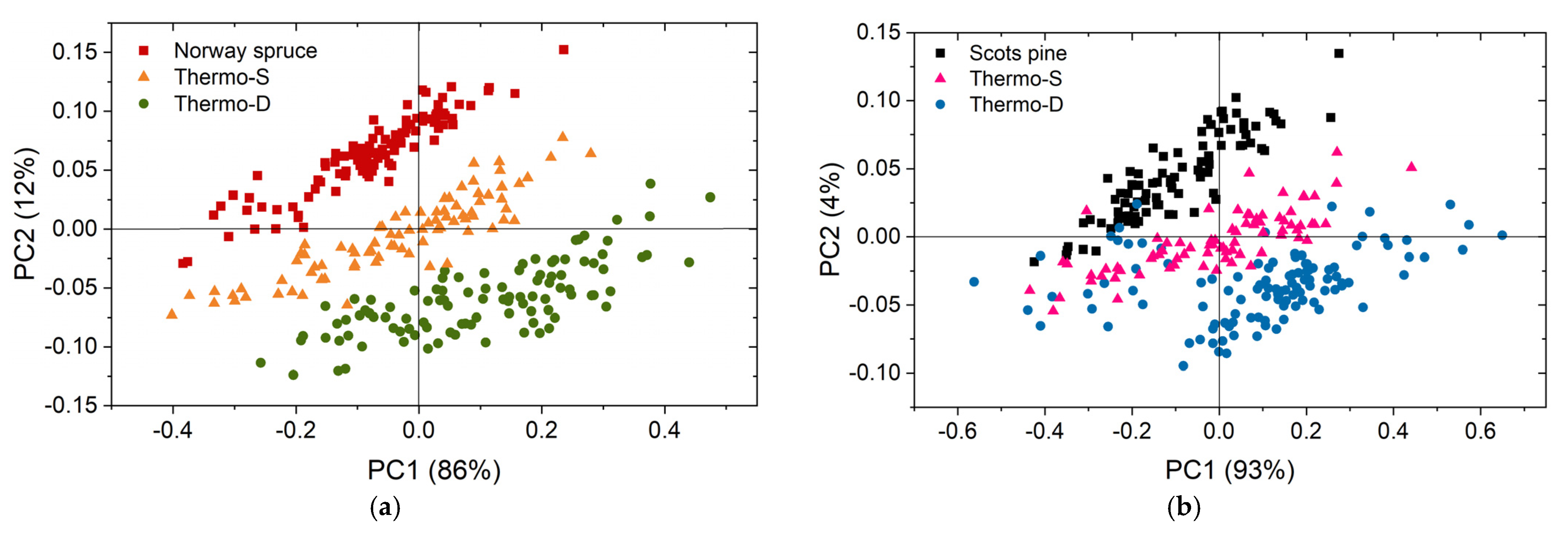

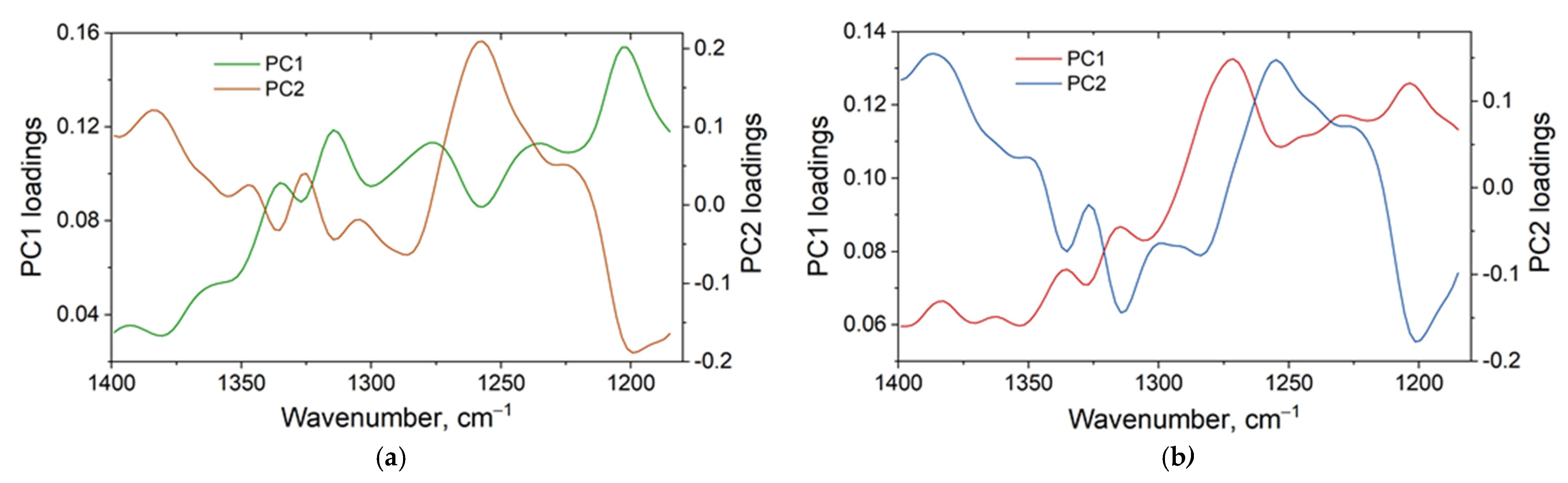

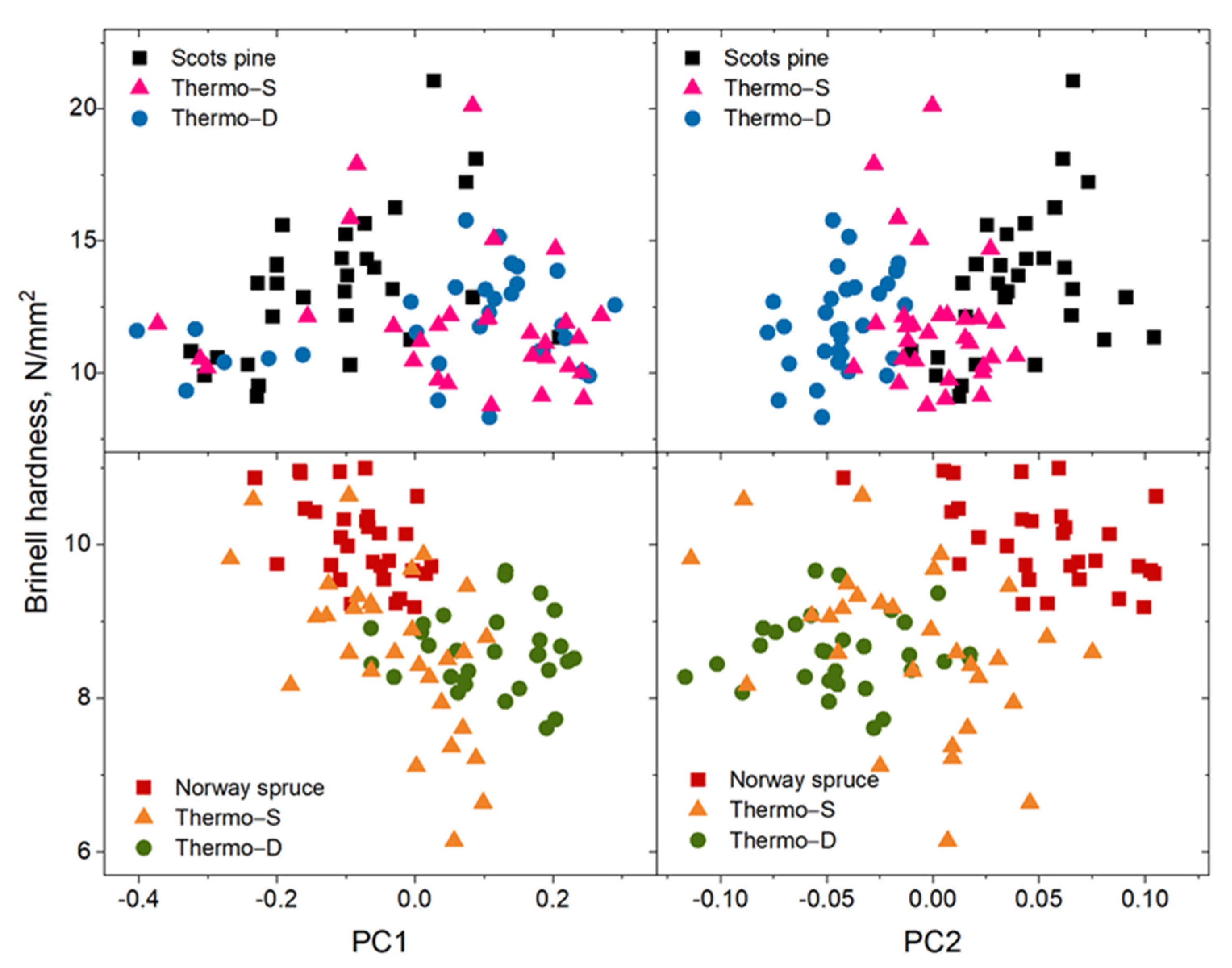

3.1. Fourier Transform Infrared (FT–IR) Spectroscopy and Principal Component Analysis (PCA)

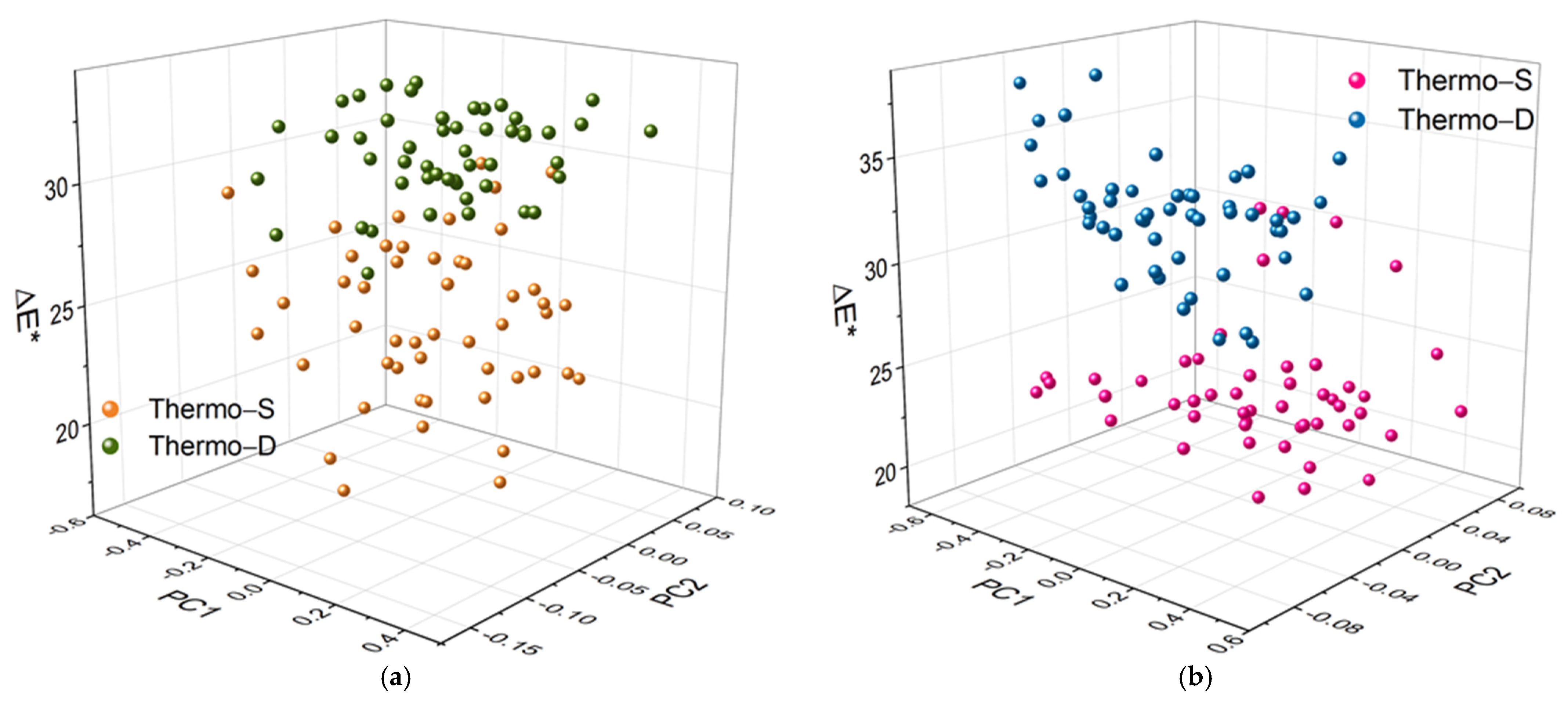

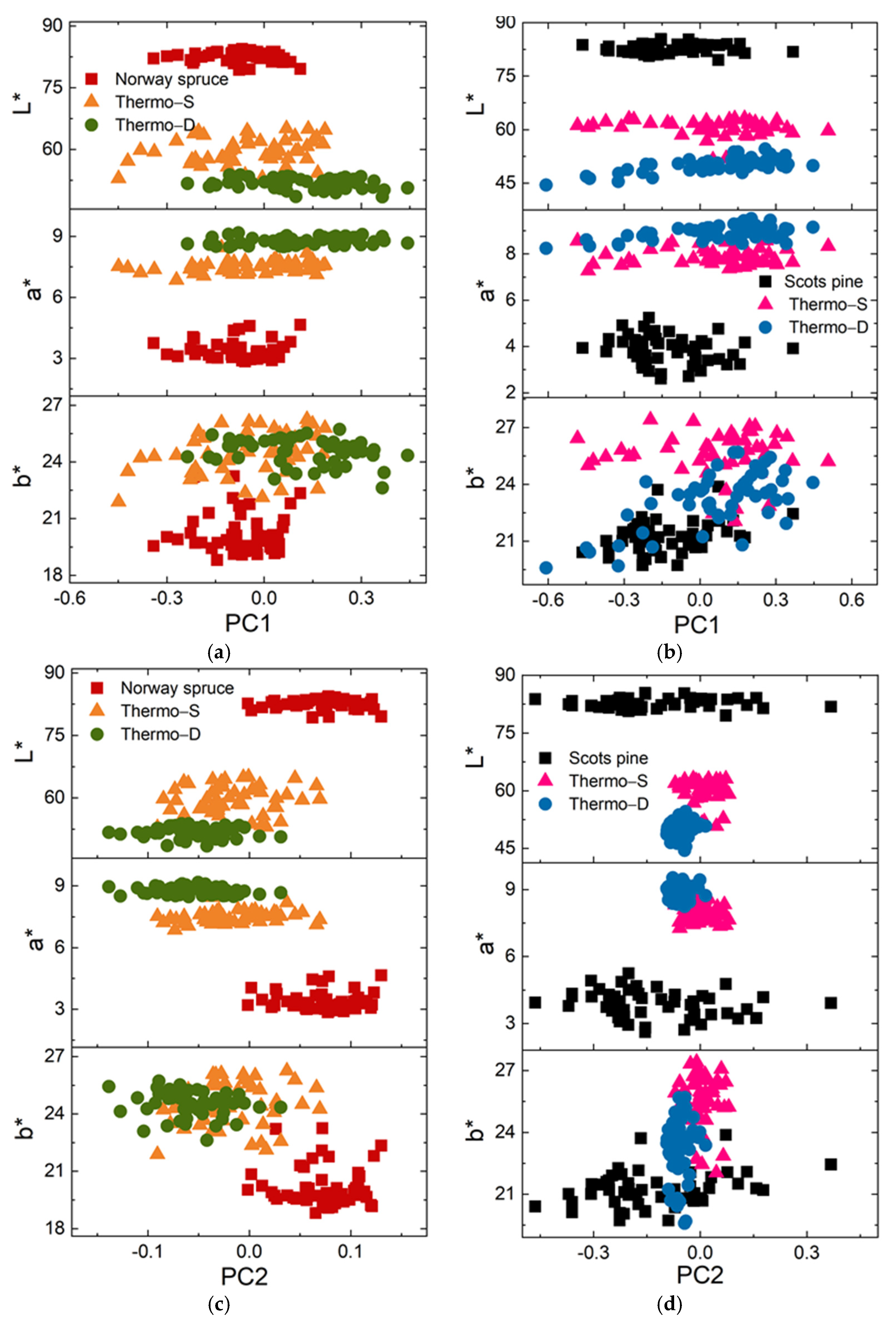

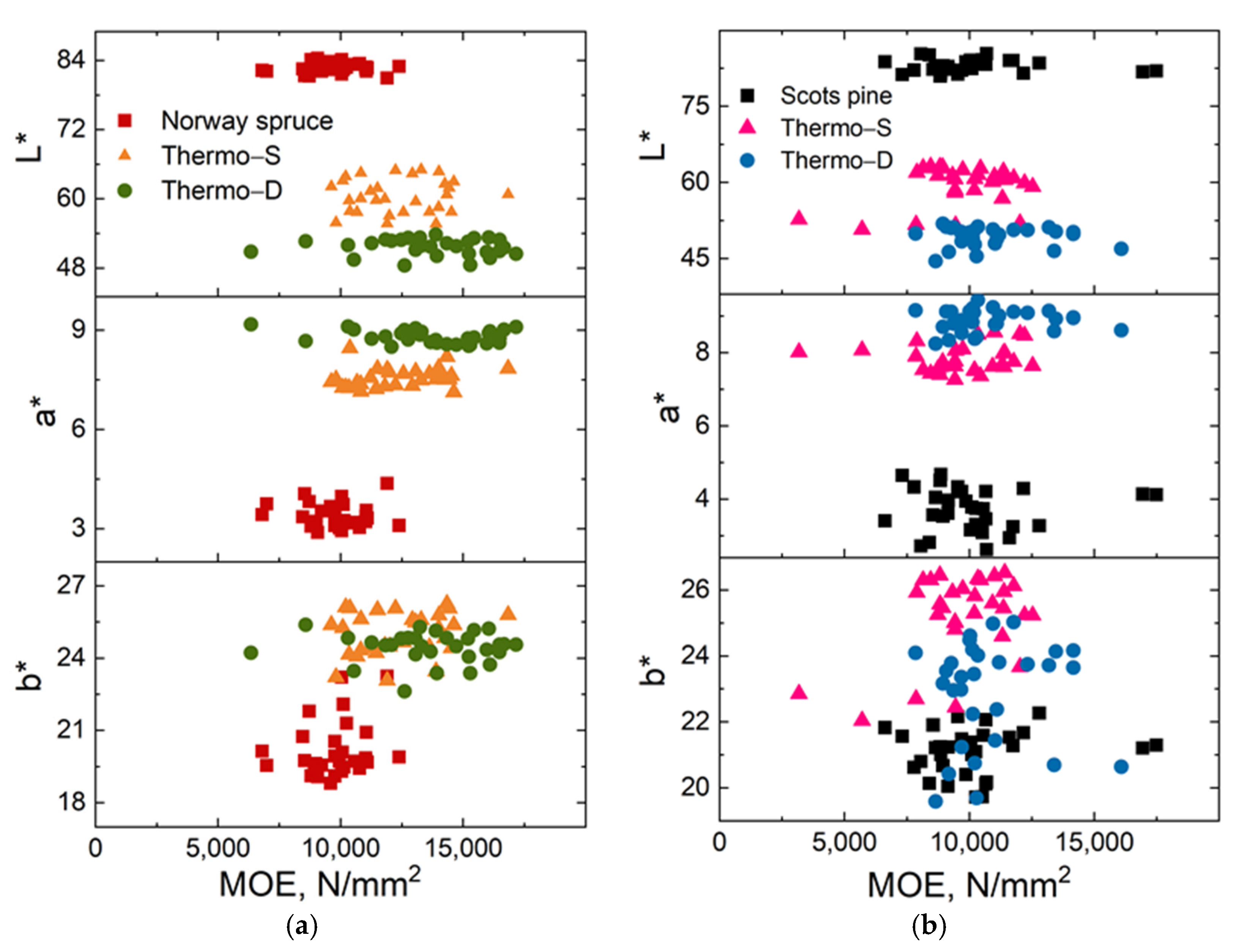

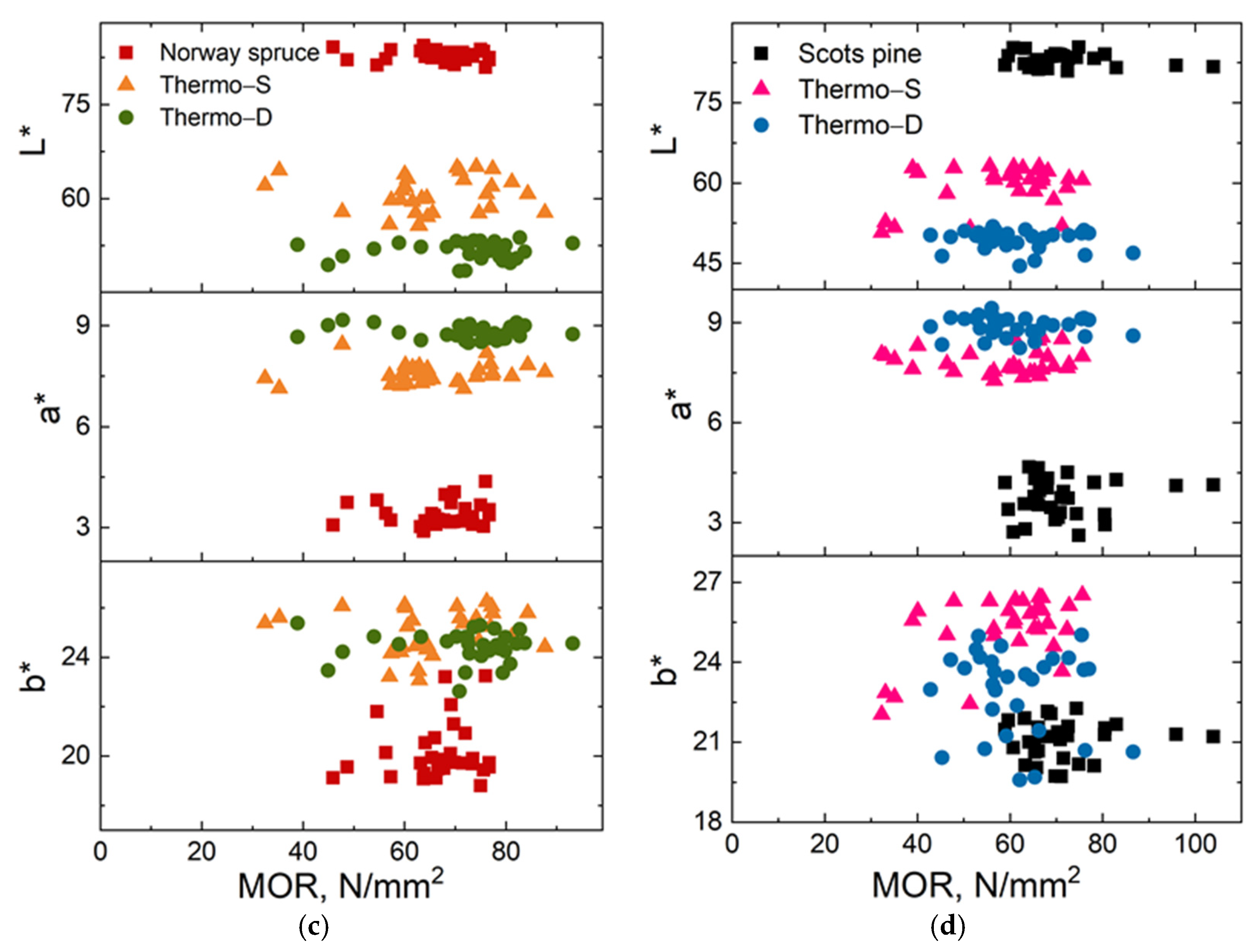

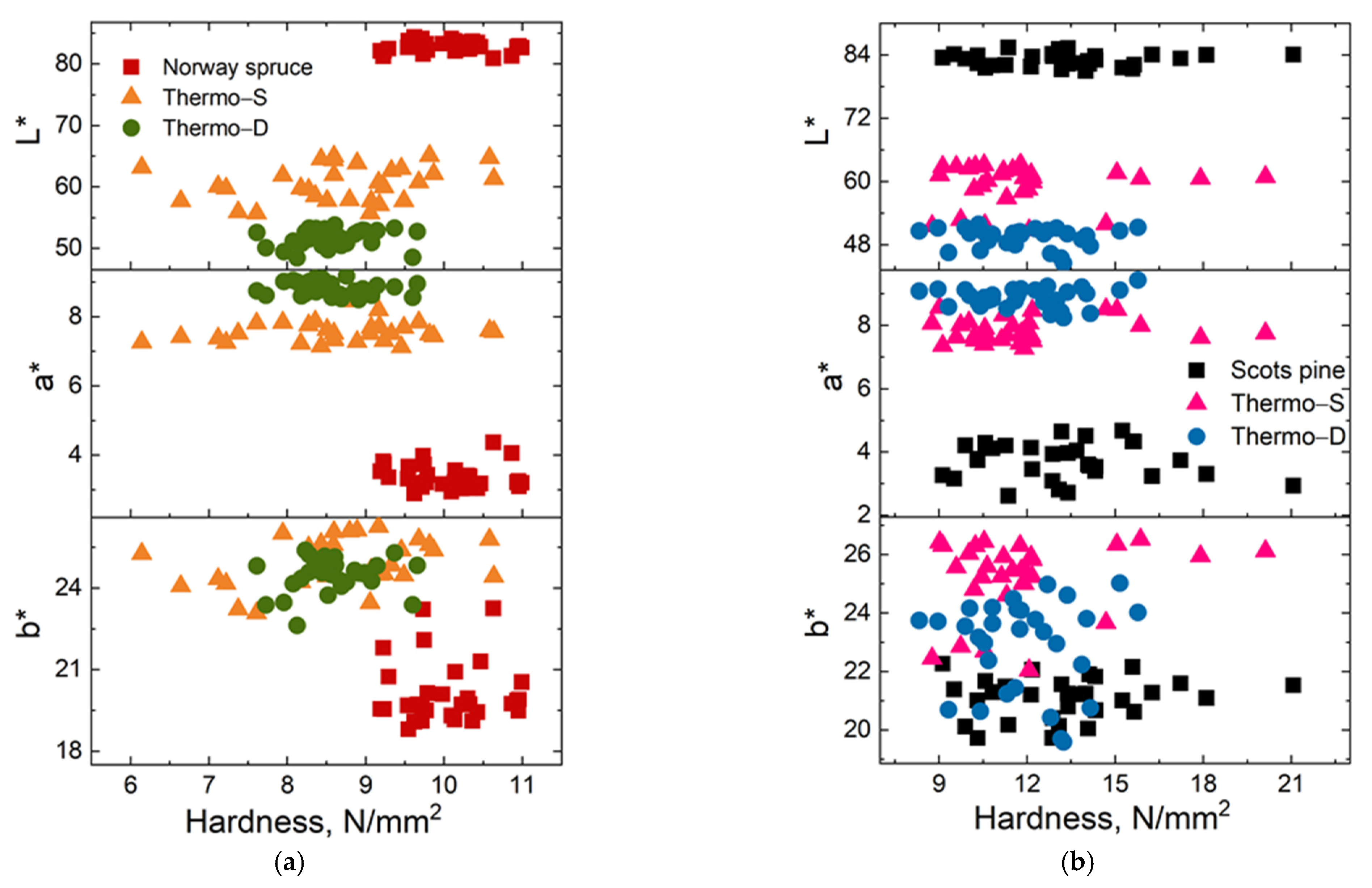

3.2. Colour Measurements

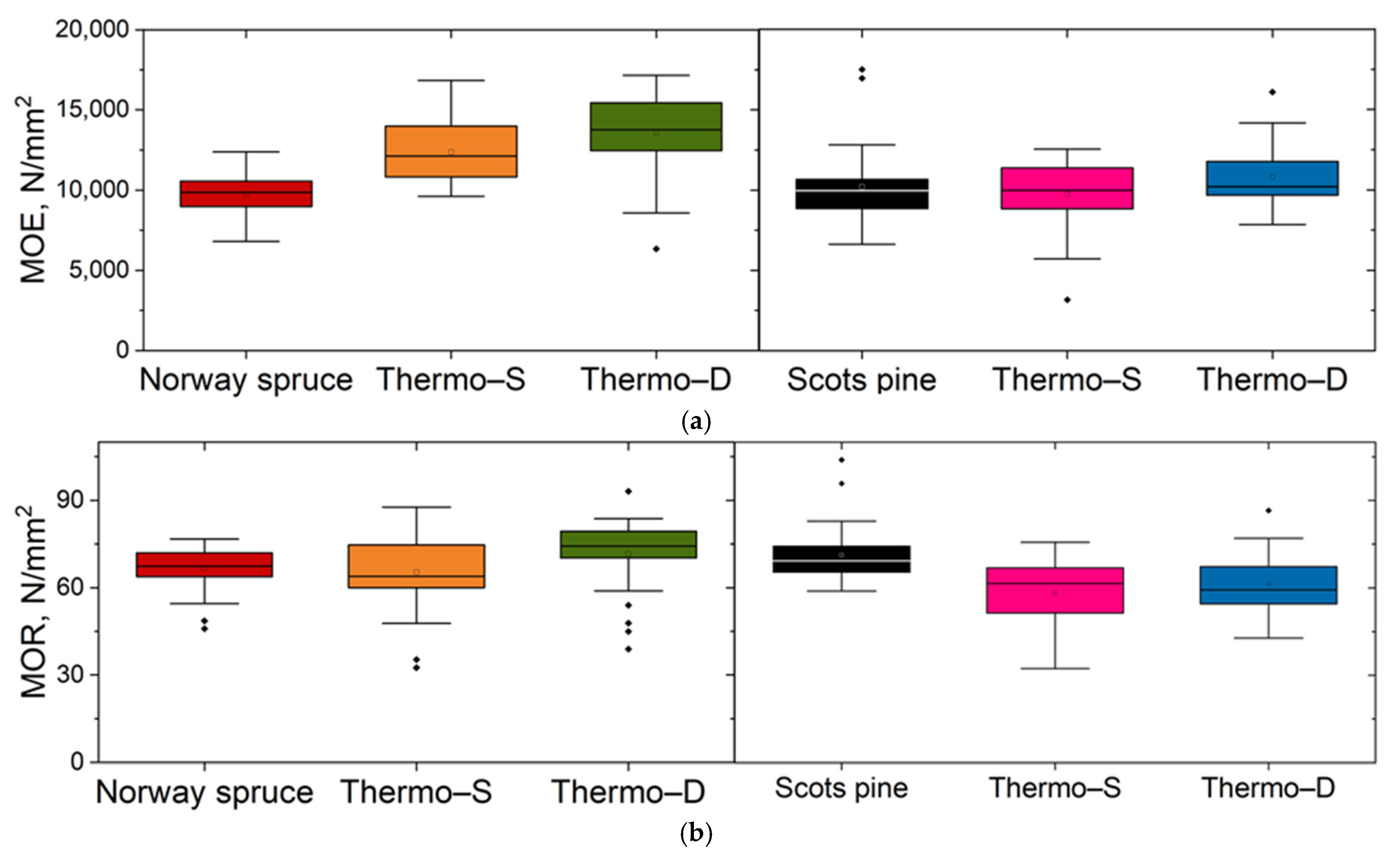

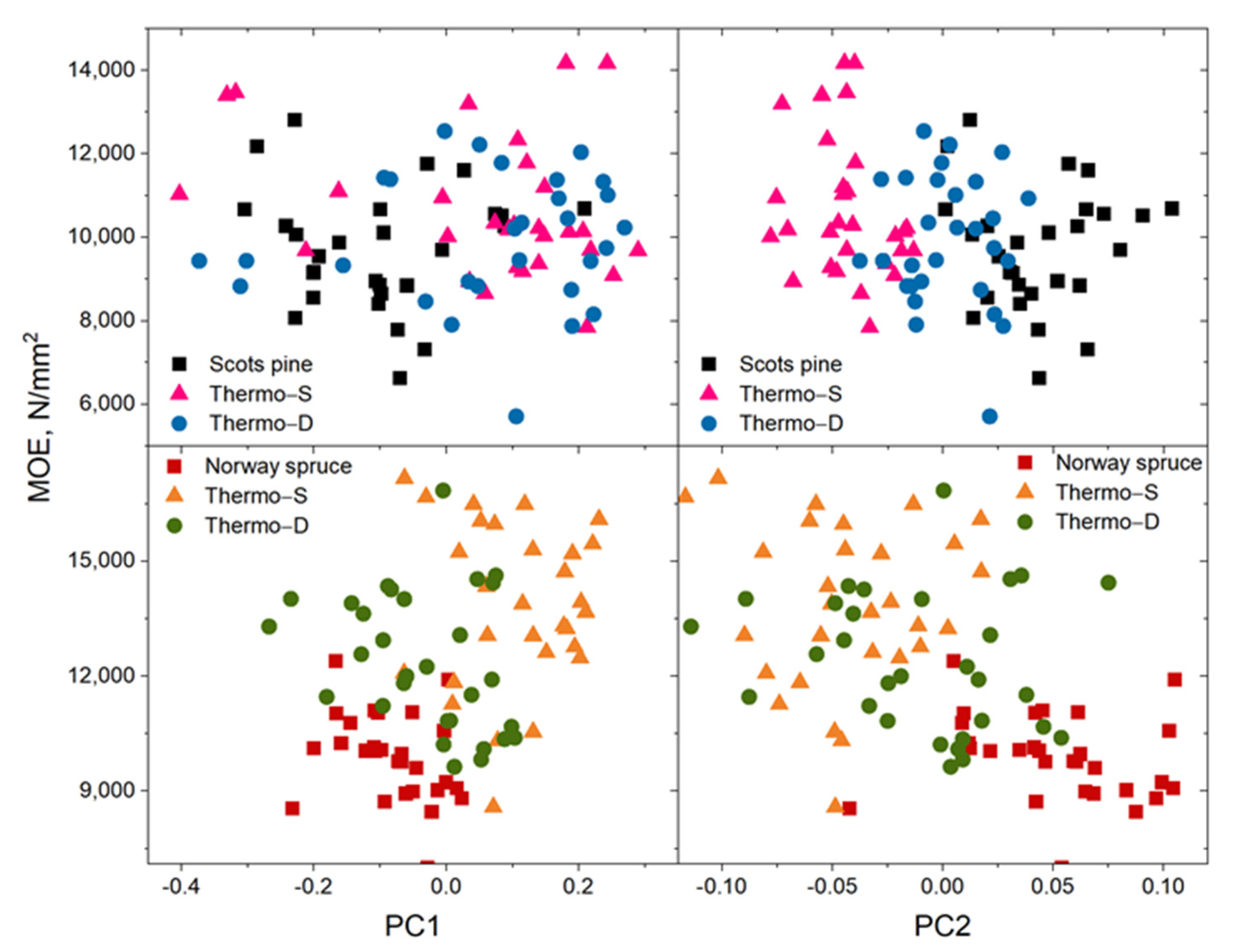

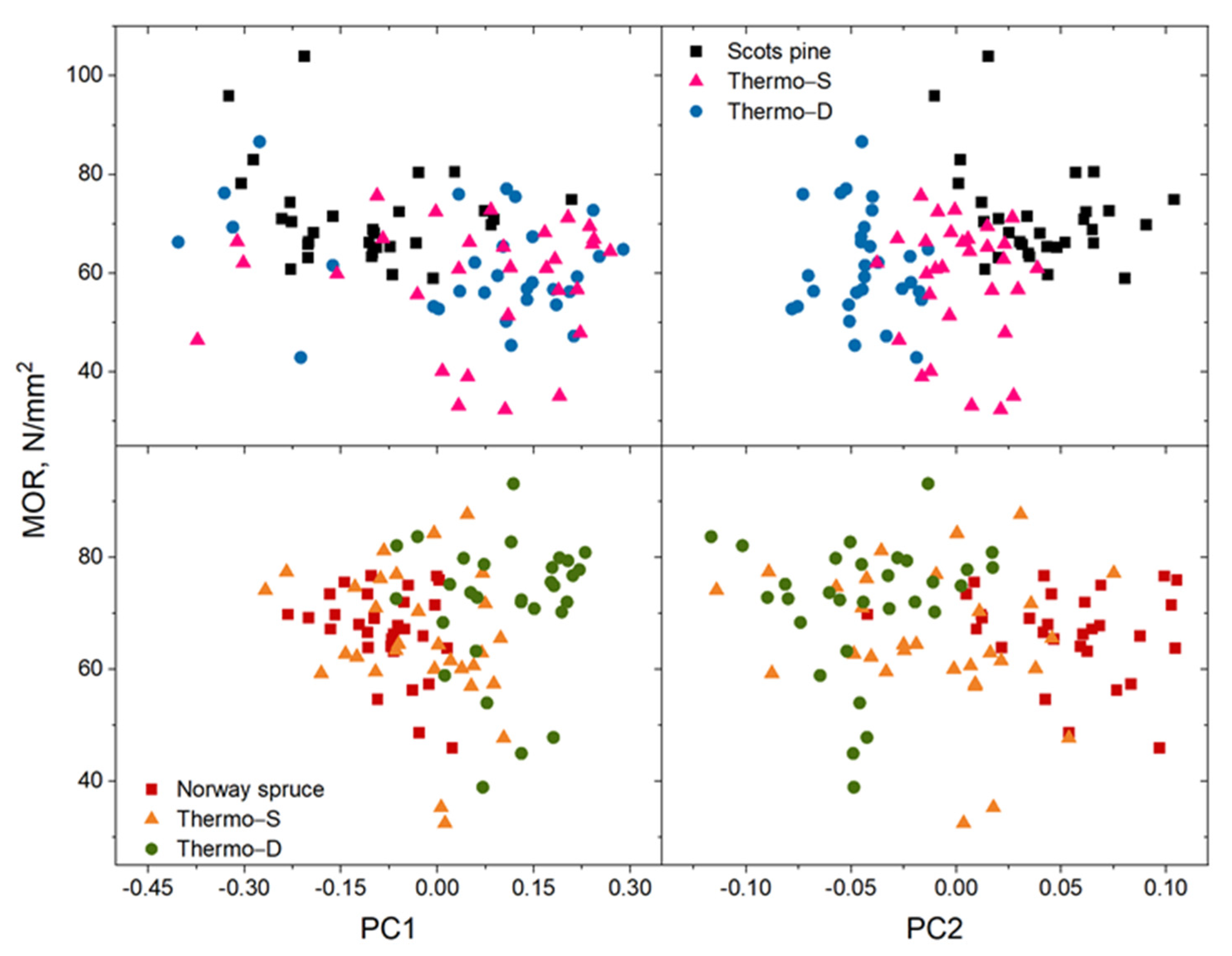

3.3. Modulus of Elasticity and Modulus of Rupture

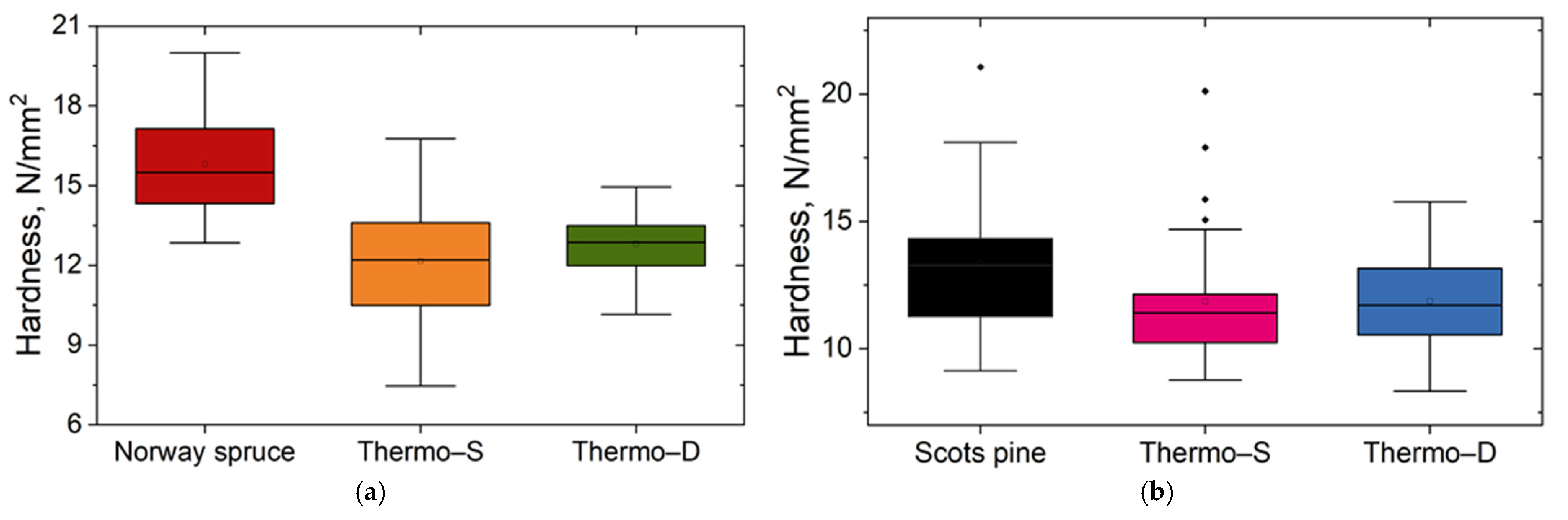

3.4. Brinell Hardness

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Hill, C.A.S. Wood Modification: Chemical, Thermal and Other Processes; John Wiley & Sons: Chichester, UK, 2006; 239p. [Google Scholar]

- Gérardin, P. New alternatives for wood preservation based on thermal and chemical modification of wood—A review. Ann. For. Sci. 2016, 73, 559–570. [Google Scholar] [CrossRef]

- Sandberg, D.; Kutnar, A.; Mantanis, G.I. Wood modification technologies—A review. iForest 2017, 10, 895–908. [Google Scholar] [CrossRef]

- Jones, D.; Sandberg, D.; Goli, G.; Todaro, L. Wood Modification in Europe: A State-of-the-Art about Processes, Products and Applications; Firenze University Press: Florence, Italy, 2019; p. 113. ISSN 2704-601X. [Google Scholar]

- Stamm, A.J.; Burr, H.K.; Kline, A.A. Staybwood. Heat stabilized wood. Ind. Eng. Chem. 1946, 38, 630–634. [Google Scholar] [CrossRef]

- Thunell, B.; Elken, E. Värmebehandling av trä för Minskning av Svällning och Krympning; Report No. 18; The Swedish Wood Technology Research Institute: Stockholm, Sweden, 1948; p. 23. (In Swedish) [Google Scholar]

- Buro, A. Die Wirkung von Hitzebehandlung auf die Pilzresistenz von Kiefern- und Buchenholz. [The influence of thermal treatment on decay resistance of pine and beech wood]. Holz Roh- Werkst. 1954, 12, 297–304. [Google Scholar] [CrossRef]

- Buro, A. Untersuchungen über die Veränderung der Pilzresistenz von Hölzern durch Hitzebehandlung in Metallschmelzen. [Investigation of the change in decay resistance of wood during thermal treatment in a metal melt]. Holzforschung 1955, 9, 177–181. [Google Scholar] [CrossRef]

- Burmester, A. Formbeständigkeit von Holz gegenüber Feuchtigkeit—Grundlagen und Vergütungsverfahren. [Influnce of Moisture on Dimension Stability of Wood–Theory and Improvements]; BAM Berichte No. 4; Bundesanstalt für Materialforschung: Berlin, Germany, 1970. (In German) [Google Scholar]

- Burmester, A. Effect of heat-pressure treatments of semi-dry wood on its dimensional stability. Holz Roh- Werkst. 1973, 31, 237–243. [Google Scholar] [CrossRef]

- Burmester, A. Zur Dimensionsstabilisierung von Holz. [The dimensional stabilization of wood]. Holz Roh- Werkst. 1975, 33, 333–335. [Google Scholar] [CrossRef]

- Burmester, A. Dimensational stabilisation of wood. In The Proceedings IRG Annual Meeting, Sarajevo, Yugoslavia; International Research Group on Wood Protection IRG/WP/3171: Stockholm, Sweden, 1981; 8p. [Google Scholar]

- Viitanen, H.A.; Jämsä, S.; Paajanen, L.M.; Nurmi, A.J.; Viitaniemi, P. The effect of heat treatment on the properties of spruce. In The Procedings IRG Annual Conference, Bali, Indonesia; International Research Group on Wood Protection IRG/WP 94-40032: Stockholm, Sweden, 1994; 5p. [Google Scholar]

- Viitaniemi, P.; Jämsa, S. Modification of Wood with Heat-Treatment; Technical Research Centre of Finland, VTT: Espoo, Finland, 1996; 57p. (In Finnish) [Google Scholar]

- Viitaniemi, P. ThermoWood-modified wood for improved performance. In Proceedings of the 4th Eurowood Symposium “Wood—The Ecological Material”, Stockholm, Sweden, 22–23 September 1997; Trätek Report No. P9709084. pp. 67–69. [Google Scholar]

- Boonstra, M.J.; Tjeerdsma, B.F.; Groeneveld, H.A.C. Thermal modification of non-durable wood species. Part 1. The Plato technology: Thermal modification of wood. In The Proceedings IRG Annual Meeting, Maastricht, The Netherlands; International Research Group on Wood Protection IRG/WP 98-40123: Stockholm, Sweden, 1998. [Google Scholar]

- Militz, H.; Tjeerdsma, B. Heat treatment of wood by the Plato-process. In Proceedings of the Seminar on Production of Heat Treated Wood in Europe, Helsinki, Stockholm and Oslo, 20 November 2000. [Google Scholar]

- Willems, W. Method and Apparatus for Preserving Wood, and Wood Product. WO Patent No. 2000405, 22 December 2006. [Google Scholar]

- Dirol, D.; Guyonnet, R. The improvement of wood durability by retification process. In The Proceedings IRG Annual Meeting, Orlando, FL, USA; International Research Group on Wood Protection IRG/WP/93-40015: Stockholm, Sweden, 1993. [Google Scholar]

- Weiland, J.J.; Guyonnet, R. Study of chemical modifications and fungi degradation of thermally modified wood using DRIFT spectroscopy. Holz Roh- Werkst. 2003, 61, 216–220. [Google Scholar] [CrossRef]

- Vernois, M. Heat treatment of wood in France–State of the art. In Proceedings of the COST Action E22; Centre technique du Bois et de l’Ameublement: Paris, France, 2000. [Google Scholar]

- Rapp, A.O.; Sailer, M. Heat treatment of wood in Germany–State of the art. In Proceedings of the Seminar on Production of Heat Treated Wood in Europe, Helsinki, Stockholm and Oslo, November 2000; 15p. [Google Scholar]

- Sailer, M.; Rapp, A.O.; Leithoff, H.; Peek, R.D. Upgrading of wood by application of an oil-heat treatment. Holz Roh- Werkst. 2000, 58, 15–22. [Google Scholar] [CrossRef]

- Ohnesorge, D.; Tausch, A.; Krowas, I.; Huber, C.; Becker, G.; Fink, S. Laboratory tests on the natural durability of six different wood species after hygrothermal treatment. In Proceedings of the Fourth European Conference on Wood Modification, Stockholm, Sweden, 27–29 April 2009; pp. 159–164. [Google Scholar]

- Sivonen, H.; Maunu, S.; Sundholm, F.; Jämsa, S.; Viitaniemi, P. Magnetic resonance studies of thermally modified wood. Holzforschung 2002, 56, 648–654. [Google Scholar] [CrossRef]

- Esteves, B.; Marques, A.; Domingos, I.; Pereira, H. Heat-induced colour changes of pine (Pinus pinaster) and eucalyptus (Eucalyptus globulus) wood. Wood Sci. Technol. 2008, 42, 369–384. [Google Scholar] [CrossRef]

- Gonzalez-Pena, M.M.; Hale, M.D.C. Colour in thermally modified wood of beech, Norway spruce and Scots pine. Part 1: Colour evolution and colour changes. Holzforschung 2009, 63, 385–393. [Google Scholar] [CrossRef]

- Schneider, A. Investigations on the convection drying of lumber at extremely high temperatures. Part II: Drying degrade, changes in sorption, colour and strength of pine sapwood and beech wood at drying temperatures from 110 to 180 °C. Holz Roh- Werkst. 1973, 31, 1998–2206. [Google Scholar]

- Bekhta, P.; Niemz, P. Effect of high temperature on the change in color, dimensional stability and mechanical properties of spruce wood. Holzforschung 2003, 57, 539–546. [Google Scholar] [CrossRef]

- Dagbro, O.; Torniainen, P.; Karlsson, O.; Morén, T. Colour responses from wood, thermally modified in superheated steam and pressurized steam atmospheres. Wood Mater. Sci. Eng. 2010, 5, 211–219. [Google Scholar] [CrossRef]

- Sullivan, J.D. Color characterization of wood: Color parameters of individual species. For. Prod. J. 1966, 17, 25–29. [Google Scholar]

- Kamperidou, V.; Barmpoutis, P. Correlation between the changes of colour and mechanical properties of thermally-modified scots pine (Pinus sylvestris L.) wood. Pro Ligno 2015, 11, 360–365. [Google Scholar]

- Brischke, C.; Welzbacher, C.R.; Brandt, K.; Rapp, A.O. Quality control of thermally modified timber: Interrelationship between heat treatment intensities and CIE L*a*b* color data on homogenized wood samples. Holzforschung 2007, 61, 19–22. [Google Scholar] [CrossRef]

- Pleschberger, H.; Teischinger, A.; Müller, U.; Hansmann, C. Change in fracturing and colouring of solid spruce and ash wood after thermal modification. Wood Mater. Sci. Eng. 2014, 9, 92–101. [Google Scholar] [CrossRef]

- Sikora, A.; Kačík, F.; Gaff, M.; Vondrová, V.; Bubeníková, T.; Kubovský, I. Impact of thermal modification on color and chemical changes of spruce and oak wood. J. Wood Sci. 2018, 64, 406–416. [Google Scholar] [CrossRef]

- Sivrikaya, H.; Tesařová, D.; Jeřábková, E.; Can, A. Color change and emission of volatile organic compounds from Scots pine exposed to heat and vacuum-heat treatment. J. Build. Eng. 2019, 26, 100918. [Google Scholar] [CrossRef]

- Torniainen, P.; Elustondo, D.; Dagbro, O. Industrial validation of the relationship between color parameters in thermally modified spruce and pine. BioResources 2016, 11, 1369–1381. [Google Scholar] [CrossRef]

- Finotrol. FC-2. Thermally Modified Timber (TMT); Finotrol Oy: Mikkeli, Finland, 2017; 13p. [Google Scholar]

- Torniainen, P.; Jones, D.; Sandberg, D. Colour as a quality indicator for industrially manufactured ThermoWood®. Wood Mater. Sci. Eng. 2021, 16, 287–289. [Google Scholar] [CrossRef]

- Sandberg, D.; Kutnar, A.; Karlsson, O.; Jones, D. Wood Modification Technologies Principles-Sustainability, and the Need for Innovation; CRC Press: Boca Raton, FL, USA, 2021; 442p. [Google Scholar]

- Willems, W.; Lykidis, C.; Altgen, M.; Clauder, L. Quality control methods for thermally modified wood. Holzforschung 2015, 69, 875–884. [Google Scholar] [CrossRef]

- Nasir, V.; Nourian, S.; Avramidis, S.; Cool, J. Prediction of physical and mechanical properties of thermally modified wood based on color change evaluated by means of “group method of data handling” (GMDH) neural network. Holzforschung 2019, 73, 381–392. [Google Scholar] [CrossRef]

- Soetedjo, H.; Niskanen, I.; Rautkari, L.; Altgen, M.; Hiltunen, E.; Thungström, G.; Zakrisson, D.; Räty, J. Determining the degree of heat treatment of wood by light polarization technique. Eur. J. Wood Wood Prod. 2018, 76, 1359–1362. [Google Scholar] [CrossRef]

- Niskanen, I.; Heikkinen, J.; Mikkonen, J.; Harju, A.; Heräjärvi, H.; Venäläinen, M.; Peiponen, K.E. Detection of the effective refractive index of thermally modified Scots pine by immersion liquid method. J. Wood Sci. 2012, 65, 46–50. [Google Scholar] [CrossRef]

- Manninen, A.-M.; Pasanen, P.; Holopainen, J.K. Comparing the VOC emissions between air-dried and heat-treated Scots pine wood. Atmos. Environ. 2002, 36, 1763–1768. [Google Scholar] [CrossRef]

- Popescu, M.-C.; Froidevaux, J.; Navi, P.; Popescu, C.-M. Structural modifications of Tilia cordata wood during heat treatment investigated by FT-IR and 2D IR correlation spectroscopy. J. Mol. Struct. 2013, 1033, 176–186. [Google Scholar] [CrossRef]

- Schwanninger, M.; Hinterstoisser, B.; Gierlinger, N.; Wimmer, R.; Hanger, J. Application of Fourier transform near infrared spectroscopy (FT-NIR) to thermally modified wood. Holz Roh- Werkst. 2004, 62, 483–485. [Google Scholar] [CrossRef]

- Esteves, B.M.; Pereira, H.M. Wood modification by heat treatment: A review. BioResources 2009, 4, 370–404. [Google Scholar] [CrossRef]

- Poncsák, S.; Kocaefe, D.; Bouazara, M.; Pichette, A. Effect of high temperature treatment on the mechanical properties of birch (Betula papyrifera). Wood Sci. Technol. 2006, 40, 647–663. [Google Scholar] [CrossRef]

- Popescu, C.-M.; Zeniya, N.; Endo, K.; Genkawa, T.; Obataya, E. Modifications in spruce wood structure following hydro-thermal treatment evaluated by NIR spectroscopy. Pro Ligno 2019, 15, 48–54. [Google Scholar]

- de Abreu Neto, R.; Guedes Ramalho, F.M.; Ribeiro Costa, L.; Gherardi Hein, P.R. Estimating hardness and density of wood and charcoal by near-infrared spectroscopy. Wood Sci. Technol. 2021, 55, 215–230. [Google Scholar] [CrossRef]

- Inagaki, T.; Mitsui, K.; Tsuchikawa, S. Near-infrared spectroscopic investigation of the hydrothermal degradation mecha-nism of wood as an analogue of archaeological objects. Part I: Softwood. Appl. Spectrosc. 2008, 62, 1209–1215. [Google Scholar] [CrossRef]

- Popescu, M.-C.; Popescu, C.-M.; Lisa, G.; Sakata, Y. Evaluation of morphological and chemical aspects of different wood species by spectroscopy and thermal methods. J. Mol. Struct. 2011, 988, 65–72. [Google Scholar] [CrossRef]

- Liu, X.Y.; Tu, X.W.; Liu, U. Effects of light thermal treatments on the color, hygroscopity and dimensional stability of wood. Wood Res. 2021, 66, 95–104. [Google Scholar] [CrossRef]

- Stefansson, P.; Thiis, T.; Gobakken, L.R.; Burud, I. Hyperspectral NIR time series imaging used as a new method for estimating the moisture content dynamics of thermally modified Scots pine. Wood Mater. Sci. Eng. 2021, 16, 49–57. [Google Scholar] [CrossRef]

- dos Santos Grasel, F.; Flôres Ferrão, M.; Wolf, C.R. Development of methodology for identification the nature of the polyphenolic extracts by FTIR associated with multivariate analysis. Spectrochim. Acta A Mol. Biomol. Spectrosc. 2016, 153, 94–101. [Google Scholar] [CrossRef] [PubMed]

- Popescu, C.-M.; Popescu, M.-C. A near infrared spectroscopic study of the structural modifications of lime (Tilia cordata Mill.) wood during hydro-thermal treatment. Spectrochim. Acta A Mol. Biomol. Spectrosc. 2013, 115, 227–233. [Google Scholar] [CrossRef] [PubMed]

- Via, B.K.; Zhou, C.; Acquah, G.; Jiang, W.; Eckhardt, L. Near infrared spectroscpy calibration for wood chemimstry: Which chemometric technique is best for the prediction and interpretation? Sensors 2014, 14, 13532–13547. [Google Scholar] [CrossRef]

- Korkut, S. The effects of heat treatment on some technological properties in Uludağ fir (Abies bornmuellerinana Mattf.) wood. Build. Environ. 2008, 43, 422–428. [Google Scholar] [CrossRef]

- Källander, B. Drying and Thermal Modification of Wood: Studies on Influence of Sample Size, Batch Size, and Climate on Wood Response. Ph.D. Thesis, Luleå University of Technology, Skellefteå, Sweden, 2016. [Google Scholar]

- Anonymous. ThermoWood® Handbook; International ThermoWood Association: Helsinki, Finland, 2021; 53p. [Google Scholar]

- CEN. EN 335: 2013. Durability of Wood and Wood-Based Products—Use Classes: Definitions, Applications to Solid Wood and Wood-Based Products; European Committee for Standardization: Brussels, Belgium, 2013. [Google Scholar]

- CIE. CIE DS 014-4.3. Colorimetry—Part. 4: CIE 1976 L*a*b* Colour Space; CIE Central Bureau: Vienna, Austria, 2007; p. 12. [Google Scholar]

- CIE. CIE S 014-1/E. Colorimetry—Part. 1: CIE Standard Colorimetric Observers; CIE Central Bureau: Vienna, Austria, 2006; 40p. [Google Scholar]

- CEN. EN 408: 2010 + A1: 2012. Timber Structures. Structural Timber and Glued Laminated Timber. Determination of Some Physical and Mechanical Properties; European Committee for Standardization: Brussels, Belgium, 2010. [Google Scholar]

- CEN. EN 1534: 2020. Wood Flooring and Parquet. Determination of Resistance to Indentation. Test. Method; European Committee for Standardization: Brussels, Belgium, 2020. [Google Scholar]

- Niemz, P.; Stübi, T. Investigations of hardness measurements on wood based materials using a new universal measurement system. In Proceedings of the Symposium on Wood Machining, Properties of Wood and Wood Composites Related to Wood Machining, Vienna, Austria, 5–7 July 2000; pp. 51–61. [Google Scholar]

- Herrera, R.; Erdocia, X.; Llano-Ponte, R.; Labidi, J. Characterization of hydrothermally treated wood in relation to changes on its chemical composition and physical properties. J. Anal. Appl. Pyrolysis 2014, 107, 256–266. [Google Scholar] [CrossRef]

- Fengel, D.; Wegener, G. Wood, Chemistry, Ultrastructure, Reactions; Walter de Gruyter & Co.: Berlin, Germany, 1984; 613p. [Google Scholar]

- Severo, E.T.D.; Calonego, F.W.; Sansígolo, C.A. Physical and chemical changes in juvenile and mature woods of Pinus elliottii var. elliottii by thermal modification. Eur. J. Wood Wood Prod. 2012, 70, 741–747. [Google Scholar] [CrossRef]

- Popescu, C.-M.; Navi, P.; Placencia Peña, M.I.; Popescu, M.-C. Evaluation of the structural changes occurring in wood during hydro-thermal and thermal treatment using NIR spectroscopy and principal component analysis. Spectrochim. Acta Part. A Mol. Biomol. Spectrosc. 2018, 191, 405–412. [Google Scholar] [CrossRef] [PubMed]

- Park, Y.; Jang, S.-K.; Park, J.-H.; Yang, S.-Y.; Chung, H.; Han, Y.; Chang, Y.-S.; Choi, I.-G.; Yeo, H. Changes of major chemical components in larch wood through combined treatment of drying and heat treatment using superheated steam. J. Wood Sci. 2017, 63, 635–643. [Google Scholar] [CrossRef]

- Popescu, C.-M.; Jones, D.; Kržišnik, D.; Humar, M. Determination of the effectiveness of a combined thermal/chemical wood modification by the use of FT-IR spectroscopy and chemometric methods. J. Mol. Struct. 2020, 1200, 127133. [Google Scholar] [CrossRef]

- Kăcíková, D.; Kubovský, I.; Ulbriková, N.; Kăcík, F. The impact of thermal treatment on structural changes of teak and iroko wood lignins. Appl. Sci. 2020, 10, 5021. [Google Scholar] [CrossRef]

- Nuopponen, M.; Vuorinen, T.; Jämsä, S.; Viitaniemi, P. Thermal modifications in softwood studied by FT-IR and UV resonance Raman spectroscopies. J. Wood Chem. Technol. 2005, 24, 13–26. [Google Scholar] [CrossRef]

- Esteves, B.; Velez Marques, A.; Domingos, I.; Pereira, H. Chemical changes of heat treated pine and eucalypt wood monitored by FTIR. Maderas. Cienc. Tecnol. 2013, 15, 245–258. [Google Scholar] [CrossRef]

- Özgenç, Ö.; Durmaz, S.; Boyaci, I.H.; Eksi-Kocak, H. Determination of chemical changes in heat-treated wood using ATR-FTIR and FT Raman spectrometry. Spectrochim. Acta A Mol. Biomol. Spectrosc. 2017, 171, 395–400. [Google Scholar] [CrossRef]

- Solár, R.; Reinprecht, L.; Kačík, F.; Melcer, J.; Horský, D. Comparison of some physico-chemical and chemical properties of carbohydrate and lignin part of contemporary and subfossil oak wood. Cellul. Chem. Technol. 1987, 21, 513–524. [Google Scholar]

- Kotilainen, R.; Toivannen, T.; Alén, R. FTIR monitoring of chemical changes in softwood during heating. J. Wood Chem. Technol. 2000, 20, 307–320. [Google Scholar] [CrossRef]

- González-Peña, M.M.; Curling, S.F.; Hale, M.D. On the effect of heat on the chemical composition and dimensions of thermally modified wood. Polym. Degrad. Stab. 2009, 94, 2184–2193. [Google Scholar] [CrossRef]

- Nuopponen, M.; Vuorinen, T.; Jämsä, S.; Viitaniemi, P. The effects of a heat treatment on the behaviour of extractives in softwood studied by FTIR spectroscopic methods. Wood Sci. Technol. 2003, 37, 109–115. [Google Scholar] [CrossRef]

- Matsuda, Y.; Isogai, A.; Onabe, F. Effects of thermal and hydrothermal treatments on the reswelling capabilities of pulps and papersheets. J. Pulp Pap. Sci. 1994, 20, 323–327. [Google Scholar]

- Borrega, M.; Kärenlampi, P.P. Hygroscopicity of heat-treated Norway spruce (Picea abies) wood. Eur. J. Wood Wood Prod. 2010, 68, 233–235. [Google Scholar] [CrossRef][Green Version]

- Esteves, B.; Velez Marques, A.; Domingos, I.; Pereira, H. Influence of steam heating on the properties of pine (Pinus pinaster) and eucalypt (Eucalyptus globulus) wood. Wood Sci. Technol. 2007, 41, 193–207. [Google Scholar] [CrossRef]

- Esteves, B.; Videira, R.; Pereira, H. Chemistry and ecotoxicity of heat treated pine wood extractives. Wood Sci. Technol. 2011, 45, 661–676. [Google Scholar] [CrossRef]

- Thompson, D.W.; Kozak, R.A.; Evans, P. Thermal modification of color in red alder veneer. 1. Effects of temperature, heating time, and wood type. Wood Fiber Sci. 2005, 37, 653–661. [Google Scholar]

- Mitsui, K.; Takada, H.; Sugiyama, M.; Hasegawa, R. Changes in the properties of light-irradiated wood with heat treatment. Part 1. Effect of treatment conditions on the change in color. Holzforschung 2001, 55, 601–605. [Google Scholar] [CrossRef]

- Welzbacher, C.R.; Brischke, C.; Rapp, A.O. Influence of treatment temperature and duration on selected biological, mechanical, physical and optical properties of thermally modified timber. Wood Mater. Sci. Eng. 2007, 2, 66–76. [Google Scholar] [CrossRef]

- Kamperidou, V.; Barboutis, I.; Vasileiou, V. Response of colour and hygroscopic properties of Scots pine wood to thermal treatment. J. For. Res. 2013, 24, 571–575. [Google Scholar] [CrossRef]

- Priadi, T.; Cesarizki Suharjo, A.A.; Karlinasari, L. Dimensional stability and colour change of heat-treated young teak wood. Int. Wood Prod. J. 2019, 10, 119–125. [Google Scholar] [CrossRef]

- Herrera-Builes, J.F.; Sepúlveda-Villarroel, V.; Osorio, J.A.; Salvo-Sepúlveda, L.; Ananías, R.A. Effect of thermal modification treatment on some physical and mechanical properties of Pinus oocarpa wood. Forests 2021, 12, 249. [Google Scholar] [CrossRef]

- Kocaefe, D.; Poncsak, S.; Boluk, Y. Effect of thermal treatment on the chemical composition and mechanical properties of birch and aspen. BioResources 2008, 3, 517–537. [Google Scholar]

- Won, K.-R.; Kim, T.-H.; Hwang, K.-K.; Chong, S.-H.; Hong, N.-E.; Byeon, H.-S. Effect of heat treatment on the bending strength and hardness of wood. J. Korean Wood Sci. Technol. 2012, 40, 303–310. [Google Scholar] [CrossRef][Green Version]

- Gunduz, G.; Aydemir, D.; Karakas, G. The effects of thermal treatment on the mechanical properties of wild pear (Pyrus elaeagnifolia Pall.) wood and changes in physical properties. Mater. Des. 2009, 30, 4391–4395. [Google Scholar] [CrossRef]

- Calenego, F.W.; Severo, E.T.D.; Furtado, E.L. Decay resistance of thermally modified Eucalyptus grandis wood at 140 °C, 160 °C, 180 °C, 200 °C and 220 °C. Bioresour. Technol. 2010, 101, 9391–9394. [Google Scholar] [CrossRef]

- Lekounougou, S.; Kocaefe, D. Effect of thermal modification temperature on the mechanical properties, dimensional stability, and biological durability of black spruce (Picea mariana). Wood Mater. Sci. Eng. 2014, 9, 59–66. [Google Scholar] [CrossRef]

- Bakar, B.F.A.; Hiziroglu, S.; Tahir, P.M. Properties of some thermally modified wood species. Mater. Des. 2013, 43, 348–355. [Google Scholar] [CrossRef]

- Kocaefe, D.; Poncsak, S.; Tang, J. Effect of heat treatment on the mechanical properties of North American jack pine: Thermogravimetric study. J. Mater. Sci. 2010, 45, 681–687. [Google Scholar] [CrossRef]

| Sample | Lightness (L*) | Red-Green Colour Parameter (a*) | Yellow-Blue Colour Parameter (b*) | Colour Difference (ΔE*) | ||||

|---|---|---|---|---|---|---|---|---|

| Average | stD | Average | stD | Average | stD | Average | stD | |

| Norway spruce | ||||||||

| Untreated | 82.55 | 1.16 | 3.40 | 0.44 | 20.19 | 1.04 | ||

| Thermo–S | 59.53 | 3.25 | 7.50 | 0.28 | 24.41 | 1.14 | 23.84 | 3.35 |

| Thermo–D | 51.75 | 1.33 | 8.78 | 0.19 | 24.53 | 0.68 | 31.60 | 1.69 |

| Scots pine | ||||||||

| Untreated | 82.73 | 1.26 | 3.87 | 0.61 | 21.21 | 0.86 | ||

| Thermo–S | 59.94 | 3.13 | 7.90 | 0.37 | 25.60 | 1.19 | 23.63 | 2.99 |

| Thermo–D | 49.99 | 2.02 | 8.92 | 0.30 | 23.15 | 1.52 | 33.23 | 2.37 |

| Class | L* | a* | b* |

|---|---|---|---|

| Thermo–S | 58–68 | 8–10 | – |

| Thermo–D | 45–55 | – | 19–24 |

| Density (stD) (kg/m3) | M.C. (stD) (%) | MOR (stD) (N/mm2) | MOE (stD) (N/mm2) | |

|---|---|---|---|---|

| Norway spruce | ||||

| Untreated | 440.8 (25.8) | 13.05 (0.70) | 66.63 (7.76) | 9762 (1243) |

| Thermo–S | 425.6 (42.6) | 8.87 (0.62) | 65.50 (12.66) | 12377 (1815) |

| Thermo–D | 448.1 (40.6) | 5.87 (0.82) | 71.69 (12.08) | 13603 (2510) |

| Scots pine | ||||

| Untreated | 486.4 (32.2) | 13.22 (0.41) | 71.29 (9.90) | 10198 (2369) |

| Thermo–S | 449.8 (29.5) | 8.76 (0.65) | 58.42 (12.38) | 9694 (2005) |

| Thermo–D | 453.4 (41.1) | 8.27 (0.94) | 61.40 (10.36) | 10737 (1853) |

| Density (stD) (kg/m3) | M.C. (stD) (%) | HBD (stD) (N/mm2) | HBP (stD) (N/mm2) | Elastic Recovery (stD) (%) | |

|---|---|---|---|---|---|

| Norway spruce | |||||

| Untreated | 440.8 (25.8) | 13.05 (0.70) | 10.05 (0.56) | 15.81 (1.89) | 35.94 (4.45) |

| Thermo–S | 425.6 (42.6) | 8.87 (0.62) | 8.66 (1.07) | 12.16 (2.38) | 27.72 (5.89) |

| Thermo–D | 448.1 (40.6) | 5.87 (0.82) | 8.59 (0.49) | 12.81 (1.16) | 32.68 (3.77) |

| Scots pine | |||||

| Untreated | 486.4 (32.2) | 13.22 (0.41) | 9.73 (1.46) | 13.33 (2.70) | 26.30 (4.29) |

| Thermo–S | 449.8 (29.5) | 8.76 (0.65) | 9.02 (1.59) | 11.85 (2.57) | 23.36 (3.73) |

| Thermo–D | 453.4 (41.1) | 8.27 (0.94) | 9.13 (1.07) | 11.86 (1.80) | 22.63 (3.41) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Torniainen, P.; Popescu, C.-M.; Jones, D.; Scharf, A.; Sandberg, D. Correlation of Studies between Colour, Structure and Mechanical Properties of Commercially Produced ThermoWood® Treated Norway Spruce and Scots Pine. Forests 2021, 12, 1165. https://doi.org/10.3390/f12091165

Torniainen P, Popescu C-M, Jones D, Scharf A, Sandberg D. Correlation of Studies between Colour, Structure and Mechanical Properties of Commercially Produced ThermoWood® Treated Norway Spruce and Scots Pine. Forests. 2021; 12(9):1165. https://doi.org/10.3390/f12091165

Chicago/Turabian StyleTorniainen, Petteri, Carmen-Mihaela Popescu, Dennis Jones, Alexander Scharf, and Dick Sandberg. 2021. "Correlation of Studies between Colour, Structure and Mechanical Properties of Commercially Produced ThermoWood® Treated Norway Spruce and Scots Pine" Forests 12, no. 9: 1165. https://doi.org/10.3390/f12091165

APA StyleTorniainen, P., Popescu, C.-M., Jones, D., Scharf, A., & Sandberg, D. (2021). Correlation of Studies between Colour, Structure and Mechanical Properties of Commercially Produced ThermoWood® Treated Norway Spruce and Scots Pine. Forests, 12(9), 1165. https://doi.org/10.3390/f12091165