Influence of Scots Pine (Pinus sylvestris L.) Veneers Quality on Selected Properties of Layered Composite for Flooring Materials

Abstract

:1. Introduction

2. Materials and Methods

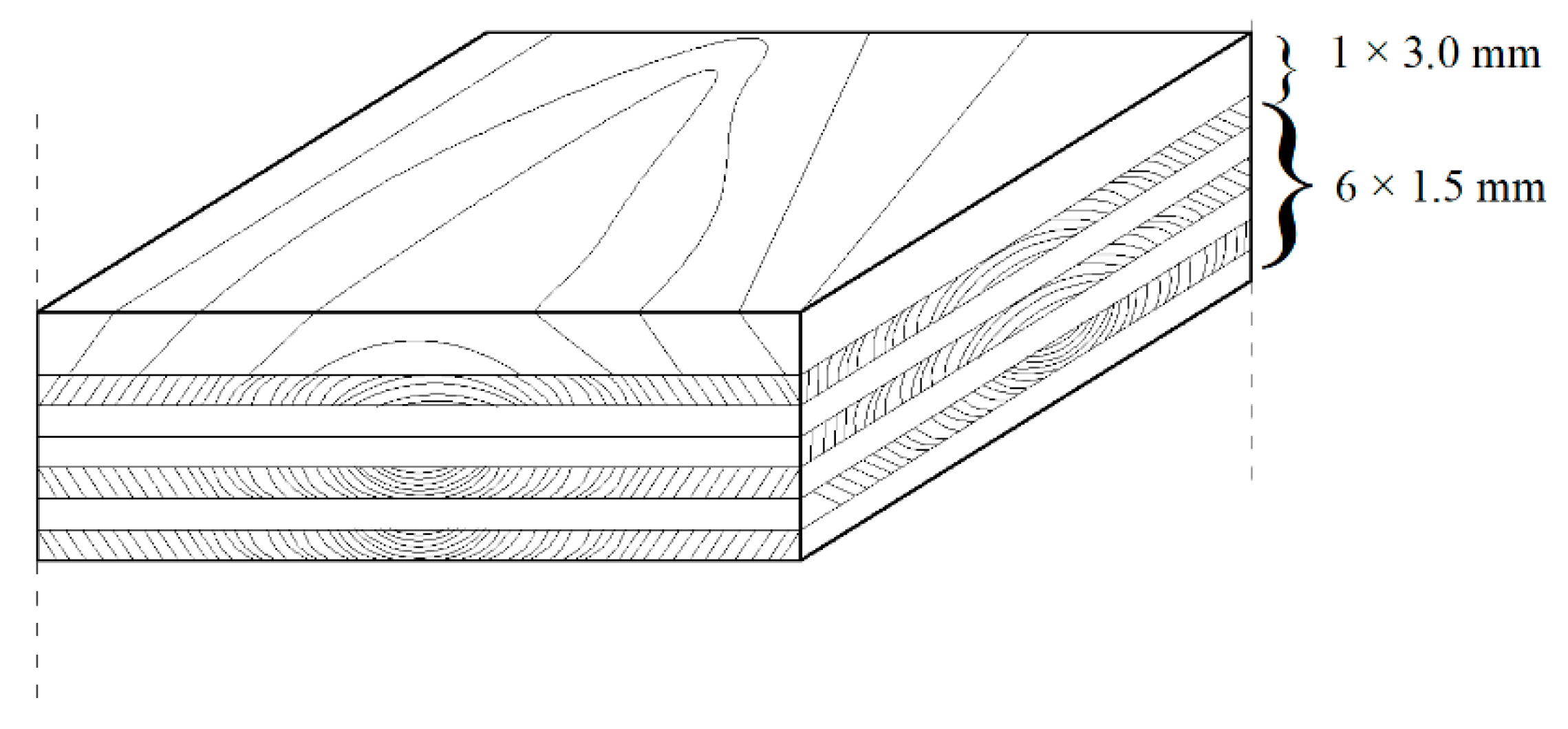

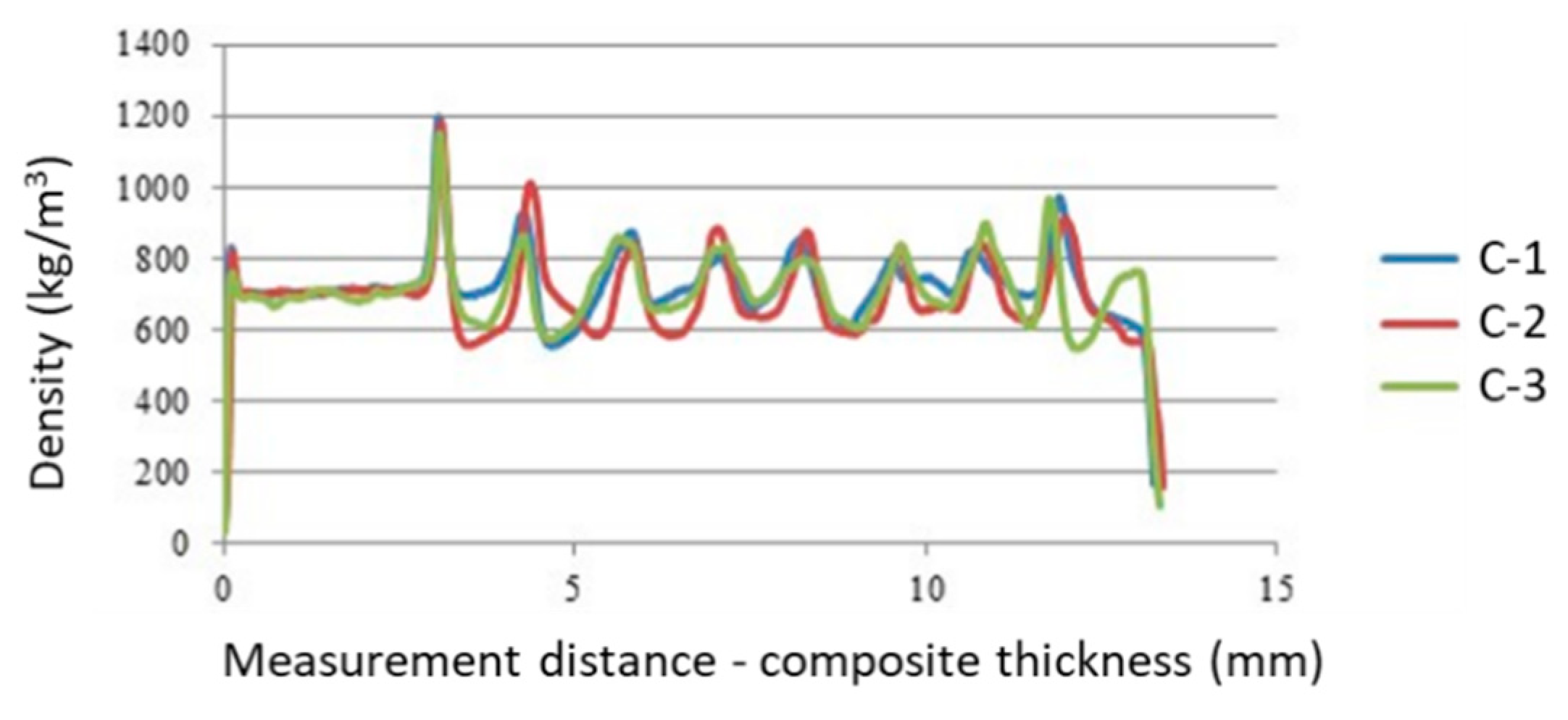

2.1. Experimental Materials and Samples

- Adhesive application 200 g/m2,

- Temperature 120 °C,

- Time 60 s (the resin used contained the addition of 10% of a hardener),

- Pressure 1.2 MPa.

2.2. Experimental Methods

2.2.1. Tests of Static Bending

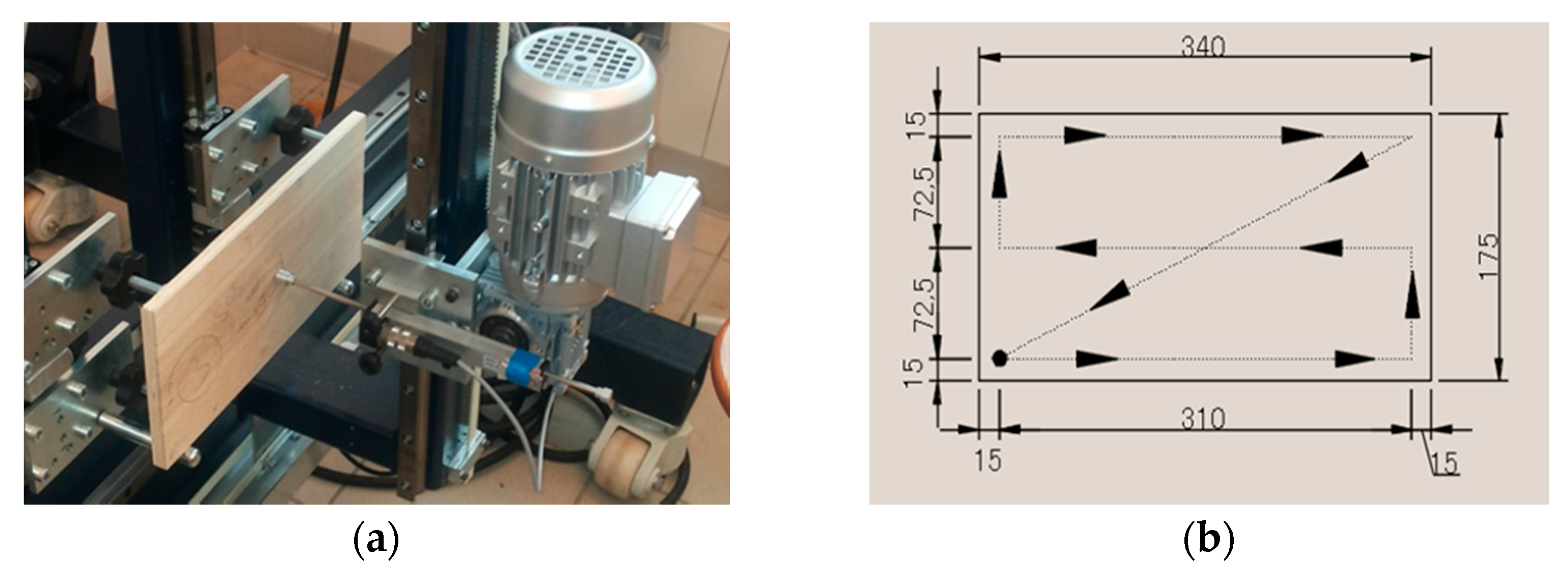

2.2.2. Tests of Dynamic Bending

2.2.3. Tests of Fatigue in Bending

2.2.4. Tests of Stiffness

3. Results

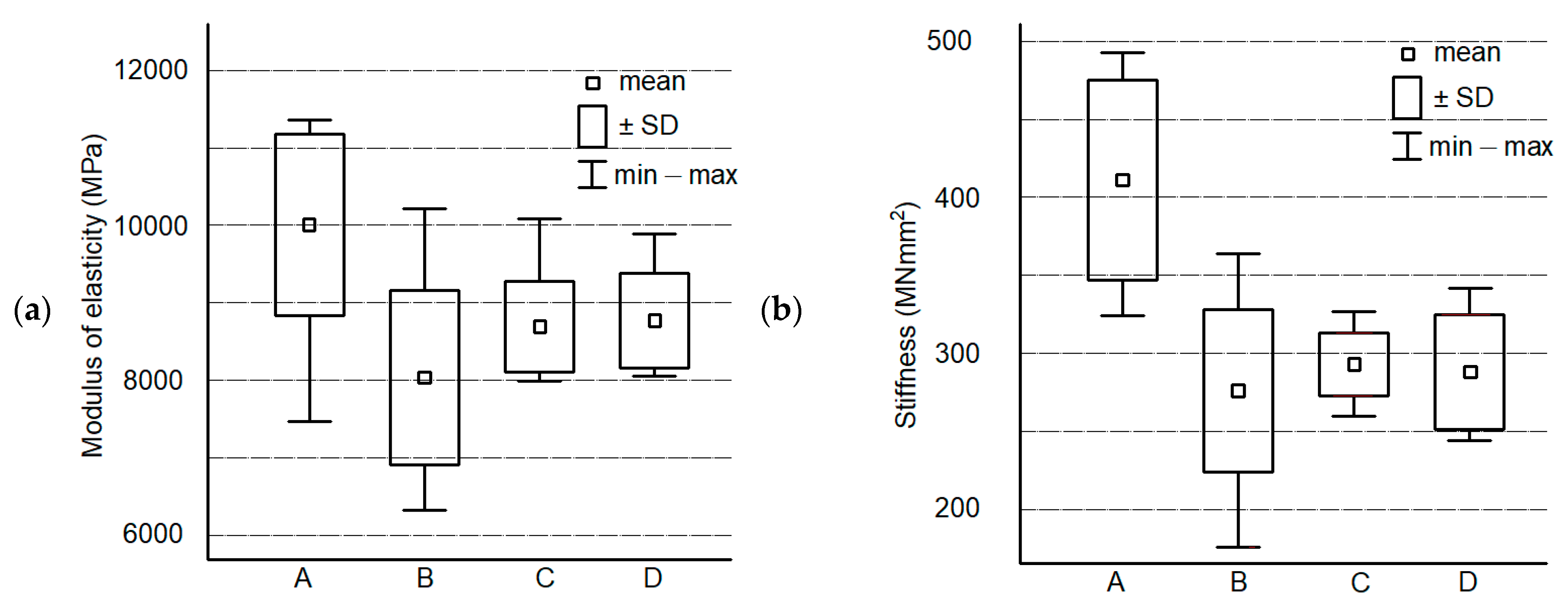

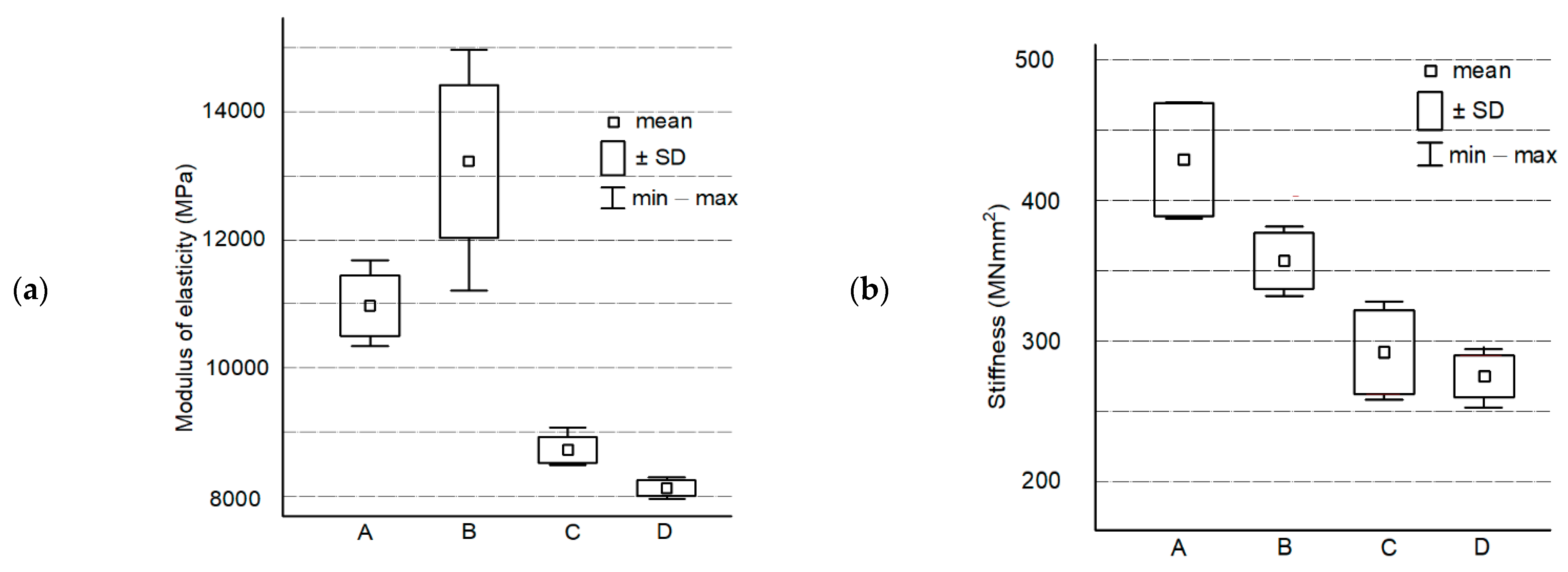

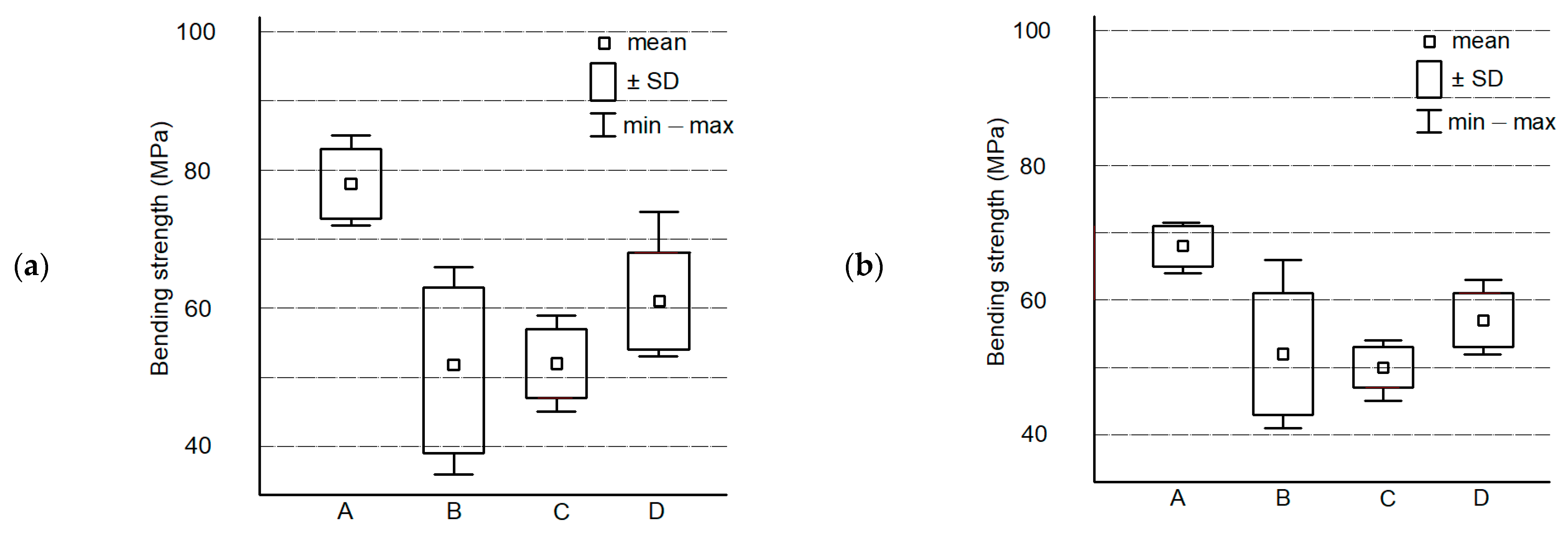

3.1. Test of Static Bending

3.2. Test of Dynamic Bending

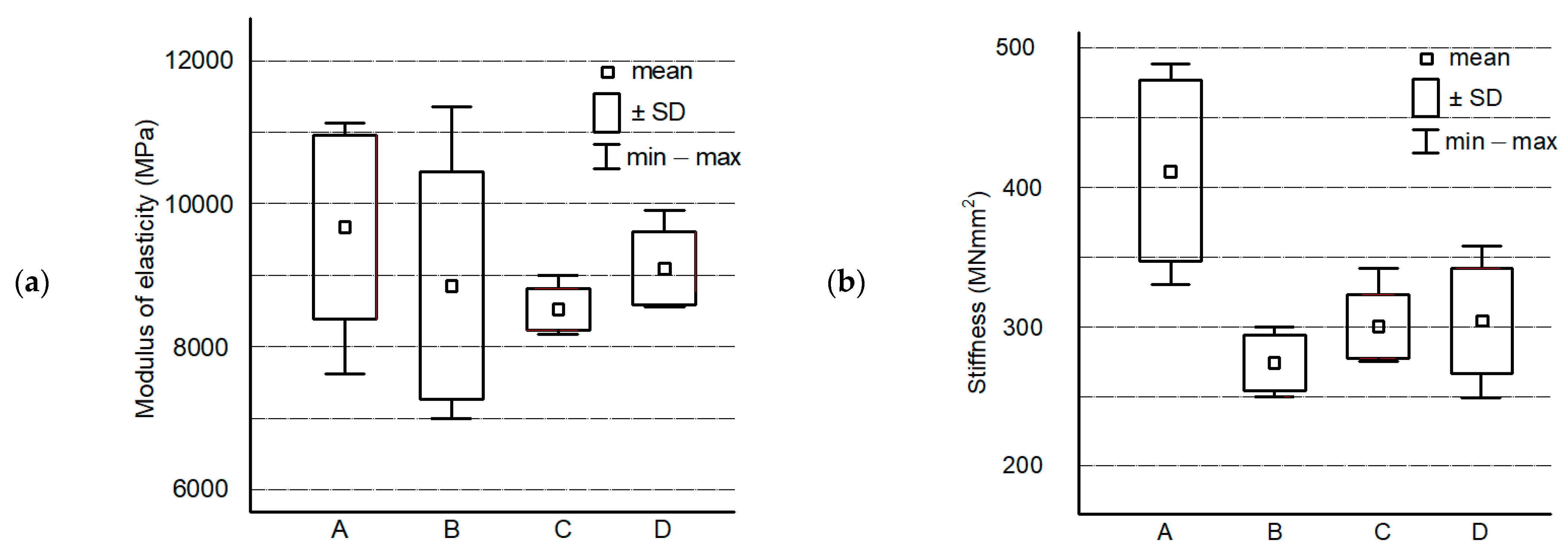

3.3. Test of Fatigue in Bending

3.4. Tests of Static Bending Strength of Air-Conditioned Composites

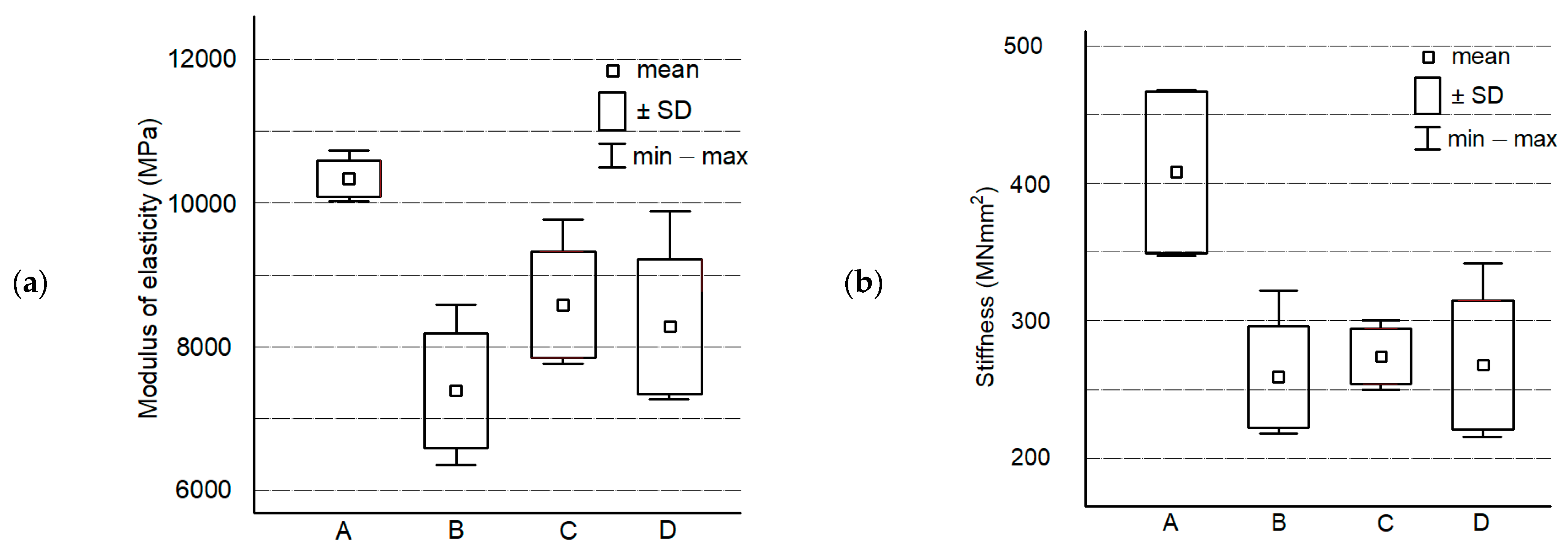

3.5. The Static Bending Strength

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Heräjärvi, H. Variation of basic density and Brinell hardness within mature Finnish Betula pendula and B. pubescens stems. Wood Fiber Sci. 2004, 36, 216–227. [Google Scholar]

- Holmberg, H. Influence of grain angle on Brinell hardness of Scots pine (Pinus sylvestris L.). Holz Roh-Und Werkst. 2000, 58, 91–95. [Google Scholar] [CrossRef]

- Wang, S.Y.; Wang, H.L. Effects of moisture content and specific gravity on static bending properties and hardness of six wood species. J. Wood Sci. 1999, 45, 127–133. [Google Scholar] [CrossRef]

- Boruszewski, P.J.; Borysiuk, P.; Mamiński, M.Ł.; Grześkiewicz, M. Gluability of thermally modified beech (Fagus silvatica L.) and birch (Betula pubescens Ehrh.) wood. Wood Mater. Sci. Eng. 2011, 6, 185–189. [Google Scholar] [CrossRef]

- Xiaoyan, Y.; Dandan, X.; Yan, S.; Yuran, G.; Jilong, F.; Xiaohan, D.; Zaixin, H.; Xiaoying, D.; Yufeng, D.; Yongfeng, L. Preparation of Wood-Based Panel Composites with Poplar Veneer as the Surface Layer Modified by In-Situ Polymerization of Active Monomers. Forests 2020, 11, 893. [Google Scholar] [CrossRef]

- Kozakiewicz, P.; Drożdżek, M.; Laskowska, A.; Grześkiewicz, M.; Bytner, O.; Radomski, A.; Zawadzki, J. Effects of thermal modification on selected physical properties of sapwood and heartwood of black poplar (Populus nigra L.). BioResources 2019, 14, 8391–8404. [Google Scholar]

- Latorraca De Figueiredo, J.V.; Texeira, D.E.; Batista, D.C. Overlay of Eucaluptus urophylla cemented-bonded particleboard for application as flooring panels. For. Prod. J. 2009, 59, 65–69. [Google Scholar]

- Amor, B.A.; Cluotier, A.; Beauregard, R. Determination of physical and mechanical properties of finishing papers used for wood-based composite products. Wood Fiber Sci. 2009, 41, 117–126. [Google Scholar]

- Makowski, A.; Noskowiak, A. Empirical verification of a digital model of a basket ball to assess elastic properties of sports floors. Ann. Wars. Univ. Life Sci. SGGW For. Wood Technol. 2016, 95, 227–230. [Google Scholar]

- LEE, C.-H.; Chung, M.-J.; Lin, C.-H.; Yang, T.-H. Effects of layered structure on the physical and mechanical properties of laminated moso bamboo (Phyllosachys eduilis) flooring. Constr. Build. Mater. 2012, 28, 31–35. [Google Scholar] [CrossRef]

- European Commission; Communication from the Commission to the European Parliament; The Council; The European Economic and Social Committee; The Committee of the Regions. Sustainable Europe Investment Plan. European Green Deal Investment Plan; European Commission: Brussels, Belgium, 2020; Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:52020DC0021&from=EN (accessed on 11 April 2021).

- European Commission; ANNEX to the Communication from the Commission to the European Parliament; The European Council; The Council; The European Economic and Social Committee; The Committee of the Regions. The European Green Deal; European Commission: Brussels, Belgium, 2019; Available online: https://ec.europa.eu/info/sites/default/files/european-green-deal-communication-annex-roadmap_en.pdf (accessed on 11 April 2021).

- European Commission. Circular Economy Action Plan. For a cleaner and more competitive Europe. In New_Circular_Economy_Action_Plan; European Commission: Brussels, Belgium, 2020; Available online: https://ec.europa.eu/environment/strategy/circular-economy-action-plan_en (accessed on 11 April 2021).

- Silva, V.U.; Nascimento, M.F.; Oliveira, P.R.; Panzera, T.H.; Rezende, M.O.; Silva, D.A.L.; Borges de Moura Aquino, V.; Lahr, F.A.R.; Christoforo, A.L. Circular vs. linear economy of building materials: A case study for particleboards made of recycled wood and biopolymer vs. conventional particleboards. Constr. Build. Mater. 2021, 285, 122906. [Google Scholar] [CrossRef]

- Luttenberger, L.R. Waste management challenges in transition to circular economy—Case of Croatia. J. Clean. Prod. 2020, 256, 120495. [Google Scholar] [CrossRef]

- International Advisory Council on Global Bioeconomy. Expending the sustainable bioeconomy—Vision and way forward. In Communique of the Global Bioeconomy Summit; International Advisory Council on Global Bioeconomy: Berlin, Germany, 2020. [Google Scholar]

- Kretschmann, D.E. Mechanical properties of wood. In Wood Handbook—Wood as an Engineering Material, Centennial ed.; Ross, R.J., Ed.; U.S. Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2010; pp. 100–145. [Google Scholar]

- Phillips, G.E.; Bodig, J.; Goodman, J.R. Flow grain analogy. Wood Sci. 1981, 14, 55–64. [Google Scholar]

- Guindos, P.; Guaita, M. A three-dimensional wood material model to simulate the behaviour of wood with any type of knot at the macro-scale. Wood Sci. Technol. 2013, 47, 585–599. [Google Scholar] [CrossRef]

- Schwab, E. Die Härte von Laubhölzern für die Parkettherstellung [The hardness of hardwoods for parquet production]. Holz Als Roh-Und Werkst. 1990, 48, 47–51. (In German) [Google Scholar] [CrossRef]

- Hirata, S.; Ohta, M.; Honma, Y. Hardness distribution on wood surface. J. Wood Sci. 2001, 47, 1–7. [Google Scholar] [CrossRef]

- Borysiuk, P.; Burawska-Kupniewska, I.; Auriga, R.; Kowaluk, G.; Kozakiewicz, P.; Zbiec, M. Influence of layered structure of composite timber floor boards on their hardness. Drv. Ind. 2019, 70, 399–406. [Google Scholar] [CrossRef]

- Doyle, J.; Walker, J.C.F. Indentation hardness of wood. Wood Fiber Sci. 1984, 17, 369–376. [Google Scholar]

- Byczek, M.; Borysiuk, P. Impact of the quality on the properties of the LVL. Ann. Wars. Univ. Life Sci. SGGW For. Wood Technol. 2017, 99, 132–142. [Google Scholar]

- Barlinek. Available online: https://www.barlinek.co.uk/ (accessed on 11 April 2021).

- iTeh Standards. EN 1927-2:2008. Qualitative Classification of Softwood Round Timber—Part 2: Pines; iTeh Standards: Toronto, ON, Canada, 2008. [Google Scholar]

- Drewspan. Available online: https://www.drewspan.com.pl/index/index/lang/en (accessed on 11 April 2021).

- Jaka Jest Optymalna Temperatura i Wilgotność w Domu? Available online: https://goodair.pl/blog/temperatura-i-wilgotnosc-w-domu (accessed on 11 April 2021).

- Modernizacja Maszyny Wytrzymałościowej. Available online: http://cms.zepwn.com.pl/Karta_maszyny_wytrzymalosciowe_2016_02_22.pdf (accessed on 11 April 2021).

- BSI. EN 310: 1993. Wood-Based Panels—Determination of Modulus of Elasticity in Bending and of Bending Strength; BSI: London, UK, 1993. [Google Scholar]

- Kokociński, W. Wood-Measurements of Physical and Mechanical Properties; PRODRUK: Poznań, Poland, 2004; p. 201. ISBN 83-88518-75-5. (In Polish) [Google Scholar]

- ISO. ISO 9052-1. Determination of Dynamic Stiffness. Part 1—Materials Used Under Floating Floors in Dwellings; ISO: Geneva, Switzerland, 1989. [Google Scholar]

| Layer | Wood Species | Number of Elements | Quality Class | |||

|---|---|---|---|---|---|---|

| A | B | C | D | |||

| Thickness (mm) | ||||||

| Face | Oak | 1 | 3.0 | 3.0 | 3.0 | 3.0 |

| Base | Pine | 6 | 1.5 | 1.5 | 1.5 | 1.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Burawska-Kupniewska, I.; Mycka, P.; Beer, P. Influence of Scots Pine (Pinus sylvestris L.) Veneers Quality on Selected Properties of Layered Composite for Flooring Materials. Forests 2021, 12, 1017. https://doi.org/10.3390/f12081017

Burawska-Kupniewska I, Mycka P, Beer P. Influence of Scots Pine (Pinus sylvestris L.) Veneers Quality on Selected Properties of Layered Composite for Flooring Materials. Forests. 2021; 12(8):1017. https://doi.org/10.3390/f12081017

Chicago/Turabian StyleBurawska-Kupniewska, Izabela, Paweł Mycka, and Piotr Beer. 2021. "Influence of Scots Pine (Pinus sylvestris L.) Veneers Quality on Selected Properties of Layered Composite for Flooring Materials" Forests 12, no. 8: 1017. https://doi.org/10.3390/f12081017

APA StyleBurawska-Kupniewska, I., Mycka, P., & Beer, P. (2021). Influence of Scots Pine (Pinus sylvestris L.) Veneers Quality on Selected Properties of Layered Composite for Flooring Materials. Forests, 12(8), 1017. https://doi.org/10.3390/f12081017