Fast Preparation of High-Performance Wood Materials Assisted by Ultrasonic and Vacuum Impregnation

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

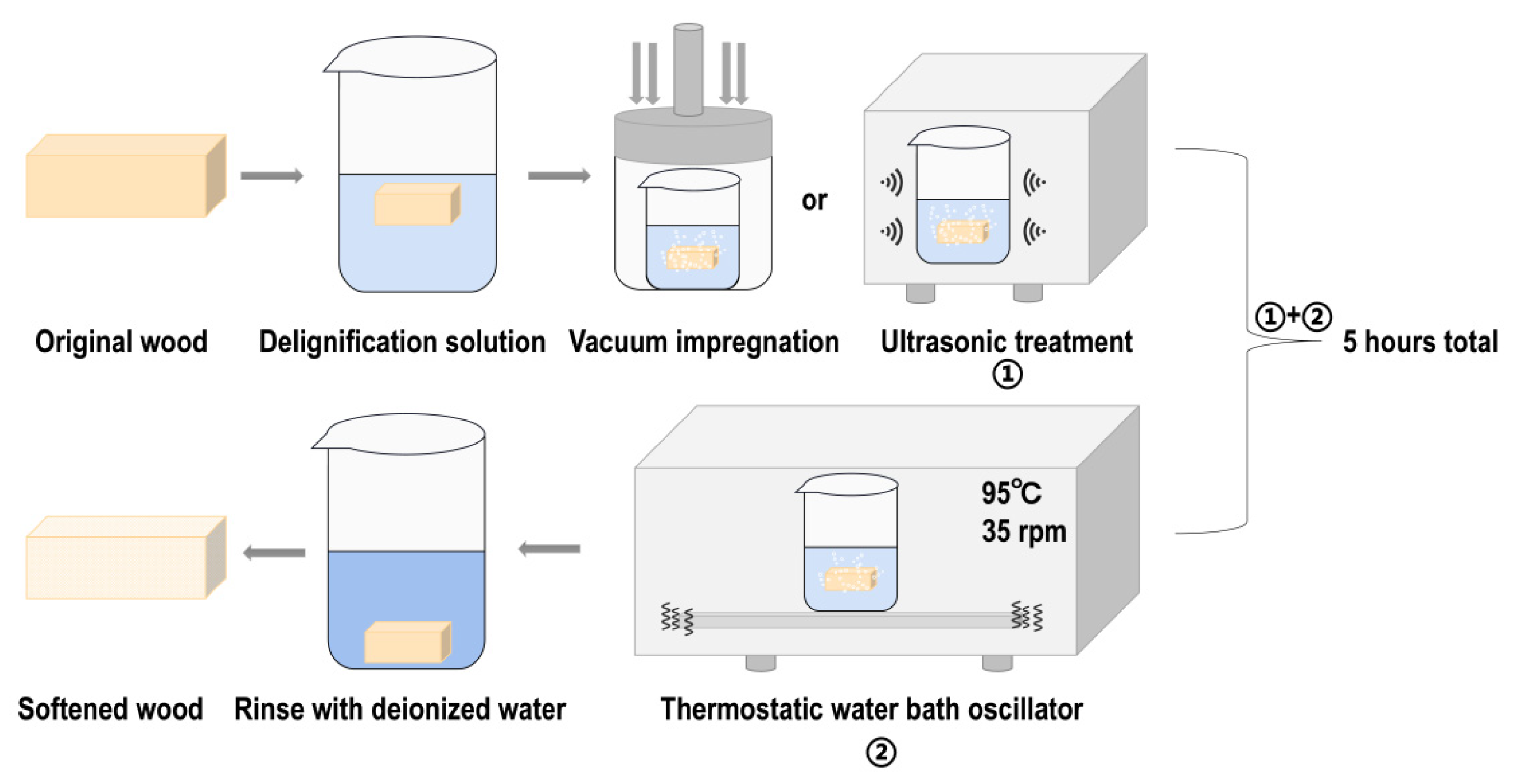

2.2. Delignification Procedure

2.3. Fourier Transform Infrared Spectroscopy

2.4. X-ray Diffraction

2.5. Densification Treatment

2.6. Physical and Mechanical Properties Measurement

2.6.1. Physical Test

2.6.2. Mechanical Test

2.7. Scanning Electron Microscope

3. Results and Discussion

3.1. Delignification and Densification

3.2. FT-IR Analysis

3.3. XRD Analysis

3.4. Physical and Mechanical Analysis

3.5. Microstructure Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Burgert, I.; Cabane, E.; Zollfrank, C.; Berglund, L. Bio-inspired functional wood-based materials–hybrids and replicates. Int. Mater. Rev. 2015, 60, 431–450. [Google Scholar] [CrossRef]

- Berglund, L.A.; Burgert, I. Bioinspired wood nanotechnology for functional materials. Adv. Mater. 2018, 30, 1704285. [Google Scholar] [CrossRef]

- Jiang, F.; Li, T.; Li, Y.; Zhang, Y.; Gong, A.; Dai, J.; Hitz, E.; Luo, W.; Hu, L. Wood-based nanotechnologies toward sustainability. Adv. Mater. 2018, 30, 1703453. [Google Scholar] [CrossRef]

- Li, J.; Zhang, A.; Zhang, S.; Gao, Q.; Chen, H.; Zhang, W.; Li, J. High-performance imitation precious wood from low-cost poplar wood via high-rate permeability of phenolic resins. Polym. Compos. 2018, 39, 2431–2440. [Google Scholar] [CrossRef]

- Li, T.; Zhai, Y.; He, S.; Gan, W.; Wei, Z.; Heidarinejad, M.; Dalgo, D.; Mi, R.; Zhao, X.; Song, J.; et al. A radiative cooling structural material. Science 2019, 364, 760–763. [Google Scholar] [CrossRef] [PubMed]

- Lang, Q.; Zeng, B.; Pu, J.W. Characterization of chemical wood modification with melamine-urea-formaldehyde prepolymer on fast-growing wood. Wood. Fiber. Sci. 2014, 46, 1–11. [Google Scholar]

- Noël, M.; Grigsby, W.J.; Ormondroyd, G.A.; Spear, M.J. Influence of water and humidity on chemically modifying wood with polybutylene succinate bio-polyester. Inter. Wood. Prod. J. 2016, 7, 80–88. [Google Scholar] [CrossRef]

- Xiao, Z.; Xie, Y.; Mai, C. The fungal resistance of wood modified with glutaraldehyde. Holzforschung 2012, 66, 237–243. [Google Scholar] [CrossRef]

- Tuong, V.M.; Li, J. Changes caused by heat treatment in chemical composition and some physical properties of acacia hybrid sapwood. Holzforschung 2011, 65, 67–72. [Google Scholar] [CrossRef]

- Ahmed, S.A.; Morén, T.; Hagman, O.; Cloutier, A.; Fang, C.H.; Elustondo, D. Anatomical properties and process parameters affecting blister/blow formation in densified European aspen and downy birch sapwood boards by thermo-hygro-mechanical compression. J. Mater. Sci. 2013, 48, 8571–8579. [Google Scholar] [CrossRef]

- Fang, C.H.; Mariotti, N.; Cloutier, A.; Koubaa, A.; Blanchet, P. Densification of wood veneers by compression combined with heat and steam. Eur. J. Wood. Wood. Prod. 2012, 70, 155–163. [Google Scholar] [CrossRef]

- Čabalová, I.; Kačík, F.; Lagaňa, R.; Výbohová, E.; Bubeníková, T.; Čaňová, I.; Ďurkovič, J. Effect of Thermal Treatment on the Chemical, Physical, and Mechanical Properties of Pedunculate Oak (Quercus robur L.) Wood. Bioresources 2017, 13, 157–170. [Google Scholar] [CrossRef]

- Song, J.; Chen, C.; Zhu, S.; Zhu, M.; Hu, L. Processing bulk natural wood into a high-performance structural material. Nature 2018, 554, 224–228. [Google Scholar] [CrossRef]

- Xu, E.; Wang, D.; Lin, L. Chemical Structure and Mechanical Properties of Wood Cell Walls Treated with Acid and Alkali Solution. Forests 2020, 11, 87. [Google Scholar] [CrossRef]

- Boshi, W.U.; Zhang, X.; Yang, J.; Feng, X.U. Dissolution Mechanism of Lignin in Chinese-fir Cell Walls during Chlorite Pretreatment. Chem. Ind. For. Prod. 2017, 37, 38–44. [Google Scholar]

- Mburu, F.; Dumar?Ay, S.; Bocquet, J.F.; Petrissans, M.; Gérardin, P. Effect of chemical modifications caused by heat treatment on mechanical properties of Grevillea robusta wood. Polym. Degrad. Stabil. 2008, 93, 401–405. [Google Scholar] [CrossRef]

- Song, J.; Chen, C.; Wang, C.; Kuang, Y.; Li, Y.; Jiang, F.; Li, Y.; Hitz, E.; Zhang, Y.; Liu, B.; et al. Superflexible Wood. ACS Appl. Mater. Inter. 2017, 9, 23520–23527. [Google Scholar] [CrossRef]

- Zhu, M.; Song, J.; Li, T.; Gong, A.; Wang, Y.; Dai, J.; Yao, Y.; Luo, W.; Henderson, D.; Hu, L. Highly Anisotropic, Highly Transparent Wood Composites. Adv. Mater. 2016, 28, 5181–5187. [Google Scholar] [CrossRef] [PubMed]

- Vasileva, E.; Li, Y.; Sychugov, I.; Mensi, M.; Berglund, L.; Popov, S. Lasing from Organic Dye Molecules Embedded in Transparent Wood. Adv. Opt. Mater. 2017, 5, 1700057. [Google Scholar] [CrossRef]

- Chao, J.; Tian, L.; Chen, C.; Dai, J.; Kierzewski, I.M.; Song, J.; Li, Y.; Yang, C.; Wang, C.; Hu, L. Scalable, Anisotropic Transparent Paper Directly from Wood for Light Management in Solar Cells. Nano Energy 2017, 36, 366–373. [Google Scholar]

- Lin, L.; Cao, J.; Zhang, J.; Cui, Q.; Liu, Y. Enhanced Anti-Mold Property and Mechanism Description of Ag/TiO2 Wood-Based Nanocomposites Formation by Ultrasound- and Vacuum-Impregnation. Nanomaterials 2020, 10, 682. [Google Scholar] [CrossRef]

- He, Z.; Yang, F.; Yi, S.; Gao, J. Effect of ultrasound pretreatment on vacuum drying of Chinese catalpa wood. Dry. Technol. 2012, 30, 1750–1755. [Google Scholar] [CrossRef]

- Chen, J.; Jiang, Q.; Yang, G.; Wang, Q.; Fatehi, P. Ultrasonic-assisted ionic liquid treatment of chemithermomechanical pulp fibers. Cellulose 2017, 24, 1483–1491. [Google Scholar] [CrossRef]

- He, Z.; Fei, Y.; Peng, Y.; Yi, S. Ultrasound-Assisted Vacuum Drying of Wood: Effects on Drying Time and Product Quality. Bioresources 2013, 8, 855–863. [Google Scholar] [CrossRef]

- Mu, H.; Wang, Y.; Tian, Y.; Duan, X.; Qi, D. Microstructure and Hydrophobic Properties of Nano-Cu-Coated Wood-Based Composites by Ultrasonic Pretreatment. Appl. Sci. 2020, 10, 5448. [Google Scholar] [CrossRef]

- Dong, Y.; Yan, Y.; Zhang, S.; Li, J. Wood/Polymer Nanocomposites Prepared by Impregnation with Furfuryl Alcohol and Nano-SiO2. Bioresources 2014, 9, 6028–6040. [Google Scholar] [CrossRef]

- Wu, Y.; Wu, J.; Yang, F.; Tang, C.; Huang, Q. Effect of H2O2 Bleaching Treatment on the Properties of Finished Transparent Wood. Polymers 2019, 11, 776. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Zhan, T.; Liu, Y.; Shi, J.; Pan, B.; Zhang, Y.; Cai, L.; Shi, S.Q. Large-Size Transparent Wood for Energy-Saving Building Applications. ChemSusChem 2018, 11, 4086–4093. [Google Scholar] [CrossRef]

- Li, Y.; Yu, S.; Veinot, J.; Linnros, J.; Berglund, L.; Sychugov, I. Luminescent Transparent Wood. Adv. Opt. Mate. 2017, 5, 1600834. [Google Scholar] [CrossRef]

- Gindl, W.; Gupta, H.S. Cell-wall hardness and Young’s modulus of melamine-modified spruce wood by nano-indentation. Compos. Part. A Appl. Sci. 2002, 33, 1141–1145. [Google Scholar] [CrossRef]

- Shams, M.I.; Kagemori, N.; Yano, H. Compressive deformation of wood impregnated with low molecular weight phenol formaldehyde (PF) resin IV: Species dependency. J. Wood. Sci. 2006, 52, 179–183. [Google Scholar] [CrossRef]

- Wang, K.; Dong, Y.; Yan, Y.; Qi, C.; Zhang, S.; Li, J. Preparation of mechanical abrasion and corrosion resistant bulk highly hydrophobic material based on 3-D wood template. RSC Adv. 2016, 6, 98248–98256. [Google Scholar] [CrossRef]

- Dong, X.; Zhuo, X.; Wei, J.; Zhang, G.; Li, J. Wood-Based Nanocomposite Derived by in Situ Formation of Organic-Inorganic Hybrid Polymer within Wood via a Sol-Gel Method. ACS Appl. Mater. Inter. 2017, 9, 9070–9078. [Google Scholar] [CrossRef] [PubMed]

- Yu, Z.L.; Ning, Y.; Zhou, L.C.; Ma, Z.Y.; Zhu, Y.B.; Lu, Y.Y.; Bing, Q.; Xing, W.Y.; Tao, M.; Li, S.C. Bioinspired polymeric woods. Sci. Adv. 2018, 4, 7223. [Google Scholar] [CrossRef] [PubMed]

- Jia, C.; Chen, C.; Mi, R.; Li, T.; Hu, L. Clear Wood toward High-Performance Building Materials. ACS Nano 2019, 13, 9993–10001. [Google Scholar] [CrossRef]

- Zhou, C.; Wei, J.; Via, B.K.; Fasina, O.; Han, G. Prediction of mixed hardwood lignin and carbohydrate content using ATR-FTIR and FT-NIR. Carbohyd. Polym. 2015, 121, 336–341. [Google Scholar] [CrossRef]

- Shi, J.; Peng, J.; Huang, Q.; Cai, L.; Shi, S.Q. Fabrication of densified wood via synergy of chemical pretreatment, hot-pressing and post mechanical fixation. J. Wood Sci. 2020, 66, 1–9. [Google Scholar] [CrossRef]

- Jiang, B.; Chen, C.; Liang, Z.; He, S.; Kuang, Y.; Song, J.; Mi, R.; Chen, G.; Jiao, M.; Hu, L. Lignin as a Wood-Inspired Binder Enabled Strong, Water Stable, and Biodegradable Paper for Plastic Replacement. Adv. Funct. Mater. 2020, 30, 1906307. [Google Scholar] [CrossRef]

- Zhang, S.Y.; Wang, C.G.; Fei, B.H.; Yu, Y.; Cheng, H.T.; Tian, G.L. Mechanical function of lignin and hemicelluloses in wood cell wall revealed with microtension of single wood fiber. BioResources 2013, 8, 2376–2385. [Google Scholar] [CrossRef]

- Wu, Y.; Han, Y.; Huang, N.; Wu, J.M.; Tang, C.Y.; Zhou, J.C.; Huang, Q.T. Effect of delignification process on properties of transparent wood (in Chinese). J. For. Eng. 2019, 4, 98–104. [Google Scholar]

- French, A.D. Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 2014, 21, 885–896. [Google Scholar] [CrossRef]

- Li, Z.; He, W.; Qiang, H.; Wang, R.; Guo, F.Y.; Cao, J.Z.; Lu, M.T. Preparation and properties of directionally reconstituted bamboo cellulose fiber/phenolic resin composites (in Chinese). Acta Mater. Compos. Sin. 2021, 38, 1–9. [Google Scholar]

- Zhu, R.; Yadama, V. Effects of hot water extraction pretreatment on physicochemical changes of Douglas fir. Biomass Bioenerg. 2016, 90, 78–89. [Google Scholar] [CrossRef]

- Pramreiter, M.; Stadlmann, A.; Huber, C.; Konnerth, J.; Müller, U. The Influence of Thickness on the Tensile Strength of Finnish Birch Veneers under Varying Load Angles. Forests 2021, 12, 87. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, H.; Gao, M.; Wang, J.; Mu, H.; Qi, D. Fast Preparation of High-Performance Wood Materials Assisted by Ultrasonic and Vacuum Impregnation. Forests 2021, 12, 567. https://doi.org/10.3390/f12050567

Yang H, Gao M, Wang J, Mu H, Qi D. Fast Preparation of High-Performance Wood Materials Assisted by Ultrasonic and Vacuum Impregnation. Forests. 2021; 12(5):567. https://doi.org/10.3390/f12050567

Chicago/Turabian StyleYang, Hong, Mingyu Gao, Jinxin Wang, Hongbo Mu, and Dawei Qi. 2021. "Fast Preparation of High-Performance Wood Materials Assisted by Ultrasonic and Vacuum Impregnation" Forests 12, no. 5: 567. https://doi.org/10.3390/f12050567

APA StyleYang, H., Gao, M., Wang, J., Mu, H., & Qi, D. (2021). Fast Preparation of High-Performance Wood Materials Assisted by Ultrasonic and Vacuum Impregnation. Forests, 12(5), 567. https://doi.org/10.3390/f12050567