1. Introduction

Mortise-and-tenon (M-T) joints have commonly been used in traditional wood frameworks, and are still used in wood structures and wood furniture. It is known that the mechanical properties of M-T joints influence the strength of the whole wood framework [

1,

2]. Withdrawal and bending loads are two common loading types that M-T joints are subjected to. It has been reported in previous studies that factors including wood species, joint type, glue type, loading type, and assembly time seriously influence the withdrawal and bending load capacities [

3,

4,

5,

6,

7,

8,

9].

Previous studies have done some works on the withdrawal load capacities of M-T joints; Eckelman and his team did a series of studies on this topic, considering factors influencing the withdrawal load capacities [

3]. In addition, the effect of wood species and tenon length on the withdrawal load capacity of M-T joint T-shaped samples has been studied [

4], indicating that the glue line in the length of the tenon had a significant effect on the withdrawal load capacity of M-T joints. Additionally, Diler et al. [

6] investigated the withdrawal load capacity of T-shaped M-T joints made from heat-treated pine, common ash, and irokowood, indicating that heat-treated wood reduced the withdrawal load capacity of the joint by 25%. Furthermore, Barboutis and Melissides [

10] reported that the withdrawal load capacity decreased with the increase of assembly delay, which might be the result of the rheology (relaxation and creep) of the wood. The methods used to increase the withdrawal load capacity of M-T joints, through using greenwood shrinkage as a clamping force, was proposed by Renbustu and Koizumi [

11]. However, few studies have been found relating to the effect of tenon geometry dimensions on withdrawal load capacities.

In the case of bending load capacities or the bending moment of M-T joints, some experimental tests have been conducted to investigate the tenon geometric dimensions on the bending moment strength of M-T joints. The following listed studies are representative of these: The effect of tenon geometric dimensions on the bending moment and stiffness were investigated by Wilczyński and Warmbier [

12] through the use of the diagonal tension test method. The results suggested that the effect of tenon length on joint strength was greater than tenon width, followed by tenon thickness. The relationship between bending moment and rotation characteristics were investigated in relation to tenon geometry, grain orientation, length, and shoulder fit [

13]. In addition, Oktaee et al. [

14] reported that the effects of tenon length on the bending moment resistance of M-T joints were more significant than tenon width when they were subjected to compression and tension. Kasal et al. [

15] also studied the bending moment resistances of L-shaped M-T joints subjected to both compression and tension loadings, considering the effects of tenon sizes (width and length). Their results also showed that the tenon length had a greater effect on the bending moment resistance than the tenon width. Additionally, Erdil et al. [

16] reported that the effect of tenon width on bending moment resistance was more significant than tenon length. Furthermore, the effects of tenon thickness on the bending elastic stiffness of samples were investigated, and the results suggested that the effect of tenon thickness on the bending elastic stiffness was more significant [

17].

Tenon sizes (length, width, and thickness) are basic parameters of M-T joints, and they affect the strength of M-T joints directly [

18]. However, how to design the tenon geometry sizes rationally while considering the bending and withdrawal load capacities of M-T joints together has rarely been studied because a large amount of work is required to make it feasible. Finite element analysis (FEA) has been confirmed as an effective method commonly used in wood engineering [

19,

20,

21,

22,

23]. Previous studies also proved that FEA can be used to analyze M-T joints [

24,

25,

26,

27,

28].

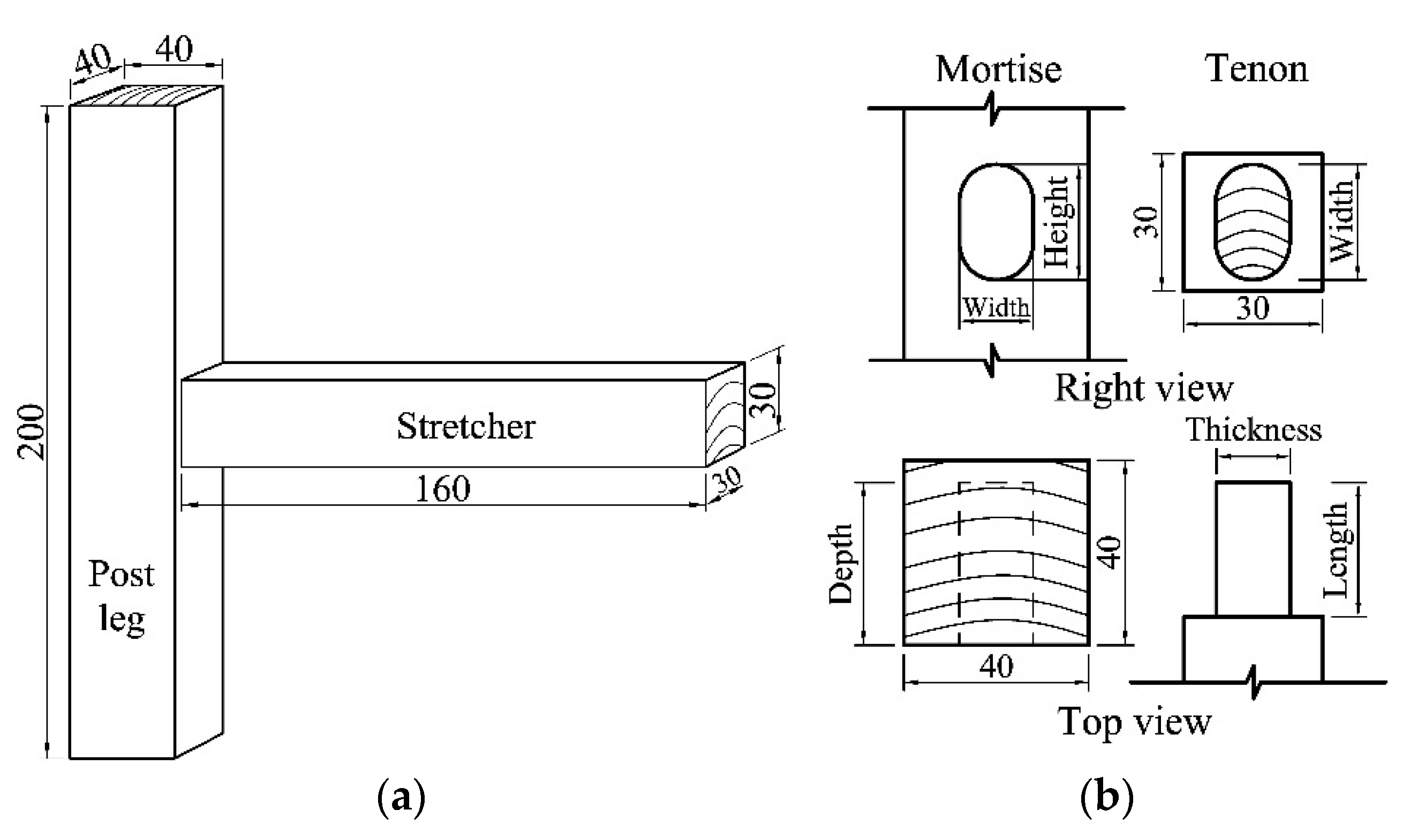

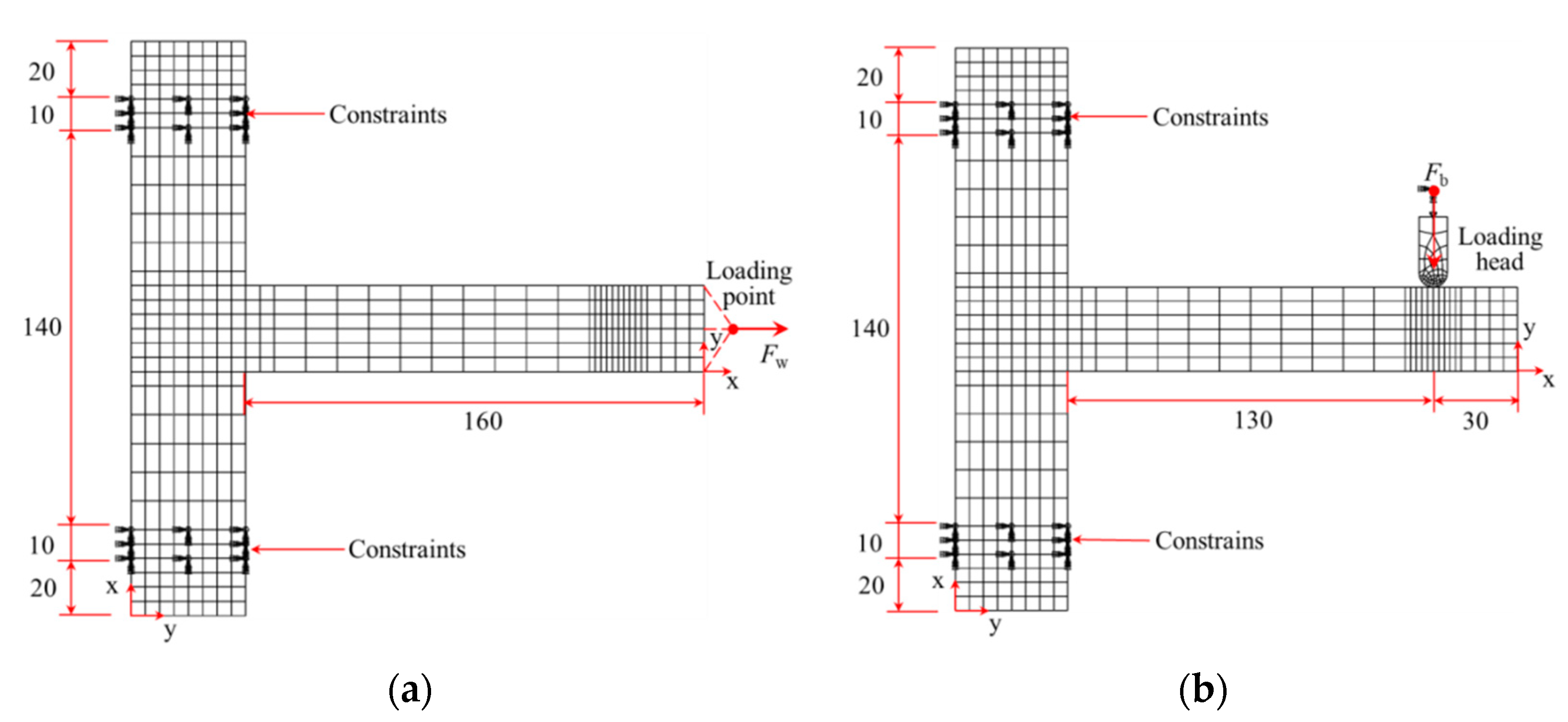

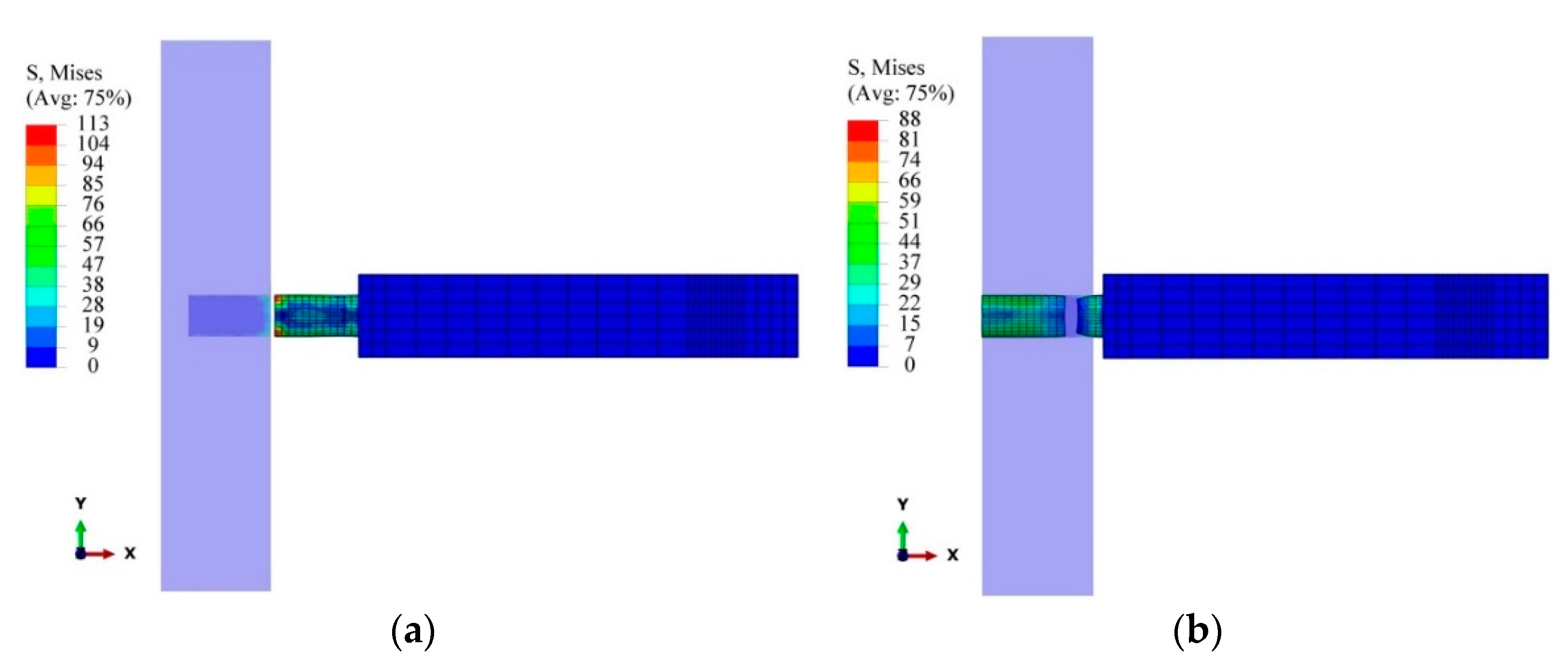

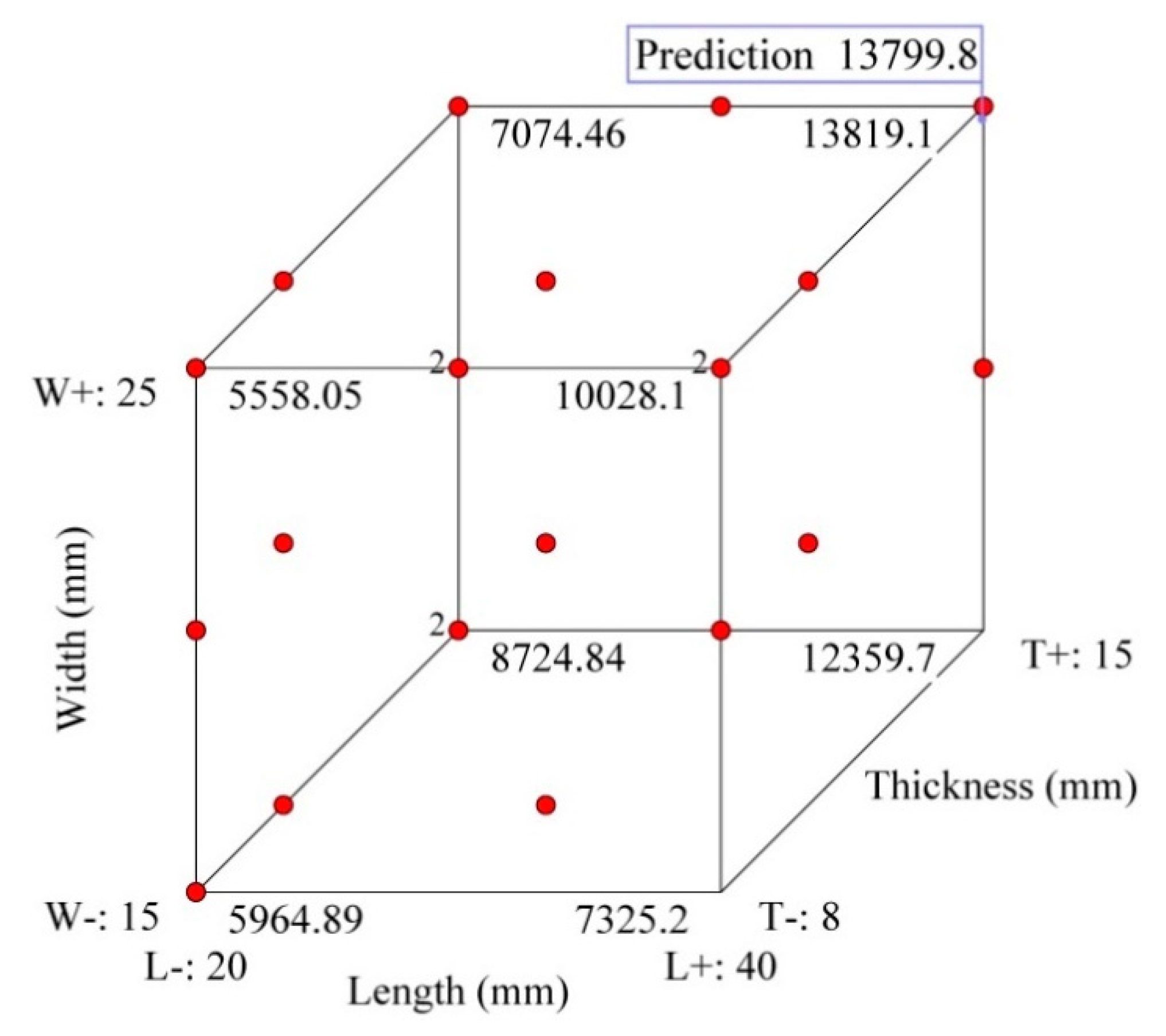

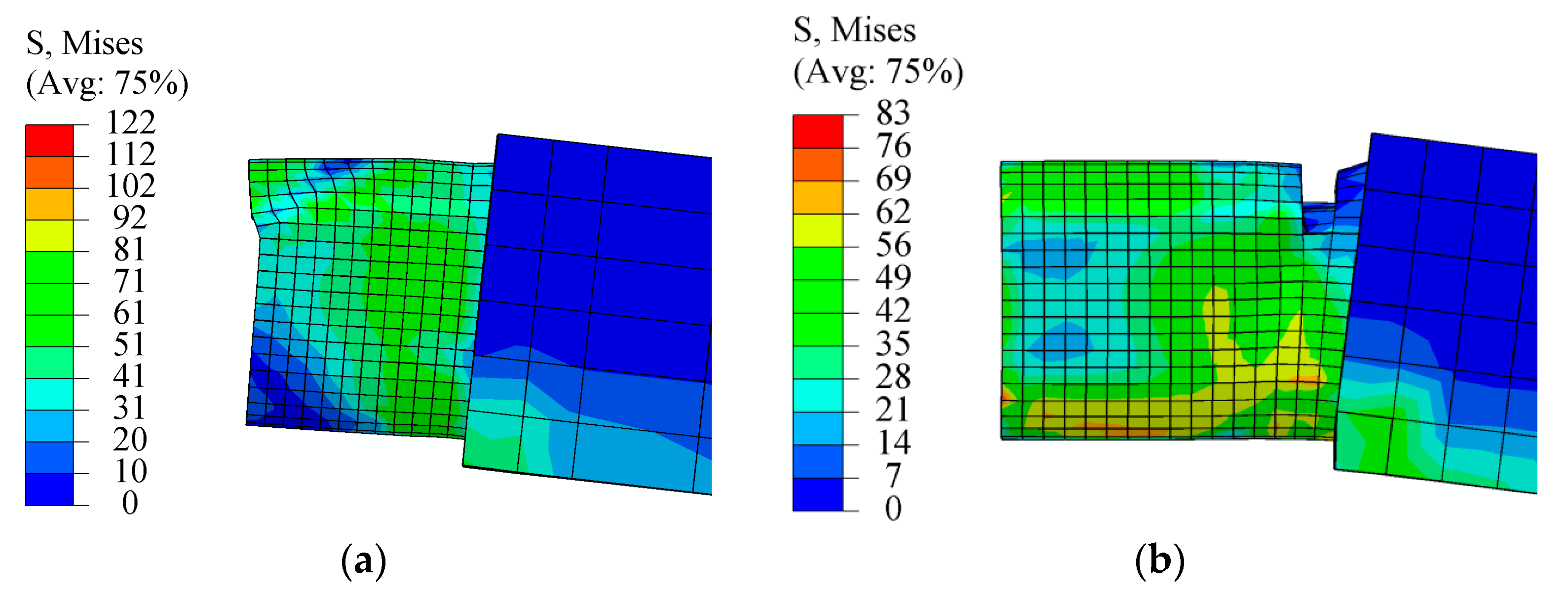

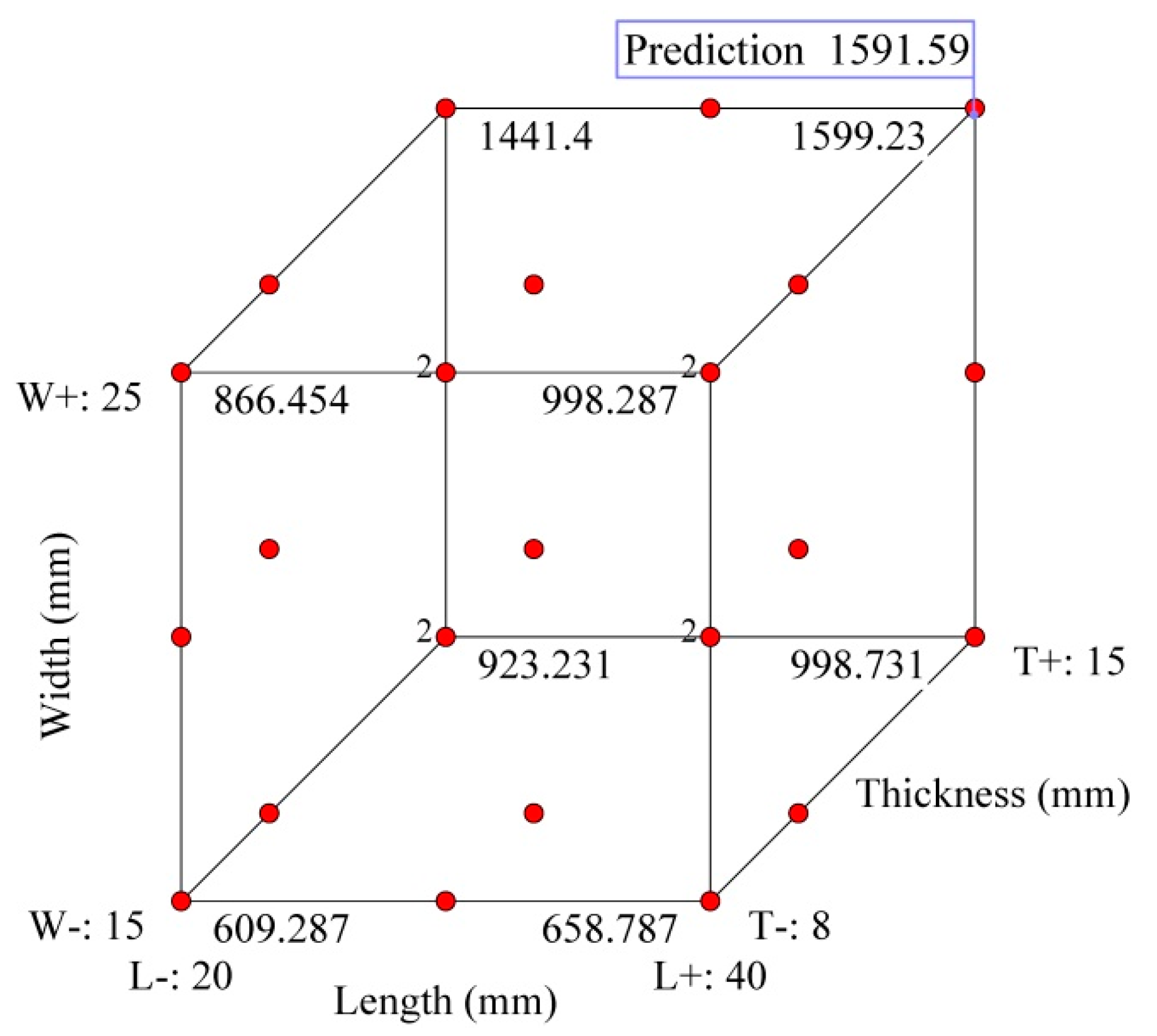

Therefore, in this study, a methodology has been proposed: The size effects of tenon geometry dimensions (length, width, and thickness) on the withdrawal and bending load resistances of M-T joints were investigated numerically by first using FEA. The relationship between withdrawal and bending load resistances relating to tenon geometric dimensions (length, width, and thickness) were then investigated using the response surface method (RSM), with the aim of resolving the issue of how to design tenon geometry rationally.

5. Conclusions

In this study, the effects of tenon geometric dimensions, including tenon length, tenon width, and tenon thickness, on bending and withdrawal load capacity were studied through the use of FEA and RSM. The following conclusions were drawn:

(1) The tenon length has a greater effect on withdrawal load resistance than tenon thickness, followed by tenon width, while the effect of tenon thickness on bending load resistance is greater than that of tenon width, followed by tenon length.

(2) It is recommended that the tenon length is greater than the tenon width and smaller than twice the tenon width (w < l < 2w), especially for relatively thin tenon thicknesses.

(3) Quadratic models relating to the tenon lengths, tenon widths, and tenon thicknesses proposed in this study was validated as an effective method to predict and optimize the withdrawal and bending load capacities of M-T joints.

(4) The maximum withdrawal and bending load resistances were obtained in this study when the tenon sizes were approximately 40 mm long × 25 mm wide × 15 mm thick.

In conclusion, the proposed method combining FEA with RSM is capable of being used to evaluate and design M-T joints, and to get more knowledge of M-T joints visually. This study contributes to reducing the costs of both time and materials used in conducting experiments.