1. Introduction

Wood was a very important raw material for mankind as early as the low stages of the development of society. Although mankind has already discovered a lot of new materials, wood has not lost its significance and is used everywhere [

1,

2]. The importance of wood raw material has increased due to the ecological characteristics of this material. The irreplaceability of wood also underlines its versatile use from cradle to grave [

1,

3]. It is used in various sectors, such as construction, pulp, wood and furniture industry and others. It can be stated that today, this ecological material plays an important role in all areas of the national economy and wood cannot be compared to any other material [

4].

The importance of the woodworking and furniture industry for the national economy of Slovakia, as well as employment in the regions, has been undervalued in recent years. It is essential that this area gets to the centre of social perception [

5,

6]. The woodworking and furniture industry should present an important part of small and medium-sized businesses in the regions. Small and medium-sized enterprises are a typical segment of the successful economy of developed countries [

7,

8]. The wood-processing industry has been fundamentally affected in recent years by globalization and the opportunities for world trade, which also brings strong competition. These facts underline the importance of a constant perception of changes in a market environment, where all companies have to react immediately and adapt their supply to current trends and strengthen their competitiveness [

5,

9].

In Slovakia, small and medium-sized enterprises (SMEs) represent the dominant group of business entities [

8]. In 2003, the European Commission determined a definition of SMEs at the European level. This definition has been adopted by all Member States. On this basis, statistics on SMEs are currently being elaborated, which can be compared among themselves because a uniform definition is applied [

10,

11,

12].

Customers perceive wood as a suitable material, whether in terms of aesthetics or colour, for both interior and exterior in residential spaces. In the woodworking and furniture industry, the way of processing the material has a large impact on the quality and cost-effectiveness of production, but not least on the price of the final product [

2,

3,

13,

14].

As stated by the authors [

14,

15,

16], wood can be divided from several basic aspects (technical, aesthetic and economic) as a material for the production of final products. The following criteria present a summary of the utility requirements of the products, the material and the way of processing.

The first is technical criteria, which mainly represent mechanical, physical, and also chemical properties of wood as a material for the manufacturing of products [

4]. These features are a prerequisite for product durability, which is essential in particular for preventing damage and wear, and are also important for the fulfilment of all essential functions that a particular product is intended to fulfil (such as furniture) [

1,

4].

The second factor is the creation of a certain aesthetic value that the wood product shall meet. Different materials may give different aesthetic value to the consumer, as each botanica species of wood has a different grain, colour or can modify this colour or grain [

14,

15]. The colour is one of the optical characteristics of the wood and is particularly important in cases where an aesthetic external appearance is required. It is important mainly in the manufacturing of furniture, works of art, musical instruments, sports equipment, etc. [

16,

17].

When assessing wood according to colour, it is also necessary to think about wood moisture and the freshness of the cut [

18]. In general, dry wood is lighter than wood that has high water content. As an example, freshly cut alder has a light pink colour, but after a few days, it turns its colour into sharp orange as a result of oxidation of the accompanying substances. After processing and drying, the colour of the alder wood becomes pink-red [

19,

20]. The colour change also occurs at spruce, pine and many other species exposed to ultraviolet radiation. According to colours, wood is divided into groups: red woods (turkey oak, cherry, pine, alder, larch, etc.), brown woods (elm, ash, oak, walnut, etc.), pale woods (hornbeam, spruce, fir etc.) and green woods (acacia etc.) [

18,

20].

As the authors [

18,

20] agree, wood is used in its natural colour only rarely. Wood finishing is a surface treatment in several ways, which can include staining, dyeing, bleaching and others. Surface treatment of wood is mainly used in the manufacture of windows, doors, floors, furniture etc.

Wood staining is a finishing process that aims to enhance the beauty and texture of the wood. At the same time, during wood staining, it changes its colour because of a chemical reaction between the stain and the wood. Through staining, dark parts of the wood get a richer colour tone than the lighter parts. The wood texture is also enhanced and the colour difference between the core and sapwood is reduced [

18,

20]. When the wood is dyed, a particular paint is applied to the wood surface; however, unlike the staining, there is no chemical reaction. The wood dyeing ultimately has an adverse effect, but it is used for wood with indistinct textures such as maple and birch. For woods with a distinct texture, such as oak and spruce, staining is used to enhance their grain. Wood dyeing is largely influenced by fashion, current trends and customer preferences [

18,

19]. Another way of wood surface treatment is bleaching. This process is used to unify the colour and partially lighten particularly bright species of wood, such as birch and maple. The effect of this process depends on the bleaching agent used. In practice, the most commonly used agent is the mixture of hydrogen peroxide and ammonia. Other bleaching preparations include ethanoic acid, citric acid, sodium sulphite and bleaching agents [

18,

20]. It is also possible to modify the wood surface, as refs. [

4,

18] point out, with oil or wax. With such treatment, the wood retains its natural properties. This also fills an aesthetic function, because the smooth matt or glossy surface, which can be created with a layer of varnish or wax, is very effective. Due to the fact that the surface is not closed, the wood can breathe; in addition, essential oils are released from it. The advantage of using oil or wax is also the protection of wood from mould, insects, UV radiation and moisture. In addition, such waxes and oils are friendly to the environment and to the wood itself. As refs. [

4,

7,

18] state, in small-scale manufacturing, other special surface treatments are also used, which do not only change the colour of the wood but also its structure. The most common special surface treatments include, e.g., sandblasting, which is used in the production of imitations of old worn wood. During sandblasting, sand is brought to the wood surface under air pressure. By sandblasting, it is possible to create various patterns and ornaments using a template. Another way is scorching, which is used mainly in the manufacture of cottage furniture. Wood species that contain a large amount of resin are not suitable for scorching. Laser cutting of wood is another example of surface treatment. Laser machining is used in the wood-processing industry to machine board materials and enables cost-effective cutting up to a thickness of 80 mm. Laser engraving, which is a modern way of branding materials, is again sought after, especially in the domain of advertising and home decoration. The principle of engraving is to remove a thin layer from the surface and thus create the desired motif—logo, graphic or pattern. It is mainly used where high accuracy and quality of the cutting edge is required.

The third factor in the manufacture of wood products is economic criteria [

21]. This group of criteria largely influences the quality of the raw wood material used, as well as the materials used in the production. The cost of finished products shall be comprehensively evaluated. In particular, the impact on production technology, production volume, labour consumption, auxiliaries etc. must be taken into account [

22,

23,

24].

Consumer preferences in the area of the surface (i.e., aesthetic) treatment of wood and furniture products have not been comprehensively mapped in the conditions of the Slovak Republic so far. It follows from the above that the current supply of tones of wood and furniture products does not fully take into account consumer preferences. Knowledge of supply and demand can protect companies from selling surplus products at minimum margins or with a loss, as stocks are significantly above demand for these products, and vice versa. Knowledge of supply and demand can represent significant opportunities for efficiency and value creation for both customers and enterprises [

22].

As ref. [

21] states, there are generally four essential requirements that are indispensable for meeting customer requirements. The first is to have a developed supply chain strategy. This must be elaborated for each product and market separately. The second key element is to have the ability to meet demand, where it is necessary to eliminate long delivery times. Furthermore, it is essential that there is a sales plan and a stock-building plan. To be effective in the production process, it is necessary to know the demand for products and the plan to build up their stocks in the warehouses. The last element is flexibility in planning and implementing the production process, which needs to be able to adapt promptly to unplanned market changes.

As ref. [

25] emphasize, the mission of marketing can be generally understood as a mean to satisfy the customer needs in the social context. In addition to the sales function, marketing should develop relationships between the enterprise and its customers. How marketing is done and what role it plays in enterprises depends on the marketing philosophy of the enterprise and its managers. Inappropriate or outdated marketing philosophy usually means the inappropriate or outdated application of marketing mix tools and the result is low business performance. Forest product marketing is in a process of constant development; in the future, these companies will have to adapt to new customer needs. It is necessary to pay attention to the issue because customers currently demand a variety of supplied wood products in terms of dimensions and quality, but also colour tones. For this reason, many companies abandon the cost leader strategy, because they realize that producing large quantities at low cost is sometimes not enough to stay competitive, to instead focus on the strategy of specializing their products and offering a wide range of products. The specialization towards customer requirements is a prerequisite for the demand of products by customers and thus their sales.

It follows from the above that it is necessary to carry out surveys in the market conditions of individual economies to ensure that the supply of wood and furniture products meets customer requirements even in an aesthetic way. Trends in the area of surface treatment, and, in particular colours, are constantly changing; enterprises need to react flexibly to these changes. Competitiveness itself also depends to a large extent on technological equipment and the quality of employees, but also on the financial capital of enterprises. Customer preferences must therefore be constantly monitored. In particular, woodworking and furniture enterprises should offer colour tones of their products that are fashionable and that customers will certainly look for.

The main objective of this paper is to identify the supply of colour tones of wood and furniture products of Slovak micro, small and medium-sized enterprises.

The following hypotheses were defined from the literature review:

Hypothesis 1 (H1). It is assumed that the Slovak MSM WFEs most frequently treat wood by staining, as it is possible to enhance the natural colour and grain of the wood.

Hypothesis 2 (H2). It is assumed that most Slovak MSM WFEs know the process of hydrothermal treatment of wood by steaming (or cooking), but they do not use it due to the financial burden of introducing this process into production.

3. Results and Discussion

The following part presents the results from respondents, i.e., micro, small and medium-sized woodworking and furniture enterprises (MSM WFEs), which actively participated in the survey. A total of 399 respondents participated in the survey on the supply of colour tones products of Slovak SMEs in the woodworking and furniture sector in Slovakia. The first part of the questionnaire (part A) contained key identification questions. The results are presented in

Table 1.

In the following part of the survey (designated as B), questions served to identify the supply of colour tones of wood that Slovak MSM WFEs offer to attract customers.

In the first question, it was examined whether the WFEs prefer the price to the quality of the wood raw material. The results clearly show that up to 78.2% of MSM WFEs will prefer quality to the price of the wood. However, a more detailed analysis found that the price of the material is more likely to be preferred by micro, small and medium-sized furniture enterprises (68.35%) than by MSM woodworking enterprises (31.65%). The Slovak MSM WFEs produce solid wood products most frequently (69.42%). A total of 17.80% of enterprises manufacture products from chipboard and fibreboard, and 12.78% of manufacturers also prefer products covered with wood veneer.

As the authors [

1,

3,

29] agree, wood is a versatile material that can be used in many sectors, such as mining, construction, furniture, carving, in the production of paper assortment or cardboard, etc. However, solid wood used in the production of the best quality products, e.g., musical instruments, is considered to be unique and most precious. On the contrary, authors [

4,

30] point to the fact that, in addition to solid wood, fibreboards and chipboards are also used in the furniture industry. This was confirmed by the results of the questionnaire survey, where the majority of MSM furniture enterprises (namely 59.7%) work mainly with chipboards and fibreboards. The authors [

31,

32,

33,

34,

35] emphasize that the use of the material primarily affects the final price of the product for consumers and determines the strength of demand for it. It also affects the quality of the product range as well as the economy of production processes.

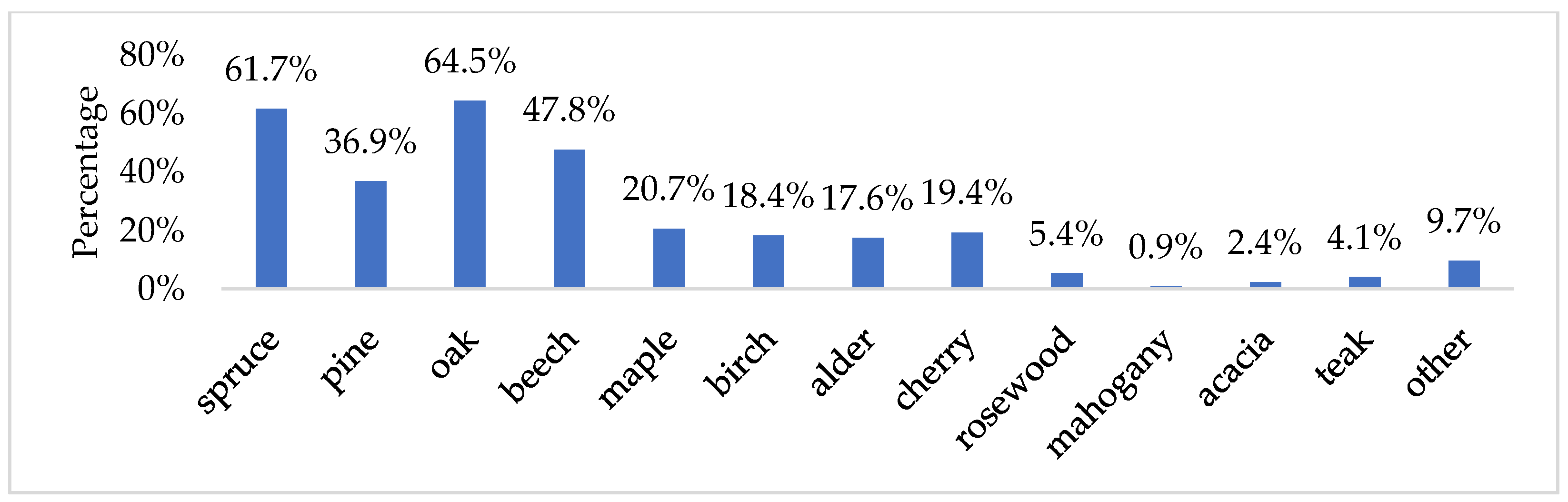

The third question uncovered that MSM WFEs mainly process domestic wood species (90.10%). Only a few produce their products from exotic trees (as stated by less than 10% of respondents). As refs. [

34,

35] state, domestic wood species in Slovakia include mainly spruce, oak, beech, cherry, alder, etc. Detailed results on the use of individual wood species by the Slovak MSM WFEs are shown in the following

Figure 1 (respondents could indicate more than one answer). As refs. [

6,

34] also claim, Slovakia is considered to be fully independent in terms of wood production. The largest proportion presents deciduous beech and oak woods and the spruce dominates from coniferous woods. The total area of forest land covers 41.2% of the total territory of Slovakia.

The next questions of the survey were directly focused on the issue of colour tones of wood. The research has shown that up to 73.60% of MSM WFEs work mainly with wood, to which they leave its natural colour. Only 26.4% of the MSM WFEs use wood that has a modified colour. A more detailed examination of the respondents’ answers confirmed that the MSM FEs more frequently change the colour of the wood (51.4%). In the case of wood treatment, respondents most frequently used the process of staining (60.64%), followed by dyeing (18.92%), while bleaching was preferred by 9.12% of respondents, and steaming only by 4.73%. Almost seven percent of respondents also used other wood treatment methods. In the answer “other”, the respondents stated the following wood treatment methods: oiling, scorching, waxing, stabilization with coloured epoxy resin, brushing and laser engraving. This question served as a basis for verifying the assumption made in the H1 hypothesis—it was assumed that the Slovak MSM WFEs most frequently treat wood by staining, as it is possible to enhance the natural colour and grain of the wood. This hypothesis was tested by the Friedman test, followed by the Wilcoxon test. The results of the Friedman test confirmed that the individual wood treatment methods are not equally significant (

p-value = 0.000). The Wilcoxon test identified the order of significance of individual wood treatment methods. It can be stated that the assumption in this hypothesis is correct, the Slovak MSM WFE most often treat the wood by staining (

p-value = 0.000).

Table 2 presents the detailed results.

The most common reasons for WFEs to change the colour of the wood are given in

Figure 2 (respondents could indicate more than one answer). As refs. [

3,

6,

36] agree, wood as a natural material is excellent for its aesthetic and decorative properties. At the same time, it also evokes in people a sense of deeper connection with nature. To preserve the natural appearance of wood, WFEs use minimal wood treatments. If it is necessary to treat it, the aim of the treatment is to improve its aesthetic appearance.

Slovak MSM WFEs offer mainly products in brown colour tones (84.2%). The second most frequently offered colour of the products is white (42.5%) and the third is black colour (31.2%). Only 26.1% of respondents are promoting grey tones of wood products. Only 18.4% of Slovak MSM WFEs have yellow wood products in their portfolio. The “other” option was marked by 5.4% of respondents. As refs. [

6,

7,

37,

38] point out, current fashion trends are trying to increase in people the sense of connection with nature. This is also one of the reasons why brown or body colour have been ranked among the most fashionable tones since 2020. Brown colour is the closest to the colour of nature and thus also to wood [

2]. Other achieved results correspond to this fact, as up to 73.3% of respondents work mainly with matt wood, mainly the furniture enterprises. Gloss wood is preferred by only 26.7% of MSM WFEs. As refs. [

4,

30] emphasizes, it is necessary to distinguish the natural gloss of wood, which is influenced by the composition of wood mesh, cut or quality of machining and gloss achieved by the use of chemical coating materials.

Hydrothermal treatment of wood by steaming is a modern way to change its colour tone. Since the application of this technique to change the colour of wood requires remarkable investments in the production process, the subject of examination was to identify whether the Slovak MSM WFEs had already heard about the hydrothermal treatment of wood by steaming and whether they have applied this process. Through this question, the authors were able to verify the validity of the assumption made in the hypothesis H2—it is assumed that most Slovak MSM WFEs know the process of hydrothermal treatment of wood by steaming, but do not use it because of the financial burden of introducing this process into production. As shown in

Table 3, the

p-value is lower than the level of significance, i.e., the hypothesis has been confirmed. The achieved results are also supported by [

33,

36,

39,

40,

41,

42,

43,

44], who stress that it is essential to comply with production parameters in the process of hydrothermal treatment of wood. It is necessary to adjust correctly and maintain both temperature and pressure or vacuum in hydrothermal treatment facilities.

In a market environment, enterprises are constantly seeking their competitive advantage to encourage customers to purchase their products. As refs. [

10,

19,

41,

43,

44] claim, the main competitive tools include price and quality of production. In the woodworking and furniture industry, these competitive tools are also being developed and applied. For example, through thermal modification, the wood of alder acquires the colour of mahogany wood and thus becomes affordable to a wider group of potential customers. The results of the survey showed that Slovak MSM WFEs very often tend to use the alder wood processed in this way (78.6%). However, 21.4% of respondents prefer to produce products from mahogany (i.e., tropical wood) and offer them to a selected group of customers.

In the last question of the survey, attention was paid to the ecological aspect of the dyeing and staining process. In total, up to 78.3% of Slovak MSM WFEs prefer paints and stains that are on a natural basis. However, 21.7% of respondents stated they prefer the price of paints and stains during their choice and the ecological characteristics of these materials are not decisive for them. As refs. [

43,

44,

45,

46] present, the environmental friendliness of enterprises has become a competitive advantage. More and more customers who choose products consider their ecological advantage or disposal. It is for this very reason that social and economic factors are no longer referred to in terms of social responsibility, but the emphasis is also placed on those ecological ones.

4. Conclusions

The main objective of this paper is to identify the supply of colour tones of wood and furniture products of Slovak micro, small and medium-sized enterprises.

The results have shown that Slovak micro, small and medium-sized woodworking and furniture enterprises prefer the quality of raw wood material to the price. Wood and furniture products are produced mainly from domestic wood species, such as spruce, oak and beech. This research has shown that up to 73.60% of MSM WFEs work mainly with wood and leave its natural colour. Only 26.4% of the MSM WFEs use wood that has a modified colour. If it is necessary to change the colour of the wood, there are several possibilities, such as dyeing, staining, bleaching, steaming and others. In particular, enterprises tend to change colour when it is necessary to enhance the grain of the wood. The assumption made in hypothesis H1 was confirmed by a binomial test, i.e., that Slovak micro, small and medium-sized woodworking and furniture enterprises mostly treat wood by staining, as this makes it possible to enhance the natural colour and grain of the wood. The enterprises offer mainly products that are in brown, white and black colour. At the same time, enterprises prefer matt wood to gloss wood. Hydrothermal treatment of wood by steaming (or cooking) presents a modern way to change its colour tone. The results pointed to the fact that most Slovak MSM WFEs know this process; however, because of the financial burden, it is not possible to implement it in the enterprise (the H2 hypothesis has been confirmed). On the other hand, the thermal modification of the alder wood, which gains the colour of mahogany wood, is used by up to 78.6% of the MSM WFEs. This finding shows that, when offering colour tones of wood, Slovak MSM WFEs seek to gain their competitive advantage on the market through the correct price-quality ratio of the supplied assortment.

The importance of the woodworking and furniture industry for the national economy of Slovakia, as well as employment in the regions, has been undervalued in recent years. It is essential that this area gets to the centre of social perception. The woodworking and furniture industry will be important and accessible, especially for small and medium-sized businesses in the regions. Due to the strong foreign competition on the market, it is essential to find financial resources which the Slovak MSM WFEs could use to modernize the production of their wood and furniture products. Only through such modernization will they be able compete effectively with large companies operating in the competitive environment of Slovakia.