Spectroscopic Stability Studies of Pressure Sensitive Labels Facestock Made from Recycled Post-Consumer Waste and Agro-Industrial By-Products

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Accelerated Ageing Tests

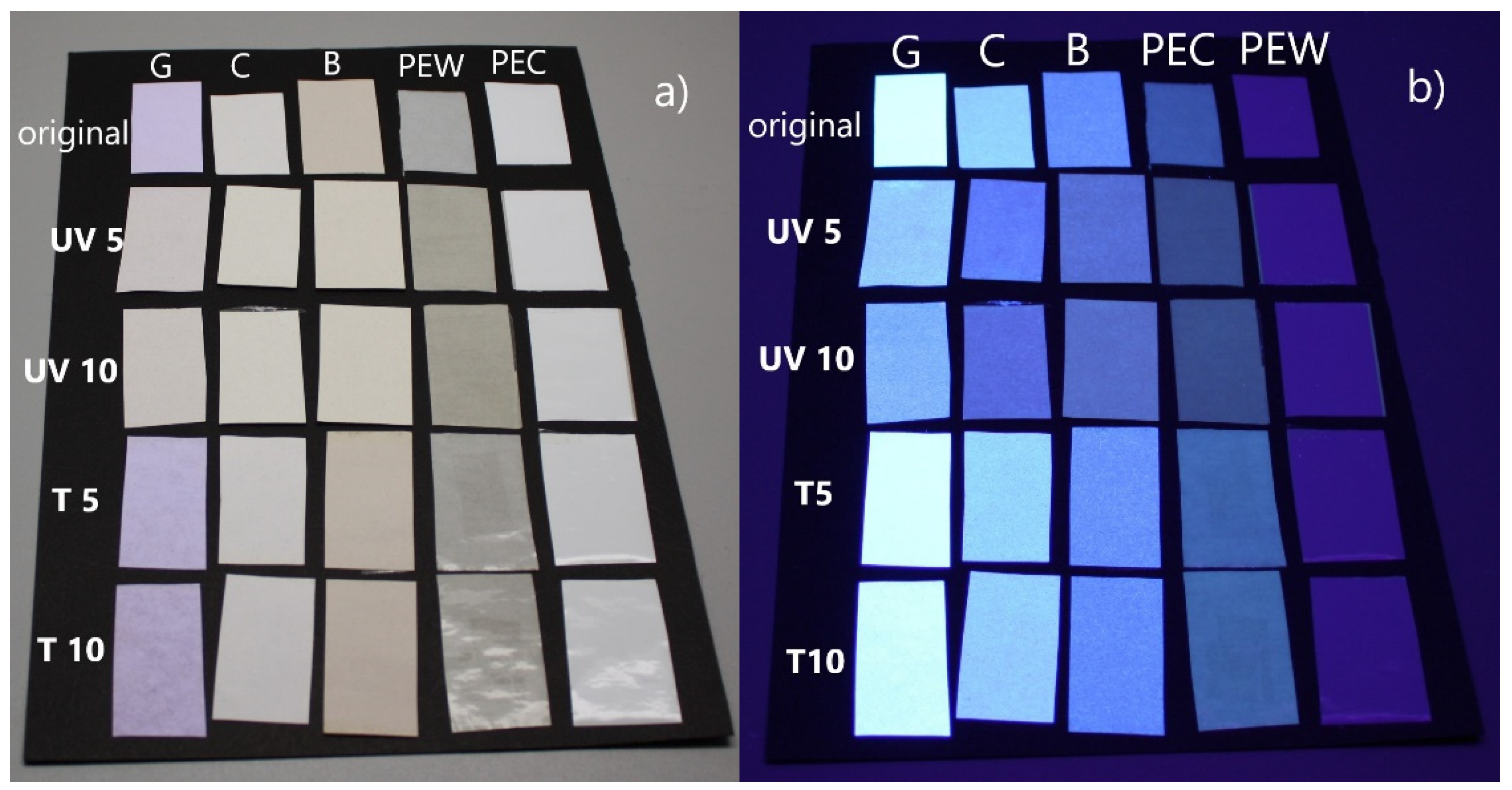

2.2.2. Visual Evaluation

2.2.3. Fluorescence Spectroscopy

2.2.4. UV-Vis Spectroscopy

2.2.5. Fourier Transform Infrared (FTIR) Spectroscopy

3. Results and Discussion

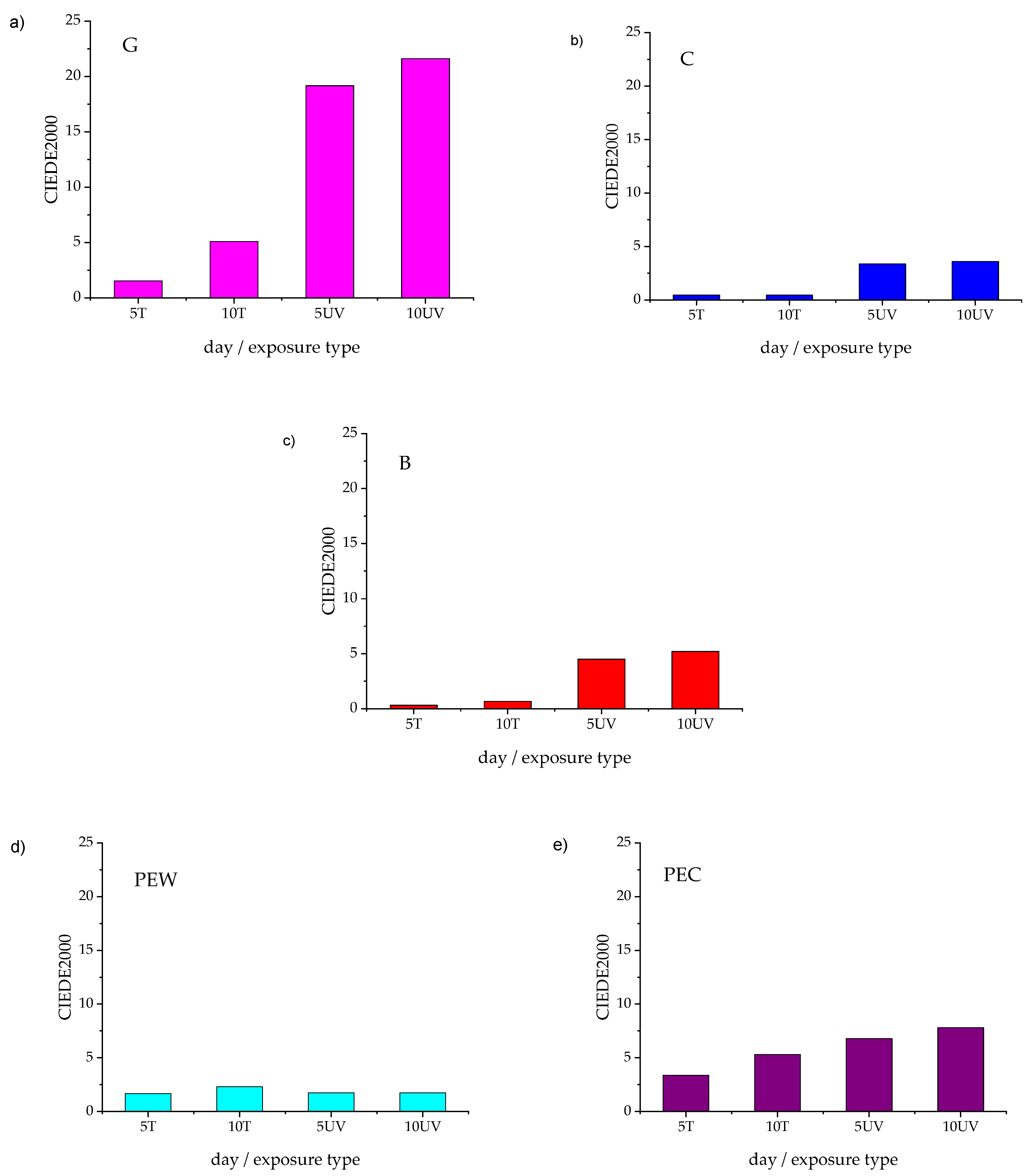

3.1. Visual Evaluation

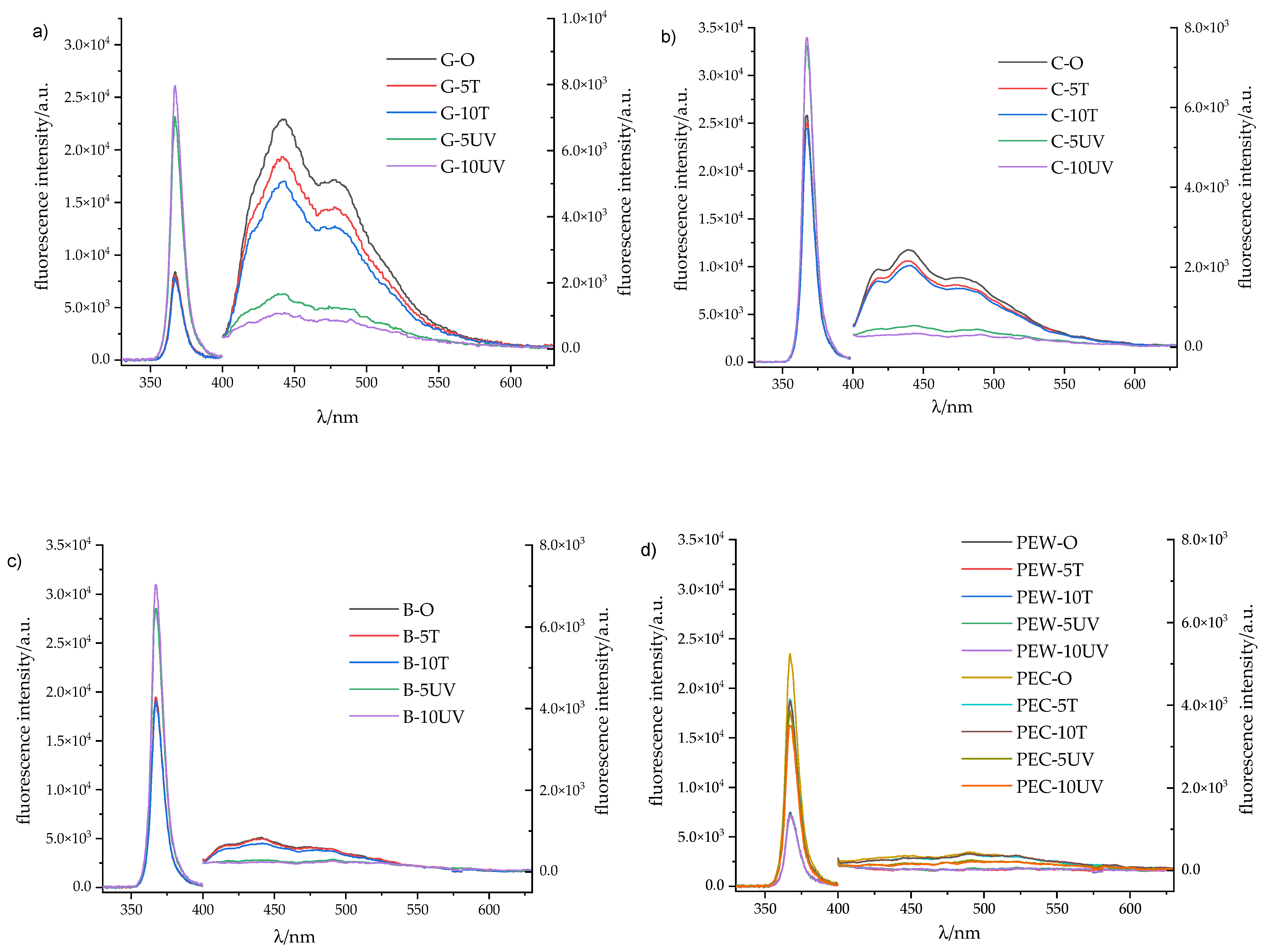

3.2. Fluorescence Spectroscopy

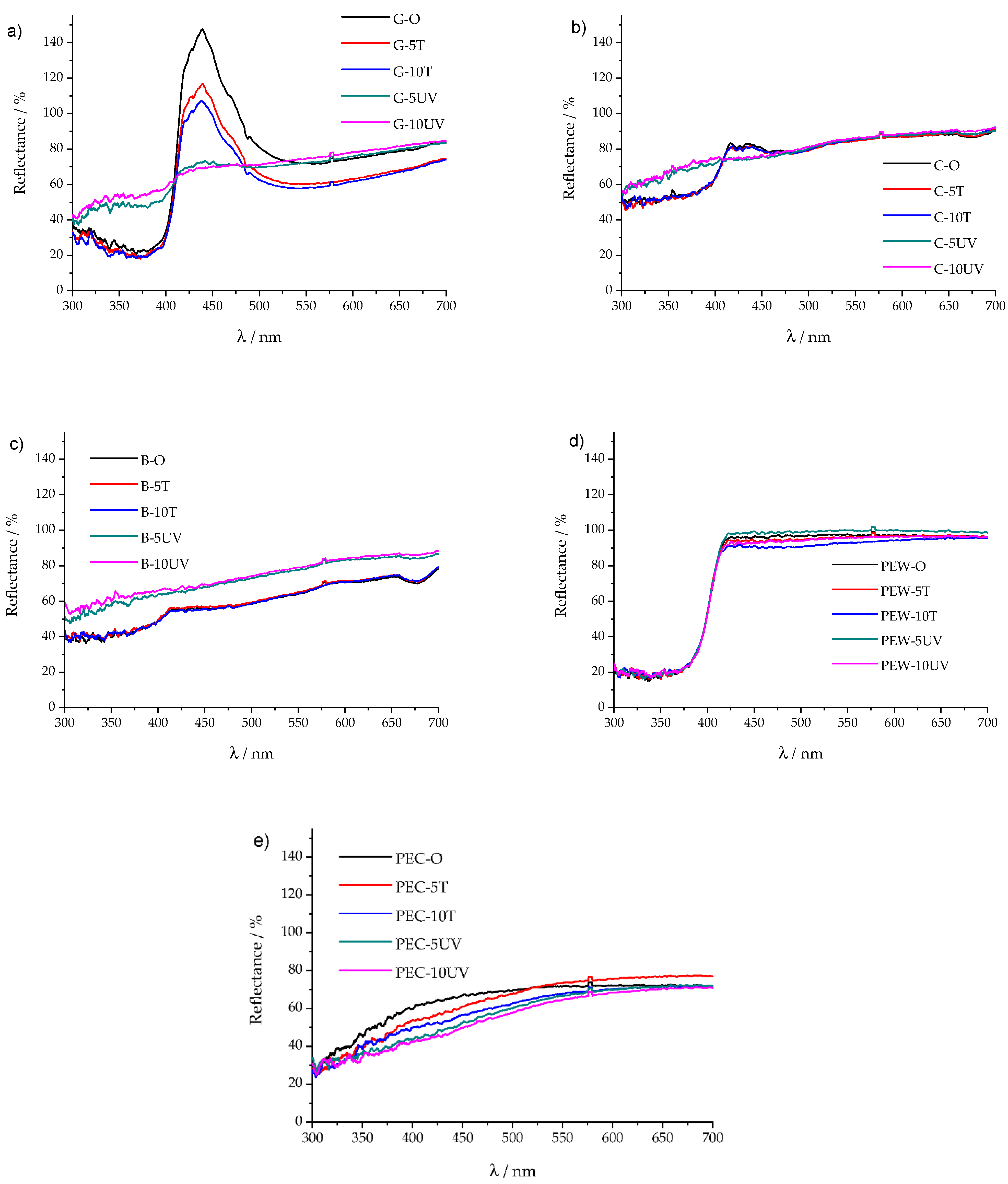

3.3. UV-Vis Spectroscopy

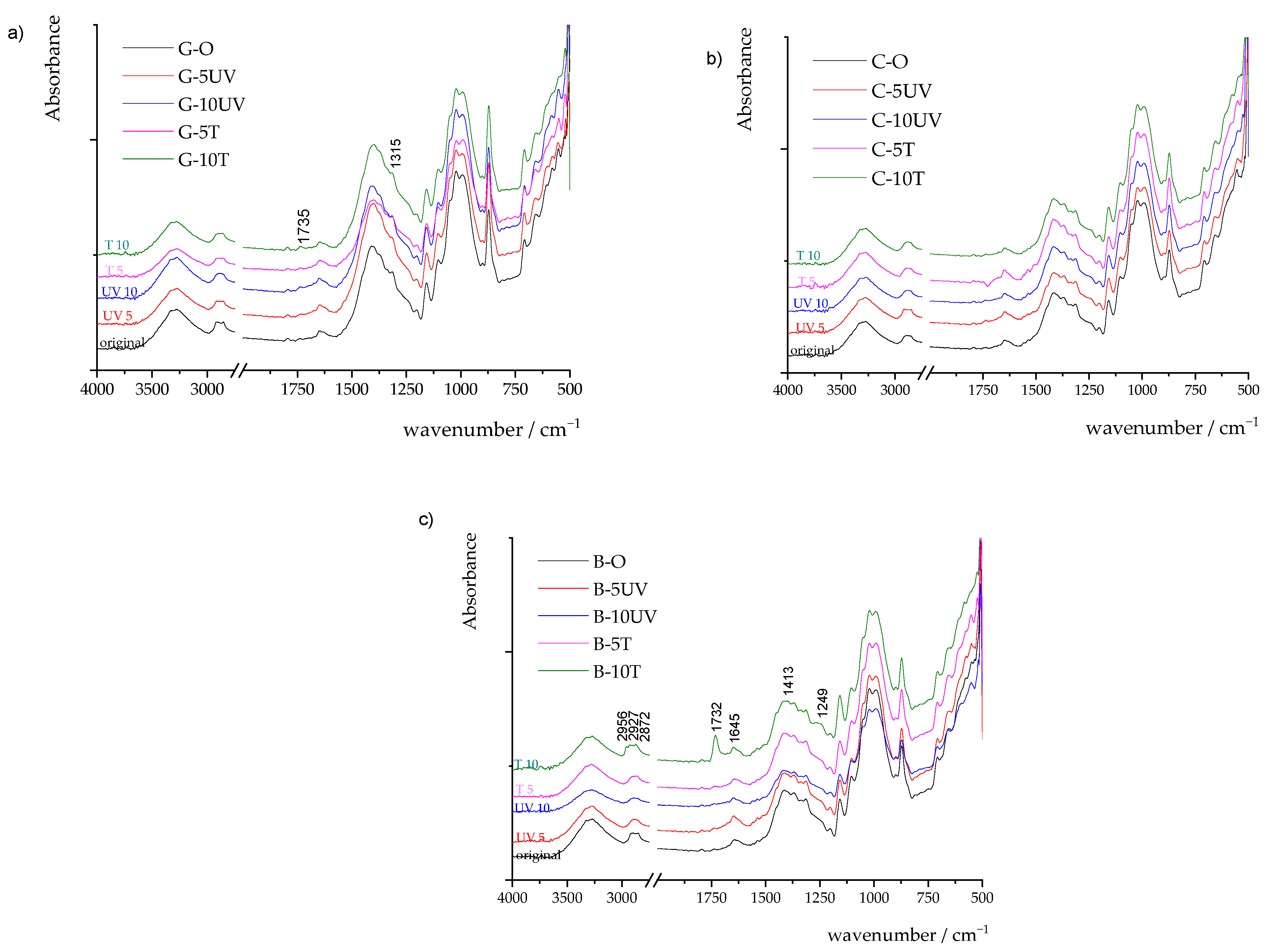

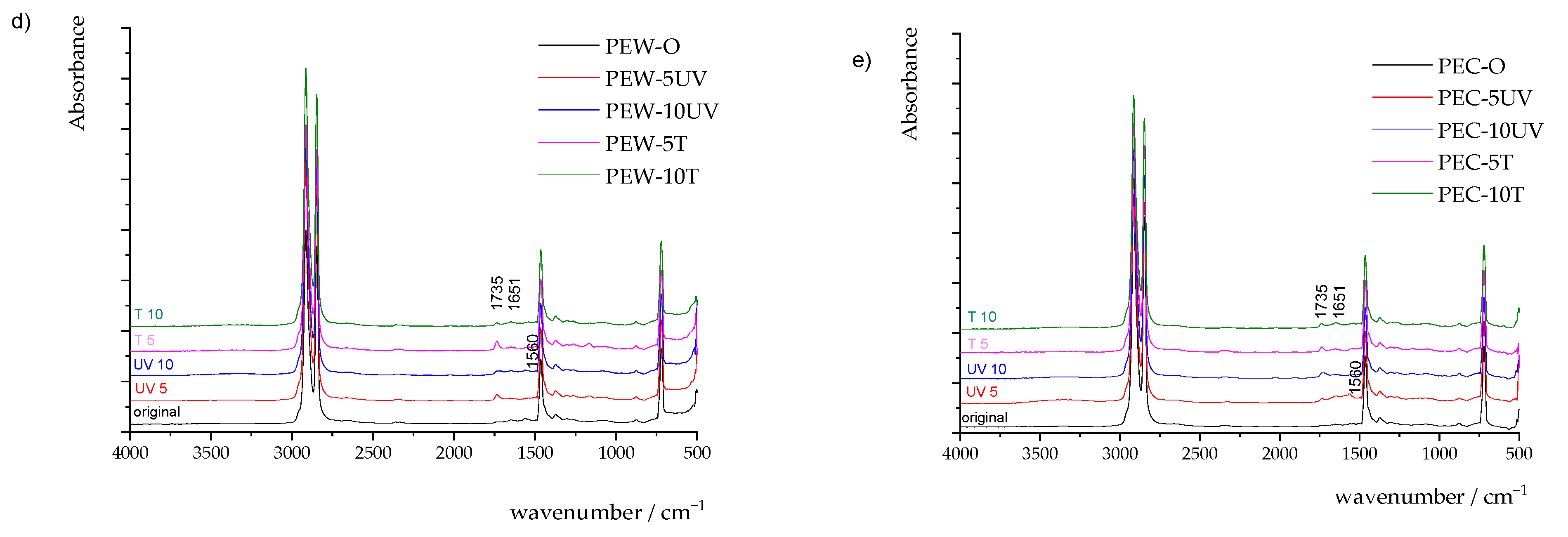

3.4. FTIR Spectroscopy

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Siracusa, V.; Rocculi, P.; Romani, S.; Rosa, M.D. Biodegradable polymers for food packaging: A review. Trends Food Sci. Technol. 2008, 19, 634–643. [Google Scholar] [CrossRef]

- Branowski, B.; Zabłocki, M.; Sydor, M. The Material Indices Method in the Sustainable Engineering Design Process: A Review. Sustainability 2019, 11, 5465. [Google Scholar] [CrossRef] [Green Version]

- OECD. Circular Economy, Waste and Materials. Environment at A Glance. 2000, pp. 1–12. Available online: https://www.oecd.org/environment/environment-at-a-glance/Circular-Economy-Waste-Materials-Archive-February-2020.pdf (accessed on 14 September 2021).

- Abd El-Sayed, E.S.; El-Sakhawy, M.; El-Sakhawy, M.A.M. Non-wood fibers as raw material for pulp and paper industry. Nord. Pulp Pap. Res. J. 2020, 35, 215–230. [Google Scholar] [CrossRef]

- Vallejo, M.; Cordeiro, R.; Dias, P.A.N.; Moura, C.; Henriques, M.; Seabra, I.J.; Malça, C.M.; Morouço, P. Recovery and evaluation of cellulose from agroindustrial residues of corn, grape, pomegranate, strawberry-tree fruit and fava. Bioresour. Bioprocess. 2021, 8, 25. [Google Scholar] [CrossRef]

- El Halal, S.L.M.; Colussi, R.; Deon, V.G.; Pinto, V.Z.; Villanova, F.A.; Carreño, N.L.V.; Dias, A.R.G.; Zavareze, E.D.R. Films based on oxidized starch and cellulose from barley. Carbohydr. Polym. 2015, 133, 644–653. [Google Scholar] [CrossRef] [Green Version]

- Espino, E.; Cakir, M.; Domenek, S.; Román-Gutiérrez, A.D.; Belgacem, N.; Bras, J. Isolation and characterization of cellulose nanocrystals from industrial by-products of Agave tequilana and barley. Ind. Crops Prod. 2014, 62, 552–559. [Google Scholar] [CrossRef]

- Alzate Acevedo, S.; Díaz Carrillo, Á.J.; Flórez-López, E.; Grande-Tovar, C.D. Recovery of Banana Waste-Loss from Production and Processing: A Contribution to a Circular Economy. Molecules 2021, 26, 5282. [Google Scholar] [CrossRef]

- Scurria, A.; Albanese, L.; Pagliaro, M.; Zabini, F.; Giordano, F.; Meneguzzo, F.; Ciriminna, R. CytroCell: Valued Cellulose from Citrus Processing Waste. Molecules 2021, 26, 596. [Google Scholar] [CrossRef]

- Mariño, M.; Lopes da Silva, L.; Durán, N.; Tasic, L. Enhanced Materials from Nature: Nanocellulose from Citrus Waste. Molecules 2015, 20, 5908–5923. [Google Scholar] [CrossRef]

- Tayengwa, T.; Mapiye, C. Citrus and Winery Wastes: Promising Dietary Supplements for Sustainable Ruminant Animal Nutrition, Health, Production, and Meat Quality. Sustainability 2018, 10, 3718. [Google Scholar] [CrossRef] [Green Version]

- Ramdhonee, A.; Jeetah, P. Production of wrapping paper from banana fibres. J. Environ. Chem. Eng. 2017, 5, 4298–4306. [Google Scholar] [CrossRef]

- Sibaly, S.; Jeetah, P. Production of paper from pineapple leaves. J. Environ. Chem. Eng. 2017, 5, 5978–5986. [Google Scholar] [CrossRef]

- Chavan, P.; Singh, A.K.; Kaur, G. Recent progress in the utilization of industrial waste and by-products of citrus fruits: A review. J. Food Process Eng. 2018, 41, 1–10. [Google Scholar] [CrossRef]

- The AWAreness Report Global Pressure-Sensitive Adhesives Market. 2021. Available online: https://www.labelsandlabeling.com/news/industry-updates/awa-publishes-2021-awareness-report (accessed on 14 September 2021).

- Tesařová, M.; Krmela, A.; Šimberová, I. Digital support to external sustainability communication in self-adhesive labelling industry. Entrep. Sustain. Issues 2020, 7, 2109–2125. [Google Scholar] [CrossRef]

- Medeiros, D.L.; Braghirolli, F.L.; Ramlow, H.; Ferri, G.N.; Kiperstok, A. Environmental improvement in the printing industry: The case study of self-adhesive labels. Environ. Sci. Pollut. Res. 2019, 26, 13195–13209. [Google Scholar] [CrossRef] [PubMed]

- Marošević Dolovski, A. Etikete i etiketiranje. Print Mag. 2016, 4, 34–40. [Google Scholar]

- Avery Dennison. Tehnical Data Sheet Fasson ® PE85 BIOB WHITE S692N-BG40WH FSC PE85. Spec Code: BC449. 2021. Available online: https://www.pds.averydennison.com/content/PDS/BC449 (accessed on 14 September 2021).

- Avery Dennison. Tehnical Data Sheet Fasson ® PE85 BIOB CLEAR S692N-BG40WH FSC PE85. Spec Code: BD380. 2021. Available online: https://www.pds.averydennison.com/content/PDS/BD380 (accessed on 14 September 2021).

- Avery Dennison. Tehnical Data Sheet Fasson ® rCRUSH CITRUS FSC S2030-BG45WH FSC. Spec Code: BT025. 2021. Available online: https://www.pds.averydennison.com/content/PDS/AE294?UL=4 (accessed on 14 September 2021).

- Avery Dennison. Tehnical Data Sheet Fasson ® rCRUSH GRAPE FSC S2047N-BG45WH IMP FSC. Spec Code: BD733. 2021. Available online: https://www.pds.averydennison.com/content/PDS/BD733 (accessed on 14 September 2021).

- Avery Dennison. Tehnical Data Sheet Fasson ® rCRUSH BARLEY FSC S2030-BG45WH FSC. Spec Code: BT024. 2021. Available online: https://www.pds.averydennison.com/content/PDS/BT024 (accessed on 14 September 2021).

- Avery Dennison. Bio-Based PE Film—A Sugar-Sweet Opportunity, Product Overview. 2016, p. 2. Available online: https://label.averydennison.com/content/dam/averydennison/lpm-responsive/na/doc/product-overviews/product/Film/sustainabiliy-and-clear-intent/po-eu-bio-based-pe.pdf (accessed on 14 September 2021).

- Shaw, P.S.; Li, Z. On the fluorescence from integrating spheres. Appl. Opt. 2008, 47, 3962–3967. [Google Scholar] [CrossRef] [PubMed]

- Zwinkels, J.C. Errors and accuracies in integrating sphere measurements of diffuse reflectance and transmittance. In Proceedings of the Workshop on Optical Property Measurement Techniques, Ispra, Italy, 27–29 October 1987. [Google Scholar]

- Zwinkels, J.C.; DeRose, P.C.; Leland, J.E. Spectral Fluorescence Measurements; Elsevier Inc.: Amsterdam, The Netherlands, 2014. [Google Scholar]

- CIE Central Bureau. Colorimetry, 3rd ed.; CIE Central Bureau: Vienna, Austria, 2004. [Google Scholar]

- Pauler, N. Paper Optics; AB Lorentzen & Wettre: Stockholm, Sweden, 2012. [Google Scholar]

- Brand, L.; Johnson, M.L. An Introduction to Fluorescence Spectroscopy; PerkinElmer: Buckinghamshire, UK, 2011; p. 15. [Google Scholar]

- Itagaki, H. Fluorescence Spectroscopy; Academic Press: San Diego, CA, USA, 2012. [Google Scholar]

- Mercer, A.V. Fluorescent Brightening Agents: Colourants and Auxiliaries. Org. Chem. Appl. Prop. 1990, 2, 471–511. [Google Scholar]

- Shakespeare, D.T.; Shakespeare, D.J. Fluorescence and the Paper Appearance-Challenges in Paper Coloring. In Proceedings of the Papermaking Research Symposium (PRS): Web Tension Variations and Runnability of the Open Draw Section, Kuopio, Finland, 1–4 June 2009; pp. 1–4. [Google Scholar]

- Coppel, L.G.; Andersson, M.; Edström, P.; Kinnunen, J. Limitations in the efficiency of fluorescent whitening agents in uncoated paper. Nord. Pulp Pap. Res. J. 2011, 26, 319–328. [Google Scholar] [CrossRef] [Green Version]

- Coppel, L.G. Whiteness and Fluorescence in Paper-Perception and Optical Modelling; Kopieringen Mittuniversitetet: Sundsvall, Sweden, 2010. [Google Scholar]

- Prozil, S.O.; Evtuguin, D.V.; Lopes, L.P.C. Chemical composition of grape stalks of Vitis vinifera L. from red grape pomaces. Ind. Crops Prod. 2012, 35, 178–184. [Google Scholar] [CrossRef]

- Amendola, D.; De Faveri, D.M.; Egües, I.; Serrano, L.; Labidi, J.; Spigno, G. Autohydrolysis and organosolv process for recovery of hemicelluloses, phenolic compounds and lignin from grape stalks. Bioresour. Technol. 2012, 107, 267–274. [Google Scholar] [CrossRef]

- Lundberg, B.; Pan, X.; White, A.; Chau, H.; Hotchkiss, A. Rheology and composition of citrus fiber. J. Food Eng. 2014, 125, 97–104. [Google Scholar] [CrossRef]

- Mussatto, S.I.; Dragone, G.; Roberto, I.C. Brewers’ spent grain: Generation, characteristics and potential applications. J. Cereal Sci. 2006, 43, 1–14. [Google Scholar] [CrossRef]

- Pickett, J.E. Permanence of UV Absorbers in Plastics and. In Handbook of Polymer Degradation; Taylor & Francis: Boca Raton, FL, USA, 2000; p. 163. [Google Scholar]

- Berns, R.S. Billmeyer and Saltzman’s Principles of Color Technology; Wiley: Hoboken, NJ, USA, 2019. [Google Scholar]

- Brinen, J.S. The observation and distribution of organic additives on paper surfaces using surface spectroscopic techniques. Nord. Pulp Pap. Res. J. 1993, 8, 123–129. [Google Scholar] [CrossRef]

- Tomšič, B.; Simončič, B.; Orel, B.; Vilčnik, A.; Spreizer, H. Biodegradability of cellulose fabric modified by imidazolidinone. Carbohydr. Polym. 2007, 69, 478–488. [Google Scholar] [CrossRef]

- Fan, M.; Dai, D.; Huang, B. Fourier Transform-Materials Analysis; InTechOpen: Shangai, China, 2012; pp. 45–68. [Google Scholar]

- Ferreira, P.J.; Gamelas, A.; Moutinho, I.M.; Ferreira, A.G.; Go, N.; Molleda, C.; Figueiredo, M.M. Application of FT-IR-ATR Spectroscopy to Evaluate the Penetration of Surface Sizing Agents into the Paper Structure; American Chemical Society: Washington, WA, USA, 2009; pp. 3867–3872. [Google Scholar]

- Grilj, S.; Klanjšek Gunde, M.; Szentgyörgyvölgyi, R.; Gregor-Svetec, D. FT-IR and UV/VIS analysis of classic and recycled papers. Papíripar 2012, 56, 7–13. [Google Scholar]

- Ciolacu, D.; Ciolacu, F.; Popa, V.I. Amorphous Cellulose–Structure and Characterization. Cellul. Chem. Technol. 2011, 45, 13–21. [Google Scholar] [CrossRef] [Green Version]

- Fjellström, H.; Höglund, H.; Forsberg, S.; Paulsson, M. The UV-screening properties of coating layers: The influence of pigments, binders and additives. Nord. Pulp Pap. Res. J. 2009, 24, 206–212. [Google Scholar] [CrossRef] [Green Version]

- Heikkilä, K.; Alatalo, M. Grankvist, Laboratory Studies of Simultaneous Use of Titanium Dioxide Pigment and Fluorescent Whitening Agent in Double Coated Printing Paper. In Proceedings of the Coating Papermakers Conference, New Orleans, LA, USA, 4–6 May 1998; pp. 355–372. [Google Scholar]

- Hamzah, M.; Khenfouch, M.; Rjeb, A.; Sayouri, S.; Houssaini, D.S.; Darhouri, M.; Srinivasu, V.V. Surface chemistry changes and microstructure evaluation of low density nanocluster polyethylene under natural weathering: A spectroscopic investigation. J. Phys. Conf. Ser. 2018, 984, 012010. [Google Scholar] [CrossRef]

- Gulmine, J.V.; Janissek, P.R.; Heise, H.M.; Akcelrud, L. Polyethylene characterization by FTIR. Polym. Test. 2002, 21, 557–563. [Google Scholar] [CrossRef]

- Durmić, A.; Rožić, M.; Vukoje, M. Mechanisms of paper degradation in different conditions. In Proceedings of the International Conference Printing and Design 2017, Zagreb, Croatia, 9–10 March 2017; pp. 118–125. [Google Scholar]

- Łojewska, J.; Lubańska, A.; Miśkowiec, P.; Łojewski, T.; Proniewicz, L.M. FTIR in situ transmission studies on the kinetics of paper degradation via hydrolytic and oxidative reaction paths. Appl. Phys. A 2006, 83, 597–603. [Google Scholar] [CrossRef]

| Facestock | Liner | Total Laminate | ||||

|---|---|---|---|---|---|---|

| Substrate Grade | Abbreviation | Basis Weight ISO 536, g/m2 | Caliper ISO 534, µm | Basis Weight ISO 536, g/m2 | Caliper ISO 534, µm | Caliper ISO 534, µm |

| Fasson® rCRUSH BARLEY FSC S2030-BG45WH FSC | B | 90 | 110 | 70 | 61 | 190 ± 10% |

| Fasson® rCRUSH GRAPE FSC S2047N-BG45WH IMP FSC | G | 90 | 114 | 70 | 61 | 192 ± 10% |

| Fasson® rCRUSH CITRUS FSC S2030-BG45WH FSC | C | 100 | 130 | 70 | 61 | 210 ± 10% |

| Fasson® PE85 BIOB CLEAR S692N-BG40WH FSC | PEC | 78 | 82 | 59 | 53 | 152 ± 10% |

| Fasson® PE85 BIOB WHITE S692N-BG40WH FSC | PEW | 82 | 82 | 59 | 53 | 152 ± 10% |

| Sample | Original | T-5 Days | T-10 Days | UV-5 Days | UV-10 Days | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L* | C* | h° | L* | C* | h° | L* | C* | h° | L* | C* | h° | L* | C* | h° | |

| B | 84.5 | 8.7 | 62.3 | 84.5 | 9.1 | 62.9 | 84.5 | 9.4 | 64.5 | 90.1 | 7.8 | 74.8 | 91.5 | 7.2 | 73.7 |

| C | 93.9 | 3.6 | 55.45 | 93.6 | 3.9 | 58.8 | 92.9 | 4.1 | 53.6 | 94.1 | 6.1 | 82.2 | 93.4 | 6.5 | 81.3 |

| G | 87.4 | 31.7 | −66.4 | 86.1 | 29.6 | −65.0 | 82.8 | 25.1 | −61.8 | 88.6 | 3.8 | 22.8 | 90.0 | 4.5 | 59.1 |

| PEW | 96.2 | 0.7 | 107.3 | 97.6 | 1.6 | 68.2 | 96.6 | 2.2 | 55.9 | 98.4 | 1.8 | 90.8 | 97.9 | 1.9 | 81.6 |

| PEC | 92.2 | 6.0 | 96.6 | 89.7 | 9.8 | 91.2 | 88.7 | 12.4 | 88.5 | 87.8 | 14.6 | 87.8 | 86.9 | 16.1 | 87.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vukoje, M.; Itrić Ivanda, K.; Kulčar, R.; Marošević Dolovski, A. Spectroscopic Stability Studies of Pressure Sensitive Labels Facestock Made from Recycled Post-Consumer Waste and Agro-Industrial By-Products. Forests 2021, 12, 1703. https://doi.org/10.3390/f12121703

Vukoje M, Itrić Ivanda K, Kulčar R, Marošević Dolovski A. Spectroscopic Stability Studies of Pressure Sensitive Labels Facestock Made from Recycled Post-Consumer Waste and Agro-Industrial By-Products. Forests. 2021; 12(12):1703. https://doi.org/10.3390/f12121703

Chicago/Turabian StyleVukoje, Marina, Katarina Itrić Ivanda, Rahela Kulčar, and Ana Marošević Dolovski. 2021. "Spectroscopic Stability Studies of Pressure Sensitive Labels Facestock Made from Recycled Post-Consumer Waste and Agro-Industrial By-Products" Forests 12, no. 12: 1703. https://doi.org/10.3390/f12121703

APA StyleVukoje, M., Itrić Ivanda, K., Kulčar, R., & Marošević Dolovski, A. (2021). Spectroscopic Stability Studies of Pressure Sensitive Labels Facestock Made from Recycled Post-Consumer Waste and Agro-Industrial By-Products. Forests, 12(12), 1703. https://doi.org/10.3390/f12121703