Innovative Model of the Cost Price Calculation of Products from Invasive Non-Native Wood Species Based on the FTDABC Method

Abstract

:1. Introduction

2. Literature Review

2.1. Wood of Non-Native Invasive Wood Species—Black Locust (Robinia Pseudoacacia)

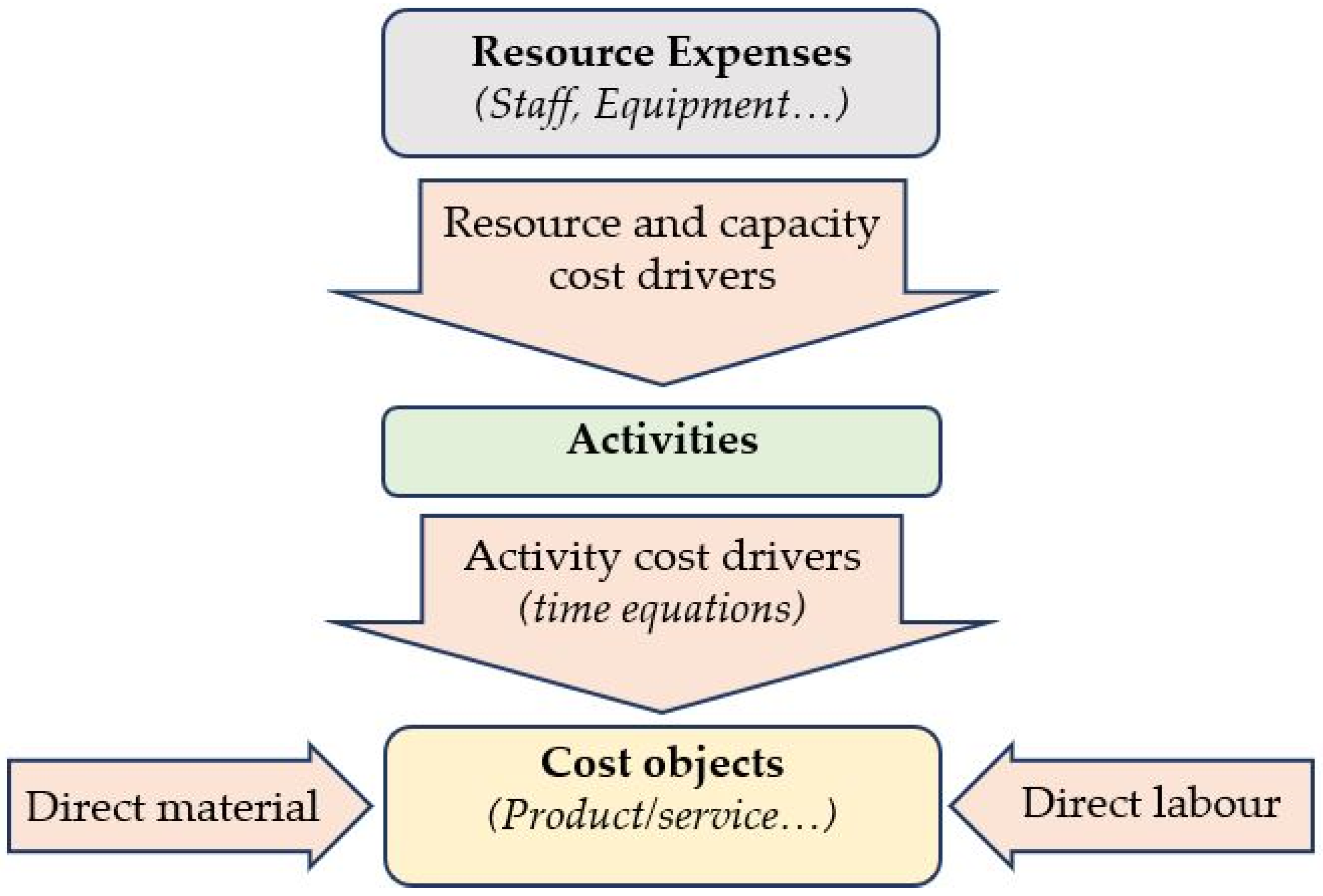

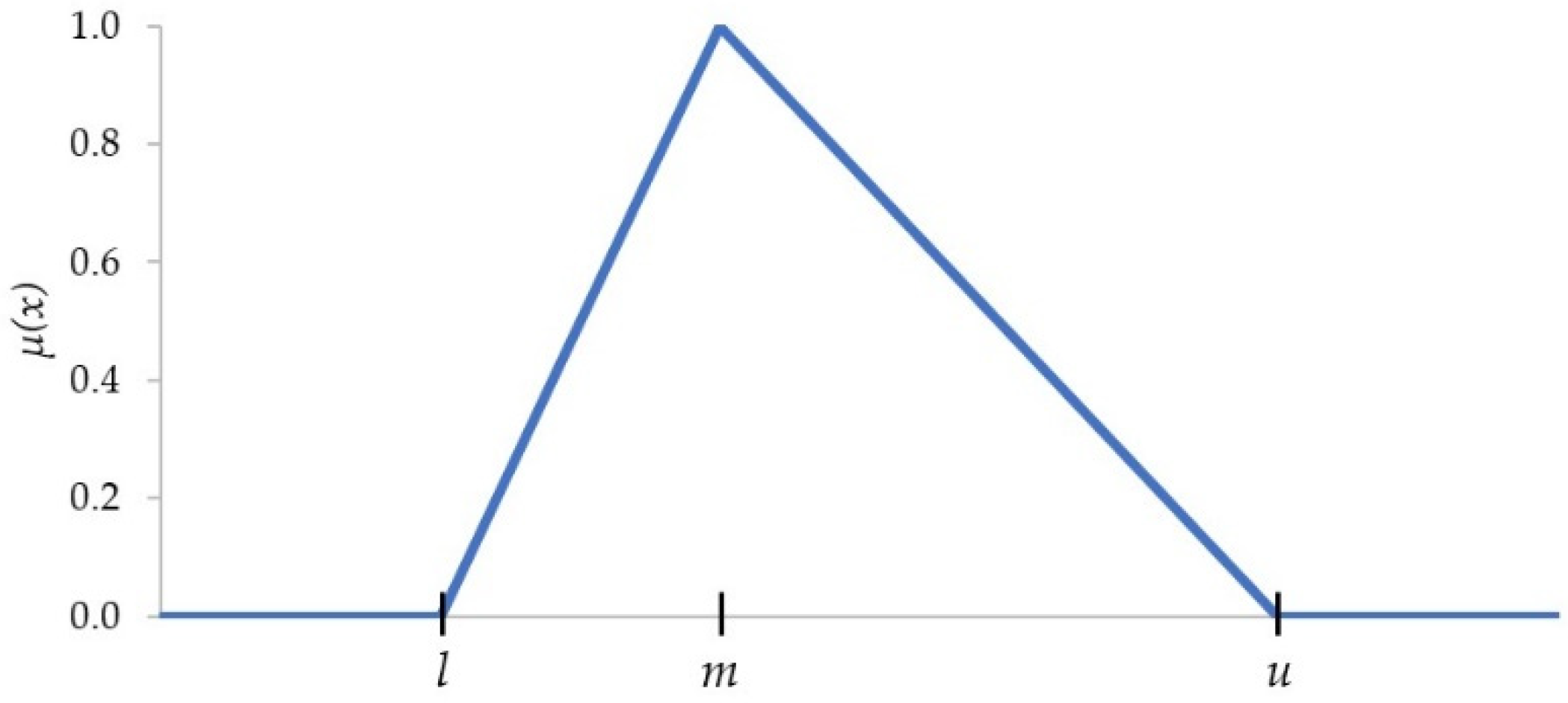

2.2. Cost Calculation Methods

3. Materials and Methods

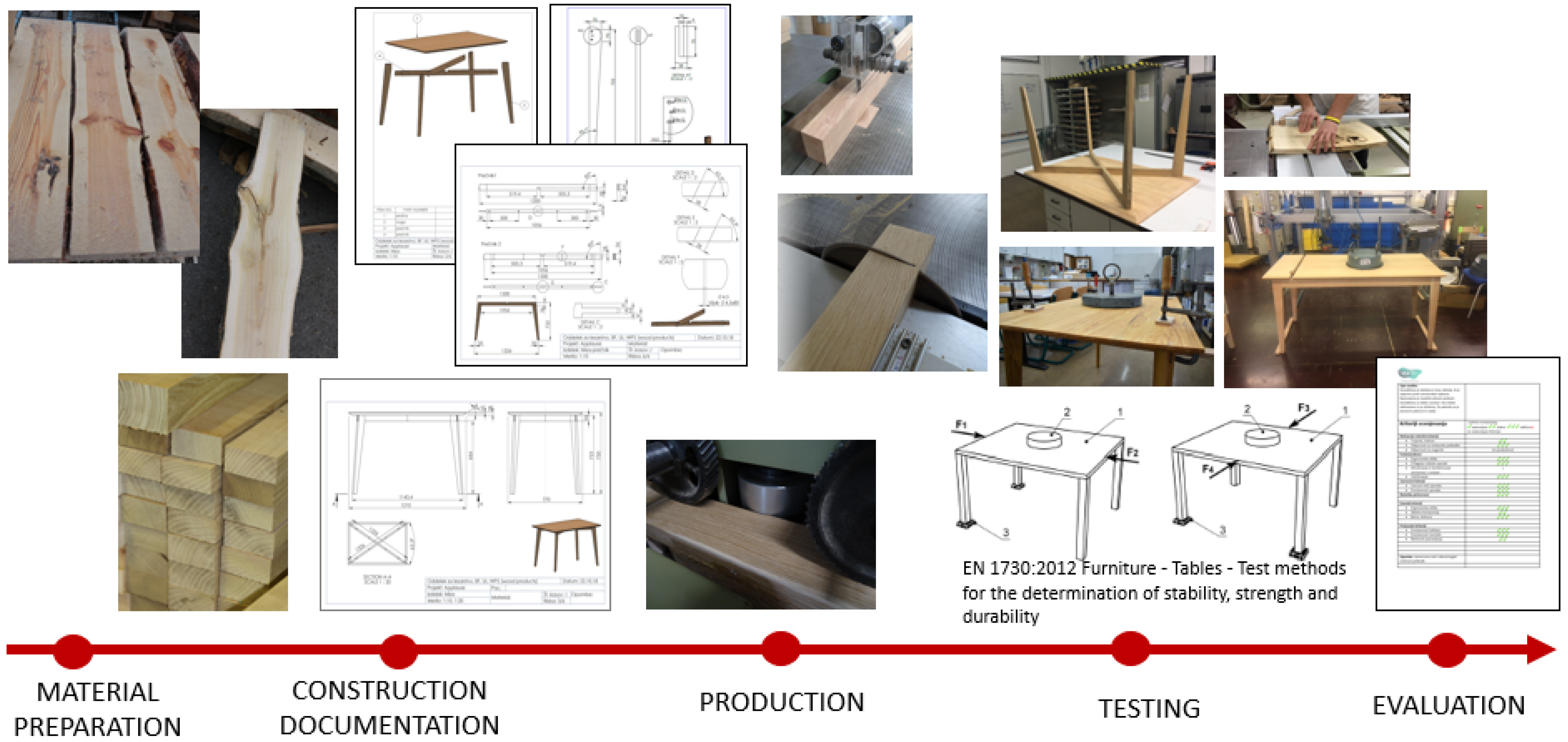

3.1. Materials

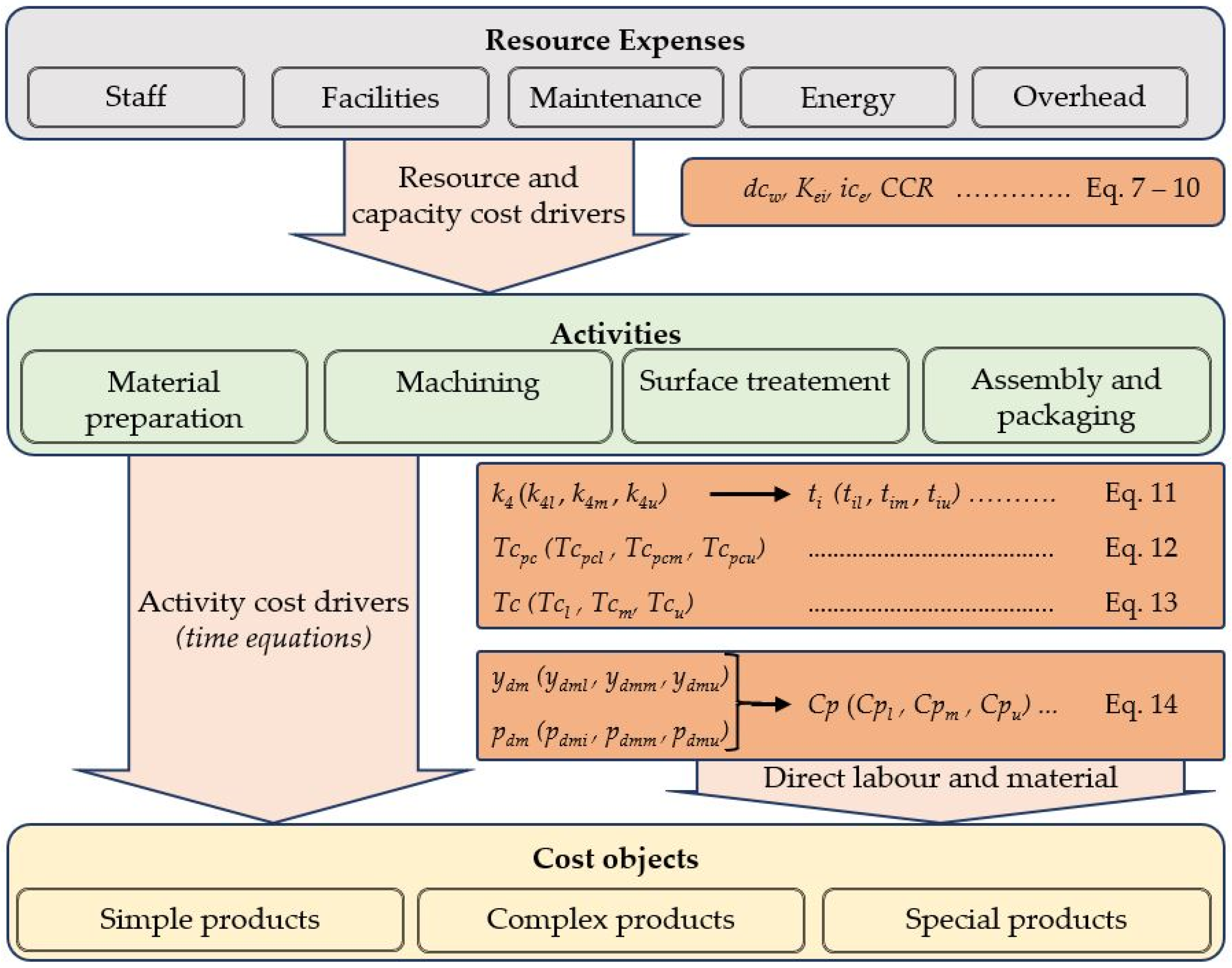

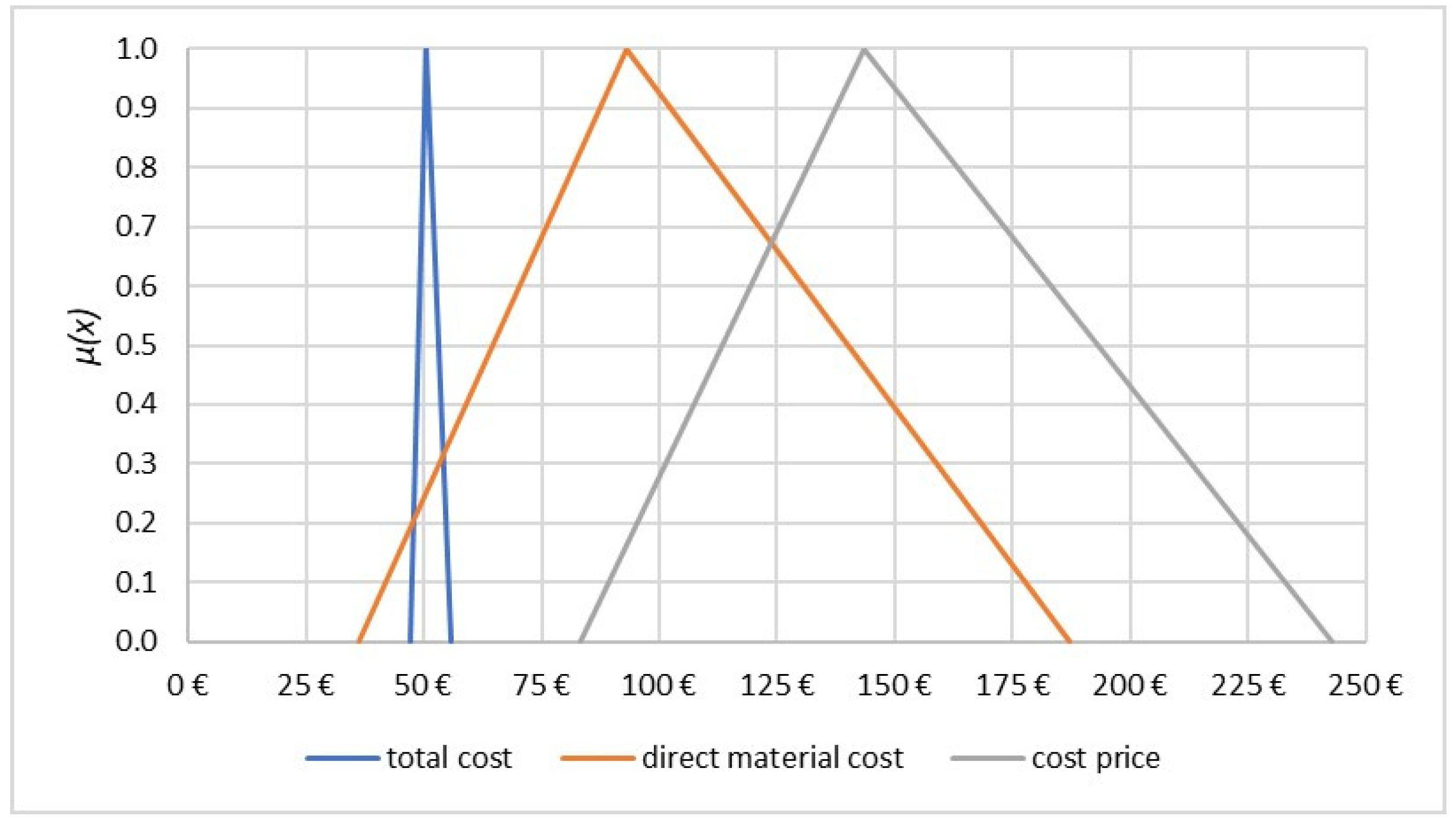

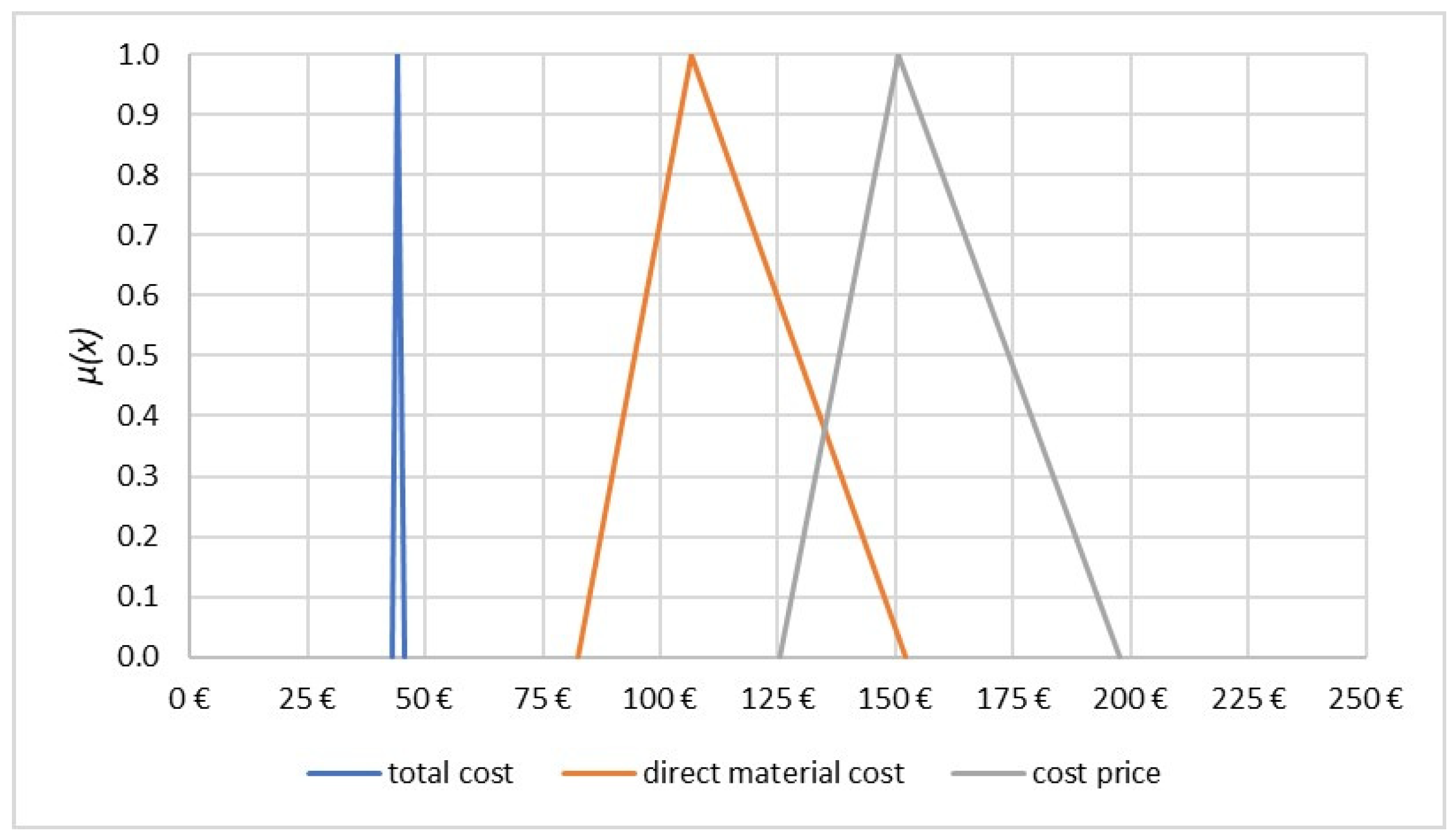

3.2. Development and Implementation of a Model for Calculating the Cost Price of Products Made from Invasive Non-Native Wood Species

- Identify the various resource expenses.

- Estimate the total cost of each resource group.

- Estimate the practical capacity of each resource group (e.g., available working hours).

- Calculate the resource and capacity cost drivers; find the capacity cost rate (CCR) for each resource group by dividing the total cost of the resource group by the practical capacity;

- Calculate the activity cost drivers; determine the time required for each event of an activity using a time equation.

- Multiply the Capacity Cost Rate (CCR) of each resource group by the time required to perform the activity.

- Calculate the total cost per unit, including all costs of all activities and overhead costs for activities’ execution.

- Estimate the direct material and labour costs with regard to the cost objects (products, services…).

- Calculate the cost price of a cost object.

4. Results

4.1. The Model for Evaluating the Cost Price of Wood Products

4.1.1. Resource and Capacity Cost Drivers

4.1.2. Activity Cost Drivers (Time Equations)

4.1.3. Direct Material and Labour Costs

4.1.4. Cost Price

4.2. The Use of the Model for Calculating Cost Price in the Case of Dining Table

5. Discussion

6. Conclusions

- The proposed model for calculating the cost price of invasive wood products enables the consideration of all variable factors (price of input raw material, variability in quality and related efficiencies, and processing procedures). However, the variability of input raw material parameters has a large impact on the product’s cost price.

- The model can be used for any tree species with known properties and for any simple/complex product and/or technology, and any size of series. The model allows a quick assessment of the economic feasibility for the use of a particular (invasive) tree species for a particular product.

- Invasive wood has high economic potential.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gorišek, Ž.; Plavčak, D.; Straže, A.; Merela, M. Tehnološke lastnosti in uporabnost lesa velikega pajesena v primerjavi z lesom velikega jesena. Les/Wood 2018, 67, 29–44. [Google Scholar] [CrossRef] [Green Version]

- Horvat, M.; Iskra, J.; Pavlič, M.; Žigon, J.; Merela, M. Barvila za les iz tujerodnih invazivnih rastlin. Les/Wood 2020, 69, 37–48. [Google Scholar] [CrossRef]

- Merela, M.; Thaler, N.; Balzano, A.; Plavčak, D. Optimal Surface Preparation for Wood Anatomy Research of Invasive Species by Scanning Electron Microscopy. Drv. Ind. 2020, 71, 117–127. [Google Scholar] [CrossRef]

- Merhar, M.; Gornik Bučar, D.; Merela, M. Machinability Research of the Most Common Invasive Tree Species in Slovenia. Forests 2020, 11, 752. [Google Scholar] [CrossRef]

- Plavčak, D.; Gorišek, Ž.; Straže, A.; Merela, M. Drying characteristics of wood of invasive tree species growing in an urban environment. Les/Wood 2019, 68, 31–43. [Google Scholar] [CrossRef] [Green Version]

- Vek, V.; Vivod, B.; Poljanšek, I.; Oven, P. Vsebnost ekstraktivov v skorji in lesu robinije (Robinia pseudoacacia L.). Acta Silvae Ligni 2019, 119, 13–25. [Google Scholar] [CrossRef] [Green Version]

- Medved, S.; Tomec, D.K.; Balzano, A.; Merela, M. Alien Wood Species as a Resource for Wood-Plastic Composites. Appl. Sci. 2020, 11, 44. [Google Scholar] [CrossRef]

- Gornik Bučar, D.; Prislan, P.; Smolnikar, P.; Stare, D.; Krajnc, N.; Gospodarič, B. Uporabnost lesnih ostankov tujerodnih invazivnih drevesnih vrst za proizvodnjo peletov. Les/Wood 2021, 70, 45–58. [Google Scholar] [CrossRef]

- RoAenbergar, D.; Nagel, T.A.; Urbas, B.; Marion, L.; Brus, R. Nekateri ukrepi za omejevanje širjenja visokega pajesena (Ailanthus altissima (Mill.) Swingle) in smernice za gozdnogojitveno ukrepanje ob vdoru potencialno invazivnih tujerodnih drevesnih vrst v ohranjene gozdove v Sloveniji. Gozdarski Vestn. 2017, 1, 3–20. [Google Scholar]

- Weidenhamer, J.D.; Callaway, R.M. Direct and Indirect Effects of Invasive Plants on Soil Chemistry and Ecosystem Function. J. Chem. Ecol. 2010, 36, 59–69. [Google Scholar] [CrossRef]

- Kropvšek, J.; Jost, M.; Grošelj, P.; Motik, D.; Pirc Barčić, A.; Perić, I. A comparative evaluation of operational efficiency of wood industry using data envelopment analysis and Malmquist productivity index. Drv. Ind. 2019, 70, 287–298. [Google Scholar] [CrossRef] [Green Version]

- Kropvšek, J.; Grošelj, P. Long-term Financial Analysis of the Slovenian Wood Industry Using DEA. Drv. Ind. 2019, 70, 61–70. [Google Scholar] [CrossRef] [Green Version]

- Eckelman, C.A. Textbook of Product Engineering and Strength Design of Furniture; Purdue University: West Lafayette, IN, USA, 2003; pp. 65–67. [Google Scholar]

- Smardzewski, J. Furniture Design; Springer: Berlin/Heidelberg, Germany, 2015; pp. 1–649. [Google Scholar] [CrossRef]

- Sun, W.; Zhang, L. Innovative Research on the Design Concept of Green Furniture Products. In Proceedings of the 2019 International Conference on Management, Education Technology and Economics (ICMETE 2019), Kyoto, Japan, 26–28 December 2019; Volume 82, pp. 113–116. [Google Scholar]

- Papadopoulos, I.; Karagouni, G.; Trigkas, M.; Beltsiou, Z. Mainstreaming green product strategies why and how furniture companies integrate environmental sustainability? EuroMed J. Bus. 2014, 9, 293–317. [Google Scholar] [CrossRef]

- McGowan, A.S.; Holmes, S.A.; Martin, M. The Association between Activity-Based Costing System Adoption and Hospital Performance. SSRN Electron. J. 2006. [Google Scholar] [CrossRef]

- Hanid, M.; Koskela, L.; Siriwardena, M. Traditional Cost Management vs. Lean Cost Management. In Proceedings of the 18th CIB World Building Congress, Salford, UK, 14 May 2010. [Google Scholar]

- Tsai, W.-H.; Lai, S.-Y. Green Production Planning and Control Model with ABC under Industry 4.0 for the Paper Industry. Sustainability 2018, 10, 2932. [Google Scholar] [CrossRef] [Green Version]

- Wedowati, E.R.; Singgih, M.L.; Gunarta, I.K. Product value analysis on customized product based on pleasurable design and time-driven activity-based costing in food industry. Cogent Bus. Manag. 2020, 7, 1823581. [Google Scholar] [CrossRef]

- Afonso, P.S.L.P.; Santana, A. Application of the TDABC model in the logistics process using different capacity cost rates. J. Ind. Eng. Manag. 2016, 9, 1003. [Google Scholar] [CrossRef] [Green Version]

- Ganorkar, A.B.; Lakhe, R.R.; Agrawal, K.N. Implementation of TDABC in SME: A Case Study. J. Corp. Account. Financ. 2018, 29, 87–113. [Google Scholar] [CrossRef]

- Adigüzel, H.; Floros, M. Capacity utilization analysis through time-driven ABC in a small-sized manufacturing company. Int. J. Prod. Perform. Manag. 2019, 69, 192–216. [Google Scholar] [CrossRef]

- Andersch, A.; Buehlmann, U.; Palmer, J.; Wiedenbeck, J.K.; Lawser, S. Product costing program for wood component manu-facturers. For. Prod. J. 2013, 63, 247–256. [Google Scholar]

- Mohsin, N.M.R.; Al-Bayati, H.A.M.; Oleiwi, Z.H. Product-Mix Decision Using Lean Production and Activity-Based Costing: An Integrated Model. J. Asian Financ. Econ. Bus. 2021, 8, 517–527. [Google Scholar] [CrossRef]

- Korpunen, H.; Mochan, S.; Uusitalo, J. An Activity-Based Costing Method for Sawmilling. For. Prod. J. 2010, 60, 420–431. [Google Scholar] [CrossRef]

- Pongwasit, R.; Chompu-Inwai, R. Analysis of Wooden Toy Manufacturing Costs through the Application of a Time-Driven Activity-Based Costing System. Muroran Inst. Technol. Acad. Resour. Arch. 2015, 65, 7–14. [Google Scholar]

- Rajnoha, R.; Chromjakova, F. Activity based costing and efficiency of its application in the wooden houses production. Drew.-Wood 2009, 52, 105–127. [Google Scholar]

- Rappold, P.M. Activity-Based Product Costing in a Hardwood Sawmill through the Use of Discrete-Event Simulation; Virginia Tech: Blacksburg, VA, USA, 2006. [Google Scholar]

- Kaplan, R.S.; Anderson, S.R. Time-Driven Activity-Based Costing. SSRN Electron. J. 2003. [Google Scholar] [CrossRef]

- Kaplan, S.R.; Anderson, R.S. Time-Driven Activity-Based Costing: A Simpler and More Powerful Path to Higher Profits; Harvard Business School Press: Boston, MA, USA, 2007; ISBN 9781422101711. [Google Scholar]

- Maiga, A.S.; Jacobs, F.A. Extent of ABC Use and Its Consequences. Contemp. Account. Res. 2008, 25, 533–566. [Google Scholar] [CrossRef]

- Namazi, M. Time Driven Activity Based Costing: Theory, Applications and Limitations. Iran. J. Manag. Stud 2016, 9, 457–482. [Google Scholar]

- Siguenza-Guzman, L.; Van den Abbeele, A.; Vandewalle, J.; Verhaaren, H.; Cattrysse, D. Recent Evolutions in Costing Systems: A Literature Review of Time-Driven Activity-Based Costing. Rev. Bus. Econ. Lit. 2013, 58, 34–64. [Google Scholar]

- Chansaad, A.; Rattanamanee, W.; Chaiprapat, A.; Yenradee, P. A fuzzy time-driven activity-based costing model in an un-certain manufacturing environment. In Proceedings of the Asia Pacific Industrial Engineering and Management Systems Conference, Phuket, Thailand, 2–5 December 2012; pp. 1949–1959. [Google Scholar]

- Esmalifalak, H.; Albin, M.S.; Behzadpoor, M. A comparative study on the activity based costing systems: Traditional, fuzzy and Monte Carlo approaches. Health Policy Technol. 2015, 4, 58–67. [Google Scholar] [CrossRef]

- Mwaikambo, E.; Rajabifard, A.; Hagai, M. Modelling cost estimation for accessing spatial data using fuzzy logic and time-driven activity based costing in the context of an NSDI. J. Spat. Sci. 2014, 60, 137–151. [Google Scholar] [CrossRef]

- Ostadi, B.; Daloie, R.M.; Sepehri, M.M. A combined modelling of fuzzy logic and Time-Driven Activity-based Costing (TDABC) for hospital services costing under uncertainty. J. Biomed. Inform. 2019, 89, 11–28. [Google Scholar] [CrossRef]

- Mortaji, S.T.H.; Bagherpour, M.; Mazdeh, M.M. Fuzzy Time-Driven Activity-Based Costing. Eng. Manag. J. 2013, 25, 63–73. [Google Scholar] [CrossRef]

- Vítková, M.; Müllerová, J.; Sádlo, J.; Pergl, J.; Pyšek, P. Black locust (Robinia pseudoacacia) beloved and despised: A story of an invasive tree in Central Europe. For. Ecol. Manag. 2017, 384, 287–302. [Google Scholar] [CrossRef]

- Vasiliki, K.; Ioannis, B. Bondability of Black locust (Robinia pseudoacacia) and Beech wood (Fagus sylvatica) with polyvinyl acetate and polyurethane adhesives. Maderas. Cienc. Y Tecnol. 2017, 19, 87–94. [Google Scholar] [CrossRef] [Green Version]

- Kadunc, A. Growth and Yield Characteristics of Black Locust (Robinia pseudoacacia L.) in Slovenia. Gozdarski Vestn. 2016, 2, 73–87. [Google Scholar]

- Dünisch, O.; Richter, H.-G.; Koch, G. Wood properties of juvenile and mature heartwood in Robinia pseudoacacia L. Wood Sci. Technol. 2010, 44, 301–313. [Google Scholar] [CrossRef]

- Roswel, D.; Sonderman, L.; Everette, D. Defects in Hardwood Timber; US Department of Agriculture, Forest Service: Honolulu, HI, USA, 1989; Volume 678, p. 93.

- Boleslaw, P.; Andrej, D.; Grzegorz, W. Cutting Force during the Turning of Wood from Black Locust |Porankiewicz| BioResources. Available online: https://ojs.cnr.ncsu.edu/index.php/BioRes/article/view/BioRes_03_3_0745_Porankiewicz_DW_TuringForce_CuttingBlackLocust/219 (accessed on 16 September 2021).

- Usta, I.; Demirci, S.; Kiliç, Y. Comparison of surface roughness of Locust acacia (Robinia pseudoacacia L.) and European oak (Quercus petraea (Mattu.) Lieble.) in terms of the preparative process by planing. Build. Environ. 2007, 42, 2988–2992. [Google Scholar] [CrossRef]

- Merela, M. 3D Model of Quercus. Available online: https://sketchfab.com/3d-models/quercus-sp-oak-hrast-1fba20f5307e471a80def6483af30a50 (accessed on 28 September 2021).

- Merela, M. 3D Model of Robinia Pseudoacacia. Available online: https://sketchfab.com/3d-models/robinia-pseudoacacia-black-locust-1-8e830010316b4d8093fb53b048cd8667 (accessed on 28 September 2021).

- Pavlič, M.; Žigon, J.; Petrič, M. Wood Surface Finishing of Selected Invasive Tree Species. Drv. Ind. 2020, 71, 271–280. [Google Scholar] [CrossRef]

- Magel, E.A.; Drouet, A.; Claudot, A.C.; Ziegler, H. Formation of heartwood substances in the stem of Robinia pseudoacacia L. Trees 1991, 5, 203–207. [Google Scholar] [CrossRef]

- Vek, V.; Poljanšek, I.; Oven, P. Efficiency of three conventional methods for extraction of dihydrorobinetin and robinetin from wood of black locust. Eur. J. Wood Wood Prod. 2019, 77, 891–901. [Google Scholar] [CrossRef]

- Straže, A.; Novak, K.; Gorišek, Ž.; Čufar, K.; Merela, M. Tehnološke lastnosti lesa izbranih tujerodnih drevesnih vrst in njihov pomen. In Tujerodne Drevesne Vrste V Slovenskih Gozdovih; Jarni, K., Ed.; Univerza v Ljubljani: Ljubljana, Slovenija, 2021; pp. 9–18. [Google Scholar]

- Gorišek, Ž.; Plavčak, D.; Gornik Bučar, D.; Merela, M.; Čufar, K.; Straže, A. Fizikalne in mehanske lastnosti svežega in osušenega lesa v bukovih deblih, izruvanih med žledolomom. Acta Silvae Ligni 2017, 112, 7–20. [Google Scholar] [CrossRef] [Green Version]

- Kovryga, A.; Gamarra, J.O.C.; Van De Kuilen, J.W.G. Strength and stiffness predictions with focus on different acoustic measurement methods. Eur. J. Wood Wood Prod. 2020, 78, 941–949. [Google Scholar] [CrossRef]

- Sonderegger, W.; Martienssen, A.; Nitsche, C.; Ozyhar, T.; Kaliske, M.; Niemz, P. Investigations on the physical and mechanical behaviour of sycamore maple (Acer pseudoplatanus L.). Eur. J. Wood Wood Prod. 2013, 71, 91–99. [Google Scholar] [CrossRef] [Green Version]

- Wagenführ, R.H. München: Fachbuchverlag Leipzig im Carl Hanser Verlag. 2007. Available online: https://plus.si.cobiss.net/opac7/bib/142779#full (accessed on 29 October 2021).

- Zhu, J.; Shi, Y.; Fang, L.; Liu, X.; Ji, C. Patterns and determinants of wood physical and mechanical properties across major tree species in China. Sci. China Life Sci. 2015, 58, 602–612. [Google Scholar] [CrossRef] [PubMed]

- Ewudzie, J.; Gemadzie, J.; Adjarko, H. Exploring the Utilization of Lesser-Known Species for Furniture Production—A Case Study in the Western Region, Ghana. OALib 2018, 05, 88468. [Google Scholar] [CrossRef]

- Ramage, M.H.; Burridge, H.; Busse-Wicher, M.; Fereday, G.; Reynolds, T.; Shah, D.; Wu, G.; Yu, L.; Fleming, P.; Densley-Tingley, D.; et al. The wood from the trees: The use of timber in construction. Renew. Sustain. Energy Rev. 2017, 68, 333–359. [Google Scholar] [CrossRef]

- Dalci, I.; Tanis, V.; Kosan, L. Customer profitability analysis with time-driven activity-based costing: A case study in a hotel. Int. J. Contemp. Hosp. Manag. 2010, 22, 609–637. [Google Scholar] [CrossRef]

- Varila, M.; Seppänen, M.; Suomala, P. Detailed cost modelling: A case study in warehouse logistics. Int. J. Phys. Distrib. Logist. Manag. 2007, 37, 184–200. [Google Scholar] [CrossRef]

- Zadeh, L. Fuzzy sets. Inf. Control. 1965, 8, 338–353. [Google Scholar] [CrossRef] [Green Version]

- Kutnar, L.; Kobler, A. The current distribution of black locust (Robinia pseudoacacia L.) in Slovenia and predictions for the future. Acta Silvae Ligni 2013, 102, 21–30. [Google Scholar] [CrossRef] [Green Version]

- Brus, R. Tujerodne drevesne vrste v evropski in slovenski perspektivi. In Tujerodne Drevesne Vrste V Slovenskih Gozdovih; Jarni, K., Ed.; Univerza v Ljubljani: Ljubljana, Slovenija, 2021; pp. 9–18. [Google Scholar]

- Hernández, J.J.C.; Fernández, L.P.S.; Carrasco-Ochoa, J.A.; Martinez-Trinidad, J.F. Immediate water quality assessment in shrimp culture using fuzzy inference systems. Expert Syst. Appl. 2012, 39, 10571–10582. [Google Scholar] [CrossRef]

- Zadeh, L.A. The concept of a linguistic variable and its application to approximate reasoning-III. Inf. Sci. 1975, 9, 43–80. [Google Scholar] [CrossRef]

- Ross, T.J. Fuzzy Logic with Engineering Applications, 4th ed.; John Wiley & Sons: Hoboken, NJ, USA, 2010. [Google Scholar]

- Mestna občina Ljubljana Project APPLAUSE. Available online: https://www.ljubljana.si/sl/moja-ljubljana/applause/ (accessed on 29 September 2021).

- Slovenian Forestry Institute Project LIFE ARTEMIS. Available online: https://www.tujerodne-vrste.info/en/project-life-artemis/ (accessed on 29 September 2021).

- Marenče, J.; Šega, B.; Bučar, D.G. Monitoring the Quality and Quantity of Beechwood from Tree to Sawmill Product. Croat. J. For. Eng. 2019, 41, 119–128. [Google Scholar] [CrossRef]

- EN 975-1:2009 Sawn Timber—Appearance Grading of Hardwoods—Part 1: Oak and Beech. Available online: https://standards.iteh.ai/catalog/standards/cen/0a583195-68ed-49b7-a710-adcbbd60477c/en-975-1-2009 (accessed on 29 October 2021).

- Sandak, A.; Sandak, J. Prediction of service life—Does aesthetic matter? In Proceedings of the International Research Group on Wood Protection. Section 2. Test Methodology and Assessment, Ghent, Belgium, 4–8 June 2017. [Google Scholar]

- Burnard, M.D.; Nyrud, A.Q.; Bysheim, K.; Kutnar, A.; Vahtikari, K.; Hughes, M. Building material naturalness: Perceptions from Finland, Norway and Slovenia. Indoor Built Environ. 2016, 26, 92–107. [Google Scholar] [CrossRef]

- Høibø, O.; Nyrud, A.Q. Consumer perception of wood surfaces: The relationship between stated preferences and visual homogeneity. J. Wood Sci. 2010, 56, 276–283. [Google Scholar] [CrossRef]

| Native Hardwoods | Non-Native Hardwoods | ||||||

|---|---|---|---|---|---|---|---|

| Fagus sylvatica | Quercus robur | Acer pseudoplatanus | Fraxinus excelsior | Robinia pseudoacacia | Ailanthus altissima | Acer negundo | |

| Physical properties | |||||||

| ρ12 [kg/m3] | 710 | 700 | 630 | 690 | 770 | 641 | 536 |

| βR [%] | 5.8 | 4.3 | 3.0 | 4.8 | 3.8 | 4.0 | 3.9 |

| βT [%] | 11.8 | 8.9 | 8.0 | 8.2 | 6.3 | 11.0 | 7.4 |

| βV [%] | 17.0 | 13.6 | 11.0 | 13.2 | 11.8 | 14.9 | 14.8 |

| qR [%/%] | 0.20 | 0.19 | 0.17 | 0.20 | 0.24 | 0.15 | 0.13 |

| qT [%/%] | 0.41 | 0.31 | 0.34 | 0.45 | 0.38 | 0.40 | 0.25 |

| qT/qR [] | 2.1 | 1.6 | 2.0 | 2.3 | 1.6 | 2.8 | 1.9 |

| Mechanical properties | |||||||

| σC [MPa] | 65 | 61 | 49 | 52 | 72 | 53 | 37.1 |

| σB [MPa] | 120 | 88 | 95 | 105 | 136 | 91 | 75.4 |

| σT [MPa] | 135 | 90 | 98 | 165 | 150 | 105 | - |

| E‖ [GPa] | 16 | 13 | 10.5 | 13.4 | 12.3 | 11.7 | 6.9 |

| Aw [J/cm2] | 6.5 | 6.8 | 14 | 6.1 | 2.8 | ||

| HB┴ [N/mm2] | 34 | 34 | 27 | 39 | 38 | 26 | |

| Pool of Activities | Activity | Simple Products | Complex Products |

|---|---|---|---|

| Material preparation | Width sawing | ++ | ++ |

| Length sawing | ++ | ++ | |

| Four-sided planing | ++ | ++ | |

| Machining | Width gluing | 0/+ | ++ |

| Calibration | 0/+ | ++ | |

| Format sawing | ++ | ++ | |

| CNC machining/milling/drilling/etc. | 0/+ | ++ | |

| Surface treatment | Repairing | + | ++ |

| Edge grinding | ++ | ++ | |

| Surface grinding | ++ | ++ | |

| Assembly gluing | + | ++ | |

| Oiling | ++ | ++ | |

| Assembly and packaging | Packing | ++ | ++ |

| Sub-Activity | CCR | ß0 | ß1 | X1 | k2 | X2 | k3 | X3 | k5 | k6 |

|---|---|---|---|---|---|---|---|---|---|---|

| €/min | min | min | unit | - | unit | - | unit | - | - | |

| Width sawing | 0.6194 € | 20 | 0.30 | 102 | 2 | 102 | 0 | 0 | 1.0 | 1.1 |

| Length sawing | 0.2907 € | 10 | 0.25 | 1020 | 0.05 | 780 | 0 | 0 | 1.0 | 1.1 |

| Four-sided planing | 0.6125 € | 15 | 0.30 | 510 | 0.3 | 390 | 0.1 | 330 | 0.5 | 1.1 |

| Width gluing | 0.2803 € | 30 | 4.00 | 30 | 0 | 0 | 0 | 0 | 0.5 | 1.0 |

| Calibration | 0.6022 € | 10 | 0.50 | 60 | 0.3 | 60 | 0 | 0 | 0.0 | 1.1 |

| Format sawing | 0.3322 € | 10 | 0.50 | 60 | 0.3 | 30 | 0 | 0 | 0.0 | 1.1 |

| CNC machining/milling/drilling/etc. | 0.4359 € | 30 | 1.50 | 210 | 0 | 0 | 2 | 30 | 0.5 | 1.0 |

| Repairing | 0.2700 € | 5 | 0.50 | 210 | 0 | 0 | 3 | 30 | 1.0 | 1.0 |

| Edge grinding | 0.2803 € | 10 | 0.50 | 210 | 3 | 30 | 1 | 30 | 0.5 | 1.1 |

| Surface grinding | 0.6125 € | 15 | 0.50 | 180 | 0 | 0 | 0.5 | 60 | 0.5 | 1.1 |

| Assembly gluing | 0.2700 € | 20 | 2.00 | 60 | 0 | 0 | 0 | 0 | 0.0 | 1.0 |

| Oiling | 0.2769 € | 15 | 0.50 | 540 | 0 | 0 | 2 | 180 | 0.5 | 1.0 |

| Packing | 0.2769 € | 10 | 3.00 | 30 | 0 | 0 | 0 | 0 | 0.0 | 1.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kropivšek, J.; Jošt, M.; Grošelj, P.; Kitek Kuzman, M.; Kariž, M.; Merela, M.; Gornik Bučar, D. Innovative Model of the Cost Price Calculation of Products from Invasive Non-Native Wood Species Based on the FTDABC Method. Forests 2021, 12, 1519. https://doi.org/10.3390/f12111519

Kropivšek J, Jošt M, Grošelj P, Kitek Kuzman M, Kariž M, Merela M, Gornik Bučar D. Innovative Model of the Cost Price Calculation of Products from Invasive Non-Native Wood Species Based on the FTDABC Method. Forests. 2021; 12(11):1519. https://doi.org/10.3390/f12111519

Chicago/Turabian StyleKropivšek, Jože, Matej Jošt, Petra Grošelj, Manja Kitek Kuzman, Mirko Kariž, Maks Merela, and Dominika Gornik Bučar. 2021. "Innovative Model of the Cost Price Calculation of Products from Invasive Non-Native Wood Species Based on the FTDABC Method" Forests 12, no. 11: 1519. https://doi.org/10.3390/f12111519

APA StyleKropivšek, J., Jošt, M., Grošelj, P., Kitek Kuzman, M., Kariž, M., Merela, M., & Gornik Bučar, D. (2021). Innovative Model of the Cost Price Calculation of Products from Invasive Non-Native Wood Species Based on the FTDABC Method. Forests, 12(11), 1519. https://doi.org/10.3390/f12111519