Natural Weathering of Bio-Based Façade Materials

Abstract

1. Introduction

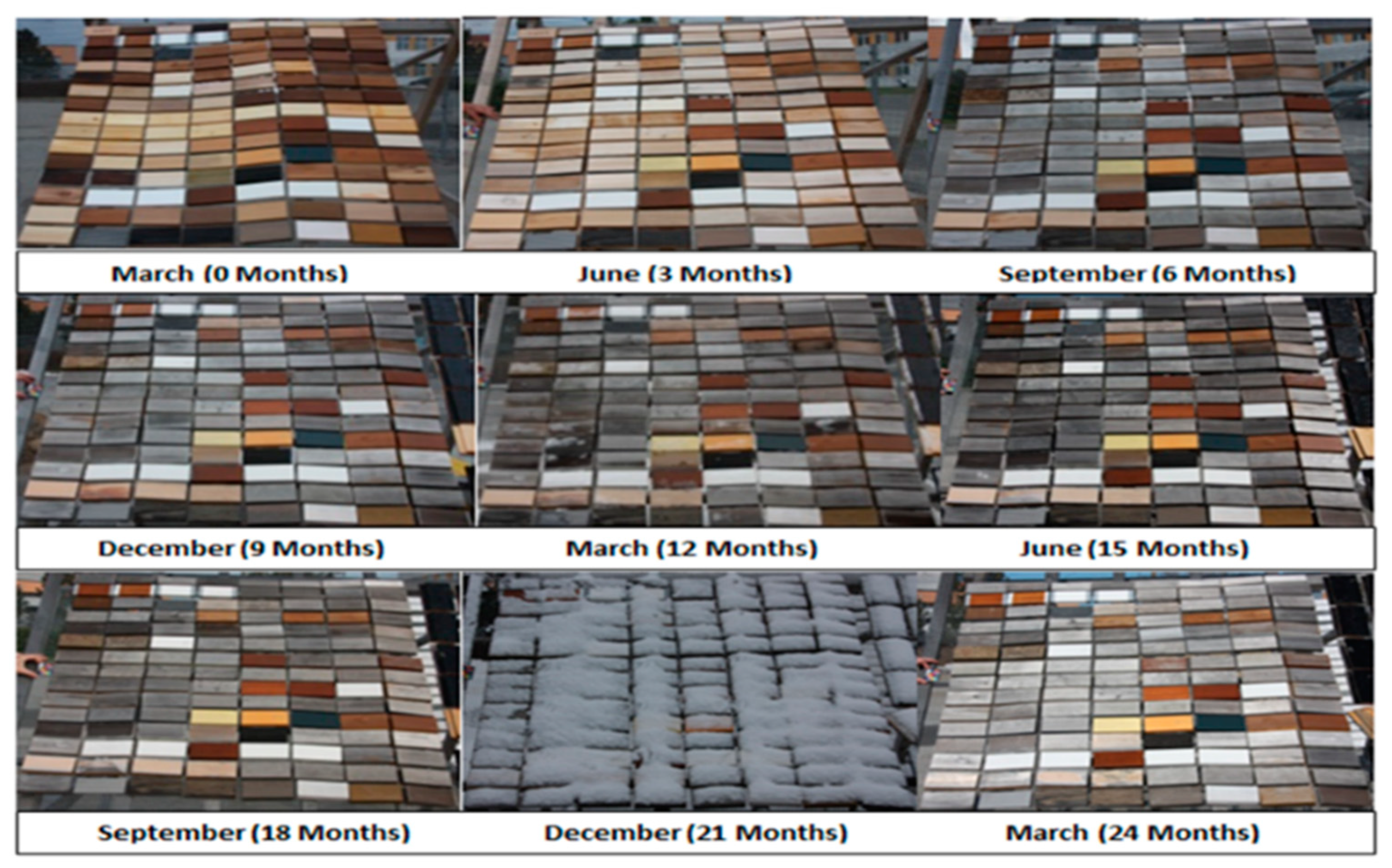

2. Materials and Methods

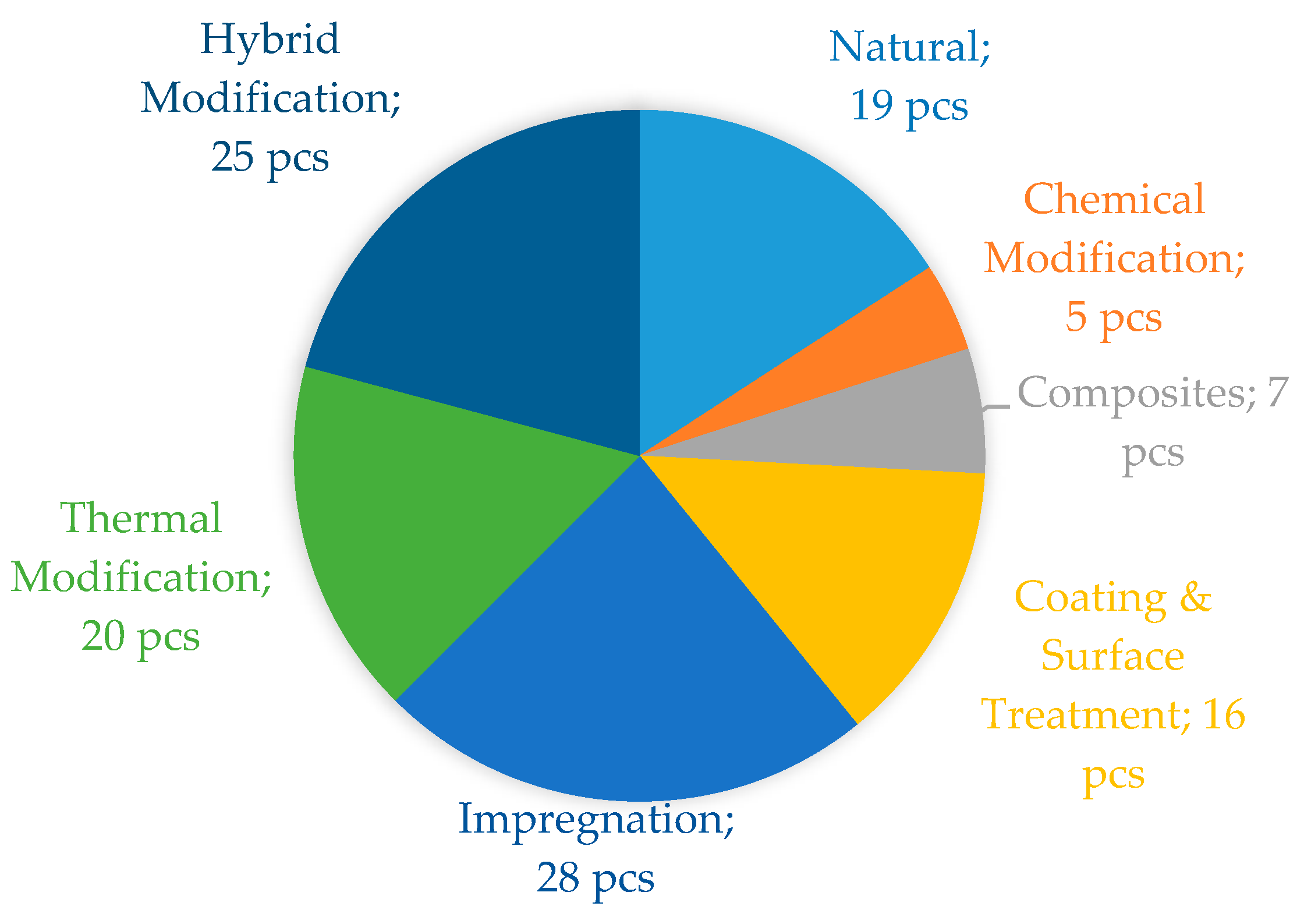

2.1. Façade Materials

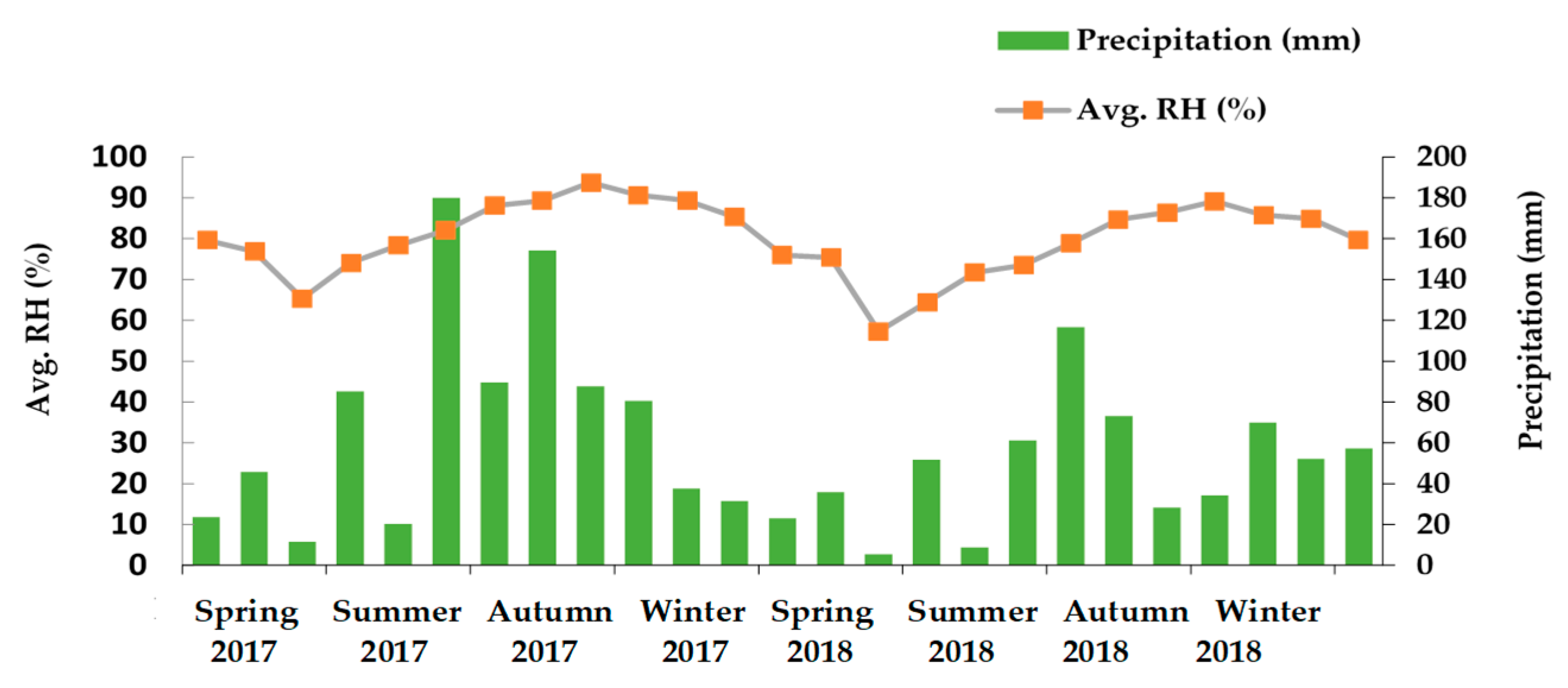

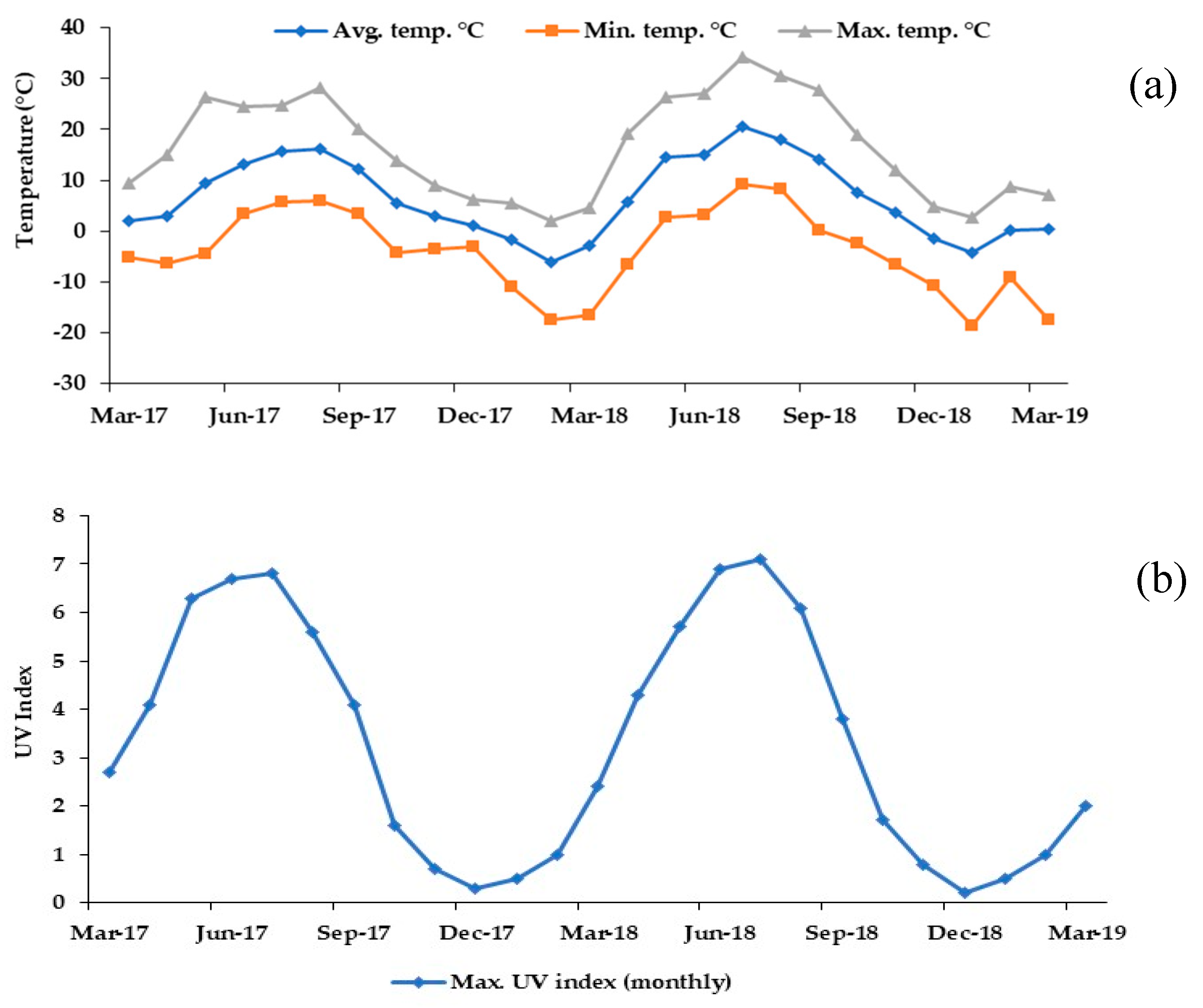

2.2. Site Description

2.3. Evaluation Method

3. Results

3.1. Weather Conditions

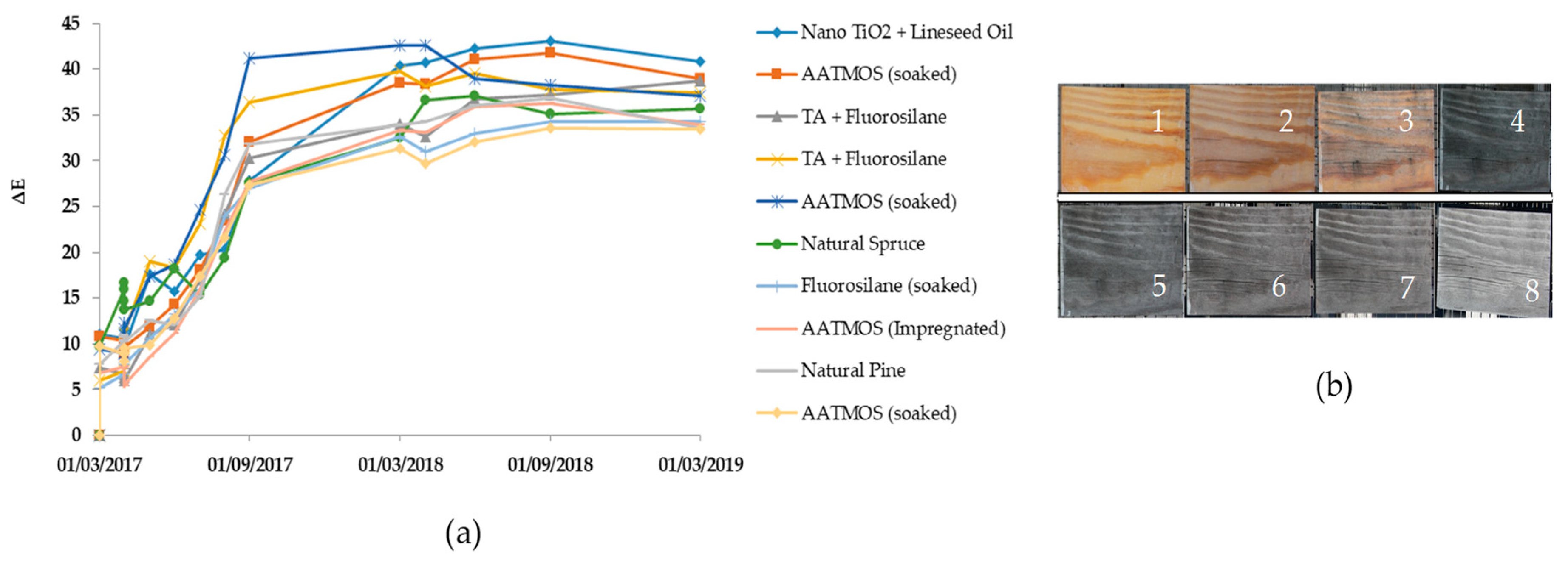

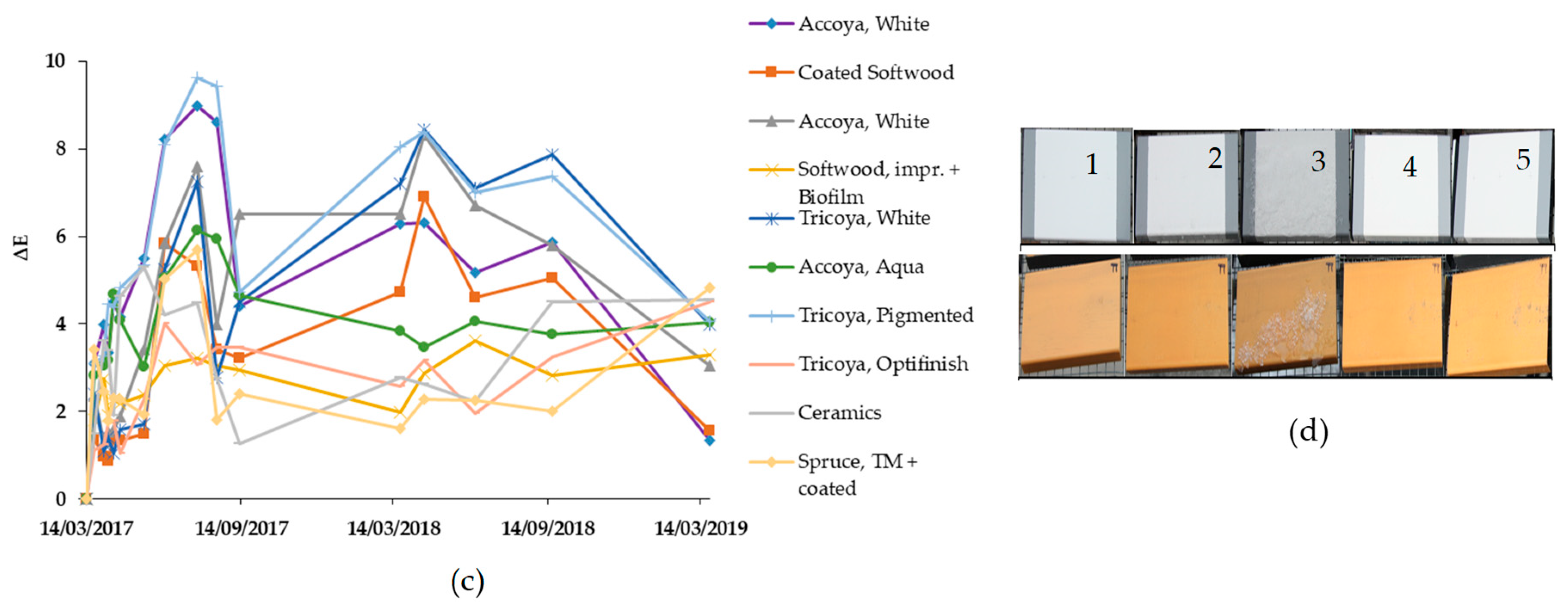

3.2. Appearance and Colour Change of Specimens after 2 Years of Weathering

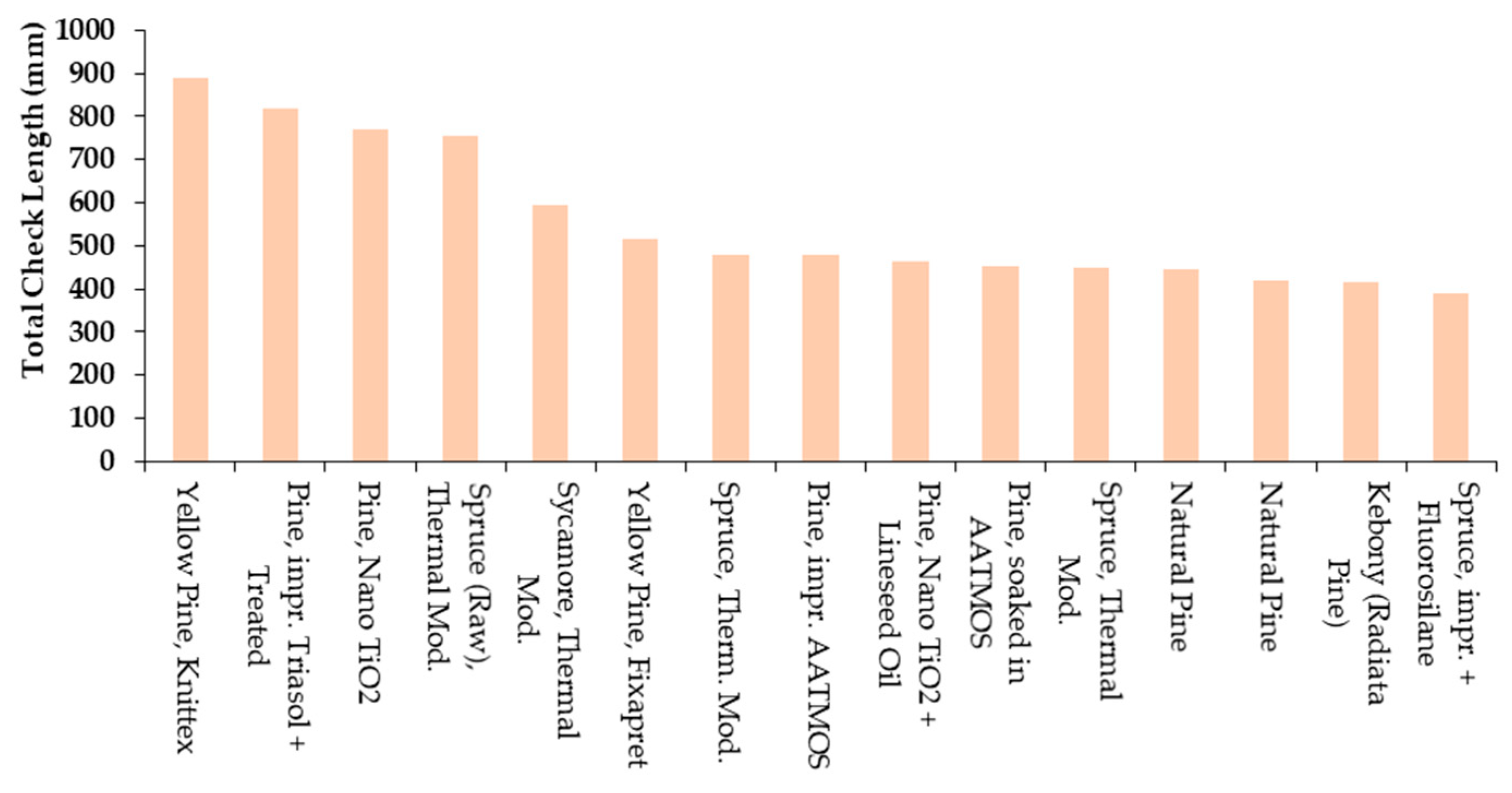

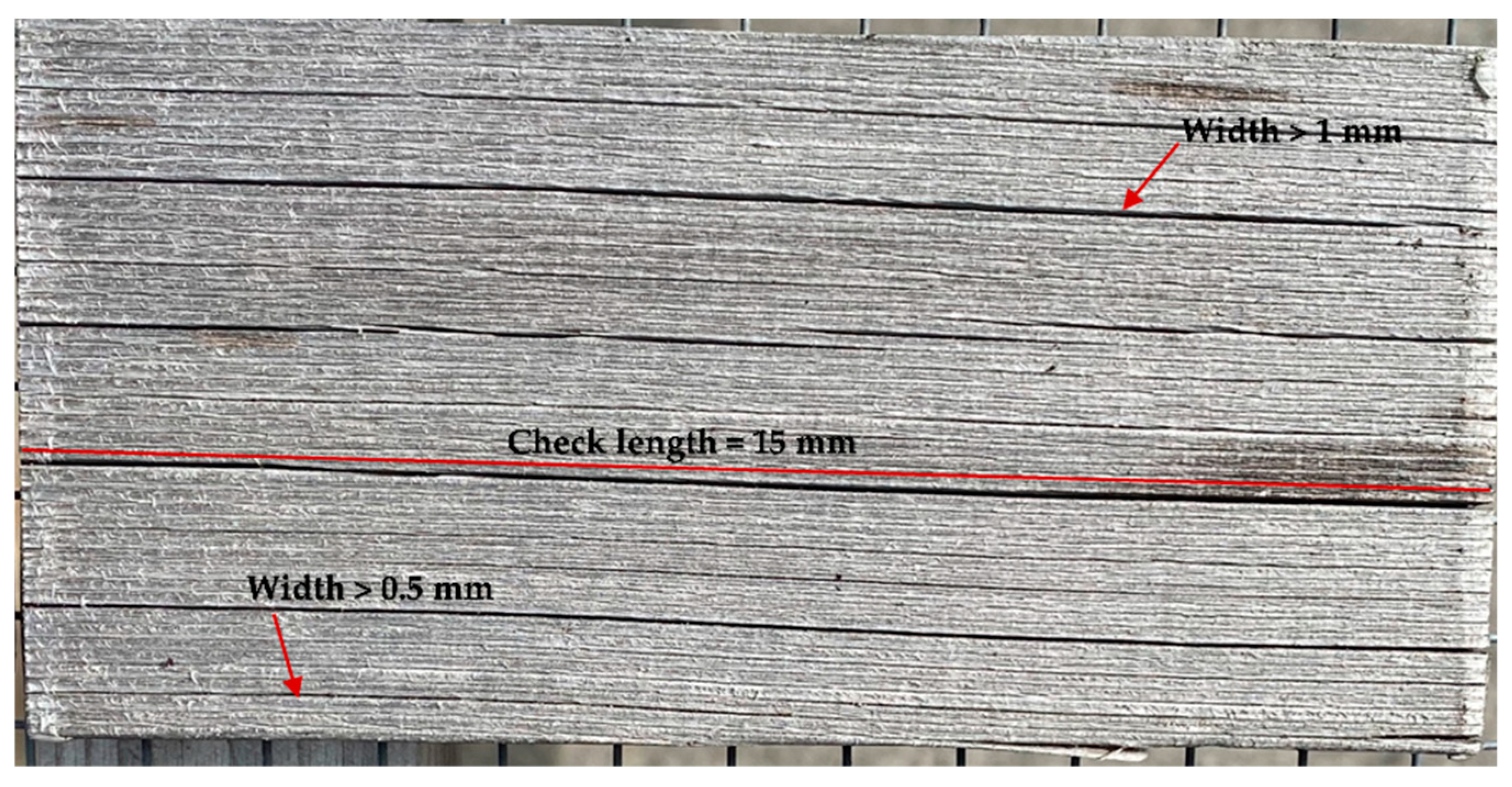

3.3. Material Surface Checks

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hill, C. Wood Modification: Chemical, Thermal and Other Processes; John Wiley and Sons, Ltd: Chichester, UK, 2006; pp. 1–18. [Google Scholar]

- Sandak, A.; Sandak, J.; Petrillo, M.; Grossi, P. Strengthening the confidence in bio-based building materials – BIO4ever project approach. Presented at Final COST FP1303 Meeting”Building with Bio-Based Materials: Best Practice and Performance Specification”, Zagreb, Croatia, 6–7 September 2017. [Google Scholar]

- Petrillo, M.; Sandak, J.; Sandak, A.; Grossi, P.; Kutnar, A. Life cycle assessment of bio-based façades during and after service life: maintenance planning and re-use. Presented at 9th European Conference on Wood Modification, Arnhem, The Netherlands, 17–18 September 2018. [Google Scholar]

- Sandak, A.; Sandak, J.; Brzezicki, M.; Kutnar, A. Bio-Based Building Skin; Springer Open: Singapore, 2019; Available online: https://doi.org/10.1007/978-981-13-3747-5 (accessed on 25 May 2019).

- Sandak, A.; Sandak, J.; Grossi, P.; Petrillo, M. Simulation and modelling tool for the evaluation of the façade performance—BIO4ever project approach. FACADE 2018. Presented at Final Conference COST Action TU1403 “Adaptive Facades Network”, Lucerne, Switzerland, 26–27 November 2018. [Google Scholar]

- Sandak, J.; Sandak, A.; Grossi, P.; Petrillo, M. Simulation and visualization of aesthetic performance of bio-based building skin. Presented at IRG49 Scientific Conference on Wood Protection, Johannesburg, South Africa, 29 April–3 May 2018. IRG/WP 18-2063. [Google Scholar]

- Rowell, R.M. Handbook of Wood Chemistry and Wood Composites, 2nd ed.; CRC Press/Taylor & Francis: Boca Raton, FL, USA, 2012; pp. 152–199. [Google Scholar]

- Reinprecht, L. Natural Durability of Wood. Wood Deterioration, Protection and Maintenance; John Wiley & Sons, Ltd: Chichester, UK, 2016; pp. 14–16. [Google Scholar]

- Evans, P.D. The influence of season and angle of exposure on the weathering of wood. Holz als Roh-und Werkstoff: Eur. J. Wood. Wood. Prod. 1996, 54, 200. [Google Scholar] [CrossRef]

- EN 350-2. Durability of Wood and Wood-Based Products; European Committee for Standardization: Brussels, Belgium, 1994. [Google Scholar]

- Tomak, E.D.; Ustaomer, D.; Ermeydan, M.A.; Yildiz, S. An investigation of surface properties of thermally modified wood during natural weathering for 48 months. Measurement 2018, 127, 187–197. [Google Scholar] [CrossRef]

- Coulson, J. Wood in Construction; John Wiley & Sons Ltd: Chichester, UK, 2014; pp. 57–78. [Google Scholar]

- Sandberg, D.; Kutnar, A.; Mantanis, G. Wood modification technologies—A review. iForest 2017, 10, 895–908. [Google Scholar] [CrossRef]

- Bulian, F.; Graystone, J.A. Wood Coatings: Theory and Practice, 1st ed.; Elsevier Radarweg: Amsterdam, The Netherlands, 2009; pp. 2–13. [Google Scholar]

- Accoya. Available online: https://www.accoya.com/wp-content/uploads/2015/09/WIG_EN_lowres.pdf (accessed on 8 April 2020).

- A New Breed of MDF an Extremely Durable and Stable Wood Panel. Available online: www.tricoya.com. https://tricoya.com/wp-content/uploads/2017/11/Tricoya_Main_Brochure_s16_FW_reduce_size-NORTH-AMERICA.pdf (accessed on 8 April 2020).

- Visnapuu, K. Natural Weathering of Bio-Based Facade Materials. Master’s Thesis, Department of Materials and Environmental Technology, Tallinn University of Technology, Tallinn, Estonia, June 2019. [Google Scholar]

- EN ISO 2810. Paints and Varnshes—Natural Weathering of Coatings—Exposure and Assessment; European Committee for Standardization: Brussels, Belgium, 2004. [Google Scholar]

- EN ISO/CIE 11664-4. Colorimtery—Part 4: CIE 1976 L*a*b* Colour Space; European Committee for Standardization: Brussels, Belgium, 2011. [Google Scholar]

- EN ISO 4628-4. Paints and Varnishes – Evaluation of Degradation of Coatings – Designation of Quantity and Size of Defects, and of Intensity of Uniform Changes in Appearance – Part 4: Assessment of Degree of Cracking; European Committee for Standardization: Brussels, Belgium, 2016. [Google Scholar]

- Brischke, C.; Humar, M.; Meyer, L.; Bardage, S.; Bulcke, J.V. Perfomance of Bio-Based Building Materials; COST Action FP 1303 – Cooperative Performance Test Instructions for participants: Brussels, Belgium, 2014. [Google Scholar]

- Oberhofnerová, E.; Pánek, M.; & García-Cimarras, A. The effect of natural weathering on untreated wood surface. Maderas-Cienc. Tecnol. 2017, 19, 173–184. [Google Scholar] [CrossRef]

- Turkoglu, T.; Baysal, E.; Toker, H. The Effects of Natural Weathering on Color Stability of Impregnated and Varnished Wood Material. Adv. Mater. Sci. Eng. 2015, 1–9. [Google Scholar] [CrossRef]

- Temiz, A.; Yildiz, U.C.; Aydin, I.; Eikenes, M.; Alfrdsen, G.; Colakoglu, G. Surface roughness and color characteristics of wood treated with preservatives after accelerated weathering test. Appl. Surf. Sci. 2005, 250, 35–42. [Google Scholar] [CrossRef]

- Broda, M.; Bart, M.; Frankowski, M. Durability of wood treated with AATMOS and caffeine – towards the long-term carbon storage. Maderas-Cienc. Tecnol. 2018, 20, 455–468. [Google Scholar]

- Nanoprotect. Nanoprotect Wood Product System. Available online: http://files.nanoprotect.de/System_Holzprodukte_englisch.pdf (accessed on 25 May 2019).

- Grüll, G.; Tscherne, F.; Spitaler, I.; Forshuber, B. Comparison of wood coating durability in natural weathering and artificial weathering using fluorescent UV-lamps and water. Eur. J. Wood. Wood. Prod. 2014, 72, 367. [Google Scholar] [CrossRef]

- Ozgenc, O.; Hiziroglu, S.; Yildiz, U.C. Weathering Properties of Wood Species Treated With Different Coating Applications. Bioresources 2012, 7. [Google Scholar] [CrossRef]

- Shen, H.; Zhang, S.Z.; Cao, J.; Jjang, J.; Wang, W. Improving anti-weathering performance of thermally modified wood by TiO2 sol or/and paraffin emulsion. Constr Build Mater. 2018, 169, 372–378. [Google Scholar] [CrossRef]

| Wood Specimens | Scientific Name | ∆E (U/M) After 2 Years |

|---|---|---|

| Norway Spruce | Picea abies | 35.7 ± 1.7 |

| Pine (Heartwood, dried 50–70 °C) | Pinus radiata | 33.6 ± 3.7 |

| Pine | Pinus radiata | 31.3 ± 4.6 |

| Larch with Laser Graver | Larix sp. | 31.0 ± 2.9 |

| Southern Yellow Pine | Pinus echinata | 30.7 ± 3.4 |

| Natural Pine | Pinus sylvestris | 30.4 ± 2.8 |

| Silver Fir | Abies alba | 30.0 ± 1.4 |

| Softwood | - | 29.0 ± 1.5 |

| Plantation Teak (Class P_B) | Tectona grandis | 28.6 ± 2.3 |

| Plantation Teak (Class A) | Tectona grandis | 26.9 ± 2.0 |

| Plantation Teak (Class B) | Tectona grandis | 24.2 ± 0.7 |

| Plantation Teak (Class C) | Tectona grandis | 21.8 ± 3.7 |

| Oak | Quercus petraea | 20.8 ± 4.1 |

| Beech | Fagus sylvatica | 19.4 ± 2.9 |

| Bamboo Cladding | Bambuseae | 18.9 ± 4.7 |

| Natural Beech | Fagus sp. | 18.5 ± 2.7 |

| Bamboo Decking | Bambuseae | 15.3 ± 0.8 |

| Poplar | Populus tremula | 14.6 ± 1.6 |

| Ceris Oak | Quercus cerris | 13.8 ± 2.2 |

| Chemically Modified Specimens | ∆E (U/M) after 2 Years | Composites | ∆E (U/M) after 2 Years |

|---|---|---|---|

| Acetylated Radiata Pine | 16.5 ± 1.3 | Particleboard and Bamboo | 23.2 ± 1.4 |

| Acetylated Alder | 16.4 ± 0.8 | Fiberboard | 18.5 ± 5.3 |

| Acetylated Beech | 14.3 ± 1.0 | Wood Plastic Composites | 7.4 ± 1.2 |

| Kebony (Furfurylated) | 12.4 ± 1.1 | Bio-Ceramics | 4.5 ± 1.0 |

| Scots Pine Kebony (Furfurylated) | 6.8 ± 3.4 | Tricoya. Opti finish | 4.5 ± 0.3 |

| Tricoya for cladding. Pigmented White | 4.1 ± 1.0 | ||

| Tricoya White | 4.0 ± 1.5 |

| Surface Coated Specimens | ∆E (U/M) after 2 Years | Impregnated Specimens | ∆E (U/M) after 2 Years |

|---|---|---|---|

| Pine. nanocoated | 27.4 ± 1.2 | Spruce. AATMOS soaked | 39.0 ± 1.3 |

| Natural Oak. Waxed | 22.9 ± 0.6 | Spruce. TA Impregnated. + Fluorosilane | 38.8 ± 4.0 |

| Larch Lightly Burned | 18.4 ± 4.2 | Poplar. TA Impregnated. + Fluorosilane | 37.5 ± 3.1 |

| Pine. Aqua Coating | 17.9 ± 2.4 | Poplar Soaked AATMOS | 37.1 ± 0.8 |

| Natural Oak Coated | 17.4 ± 3.7 | Spruce. TA Fluorosilane soaked | 34.2 ± 1.6 |

| White Treatment Solas | 14.0 ± 0.2 | Spruce. Impregnated. AATMOS | 33.9 ± 1.6 |

| Softwood. Coated | 12.1 ± 2.6 | Pine. Soaked AATMOS | 33.5 ± 1.9 |

| Pine. Grey Coating | 9.3 ± 1.4 | Pine. Impregnated + Soaking in Fluorosilane | 32.6 ± 1.7 |

| Pine. White Coating | 9.3 ± 2.6 | Poplar. Impregnated AATMOS | 32.2 ± 3.4 |

| Natural Spruce. Oiled | 9.3 ± 0.5 | Pine. Impregnated AATMOS | 31.6 ± 4.6 |

| Hardwood. for Windows (coated) | 9.1 ± 1.2 | Spruce. Fluorosilane | 30 ± 1.5 |

| Larch Carbonised | 8.8 ± 4.0 | Beech. Silicone | 29.8 ± 3.9 |

| Softwood. Water Base | 8.5 ± 1.7 | Poplar. Impregnated + Fluorosilane | 29.6 ± 2.5 |

| Softwood. Solvent Base | 7.9 ± 0.3 | Poplar. Fluorosilane | 28.6 ± 1.7 |

| Spruce. Coated | 5.5 ± 0.7 | Spruce. Impregnated + Fluorosilane | 28.6 ± 2.7 |

| Softwood. for Windows | 1.6 ± 0.3 | Poplar. Impregnated. + Soaking in Fluorosilane | 28.5 ± 1.4 |

| Pine. DMDHEU | 27.8 ± 1.6 | ||

| Fixapret | 25.0 ± 3.2 | ||

| Pine. TiO2 | 24.2 ± 0.2 | ||

| Silver Fir | 23.4 ± 4.2 | ||

| Silver Fir. treated | 21.5 ± 0.9 | ||

| Beech. impregnated | 20.7 ± 3.1 | ||

| Silver Fir | 20.5 ± 1.6 | ||

| Madurit | 20.3 ± 3.1 | ||

| Beech. PBS | 19.6 ± 1.7 | ||

| Knittex | 18.3 ± 0.2 | ||

| Beech. PLA | 11.3 ± 0.9 | ||

| CEA impregnated Softwood | 10.1 ± 1.7 |

| Thermally Modified Specimens | ∆E (U/M) after 2 Years | Hybrid Modified Specimens | ∆E (U/M) after 2 Years |

|---|---|---|---|

| Frake. TM | 25.4 ± 2.2 | Pine. Nano TiO2 + Linseed Oil | 40.8 ± 2.2 |

| Radiata Pine. TM | 24.2 ± 1.9 | Spruce. TM + Oil | 25.2 ± 1.9 |

| Pine. TM | 23.8 ± 3.1 | Poplar. Madurit + TM | 22.9 ± 1.8 |

| Spruce. TM | 23.1 ± 1.2 | Accoya (Poseidon) | 20.8 ± 3.0 |

| Spruce. TM | 22.0 ± 1.4 | TM Oak + Coated | 19.7 ± 5.6 |

| Spruce. TM | 21.9 ± 2.6 | Accoya (Hydro-Oil) | 17.9 ± 1.4 |

| Poplar. TM | 20.0 ± 1.1 | Softwood. TM + Wax | 14.8 ± 1.6 |

| Ayous. TM | 19.3 ± 1.8 | Pine. TM + Coating | 14.3 ± 4.0 |

| Frake. TM | 19.2 ± 1.7 | Spruce. TM + Coating | 14.2 ± 2.3 |

| Pine Thermo D 212 °C | 18.7 ± 2.1 | Oak. TM + Wax | 13.4 ± 0.5 |

| Spruce Thermo D 212 °C | 18.6 ± 4.9 | Radiata Pine. Silicate | 13.2 ± 2.5 |

| Sycamore. TM | 17.4 ± 1.4 | Radiate Pine. TM + Coating | 12.1 ± 0.8 |

| Pine. TM | 17.0 ± 0.4 | Pine. Treated + Triazole | 11.1 ± 1.6 |

| Poplar. TM | 16.7 ± 2.3 | Spruce TM + FeSo4 | 10.4 ± 1.8 |

| Thermally Treated Obeche | 15.4 ± 2.3 | Ayous TM + Coating | 10.3 ± 0.8 |

| Pine. OHT | 14.8 ± 2.2 | Accoya (Dark) | 10.2 ± 0.7 |

| Ash Thermally Treated | 13.5 ± 2.6 | Accoya (Matt) | 9.2 ± 3.8 |

| Thermally Modified Oak | 12.6 ± 0.2 | Radiata Pine. Water | 8.6 ± 0.5 |

| Softwood. TM | 12.0 ± 1.3 | Frake. TM + Coating | 7.8 ± 0.8 |

| TM Spruce. Over treated | 7.1 ± 1.8 | Pine. Triazole + Treated | 7.0 ± 4.0 |

| TM Spruce. Coated | 4.8 ± 1.0 | ||

| Accoya (Aqua) | 4.0 ± 0.9 | ||

| Softwood. Biofilm | 3.3 ± 0.4 | ||

| Accoya (White) | 3.0 ± 0.2 | ||

| Accoya (Pigmented White) | 1.3 ± 0.3 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alao, P.; Visnapuu, K.; Kallakas, H.; Poltimäe, T.; Kers, J. Natural Weathering of Bio-Based Façade Materials. Forests 2020, 11, 642. https://doi.org/10.3390/f11060642

Alao P, Visnapuu K, Kallakas H, Poltimäe T, Kers J. Natural Weathering of Bio-Based Façade Materials. Forests. 2020; 11(6):642. https://doi.org/10.3390/f11060642

Chicago/Turabian StyleAlao, Percy, Kevin Visnapuu, Heikko Kallakas, Triinu Poltimäe, and Jaan Kers. 2020. "Natural Weathering of Bio-Based Façade Materials" Forests 11, no. 6: 642. https://doi.org/10.3390/f11060642

APA StyleAlao, P., Visnapuu, K., Kallakas, H., Poltimäe, T., & Kers, J. (2020). Natural Weathering of Bio-Based Façade Materials. Forests, 11(6), 642. https://doi.org/10.3390/f11060642