Experimental and Numerical Study on Methods of Testing Withdrawal Resistance of Mortise-and-Tenon Joint for Wood Products

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

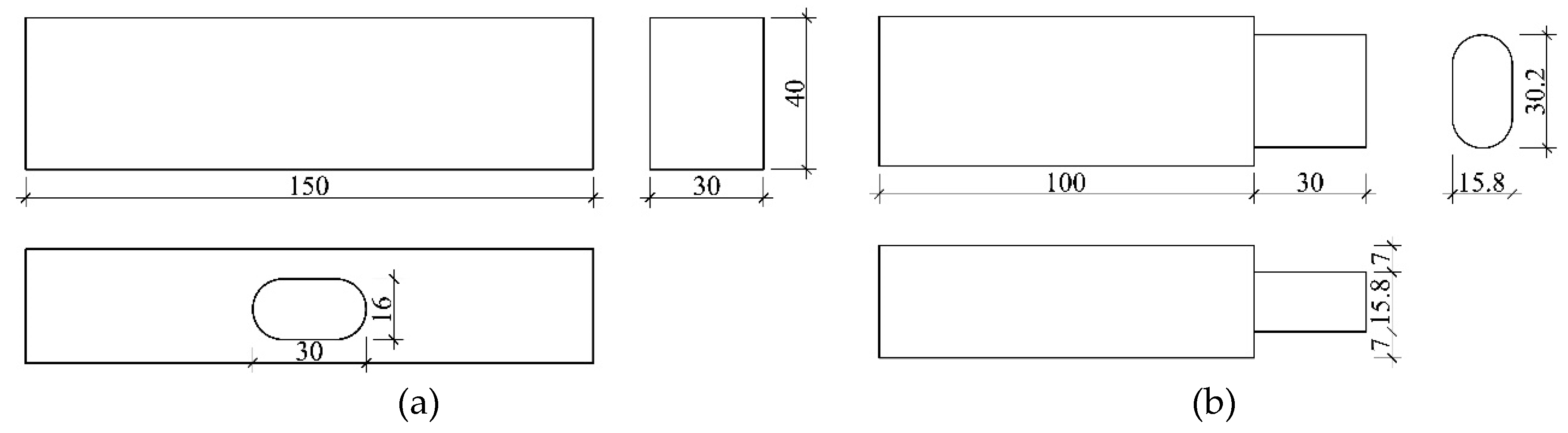

2.2. Description of the Specimens

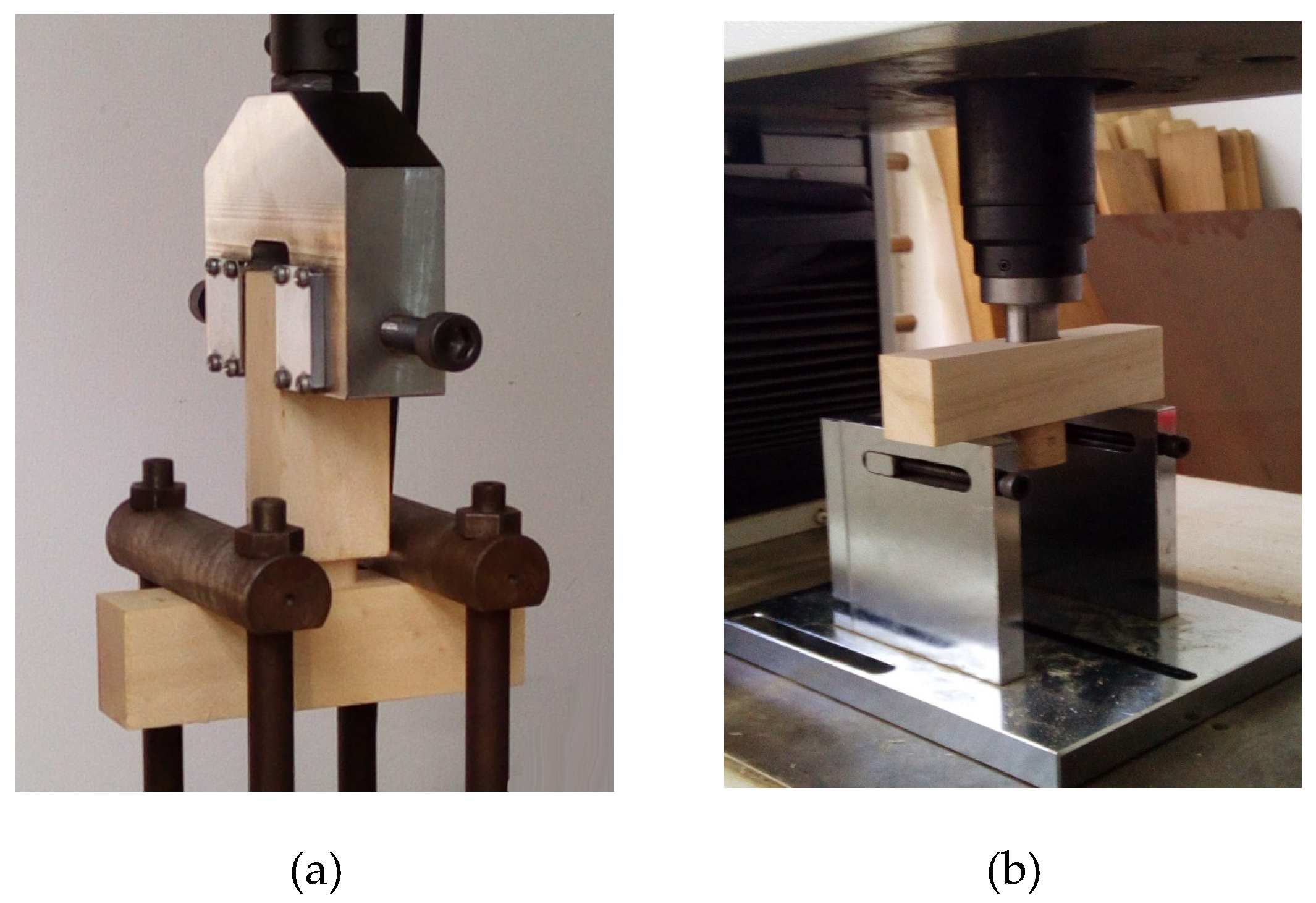

2.3. Testing Methods

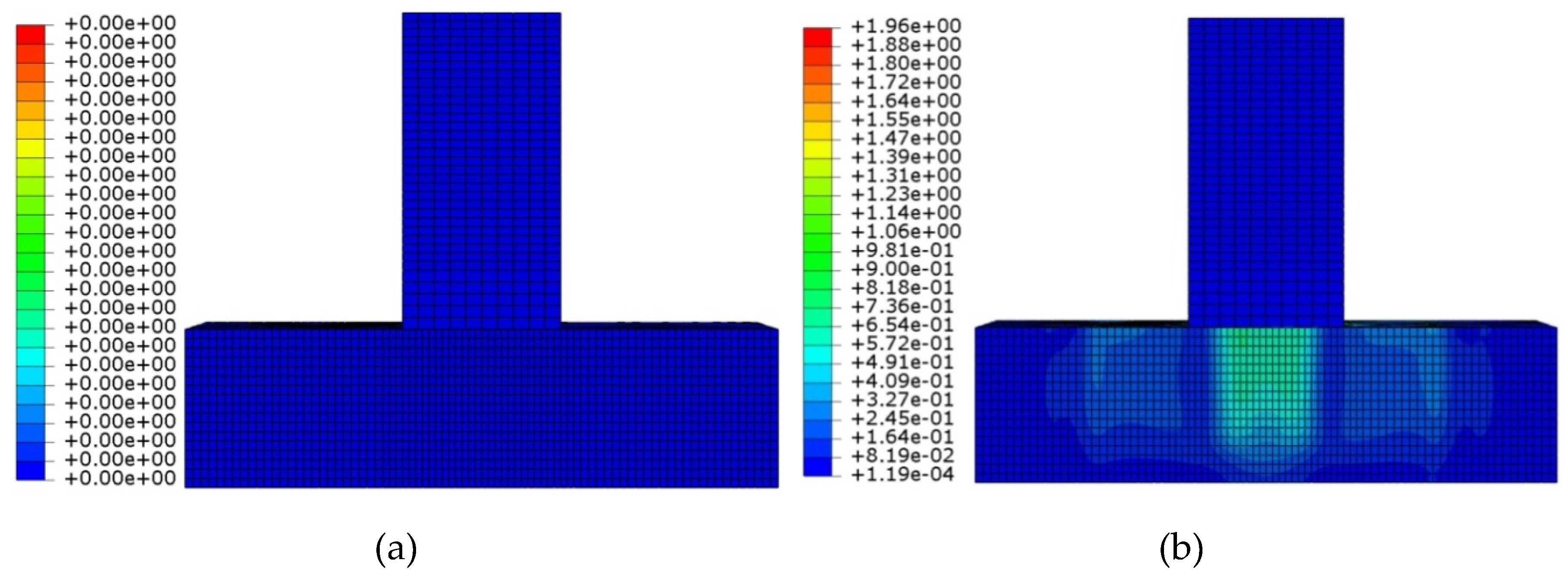

2.4. Finite Element Model

3. Results and Discussions

3.1. Withdrawal Resistance of M&T joint

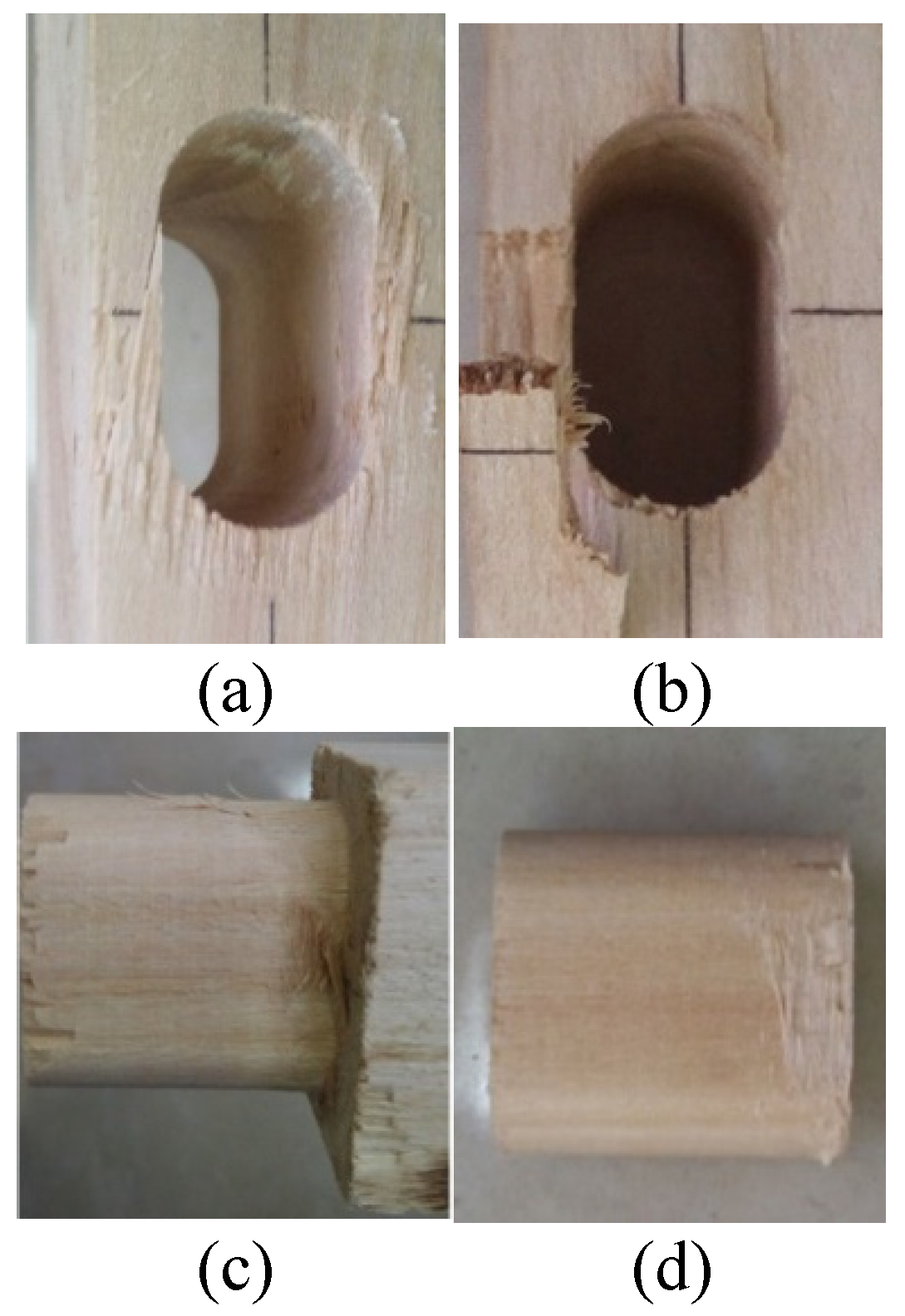

3.2. Failure Modes

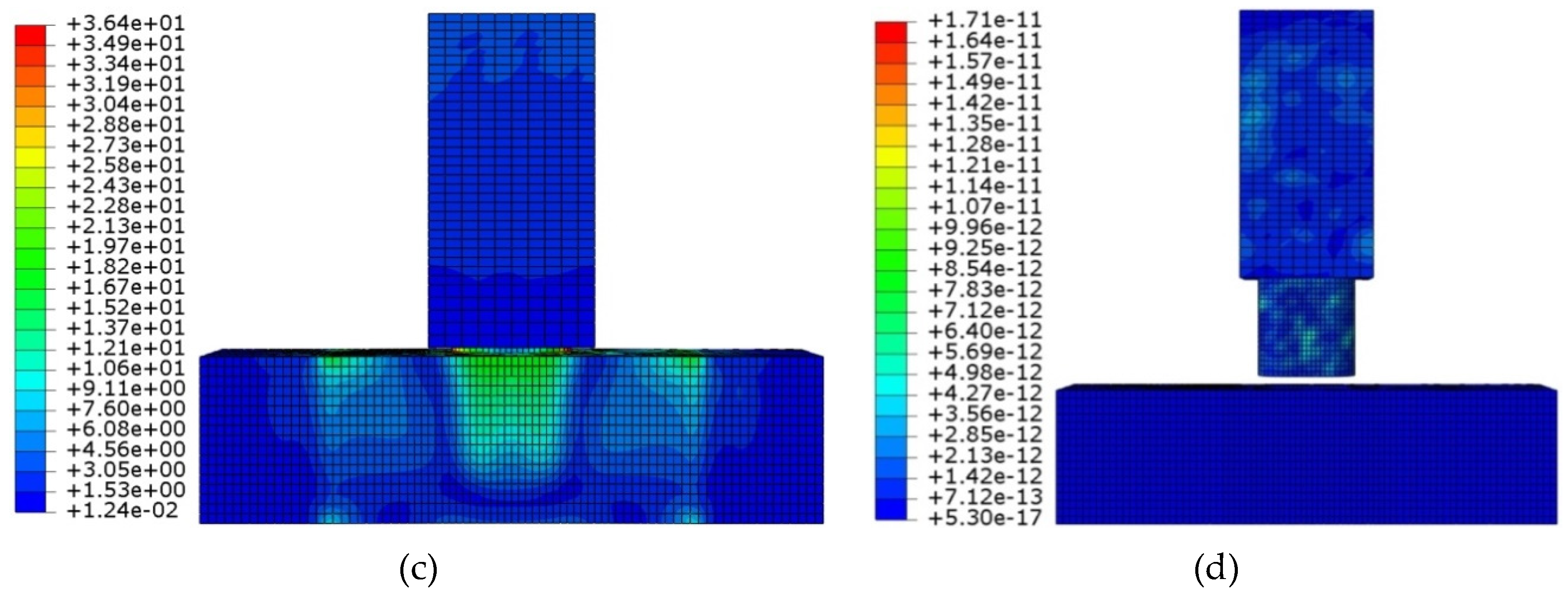

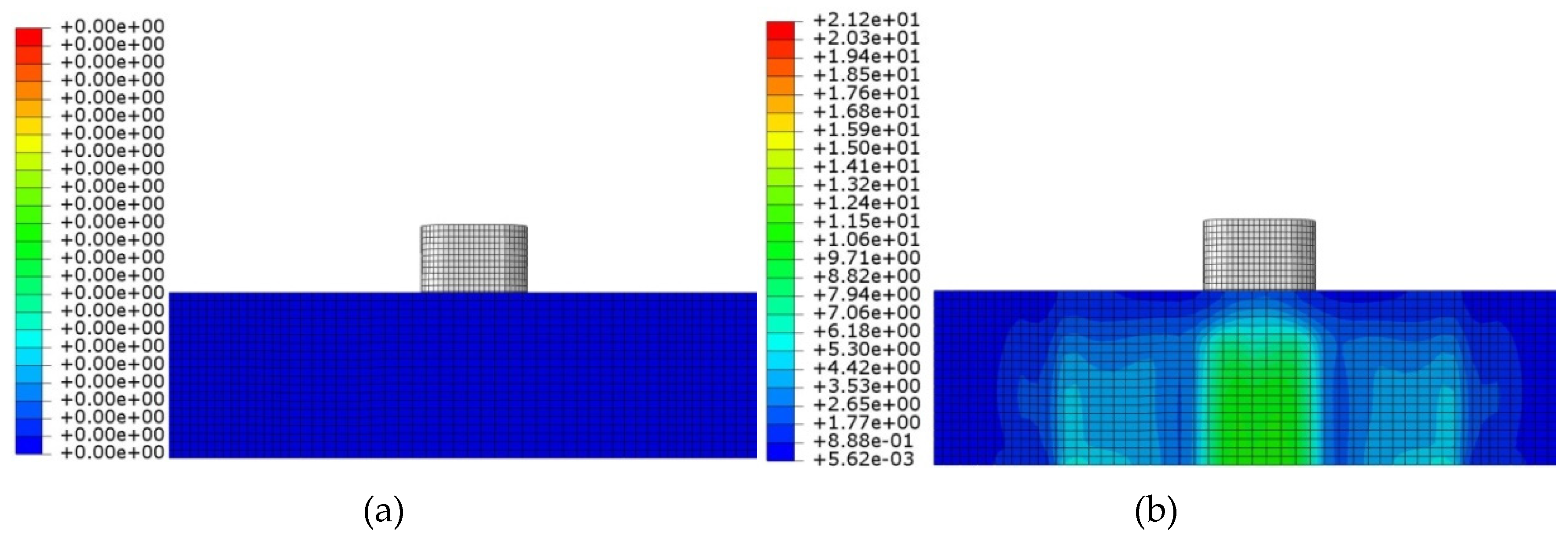

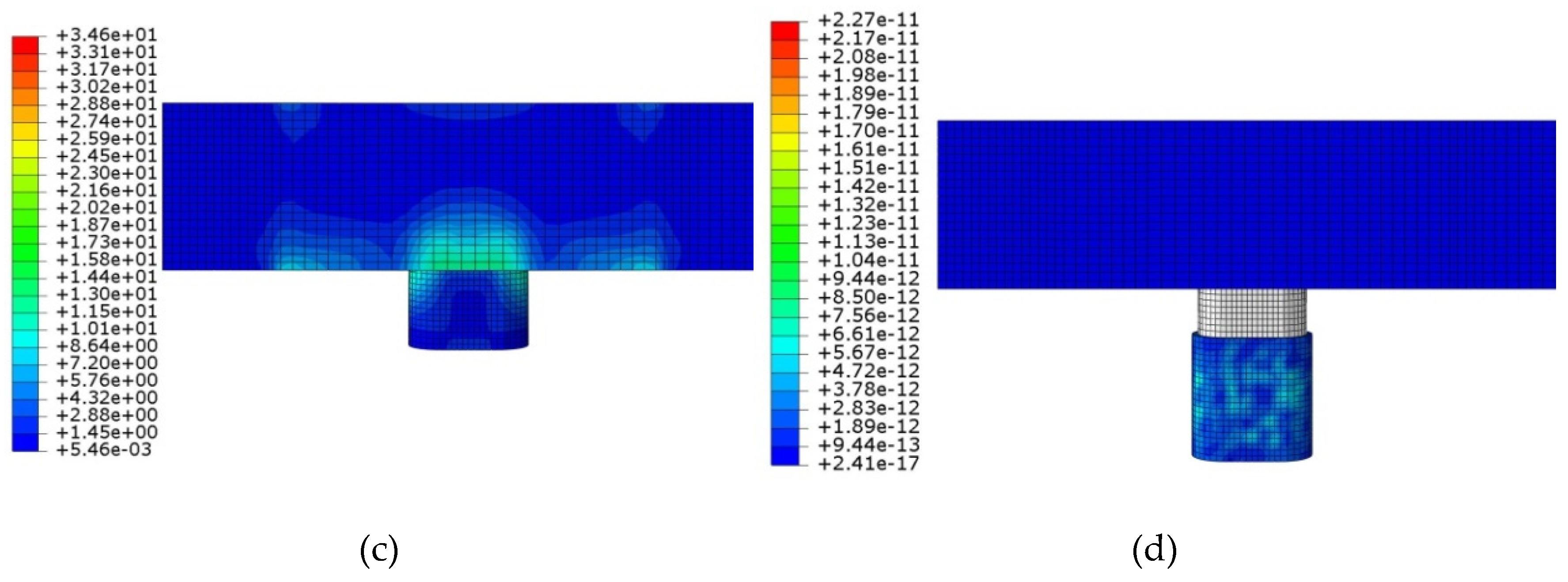

3.3. Finite Element Analysis

4. Conclusions

- The effects of glue and testing methods on withdrawal resistance of the M&T joint were statistically significant. The withdrawal resistances measured by the tensile method were higher than those measured by the compressive method, no matter whether the joints were glued or not.

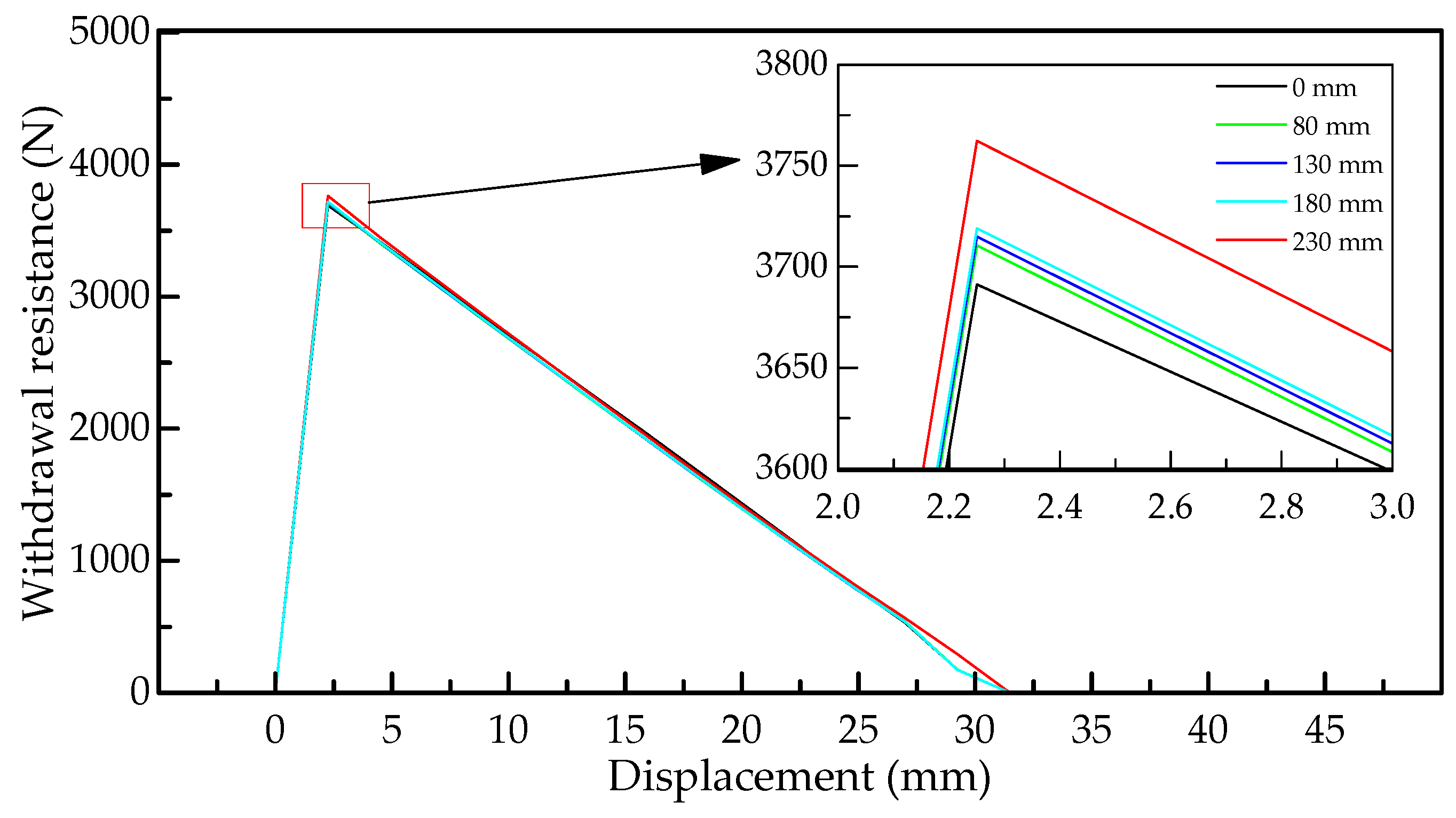

- The withdrawal resistance of the M&T joint increased gradually in line with the growth of the tenon member length based on the finite element method.

- The compressive method proposed has an advantage in measuring the true withdrawal resistance of the M&T joint, while the tensile method suited to measure the withdrawal resistance of T-shaped samples for comparative experiments.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Eckelman, C.A. Bending strength and moment–rotation characteristics of two–pin moment–resisting dowel joints. Forest Prod. J. 1971, 21, 35–39. [Google Scholar]

- Feio, A.O.; Lourenço, P.B.; Machado, J.S. Testing and modeling of a traditional timber mortise and tenon joint. Mater. Struct. 2014, 47, 213–225. [Google Scholar] [CrossRef]

- Smardzewski, J.; Lewandowski, W.; İmirzi, H.Ö. Elasticity modulus of cabinet furniture joints. Mater. Design. 2014, 60, 260–266. [Google Scholar] [CrossRef]

- Gu, Y.T.; Wu, Z.H.; Zhang, Z.L. Load–deflection behavior of rattan chair seats. Wood Fiber Sci. 2016, 48, 1–12. [Google Scholar]

- Hu, H.; Yang, J.; Wang, F.L.; Zhang, Y.M. Mechanical properties of bolted joints in prefabricated round bamboo structures. J. Forest Eng. 2018, 3, 128–135. [Google Scholar] [CrossRef]

- Diler, H.; Acar, M.; Balıkçı, E.; Demirci, S.; Erdil, Y.Z. Withdrawal force resistance of T–type furniture joints constructed from various heat–treated wood species. BioResources 2017, 12, 7466–7478. [Google Scholar] [CrossRef]

- Renbutsu, T.; Koizumi, A. Withdrawal properties of glued, round, mortise and tenon joints using greenwood shrinkage as a clamping pressure. Mokuzai Gakkaishi 2018, 64, 187–194. [Google Scholar] [CrossRef]

- Eckelman, C.A.; Haviarova, E.; Tankut, A.; Denizli, N.; Akcay, H.; Erdil, Y. Withdrawal capacity of pinned and unpinned round mortise and tenon furniture joints. Forest Prod. J. 2004, 54, 185–191. [Google Scholar]

- Xi, X.; Yang, Y.; Zhang, Z.F. Pull–out force and finite element analysis of T–type components of Vitex negundo L. scrimber with different node forms. J. Forest Eng. 2020, 5, 182–187. [Google Scholar] [CrossRef]

- Carpinteri, A.; Pugno, N. Are scaling laws on strength of solids related to mechanics or to geometry. Nat. Mater. 2005, 4, 421–423. [Google Scholar] [CrossRef] [PubMed]

- Hu, W.G.; Wan, H.; Guan, H.Y. Size effect on the elastic mechanical properties of beech and its application in finite element analysis of wood structures. Forests 2019, 10, 783. [Google Scholar] [CrossRef]

- ASTM D2395–93. Standard Test Methods for Specific Gravity of Wood and Wood–Based Materials; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- ASTM D 4442–92. Test Methods for Direct Moisture Content Measurement of Wood and Wood–Base Materials; ASTM, International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- Hu, W.G.; Guan, H.Y. Investigation on withdrawal resistance of mortise and tenon joint based on friction properties. J. Forest Eng. 2017, 2, 158–162. [Google Scholar] [CrossRef]

- Hu, W.G.; Guan, H.Y. Study on elastic constants of beech in different stress states. J. Forest Eng. 2017, 2, 31–36. [Google Scholar] [CrossRef]

- Hu, W.G.; Guan, H.Y.; Zhang, J.L. Finite element analysis of tensile load resistance of mortise–and–tenon joints considering tenon fit effects. Wood Fiber Sci. 2018, 50, 121–131. [Google Scholar] [CrossRef]

- Li, R.; Cao, P.; Xu, W.; Ekevad, M.; Wang, X.A. Experimental and Numerical Study of Moisture–induced Stress Formation in Hexagonal Glulam Using X–ray Computed Tomography and Finite–element Analysis. Bioresources 2018, 13, 7395–7403. [Google Scholar] [CrossRef]

- Eckelman, C.A.; Haviarova, E. Effect of shoulders on bending moment capacity of round mortise and tenon joints. Forest Prod. J. 2006, 56, 82–86. [Google Scholar]

- Džinčić, I.; Nestorović, B.; Dacić, V. The effect of shoulder on the strength of the oval tenon–mortis. Glasnik Sumarskog Fakulteta 2016, 113, 35–46. [Google Scholar] [CrossRef]

- Kasal, A.; Smardzewski, J.; Kuşkun, T.; Erdil, Y.Z. Numerical analyses of various sizes of mortise and tenon furniture joints. BioResources 2016, 11, 6836–6853. [Google Scholar] [CrossRef]

- Kılıç, K.; Kasal, A.; Kuşkun, T.; Acar, M.; Erdil, Y.Z. Effect of tenon size on static front to back loading performance of wooden chairs in comparison with acceptable design loads. BioResources 2018, 13, 256–271. [Google Scholar] [CrossRef]

- Záborský, V.; Borůvka, V.; Kašičková, V.; Ruman, D. Effect of wood species, adhesive type and annual ring directions on the stiffness of rail to leg mortise and tenon furniture joints. BioResources 2017, 12, 7016–7031. [Google Scholar] [CrossRef]

| Source | F-value | Significance |

|---|---|---|

| Glue | 9.060 | < 0.01 |

| Testing method | 361.566 | < 0.01 |

| Glue × Testing method | 4.148 | 0.055 |

| Glue | Testing Method | Mean (N) | COV |

|---|---|---|---|

| Unglued | Tension | 597 (A) | 20.7 |

| Compression | 421 (B) | 15.8 | |

| Glued | Tension | 4414 (A) | 11.2 |

| Compression | 3499 (B) | 20.6 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, W.; Liu, N.; Guan, H. Experimental and Numerical Study on Methods of Testing Withdrawal Resistance of Mortise-and-Tenon Joint for Wood Products. Forests 2020, 11, 280. https://doi.org/10.3390/f11030280

Hu W, Liu N, Guan H. Experimental and Numerical Study on Methods of Testing Withdrawal Resistance of Mortise-and-Tenon Joint for Wood Products. Forests. 2020; 11(3):280. https://doi.org/10.3390/f11030280

Chicago/Turabian StyleHu, Wengang, Na Liu, and Huiyuan Guan. 2020. "Experimental and Numerical Study on Methods of Testing Withdrawal Resistance of Mortise-and-Tenon Joint for Wood Products" Forests 11, no. 3: 280. https://doi.org/10.3390/f11030280

APA StyleHu, W., Liu, N., & Guan, H. (2020). Experimental and Numerical Study on Methods of Testing Withdrawal Resistance of Mortise-and-Tenon Joint for Wood Products. Forests, 11(3), 280. https://doi.org/10.3390/f11030280