Abstract

The use of wood for road construction in biologically valuable areas seems to be a good alternative to solutions based on less ecologically-friendly materials. The key issue is the durability of the wood in specific conditions of use, i.e., in the substrate of the actual road. Among other issues, this study analyzes the existing road surfaces constructed on timber log foundations and the selected properties of the wood taken from designated road sections—to measure the properties of durability, such as density, modulus of elasticity and compression strength parallel to the grain. Based on the analysis of the aforementioned properties, we confirmed the highest durability for oak heartwood as the most predisposed in building forest road substrates. Next in order were the resinous conifers of pine and spruce, and the least durable was alder. Maintaining the wood in a good condition is mainly influenced by the conditions of its use. Using wooden substrates for forest roads is best suited in marshy areas.

1. Introduction

Road subgrades with poor-bearing soils are most frequently found in marshy forest areas with organic soils and in areas with mineral soils having impermeable layers in the subgrade profile [1]. The total area of coniferous and deciduous forest habitats on wet and marshy soils and alder forests in the State Forests National Forest Holding in Poland amounts to 1,478,000 ha, which constitutes 16% of the total forest area. These are usually forest areas that are inaccessible or difficult to access, which is linked to the lack of road infrastructure.

Many authors, including Saunders et al. [2] and Demir [3] believe that forest roads can be defined as ecosystems because they occupy space in the natural environment in which matter and energy are exchanged. Among the ecological effects of road construction, the most important are the movement and erosion of soils as well as interference with hydrological processes [2,4,5]. The construction and use of roads should be conducted, on the one hand, in compliance with the protection of the forest environment and, on the other hand, in accordance with the rational needs of logistics, the principles of traffic safety and road construction [3]. Forest roads, despite their poor soil substrates, must be prepared for the heavy loads of wood transport [6,7,8].

The above premises provide support for the use of wood (a natural material) in forest road construction, especially in marshy areas, where high soil moisture will be conducive to its durability. Compared to other materials: geosynthetics and aggregates, wood is not a littering material for the environment, without the need for later remediation. In addition, processing wood into material suitable for road construction does not provide significant energy consumption. Also wood accumulates carbon absorbed by trees in the form of carbon dioxide from the atmosphere.

This is not a new solution, as the use of wooden roads dates back to the time of Neolithic culture, when passages through moors and marshes were built on timber logs [9]. However, the question still valid today is: how long will such a road last?

The authors of many studies, point to the significant influence of the road substrate on the bearing capacity of forest roads [1,10,11,12]. The key factor when using timber logs is the resistance of the wood to decay from biotic factors, especially fungi. Classification of the conditions of use (determining the intensity of the impact of various factors causing the wood to degrade) is provided in the EN 335:2013 standard [13], while the natural durability of particular wood species (resulting from their structure and chemical composition) tested under laboratory conditions is specified in the EN 350:2016 standard [14]. These data are the basis for the analysis of the possibility of using wood in road construction, but they do not exhaust the issue due to the complexity of the conditions of its actual use. Studies on the durability of wooden structures given the conditions of the soil have been the subject of many studies e.g., [15,16,17,18,19], however, it is still difficult to reach unambiguous conclusions due to the methodological diversity of these studies and usually, the lack of a good reference point. The decisive issue for the correctness (representativeness) of the obtained research results and their proper interpretation is the description and assessment of the environment in which the wood was placed and the skillful taking of samples.

The Aim and Scope of the Study

The aim of the study was to analyze the possibility of using timber logs for the construction of forest roads. The technical aspects, effects of road load-bearing capacity and durability, as well as the progressive degradation of the wood used in forest road construction were analyzed. The analysis of forest road construction was conducted on substrates reinforced with timber logs.

To achieve the research aim formulated above, the following work was conducted and presented in this article:

- identification of the technologies and applied solutions used to reinforce road subgrades with poor load-bearing capacity using timber logs;

- analysis of the existing road surface construction over a substrate of timber logs;

- analysis and testing of wood samples taken from selected road substrates.

2. Material and Methods

Data on forest roads constructed with timber log substrates were obtained from the information system and interviews with staff of forest districts of the State Forests in Poland. After a preliminary selection, roads were indicated for further verification in the field, their pavement construction and the construction technology used, and the result of this work was the establishment of test sections. In the test sections, field tests of the wood embedded in the road bed were conducted and samples were taken for laboratory tests.

Their acquisition was preceded by a thorough analysis of the documentation, including the composition and construction of the road, soil type and field interviews—information obtained from the landowner on the annual moisture levels of a given area and groundwater levels.

On the basis of data from the forest inspectorates (forestry management) and field verifications of roads reinforced with wooden logs in areas of poor bearing soil, four forest inspectorates were selected for the road studies, where seven test sections were established.

The choice of road was determined by the following factors:

- the value and character must indicate a sufficiently high stream a heavy loads (so that the section is a transport road and not an operating/harvesting track),

- heavy vehicles must use the road (high-tonnage timber transport vehicles or others),

- the minimum width over which the reinforcement is applied is the width of the roadway,

- the timber logs were covered with foreign material or native soil,

- the character of the forest habitats is varied,

- the length of the reinforced section is appropriate for the study.

The characteristics of selected study plots are presented in Table 1.

Table 1.

Characteristics of forest road construction on a subgrade reinforced with timber logs.

Wooden elements from the pavement and substrate of the forest roads placed in shallow layers of soil are mainly functioning in hazard class 4 according to EN 335:2013 standard [13]. Class 4 is a very high threat category (favorable conditions for extensive threat) to the attack and decay of wood by fungi—this is the main cause of its destruction.

Each examined section of the roads (study plots) was excavated to reveal its wooden base. Individual layers of the roads construction were measured (thickness) and described. Samples in the form of disks were taken from whole sections of the timber logs at a distance of at least 30 cm from their tops, from knotless zones. In order for the samples to be representative of the entire wooden road surface and substrate, their collection was preceded by an organoleptic assessment of the condition of the wood were made using a metal millimeter probe in accordance with EN 252:214 [20].

In order to assess the degree of wood degradation and loss of its values, the appropriate indicators of this process need to be selected. For the purpose of this study, the loss of wood density, modulus of elasticity and compression strength parallel to the grain were the indicators considered.

Due to the absence of data on the initial properties of the wood examined (its properties before being laid in the road), they were determined indirectly. For this purpose, the width of annual increments was determined from the cross-section (from an area of the log with no defects, i.e., in the cross-section without knots) [21]. The width of annual growth increments in wet wood can be considered as a fixed (constant) feature. On this basis, using known correlations [22,23,24,25,26], the expected (initial) density and compressive strength parallel to the grain were determined. In order to confirm these values, a supplemental element was the reference wood taken from a tree stand near the log-reinforced road (it should be assumed that the wood used for road construction was not transported over long distances and that local raw material was used). The reference wood was taken from the same tree species as the wood extracted from the road substrate and had similar graininess and cambial age.

After seasoning (drying to an air-dry state), rectangular samples with cross-sectional dimensions of 20 × 20 mm and a length (length parallel to the grain) of 60 mm were cut out from the disk of the obtained log. The specimens were cross-cut (ISO 3129:2012) [27] from the core to the original circumference of the log. After conditioning (to about 12% moisture content), wood density (ISO 13061-2:2014) [28] and compression strength parallel to the grain (ISO/DIS 13061-17) [29] were tested.

Slightly longer samples of 60 mm in length than the 30 mm required for the compression strength test allow for the modulus of elasticity to also be tested during the compression test parallel to the grain.

The obtained results were also statistically analyzed. For the individual properties of the wood, the results of the tests were statistically elaborated, i.e., arithmetic mean, standard deviation, coefficient of variation as well as the percentage index of the precision of the test at the confidence level of 0.95) were determined.

To assess the state of the preservation of the wood (its degradation), a 4-point scale of initial property loss (density, modulus of elasticity parallel to the grain and compression strength parallel to the grain) was adopted:

- level 1—if the value of the given property has not changed (fluctuations up to 5%), it is full value wood (undegraded);

- level 2—if the value of the given property is reduced by 5–25%, the wood is partially degraded;

- level 3—if the value of the property is reduced by 25–50%, the wood is severely degraded,

- level 4—if the value of the property is reduced by more than 50%, the wood is destroyed.

Additionally, we investigated the possibility of using X-ray computed tomography to assess the quality of the wood—the degree of its degradation. The tomography was performed with the use of Nueusoft X-ray computed tomography with an integrated DAS system detector (16-row tomography—activation of 16 layers at one gantry rotation in 0.5 s—minimum resolution of 0.75 mm)—with the following measurement bases: HFP, 120 kV, 40 mA, CTDI val.:40, 3mGy, Helical scanning mode without contrast, 1 mm thickness of the scanned layer, up to 40 cm diameter of the objects.

3. Results and Discussion

Test Sections

Among the 4 types of wood analyzed, the highest natural durability was observed for oak heartwood (class 2), while the lowest durability, regardless of the type of wood, was observed for sapwood (class 5). A full description of the natural durability of wood taken from the roads in accordance with the EN 350:2016 classification [14] is provided in Table 2.

Table 2.

Natural resistance of selected types of wood to fungi—five-step classification and ease of impregnation in accordance with the data in EN 350:2016 [14].

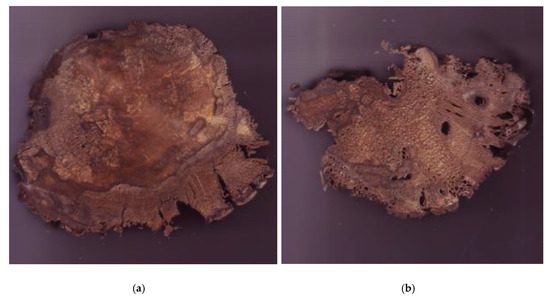

The moisture content of wood in the substrate of all analyzed forest roads (test sections) was high, i.e., over 50%. This was wet wood with a moisture content above the fiber saturation point, sometimes, especially in the sapwood zone, reaching even more than 200%, which indicates, at least indirectly, the partial degradation of its structure. Cross-sections of selected samples (wood disks) were typical for a given test section (Figure 1, Figure 2, Figure 3, Figure 4 and Figure 5).

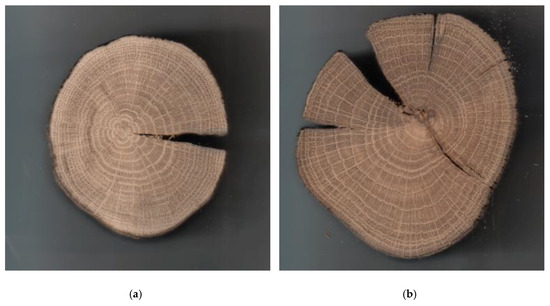

Figure 1.

Full cross sections of typical oak wood samples taken from section KRW2 of the forest road in Rogóźno Forest District of the Koło Forest Inspectorate: (a) sample no. Db4-KRW2, (b) sample no. Db5-KRW2.

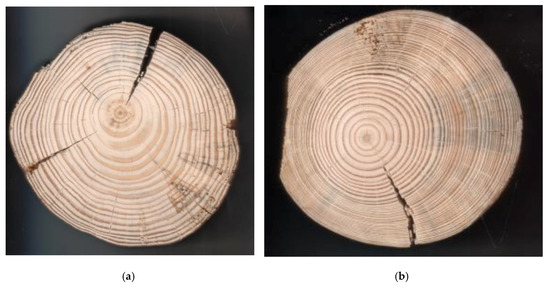

Figure 2.

Cross-sections of typical pine wood samples taken from the forest road of the Koło Forest Inspectorate: (a) from section KRW1 of Rogóźno Forest District—sample So1-KRW1, (b) from section KLG2 of Lipie Góry Forest District—sample no. So1-KLG2.

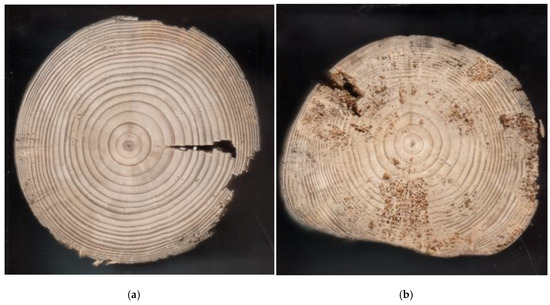

Figure 3.

Full cross-sections of spruce wood samples taken from the forest road in section SW of Czereszenka Forest District in the Stuposiany Forest Subdistrict: (a) sample no. Sw2-SW, (b) sample no. Sw6-SW.

Figure 4.

Cross-sections of spruce wood samples taken from the forest road in section OGW of Graszk Forest District in the Olsztyn Forest Inspectorate: (a) sample no. Sw1-OGW, (b) sample no. Sw3-OGW.

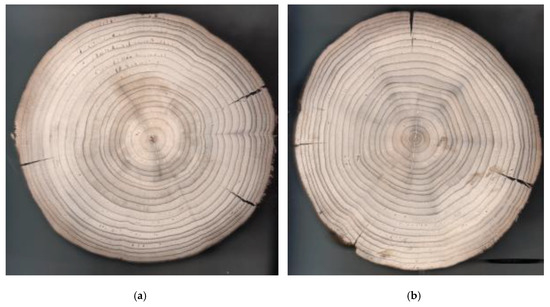

Figure 5.

Cross-sections of typical (representative) samples of alder wood from section LW of the forest road in Chmiel Forest District of the Lutowiska Forest Inspectorate: (a) sample no. Ols2-LW, (b) sample no. Ols3-LW,

The oak wood (Figure 1) extracted from the forest roads of Rogóźno Forest District (section marked KR2W) in the Koło Forest Subdistrict was only heartwood, except for one sample—only the heartwood survived, with the sapwood completely decayed by fungi. These elements had small diameters, because the original share of sapwood in the volume of the wood was significant and can be estimated at about 25% to 50%. The heartwood, apart from radially running cracks, did not show any visual signs of damage. Wood from all the elements taken was juvenile wood, which mainly consisted of annual core growth increments.

Oak samples obtained from the forest road in an air-dried state (moisture content ca. 12%) showed a strict dependence of their density on graininess. As the width of the annual growth increments increased, starting from 2.3 mm to 4.7 mm, the average density of the wood increased, from 641 to 766 kg/m3. The reference wood of oak heartwood with a 2.9 mm grain size had a density of 640 kg/m3. According to the data in the literature [23,24], oak wood with such a grain value should have a density at the level of 620–650 kg/m3. The higher density of the wood extracted from the forest road is most probably due to its partial mineralization, which is confirmed by its distinctly darker color. The obtained compressive strength of this wood does not exceed that of the contemporary reference wood, whereas the modulus of elasticity is slightly higher.

To summarize, the heartwood of the oak elements from the forest road was fully preserved, while the sapwood was completely decomposed. Due to the significant volume share of sapwood in juvenile wood (up to 50%), we can consider that these elements were heavily degraded.

The pine wood (Figure 2a) obtained from the Rogóźno Forest District (section KR1W) of the Koło Forest Subdistrict is diversified in terms of average grain size: from 4.3 mm to 6.2 mm. In accordance with the typical dependence found for coniferous wood, samples with wider growth increments showed lower density, compression strength and modulus of elasticity. According to the dependencies provided in the literature [23,24], air-dried pine wood with a grain size of approx. 6.2 mm is characterized by a density of 350 kg/m3, and a grain size of approx. 4.3 mm has a density of 440 kg/m3. Analyzing the compression strength parallel to the grain of visually undamaged elements, the test values obtained are in accordance with the dependencies provided in the literature [22,31]. Samples showing that about 5% of their cross-sectional area was damaged by fungi had an average compression strength of about 39 MPa compared to the expected 45 MPa (a decrease of about 15%). In summary, using the density criterion, we can conclude that pine wood from the forest road in the Rogóźno Forest District of the Koło Forest Subdistrict is practically healthy (undamaged).

To summarize, on the basis of the pine wood tests, we can conclude that the pine wood has generally maintained its durability, but that elements with slightly reduced durability are present.

Pine wood (Figure 2b) from section KLG1 of the forest road in Lipie Góry Forest District of the Koło Forest Subdistrict does not show any signs of decay, whereas pine wood from section KLG2 is destroyed in about 5% of its area—mainly the sapwood.

Applying analogous assessment rules, we should assume that the narrow-grained pinewood from the forest road in Lipie Góry Forest District of the Koło Forest Inspectorate from sections KLG1 and KLG2 is partially degraded (there was a decrease in the density from 10% (KLG1W) to approx. 20% (KLG2W). Partial degradation is also evidenced by the increased coefficients of variation of the examined traits.

The study of spruce wood (Figure 3) from the forest road in Czereszenka Forest District (section SW) of the Stuposiany Forest Subdistrict indicates that it was partially infested by fungi and its preservation condition was varied. 40% of the samples had no visual changes, 20% showed partial changes and the remaining 40% showed strong changes. Samples having an unchanged visible appearance with an average graininess of 2.4 to 3.3 mm exhibited an average density of 382 to 522 kg/m3. At the given graininess and moisture content, healthy spruce wood should have an average density of about 390 to 500 kg/m3 [24,32]. Given the above, we can assume that the wood from these elements did not change significantly—it remained undamaged.

Using analogous comparisons of spruce wood exhibiting extensive changes visually is characterized by lover density. For example, heavily changed spruce wood had an average density of about 300 kg/m3 with an average grain size of 2.9 mm. Healthy spruce wood should have an average density of approx. 400 to 440 kg/m3 at the specified grain size and moisture content [24,32]. The density of the examined wood represents only about 70% of the density of healthy spruce wood at a comparable grain size. This is fully confirmed by the obtained compressive strength, where the mean value is only 23.5 MPa compared to the expected 53 MPa in healthy wood [22].

This comparison is fully confirmed by the results of the reference spruce wood, where at a slightly larger average annual growth increment width of 3.7 mm, a significantly higher density of approx. 500 kg/m3, a compression strength parallel to the grain of approx. 56 MPa and modulus of elasticity of approx. 4000 MPa were obtained.

Spruce wood from the forest road in Graszk Forest District of the Olsztyn Forest Subdistrict from the section marked OGW is wide-grained wood with an average width of annual growth increments of more than 4.5 mm. The density is appropriate to the width of the annual growth increments and is approximately 360 kg/m3 on average. The wood is still healthy and has not been damaged (Figure 4).

Alder wood (Figure 5) from the forest road in section LW of Chmiel Forest District in the Lutowiska Forest Inspectorate shows an advanced stage of decomposition by fungi covering practically 100% of the cross-section of the samples obtained.

Alder wood taken from section LW of the forest road in Chmiel Forest District of the Lutowiska Forest Subdistrict is heavily degraded, which translates into a drastic decrease in the density of this wood as well as in the modulus of elasticity and compression strength parallel to the grain. The wood of alder, as a scattered vascular species, shows low variability in the width of annual growth increments. This factor has little influence on the physical and mechanical properties of this wood species [Kollmann and Cote 1984]. Relating the features of the wood from the forest road to the reference alder wood, a decrease in density from 25% to over 60% is visible. In the case of alder, the values of the coefficients of variation for density, compression strength and modulus of elasticity also indicate the degree of wood degradation. The higher the value of these coefficients, the greater the damage to the wood.

The obtained average results of the tested features are presented in Table 3.

Table 3.

Results of selected physical and mechanical properties of wood from forest roads and references—mean value (standard deviation).

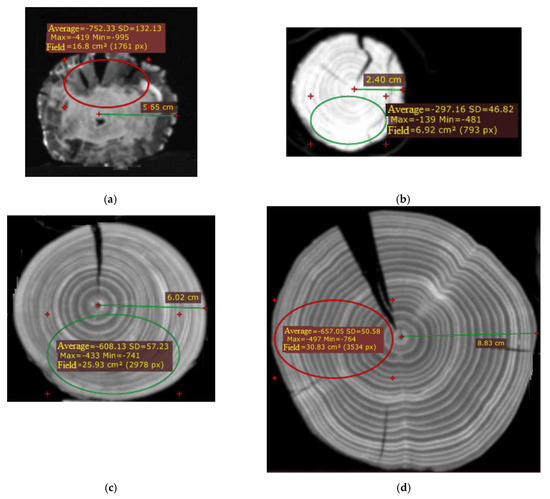

Within a pilot trial, the possibility of using X-ray computed tomography to reach conclusions on the state of the preservation of wood from forest road substrates was tested. Examples of the reconstructions of cross-sectional images of wood are shown in Figure 6. The brighter areas correspond to higher material density, e.g., latewood zones, and the darker areas to lower density, e.g., earlywood zones. These images can be used to read, among other things, annual growth patterns and, more importantly, the Hounsfield scale density for any area. After using the Hounsfield density scale on the reference samples, the results were converted to actual densities in kg/m3, which confirmed the previous findings. The resulting images provide information, among others, about the size and arrangement of wood defects. For example, “blurred” annual growth increments and darker areas are zones of wood damaged by decay.

Figure 6.

Computed tomographic reconstruction of a cross-sectional image (lighter shade of grey corresponds to higher wood density): (a) alder wood sample Ols1–LW, (b) oak wood sample Db3–KR2W, (c) pine wood sample So2–KR1W, (d) spruce wood sample Sw2–OGW.

On the basis of the obtained results, we found that the material taken from the elements of the forest roads showed a high variability of properties. The obtained results of density, modulus of elasticity and compressive strength parallel to the grain (at a stabilized moisture content of about 12%) are significantly influenced, apart by graininess, also by the wood zone from which the samples were obtained, sapwood and hardwood as well as mature circumferential wood and juvenile core wood, including up to 20 first annual growth increments (shorter structural elements and a greater angle of inclination of the cellulose fibrils [33]). In coniferous species, a strong dependence of strength properties on wood graininess and density may be additionally disturbed by excessive resin content or the presence of sclerenchyma, and in deciduous species by the presence of tension wood.

For the construction of new roads where test sections are to be selected, it would be appropriate to perform twin samples (one used for the construction of the road and one stored in dry conditions), which could be an excellent reference point for comparison in the future, replacing the wood currently harvested but far from perfect as a reference. Analyzes regarding the estimation of wooden forest road construction and their technical specifications (e.g., surface bearing capacity) and useful life of this roads were the subject of another publication [12].

It should also be noted the durability of the wood depends of environmental conditions, the characteristics of the wood and also affected by time. In the analyzed cases, probably the worst condition of alder wood resulted from its longest use on the road (almost 40 years). On the other hand, the spruce wood used for over 20 years was in a similar condition as the pine wood used for only 5 years.

4. Conclusions

Field studies are decisive for assessing the durability of wood. It is necessary to carefully visualize and measure the samples of the elements when they are taken so that they are representative of the forest road and allow the reference wood to be precisely selected. Due to the high natural variability of wood characteristics within a single species or even a single tree trunk, the reference material must be harvested from trees of the same cambial age and have similar visual characteristics (graininess, position of the core, possible defects) as the samples of wood taken from the pavement and substrate of a forest road.

The decay caused by fungi is not uniform—it is most intensive in the surface layers and especially on the top of the elements, therefore, in order to assess the durability of the wood and especially to verify this, several features need to be examined (density, compression strength, modulus of elasticity). Moreover, due to the individual character of the natural durability and the individual character of the dependence of particular features on wood graininess, each tree species should be considered separately, taking into account the following wood zones: sapwood and heartwood, as well as juvenile and mature wood.

On the basis of the conducted research, we found that in terms of durability and strength, the heartwood of oak is the most useful for the construction of forest road pavements and substrates. The next in order is pine wood, then spruce wood, and the least useful is alder wood. In addition to the natural durability of a species, the good condition of the wood is influenced primarily by the conditions in which it is used. Wooden substrates and pavements of forest roads are best suited in marshy areas.

Author Contributions

P.K. and G.T. performed all the elements of the manuscript together. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Directorate General of State Forests, grant number nr 1830 (ER-0333-1/14).

Acknowledgments

Research was in cooperation with the Centre for Development and Implementation of National Forests in Bedoń.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Miler, A.T.; Czerniak, A.; Grajewski, S.; Kamiński, B.; Okoński, B. Marshlands of “LasyRychtalskie” forest promotion complex—Present state and perspective of changes. Infrastruct. Ecol. Rural. Areas 2007, 3, 21–36. Available online: http://www.infraeco.pl/pl/art/a_15119.htm?plik=289 (accessed on 14 December 2019).

- Saunders, S.C.; Mislivets, M.R.; Chen, J.; Cleland, D.T. Effects of roads on landscape structure within nested ecological units of the Northern Great Lakes Region, USA. Biol. Conserv. 2002, 103, 209–225. [Google Scholar] [CrossRef]

- Demi, M. Impacts, management and functional planning criterion of forest road network system in Turkey. Transp. Res. Part A Policy Pract. 2007, 41, 56–68. [Google Scholar] [CrossRef]

- Lugo, A.E.; Gucinski, H. Function, effects, and management of forest roads. For. Ecol. Manag. 2000, 133, 249–262. [Google Scholar] [CrossRef]

- Dunn, R.R.; Danoff-Burg, J.D. Road size and carrion beetle assemblages in a New York forest. J. Insect Conserv. 2007, 11, 325–332. [Google Scholar] [CrossRef]

- Devlin, G.J.; McDonnell, K.; Ward, S. Timber haulage routing in Ireland: an analysis using GIS and GPS. J. Transp. Geogr. 2008, 16, 63–72. [Google Scholar] [CrossRef]

- Palander, T.; Kärhä, K. Potential traffic levels after increasing the maximum vehicle weight in environmentally efficient transportation system: The Case of Finland. J. Sustain. Dev. Energy Water Environ. Syst. 2017, 5, 417–429. [Google Scholar] [CrossRef]

- Trzciński, G.; Moskalik, G.; Wojtan, R. Total Weight and Axle Loads of Truck Units in the Transport of Timber Depending on the Timber Cargo. Forests 2018, 9, 164. [Google Scholar] [CrossRef]

- Munro, R. Dealing with Bearing Capacity Problems on Low Volume Roads Constructed on Peat [online]. ROADEX II Project. Scotland. Available online: http://www.roadex.org/wp-content/uploads/2014/01/2_5-Roads-on-Peat_l.pdf (accessed on 14 December 2019).

- O’Mahony, M.J.; Ueberschaer, A.; Owende, P.M.O.; Ward, S.M. Bearing capacity of forest access roads built on peat soils. J. Terramechanics 2000, 37, 127–138. [Google Scholar] [CrossRef]

- Martin, A.M.; Owende, P.M.O.; O’Mahony, M.J.; Ward, S.M. Estimation of the serviceability of forest access roads. J. For. Eng. 1999, 10, 55–61. [Google Scholar]

- Trzciński, G.; Kozakiewicz, P.; Selwakowski, R. The technical aspects of using timber in the construction of forest roads. J. Water Land Dev. 2017, 34, 241–247. [Google Scholar] [CrossRef]

- EN 335 Durability of Wood and Wood-Based Products—Use Classes: Definitions, Application to Solid Wood and Wood-Based Products; CEN (European Committee for Standardization): Brussels, Belgium, 2013.

- EN 350 Durability of Wood and Wood-Based Products—Testing and Classification of the Durability to Biological Agents of Wood and Wood-Based Materials; CEN (European Committee for Standardization): Brussels, Belgium, 2016.

- Jensen, P.; Gregory, D.J. Selected physical parameters to characterize the state of preservation of waterlogged archaeological wood: A practical guide for their determination. J. Archaeol. Sci. 2006, 33, 551–559. [Google Scholar] [CrossRef]

- Kim, Y.S.; Singh, A.P. Micromorphological characteristics of wood biodegradation in wet environments: A review. IAWA J. 2000, 21, 135–155. [Google Scholar] [CrossRef]

- Singh, A.P. A review of microbial decay types found in wooden objects of cultural heritage recovered from buried and waterlogged environments. J. Cult. Herit. 2012, 13, 16–20. [Google Scholar]

- Zborowska, M.; Babiński, L.; Gajewska, J.; Waliszewska, B.; Prądzyński, W. Physical and chemical properties of contemporary pine wood (Pinus sylvestris L.) in conditions of a wet archaeological site in Biskupin. Folia For. Pol. B 2007, 38, 13–26. [Google Scholar]

- Mańkowski, P.; Kozakiewicz, P.; Drożdżek, M. The selected properties of fossil oak wood from medieval burgh in Płońsk. Wood Res. 2016, 61, 287–298. Available online: http://www.centrumdp.sk/wr/201602/12.pdf (accessed on 14 December 2019).

- EN 252 Field Test Method for Determining the Relative Protective Effectiveness of a Wood Preservative in Ground Contact; CEN (European Committee for Standardization): Brussels, Belgium, 2014.

- PN-D-04110 Fizyczne i mechaniczne własności drewna—Badanie procentowego udziału drewna wczesnego i późnego (in Polish); Physical and mechanical properties of wood—Investigation of the percentage early and late wood; PKN (Polski Komitet Normalizacyjny): Warsaw, Poland, 1995.

- Vorreiter, L. Holztechnologisches Handbuch. Band I: Allgemeines, Holzkunde, Holzschutz und Holzvergütung; Verlag Georg Fromme& Co.: Wien, Austria, 1949. [Google Scholar]

- Kollmann, F.; Cote, W. Principles of Wood Science and Technology. Volume I: Solid Wood; Springer: Berlin/Heidelberg, Germany; New York, NY, USA; Tokyo, Japan, 1984. [Google Scholar]

- Trendelenburg, R.; Mayer-Wegelin, H. Das Holz als Rohstoff. 2. Vollig überarbeitete Ahflage; Carl Hanser Verlag: Munchen, Germany, 1955. [Google Scholar]

- Dzbeński, W. Kryteria oceny technicznych własności dębowego drewna wykopaliskowego. Zeszyty Naukowe Szkoly Glownej Gospodarstwa Wiejskiego, Lesnic-two (Forrestry) 1970, 14, 171–190. [Google Scholar]

- Krzysik, F. Nauka o Drewnie. (in Polish) Wood Science; PWN: Warsaw, Poland, 1978. [Google Scholar]

- ISO 3129. Wood-Sampling Methods and General Requirements for Physical and Mechanical Testing Of Small Clear Wood Specimens; ISO (International Organization for Standardization): Geneva, Switzerland, 2012.

- ISO 13061-2. Physical and Mechanical Properties of Wood—Test Methods for Small Clear Wood Specimens. Part 2: Determination of Density for Physical and Mechanical Tests; ISO (International Organization for Standardization): Geneva, Switzerland, 2014.

- ISO/DIS 13061-17. Physical and Mechanical Properties of Wood—Test Methods for Small Clear Wood Specimens—Part 17: Determination of Ultimate Stress in Compression Parallel To Grain; ISO (International Organization for Standardization): Geneva, Switzerland, 2015.

- EN 13556 Round and Sawn Timber—Nomenclature of Timbers Used in Europe; CEN (European Committee for Standardization): Brussels, Belgium, 2003.

- Kozakiewicz, P. Wpływ Temperatury i Wilgotności na Wytrzymałość na ściskanie wzdłuż włókien wybranych rodzajów drewna o zróżnicowanej gęstości i budowie anatomicznej. Effect of Temperature and Moisture Content on Compression Strength Parallel to the Grain of Selected Species of Wood with Variable Density and Anatomical Structures; SGGW: Warsaw, Poland, 2010. [Google Scholar]

- Kozakiewicz, P.; Matejak, M. Klimat a Drewno Zabytkowe. Dawna i Współczesna Wiedza o drewnie. Climate and Antique Wood—Past and Contemporary Knowledge about Wood; SGGW: Warsaw, Poland, 2013. [Google Scholar]

- Roszyk, E. Wilgotnościowe i ultrastrukturalne uwarunkowania parametrów Mechanicznych Drewna Sosny (Pinus sylvestris L.) rozciąganego wzdłuż włókien. Mechanical Parameters of Scots Pine Wood (Pinus sylvestris L.) upon Tensile Stress along the Grains in Relation to its Moisture Content and Ultrastructure; Poznan University of Life Sciences: Poznan, Poland, 2016. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).