Comparative Life Cycle Assessment of Bioenergy Production from Different Wood Pellet Supply Chains

Abstract

1. Introduction

2. Materials and Methods

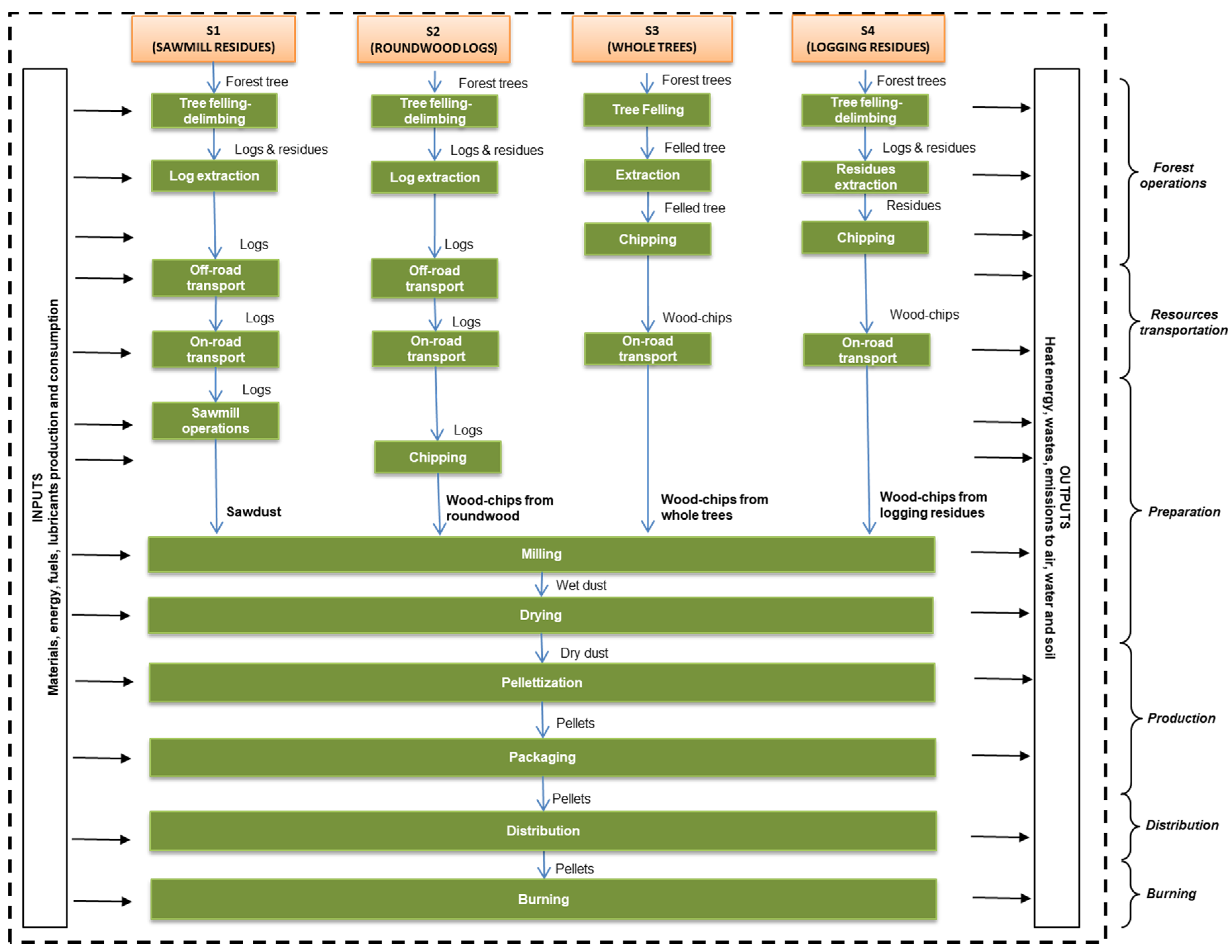

2.1. System Description and Data Collection

3. Results

3.1. Global Warming Potential (GWP)

3.2. Ozone Depletion Potential (ODP)

3.3. Photochemical Ozone Creation Potential (POCP)

3.4. Human Toxicity Potential (HTP)

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- European Commission 2030. Climate and Energy Framework. Available online: https://ec.europa.eu/clima/policies/strategies/2030_en (accessed on 28 August 2020).

- Directive (EU) 2018/2001 of the European Parliament and of the Council of 11 December 2018 on the Promotion of the Use of Energy from Renewable Sources (Text with EEA Relevance.). 2018. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32018L2001 (accessed on 28 August 2020).

- Mandley, S.J.; Daioglou, V.; Junginger, H.M.; van Vuuren, D.P.; Wicke, B. EU bioenergy development to 2050. Renew. Sustain. Energy Rev. 2020, 127. [Google Scholar] [CrossRef]

- Directive 2009/28/EC of the European Parliament and of the Council of 23 April 2009 on the Promotion of the Use of Energy from Renewable Sorurces and Amending and Subsequently Repealing Directives 2001/77/EC and 2003/30/EC (Text with EEA Relavance). 2009. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=CELEX%3A32009L0028 (accessed on 28 August 2020).

- European Commission’s Knowledge Centre for Bioeconomy. Brief on Biomass for Energy in the European Union; 2019; Available online: https://op.europa.eu/en/publication-detail/-/publication/7931acc2-1ec5-11e9-8d04-01aa75ed71a1 (accessed on 28 August 2020). [CrossRef]

- Calderón Cristina, C.; Colla Martin, C.; Jossart Jean-Marc, J.; Hemeleers Nathalie, H.; Cancian Giulia, C.; Aveni Nino, C.C. Statistical Report 2019, Pellet; Bioenergy Europe: Brussels, Belgium, 2019. [Google Scholar]

- Dhamodaran, A.; Afzal, M. Compression and springback properties of hardwood and softwood pellets. BioResources 2012, 7, 4362–4376. [Google Scholar]

- Mobini, M.; Meyer, J.C.; Trippe, F.; Sowlati, T.; Fröhling, M.; Schultmann, F. Assessing the integration of torrefaction into wood pellet production. J. Clean. Prod. 2014, 78, 216–225. [Google Scholar] [CrossRef]

- Thek, G.; Obernberger, I. The Pellet Handbook: The Production and Thermal Utilization of Biomass Pellets, 1st ed.; Earthscan: London, UK; Washington, DC, USA, 2010; ISBN 978-1-84407-631-4. [Google Scholar]

- van Loo, S.; Koppejan, J. The Handbook of Biomass Combustion and Co-Firing; Earthscan: London, UK; Sterling, TX, USA, 2008; ISBN 978-1-84407-249-1. [Google Scholar]

- Lewandowski, I.; Weger, J.; van Hooijdonk, A.; Havlickova, K.; van Dam, J.; Faaij, A. The potential biomass for energy production in the Czech Republic. Biomass Bioenergy 2006, 30, 405–421. [Google Scholar] [CrossRef]

- Valente, C.; Spinelli, R.; Hillring, B.G. LCA of environmental and socio-economic impacts related to wood energy production in alpine conditions: Valle di Fiemme (Italy). J. Clean. Prod. 2011, 19, 1931–1938. [Google Scholar] [CrossRef]

- Sacchelli, S.; Bernetti, I.; De Meo, I.; Fiori, L.; Paletto, A.; Zambelli, P.; Ciolli, M. Matching socio-economic and environmental efficiency of wood-residues energy chain: A partial equilibrium model for a case study in Alpine area. J. Clean. Prod. 2014, 66, 431–442. [Google Scholar] [CrossRef]

- Giuntoli, J.; Caserini, S.; Marelli, L.; Baxter, D.; Agostini, A. Domestic heating from forest logging residues: Environmental risks and benefits. J. Clean. Prod. 2015, 99, 206–216. [Google Scholar] [CrossRef]

- Hurteau, M.; North, M. Fuel treatment effects on tree-based forest carbon storage and emissions under modeled wildfire scenarios. Front. Ecol. Environ. 2009, 7, 409–414. [Google Scholar] [CrossRef]

- Ganguly, I.; Pierobon, F.; Bowers, T.C.; Huisenga, M.; Johnston, G.; Eastin, I.L. ‘Woods-to-Wake’ Life Cycle Assessment of residual woody biomass based jet-fuel using mild bisulfite pretreatment. Biomass Bioenergy 2018, 108, 207–216. [Google Scholar] [CrossRef]

- Pierobon, F.; Eastin, I.L.; Ganguly, I. Life cycle assessment of residual lignocellulosic biomass-based jet fuel with activated carbon and lignosulfonate as co-products. Biotechnol. Biofuels 2018, 11. [Google Scholar] [CrossRef]

- Cherubini, F.; Bird, N.D.; Cowie, A.; Jungmeier, G.; Schlamadinger, B.; Woess-Gallasch, S. Energy- and greenhouse gas-based LCA of biofuel and bioenergy systems: Key issues, ranges and recommendations. Resour. Conserv. Recycl. 2009, 53, 434–447. [Google Scholar] [CrossRef]

- Guest, G.; Bright, R.M.; Cherubini, F.; Michelsen, O.; Strømman, A.H. Life cycle assessment of biomass-based combined heat and power plants: Centralized versus decentralized deployment strategies. J. Ind. Ecol. 2011, 15, 908–921. [Google Scholar] [CrossRef]

- Magelli, F.; Boucher, K.; Bi, H.T.; Melin, S.; Bonoli, A. An environmental impact assessment of exported wood pellets from Canada to Europe. Biomass Bioenergy 2009, 33, 434–441. [Google Scholar] [CrossRef]

- Fantozzi, F.; Buratti, C. Life cycle assessment of biomass chains: Wood pellet from short rotation coppice using data measured on a real plant. Biomass Bioenergy 2010, 34, 1796–1804. [Google Scholar] [CrossRef]

- Katers, J.F.; Snippen, A.J.; Puettmann, M.E. Life-cycle inventory of wood pellet manufacturing and utilization in Wisconsin. For. Prod. J. 2012, 62, 289–295. [Google Scholar] [CrossRef]

- Pa, A.; Craven, J.S.; Bi, X.T.; Melin, S.; Sokhansanj, S. Environmental footprints of British Columbia wood pellets from a simplified life cycle analysis. Int. J. Life Cycle Assess. 2012, 17, 220–231. [Google Scholar] [CrossRef]

- Hossain, M.U.; Leu, S.Y.; Poon, C.S. Sustainability analysis of pelletized bio-fuel derived from recycled wood product wastes in Hong Kong. J. Clean. Prod. 2016, 113, 400–410. [Google Scholar] [CrossRef]

- Laschi, A.; Marchi, E.; González-García, S. Environmental performance of wood pellets’ production through life cycle analysis. Energy 2016, 103, 469–480. [Google Scholar] [CrossRef]

- Pergola, M.; Gialdini, A.; Celano, G.; Basile, M.; Caniani, D.; Cozzi, M.; Gentilesca, T.; Mancini, I.M.; Pastore, V.; Romano, S.; et al. An environmental and economic analysis of the wood-pellet chain: Two case studies in Southern Italy. Int. J. Life Cycle Assess. 2018, 23, 1675–1684. [Google Scholar] [CrossRef]

- Quinteiro, P.; Greco, F.; da Cruz Tarelho, L.A.; Righi, S.; Arroja, L.; Dias, A.C. A comparative life cycle assessment of centralised and decentralised wood pellets production for residential heating. Sci. Total Environ. 2020, 730. [Google Scholar] [CrossRef] [PubMed]

- Sjølie, H.K.; Solberg, B. Greenhouse gas emission impacts of use of Norwegian wood pellets: A sensitivity analysis. Environ. Sci. Policy 2011, 14, 1028–1040. [Google Scholar] [CrossRef]

- Murphy, F.; Devlin, G.; McDonnell, K. Greenhouse gas and energy based life cycle analysis of products from the Irish wood processing industry. J. Clean. Prod. 2015, 92, 134–141. [Google Scholar] [CrossRef]

- Buchholz, T.; Gunn, J.S.; Saah, D.S. Greenhouse gas emissions of local wood pellet heat from northeastern US forests. Energy 2017, 141, 483–491. [Google Scholar] [CrossRef]

- Taskhiri, M.S.; Garbs, M.; Geldermann, J. Sustainable logistics network for wood flow considering cascade utilisation. J. Clean. Prod. 2016, 110, 25–39. [Google Scholar] [CrossRef]

- Röder, M.; Whittaker, C.; Thornley, P. How certain are greenhouse gas reductions from bioenergy? Life cycle assessment and uncertainty analysis of wood pellet-to-electricity supply chains from forest residues. Biomass Bioenergy 2014, 79, 50–63. [Google Scholar] [CrossRef]

- McManus, M.C. Life cycle impacts of waste wood biomass heating systems: A case study of three UK based systems. Energy 2010, 35, 4064–4070. [Google Scholar] [CrossRef]

- Lippke, B.; Oneil, E.; Harrison, R.; Skog, K.; Gustavsson, L.; Sathre, R. Life cycle impacts of forest management and wood utilization on carbon mitigation: Knowns and unknowns. Carbon Manag. 2011, 2, 303–333. [Google Scholar] [CrossRef]

- McKechnie, J.; Colombo, S.; Chen, J.; Mabee, W.; MacLean, H.L. Forest bioenergy or forest carbon? Assessing trade-offs in greenhouse gas mitigation with wood-based fuels. Environ. Sci. Technol. 2011, 45, 789–795. [Google Scholar] [CrossRef]

- Whittaker, C.; Mortimer, N.; Murphy, R.; Matthews, R. Energy and greenhouse gas balance of the use of forest residues for bioenergy production in the UK. Biomass Bioenergy 2011, 35, 4581–4594. [Google Scholar] [CrossRef]

- Routa, J.; Kellomäki, S.; Strandman, H. Effects of forest management on total biomass production and CO2 emissions from use of energy biomass of Norway Spruce and Scots Pine. BioEnergy Res. 2012, 5, 733–747. [Google Scholar] [CrossRef]

- Helin, T.; Sokka, L.; Soimakallio, S.; Pingoud, K.; Pajula, T. Approaches for inclusion of forest carbon cycle in life cycle assessment—A review. GCB Bioenergy 2013, 5, 475–486. [Google Scholar] [CrossRef]

- Levasseur, A.; Lesage, P.; Margni, M.; Deschěnes, L.; Samson, R. Considering time in LCA: Dynamic LCA and its application to global warming impact assessments. Environ. Sci. Technol. 2010, 44, 3169–3174. [Google Scholar] [CrossRef] [PubMed]

- Cherubini, F.; Peters, G.P.; Berntsen, T.; Strømman, A.H.; Hertwich, E. CO2 emissions from biomass combustion for bioenergy: Atmospheric decay and contribution to global warming. GCB Bioenergy 2011, 3, 413–426. [Google Scholar] [CrossRef]

- Brandão, M.; Levasseur, A.; Kirschbaum, M.U.F.; Weidema, B.P.; Cowie, A.L.; Jørgensen, S.V.; Hauschild, M.Z.; Pennington, D.W.; Chomkhamsri, K. Key issues and options in accounting for carbon sequestration and temporary storage in life cycle assessment and carbon footprinting. Int. J. Life Cycle Assess. 2013, 18, 230–240. [Google Scholar] [CrossRef]

- Cherubini, F.; Fuglestvedt, J.; Gasser, T.; Reisinger, A.; Cavalett, O.; Huijbregts, M.A.J.; Johansson, D.J.A.; Jørgensen, S.V.; Raugei, M.; Schivley, G.; et al. Bridging the gap between impact assessment methods and climate science. Environ. Sci. Policy 2016, 64, 129–140. [Google Scholar] [CrossRef]

- Brandão, M.; Kirschbaum, M.U.F.; Cowie, A.L.; Hjuler, S.V. Quantifying the climate change effects of bioenergy systems: Comparison of 15 impact assessment methods. GCB Bioenergy 2019, 11, 727–743. [Google Scholar] [CrossRef]

- Ganguly, I.; Pierobon, F.; Hall, E.S. Global warming mitigating role of wood products from Washington state’s private forests. Forests 2020, 11, 194. [Google Scholar] [CrossRef]

- ISO (International Organisation for Standardization). Norm ISO 17225-1:2014. Solid Biofuel. Fuel Specifications and Classes; Part 1: General Requirements; ISO (International Organisation for Standardization): Geneva, Switzerland, 2014. [Google Scholar]

- ISO (International Organisation for Standardization). Norm ISO 17225-2:2014. Solid Biofuel. Fuel Specifications and Classes; Part 2: Graded Wood Pellet; ISO (International Organisation for Standardization): Geneva, Switzerland, 2014. [Google Scholar]

- ISO (International Organisation for Standardization). ISO 14040: 2006 Environmental Management—Life Cycle Assessment—Principles and Framework; ISO (International Organisation for Standardization): Geneva, Switzerland, 2006. [Google Scholar]

- ISO (International Organisation for Standardization). ISO 14044:2006. Environmental Management—Life Cycle Assessment—Requirements and Guidelines; ISO (International Organisation for Standardization): Geneva, Switzerland, 2006. [Google Scholar]

- Sphera Solutions GmbH. Part 1: What Is LCA, and How do You Carry out an LCA with GaBi? Available online: http://www.gabi-software.com/support/gabi-learning-center/gabi-learning-center/part-1-lca-and-introduction-to-gabi/ (accessed on 5 October 2020).

- Guinee, J.B.; Gorrée, M.; Heijungs, R.; Huppes, G.; Kleijn, R.; de Koning, A.; van Oers, L.; Wegener Sleeswijk, A.; Suh, S.; Udo de Haes, H.A.; et al. Handbook on Life Cycle Assessment. Operational Guide to the ISO Standards. I: LCA in Perspective. IIa: Guide. IIb: Operational Annex. III: Scientific Background; Guinee, J.B., Ed.; Kluwer Academic Publishers: Dordrecht, The Netherlands, 2002; ISBN 1-4020-0228-9. [Google Scholar]

- Frischknecht, R.; Jungbluth, N.; Althaus, H.-J.; Doka, G.; Dones, R.; Heck, T.; Al, E. The ecoinvent database: Overview and methodological framework. Int. J. Life Cycle Assess. 2005, 10, 3–9. [Google Scholar] [CrossRef]

- Boschiero, M.; Kelderer, M.; Schmitt, A.O.; Andreotti, C.; Zerbe, S. Influence of agricultural residues interpretation and allocation procedures on the environmental performance of bioelectricity production—A case study on woodchips from apple orchards. Appl. Energy 2015, 147. [Google Scholar] [CrossRef]

- Milota, M. CORRIM Report: Module B—Life Cycle Assessment for the Production of Pacific Northwest Softwood Lumber; 2015; Available online: https://www.corrim.org/wp-content/uploads/Module-B-PNW-Lumber.pdf (accessed on 2 October 2020).

- Cespi, D.; Passarini, F.; Ciacci, L.; Vassura, I.; Castellani, V.; Collina, E.; Piazzalunga, A.; Morselli, L. Heating systems LCA: Comparison of biomass-based appliances. Int. J. Life Cycle Assess. 2014, 19, 89–99. [Google Scholar] [CrossRef]

- Solli, C.; Reenaas, M.; Strømman, A.; Hertwich, E. Life cycle assessment of wood-based heating in Norway. Int. J. Life Cycle Assess. 2009, 14, 517–528. [Google Scholar] [CrossRef]

- Pierobon, F.; Zanetti, M.; Grigolato, S.; Sgarbossa, A.; Anfodillo, T.; Cavalli, R. Life cycle environmental impact of firewood production—A case study in Italy. Appl. Energy 2015, 150, 185–195. [Google Scholar] [CrossRef]

- Hansson, J.; Martinsson, F.; Gustavsson, M. Greenhouse gas performance of heat and electricity from wood pellet value chains—Based on pellets for the Swedish market. Biofuels Bioprod. Biorefining 2015, 9, 378–396. [Google Scholar] [CrossRef]

- Adams, P.W.R.; Shirley, J.E.J.; McManus, M.C. Comparative cradle-to-gate life cycle assessment of wood pellet production with torrefaction. Appl. Energy 2015, 138, 367–380. [Google Scholar] [CrossRef]

- Giuntoli, J.; Agostini, A.; Edwards, R.; Marelli, L. Solid and Gaseous Bioenergy Pathways: Input Values and GHG Emissions. Calculated According to the Methodology Set in COM(2016) 767; EUR 27215 EN, 2017; Publications Office of the European Union: Luxembourg, 2017. [Google Scholar] [CrossRef]

- AIEL (Associazione Italiana Energia Agroforestale). Mercati&prezzi. Available online: https://www.aielenergia.it/public/pubblicazioni/170_M_P_2-2020_ia.pdf (accessed on 2 October 2020).

- Visser, L.; Hoefnagels, R.; Junginger, M. Wood pellet supply chain costs—A review and cost optimization analysis. Renew. Sustain. Energy Rev. 2020, 118, 109506. [Google Scholar] [CrossRef]

| Unit | S1 | S2 | S3 | S4 | |

|---|---|---|---|---|---|

| Sawdust | Roundwood | Whole Trees | Logging Residues | ||

| Operation and machine characteristics | |||||

| Harvester | kW | 190 | 190 | 150 | 190 |

| Forwarder | kW | 180 | 180 | 180 | 180 |

| Chipper | kW | - | 132 | 335 | 335 |

| Sawmill | kWh t−1 | 90.5 | - | - | - |

| Hammer mill | kW | 350 | 350 | 350 | 350 |

| Dryer heat | kWh t−1 | 896 | 896 | 727 | 1097 |

| Conditioner | kW | 30 | 30 | 30 | 30 |

| Press | kW | 750 | 750 | 750 | 750 |

| Nominal press productivity | t h−1 | 10 | 10 | 10 | 10 |

| Real plant productivity | t h−1 | 8 | 4.5 | 10 | 8 |

| Cooler | kW | 50 | 50 | 50 | 50 |

| Sieve | kW | 81 | 81 | 81 | 81 |

| Internal transportation | kW | 220 × 2 | 220 × 3 | 220 × 2 | 220 × 2 |

| Ventilation and conveying system | kW | 100 | 100 | 100 | 100 |

| Packaging | kW | 90 | 90 | 90 | 90 |

| Boiler | kW | 50 | 50 | 50 | 50 |

| Pellet characteristics | |||||

| Moisture content | % | 8 | 8 | 8 | 8 |

| Net calorific value | MJ kg−1 | 16.74 | 16.56 | 17.28 | 17.64 |

| System Phases | Supply Chain Products | Mass Allocation Factors (%) | |||

|---|---|---|---|---|---|

| System Assessed | |||||

| S1 | S2 | S3 | S4 | ||

| Felling and delimbing | Logs | 67.5 | 67.5 | - | 67.5 |

| Residues | 32.5 | 32.5 | - | 32.5 | |

| Whole trees | - | - | 100 | - | |

| Debarking | Debarked logs | 90 | 90 | - | - |

| Bark | 10 | 10 | - | - | |

| Sawing | Lumber | 50 | - | - | - |

| Sawmill by-products | 50 | - | - | - | |

| Emissions | S1 | S2 | S3 | S4 |

|---|---|---|---|---|

| Sawdust | Roundwood | Whole Trees | Logging Residues | |

| GWP | g CO2eq | |||

| Emissions to air (total) | 187.97 | 185.70 | 159.84 | 195.79 |

| Carbon dioxide (biotic) | 160.36 | 160.25 | 144.94 | 177.89 |

| Carbon dioxide | 20.97 | 18.92 | 12.97 | 15.58 |

| Nitrous oxide | 1.33 | 1.31 | 1.18 | 1.42 |

| Methane (biotic) | 4.24 | 4.24 | 0.04 | 0.05 |

| Methane | 1.03 | 0.95 | 0.68 | 0.80 |

| Group NMVOC to air a | 0.03 | 0.03 | 0.03 | 0.05 |

| ODP | µg R11eq | |||

| Halogenated organic emissions to air b | 1.98 | 2.02 | 1.85 | 2.16 |

| POCP | mg Etheneeq | |||

| Emissions to air (total) | 19.82 | 19.45 | 16.88 | 20.98 |

| Carbon monoxide (biotic) | 2.49 | 2.49 | 2.34 | 2.70 |

| Group NMVOC to air | 7.41 | 7.44 | 7.53 | 9.44 |

| Nitrogen oxides | 4.98 | 4.89 | 4.29 | 5.40 |

| Carbon monoxide | 0.50 | 0.49 | 0.56 | 0.80 |

| Sulfur dioxide | 3.16 | 2.89 | 1.99 | 2.45 |

| Methane (biotic) | 1.02 | 1.02 | 0.01 | 0.01 |

| Methane | 0.25 | 0.23 | 0.16 | 0.19 |

| HTP | g DCBeq | |||

| Heavy metals to air c | 3.96 | 3.72 | 2.97 | 3.71 |

| Inorganic emissions to air d | 0.92 | 0.83 | 0.53 | 0.67 |

| Organic emissions to air (group VOC—volatile organic compound) | 14.54 | 14.46 | 13.36 | 16.57 |

| Polycyclic aromatic hydrocarbons (PAH) | 11.30 | 11.30 | 10.50 | 13.10 |

| Other organic emissions to air e | 3.13 | 3.05 | 2.76 | 3.35 |

| Halogenated organic emissions to air f | 0.11 | 0.11 | 0.10 | 0.13 |

| Particles | 1.01 × 10−1 | 9.89 × 10−2 | 8.39 × 10−2 | 1.11 × 10−1 |

| Dust (PM2.5) | 4.83 × 10−2 | 4.79 × 10−2 | 3.99 × 10−2 | 5.69 × 10−2 |

| Dust (>PM10) | 5.07 × 10−2 | 4.95 × 10−2 | 4.27 × 10−2 | 5.22 × 10−2 |

| Dust (PM2.5–PM10) | 1.60 × 10−3 | 1.50 × 10−3 | 1.31 × 10−3 | 1.60 × 10−3 |

| Silicon dust | 4.65 × 10−5 | 4.10 × 10−5 | 2.61 × 10−5 | 3.35 × 10−5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sgarbossa, A.; Boschiero, M.; Pierobon, F.; Cavalli, R.; Zanetti, M. Comparative Life Cycle Assessment of Bioenergy Production from Different Wood Pellet Supply Chains. Forests 2020, 11, 1127. https://doi.org/10.3390/f11111127

Sgarbossa A, Boschiero M, Pierobon F, Cavalli R, Zanetti M. Comparative Life Cycle Assessment of Bioenergy Production from Different Wood Pellet Supply Chains. Forests. 2020; 11(11):1127. https://doi.org/10.3390/f11111127

Chicago/Turabian StyleSgarbossa, Andrea, Martina Boschiero, Francesca Pierobon, Raffaele Cavalli, and Michela Zanetti. 2020. "Comparative Life Cycle Assessment of Bioenergy Production from Different Wood Pellet Supply Chains" Forests 11, no. 11: 1127. https://doi.org/10.3390/f11111127

APA StyleSgarbossa, A., Boschiero, M., Pierobon, F., Cavalli, R., & Zanetti, M. (2020). Comparative Life Cycle Assessment of Bioenergy Production from Different Wood Pellet Supply Chains. Forests, 11(11), 1127. https://doi.org/10.3390/f11111127