Abstract

It is challenging to quantify the production of wood-based biomass, to define the type and where it comes from, how it is used, and the amount that remains available. This information is crucial for the implementation of national and transnational regulations and is a pillar for the development of the future bio-based circular economy. A variety of studies estimate the production of biomass, performs material flow analyses, or addresses supply chain modelling. These studies are often built upon distinct assumptions, tailored to a specific purpose, and often poorly described. This makes comparison amongst studies, generalization of results, or replication hard to even impossible. This paper presents a comprehensive methodology for wood-based biomass material flow analysis, anchored in Material Flow Analysis, built upon literature review and deducted through systematization of previous studies. This is a five-step approach, consisting of (1) adopt proper terminology; (2) obtain accurate estimates for the biomass flows; (3) Sankey diagram for resource balance representation; (4) scenario analysis; (5) stakeholders validation. The focus is to provide instructions for producing a generalized Sankey diagram, from the categorization of biomass resources, uses/applications in a circular economy setting, towards the development of scenario analysis. Its practical implementation is presented by defining the yearly wood-based biomass resource balance of Portugal and the waste wood resource balance of Flanders. The main data sources for the quantification of the biomass sources and uses/applications are identified. Based on the insights from these case studies, our methodological approach already shows to be replicable and with comparable results. This enables the comparison of resource flows between different regions and countries and also monitoring the progress over time. This leads to improved data which can be instruments for supporting companies’ decision-making processes (e.g., infrastructure investments or other strategic decisions), as well as designing policy strategies and incentives.

1. Introduction

Increasing the efficiency of the use of wood-based biomass in Europe is a prerogative of forest and energy national and transnational regulation and a pillar of the future circular economy. The EU Forest Strategy [], among other sectoral strategies, emphasizes the importance of reinforcing the supply of wood-based biomass in terms of its quantity and quality, namely through the collection of waste wood and the collection of residues that up to now are seldom used, such as the residues from harvesting, thinning, pruning, landscape management, and fuel removal in sites with high risk of forest fires. There are strong policy incentives (e.g., National Energy and Climate Plan 2021–2030) to increase the use of this renewable energy source for producing electricity and heat, which is contributing to rising the share of biomass in the total energy market in EU28, as confirmed in recent EU reports []. However, the portfolio of bio-based products derived from biomass is growing, as new biorefineries enter into production, as part of the Updated Bioeconomics Strategic and the Blueprint for the EU Forest-Based Industries []. The principle of “cascade use” deals with concurrent uses for the biomass by establishing a priority based on the added value that can be potentially generated [,,]. Although many political systems intend to present cascading as a hierarchical approach in which other uses of wood should hold priority over energy purposes, in reality cascading use of natural resources varies with time and place []. Additionally, the characteristics of the wood-based biomass should be taken into consideration, as this is a heterogeneous material, for example in terms of its granularity, moisture content, and level of impurities, which makes certain types of biomass more suitable to some applications than to others.

Being able to quantify how much wood-based biomass is produced, of which type and where, how it is used, and for what, and the amount that remains available is a basilar stage of the implementation of the aforementioned policies for increasing the efficient use of wood-based biomass. Updated and harmonized spatially-explicit estimates of the forest biomass stocks are necessary to support the design of policies, incentives, and guide investment decisions related with bioeconomy and sustainable use of renewable resources, as well as to improve climate change modelling and design appropriate mitigation actions [,,].

This is a challenging task for which a vast literature exists, although fragmented. There are many studies that provide estimates on the production of biomass, making a distinction between different sources, e.g., agriculture residues, forestry residues, urban greenery management, post-consumer wood, among others. For example, in [] the authors assess the potential availability of forest biomass from European forests and its spatial distribution and in [] the authors present a spatial approach for quantifying residual biomass potential in the EU-27, where a broad range of residual organic substrates have been simultaneously quantified from a theoretical point of view which does not take into account technical limitations related with its collection and mobilization.

The studies that analyze biomass uses and quantify biomass flows along the value chain are also abundant. This is a research area that typically falls in the field of Material Flow Analysis (MFA), that in general terms, consists of a systematic assessment of the flows and stocks of materials within a system defined in space and time []. In the context of this study, the resource balance representation summarizes all flows of wood-based biomass from the forest to wood-based industries, biomass conversion units, including bioenergy production. This representation takes into account the fact that wood is a highly versatile material, which can be used and reused in many different processes, so-called cascading. The Sankey diagrams are a common form of representation of the wood resource balance []. Some examples are the work done by the International Renewable Energy Agency (Irena) [,] and by the European Commission [,]. Other wood flow studies have focused on regional and national levels such as in [,,,]. Further studies addressing the increased demand for forest biomass and its impacts can be found in [,]. The authors of [] have extensively quantified wood flows at the global scale, suggesting that there are still considerable uncertainties about the extraction of wood at the global level and especially of wood fuels. These studies can be instrumental for supporting policy design in respect to cascading use of biomass in the future bioeconomy due to the possibility to model the interlinked relations between the biomass sources and applications. In [] the authors identify influence factors for the future development of a wood-based bioeconomy in Germany, four scenarios were generated based on different assumptions about the development of relevant influence factors, and what developments in politics, industry, and society have a central impact on shaping alternative futures were discussed. Some authors (e.g., of []) suggest the possibility to perform scenario analysis based on Sankey diagrams or similar representations, with the aim of assessing the impact of changes in biomass production or use, considering the overall flows and the alternative uses under the cascading production and trade-offs between them. The authors of [] present a prospective analysis in this direction but this is still an aspect poorly covered in the literature.

Complementary to the latter, are the studies on supply chain modelling and optimization. In [,] the authors present reviews of biomass supply chain modeling approaches. Optimization and simulation techniques are amongst the most commonly used to predict supply chain performance [], select the most efficient supply chain configuration [,], optimize the sizing of supply chain components to minimize cost [], or optimize scheduling of supply chain operations []. MFA are instrumental for generating good quality input data for these models, which will lead to better quality model results [].

The comparison amongst existing studies that apply MFA for wood-based biomass is often difficult as they are built upon a different terminology. Often the concepts and data sources seem similar but do not necessarily have the same meaning. The studies are also often built upon distinct assumptions, tailored to a specific purpose which makes the generalization of results quite hard []. Besides the lack of harmonization from one study to another, methodologies are often poorly described [,], hence hardly replicable.

The main contribution of this paper is the development of a comprehensive methodology for wood-based biomass flow analysis, anchored in Material Flow Analysis, and built upon literature review. This stepwise approach is deducted through systematization of previous studies. The main focus is providing instructions for producing a generalized Sankey diagram, starting downstream with both the description of the types of biomass sources and the main uses in a circular economy setting, which extends beyond the bioenergy production. Another innovative aspect of the proposed approach is the development of scenario analysis based on the Sankey diagram. This methodology approach should be replicable and with comparable results, hence, enabling the comparison between different regions and countries. The second main contribution of this work relates to terminology harmonization, extending the EU-wide referential of UNECE-Joint Forest Sector Questionnaire (JFSQ) to consider a wider range of biomass sources and some other aspects that can be relevant for addressing circular economy principles. In this way, the methodology is a crucial instrument for supporting companies’ decision-making processes, e.g., infrastructure investments or other strategic decisions, as well as policy design strategies and incentives.

This methodology has been applied for two case studies—wood-based biomass resource balance of Portugal and the waste wood resource balance of Flanders, for the year 2016 and 2014, respectively—and several scenarios have been proposed taking into account the new trends in the wood-based biomass sector.

2. Literature Review

2.1. Selection Criteria and Analysis

The literature review, conducted between September and December 2019, consisted of the search of technological and scientific publications in the Science Direct portal. The search criteria were (“wood” OR “biomass”) AND “material flow” NOT “life cycle” in the title, abstract or author-specified keywords. The search results were filtered to include only review and research articles published since 2010 until December 2019. The studies that include life cycle analysis were excluded from this research because their purpose is to quantify the ecological, social, and economic impacts, hence, beyond biomass flow balance (e.g., in [,,]).

In total, 86 publications were identified. The publications were evaluated by the authors based on relevancy, consistency, and objectivity resulting in a selection of 17 relevant papers, two of which are reviews. These papers were analyzed in more detail based on a Content Analysis Technique, considering: (i) description of the key concepts and terminology; (ii) form of representation of the biomass flows (e.g., Sankey or other), excluding papers on supply chain modelling and optimization; (iii) description of the methodological approach; (iv) scope of the analysis, i.e., which biomass sources and uses are covered, geographical and temporal scales.

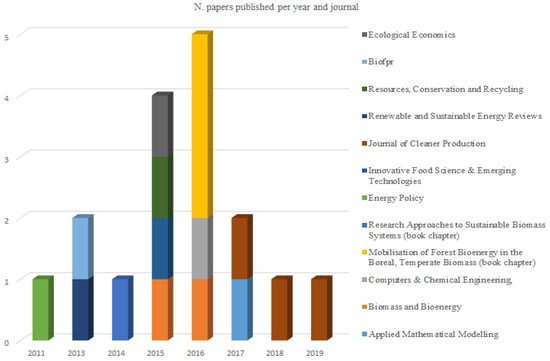

The selected papers were published in 12 distinct journals, mostly in 2015 and 2016. The Journal of Cleaner Production was the most used. The book on Mobilization of Forest Bioenergy in the Boreal, Temperate Biomass published in 2016, contains three of the selected articles (Figure 1).

Figure 1.

Selected papers for this study, distributed according to the year of publication and journal.

2.2. Main Findings of the Literature Review

The literature review evidences the lack of consensus and homogenization of concepts, terms, definitions, and data sources for the characterization of the wood-based biomass flows. Biomass sources are often referred to as “forestry” (e.g., in []), annual forest increment” (e.g., in []), hence it is unclear it if references to a theoretical potential or biomass that can actually be mobilized and used. There are few studies including the identification and description of the categories/subcategories, and the identification of the data sources used, which leads to some difficulty in understanding exactly what is considered in each one. Authors often identify as the main gaps in this type of analysis, the uncertainty in the quality of the input data, accessibility to adequate data sources, and difficulties in the compatibilization of flows measured with different units, namely finding adequate conversion factors.

There are significant differences in the methodological approaches that are followed, which makes their comparison difficult. Amongst those that present resource balance representations, Sankey diagrams are the most frequently used [,,,,]. Sankey diagrams are used to perform the analysis at different geographical scales, e.g., one global case, one regional at European level, and three national-wide in France, Netherlands, and Austria. In respect to the biomass sources, only half of the papers focus exclusively on wood-based biomass while the others also include agricultural and other non-wood wastes. With respect to biomass uses and applications, bioenergy is always considered, in parallel with other traditional wood applications such as sawmilling and pulp and paper. Hence, considering the by-products that re-enter the streams, usually in a clustered manner (e.g., industrial waste). Post-consumer wood is also acknowledged in the several studies. None of the selected papers addresses other uses related to biorefineries, however, this is considered promising for biomass cascade use. With respect to circularity, in [] the authors concluded that it has been assessed mainly at product level (an example can be found in [], that explores the challenges related to the End-Of-Life phase of products and circular systems of reuse and recycling within the commonly established frameworks of product lifecycle), but national and regional level assessment is also essential in evaluating the effectiveness of circular economy strategies. The possibility to use the resource balance representations to support scenario analysis is referred by several authors, but there were no examples of its application.

3. Proposed Stepwise Methodological Approach

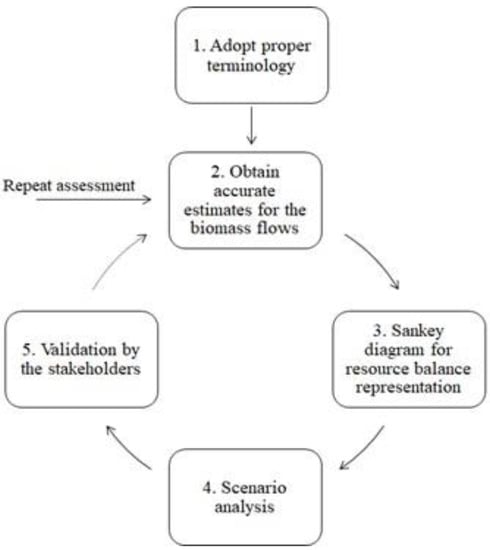

The approaches applied in prior studies on biomass material flow analyses were systematized into a novel five-step methodological approach, presented in Figure 2. The main application of this approach is supporting the design of public policies related with the biomass sector, as well as supporting decisions concerning companies’ investments. However, it can be adapted for wider purposes, whenever is relevant to characterize current wood-based biomass flow balance and analyze future scenarios that anticipate the impacts from changes in the biomass demand and/or consumption. The geographical scale of analysis can be a country or a large region. More detailed analysis, e.g., at a municipality level, benefit from spatial-explicit data and spatial analysis that help to address the transportation costs among other technical and business limitations impacting in the amount of biomass that can actually be mobilized. The temporal scale of analysis can be a year or multi-year, as the statistics related with biomass flows are often computed at a yearly basis.

Figure 2.

Five-step methodological approach for wood-based biomass material flow analysis.

3.1. Adopt Common Concepts and Terminology

The concepts and terminology should be common and widely applicable to enable comparison among studies in different locations, as well as to monitor biomass flows over time at a certain location. The two fundamental concepts in material flow analysis are flow and process. In most studies, the flow (or stream) represents the movement of material or energy, associated with a given time interval or functional unit. The process is the endpoint of the flow where the material is demanded, that can include transformation, transportation, and/or storage (e.g., in []). The flow starting point is also a downstream process of the value chain. The origin of the flow is often called the biomass source and the final endpoint (or sink) is the biomass product, use, or application.

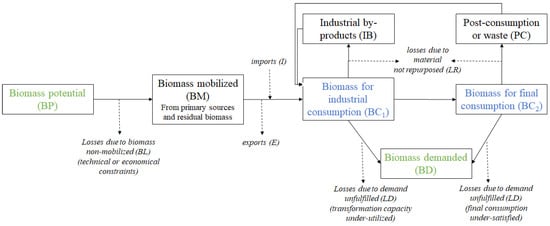

The Eurosat 2001 is the first framework for establishing material flow accounts and material balances for a whole economy, including biomass flows from forestry. This terminology, in combination with those proposed in [] was integrated, resulting in our new terminology for the categorization of the types of biomass flows (Figure 3):

Figure 3.

Characterization of the wood-based biomass flows.

- Biomass potential (BP) (or total production): total volume of wood-base biomass that is theoretically available to be used by all the transformation processes that consume biomass (some papers refer to this as growing stock or Net Primary Production);

- Biomass mobilized (BM): total volume of wood-based biomass that is technically and economically mobilizable, and therefore is the amount that can actually be used by the transformation processes. Corresponds to biomass from primary sources, either roundwood, woodfuel, or residues from forest management, among others;

- Biomass demanded (BD): total volume of wood-based biomass that is required by the transformation processes, in order to assure that their transformation facilities work in full capacity;

- Biomass consumed (BC): total volume of wood-based biomass that is actually consumed by the transformation processes. For the purpose of generalization, we made a distinction between industrial consumption (BC1) and final consumption (BC2);

- Biomass repurposed (BR): total volume of wood-based biomass sourced in the form of by-products from the wood processing industry (IB) or post-consumption waste (PC), that is supplied to the transformation processes.

There is a fraction of BM that is for exports (E), i.e., for transformation in facilities outside the location/region under study. Similarly, there is a fraction of the BC corresponding to imports (I), i.e., biomass originated outside the location/region under study.

A novelty in the proposed terminology of the wood-based biomass material flows is the identification of the material losses and waste, as a main concern of circular economy. We adopt the generic terminology that refers to waste as the unused material in the final consumption and to losses as the unused material during the supply chain. Studying these losses can be instrumental for designing effective policies for collecting and repurposing these materials for higher valorization. As so, the losses of biomass potential that are not mobilizable (LM) correspond to the difference between BM and BP. The losses due to demand unfulfilled (LD) correspond to the difference between BD and BC. The losses due to material that is not repurposed (LR) corresponds to the difference between (IB plus PC) and (BC1 plus BC2).

Wood-based biomass resources are, in many studies, categorized according to the provenance: primary biomass; industrial by-products (IB) that are the leftovers from the industrial transformation of the wood; and the post-consumption or waste materials (PC) that are the leftovers of final consumers that are reincorporated by the industry. These categories are considered in the terminology described before (Figure 1). Each category is typically partitioned into subcategories. However, in many cases, the subcategories are tailored to the purpose of the analysis, leading to a lack of homogeneity that hinders comparative analysis. The subcategories for the wood-based biomass proposed in this study match those used in the Eurostat in the Joint Forest Sector questionnaire (JFSQ), which were extended with additional subcategories for the primary biomass and byproducts (see Table 1).

Table 1.

Categorization of the wood-based biomass sources (definitions adapted for Eurostat-Joint Forest Sector Questionnaire (JFSQ) are marked with *).

It is noteworthy that the byproducts were subcategorized according to the industry of origin as it is often presented in previous studies (e.g., in [,]). An alternative subcategorization that reflects the material characteristics (i.e., chips, particles, dust, etc.), could perhaps be more adequate for analyses concerning the biomass cascading use that consider concurrent biomass uses, because these are, in many cases, characteristics dependent.

The typification of the cascading uses and products resulting from the conversion of wood-based biomass is more challenging task. No systematic classification was found and doing such a comprehensive review is outside the scope of this work. In respect to the processes, aside from bioenergy production, two main biorefinery platforms are often referred (e.g., by the National Renewable Energy Laboratory (NREL) (Table 2)). The thermochemical (or syngas platform) transforms biomass into synthesis gas (hydrogen and carbon monoxide) or pyrolysis oil. The biochemical platform (or sugar platform) breaks down biomass into different types of component sugars for fermentation or other biological processing. Hence, both platforms can produce a wide range of fuels, chemicals, and materials and also bioenergy in the form of heat and power.

Table 2.

Main wood-based biomass uses and applications (definitions adapted for Eurostat-JFSQ are marked with *).

3.2. Obtain Accurate Estimates for the Biomass Flows

The main data sources on wood-base biomass flows are official statistics. Data is aggregated and hierarchized within each subcategory. National or regional statistics are mainly used. Existing aggregated international statistics are produced by Eurostat and FAO, including Joint Forest Sector Questionnaire (JFSQ), Joint Wood Energy Enquiry (JWEE). When no official or scientific data is available, expert’s opinions are collected, either through questionnaires or workshops.

The estimates on biomass potential (BP) for roundwood are commonly available in the National Forest Inventories. There is a vast literature on biomass statistic models being used, especially to estimate above ground, stem-related biomass, which rely on forest inventory data (e.g., growing stock) collected through a multitude of techniques, such as remote sensing, traditional inventory plot measurements, or destructive field measurements. Specific statistical models have been proposed in the literature for estimating the potential amount of shrubs and under canopy vegetation (e.g., in [,]). Geographical Information Systems (GIS) are often used to display spatial availability. However, comparative analysis is subjected to considerable uncertainty due to lack of harmonization and compatibility on the definitions and specifications of inventory processes [].

The estimates on biomass mobilized (BM) for roundwood and woodfuel are commonly available in the Forest and Agriculture national statistics, which are gathered with questionnaires to the entities that are involved in forest-based products commercialization and regulation. Estimates of the wood-based biomass that can be mobilized, can be obtained from the biomass potential estimates through spatial explicit analysis (e.g., in []). To our knowledge, shrubs and under canopy vegetation are not systematically collected as biomass sources, therefore, are not presented in the statistics. The estimates of mobilized forest residues are not commonly found in the official statistics. In respect to the fraction of forest residues resulting from harvesting operations, it can be estimated indirectly as a percentage of the total amount of wood harvested (and mobilized) each year. In generic terms, it is assumed that 60% of the total tree volume is used in the industry (corresponding to the stem), while the remaining (branches, leaves stumps) are residues []. Official statistics often do not account for the amount of forest residues resulting from thinning operations.

For the biomass repurposed (BR), statistical data is more scarce. Sectorial organizations collect data on byproducts that are mobilized but not all the material is considered. In pulp and paper industries or panel industries there is some degree of biomass incorporation already within the industrial process, which is not accounted for in the statistics.

Estimates of the post-consumer waste that is mobilized can often be found in national environmental-related statistics, although the underlying data gathering method is often unclear.

In respect to biomass consumption (BC), the national energy statistics provide estimates on the consumption of biomass for bioenergy and the corresponding energy production. Data on other uses/applications is scarce. Information on biomass demanded (BD) is not usually found in official statistics and can be provided by industrial sectoral organizations. Imports and exports of primary biomass can be taken also from national statistics. The imports that do not relate directly with raw materials for the industries under study are excluded from this research. This includes, for example, the imports of finished goods like wood furniture.

3.3. Sankey Diagram for Resource Balance Representation

A Sankey diagram is used to provide a representation of the material flows between the processes, making a distinction between the different sources and its distinct uses/applications. The adoption of Sankey diagrams has been a common practice in science and engineering []. Examples of applications include the analysis of energy flows and their distribution in several power systems [] and the visualization of the dynamics of land use change []. The authors of [] combined a Sankey diagram for material flow analysis with economic models applied to the forest-based industrial sector in France. These Sankey diagrams depict particularly well the re-use of wood-based biomass, i.e., the cascade uses of wood-based biomass, as well as potential synergies and competition between its different uses/applications. Other studies with Sankey diagram to represent biomass flows include [,,,]. There are several software packages for creating Sankey diagrams, such as e!sankey (www.ifu.com/en/e-sankey/), SankeyMATIC (http://sankeymatic.com/), and on several dedicated software for Material Flow Analysis.

In a Sankey diagram, the processes are represented as nodes and the flows as links. In this study, the subcategories of the wood-based biomass are sinks, at the left side of the diagram, and subcategories of biomass uses and products are sinks, at the right side of the diagram. The distinctive aspects of a Sankey diagram are that (1) the diagram represents the physical flows, related to a given functional unit or period of time; (2) the magnitude of the is shown by the link widths, which are proportional to an extensive property of the flow, such as mass or energy. In respect to the reference unit, we adopted million tons, as in [,]. Some authors make a distinction between wet and dry mass, mainly to discount the amount of water that is included in the biomass in the upstream flows. In this study we do not provide this distinction because it can be very difficult to establish the average moisture content of the primary biomass, as it varies according to the stocking conditions and socking duration. Previous studies, such as the the wood resource balance sheets [], adopt the cubic meters solid wood equivalent (1 hm3 (corresponding to 1,000,000 m3 [])); wood fiber equivalent (m3 [f] i.e., the volume of the wood fibers that are contained in the product at the fiber saturation point (e.g., in [])). Whenever needed, conversions were made from the original reported units using the forest conversion factors published by UNECE-JFSQ and UNECE-FAO.

The mass conservation principle, expressed in the continuity equation of the flows in the processes, is transversal to Material Flow Analysis representations. However, as in previous studies related with wood-based products, there are difficulties in is application. The water content that is part of some of the biomass flows and can change during conversion processes, and the incomplete information on some subcategories, are amongst the most important difficulties pinpointed in the literature [].

The total balance of forest biomass (BTB) can be computed as the difference between the production (i.e., BM, IB, and PC) and the consumption (BC1 and BC2), summing up the Imports (I) and Exports (E) of roundwood. Stock levels (S) are included to assure balance between the total production and the total consumption. Hence, BTB is given by the equation:

Complementary to the Sankey diagram, a wood resource balance sheet can be produced, as presented in []. Biomass sources—i.e., production—is represented in one side, and biomass uses—i.e., consumption—are represented in the other side. As for any balance sheet, the two sides should balance, and were all data reported correctly.

3.4. Scenario Analysis

Scenario analysis can be valuable to support policy design and decision making because throughout the creation of a scenario that considers the occurrence of a possible event, the diagram can anticipate its likelier outcomes. In the context of the material flow analysis, the Sankey diagram can be used to build up a scenario that corresponds to a change in the biomass production or consumption and project the impact over the flow balance and stock, considering the interlinkages between the processes and the trade-offs between alternative biomass uses.

The first step for creating a scenario consists of estimating the impact of the event in the conversion processes that consume biomass, or in the volume available at the biomass sinks. A new Sankey diagram is then created to reflect these changes, all other flows and processes remaining unchanged. The overall material flow balance is recomputed, and results are compared with the baseline Sankey diagram. Dashboards with relevant key performance indicators can be developed to help to compare amongst scenarios.

As an example, a scenario analysis can be conducted to assess the impact of an increase of the burned wood resulting from intense forest fires. In this situation, the total amount of burned wood is firstly estimated. The maps of burned areas are provided by the responsible national authorities and estimates for future years can be obtained with adequate fire risk analysis. Then, the fraction of burned wood that is mobilized can be computed considering the technical and economic constraints that may be applied. The final volume is added to the subcategory roundwood and the new Sankey diagram is created and then compared with the baseline scenario. If there is still available transformation capacity for the roundwood, the increase of the burned wood will lead to an increase of the wood-based products, uses and applications, including the byproducts which are refeeding the processes. Otherwise, the burned wood will be stocked.

3.5. Validation by the Stakeholders

The stakeholders have a fundamental role in this process by helping to improve data quality and providing missing data. They also can help to validate the results, discussing relevant shortcomings of the data gathering process and helping to set in place improved data gathering processes for the relevant statistics. As reported in previous studies, stakeholders can be engaged in this process through questionnaires and/or workshops. The design of the questionnaires is tailored to the purpose of the material flow analysis and no examples of questionnaires found in literature.

4. Application of the Methodological Approach into Case Studies

4.1. Wood-Based Biomass Resource Balance of Portugal

Portuguese forestland areas (forest stands, scrubs, and also unproductive land) occupy 6.2 million hectares (69.4%) of the Portuguese mainland and is the most important land use (36% of the territory). The main forest species and uses are Eucalyptus globulus plantations, logs are mostly used in the pulp and paper industry; Pinus pinaster plantations, logs mostly used for sawmilling and by the panel-based industry; and Quercus suber plantations, cork bark is transformed by the industry into cork stoppers and other cork-based products. There are strong incentives to increase the use of biomass, especially the wood-based, as part of the strategy to reduce the risk of forest fires and increase the contribution of renewable energy sources (RES) in the total energy consumption. In 2016, the contribution of RES on primary energy consumption was 25.4%, from which, 46% corresponds to biomass, 19% wind, and 26% hydroelectricity. Biofuels contributed 5% to RES []. In the year of analysis, 2016, there were in operation 12 dedicated biomass centrals and nine in cogeneration, corresponding to a total of 2481 GMh of bioenergy production, both electricity and heat. The pellet industry has been in expansion since 2013. There were 25 production facilities producing around 850 kton/year of pellets. Briquettes production is still residual. The National Plan for Promotion Biorefineries (RCM No. 163/2017) was recently approved for promoting next-generation biomass-based industries for 2030.

Terminology and estimation of wood-based biomass wood flows: for the year of 2016, wood-based biomass flows were reconstructed manly through national statistics, related with agriculture and trade, but also industrial declarations, interviews, and data reconciliation (Table 3).

Table 3.

Main data sources for characterizing the wood-based biomass sources in Portugal for 2016.

One of the main data gaps relates to the amount of forest residues that are mobilized. In this study, we estimated this amount as a percentage of the total harvested volume and validated the procedure with the stakeholders in the course of a workshop organized together with the National Forest Authority. It was not possible to estimate the amount of wood removed in thinning and other forest management operations. Due to lack or difficulty in estimating data related with stocks and other wood losses along the value chain, in some cases, the mobilized biomass is equal to the consumed biomass. Both subcategories of post-consumer waste are clustered in this analysis to better fit to the nature of the data available. In respect to biomass uses/applications, bioenergy production is the only one currently available in Portugal. Statistics on the production of electricity and steam, pellets, wood fuel, and charcoal were provided by the National Energy Regulatory Entity.

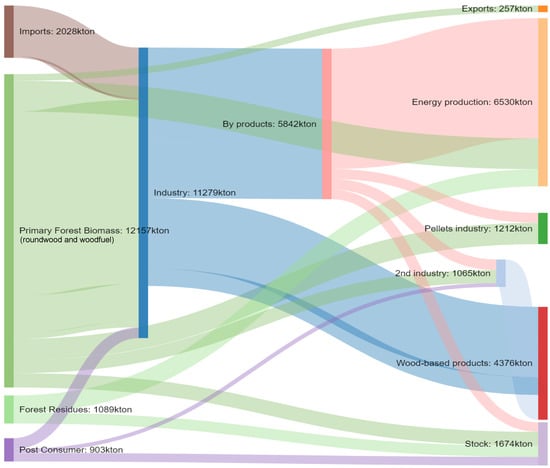

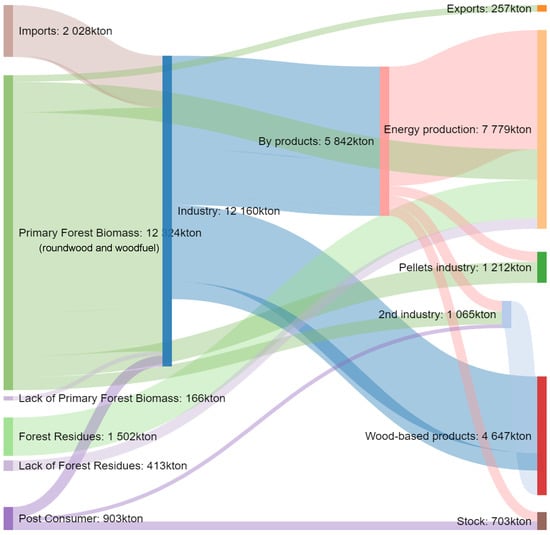

Wood-based biomass balance: the Sankey diagram was produced with Sankeymatic (Figure 4). The biomass resource balance is systematized in Table 4.

Figure 4.

Sankey diagram of the wood-based biomass flows in Portugal, 2016.

Table 4.

Wood-based biomass resource balance table (Portugal mainland, 2016) (kton).

Considering all sources of wood-based biomass (RW, WF, FR, IB, and PC) the total amount consumed for bioenergy production was 7744.53 kton. Primary forest biomass (roundwood and woodfuel), were mainly used for industrial processes, including pulp and paper, sawmills, and panel industry (7142.30 kton). A total of 2017.26 kton were used for bioenergy production. Results suggest that there is a surplus of RW, FR, and IB (of about 548, 423, 370 kton, respectively) that is not transformed by the industrial processes nor converted into bioenergy. Hence, the BTB points towards a wood-based biomass surplus of 1644.44 kton (corresponding to the stock amount represented in the Sankey diagram). However, these results should be dealt with caution because of the uncertainty in the data, especially in respect to the estimates of FR and IB, for which there is no adequate official data available. Another relevant aspect is the logistics costs which are not considered in this study and can impact the estimates of the biomass mobilized.

Scenario analysis: in this case study, scenarios were built to help address the uncertainty related with foreseen changes in the wood-based biomass demand. Specifically, a scenario was built to analyze the impact of three main drivers of the national policies and on-going companies’ investments:

- (i).

- Increase of installed capacity of dedicated bioenergy plants by 116 MW;

- (ii).

- A 10% increase in pulp and paper industry capacity; and

- (iii).

- Introduction of three new biorefineries with a consumption of 100 kton of residual forest biomass per biorefinery, as foreseen by the National Plan for the Promotion of Biorefineries.

The new scenario is presented in Figure 5. Under these conditions, the results point towards a deficit in biomass supply, specifically related to the scarcity of primary forest biomass, including roundwood, woodfuel, shrubs, and forest residues, which may be eventually partially compensated by a surplus of post-consumer material. In this case, to be able to increase the consumption as foreseen, efforts are needed to guarantee the necessary availability of wood resources, for example increasing the quantity of roundwood harvested or the quantity imported. In either case, the sustainability of resource use and economic issues will need to be properly addressed.

Figure 5.

Sankey diagram driven by the scenario analyses applied for the Portuguese case.

4.2. Waste Wood Resource Balance of Flanders

The chemical industry is at the core of Flemish industry, but until today it is almost completely dependent on fossil-based feedstock. The FWO-funded project “BioWood” has the objective to develop a new wood-to-lignin (BChL) value chain in Flanders, mainly relying on locally available lignocellulosic biomass, such as waste wood, which is one of the largest biomass waste streams in Flanders, being produced at household and business level. Bringing together information in relation to waste wood production and its destination is a huge challenge due to the use of different terminologies for the same waste wood types, the Green list regime, and lack of and accessibility to data. Furthermore, its quantity and quality vary considerably depending on its origin, its time of production, recycling rate, etc. Furthermore, waste wood supply and demand in Flanders are rapidly affected by the economic/financial situation of the market, policy changes, and international trade.

Terminology and estimation of waste wood flows: for the period 2002–2015, waste wood flows were reconstructed based on the industry declarations, inventories, trade statistics, interviews, and data reconciliation. The main challenge in performing the waste wood flow analysis is the heterogeneous nature of the wood waste stream and lack of clear terminology to characterize waste wood flows. Every data source assumes a different definition while deriving numbers (Table 5). The waste wood flow analysis in this paper brings all data to the same terminology and denominator, allowing comparison between time periods and between waste wood types. Data gaps are solved by interviews with experts and data reconciliation. The analysis highlights two industries that play a central role consumption of waste wood in Flanders: i.e., green-energy (BE) and wood panel (mainly particleboard) producers.

Table 5.

Terminology and sources to define the waste wood balance in Flanders (OVAM = Flemish Waste Management Agency).

One of the data gaps can be observed in the amount of waste wood supplied and the amount of waste wood being consumed by wood-panel producers. This discrepancy can be related to the stocking of waste wood which is often done when the company faces technical challenges in the production line or to handle the dynamic nature of waste wood market (i.e., when the supply of waste wood exceeds the demand). Indeed, the wood panel industry in Flanders has seen massive fluctuations in their operations in the last decade. It has been severely affected by the economic situation of the market, technical challenges, and fluctuations in the supply of waste wood in the international market. In some cases, the fluctuations are tackled by increasing operations, whereas in other cases waste wood is stored at production sites.

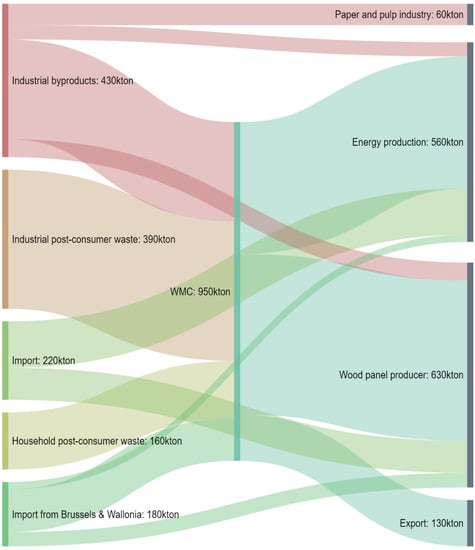

Waste wood balance:Figure 6 presents the total production and use of waste wood in the Flemish economy in the year 2014.

Figure 6.

Sankey diagram of the waste wood flows in Flanders in 2014 (executed by Kranti Navare, 2019) (WMC = waste management centre).

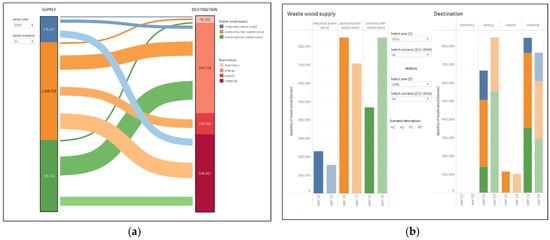

Scenario analysis: de-risking feedstock supply for the lignin-first refinery needs a realistic estimate of feedstock supply in the coming decades. Analysis of the historical flows of feedstock informs the definition of trends in the supply quantity and the quality, the competing demands and the way the bio-based industries will be introduced in the current value chains. The future is always uncertain, and we have only limited influence on the basic developments that will shape our future. In the development of a bio-based chemical industry, uncertainties arise for supply growth of biomass and demand growth for biomass for materials, chemicals, and energy []. To estimate wood-based biomass potential available for the bio-based refinery in the long term, contrasting scenarios are defined based on the integration of the bio economy scenarios defined in the SCAR report [], the scenarios in biomass demand for chemicals, materials, and energy defined in the Euralis project and the National Renewable Energy Action plan (2016). These parameters will vary depending on how markets will evolve and how sustainability will be perceived. As in [], this paper presents four contrasting scenarios based on two axes: open markets vs. local markets and high vs. low importance of sustainability and regulation: A1—Global economy, A2—Continental Market, B1—Global cooperation, and B2—Regional communities. These four scenarios are related to the scenarios on demand and supply growth for biomass in SCAR [] and the National Renewable Energy Action plan (2016).

This scenario analysis results in a large dataset and the huge variety of combinations between scenarios, biomass types, and destinations. To investigate the different scenarios, focus on biomass types or destination types, or to select a specific year, a dashboard was created to enable a user to filter out a specific waste wood type, a specific destination, a specific scenario, or a combination of these. Additionally, the dashboard on waste wood streams shows a Sankey diagram indicating the destination of the waste wood (export, energy, material, or chemistry) for a specific year (Figure 7a) and includes a sheet in which the supply and demand can be compared next to each other for a specific year or a specific scenario (Figure 7b).

Figure 7.

Screenshots of the dashboard presenting (a) a Sankey diagram of the year 2030 according to scenario A1—Global economy; (b) the supply-demand comparison between the year 2013 and 2005.

Stakeholder’s validation: the results from the scenario analysis were presented to the experts from the OVAM (Flemish Waste Management Agency) by means of the dashboards. Main conclusions from these interviews are that by presenting the material flows by means of a Sankey diagram increases the ability to derive insights as well as to define other kinds of questions to be solved with scenario analysis. The added value for the design of policy strategies and incentives is confirmed.

4.3. Comparison amongst Case Studies

The comparison amongst these case studies is facilitated to some extent, since the concepts are the same and the results are derived in a similar way. The time frame of one year is the same in both cases. However, significant differences emerge in respect to the geographical scale (national vs. regional) and the specific purpose of analysis (overall wood-based biomass sources vs. only post-consumer wood).

Considering the household post-consumer wood (HW), recovered post-consumer wood, and industrial post-consumer wood (IW) assessed in both cases, it is possible to conclude that the amount of HW + IW used in Flanders is higher than in Portugal, 550 and 151 kton, respectively. However, the total amount of post-consumer waste (PC) transformed in Portugal can actually be higher than in Flanders because the recovered fiber, pulp, and recovered paper is a major fraction of the PC, which was not accounted for in Flanders.

The supply of wood-based panel industries (second industry) is the most important application of waste wood in both case studies, followed by bioenergy production. In Portugal the panel industry consumes around 1065 kton of biomass per year, while in Flanders the value is 630 kton.

5. Conclusions

This paper contributes to solving the research gap identified in the literature review related to the lack of consensus and homogenization about concepts, terms, definitions, and comparable methodological approaches for characterizing wood-based biomass flows.

This paper describes a comprehensive five-step methodological approach for analyzing wood-based biomass material flows analysis that builds on the findings of a literature review. The concepts, categories of biomass sources, and biomass uses and applications are proposed to overcome the lack of harmonization found in previous studies, which hinder the possibility to replicate the study in order to monitor progress in a biomass value chain over time or compare results amongst different countries or regions.

At the core of the proposed approach is a Sankey diagram to visualize the material flows among the value chain. The underlying Biomass Total Balance compares total production and consumption on a yearly basis. Its application in the wood-based biomass in Portugal foresees a surplus of production.

Sankey diagrams are widely used in Material Flow Analysis with similar purposes.

Previous studies state the main limitations of this type of analysis, imposing caution in the interpretation of the results. The main limitations relate to the uncertainty in the quality of the input data, data sources, and difficulties related with compatibilizing flows that are measured with different units. In this study, we tried to overcome the limitations of low quality and absence of important statistical data, by engaging the stakeholders thought workshops and interviews. Nonetheless, this study showcases the use of such information and helps to identify which data sources could be relevant to consider in the future. For flow compatibilization, we adopted, whenever possible, the conversion factors published by UNECE-JFSQ and UNECE-FAO. We adopted the referential measurement unit that best fit the analysis along the value chain (kton) and acknowledged limitations related to the fact that moisture content in primary forest biomass cannot be accurately estimated.

Another important feature of the proposed methodology is the development of scenario analysis. Several scenarios were drawn for the case study of wood-biomass value chain in Portugal and waste wood in Flanders in order to deal with possible sources of uncertainty with impact in the biomass flows. The comparison amongst scenarios provides valuable information to support the decision concerning future investments (e.g., biorefineries) and/or the design of adequate policy incentives for the biomass utilization markets.

Material flow analysis is a promising technique for enhancing cascade biomass use in a circular economy, as also pointed out by []. The Sankey diagram successfully can represent the byproducts and wastes and its reutilization in biomass conversion processes, as well as concurrent uses of the wood-based biomass, despite the fact that currently available data on wood-based biomass consumption in biorefineries is still scarce. In respect to this, the authors of [] alert for the need of complementary studies for possible negative spillover effects. For example, increasing the use of forest-wood biomass in biorefineries to produce an alternative to fossil fuel, may lead to imports for the forest industries, which ultimately can increase fuel consumption and green gas emissions.

The proposed conceptual framework was successfully applied in two case studies with distinct purposes in Portugal and Flanders. The application of this methodology allows a common characterization of the wood biomass chains and thus the possibility of comparing the flows, balance sheets, as well as the possibility of making scenarios about the obtained results.

Considering the heterogeneity of the forest and biomass sector, future work can include regional studies and comparison between regions. At a regional scale, logistics aspects should be taken into account to better estimate biomass mobilized. Future work can also extend the scope of analysis for covering other biomass sources beyond wood, such as agriculture-based biomass and aquatic biomass.

Author Contributions

A.M. and A.D.M. were responsible for article conceptualization, based on the results of ongoing research projects. J.C. was responsible for characterizing the Portuguese case and K.N. produced the Flemish case. All authors have read and agreed to the published version of the manuscript.

Funding

This work is co-financed by the European Regional Development Fund (ERDF) through the Interreg V-A Espanha-Portugal Programme (POCTEP) 2014–2020 within project 0095_BIOTECFOR_1_P. This work also received funding from ERDF—European Regional Development Fund through the Operational, Programme for Competitiveness and Internationalisation-COMPETE 2020 Programme and by National Funds through the Portuguese, funding agency, FCT—Fundação para a Ciência e a Tecnologia within project POCI-01-0145-FEDER-016733 (Easyflow). Finally, this work is co-financed by the Research Foundation Flanders (FWO) through the project ‘BioWood’ in which the MooV service of VITO is applied to define the optimal location of the refinery and to analyze and optimize the wood-based value chain in Flanders. The opinions contained in this article are the sole responsibility of their authors. The European Commission and the Program Authorities are not responsible for the use of the information contained therein.

Conflicts of Interest

The authors declare no conflict of interest.

References

- European Commission. A New Eu Forest Strategy: For Forests and the Forest-Based Sector; no. SWD(2013) 342 final; Communication from the Commission to the European Parliament and the Council, the Economic and Social Committee and the Committee of the Regions: Copenhagen, Denmark, 2013; p. 17. [Google Scholar]

- Calderón, C.; Colla, M.; Jossart, J.-M.; Hemeleers, N.; Cancian, G.; Aveni, N. Bioenergy Europe Statistical Report 2019; European Association Bioenergy Europe: Brussels, Belgium, 2019. [Google Scholar]

- European Commission. A Blueprint for the EU Forest-Based Industries (Woodworking, Furniture, Pulp & Paper Manufacturing and Converting, Printing); Brussels 20.9.2013 SWD(2013) 343 Final Comm.; European Commission: Brussels, Belgium, 2013; p. 41. [Google Scholar]

- Ciccarese, L.; Pellegrino, P.; Pettenella, D. A new principle of the European Union forest policy: The cascading use of wood products. L’italia For. Mont. 2014, 69, 285–290. [Google Scholar] [CrossRef][Green Version]

- Keegan, D.; Kretschmer, B.; Elbersen, B.; Panoutsou, C. Cascading use: A systematic approach to biomass beyond the energy sector. Biofuels Bioprod. Biorefin. 2013, 7, 193–206. [Google Scholar] [CrossRef]

- Sokka, L.; Koponen, K.; Keränen, J.T. Cascading Use of Wood in Finland–with Comparison to Selected EU Countries; Metsäenergian kestävyysselvitys 101701-FE2020 kestävyys; VTT: Isbo, Finland, 2015. [Google Scholar]

- Olsson, O.; Bruce, L.; Hektor, B.; Roos, A.; Guisson, R.; Lamers, P.; Hartley, D.; Ponitka, J.; Hildebrandt, J.; Thrän, D. Cascading of Woody Biomass: Definitions, Policies and Effects on International Trade; IEA Bioenergy Task 40 Working Paper; IEA Bioenergy: Canberra, Australia, April 2016. [Google Scholar]

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions-Innovating for Sustainable Growth: A Bioeconomy for Europe; European Commission: Brussels, Belgium, 2012; Volume 8. [Google Scholar]

- Grassi, G.; House, J.; Dentener, F.; Federici, S.; den Elzen, M.; Penman, J. The key role of forests in meeting climate targets requires science for credible mitigation. Nat. Clim. Chang. 2017, 7, 220–226. [Google Scholar] [CrossRef]

- Scarlat, N.; Dallemand, J.F.; Monforti-Ferrario, F.; Nita, V. The role of biomass and bioenergy in a future bioeconomy: Policies and facts. Environ. Dev. 2015, 15, 3–34. [Google Scholar] [CrossRef]

- Verkerk, P.J.; Anttila, P.; Eggers, J.; Lindner, M.; Asikainen, A. The realisable potential supply of woody biomass from forests in the European Union. For. Ecol. Manag. 2011, 261, 2007–2015. [Google Scholar] [CrossRef]

- Hamelin, L.; Borzęcka, M.; Kozak, M.; Pudełko, R. A spatial approach to bioeconomy: Quantifying the residual biomass potential in the EU-27. Renew. Sustain. Energy Rev. 2019, 100, 127–142. [Google Scholar] [CrossRef]

- Schaffartzik, A.; Mayer, A.; Gingrich, S.; Eisenmenger, N.; Loy, C.; Krausmann, F. The global metabolic transition: Regional patterns and trends of global material flows, 1950–2010. Glob. Environ. Chang. 2014, 26, 87–97. [Google Scholar] [CrossRef] [PubMed]

- Lupton, R.C.; Allwood, J.M. Hybrid Sankey diagrams: Visual analysis of multidimensional data for understanding resource use. Resour. Conserv. Recycl. 2017, 124, 141–151. [Google Scholar] [CrossRef]

- IRENA. Solid Biomass Supply for Heat and Power; International Renewable Agency: Abu Dhabi, UAE, 2019. [Google Scholar]

- IRENA. Bioenergy from Boreal Forests: Swedish Approach to Sustainable Wood Use; International Renewable Agency: Abu Dhabi, UAE, 2019. [Google Scholar]

- Avitabile, V.; Camia, A. An assessment of forest biomass maps in Europe using harmonized national statistics and inventory plots. For. Ecol. Manag. 2018, 409, 489–498. [Google Scholar] [CrossRef] [PubMed]

- Camia, A.; Robert, N.; Jonsson, R.; Pilli, R.; García-Condado, S.; López-Lozano, R.; Tamosiunas, S. Biomass Production, Supply, Uses and Flows in the European Union; First results from an integrated assessment; European Union: Luxembourg, 2018; pp. 1–126. ISBN 978-92-79-77237-5. [Google Scholar] [CrossRef]

- Binder, C.R.; Hofer, C.; Wiek, A.; Scholz, R.W. Transition towards improved regional wood flows by integrating material flux analysis and agent analysis: The case of Appenzell Ausserrhoden, Switzerland. Ecol. Econ. 2004, 49, 1–17. [Google Scholar] [CrossRef]

- XERA. La Cadena Forestal-Madera en Galicia 2017. Axencia Galega da Industria Forestal. Consellerıa de Economi’ a e Industria; coordinated by Juan Picos; Universidade de Vigo: Vigo, Spain, 2018; 54p. [Google Scholar]

- Koen, B.; Ive, V.; Kranti, N. Biomass Flows in the Flemish Economy; CE Center: Boeretang, Belgium, 2019. [Google Scholar]

- Parobek, J.; Paluš, H.; Kaputa, V.; Šupín, M. Analysis of wood flows in Slovakia. BioResources 2014, 9, 6453–6462. [Google Scholar] [CrossRef]

- van den Born, G.J.; van Minnen, J.G.; Olivier, J.G.J.; Ros, J.P.M. Integrated Analysis of Global Biomass Flows in Search of the Sustainable Potential for Bioenergy Production; PBL Netherlands Environmental Assessment Agency: Hague, The Netherlands, 2014; p. 24. [Google Scholar]

- Börjesson, P.; Hansson, J.; Berndes, G. Future demand for forest-based biomass for energy purposes in Sweden. For. Ecol. Manag. 2017, 383, 17–26. [Google Scholar] [CrossRef]

- Bais, A.L.S.; Lauk, C.; Kastner, T.; Erb, K. Global patterns and trends of wood harvest and use between 1990 and 2010. Ecol. Econ. 2015, 119, 326–337. [Google Scholar] [CrossRef]

- Hagemann, N.; Gawel, E.; Purkus, A.; Pannicke, N.; Hauck, J. Possible futures towards awood-based bioeconomy: A Scenario Analysis for Germany. Sustainability 2016, 8, 98. [Google Scholar] [CrossRef]

- Kalt, G. Biomass streams in Austria: Drawing a complete picture of biogenic material flows within the national economy. Resour. Conserv. Recycl. 2015, 95, 100–111. [Google Scholar] [CrossRef]

- Lenglet, J.; Courtonne, J.; Caurla, S. Material flow analysis of the forest-wood supply chain: A consequential approach for log export policies in France. J. Clean. Prod. 2017, 165, 1296–1305. [Google Scholar] [CrossRef]

- Nunes, L.J.R.; Causer, T.P.; Ciolkosz, D. Biomass for energy: A review on supply chain management models. Renew. Sustain. Energy Rev. 2020, 120, 109658. [Google Scholar] [CrossRef]

- Akhtari, S.; Sowlati, T.; Siller-Benitez, D.G.; Roeser, D. Impact of inventory management on demand fulfilment, cost and emission of forest-based biomass supply chains using simulation modelling. Biosyst. Eng. 2019, 178, 184–199. [Google Scholar] [CrossRef]

- De Meyer, A.; Cattrysse, D.; Rasinmäki, J.; Van Orshoven, J. Methods to optimise the design and management of biomass-for-bioenergy supply chains: A review. Renew. Sustain. Energy Rev. 2014, 31, 657–670. [Google Scholar] [CrossRef]

- De Meyer, A.; Cattrysse, D.; Van Orshoven, J. A generic mathematical model to optimise strategic and tactical decisions in biomass-based supply chains (OPTIMASS). Eur. J. Oper. Res. 2015, 245, 247–264. [Google Scholar] [CrossRef]

- De Meyer, A.; Snoeck, M.; Cattrysse, D.; Van Orshoven, J. A reference data model to support biomass supply chain modelling and optimization. Environ. Model. Softw. 2016, 83, 1–11. [Google Scholar] [CrossRef]

- Marques, A.; Rasinmäki, J.; Soares, R.; Amorim, P. Planning woody biomass supply in hot systems under variable chips energy content. Biomass Bioenergy 2018, 108, 265–277. [Google Scholar] [CrossRef]

- Yazan, D.M.; van Duren, I.; Mes, M.; Kersten, S.; Clancy, J.; Zijm, H. Design of sustainable second-generation biomass supply chains. Biomass Bioenergy 2016, 94, 173–186. [Google Scholar] [CrossRef]

- Asveld, L.; van Est, R.; Stemerding, D. Getting to the Core of the Bio-Economy: A Perspective on the Sustainable Promise of Biomass; Rathenau Instituut: Den Haag, The Netherlands, 2011. [Google Scholar]

- Kalverkamp, M. Cascade Use and the Management of Product Lifecycles. Sustainability 2017, 9, 1540. [Google Scholar] [CrossRef]

- Rao, S.R.R. Resource Recovery and Recycling from Metallurgical Wastes; Elsevier: Amsterdam, The Netherlands, 2006; pp. 389–392. [Google Scholar]

- Suter, F.; Steubing, B.; Hellweg, S. Life Cycle Impacts and Benefits of Wood along the Value Chain: The Case of Switzerland. J. Ind. Ecol. 2017, 21, 874–886. [Google Scholar] [CrossRef]

- Faaij, A.; Goh, C.S.; Junginger, M. Monitoring sustainable biomass flows: General methodology development. Biofuels Bioprod. Biorefin. 2013, 8, 83–102. [Google Scholar]

- Mantau, U. Wood flow analysis: Quantification of resource potentials, cascades and carbon effects. Biomass Bioenergy 2015, 79, 28–38. [Google Scholar] [CrossRef]

- Virtanen, M.; Manskinen, K.; Uusitalo, V.; Syvänne, J.; Cura, K. Regional material flow tools to promote circular economy. J. Clean. Prod. 2019, 235, 1020–1025. [Google Scholar] [CrossRef]

- Fischer-Kowalski, M.; Krausmann, F.; Giljum, S.; Lutter, S.; Mayer, A.; Bringezu, S.; Moriguchi, Y.; Schütz, H.; Schandl, H.; Weisz, H. Methodology and indicators of economy-wide material flow accounting: State of the art and reliability across sources. J. Ind. Ecol. 2011, 15, 855–876. [Google Scholar] [CrossRef]

- Ventura, J.; Vasconcelos, M.J. O Fogo Como Processo Fisico-Químico e Ecológico; Pereira, J.S., Pereira, J.M.C., Rego, F.C., Silva, J.M.N., Silva, T.P., Eds.; Incêndios Florestais em Port. Caracter. Impactes e Prevenção, ISA Press: Lisboa, Portugal, 2006; pp. 93–113. [Google Scholar]

- Fernandes, P.M. Original article Combining forest structure data and fuel modelling to classify fire hazard in Portugal. Ann. For. Sci. 2009, 66, 1–9. [Google Scholar] [CrossRef]

- Beccali, M.; Columba, P.; D’Alberti, V.; Franzitta, V. Assessment of bioenergy potential in Sicily: A GIS-based support methodology. Biomass Bioenergy 2009, 33, 79–87. [Google Scholar] [CrossRef]

- Karjalainen, T.; Asikainen, A.; Ilavsky, J.; Zamboni, R.; Hotari, K.-E.; Röser, D. Estimation of Energy Wood Potential in Europe; Finnish Forest Research Institute (Metlan): Joensuu, Finland, 2004. [Google Scholar]

- Schmidt, M. The Sankey Diagram in Energy and Material Flow Management Part I: History. J. Ind. Ecol. 2008, 12, 82–94. [Google Scholar] [CrossRef]

- Soundararajan, K.; Ho, H.K.; Su, B. Sankey diagram framework for energy and exergy flows. Appl. Energy 2014, 136, 1035–1042. [Google Scholar] [CrossRef]

- Cuba, N. Research note: Sankey diagrams for visualizing land cover dynamics. Landsc. Urban Plan. 2015, 139, 163–167. [Google Scholar] [CrossRef]

- Mathijs, E.; Brunori, G.; Carus, M.; Griffon, M.; Last, L.; Gill, M.; Koljonen, T.; Lehoczky, E.; Olesen, I.; Potthast, A. Sustainable Agriculture, Forestry and Fisheries in the Bioeconomy—A Challenge for Europe; 4th SCAR Foresight Exercise; Kovacs, B., Ed.; European Commission: Brussels, Belgium, 2015; p. 141. [Google Scholar]

- Elbersen, H.W.; van der Zee, M.; Bos, H.L. The role of 4F Crops in EU27 under Contrasting Future Scenarios. Final report on WP6. In ‘Scenarios for Successful Establishment of Future Crops’ of the 4F CROPS Project; Wageningen UR Food Biobased Research: Wageningen, The Netherlands, 2010. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).