Optimizing Quality of Wood Pellets Made of Hardwood Processing Residues

Abstract

1. Introduction

2. Materials and Methods

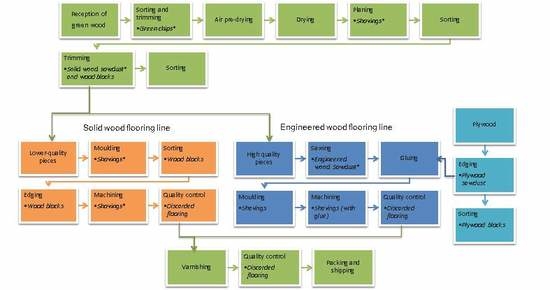

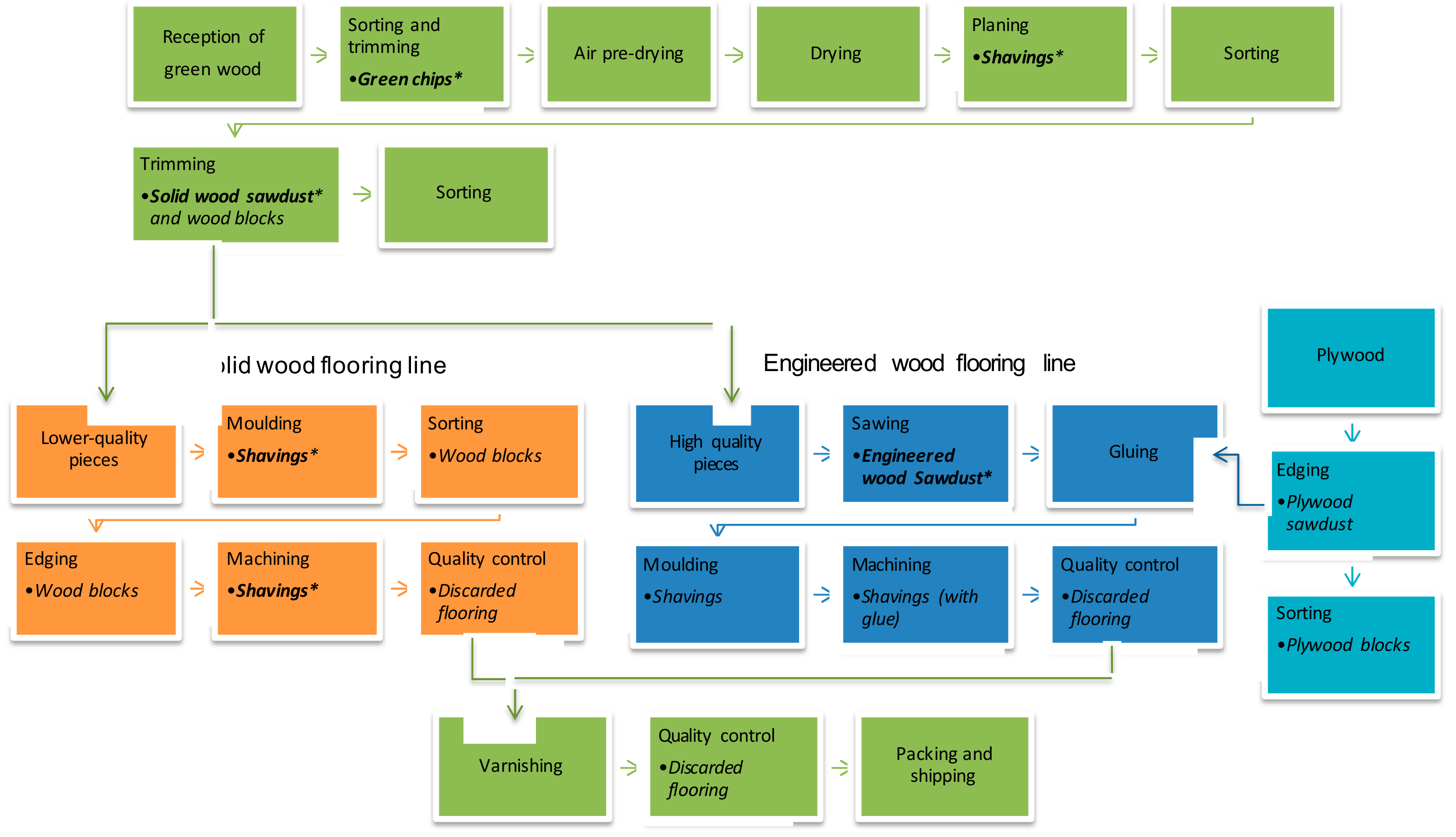

2.1. Sample Collection and Preparation

2.2. Characterization of Hardwood Flooring Residues

2.3. Pellet Production and Characterization

2.4. Data Analysis

3. Results

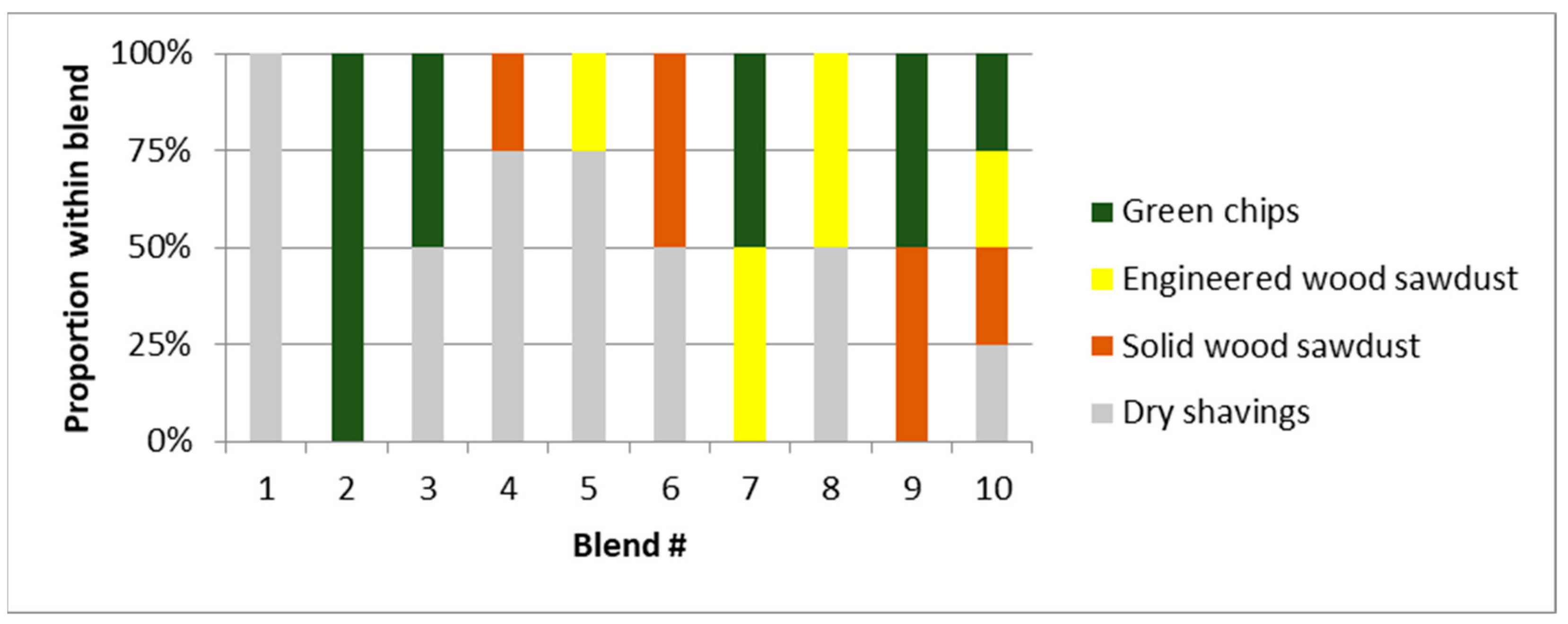

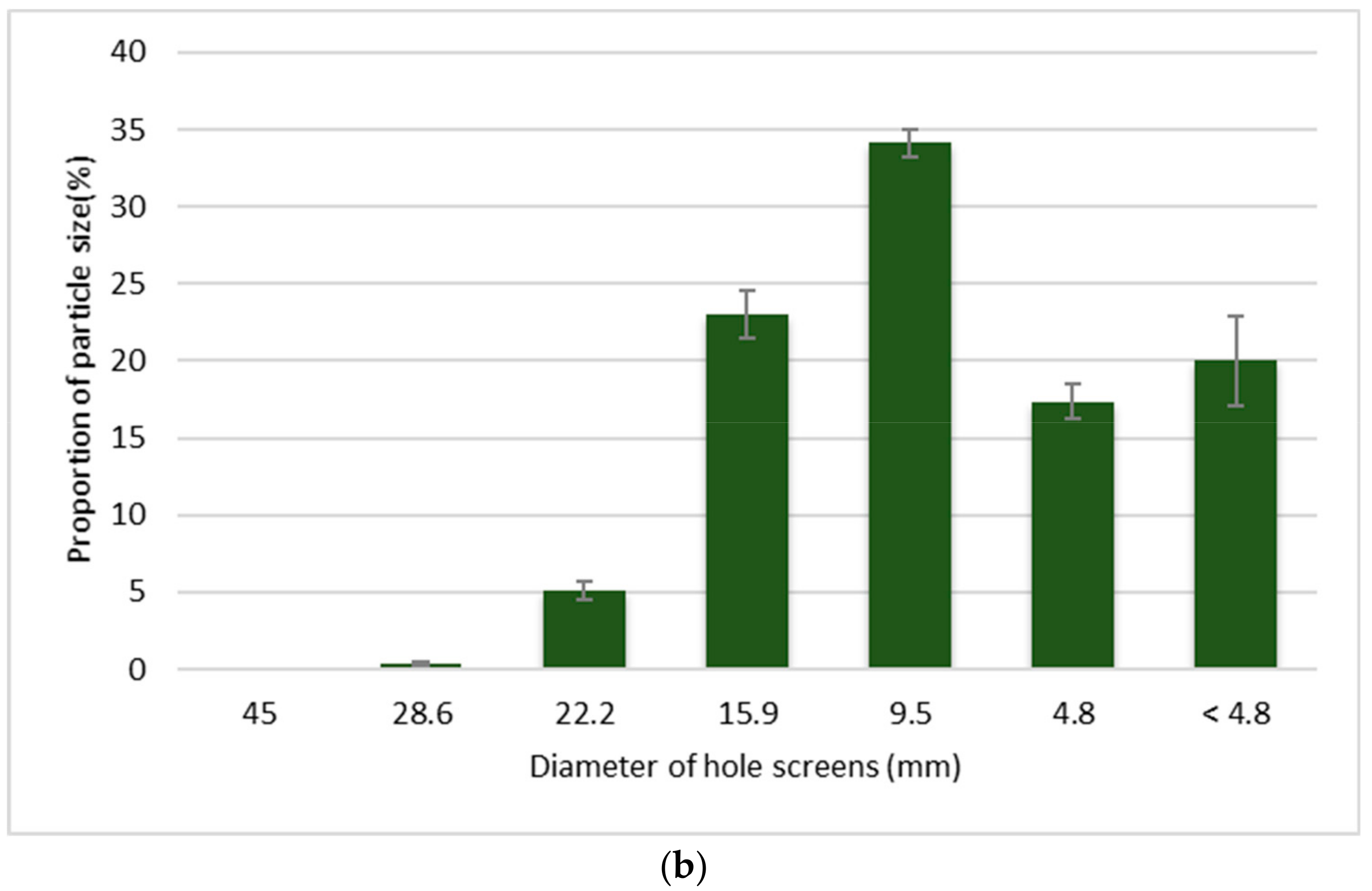

3.1. Properties of Residues

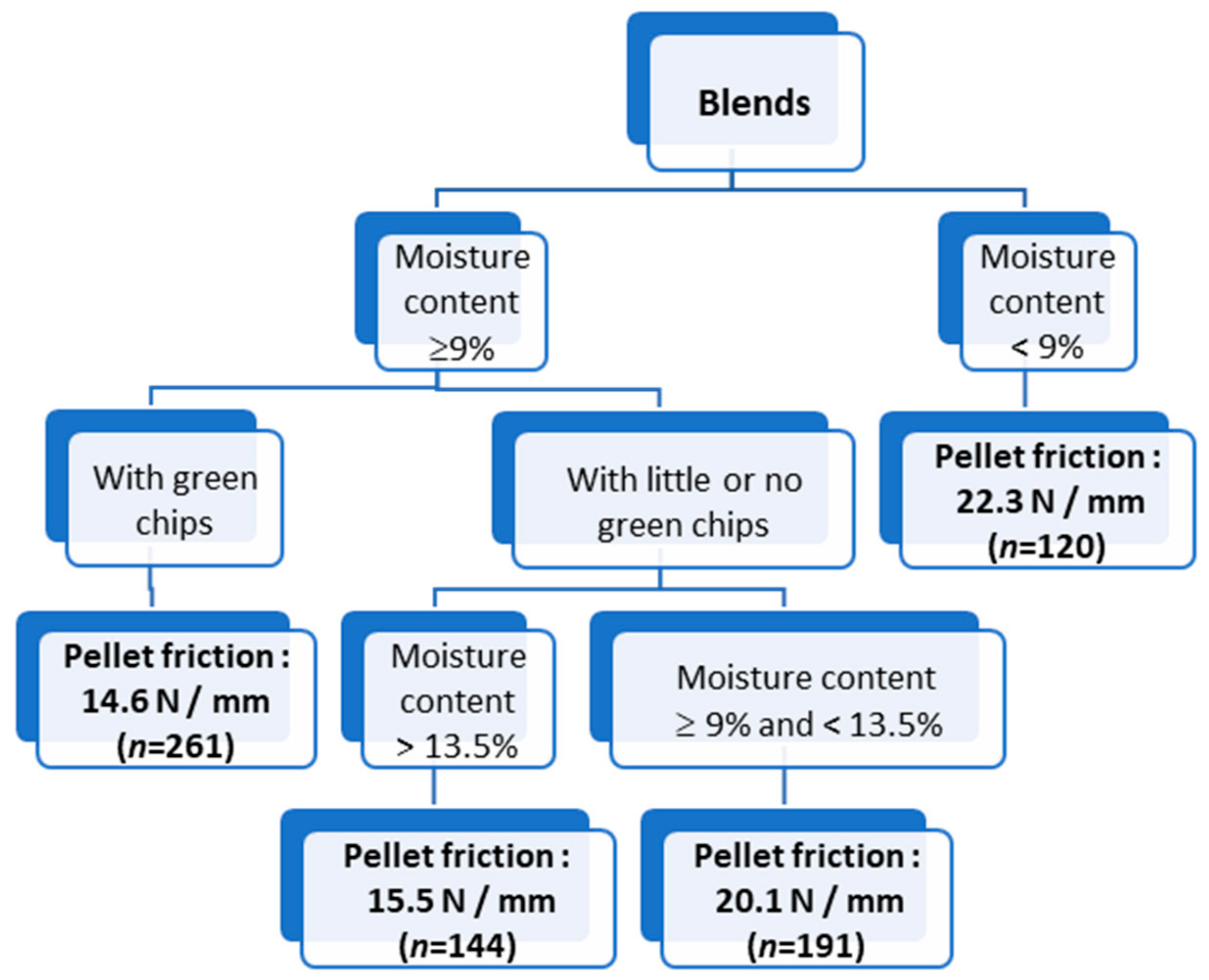

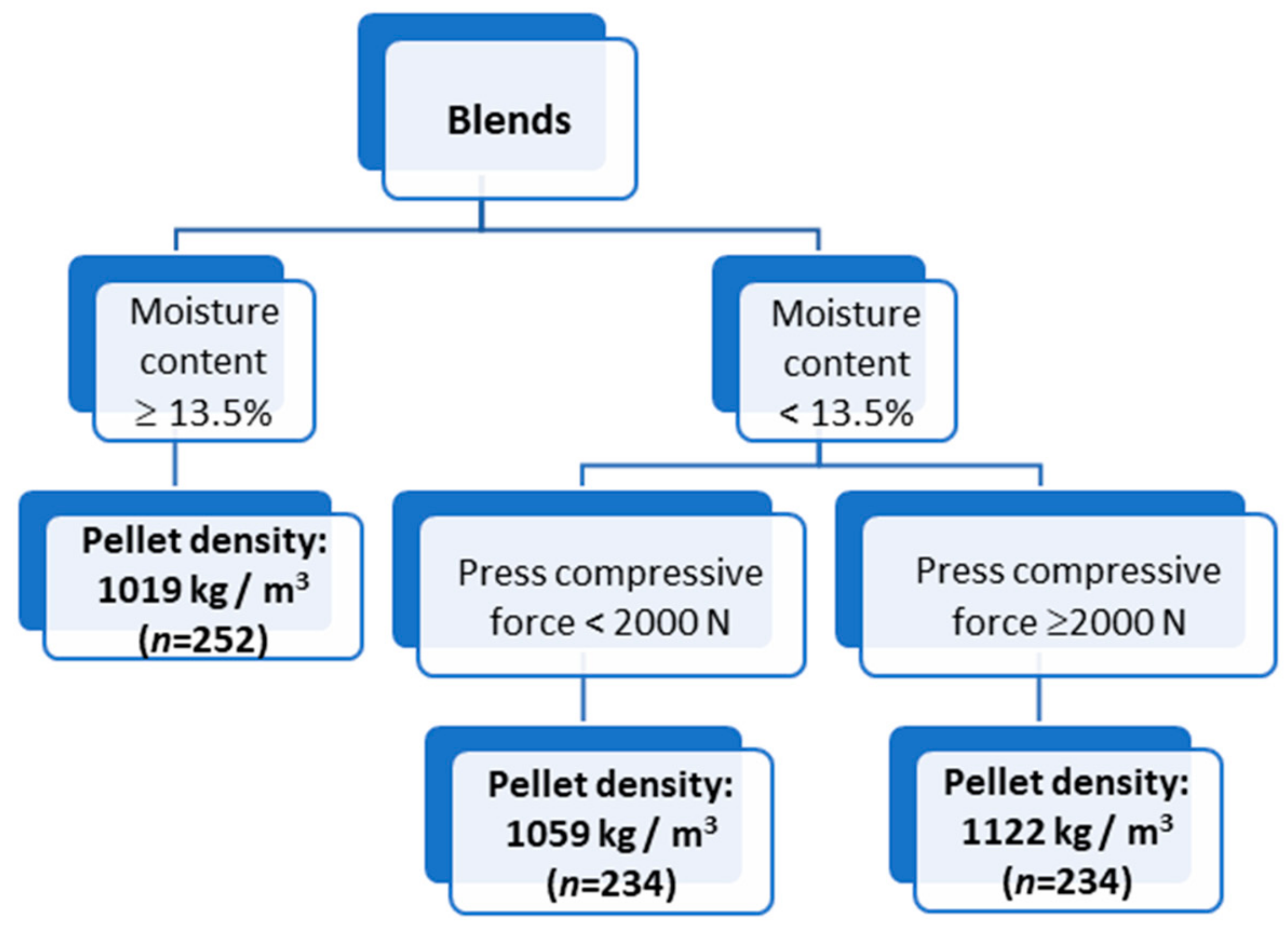

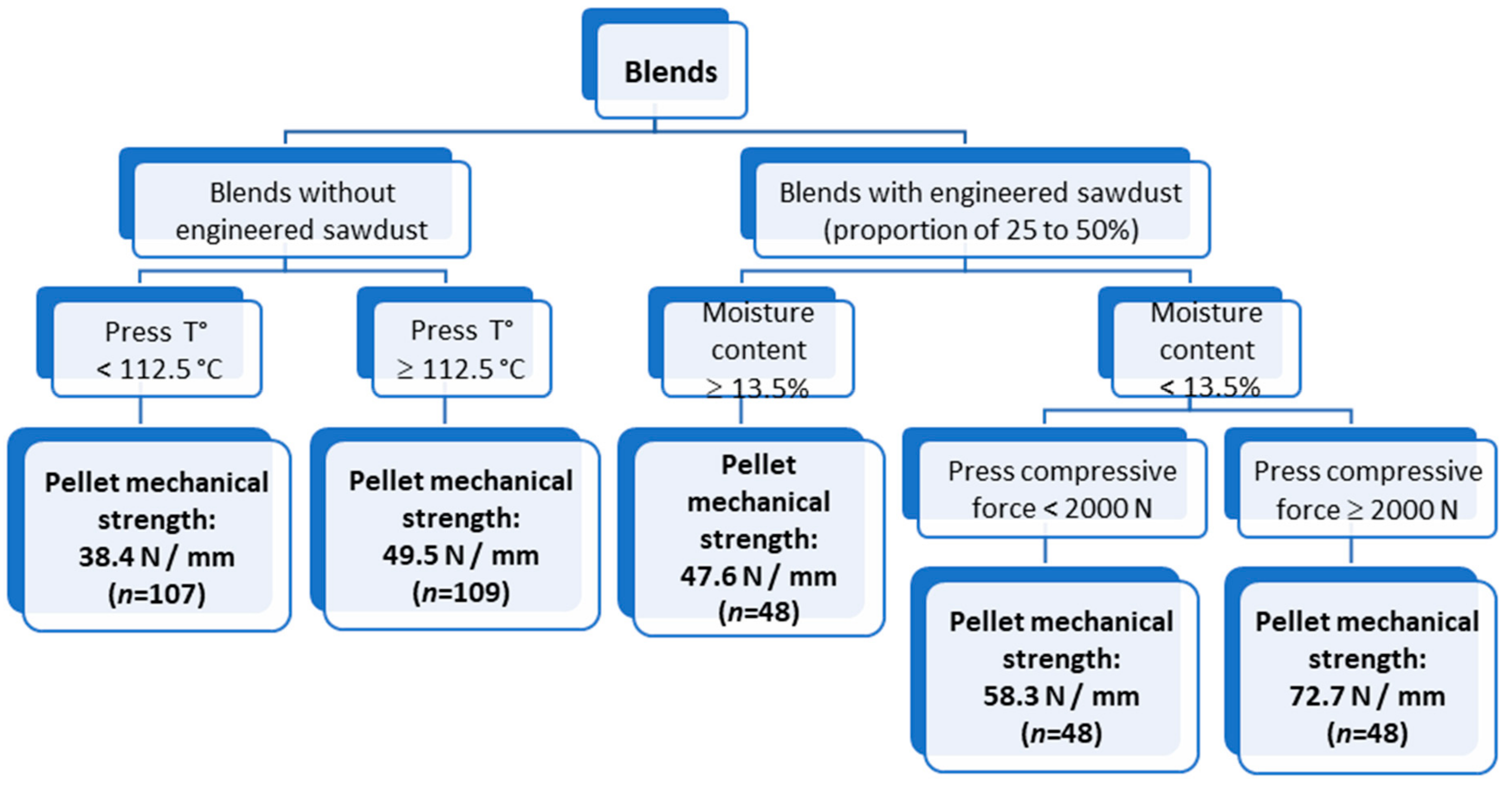

3.2. Pelletizing Characteristics and Quality of Pellets

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Feedstock Moisture Content (%) | 12 | 15 | As Received | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Compressive Force (N) | 1500 | 2500 | 1500 | 2500 | 1500 | 2500 | ||||||

| Temperature (°C) | 100 | 125 | 100 | 125 | 100 | 125 | 100 | 125 | 100 | 125 | 100 | 125 |

| Blend # | Pellet Moisture Content | |||||||||||

| 1 | 6.57 (0.05) | 2.79 (0.18) | 7.10 (.) | 3.15 (.) | 8.39 (0.48) | 3.13 (0.00) | 8.49 (0.09) | 2.88 (0.13) | 4.51 (0.17) | 2.68 (0.63) | 5.26 (0.21) | 3.88 (1.94) |

| 2 | 5.94 (2.68) | 1.42 (0.93) | 7.28 (0.14) | 2.16 (0.11) | 9.16 (1.91) | 2.92 (0.13) | 8.07 (0.51) | 1.88 (0.61) | 7.31 (2.54) | 2.76 (1.04) | 8.03 (0.00) | 2.39 (0.26) |

| 3 | 6.51 (0.10) | 1.78 (0.21) | 6.37 (0.14) | 2.00 (0.11) | 6.07 (2.72) | 2.33 (0.34) | 6.16 (0.80) | 2.57 (0.00) | 6.51 (0.10) | 1.78 (0.21) | 6.37 (0.14) | 2.00 (0.11) |

| 4 | 5.64 (.) | 1.08 (0.81) | 5.98 (0.09) | 2.00 (0.66) | 7.57 (0.46) | 1.36 (1.01) | 6.91 (0.09) | 2.17 (0.04) | 4.84 (0.07) | 1.79 (0.12) | 4.53 (0.52) | 2.31 (0.19) |

| 5 | 5.34 (0.39) | 0.99 (0.96) | 6.05(.) | 1.40 (0.49) | 7.75 (0.50) | 1.42 (0.40) | 7.94 (0.40) | 1.71 (0.72) | 4.16 (0.07) | 2.67 (0.38) | 4.72 (0.21) | 2.38 (0.49) |

| 6 | 5.78 (0.29) | 2.12 (0.57) | 6.77 (0.06) | 2.78 (0.02) | . (.) | 3.07 (0.31) | 8.32 (0.01) | 3.34 (0.87) | 4.39 (0.11) | 1.63 (0.26) | 4.68 (0.19) | 2.95 (0.20) |

| 7 | 7.06 (0.26) | 2.73 (0.25) | 7.27 (0.44) | 2.69 (0.68) | 9.07 (0.35) | 3.37 (0.53) | 8.05 (1.12) | 3.33 (0.54) | 7.06 (0.26) | 2.73 (0.25) | 7.27 (0.44) | 2.69 (0.68) |

| 8 | 6.25 (.) | 3.05 (.) | 6.15 (.) | 2.75 (.) | 8.38 (0.19) | 3.01 (0.79) | 8.69 (0.07) | 2.91 (0.21) | 5.05 (0.09) | 2.52 (0.37) | 5.34 (0.45) | 2.48 (0.39) |

| 9 | 6.84 (0.19) | 1.76 (0.10) | 6.18 (0.21) | 2.08 (0.51) | 8.45 (0.54) | 2.48 (0.14) | 7.98 (0.37) | 3.37 (0.40) | 6.48 (0.19) | 1.76 (0.10) | 6.18 (0.20) | 2.08 (0.51) |

| 10 | 5.73 (0.16) | 1.77 (0.06) | 6.35 (0.14) | 1.53 (0.76) | 8.99 (0.19) | 2.60 (0.14) | 8.49 (0.81) | 2.92 (0.29) | 5.73 (0.16) | 1.77 (0.06) | 6.35 (0.14) | 1.53 (0.76) |

| Pellet friction force (N·mm−1) | ||||||||||||

| 1 | 18.96 (1.20) | 22.11 (3.02) | 22.30 (2.18) | 21.97 (2.01) | 14.38 (1.18) | 16.80 (2.10) | 16.92 (1.83) | 18.33 (1.44) | 22.11 (1.25) | 24.14 (0.93) | 28.08 (2.26) | 25.96 (1.58) |

| 2 | 10.71 (1.06) | 8.91 (2.81) | 14.99 (1.48) | 11.70 (0.41) | 22.65 (2.17) | 17.16 (1.57) | 24.51 (1.45) | 13.66 (1.05) | 12.75 (1.31) | 14.89 (5.99) | 15.87 (1.81) | 14.09 (3.91) |

| 3 | 18.94 (1.02) | 17.57 (1.81) | 22.38 (2.34) | 20.70 (2.90) | 20.66 (1.54) | 16.65 (1.96) | 21.10 (1.92) | 17.20 (1.35) | 18.94 (1.02) | 17.57 (1.81) | 22.38 (2.34) | 20.70 (2.90) |

| 4 | 17.65 (1.20) | 17.56 (1.75) | 20.22 (1.77) | 20.85 (1.47) | 14.09 (1.97) | 16.29 (2.28) | 15.90 (0.82) | 15.45 (2.01) | 18.06 (2.61) | 19.11 (2.12) | 21.01 (2.56) | 22.59 (1.53) |

| 5 | 19.92 (2.20) | 19.37 (2.49) | 22.83 (1.95) | 18.97 (2.63) | 15.05 (1.23) | 12.83 (2.57) | 14.23 (0.90) | 13.69 (1.35) | 20.44 (1.72) | 23.14 (1.43) | 24.69 (1.50) | 23.68 (1.88) |

| 6 | 16.86 (1.46) | 15.01 (1.57) | 17.59 (1.44) | 15.87 (2.26) | 16.90 (7.06) | 15.52 (2.27) | 15.87 (1.09) | 14.10 (2.07) | 16.54 (2.25) | 17.65 (2.02) | 18.96 (1.39) | 26.08 (2.16) |

| 7 | 19.87 (2.11) | 18.77 (3.60) | 19.04 (2.15) | 19.46 (2.67) | 11.26 (0.69) | 10.80 (0.95) | 12.64 (1.39) | 13.41 (2.76) | 19.87 (2.11) | 18.77 (3.60) | 19.04 (2.15) | 19.46 (2.67) |

| 8 | 21.62 (3.29) | 22.22 (2.88) | 21.16 (1.12) | 21.38 (3.07) | 15.97 (1.95) | 15.76 (2.35) | 17.05 (0.97) | 16.87 (2.93) | 20.21 (0.93) | 23.22 (1.54) | 24.62 (1.81) | 25.06 (3.11) |

| 9 | 14.10 (2.42) | 10.78 (1.59) | 14.20 (2.14) | 14.04 (2.13) | 12.16 (1.22) | 12.42 (1.32) | 12.78 (1.52) | 12.68 (1.47) | 14.10 (2.43) | 10.78 (1.59) | 14.20 (2.14) | 14.04 (2.13) |

| 10 | 14.11 (1.14) | 11.83 (1.39) | 19.14 (2.08) | 16.05 (1.74) | 13.62 (1.11) | 11.49 (0.83) | 14.83 (1.42) | 11.88 (1.02) | 14.11 (1.14) | 11.83 (1.39) | 19.14 (2.08) | 16.05 (1.74) |

| Pellet density (kg·m−3) | ||||||||||||

| 1 | 1000 (11) | 1063 (15) | 1070 (13) | 1127 (14) | 904 (20) | 1023 (28) | 950 (26) | 1113 (23) | 1000 (18) | 1071 (13) | 1094 (14) | 1146 (25) |

| 2 | 930 (17) | 990 (20) | 969 (11) | 1023 (32) | 978 (20) | 1027 (13) | 1028 (14) | 1042 (26) | 936 (35) | 990 (30) | 968 (18) | 1022 (43) |

| 3 | 1012 (16) | 1034 (15) | 1070 (17) | 1098 (13) | 991 (15) | 1062 (14) | 1049 (11) | 1143 (9) | 1012 (16) | 1034 (15) | 1070 (17) | 1098 (13) |

| 4 | 1032 (16) | 1070 (28) | 1102 (9) | 1132 (23) | 938 (52) | 1018 (27) | 963 (15) | 1037 (43) | 1032 (16) | 1070 (12) | 1108 (11) | 1154 (13) |

| 5 | 1033 (19) | 1079 (7) | 1119 (15) | 1125 (51) | 966 (40) | 1012 (42) | 981 (17) | 1007 (40) | 1030 (9) | 1100 (10) | 1126 (9) | 1151 (39) |

| 6 | 1056 (10) | 1079 (23) | 1114 (9) | 1148 (44) | 1195 (513) | 1032 (49) | 1010 (18) | 1064 (45) | 1070 (14) | 1077 (17) | 1147 (12) | 1162 (13) |

| 7 | 1097 (24) | 1104 (20) | 1147 (15) | 1146 (33) | 1005 (14) | 1042 (35) | 1034 (10) | 1085 (47) | 1097 (24) | 1104 (20) | 1147 (15) | 1146 (33) |

| 8 | 1092 (44) | 1125 (9) | 1167 (14) | 1149 (34) | 997 (17) | 1050 (43) | 1037 (20) | 1089 (69) | 1078 (14) | 1091 (23) | 1168 (16) | 1180 (29) |

| 9 | 1057 (20) | 1094 (6) | 1121 (27) | 1138 (16) | 991 (26) | 1030 (37) | 1022 (41) | 1035 (32) | 1057 (20) | 1094 (6) | 1121 (27) | 1138 (16) |

| 10 | 1064 (30) | 1096 (5) | 1127 (12) | 1172 (26) | 985 (12) | 1002 (15) | 1007 (18) | 1020 (14) | 1064 (18) | 1096 (13) | 1127 (14) | 1172 (25) |

| Pellet strength (N·mm−1) | ||||||||||||

| 1 | 33.30 (2.18) | 53.39 (3.51) | 40.82 (1.94) | 62.43 (2.69) | 24.78 (1.34) | 39.99 (6.77) | 26.20 (7.28) | 42.48 (26.62) | 31.36 (3.18) | 54.67 (1.50) | 43.72 (4.96) | 61.33 (5.85) |

| 2 | 38.84 (3.73) | 40.51 (5.56) | 29.46 (1.06) | 39.35 (2.73) | 35.30 (5.45) | 53.05 (6.13) | 42.15 (3.42) | 39.81 (3.30) | 36.43 (1.15) | 39.42 (5.08) | 35.72 (9.18) | 36.75 (5.64) |

| 3 | 39.63 (2.54) | 44.96 (6.49) | 44.00 (4.25) | 48.25 (1.51) | 39.80 (9.28) | 48.63 (2.11) | 39.86 (3.35) | 58.94 (1.57) | 39.63 (2.54) | 44.96 (6.49) | 44.00 (4.25) | 48.25 (1.51) |

| 4 | 34.88 (4.24) | 54.15 (11.28) | 45.06 (6.38) | 55.21 (7.59) | 28.00 (7.36) | 36.58 (5.00) | 28.63 (2.05) | 45.84 (4.66) | 35.44 (1.68) | 50.72 (3.05) | 45.41 (4.04) | 64.20 (3.88) |

| 5 | 43.97 (1.93) | 60.68 (1.75) | 55.43 (3.67) | 77.07 (4.91) | 33.38 (8.05) | 47.08 (10.90) | 38.81 (1.00) | 45.35 (9.48) | 44.55 (2.00) | 65.31 (3.77) | 63.35 (2.91) | 80.54 (6.23) |

| 6 | 41.43 (1.41) | 52.59 (7.85) | 49.37 (1.32) | 44.68 (29.15) | 32.55 (1.87) | 50.59 (5.72) | 33.08 (4.60) | 53.30 (8.87) | 35.93 (1.42) | 48.05 (8.34) | 50.65 (4.15) | 55.72 (10.49) |

| 7 | 65.49 (3.42) | 69.02 (7.49) | 67.00 (3.82) | 81.46 (2.28) | 42.61 (1.96) | 60.16 (90.50) | 45.96 (1.48) | 62.24 (6.62) | 65.49 (3.42) | 69.02 (7.49) | 67.00 (3.82) | 81.46 (2.28) |

| 8 | 53.89 (13.24) | 71.00 (8.30) | 74.34 (6.26) | 86.88 (1.50) | 38.78 (2.23) | 65.77 (9.26) | 43.31 (6.87) | 66.73 (16.80) | 53.37 (4.28) | 65.97 (6.49) | 74.07 (3.61) | 80.54 (12.06) |

| 9 | 44.85 (2.14) | 53.06 (3.76) | 49.70 (2.12) | 56.76 (4.29) | 32.46 (4.73) | 43.55 (7.40) | 34.27 (4.05) | 38.24 (5.61) | 44.85 (2.14) | 53.06 (3.76) | 49.70 (2.12) | 56.76 (4.29) |

| 10 | 43.32 (13.37) | 59.53 (4.85) | 60.98 (3.31) | 76.35 (4.86) | 37.78 (2.58) | 47.31 (6.89) | 42.81 (2.74) | 43.87 (3.47) | 43.32 (13.37) | 59.53 (4.85) | 60.98 (3.31) | 76.35 (4.86) |

References

- Chum, H.; Faaij, A.; Moreira, J.; Berndes, G.; Dhamija, P.; Dong, H.; Gabrielle, B.; Goss Eng, A.; Lucht, W.; Mapako, M.; et al. Bioenergy. In IPCC Special Report on Renewable Energy Sources and Climate Change Mitigation; Edenhofer, O., Pichs-Madruga, R., Sokona, Y., Seyboth, K., Matschoss, P., Kadner, S., Zwickel, T., Eickemeier, P., Hansen, G., Schlömer, S., et al., Eds.; Cambridge University Press: Cambridge, UK, 2011. [Google Scholar]

- Kopetz, H. Build a biomass energy market. Nature 2013, 494, 29. [Google Scholar] [CrossRef] [PubMed]

- Majer, S.; Thrän, D. Biomass Resources and Sustainability Issues for a Flexible Bioenergy Provision. In Smart Bioenergy: Technologies and Concepts for a More Flexible Bioenergy Provision in Future Energy Systems; Thrän, D., Ed.; Springer International Publishing: Cham, Switzerland, 2015; pp. 33–48. [Google Scholar] [CrossRef]

- Lamers, P.; Hoefnagels, R.; Junginger, M.; Hamelinck, C.; Faaij, A. Global solid biomass trade for energy by 2020: An assessment of potential import streams and supply costs to North-West Europe under different sustainability constraints. GCB Bioenergy 2015, 7, 618–634. [Google Scholar] [CrossRef]

- Sultana, A.; Kumar, A. Ranking of biomass pellets by integration of economic, environmental and technical factors. Biomass Bioenergy 2012, 39, 344–355. [Google Scholar] [CrossRef]

- Thrän, D.; Peetz, D.; Schaubach, K. Global Wood Pellet Industry and Trade Study 2017. Available online: http://task40.ieabioenergy.com/wp-content/uploads/2013/09/IEA-Wood-Pellet-Study_final-2017-06.pdf (accessed on 23 July 2019).

- Gouvernement du Québec. Production et Utilisation des Sous-Produits Générés par les Entreprises de Deuxième Transformation du Bois du Québec en 2013; Ministère des Forêts, de la Faune et des Parcs, Ed.; Gouvernement du Québec: Quebec City, QC, Canada, 2014; p. 36.

- Ghafghazi, S.; Lochhead, K.; Mathey, A.-H.; Forsell, N.; Leduc, S.; Mabee, W.; Bull, G. Estimating mill residue surplus in Canada: A spatial forest fiber cascade modeling approach. For. Prod. J. 2017, 67, 205–218. [Google Scholar] [CrossRef]

- Bradfield, J.; Levi, M. Effect of species and wood to bark ratio on pelleting of southern woods. For. Prod. J. 1984, 34, 61–63. [Google Scholar]

- Holm, J.K.; Henriksen, U.B.; Hustad, J.E.; Sørensen, L.H. Toward an Understanding of Controlling Parameters in Softwood and Hardwood Pellets Production. Energy Fuel 2006, 20, 2686–2694. [Google Scholar] [CrossRef]

- Nguyen, Q.N.; Cloutier, A.; Achim, A.; Stevanovic, T. Effect of process parameters and raw material characteristics on physical and mechanical properties of wood pellets made from sugar maple particles. Biomass Bioenergy 2015, 80, 338–349. [Google Scholar] [CrossRef]

- Obernberger, I.; Thek, G. The Pellet Handbook: The Production and Thermal Utilisation of Pellets; Earthscan: London, UK, 2010; p. 592. [Google Scholar]

- Arshadi, M.; Gref, R.; Geladi, P.; Dahlqvist, S.-A.; Lestander, T. The influence of raw material characteristics on the industrial pelletizing process and pellet quality. Fuel Process. Technol. 2008, 89, 1442–1447. [Google Scholar] [CrossRef]

- Junginger, M.; van Dam, J.; Zarrilli, S.; Ali Mohamed, F.; Marchal, D.; Faaij, A. Opportunities and barriers for international bioenergy trade. Energy Policy 2011, 39, 2028–2042. [Google Scholar] [CrossRef]

- Goh, C.S.; Junginger, M.; Cocchi, M.; Marchal, D.; Thrän, D.; Hennig, C.; Heinimö, J.; Nikolaisen, L.; Schouwenberg, P.-P.; Bradley, D.; et al. Wood pellet market and trade: A global perspective. Biofuel. Bioprod. Biorefin. 2013, 7, 24–42. [Google Scholar] [CrossRef]

- BSI. DD CEN/TS 15149-1:2006 Solid Biofuels. Methods for the Determination of Particle Size Distribution. Oscillating Screen Method Using Sieve Apertures of 3,15 mm and Above; BSI: London, UK, 2006. [Google Scholar]

- BSI. DD CEN/TS 15149-2:2006 Solid Biofuels. Methods for the Determination of Particle Size Distribution. Vibrating Screen Method Using Sieve Apertures of 3,15 mm and Below; BSI: London, UK, 2006. [Google Scholar]

- Barrette, J.; Pothier, D.; Duchesne, I. Lumber and wood chips properties of dead and sound black spruce trees grown in the boreal forest of Canada. For. Int. J. For. Res. 2015, 88, 108–120. [Google Scholar] [CrossRef]

- European Committee for Standardization. EN ISO 18134-3:2015. Solid Biofuels. Determination of Moisture Content. Oven Dry Method. Moisture in General Analysis Sample; European Committee for Standardization: Brussels, Belgium, 2015. [Google Scholar]

- ASTM International. ASTM D5057-10 (2010) Standard Test Method for Screening Apparent Specific Gravity and Bulk Density of Waste; ASTM International: West Conshohocken, PA, USA, 2010. [Google Scholar]

- European Committee for Standardization. EN ISO 18125:2017. Solid Biofuels. Determination of Calorific Value; European Committee for Standardization: Brussels, Belgium, 2017. [Google Scholar]

- Van Soest, P.J.; Robertson, J.B.; Lewis, B.A. Methods for Dietary Fiber, Neutral Detergent Fiber, and Nonstarch Polysaccharides in Relation to Animal Nutrition. J. Dairy Sci. 1991, 74, 3583–3597. [Google Scholar] [CrossRef]

- Godin, B.; Agneessens, R.; Gofflot, S.; Lamaudière, S.; Sinnaeve, G.; Gerin, P.A.; Delcarte, J. Revue bibliographique sur les méthodes d’analyse des polysaccharides structuraux des biomasses lignocellulosiques/Review on analytical methods for lignocellulosic biomass structural polysaccharides. Biotechnol. Agron. Société Environ. 2011, 15, 165. [Google Scholar]

- ASTM International. ASTM D1102-84(2013), Standard Test Method for Ash in Wood; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- Team, R.C. R: A Language and Environment for Statistical Computing, v. 3.0.1; R Foundation for Statistical Computing: Vienna, Austria, 2013. [Google Scholar]

- Coronella, C.J.; Yan, W.; Reza, M.T.; Vasquez, V.R. Method for Wet Torrefacton of Biomass. US Patent App. 13/223,562, 10 May 2012. [Google Scholar]

- Bhattacharya, S.C.; Sett, S.; Shrestha, R.M. State of the Art for Biomass Densification. Energy Sour. 1989, 11, 161–182. [Google Scholar] [CrossRef]

- Hansen, M.T.; Jein, A.R.; Hayes, S.; Bateman, P. English Handbook for Wood Pellet Combustion; National Energy Foundation: Milton Keynes, UK, 2009; p. 85. [Google Scholar]

- Tillman, D.A. Wood as an Energy Resource; Academic Press: New York, NY, USA, 1978; p. 266. [Google Scholar]

- Panshin, A.J.; Zeeuw, C.D. Textbook of Wood Technology; McGraw-Hill Book Co.: New York, NY, USA, 1980; p. 772. [Google Scholar]

- Telmo, C.; Lousada, J. Heating values of wood pellets from different species. Biomass Bioenergy 2011, 35, 2634–2639. [Google Scholar] [CrossRef]

- Demirbas, A. Relationships between Heating Value and Lignin, Moisture, Ash and Extractive Contents of Biomass Fuels. Energy Explor. Exploit. 2002, 20, 105–111. [Google Scholar] [CrossRef]

- Kataki, R.; Konwer, D. Fuelwood characteristics of some indigenous woody species of north-east India. Biomass Bioenergy 2001, 20, 17–23. [Google Scholar] [CrossRef]

- Alakangas, E.; Valtanen, J.; Levlin, J.-E. CEN technical specification for solid biofuels—Fuel specification and classes. Biomass Bioenergy 2006, 30, 908–914. [Google Scholar] [CrossRef]

- Obernberger, I.; Brunner, T.; Bärnthaler, G. Chemical properties of solid biofuels—Significance and impact. Biomass Bioenergy 2006, 30, 973–982. [Google Scholar] [CrossRef]

- Werther, J.; Saenger, M.; Hartge, E.-U.; Ogada, T.; Siagi, Z. Combustion of agricultural residues. Prog. Energy Combust. Sci. 2000, 26, 1–27. [Google Scholar] [CrossRef]

- Tarasov, D.; Shahi, C.; Leitch, M. Effect of additives on wood pellet physical and thermal characteristics: A review. Isrn For. 2013, 1–6. [Google Scholar] [CrossRef]

- Telmo, C.; Lousada, J.; Moreira, N. Proximate analysis, backwards stepwise regression between gross calorific value, ultimate and chemical analysis of wood. Bioresour. Technol. 2010, 101, 3808–3815. [Google Scholar] [CrossRef] [PubMed]

- Leckner, B.; Karlsson, M. Gaseous emissions from circulating fluidized bed combustion of wood. Biomass Bioenergy 1993, 4, 379–389. [Google Scholar] [CrossRef]

- Shang, L.; Nielsen, N.P.K.; Stelte, W.; Dahl, J.; Ahrenfeldt, J.; Holm, J.K.; Arnavat, M.P.; Bach, L.S.; Henriksen, U.B. Lab and bench-scale pelletization of torrefied wood chips—Process optimization and pellet quality. BioEnergy Res. 2014, 7, 87–94. [Google Scholar] [CrossRef]

- Kuang, X.; Shankar, T.J.; Bi, X.T.; Lim, C.J.; Sokhansanj, S.; Melin, S. Rate and peak concentrations of off-gas emissions in stored wood pellets—Sensitivities to temperature, relative humidity, and headspace volume. Anna. Occup. Hyg. 2009, 53, 789–796. [Google Scholar]

- Stelte, W.; Holm, J.K.; Sanadi, A.R.; Barsberg, S.; Ahrenfeldt, J.; Henriksen, U.B. Fuel pellets from biomass: The importance of the pelletizing pressure and its dependency on the processing conditions. Fuel 2011, 90, 3285–3290. [Google Scholar] [CrossRef]

- Asikainen, A.; Ikonen, T.; Routa, J. Challenges and opportunities of logistics and economics of forest biomass. In Mobilisation of Forest Bioenergy in the Boreal and Temperate Biomes: Challenges, Opportunities and Case Studies; Thiffault, E., Berndes, G., Junginger, M., Saddler, J., Smith, T., Eds.; Academic Press: Cambridge, MA, USA, 2016; pp. 68–83. [Google Scholar]

- Kong, J.; Rönnqvist, M.; Frisk, M. Modeling an integrated market for sawlogs, pulpwood, and forest bioenergy. Can. J. For. Res. 2012, 42, 315–332. [Google Scholar] [CrossRef]

| Parameter | Dry Shavings | Solid Wood Sawdust | Engineered Wood Sawdust | Green Wood Chips |

|---|---|---|---|---|

| Moisture content (%, d.b.) | 6.97 ± 0.08 | 8.21 ± 0.31 | 10.01 ± 0.21 | 42.91 ± 2.17 |

| Moisture content (%, w.b.) | 6.52 ± 0.07 | 7.59 ± 0.27 | 9.10 ± 0.17 | 30.02 ± 1.07 |

| Bulk density (kg m−3) | 123 ± 19 | 195 ± 12 | 133 ± 8 | 52 ± 5 |

| Higher heating value (MJ kg−1) | 19.7 ± 0.1 | 19.7 ± 0.1 | 19.4 ± 0.1 | 19.6 ± 0.5 |

| Chemical composition (%) | ||||

| Extractives | 6.1 ± 0.1 | 8.1 ± 0.2 | 7.0 ± 0.3 | 5.1 ± 0.4 |

| Cellulose | 51.0 ± 0.8 | 48.8 ± 1.2 | 50.1 ± 1.4 | 51.0 ± 0.3 |

| Hemicellulose | 24.6 ± 0.8 | 24.5 ± 0.6 | 27.0 ± 0.3 | 26.7 ± 0.9 |

| Lignin | 18.4 ± 0.2 | 18.6 ± 1.0 | 16.0 ± 1.4 | 17.2 ± 0.3 |

| Ash | 0.43 ± 0.03 | 0.69 ± 0.05 | 0.60 ± 0.04 | 0.44 ± 0.03 |

| Ultimate analysis (wt %, dry ash free) | ||||

| Carbon | 48.03 ± 0.51 | 48.01 ± 0.19 | 47.57 ± 0.59 | 48.95 ± 0.21 |

| Nitrogen | 0.06 ± 0.02 | 0.07 ± 0.00 | 0.05 ± 0.01 | 0.06 ± 0.00 |

| Sulfur | 0.01 ± 0.01 | 0.02 ± 0.01 | 0.02 ± 0.01 | 0.02 ± 0.03 |

| Major element analysis (mg kg−1) | ||||

| Al | 680 ± 129 | 30 ± 0 | 110 ± 140 | 50 ± 10 |

| Ca | 870 ± 80 | 1480 ± 170 | 760 ± 100 | 1200 ± 90 |

| Fe | 0 ± 0 | 0 ± 0 | 10 ± 10 | 10 ± 10 |

| K | 740 ± 120 | 520 ± 40 | 680 ± 130 | 360 ± 40 |

| Mg | 20 ± 70 | 180 ± 30 | 290 ± 110 | 190 ± 10 |

| P | 70 ± 30 | 40 ± 10 | 30 ± 10 | 80 ± 40 |

| Minor element analysis (mg kg−1) | ||||

| Cu | 20 ± 20 | 10 ± 10 | 30 ± 10 | 40 ± 20 |

| Mn | 40 ± 10 | 40 ± 0 | 40 ± 20 | 130 ± 10 |

| Zn | 10 ± 0 | 10 ± 0 | 10 ± 0 | 20 ± 0 |

| Particle Size Distribution (% per Diameter of Hole Screen) | Moisture Content (%, d.b.) | Bulk Density (kg m−3) | Higher Heating Value (MJ kg−1) | Ash Content (%) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Blend # | 3.35 mm | 2.80 mm | 1.40 mm | 1.00 mm | 0.50 mm | 0.25 mm | <0.25 mm | ||||

| 1 | 0.0 | 0.0 | 3.0 | 10.0 | 38.0 | 33.0 | 16.0 | 6.8 | 220 | 19.79 | 0.37 |

| 2 | 0.0 | 0.0 | 15.0 | 23.0 | 36.0 | 18.0 | 8.0 | 16.8 | 99 | 19.69 | 0.44 |

| 3 | 0.0 | 0.0 | 8.0 | 19.0 | 39.0 | 24.0 | 11.0 | 11.0 | 163 | 19.78 | 0.41 |

| 4 | 0.0 | 0.0 | 3.0 | 9.0 | 31.0 | 28.0 | 28.0 | 6.9 | 236 | 19.72 | 0.47 |

| 5 | 0.0 | 0.0 | 3.0 | 10.0 | 32.0 | 27.0 | 28.8 | 7.2 | 206 | 19.55 | 0.45 |

| 6 | 0.0 | 0.0 | 2.0 | 5.0 | 21.0 | 24.0 | 47.0 | 7.5 | 235 | 19.79 | 0.53 |

| 7 | 0.0 | 0.0 | 4.0 | 9.0 | 19.0 | 18.0 | 49.0 | 11.7 | 129 | 19.56 | 0.53 |

| 8 | 0.0 | 0.0 | 2.0 | 7.0 | 24.0 | 25.0 | 42.0 | 7.8 | 185 | 19.69 | 0.52 |

| 9 | 0.0 | 0.0 | 7.0 | 11.0 | 20.0 | 17.0 | 44.0 | 11.0 | 179 | 19.69 | 0.62 |

| 10 | 0.0 | 0.0 | 5.0 | 10.0 | 21.0 | 19.0 | 45.0 | 10.0 | 169 | 19.74 | 0.60 |

| Factor | Df | Sum sq | Mean sq | F-Value | p-Value |

|---|---|---|---|---|---|

| Blend composition | 9 | 4459.4 | 495.49 | 109.2242 | <0.001 |

| Blend moisture content | 2 | 1988.2 | 994.08 | 219.133 | <0.001 |

| Press compressive force | 1 | 532.3 | 532.26 | 117.3301 | <0.001 |

| Press temperature | 1 | 94.2 | 94.15 | 20.7551 | <0.001 |

| Press compressive force: Blend composition | 9 | 93.3 | 10.37 | 2.2857 | 0.015 |

| Press temperature: Blend composition | 9 | 386.6 | 42.95 | 9.4686 | <0.001 |

| Blend moisture content: Blend composition | 18 | 2842.9 | 157.94 | 34.8159 | <0.001 |

| Press compressive force: Blend moisture content | 2 | 175.6 | 87.81 | 19.3562 | <0.001 |

| Press compressive force: Press temperature | 1 | 11 | 10.96 | 2.4161 | 0.121 |

| Blend moisture content: Press temperature | 2 | 84.9 | 42.45 | 9.3569 | <0.001 |

| Press compressive force: Blend moisture content: Press temperature | 2 | 0.3 | 0.16 | 0.0356 | 0.965 |

| Press compressive force: Blend moisture content: Blend composition | 18 | 255.6 | 14.2 | 3.1303 | <0.001 |

| Press compressive force: Press temperature: Blend composition | 9 | 151.3 | 16.81 | 3.7055 | <0.001 |

| Blend moisture content: Press temperature: Blend composition | 18 | 351.7 | 19.54 | 4.3074 | <0.001 |

| Press compressive force: Blend moisture content: Press temperature: Blend composition | 18 | 115.4 | 6.41 | 1.4133 | 0.118 |

| Residuals | 596 | 2703.7 | 4.54 |

| Factor | Df | Sum sq | Mean sq | F-Value | p-Value |

|---|---|---|---|---|---|

| Blend composition | 9 | 679,781 | 75,531 | 23.2459 | <0.001 |

| Blend moisture content | 2 | 622,911 | 311,456 | 95.8554 | <0.001 |

| Press compressive force | 1 | 439,546 | 439,546 | 135.2774 | <0.001 |

| Press temperature | 1 | 232,895 | 232,895 | 71.6771 | <0.001 |

| Press compressive force: Blend composition | 9 | 36,322 | 4036 | 1.2421 | 0.266 |

| Press temperature: Blend composition | 9 | 96,469 | 10,719 | 3.2989 | <0.001 |

| Blend moisture content: Blend composition | 18 | 380,266 | 21,126 | 6.5018 | <0.001 |

| Press compressive force: Blend moisture content | 2 | 63,947 | 31,973 | 9.8404 | <0.001 |

| Press compressive force: Press temperature | 1 | 94 | 94 | 0.0289 | 0.865 |

| Blend moisture content: Press temperature | 2 | 7466 | 3733 | 1.1489 | 0.317 |

| Press compressive force: Blend moisture content: Press temperature | 2 | 8885 | 4443 | 1.3673 | 0.255 |

| Press compressive force: Blend moisture content: Blend composition | 18 | 78,938 | 4385 | 1.3497 | 0.151 |

| Press compressive force: Press temperature: Blend composition | 9 | 38,329 | 4259 | 1.3107 | 0.228 |

| Blend moisture content: Press temperature: Blend composition | 18 | 81,155 | 4509 | 1.3876 | 0.131 |

| Press compressive force: Blend moisture content: Press temperature: Blend composition | 18 | 42,871 | 2382 | 0.733 | 0.778 |

| Residuals | 600 | 1,949,534 | 3249 |

| Factor | Df | Sum sq | Mean sq | F-Value | p-Value |

|---|---|---|---|---|---|

| Press compressive force | 1 | 3649.4 | 3649.4 | 84.4256 | <0.001 |

| Blend moisture content | 2 | 9155.2 | 4577.6 | 105.8972 | <0.001 |

| Press temperature | 1 | 13,419.2 | 13,419.2 | 310.4363 | <0.001 |

| Blend composition | 9 | 26,164.4 | 2907.2 | 67.2535 | <0.001 |

| Press compressive force: Blend composition | 9 | 2005.9 | 222.9 | 5.156 | <0.001 |

| Press temperature: Blend composition | 9 | 1994.8 | 221.6 | 5.1276 | <0.001 |

| Blend moisture content: Blend composition | 18 | 5842.5 | 324.6 | 7.5089 | <0.001 |

| Press compressive force: Blend moisture content | 2 | 855.2 | 427.6 | 9.8926 | <0.001 |

| Press compressive force: Press temperature | 1 | 32.5 | 32.5 | 0.753 | 0.386 |

| Blend moisture content: Press temperature | 2 | 144 | 72 | 1.6658 | 0.191 |

| Press compressive force: Blend moisture content: Press temperature | 2 | 0.6 | 0.3 | 0.0072 | 0.993 |

| Press compressive force: Blend moisture content: Blend composition | 18 | 1000.9 | 55.6 | 1.2863 | 0.197 |

| Press compressive force: Press temperature: Blend composition | 9 | 405.1 | 45 | 1.0412 | 0.408 |

| Blend moisture content: Press temperature: Blend composition | 18 | 1407.4 | 78.2 | 1.8088 | 0.025 |

| Press compressive force: Blend moisture content: Press temperature: Blend composition | 18 | 956.9 | 53.2 | 1.2298 | 0.238 |

| Residuals | 240 | 10,374.4 | 43.2 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Thiffault, E.; Barrette, J.; Blanchet, P.; Nguyen, Q.N.; Adjalle, K. Optimizing Quality of Wood Pellets Made of Hardwood Processing Residues. Forests 2019, 10, 607. https://doi.org/10.3390/f10070607

Thiffault E, Barrette J, Blanchet P, Nguyen QN, Adjalle K. Optimizing Quality of Wood Pellets Made of Hardwood Processing Residues. Forests. 2019; 10(7):607. https://doi.org/10.3390/f10070607

Chicago/Turabian StyleThiffault, Evelyne, Julie Barrette, Pierre Blanchet, Quy Nam Nguyen, and Kokou Adjalle. 2019. "Optimizing Quality of Wood Pellets Made of Hardwood Processing Residues" Forests 10, no. 7: 607. https://doi.org/10.3390/f10070607

APA StyleThiffault, E., Barrette, J., Blanchet, P., Nguyen, Q. N., & Adjalle, K. (2019). Optimizing Quality of Wood Pellets Made of Hardwood Processing Residues. Forests, 10(7), 607. https://doi.org/10.3390/f10070607