5.3.1. Grading Results

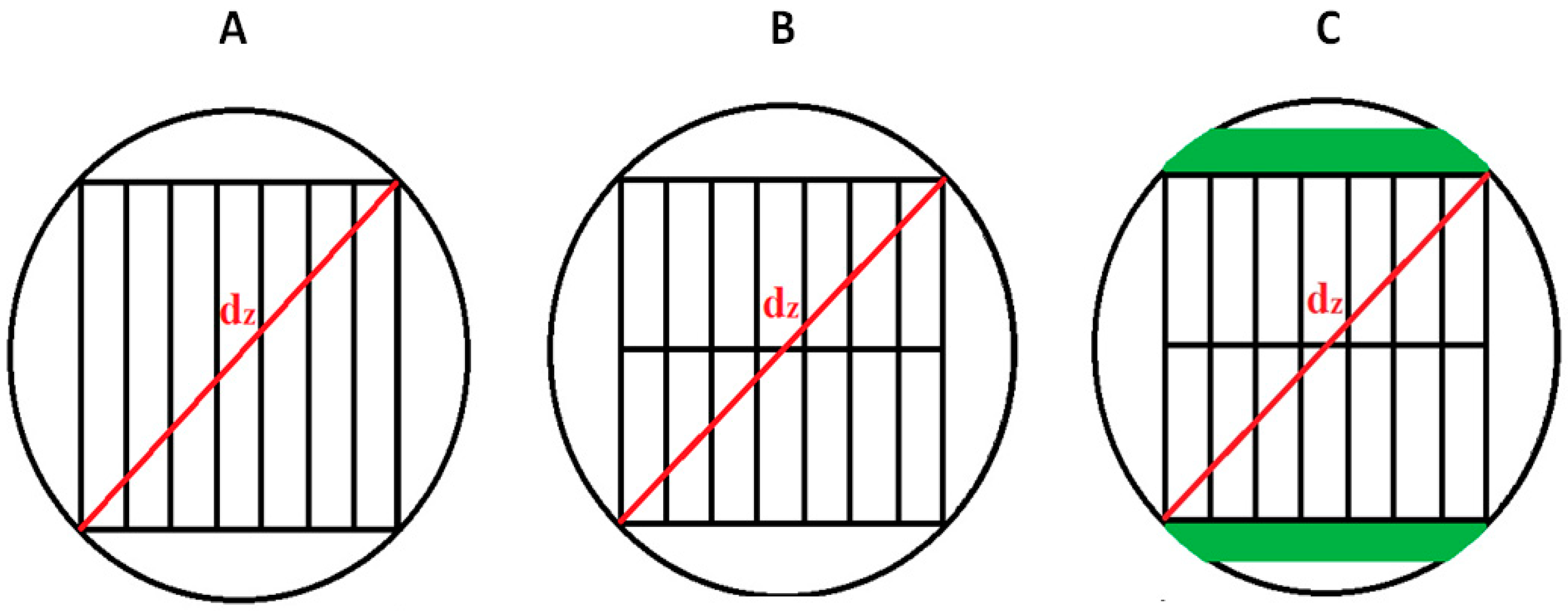

As explained in

Section 4.5, the planed boards were graded visually according to the German visual strength grading standard DIN 4074-5 [

16]. Furthermore, the result of two adjusted grading schemes were compared—when the criterion “pith” is excluded from visual strength grading according to DIN 4074-5 [

16] and when only single knots (DEB) are evaluated according to DIN 4074-5 [

16]. Additionally, the lamellas were graded following the combined visual and machine grading proposed by Kovryga et al. [

31] and presented in

Table 3.

Figure 3 shows the grading results for ash and maple, respectively. The second box of each diagram gives the results of visual grading according to DIN 4074-5 [

16]. For both ash and maple, only few boards are sorted into the classes LS7 and LS10. The majority is either sorted into the highest quality class LS13 or rejected. When excluding the criterion pith from DIN 4074-5 [

16] sorting (see third box), no ash lamellas and four maple lamellas were rejected. The majority of the lamellas is graded into LS13 (ash: 195; maple: 238). Only applying the DIN 4074-5 [

16] boundary values for the criterion DEB (single knot) gives almost identical sorting results. The combined grading proposed and optimized by Kovryga et al. [

31] for the here studied lamellas result in a relatively even distribution of lamellas over the three grades. For ash 6.8% and for maple 15.7% of the lamellas are rejected.

For grading according to DIN 4074-5 [

16], a high effect of the pith criterion on the grade class assignment can be stated. Grading with pith as rejection criterion results in a reject rate of 48% for the ash boards and 38% for the maple boards. If the pith criterion is excluded from grading, none of the ash boards and only 1% of the maple boards are rejected. Similar results are reported by Torno et al. [

12], who detected pith in 26% and 30% of the graded beech boards. Here the sawing pattern was similar to this study, but logs with larger diameters were sawn. Van de Kuilen and Torno [

15] calculated for their study the ratio of pith containing board volume to initial round wood volume (inside bark) to be 0.2% for ash and 0.9% for beech. In this study, this ratio is 9.1% for ash and 8.0% for maple. This much higher appearance of pith can be explained by the fact that lower dimension logs were sawn and the overall log quality was poorer. Furthermore, the study of Van de Kuilen and Torno [

15] used a special sawing pattern (“sawing around the log” or “grade sawing”) designed to produce boards without pith. Generally, it can be concluded that the sawing pattern and the low log dimensions chosen for this study resulted in a high amount of pith boards, which have to be sorted out, when sorting according to DIN 4074-5 [

16]. Pith is also the main downgrading criterion in the grading of ash and maple lamellas studied by Glos and Torno [

28]. The rest of the boards of this study show good quality for both species, resulting in a high proportion in LS13 grading.

One explanation for the higher amount of pith containing boards in the ash compared to the maple collective can be the fact that in ash trees the pith is typically “wandering”, which is due to crooked growth in early years [

17,

37]. Other reasons can be more severe bowing of the ash logs or littler log dimensions.

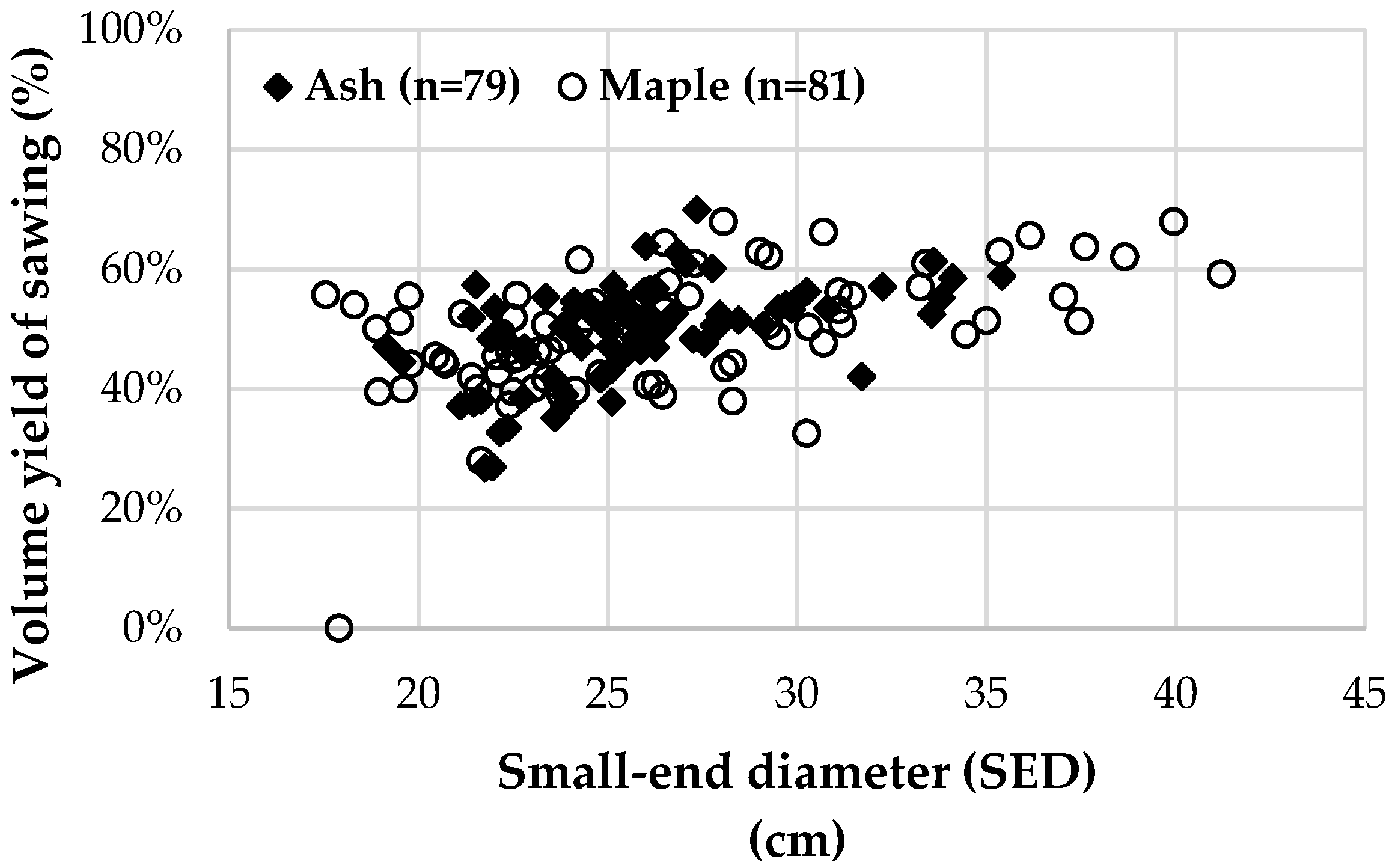

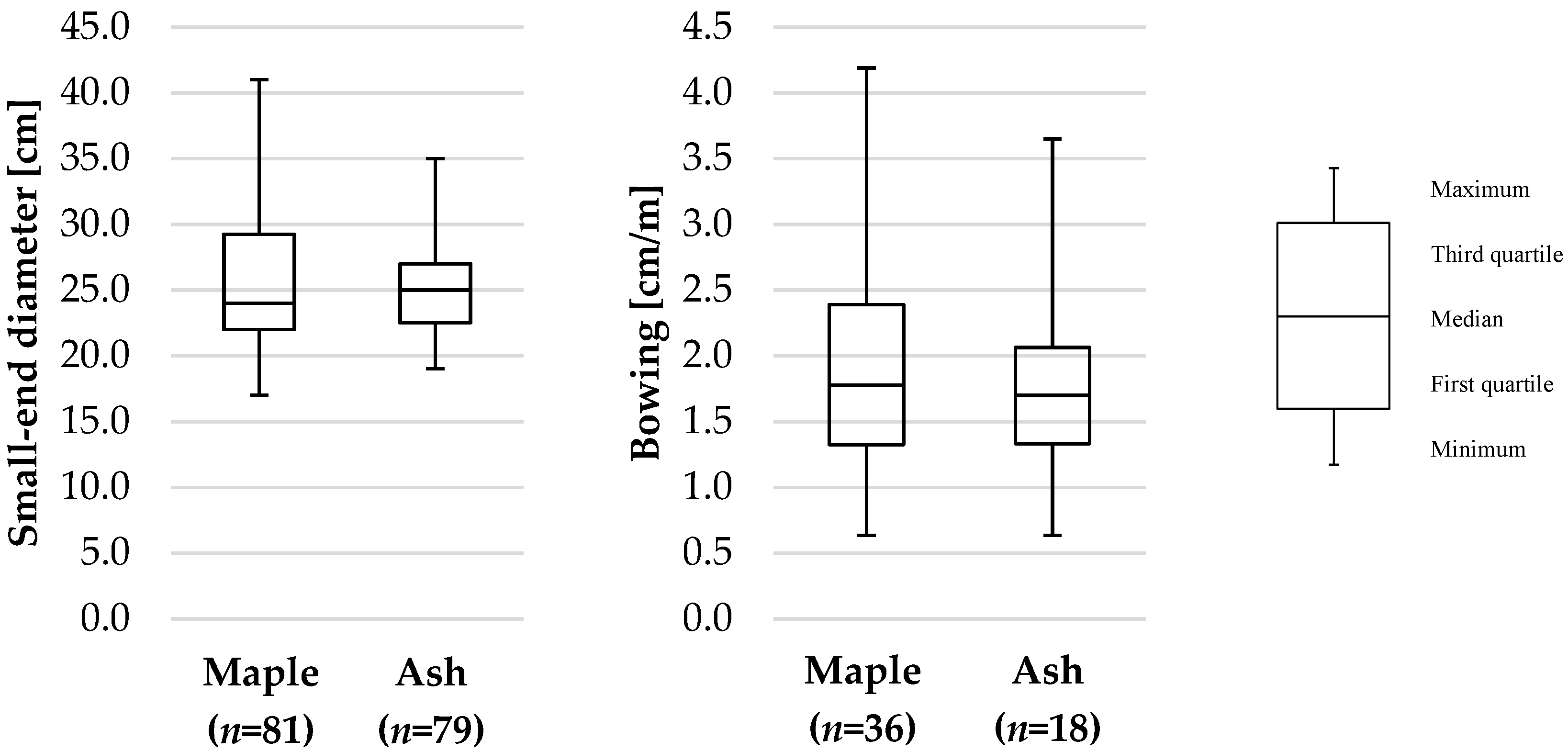

Figure 4 proves that the small-end diameters are not severely different for the 81 maple and 79 ash log sections.

The bowing of the raw material was according to RVR [

29] specifications only measured for log sections that had one bow over the entire log length. This criterion shows now difference between the species ash and maple as well (see

Figure 4). Checking the number of logs with compound bowing (bowing into two or more directions) reveals a different picture, though. While only 55% of the maple log sections are characterized by compound bowing, 77% of the ash log sections have compound bows. This could be an explanation for the higher amount of pith containing boards in the ash collective. Since the collected data does not contain information on the degree of compound bowing, one cannot distinguish between the influence of the “wandering pith” and the log section bowing.

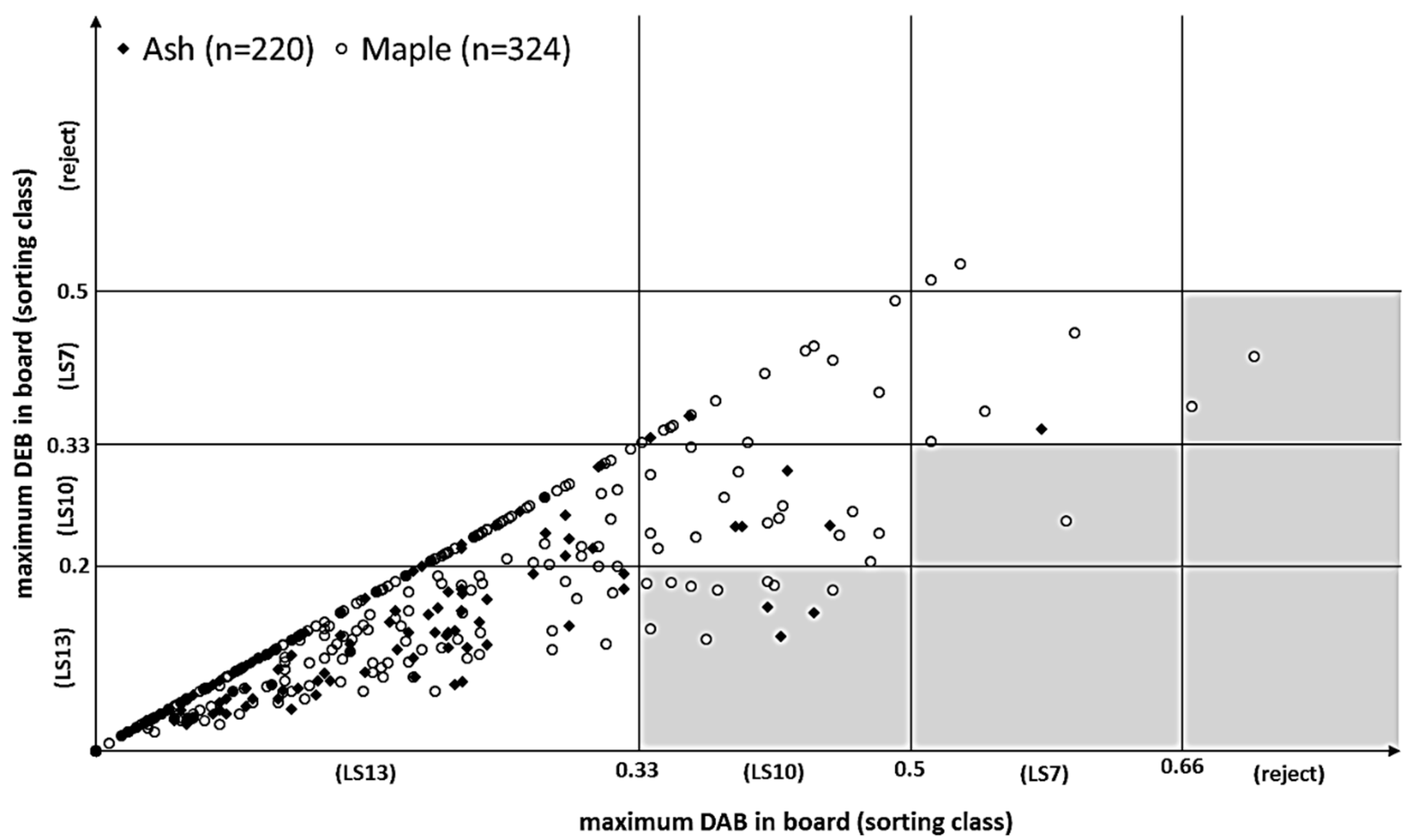

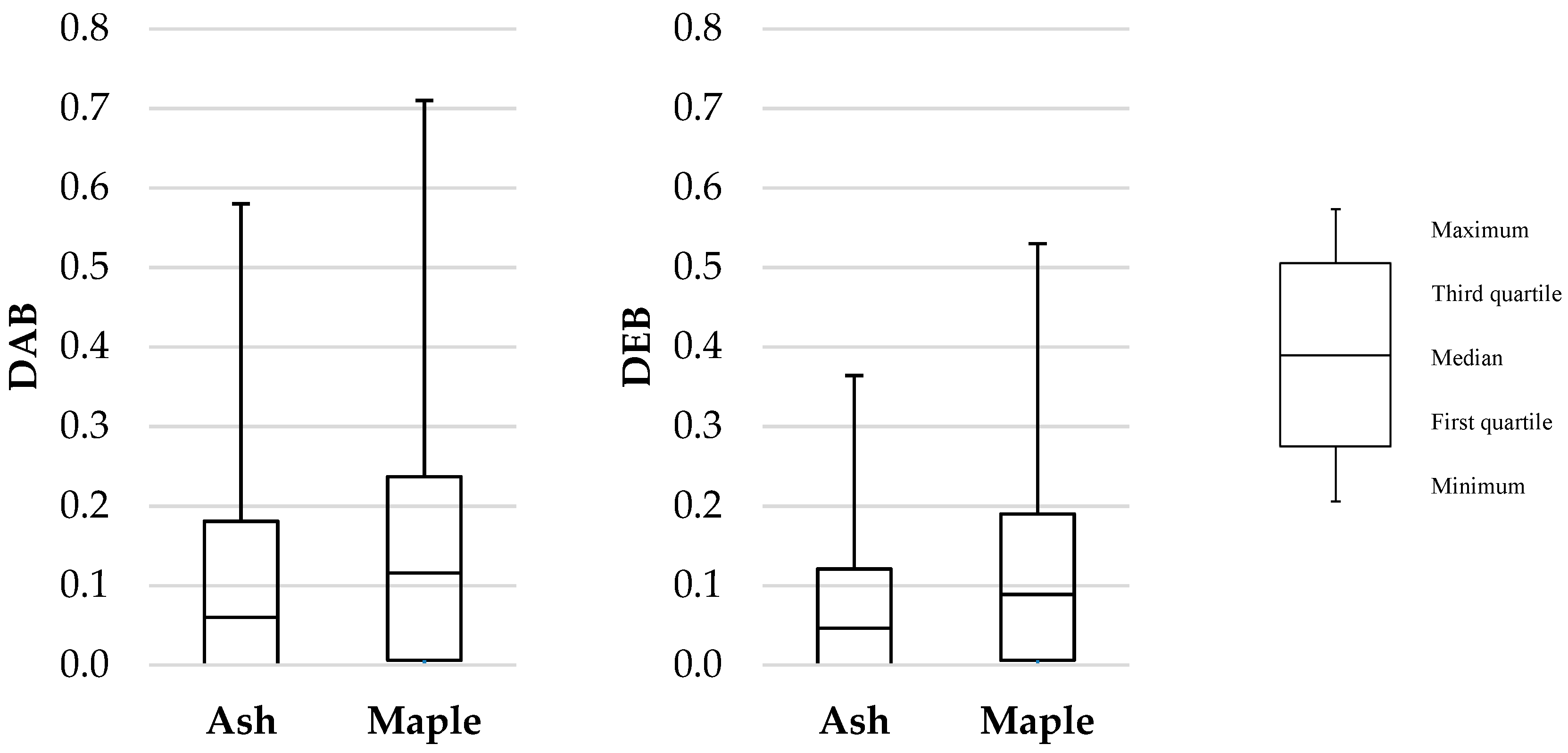

To finalize the discussion of the effect of the grading parameters on the yield, the effect of the knot cluster criterion (DAB) is observed. Comparing both visual grading options—for DIN 4074-5 [

16] “without considering pith” and “only DEB (without considering pith and DAB)”—little to no changes can be observed (see

Figure 3). The added value (information) of DAB for grading is illustrated in

Figure 5, which plots the maximum DEB against maximum DAB values for all ash and maple boards. The paired values (boards) on the bisector show those boards, where the maximum DEB is bigger than or equal to any found DAB. For all other boards a DAB greater then the DEB is reported. The grey area indicates those boards, for which the criterion DAB leads to a sorting class downgrading, when sorting according to for DIN 4074-5 [

16]. This is the case for only twelve maple boards (3.7%) and three ash boards (1.4%). Therefore, the criterion knot cluster (DAB) is not decisive for downgrading into a lower sorting class, if graded after DIN 4074-5 [

16].

This confirms the findings made by other authors for the hardwood species beech. Frese and Riedler [

38] postulate that for flat sawn beech lamellas (with lying annual rings) the sorting criterion DAB is not decisive for downgrading. Glos and Lederer [

33] state that out of 219 beech boards only for one board the criterion DAB is sorting class determining. Blaß et al. [

2] find similar results for a set of 350 beech boards (for 1.4% DAB decisive) and another set of 1888 beech boards (for 0.4% DAB decisive).

When applying stricter boundary values for the DAB than stated by the DIN 4074-5 [

16], the DAB´s influence on the grade rises. In the combined grading proposed by Kovryga et al. [

31], the boundary values for DEB and DAB for ash were set to be identical—i.e., the strictest DAB setting possible. Thus, 13.6% of the ash lamellas of this study are downgraded due to the criterion DAB (cluster knot). For maple grading according to the settings proposed by Kovryga et al. [

31] only 6.5% of the studied lamellas are downgraded due to the criterion DAB (cluster knot). This is because the proposed DAB boundary values for maple are not as strict as for ash. Regarding knot clusters (DAB),

Figure 5 suggests that the investigated maple wood contains proportionally more knot clusters than the ash wood. Further analysis reveals only a difference of 6%, though. A total of 33% of the ash boards and 39% of the maple boards contain knot clusters (greater than the max. DEB).

Figure 6 shows that these maximum knot clusters are bigger in the maple collective than in the ash collective. The same holds for single knots. This leads to a higher proportion of LS7 and LS10 boards in the maple collective compared to the ash group (see

Figure 3).

In general, special care must be taken when comparing grading results of different publications. The research material can be extremely diverse (i.e., species, origin, quality, sawing pattern, etc.), but also data acquisition for grading can be different. For example, Glos and Torno [

28] grade the evaluated lumber only after the sorting criteria occurring within the tension test length, while for this study the entire board length is evaluated. Furthermore, the sorting criterion “grain angle” is a source of confusion, since its visual determination on unbroken boards is problematic [

33,

34].

5.3.2. Yields of Graded Lumber

The four sorting schemes presented in

Figure 3 lead to different rates of so-called “rejects”, i.e., boards that have to be sorted out.

Table 8 lists the relative and absolute losses for the production step “grading” for each grading scheme and the resulting overall yields (referring to the round wood volume).

When grading the lamellas according to DIN 4074-5 [

16], for ash yield values lie around 9%, for maple around 13%. When excluding the sorting criterion “pith”, total yields of ash are doubled (18.2%), those of maple rise to 20.6%. The difference between grading scheme III and IV is very little to none. This is due to the fact that the DAB (KC) has very little influence on the strength grading according to DIN 4074-5 [

16].

As

Table 8 shows, excluding the sorting criterion pith from the sorting scheme, raises the final yield considerably. Since board tension strength is the key influencing factor on glulam bending strength, tension testing of glulam lamellas has to show the effect the pith has on the board tension strength and stiffness (see [

31]). If this influence is neglectable, the yield of grading can be raised extremely. It is important to state, though, that this does not hold equally for other strength properties. Glos and Torno [

28], for example, prove for ash and maple that pith has a significant influence on the bending strength of square-edged lumber. They also stress the fact that the appearance of pith is often accompanied by bows, twists, and cracks. Similar results are presented by Glos and Lederer [

33] for beech and oak square-edged lumber. Hübner [

39] proves the pith’s significant influence on the tension strength perpendicular to grain of ash glulam.

Further research has to work towards a hardwood strength grading system that is based on the mechanical properties of the resulting glulam. Kovryga et al. [

31] proposes different optimized grading schemes for ash and maple glulam lamellas. For this study, one optimized combined grading solution from Kovryga et al. [

31] was chosen for each species (see

Table 3) to show an example of resulting yield. The chosen grading scheme distinguishes between three grades resulting in three board tensile strength classes based on destructive tension testing. For ash, the lowest class is DT22 with a characteristic tensile strength higher than 22 N/mm². For hardwoods, Kovryga et al. [

40] proposes no tensile strength class lower than DT18. For lower mechanical properties softwood T-classes can be used. Therefore, for maple the lowest class is T15 (softwood tensile strength class) with a characteristic tensile strength not lower than 15 N/mm² (see

Table 3). In this study, the proposed strength grading results in 15.7% rejects for maple and 6.8% rejects for ash. The resulting yields of 17.8% and 17.0% are considerably higher compared to grading according to DIN 4074-5 [

16].

The economic feasibility of the production of hardwood glulam is strongly influenced by the final yield of glulam lamellas. Torno et al. [

12] calculated that the production of beech glulam lamellas costs at least three times as much as that of spruce lamellas, calculating with beech round wood prices of €53.50–€80.00 per cubic meter. Since final yield figures of this study and Torno et al. [

12] lie in a similar range, these costs can also be assumed for the lamellas of this study. This makes raising the yield inevitable, if a competitive hardwood product shall be produced.

When evaluating the competitiveness of a product, not only the production cost, but also the added value should be considered. Following the proposed combined grading of Kovryga et al. [

31], for this study strength classes with a characteristic tensile strength as high as 38 N/mm² can be produced. With ash lamellas of this characteristic strength, glulam with bending strength values of as high as 48 N/mm² can be achieved [

4]. Via “upgrading”, i.e., cutting out large knots, the characteristic tensile strength of ash lamellas can be raised up to 54 N/mm² [

31]. Using the combined grading approach for beech lamellas, Erhardt et al. [

41] report tensile strength values of as high as 50 N/mm². This raised strength allows the production of more slender structures, which means material savings but also more construction possibilities for the architect and engineer. The listed benefits would yield obviously in higher reward for the producer. Although the present market situation has not led to a wide spread use of hardwood glulam, future changes in spruce availability, round wood prices (especially hardwood) and wood processing technology (etc.) might make the production lucrative.