The Impact of Anatomical Characteristics on the Structural Integrity of Wood

Abstract

1. Introduction

Objective

2. Materials and Methods

- ρ0 is the oven-dry density, in g∙cm−³;

- m0 is the oven-dry mass, in g;

- V0 is the oven-dry volume, in cm³.

- I is the degree of integrity, in %;

- m20 is the oven-dry mass of the 20 biggest fragments, in g;

- mall is the oven-dry mass of all the fragments, in g.

- F is the fine percentage, in %;

- mfragments<1mm is the oven-dry mass of fragments smaller than 1 mm, in g;

- mall is the oven-dry mass of all the fragments, in g.

- RIM is the Resistance to Impact Milling, in %;

- I is the degree of integrity, in %;

- F is the fine percentage, in %.

3. Results and Discussion

3.1. Structural Integrity

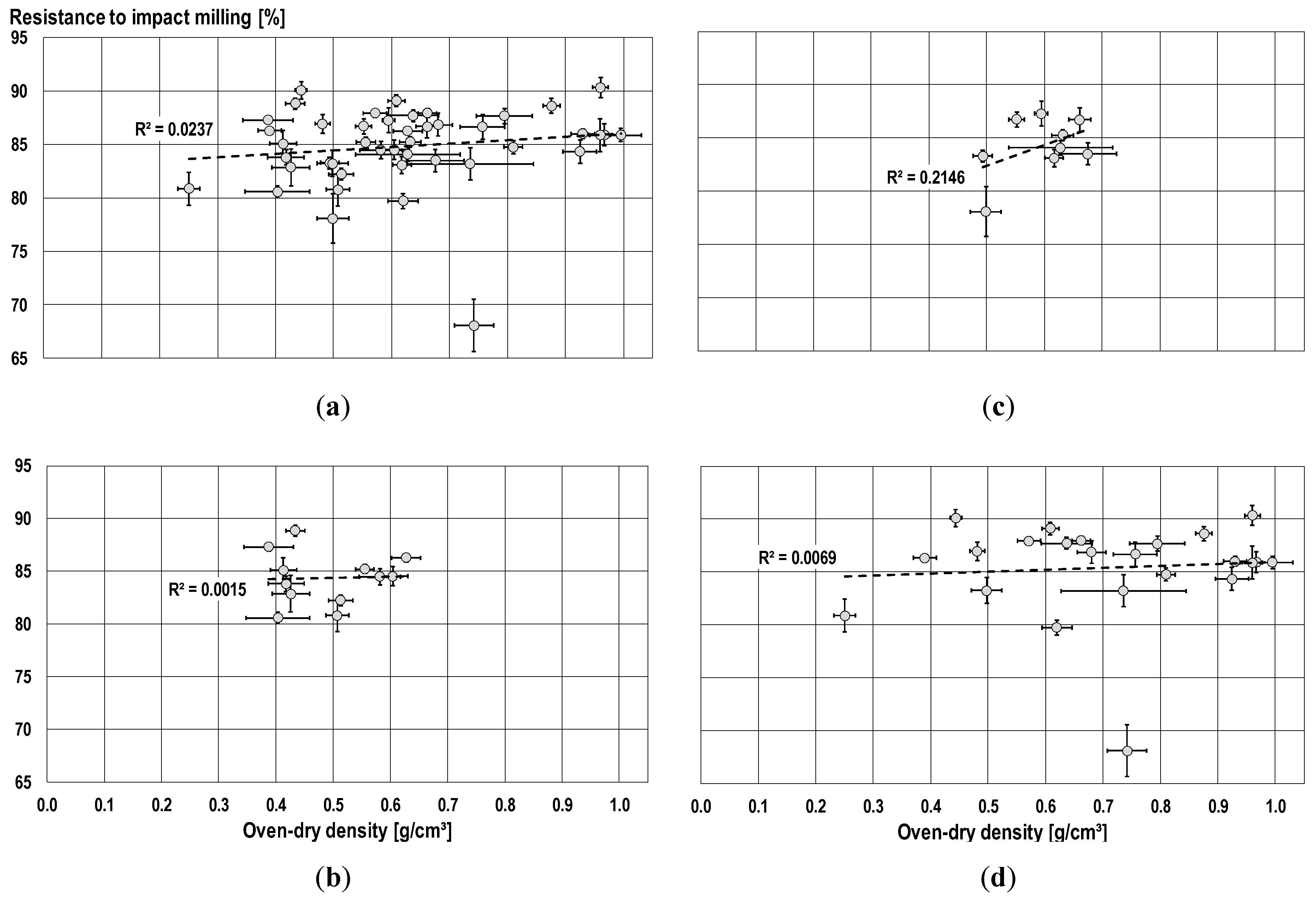

3.2. Impact of Oven-Dry Density on Structural Integrity

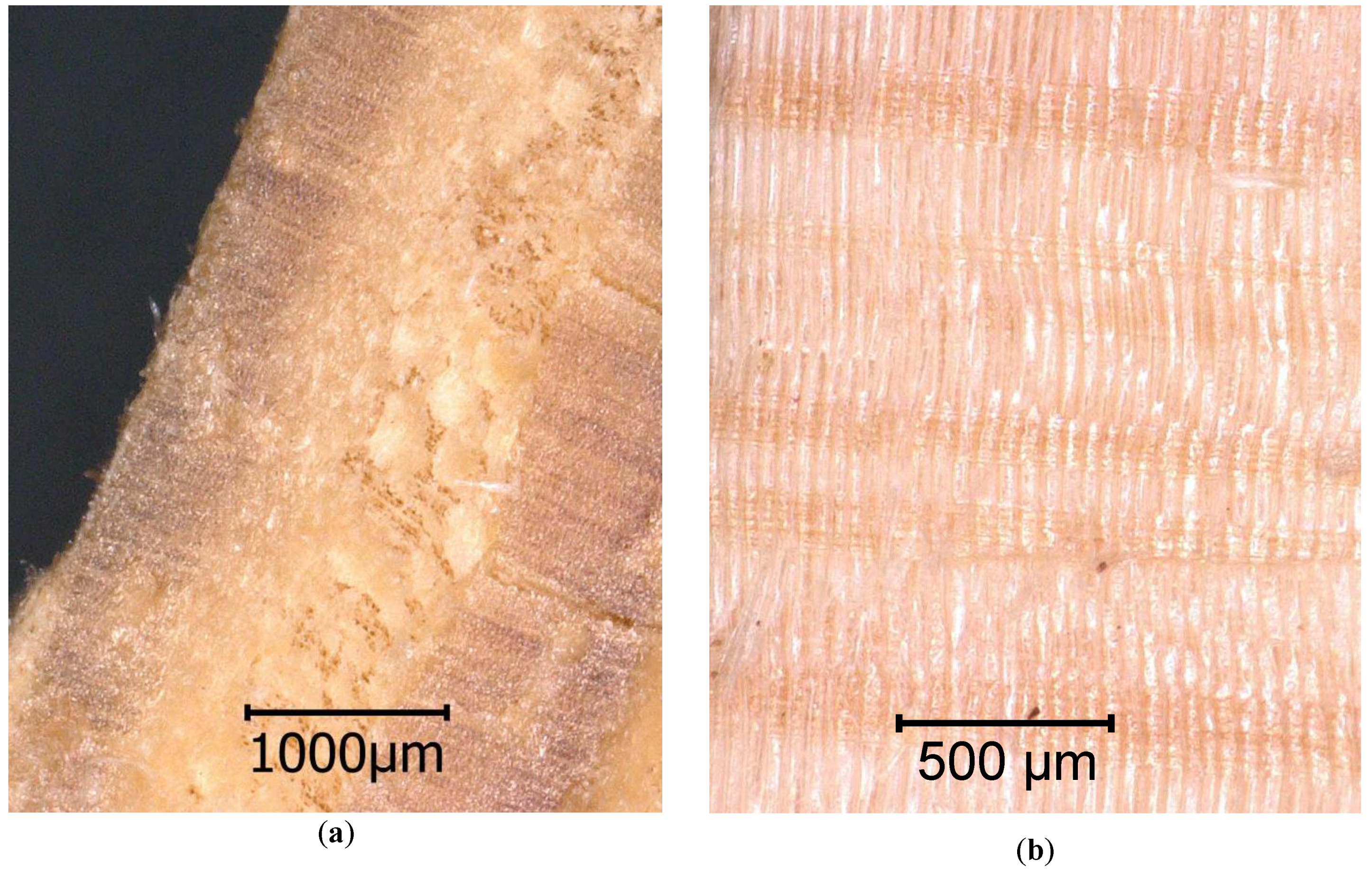

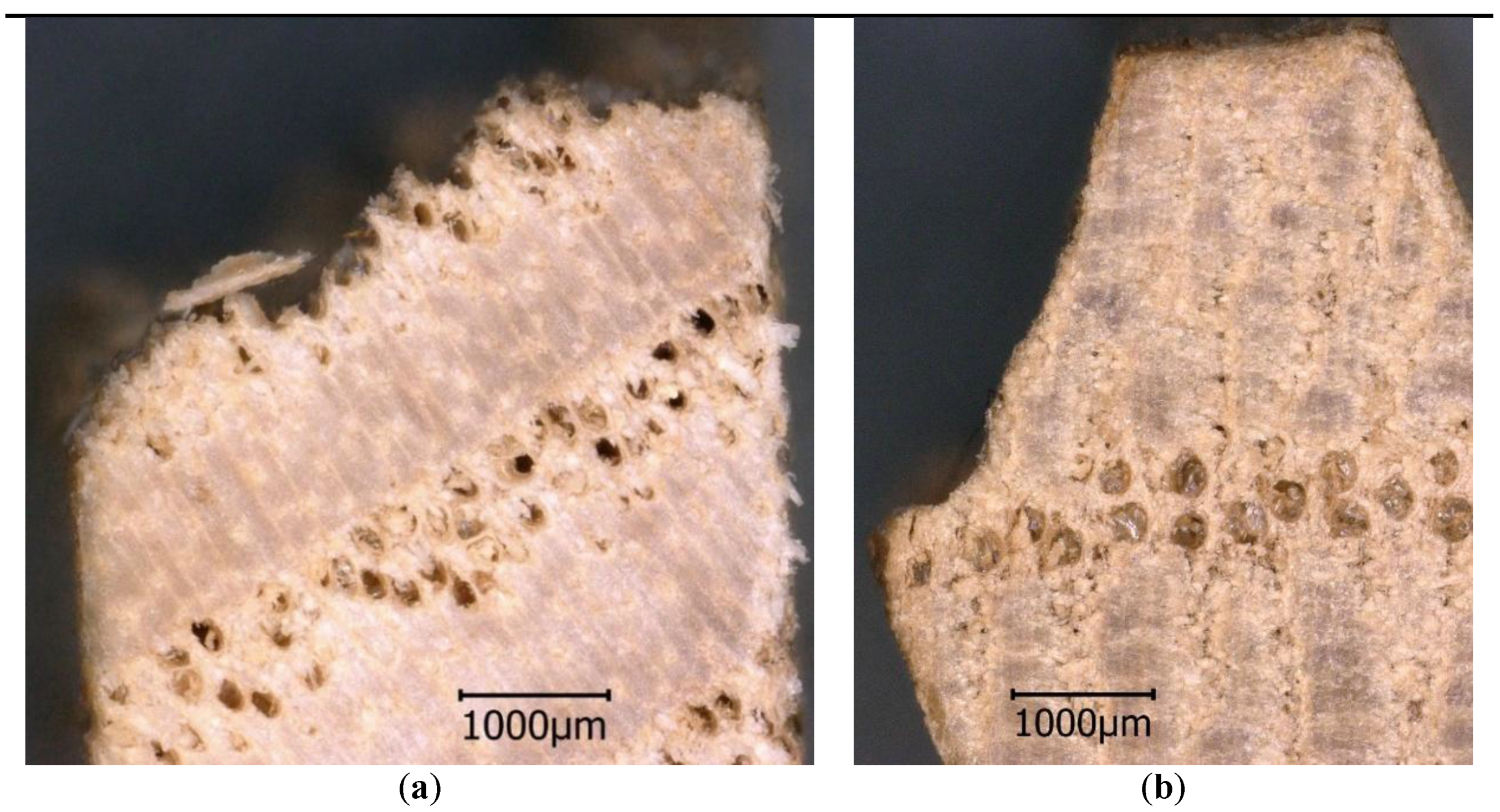

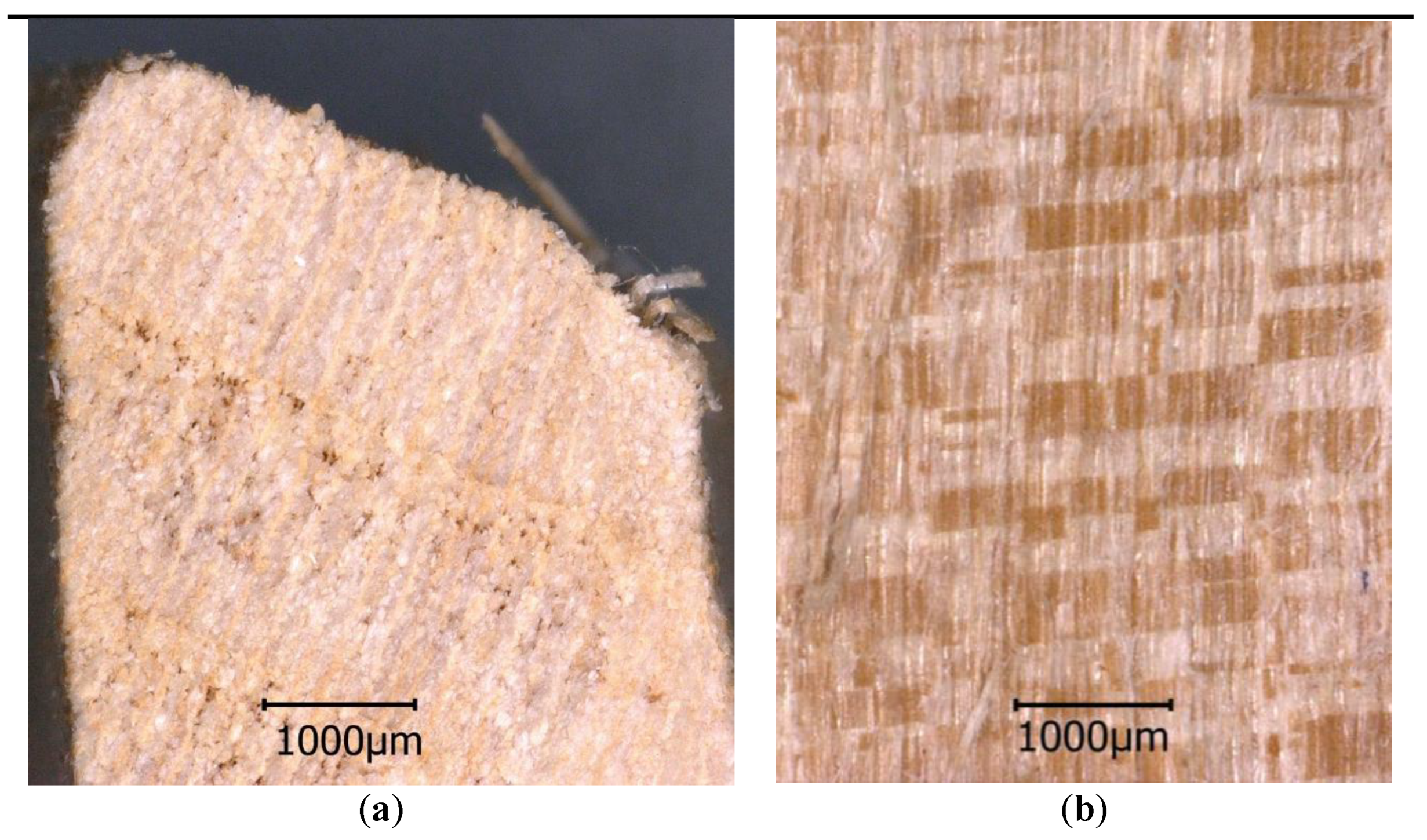

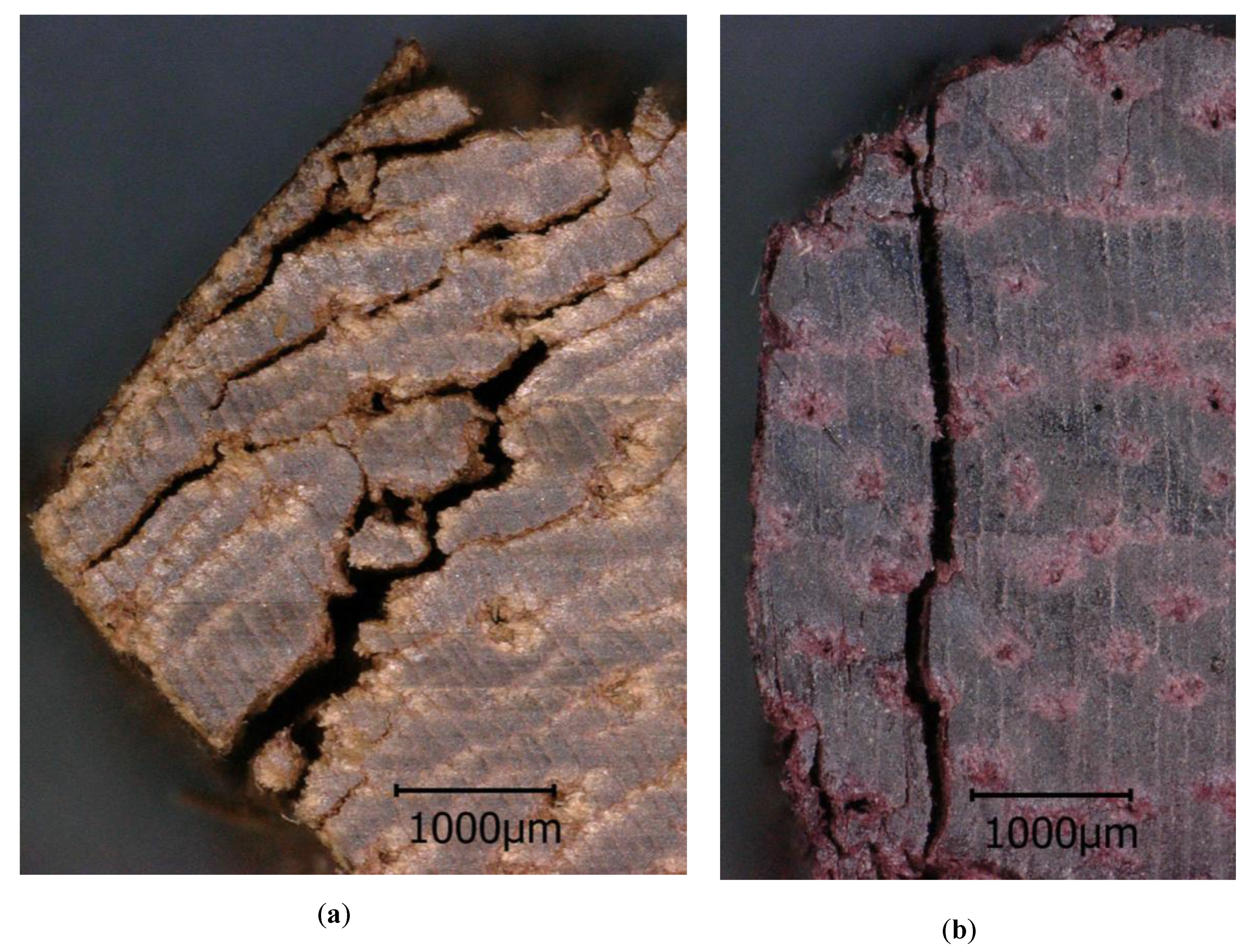

3.3. Impact of Anatomical Characteristics on Structural Integrity

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ghelmeziu, N. Untersuchungen über die Schlagfestigkeit von Bauhölzern. Holz Roh. Werkst. 1938, 1, 585–601. [Google Scholar] [CrossRef]

- Beery, W.H.; Ifju, G.; McLain, T.E. Quantitative wood anatomy–Relating anatomy to transverse tensile strength. Wood Fiber Sci. 1983, 15, 395–407. [Google Scholar]

- Alteyrac, J.; Cloutier, A.; Ung, C.H.; Zhang, S.Y. Mechanical properties in relation to selected wood characteristics of black spruce. Wood Fiber Sci. 2007, 38, 229–237. [Google Scholar]

- Rapp, A.O.; Brischke, C.; Welzbacher, C.R. Interrelationship between the severity of heat treatments and sieve fractions after impact ball milling: A mechanical test for quality control of thermally modified wood. Holzforschung 2006, 60, 64–70. [Google Scholar] [CrossRef]

- Brischke, C. Agents affecting the structural integrity of wood. In Proceedings of the 10th Meeting of the Northern European Network on Wood Science and Engineering, Edinburgh, UK, 13−14 October 2014; pp. 43–48. [Google Scholar]

- Zimmer, K.; Brischke, C. Within-species variation of structural integrity—A test on 204 Scots pine trees from Northern Europe. In Proceedings of the 12th Meeting of the Northern European Network on Wood Science and Engineering, Riga, Latvia, 12−13 September 2016. [Google Scholar]

- Brischke, C. Interrelationship between static and dynamic strength properties of wood and its structural integrity. Drvna Ind. 2017, 68, 53–60. [Google Scholar] [CrossRef]

- Brischke, C.; Rapp, A.O.; Welzbacher, C.R. High-energy multiple impact (HEMI)-test—Part1: A new tool for quality control of thermally modified timber. In Proceedings of the The International Research Group on Wood Preservation, Tromsø, Norway, 18–22 June 2006. IRG Document No: IRG/WP/06-20346. [Google Scholar]

- ISO 5223. Test sieves for cereals; ISO (International Organization for Standardization): Geneva, Switzerland, 1996. [Google Scholar]

- Reiterer, A.; Burgert, I.; Sinn, G.; Tschegg, S. The radial reinforcement of the wood structure and its implication on mechanical and fracture mechanical properties-a comparison between two tree species. J. Mater. Sci. 2002, 37, 935–940. [Google Scholar] [CrossRef]

- Bamber, R.K. Sapwood and heartwood. In Forestry Commission of New South Wales; Wood Technology and Forest Research Division: Beecroft, Australia, 1987; Volume 2, pp. 1–7. [Google Scholar]

- Zanne, A.E.; Westoby, M.; Falster, D.S.; Ackerly, D.D.; Loarie, S.R.; Arnold, S.E.J.; Coomes, D.A. Angiosperm wood structure: Global patterns in vessel anatomy and their relation to wood density and potential conductivity. Am. J. Bot. 2010, 97, 207–215. [Google Scholar] [CrossRef] [PubMed]

| Name 1 | Botanical Name | ODD | RIM | I | F | ||||

|---|---|---|---|---|---|---|---|---|---|

| [g cm−³] | [%] | [%] | [%] | ||||||

| Scots pine sw | Pinus sylvestris | 0.41 | (0.02) | 88.2 | (0.9) | 67.4 | (1.1) | 13.5 | (1.1) |

| Scots pine hw | 0.58 | (0.04) | 84.5 | (0.8) | 41.9 | (3.1) | 1.3 | (0.4) | |

| Radiata pine sw | Pinus radiata | 0.43 | (0.02) | 88.8 | (0.5) | 55.4 | (2.1) | 0.0 | (0.0) |

| Carribean pine hw | Pinus carribaea | 0.39 | (0.04) | 87.3 | (0.4) | 52.4 | (1.8) | 1.1 | (0.3) |

| European Larch sw | Larix decidua | 0.56 | (0.02) | 85.2 | (0.4) | 44.5 | (2.2) | 1.2 | (0.3) |

| European Larch hw | 0.51 | (0.02) | 80.8 | (1.5) | 35.5 | (4.8) | 4.1 | (0.4) | |

| Douglas fir sw | Pseudotsuga menziesii | 0.63 | (0.02) | 86.3 | (0.4) | 45.6 | (1.8) | 0.2 | (0.2) |

| Douglas fir hw | 0.51 | (0.02) | 82.2 | (0.5) | 34.8 | (1.3) | 1.9 | (0.3) | |

| Norway spruce | Picea abies | 0.43 | (0.03) | 82.9 | (1.7) | 35.9 | (6.1) | 1.5 | (0.4) |

| Coastal fir | Abies grandis | 0.40 | (0.06) | 80.6 | (0.5) | 26.5 | (1.3) | 1.4 | (0.4) |

| Western hemlock | Tsuga heterophylla | 0.42 | (0.03) | 83.8 | (0.7) | 40.0 | (2.1) | 1.6 | (0.3) |

| Yew | Taxus baccata | 0.60 | (0.03) | 84.5 | (0.9) | 43.9 | (3.2) | 1.9 | (0.3) |

| Name 1 | Botanical Name | ODD | RIM | I | F | ||||

|---|---|---|---|---|---|---|---|---|---|

| [g cm−3] | [%] | [%] | [%] | ||||||

| English oak sw | Quercus robur | 0.49 | (0.02) | 83.3 | (0.5) | 44.2 | (1.7) | 3.7 | (0.4) |

| English oak hw | 0.59 | (0.01) | 87.3 | (1.2) | 59.0 | (4.3) | 3.3 | (0.4) | |

| Black locust | Robinia pseudoacacia | 0.68 | (0.05) | 83.5 | (1.2) | 41.0 | (3.9) | 2.3 | (0.2) |

| Sweet chestnut | Castanea sativa | 0.50 | (0.03) | 78.1 | (2.3) | 36.0 | (4.2) | 7.9 | (1.8) |

| Ash | Fraxinus excelsior | 0.62 | (0.02) | 83.1 | (0.8) | 40.4 | (2.6) | 2.7 | (0.3) |

| Locust | Gleditsia sp. | 0.66 | (0.02) | 86.7 | (1.1) | 52.6 | (3.4) | 1.9 | (0.4) |

| Common walnut | Juglans regia | 0.63 | (0.02) | 85.2 | (0.5) | 49.8 | (2.1) | 2.9 | (0.3) |

| Wild cherry | Prunus avium | 0.55 | (0.01) | 86.7 | (0.7) | 53.0 | (2.2) | 2.0 | (0.3) |

| Black cherry | Prunus serotina | 0.64 | (0.04) | 87.7 | (0.6) | 54.9 | (2.1) | 1.4 | (0.2) |

| Beech | Fagus sylvatica | 0.66 | (0.02) | 88.0 | (0.4) | 55.9 | (2.2) | 1.4 | (0.3) |

| Maple | Acer sp. | 0.61 | (0.01) | 89.1 | (0.6) | 58.0 | (2.3) | 0.5 | (0.1) |

| Lime | Tilia sp. | 0.44 | (0.01) | 90.1 | (0.8) | 61.1 | (2.6) | 0.2 | (0.3) |

| Birch | Betula pendula | 0.57 | (0.02) | 87.9 | (0.4) | 54.2 | (1.6) | 0.8 | (0.1) |

| Hazel | Corylus avellana | 0.68 | (0.02) | 86.9 | (1.0) | 52.8 | (3.9) | 1.8 | (0.2) |

| Boxwood | Buxus sempervirens | 0.96 | (0.01) | 90.3 | (0.9) | 64.1 | (3.7) | 0.9 | (0.0) |

| Poplar | Populus nigra | 0.39 | (0.02) | 86.3 | (0.3) | 50.5 | (0.9) | 1.8 | (0.3) |

| Alder | Alnus glutinosa | 0.48 | (0.01) | 86.9 | (0.9) | 54.6 | (3.3) | 2.3 | (0.5) |

| Kiri | Paulownia tomentosa | 0.25 | (0.02) | 80.9 | (1.5) | 40.0 | (4.0) | 5.5 | (0.9) |

| Shining gum | Eucalyptus nitens | 0.74 | (0.11) | 83.2 | (1.5) | 46.7 | (4.5) | 4.6 | (0.9) |

| Teak | Tectona grandis | 0.63 | (0.09) | 84.1 | (0.7) | 48.0 | (2.1) | 3.9 | (0.8) |

| Ipe | Handroanthus sp. | 0.93 | (0.02) | 86.0 | (0.5) | 51.8 | (1.2) | 2.6 | (0.7) |

| Merbau | Intsia spp. | 0.74 | (0.03) | 68.1 | (2.4) | 27.9 | (1.8) | 18.6 | (2.7) |

| Bangkirai | Shorea laevis | 0.79 | (0.05) | 87.7 | (0.7) | 54.9 | (1.9) | 1.4 | (0.4) |

| Balau | Shorea spp. | 0.92 | (0.03) | 84.3 | (1.1) | 51.7 | (2.8) | 4.8 | (1.0) |

| Bongossi | Lophira alata | 0.97 | (0.03) | 85.9 | (1.0) | 51.9 | (2.7) | 2.8 | (0.7) |

| Amaranth | Peltogyne sp. | 0.88 | (0.01) | 88.6 | (0.7) | 57.9 | (2.7) | 1.1 | (0.0) |

| Basralocus | Dicorynia sp. | 0.81 | (0.02) | 84.8 | (0.6) | 50.9 | (1.9) | 4.0 | (0.4) |

| Garapa | Apuleia sp. | 0.76 | (0.04) | 86.7 | (1.1) | 53.0 | (3.3) | 2.1 | (0.5) |

| Limba | Terminalia superba | 0.50 | (0.03) | 83.2 | (1.2) | 45.1 | (2.7) | 4.1 | (0.9) |

| Kambala | Milicia sp. | 0.62 | (0.03) | 79.7 | (0.7) | 45.2 | (2.7) | 8.8 | (0.4) |

| Massaranduba | Manilkara bidentata | 0.99 | (0.04) | 85.9 | (0.6) | 53.2 | (2.5) | 3.2 | (0.2) |

| Greenheart | Chlorocardium rodiei | 0.96 | (0.02) | 85.9 | (1.5) | 49.9 | (5.3) | 2.1 | (0.8) |

| Wood Species | Tracheid Ø | Wood Ray Density | Fracture Behaviour | Remarks | |||

|---|---|---|---|---|---|---|---|

| [μm] | [mm−1] | tang. | rad. | ||||

| Scots pine sw | 29 | (6) | 4.6 | (1.2) | GR | RC | wider rings compared to hw |

| Scots pine hw | 25 | (5) | 3.7 | (1.5) | GR | RC | - |

| Radiata pine sw | 22 | (4) | 4.4 | (1.3) | GR | R, RC | - |

| Carribean pine hw | 28 | (4) | 5.2 | (1.2) | GR | R, RC | - |

| European larch sw | 35 | (7) | 5.9 | (1.7) | GR | R | wider rings compared to hw |

| European larch hw | 35 | (6) | 4.4 | (1.1) | GR | R | - |

| Douglas fir sw | 25 | (6) | 4.3 | (1.2) | GR | R, RC | - |

| Douglas fir hw | 23 | (5) | 3.9 | (1.2) | GR | R | - |

| Norway spruce | 25 | (5) | 4.5 | (1.0) | GR | R | - |

| Coastal fir | 28 | (5) | 5.7 | (1.3) | GR | R | - |

| Western hemlock | 25 | (5) | 5.0 | (1.3) | GR | R | - |

| Yew | 10 | (3) | 7.1 | (1.4) | (GR) | (R) | Irregular fracture pattern |

| Wood Species | Earlywood Vessel Ø | Vessel Density | Wood Ray Density | Fracture Behaviour 1 | ||||

|---|---|---|---|---|---|---|---|---|

| [μm] | [mm−2] | [mm−1] | tang. | rad. | ||||

| English oak sw 2 | 247 | (51) | 7.7 | (1.6) | 8.4 | (2.0) | EW | P |

| English oak hw | 202 | (49) | 10.1 | (2.0) | 10.7 | (1.8) | EW | P |

| Black locust | 190 | (40) | 11.5 | (1.0) | 6.9 | (1.1) | EW | R * |

| Sweet chestnut | 209 | (30) | 7.7 | (1.5) | 11.8 | (1.5) | EW | V-V |

| Ash 3 | 169 | (21) | 13.8 | (1.7) | 6.6 | (0.8) | EW | n.a. |

| Locust | 165 | (25) | 16.1 | (2.0) | 4.4 | (1.2) | EW | R, P * |

| Common walnut | 134 | (32) | 7.7 | (2.0) | 5.7 | (1.3) | V-V | V-V |

| Wild cherry | 33 | (8) | 171.6 | (31.3) | 6.1 | (1.4) | GR | R |

| Black cherry 4 | 33 | (9) | 67.9 | (22.9) | 5.6 | (1.3) | n.a. | R |

| European beech | 40 | (8) | 131.9 | (15.4) | 3.0 | (1.3) | GR * | n.a. |

| Maple 5 | 46 | (7) | 54.5 | (3.4) | 7.9 | (1.7) | GR | R * |

| Lime 6 | 39 | (9) | 104.7 | (14.0) | 4.8 | (1.1) | n.a. | n.a. |

| Birch | 54 | (13) | 45.2 | (8.5) | 8.3 | (2.4) | n.a. | R |

| Hazel | 28 | (6) | 98.9 | (20.2) | 11.6 | (2.5) | GR | n.a. |

| Boxwood 6 | 10 | (4) | 213.9 | (14.0) | 11.0 | (2.5) | n.a. | R * |

| Poplar 7 | 58 | (13) | 33.7 | (6.4) | 11.0 | (1.5) | n.a. | R |

| Alder | 41 | (10) | 108.0 | (16.7) | 11.7 | (2.0) | GR * | R |

| Kiri | 164 | (55) | 5.2 | (2.0) | 2.4 | (0.8) | V-V | V-V, R * |

| Shining gum 2 | 144 | (25) | 7.6 | (3.2) | 11.3 | (1.1) | V-V | V-V |

| Teak 8 | 184 | (57) | 6.3 | (1.7) | 4.1 | (0.7) | V-V | R * |

| Ipé 2 | 103 | (9) | 23.2 | (2.7) | 7.8 | (0.9) | P * | V-V |

| Merbau | 250 | (40) | 4.0 | (1.4) | 4.2 | (0.9) | V-V, P * | V-V, P * |

| Bangkirai | 207 | (32) | 7.3 | (1.7) | 3.7 | (1.3) | P | V-V, R * |

| Balau | 137 | (13) | 11.9 | (2.9) | 9.1 | (1.2) | P | V-V, R * |

| Bongossi | 232 | (41) | 2.9 | (1.1) | 9.9 | (1.2) | P | V-V, P * |

| Amaranth | 109 | (16) | 4.4 | (1.7) | 6.9 | (1.7) | P, V * | R |

| Basralocus 2 | 190 | (33) | 2.8 | (1.0) | 7.9 | (1.0) | P * | V-V |

| Garapa | 121 | (19) | 15.2 | (3.0) | 8.3 | (1.3) | P | V-V |

| Limba | 139 | (28) | 4.4 | (1.7) | 10.2 | (1.0) | n.a. | R |

| Kambala | 193 | (41) | 2.8 | (0.8) | 4.4 | (1.0) | (P) | R |

| Massaranduba | 113 | (18) | 13.1 | (3.3) | 10.5 | (1.5) | (P) | R |

| Greenheart 2 | 90 | (16) | 14.0 | (2.0) | 7.5 | (0.9) | n.a. | V-V |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Emmerich, L.; Wülfing, G.; Brischke, C. The Impact of Anatomical Characteristics on the Structural Integrity of Wood. Forests 2019, 10, 199. https://doi.org/10.3390/f10020199

Emmerich L, Wülfing G, Brischke C. The Impact of Anatomical Characteristics on the Structural Integrity of Wood. Forests. 2019; 10(2):199. https://doi.org/10.3390/f10020199

Chicago/Turabian StyleEmmerich, Lukas, Georg Wülfing, and Christian Brischke. 2019. "The Impact of Anatomical Characteristics on the Structural Integrity of Wood" Forests 10, no. 2: 199. https://doi.org/10.3390/f10020199

APA StyleEmmerich, L., Wülfing, G., & Brischke, C. (2019). The Impact of Anatomical Characteristics on the Structural Integrity of Wood. Forests, 10(2), 199. https://doi.org/10.3390/f10020199