Influence of the Duration of Microwave Irradiation of Scots Pine (Pinus sylvestris L.) Cones on the Quality of Harvested Seeds

Abstract

1. Introduction

2. Materials and Methods

2.1. Study Material and Physical Characteristics of Cones

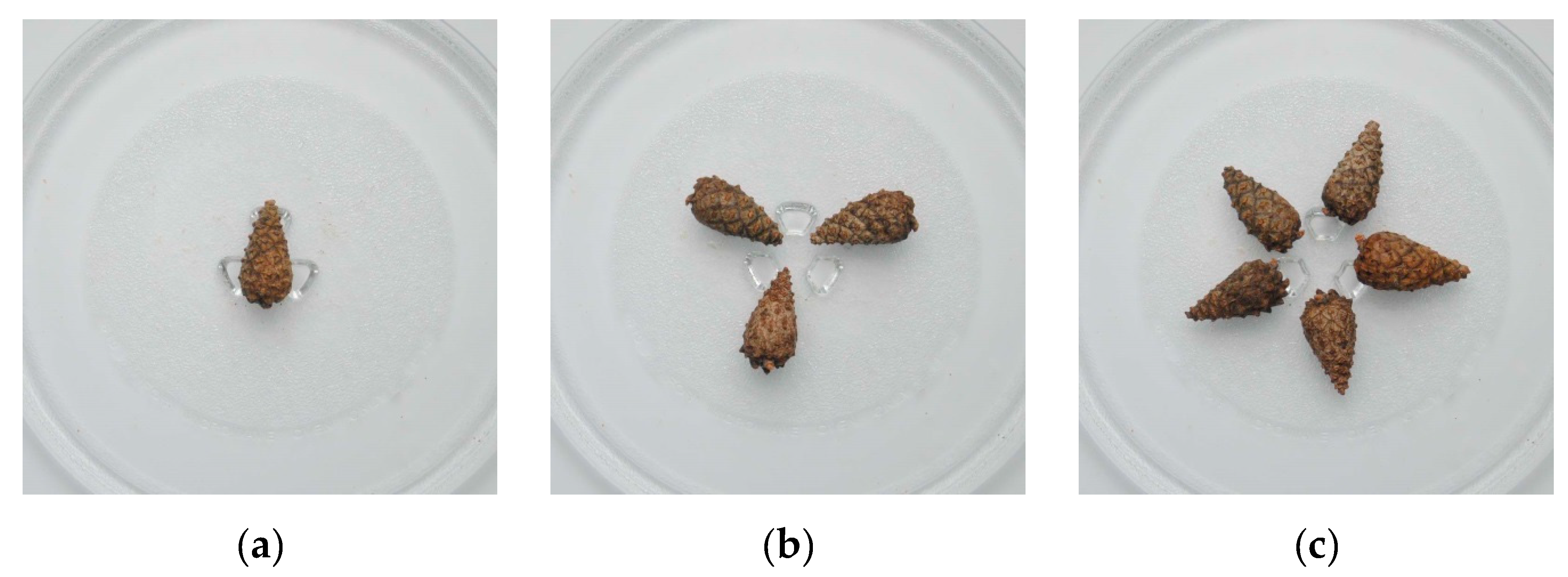

2.2. Microwave Irradiation and Temperature Distribution

2.3. Measurement Modes

2.4. Seed Quality

2.5. Statistical Analysis

3. Results

3.1. Physical Characteristics of Scots Pine Cones

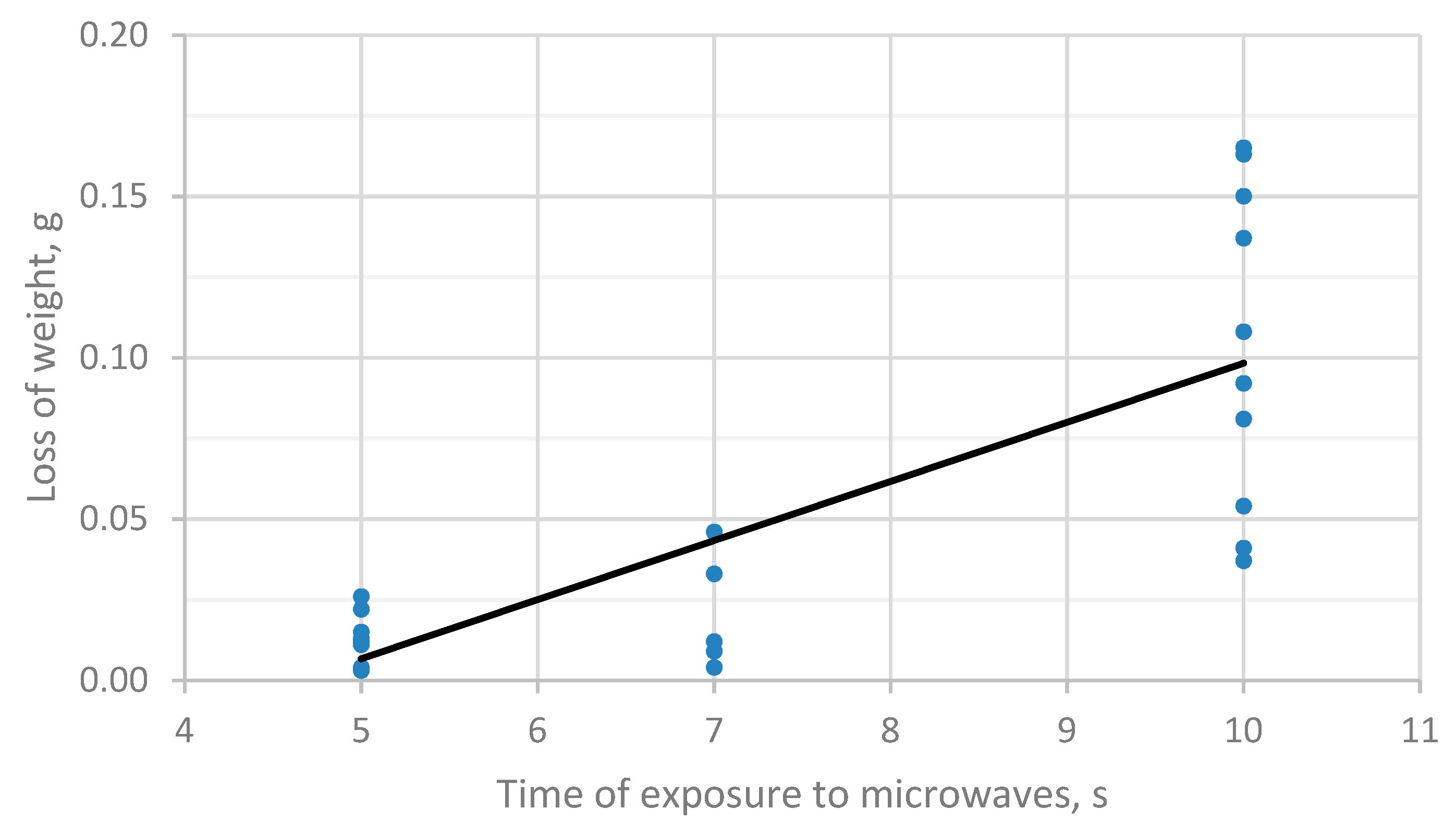

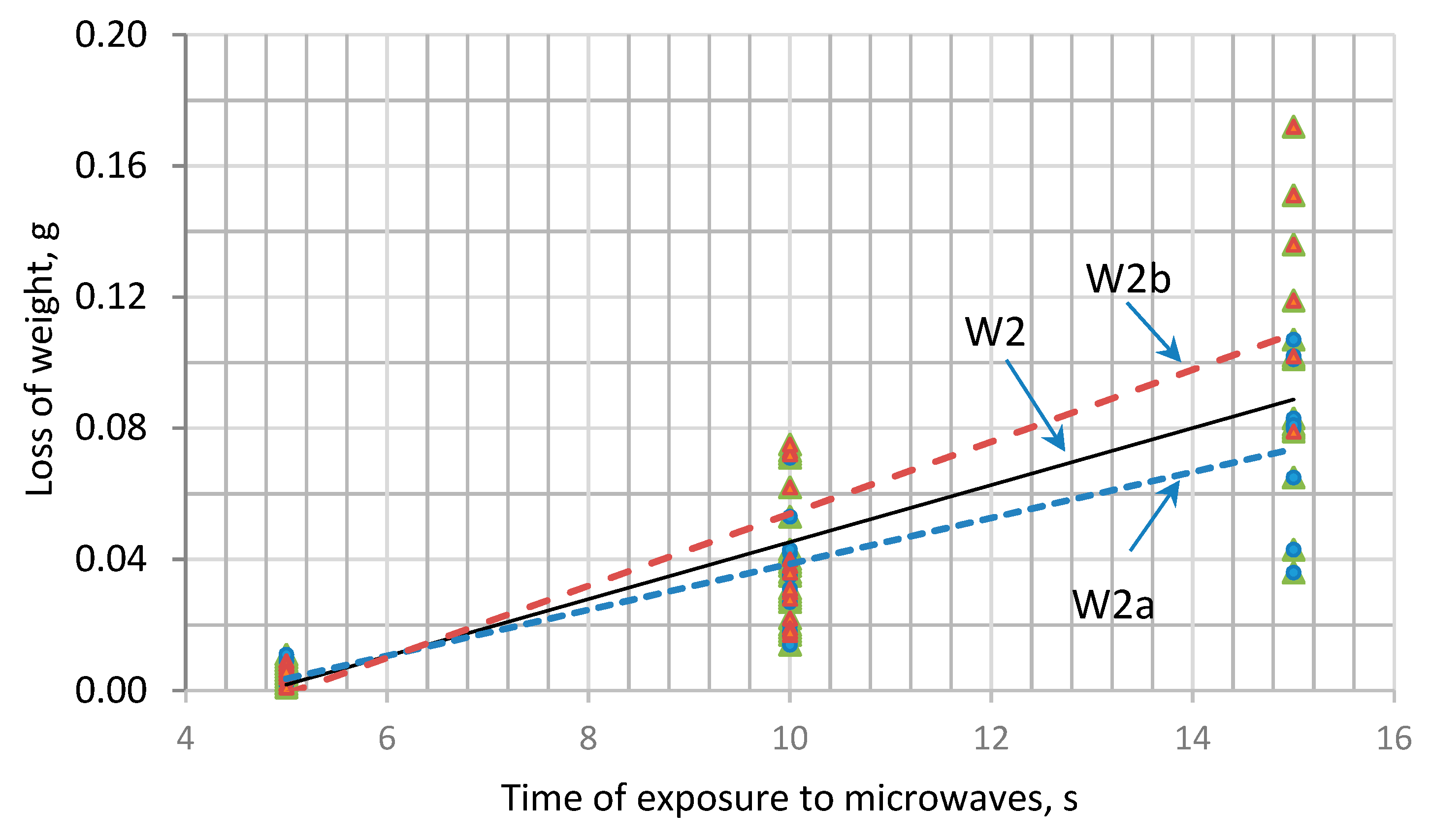

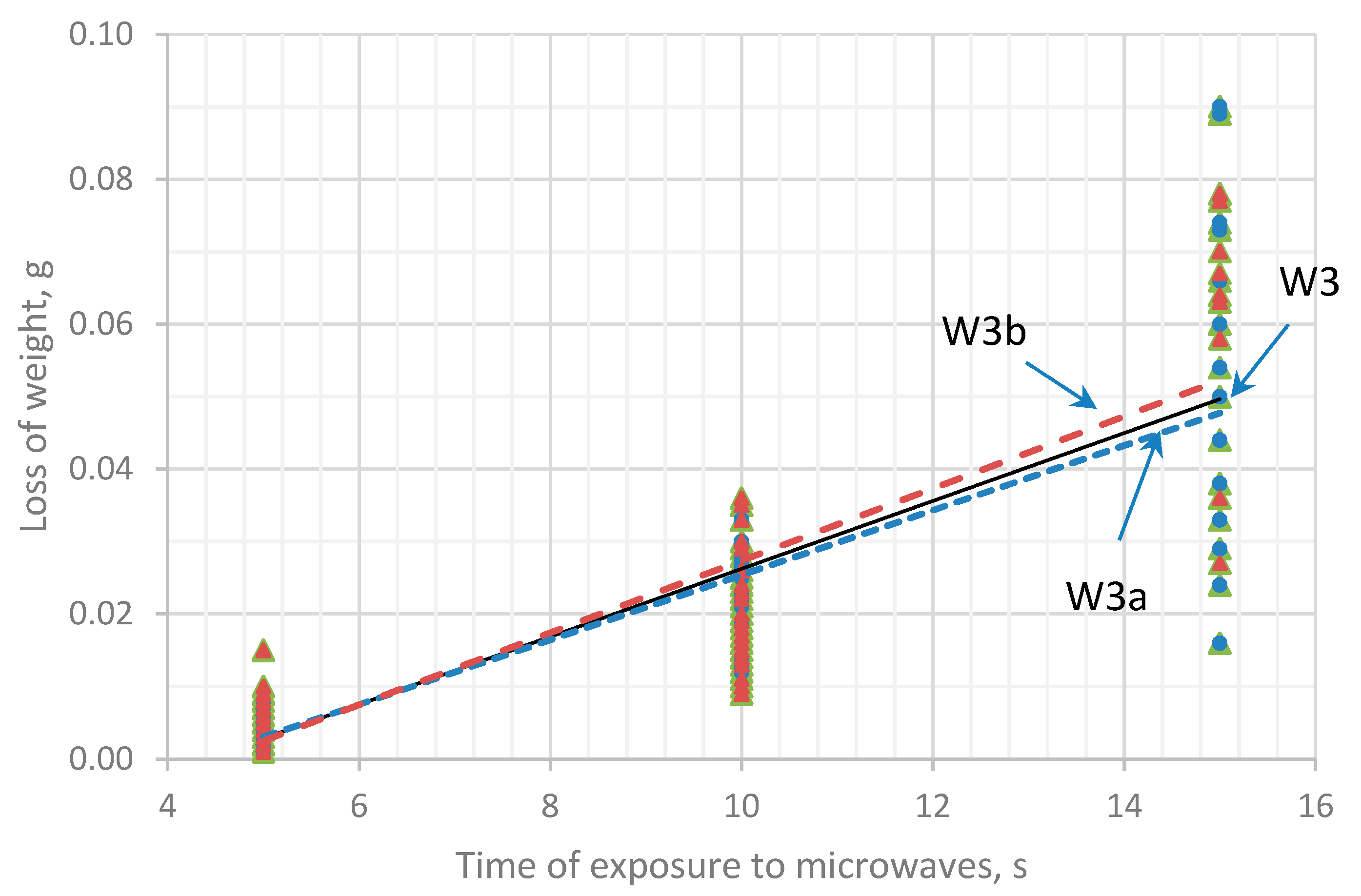

3.2. Loss of Weight under the Influence of Microwaves

3.3. Change in Cone Temperature under the Influence of Microwaves

3.4. Analysis of the Germination Energy and Capacity of Scots Pine Seeds

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Aniszewska, M. The change in weight and surface temperature of a pine cone (Pinus sylvestris L.) as a result of microwave irradiation. For. Res. Pap. 2016, 77, 56–67. [Google Scholar] [CrossRef][Green Version]

- Antosiewicz, Z.; Załęski, A. Technika i technologia wyłuszczania nasion sosny, świerka i modrzewia w Polsce. Las Pol. 1987, 23, 7–11. (In Polish) [Google Scholar]

- Aniszewska, M. Changes in humidity and temperature inside the pine cones (Pinus sylvestris L.) in two stages seed extraction. For. Res. Pap. 2013, 74, 205–214. [Google Scholar] [CrossRef][Green Version]

- Załęski, A. Nasiennictwo Leśnych Drzew i Krzewów Iglastych [Seeds of Forest Trees and Coniferous Shrubs]; Oficyna Edytorska Wydawnictwo Świat: Warszawa, Poland, 1995; ISBN 978-83-85597-27-8. (In Polish) [Google Scholar]

- Załęski, A.; Aniśko, E. Suszenie nasion wybranych gatunków drzew. Not. Nauk. Inst. Badaw. Leśnictwa 2003, 1, 1–4. (In Polish) [Google Scholar]

- Li, Z.Y.; Wang, R.F.; Kudra, T. Uniformity Issue in Microwave Drying. Dry. Technol. 2011, 29, 652–660. [Google Scholar] [CrossRef]

- Alpert, P.; Oliver, M.J. Drying without dying. In Desiccation and Survival in Plants: Drying without Dying; Black, M., Pritchard, H.W., Eds.; CABI: Wallingford, UK, 2002; pp. 3–43. ISBN 978-0-85199-534-2. [Google Scholar]

- Kermode, A.R.; Finch-Savage, B.E. Desiccation sensitivity in orthodox and recalcitrant seeds in relation to development. In Desiccation and Survival in Plants: Drying without Dying; Black, M., Pritchard, H.W., Eds.; CABI: Wallingford, UK, 2002; pp. 149–184. ISBN 978-0-85199-534-2. [Google Scholar]

- Khraisheh, M.A.M.; McMinn, W.A.M.; Magee, T.R.A. Quality and structural changes in starchy foods during microwave and convective drying. Food Res. Int. 2004, 37, 497–503. [Google Scholar] [CrossRef]

- Nowacka, M.; Śledź, M.; Wiktor, A.; Witrowa-Rajchert, D. Physical and Chemical Properties of Microwave Dried Food Products. Żywność Nauka Technol. Jakość 2012, 6, 5–20. [Google Scholar] [CrossRef]

- Rząca, M.; Witrowa-Rajchert, D. Influence of convective-microwave drying parameters on radicalscavenging activity of dried apples. Żywność Nauka Technol. Jakość 2007, 14, 222–230. [Google Scholar]

- Jakubowski, T. Effect of seed potatoes microwave stimulation on the growth and yields of potato (Solanum tuberosum L.). Acta Agrophys. 2010, 16, 295–313. [Google Scholar]

- Pietruszewski, S.; Kania, K. Microwave effect on the germination kinetics of seeds of white lupine and consumptive pea. Acta Agrophys. 2011, 18, 121–129. [Google Scholar]

- Słowiński, K. The influence of microwave radiation emitted to non-disinfected nursery soil on the survivability and chosen biometric characteristics of Scots pine (Pinus sylvestris L.). Zesz. Nauk. Uniw. Rol. Kołłątaja Krakowie 2013, 517, 122. [Google Scholar]

- Friesen, A.P.; Conner, R.L.; Robinson, D.E.; Barton, W.R.; Gillard, C.L. Effect of microwave radiation on dry bean seed infected with Xanthomonas axonopodis pv. phaseoli with and without the use of chemical seed treatment. Crop Prot. 2014, 65, 77–85. [Google Scholar] [CrossRef]

- Sahin, H. Effects of Microwaves on the Germination of Weed Seeds. J. Biosyst. Eng. 2014, 39, 304–309. [Google Scholar] [CrossRef]

- Çelen, S. Effect of Microwave Drying on the Drying Characteristics, Color, Microstructure, and Thermal Properties of Trabzon Persimmon. Foods 2019, 8, 84. [Google Scholar] [CrossRef]

- Ryszard, J.; Dolińska, R.; Błaszczak, W. Microscope analysis of two generations of wheat grain crops grown from microwave heated seeds. Acta Agrophys. 2007, 10, 727–737. [Google Scholar]

- Tkalec, M.; Malarić, K.; Pavlica, M.; Pevalek-Kozlina, B.; Vidaković-Cifrek, Ž. Effects of radiofrequency electromagnetic fields on seed germination and root meristematic cells of Allium cepa L. Mutat. Res. Genet. Toxicol. Environ. Mutagen. 2009, 672, 76–81. [Google Scholar] [CrossRef]

- Sharma, S.; Parihar, L. Effect of mobile phone radiation on nodule formation in the leguminous plants. Curr. World Environ. 2014, 9, 145–155. [Google Scholar] [CrossRef]

- Stefi, A.L.; Margaritis, L.H.; Christodoulakis, N.S. The aftermath of long-term exposure to non-ionizing radiation on laboratory cultivated pine plants (Pinus halepensis M.). Flora 2017, 234, 173–186. [Google Scholar] [CrossRef]

- Stefi, A.L.; Margaritis, L.H.; Christodoulakis, N.S. The effect of the non-ionizing radiation on exposed, laboratory cultivated maize (Zea mays L.) plants. Flora 2017, 233, 22–30. [Google Scholar] [CrossRef]

- Vian, A.; Davies, E.; Gendraud, M.; Bonnet, P. Plant responses to high frequency electromagnetic fields. BioMed Res. Int. 2016, 2016, 1830262. [Google Scholar] [CrossRef]

- Xu, F.; Chen, Z.; Huang, M.; Li, C.; Zhou, W. Effect of intermittent microwave drying on biophysical characteristics of rice. J. Food Process Eng. 2017, 40, e12590. [Google Scholar] [CrossRef]

- Isaev, A.V.; Bastron, A.V.; Yakhontova, V.S. The research of unevenness degree influence of heating of colza seeds in emf uhf on their energy of germination and viability. Bull. KrasGAU 2016, 4, 131–137. [Google Scholar]

- Mishra, R.; Dash, A.; Pattanaik, S.; Nayak, P.; Mohanty, R. Seed Germination and Seedling Survival Percentage of Shorea robusta Gaertn.f. in Buffer Areas of Similipal Biosphere Reserve, Odisha, India. J. Ecosyst. Ecograph. 2015, 4, 153. [Google Scholar]

- Aniszewska, M.; Słowiński, K. Effects of microwave irradiation by means of a horn antenna in the process of seed extraction on Scots pine (Pinus sylvestris L.) cone moisture content and seed germination energy and capacity. Eur. J. For. Res. 2016, 135, 633–642. [Google Scholar] [CrossRef]

- Hemis, M.; Choudhary, R.; Gariépy, Y.; Raghavan, V.G.S. Experiments and modelling of the microwave assisted convective drying of canola seeds. Biosyst. Eng. 2015, 139, 121–127. [Google Scholar] [CrossRef]

- Jasińska, A.K. Zmienność genetyczna Pinus sylvestris L. na terenie ostoi flor trzeciorzędowych w południowej Europie i południowo-zachodniej Azji. In Zastosowanie Metod Statystycznych w Badaniach Naukowych IV; Jakubowski, J., Wątroba, J., Eds.; Wydawnictwo StatSoft Polska: Kraków, Poland, 2012; pp. 449–458. (In Polish) [Google Scholar]

- BN-76/9211-02—Leśnictwo; Wydawnictwa Normalizacyjne: Warsaw, Poland, 1976. (In Polish)

- N-R-65700—Materiał siewny. Nasiona drzew i krzewów leśnych i zadrzewieniowych; Polish Committee for Standardization: Warsaw, Poland, 1998. (In Polish)

- Banach, J.; Skrzyszewska, K.; Sobaszek, D. Assessment comparison of viability of Scots pine seeds executed by X-ray and germination methods. Acta Agrar. Silvestria Ser. Silvestris 2015, 53, 3–13. [Google Scholar]

- Staszkiewicz, L. Staszkiewicz Investigation on Pinus sylvestris L. from South-estern Europe and from Caucasus and its relation to the pine from other territories of Europe based on morphological variability of cones. Flor. Geobot 1968, 14, 259–315. [Google Scholar]

- Białobok, S.; Boratyński, A.; Bugała, W. Biologia Sosny Zwyczajnej [Biology of Scots Pine]; Polska Akademia Nauk Instytut Dendrologii: Poznań-Kórnik, Poland, 1993; ISBN 978-83-85599-21-0. (In Polish) [Google Scholar]

- Aniszewska, M. The impact of selected morphological features of Scotch Pine cones on the progress of hulling process. Inż. Rol. 2008, 1, 9–15. [Google Scholar]

- Bruchwald, A. Statystyka Matematyczna Dla Leśników; Wydawnictwo SGGW: Warszawa, Poland, 1989; ISBN 978-83-00-02187-1. (In Polish) [Google Scholar]

- Aniszewska, M. Connection between shape of pine (Pinus sylvestris) cones and weight, colour and number of seeds, extracted from them. Electron. J. Pol. Agric. Univ. For. 2006, 9, 3. [Google Scholar]

- Tyszkiewicz, S. Wyłuszczanie Nasion Leśnych; Państwowe Wydawnictwo Rolnicze i Leśne: Warszawa, Poland, 1951. (In Polish) [Google Scholar]

- Dong, W.; Cheng, K.; Hu, R.; Chu, Z.; Zhao, J.; Long, Y. Effect of Microwave Vacuum Drying on the Drying Characteristics, Color, Microstructure, and Antioxidant Activity of Green Coffee Beans. Molecules 2018, 23, 1146. [Google Scholar] [CrossRef]

- Witowska, O.; Aniśko, E.; Załęski, A. The effect of drying seeds of European larch, Douglas-fir and mountain pine foreseen for a long-term storage on their viability. For. Res. Pap. 2009, 70, 253–269. [Google Scholar] [CrossRef]

- Aniśko, E.; Witowska, O.; Załęski, A. Effect of drying conditions on viability of common birch, black alder, Scots pine and Norway spruce seeds. For. Res. Pap. 2006, 2, 91–113. [Google Scholar]

- Sham, P.W.Y.; Scaman, C.H.; Durance, T.D. Texture of Vacuum Microwave Dehydrated Apple Chips as Affected by Calcium Pretreatment, Vacuum Level, and Apple Variety. J. Food Sci. 2001, 66, 1341–1347. [Google Scholar] [CrossRef]

- Funebo, T.; Ahrné, L.; Kidman, S.; Langton, M.; Skjöldebrand, C. Microwave heat treatment of apple before air dehydration—Effects on physical properties and microstructure. J. Food Eng. 2000, 46, 173–182. [Google Scholar] [CrossRef]

| Mode | Variant | Cone Arrangement | Number of Cones Under the Generator (pcs.) | Duration of Microwave Irradiation (s) |

|---|---|---|---|---|

| W1 | - | - | 1 | 5, 7, 10 |

| W2 | W2a | Apexes towards the centre | 3 | 5, 10, 15 |

| W2b | Apexes towards the edge | 3 | 5, 10, 15 | |

| W3 | W3a | Apexes towards the centre | 5 | 5, 10, 15 |

| W3b | Apexes towards the edge | 5 | 5, 10, 15 |

| Statistics | Length (mm) | Thickness (mm) | Distance Between the Maximum Thickness Point and the Cone Base (mm) | Initial Weight (g) |

|---|---|---|---|---|

| Mean (±SD) | 43.92 ± 4.2 | 19.87 ± 1.64 | 11.12 ± 1.6 | 6.789 ± 1.68 |

| Minimum | 35.2 | 16.2 | 7.0 | 4.224 |

| Maximum | 57.6 | 25.7 | 18.7 | 12.973 |

| Range | 22.4 | 9.5 | 11.7 | 8.749 |

| Coefficient of variation | 9.50 | 8.26 | 13.9 | 24.7 |

| Standard deviation | 0.28 | 0.11 | 0.10 | 0.11 |

| Loss of Weight (g) | ||||

|---|---|---|---|---|

| Exposure Time | 5 s | 7 s | 10 s | 15 s |

| W1 | 0.014 ± 0.008 | 0.021 ± 0.018 | 0.103 ± 0.049 | - |

| W2 | 0.006 ± 0.003 | - | 0.037 ± 0.018 | 0.097 ± 0.037 |

| W3 | 0.005 ± 0.003 | - | 0.022 ± 0.007 | 0.054 ± 0.022 |

| Loss of Weight (g) | |||

|---|---|---|---|

| Exposure Time | 5 s | 10 s | 15 s |

| W2a | 0.006 ± 0.003 | 0.034 ± 0.015 | 0.078 ± 0.025 |

| W2b | 0.006 ± 0.002 | 0.040 ± 0.021 | 0.127 ± 0.034 |

| W3a | 0.005 ± 0.002 | 0.022 ± 0.006 | 0.050 ± 0.025 |

| W3b | 0.006 ± 0.003 | 0.021 ± 0.008 | 0.060 ± 0.017 |

| Time of Exposure to Microwaves (s) | Maximum Temperature of the Whole Cone (°C) | Half No. | Maximum Temperature of the Cone Half (°C) |

|---|---|---|---|

| W1 | |||

| 5 | 62.52 ± 10.24 | 1 | 53.25 ± 15.24 |

| 2 | 43.10 ± 7.04 | ||

| 7 | 88.29 ± 14.49 | 1 | 60.58 ± 14.37 |

| 2 | 72.74 | ||

| 10 | 103.43 ± 13.22 | 1 | 75.58 ± 4.69 |

| 2 | 77.67 | ||

| W2a | |||

| 5 | 63.07 ± 11.76 | 1 | 49.15 ± 6.36 |

| 2 | 48.04 | ||

| 10 | 84.69 ± 8.59 | 1 | 68.35 ± 8.93 |

| 2 | 63.71 ± 9.03 | ||

| 15 | 99.23 ± 0.16 | 1 | - |

| 2 | 78.76 ± 0.45 | ||

| W2b | |||

| 5 | 48.58 ± 7.78 | 1 | 42.43 ± 5.01 |

| 2 | - | ||

| 10 | 79.35 ± 10.87 | 1 | 66.5 ± 4.48 |

| 2 | 56.65 ± 0.99 | ||

| 15 | 95.19 ± 1.45 | 1 | 75.85 ± 1.42 |

| 2 | - | ||

| W3a | |||

| 5 | 52.53 ± 6.29 | 1 | 43.73 ± 4.42 |

| 2 | 50.00 | ||

| 10 | 78.35 ± 9.15 | 1 | 60.58 ± 1.55 |

| 2 | - | ||

| 15 | 85.14 ± 3.59 | 1 | 66.56 ± 3.63 |

| 2 | 67.21 | ||

| W3b | |||

| 5 | 42.65 ± 7.04 | 1 | 37.70 ± 4.23 |

| 2 | - | ||

| 10 | 70.26 ± 6.02 | 1 | 60.47 ± 1.81 |

| 2 | 60.19 | ||

| 15 | 84.26 ± 3.75 | 1 | 66.17 ± 4.21 |

| 2 | - |

| Mode | Microwave Exposure Time (s) | Germination Energy (%) | Germination Capacity (%) | Seed Quality Class |

|---|---|---|---|---|

| W1 | ||||

| 5 | 38 | 42 | substandard | |

| 7 | 33 | 35 | substandard | |

| 10 | 10 | 11 | substandard | |

| W2 | ||||

| 5 | 62 | 65 | substandard | |

| 10 | 19 | 20 | substandard | |

| 15 | 0 | 0 | substandard | |

| W3 | ||||

| 5 | 74 | 81 | II | |

| 10 | 39 | 45 | substandard | |

| 15 | 2 | 3 | substandard |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aniszewska, M.; Gendek, A.; Tulska, E.; Pęska, P.; Moskalik, T. Influence of the Duration of Microwave Irradiation of Scots Pine (Pinus sylvestris L.) Cones on the Quality of Harvested Seeds. Forests 2019, 10, 1108. https://doi.org/10.3390/f10121108

Aniszewska M, Gendek A, Tulska E, Pęska P, Moskalik T. Influence of the Duration of Microwave Irradiation of Scots Pine (Pinus sylvestris L.) Cones on the Quality of Harvested Seeds. Forests. 2019; 10(12):1108. https://doi.org/10.3390/f10121108

Chicago/Turabian StyleAniszewska, Monika, Arkadiusz Gendek, Ewa Tulska, Paulina Pęska, and Tadeusz Moskalik. 2019. "Influence of the Duration of Microwave Irradiation of Scots Pine (Pinus sylvestris L.) Cones on the Quality of Harvested Seeds" Forests 10, no. 12: 1108. https://doi.org/10.3390/f10121108

APA StyleAniszewska, M., Gendek, A., Tulska, E., Pęska, P., & Moskalik, T. (2019). Influence of the Duration of Microwave Irradiation of Scots Pine (Pinus sylvestris L.) Cones on the Quality of Harvested Seeds. Forests, 10(12), 1108. https://doi.org/10.3390/f10121108