Functionalized Surface Layer on Poplar Wood Fabricated by Fire Retardant and Thermal Densification. Part 2: Dynamic Wettability and Bonding Strength

Abstract

1. Introduction

2. Materials and Methods

2.1. Treatment

2.2. Surface Free Energy

2.3. Contact Angles and Dynamic Wettability

2.4. Surface Characteristics and Bonding Strength

3. Results and Discussion

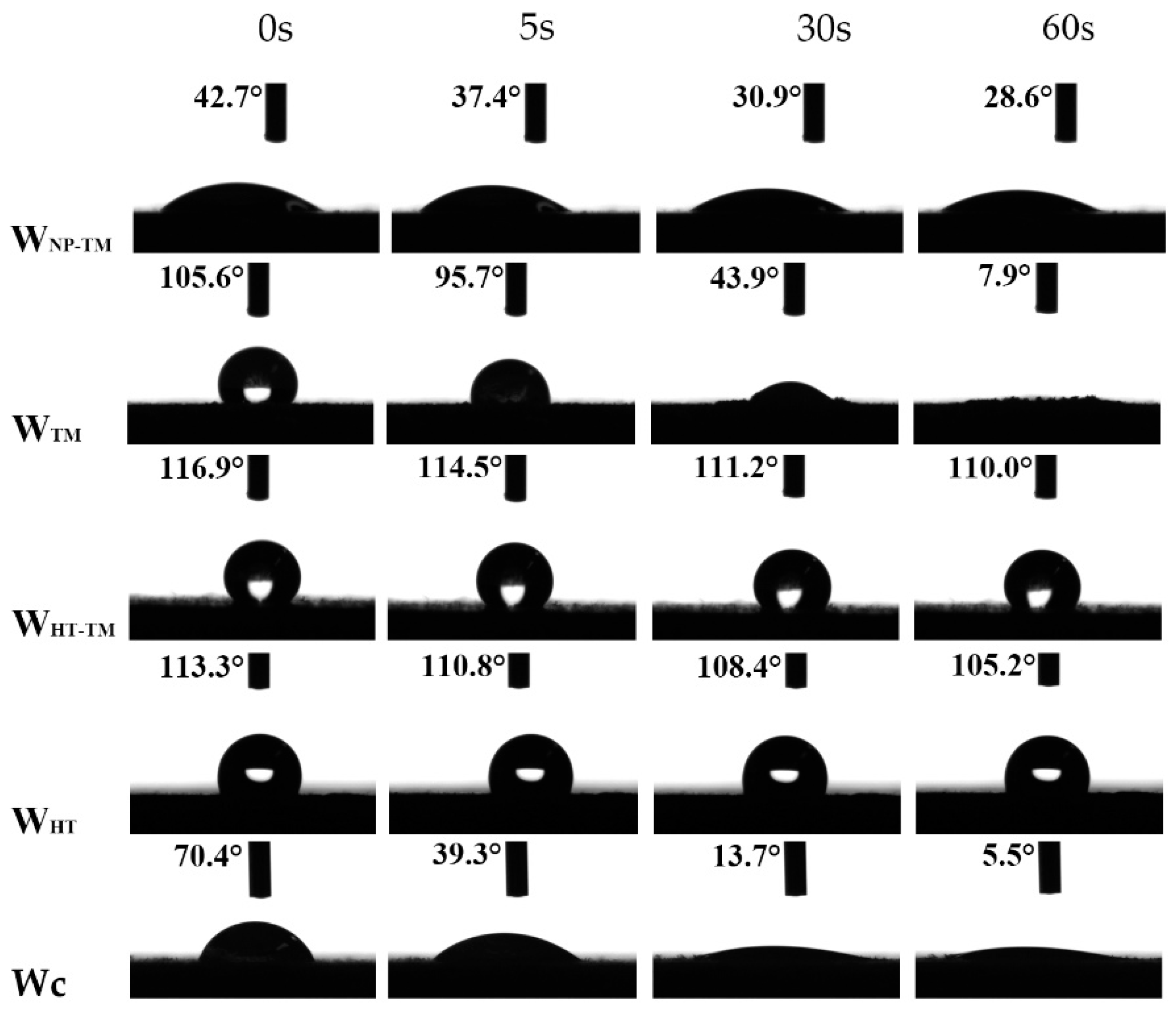

3.1. Contact Angles and Surface Free Energy

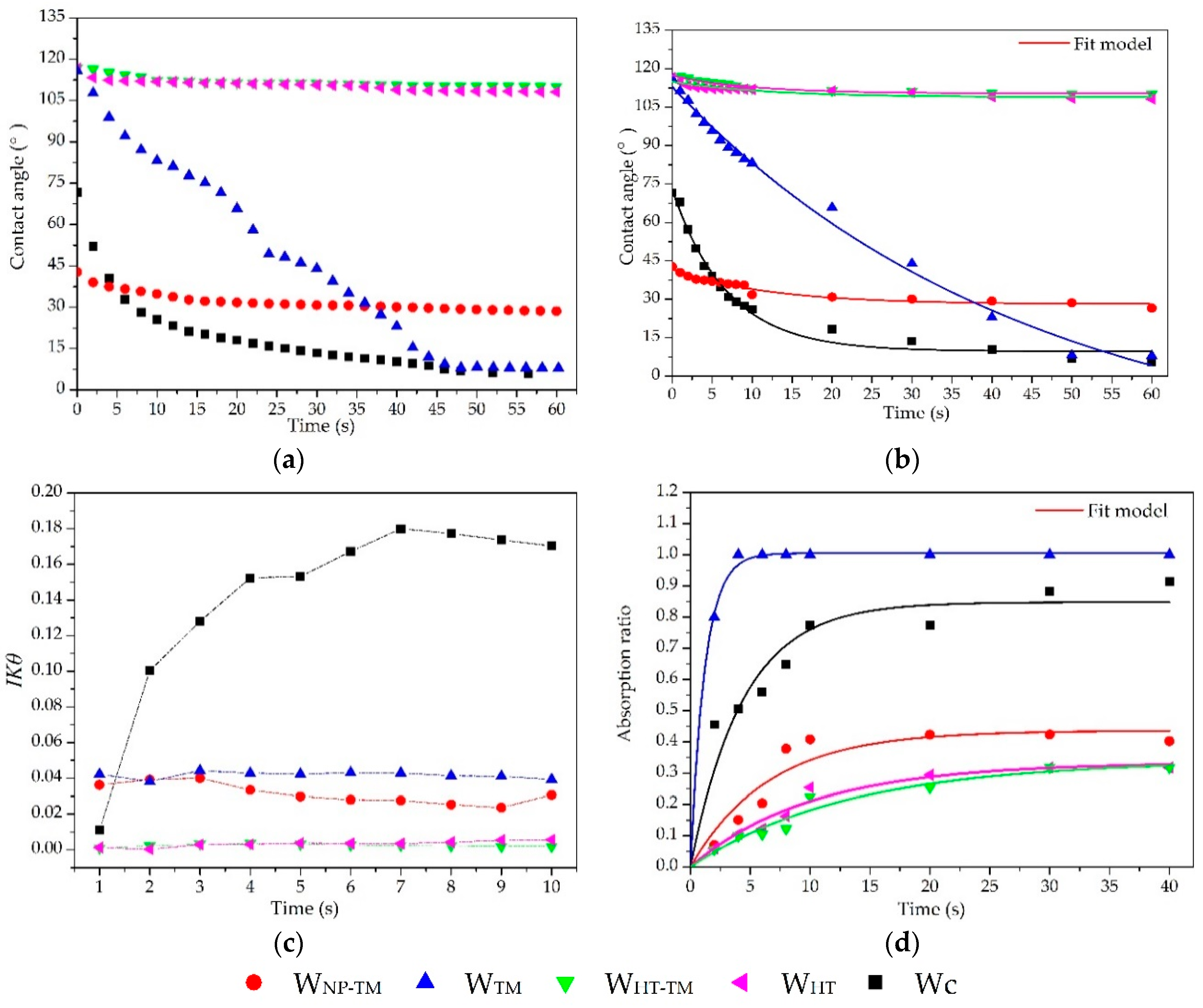

3.2. Dynamic Wetting Process

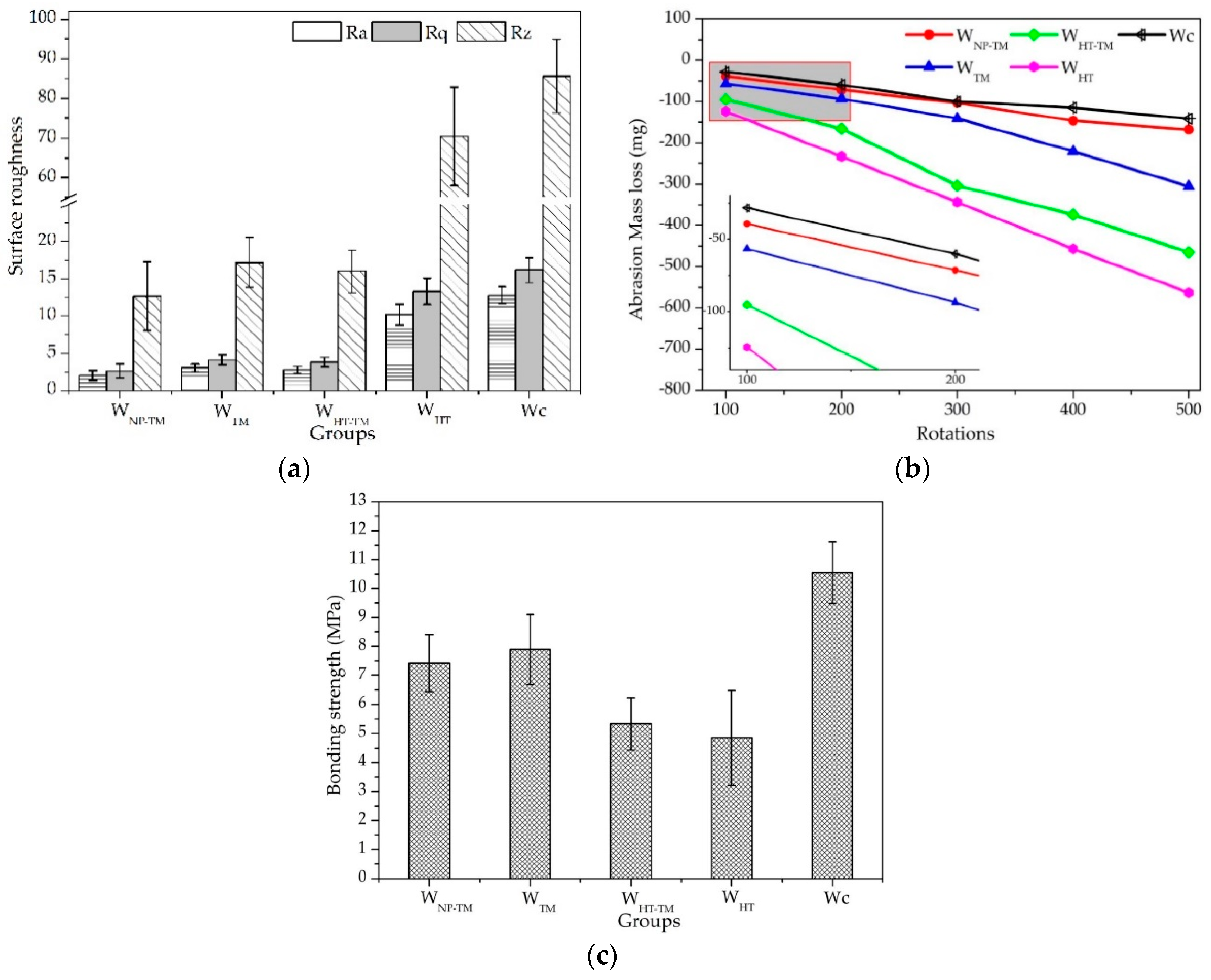

3.3. Surface Characteristics and Bonding Strength

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Hill, C.A.S. Wood Modification: Chemical, Thermal and Other Processes; John Wiley & Sons: Chichester, UK, 2006. [Google Scholar]

- Lin, H.; Wang, Y.; Chen, Z.D.; Yang, B.X. Progress & Application Prospects of Modified Wood. For. Mach. Woodwork. Equip. 2006, 34, 11–13. [Google Scholar]

- Yuan, Q.P.; Su, C.W.; Xiong, J.B. Research Progress of Plantation Wood Machining Properties. J. Anhui Agric. Sci. 2011, 3, 42–45. [Google Scholar]

- Kiaei, M.; Naji, H.R.; Abdul-Hamid, H.; Farsi, M. Radial variation of fiber dimensions, annual ring width, and wood density from natural and plantation trees of alder (Alnus glutinosa) wood. Drev. Vysk. Wood Res. 2016, 61, 55–64. [Google Scholar]

- Xu, K.; Lu, J.X.; Li, X.J.; Wu, Y.Q. Effect of heat treatment on dimensional stability of phenolic resin impregnated poplar wood. J. Beijing For. Univ. 2015, 37, 70–77. [Google Scholar]

- Fang, C.H.; Mariotti, N.; Cloutier, A.; Koubaa, A.; Blanchet, P. Densification of wood veneers by compression combined with heat and steam. Eur. J. Wood Prod. 2012, 70, 155–163. [Google Scholar] [CrossRef]

- Laskowska, A. The Influence of Process Parameters on the Density Profile and Hardness of Surface-densified Birch Wood (Betula pendula Roth). BioResources 2017, 12, 6011–6023. [Google Scholar] [CrossRef][Green Version]

- Kariz, M.; Kuzman, M.K.; Sernek, M.; Hughes, M.; Rautkari, L.; Kamke, F.A.; Kutnar, A. Influence of temperature of thermal treatment on surface densification of spruce. Eur. J. Wood Prod. 2017, 75, 113–123. [Google Scholar] [CrossRef]

- Chu, D.M.; Mu, J.; Avramidis, S.; Rahimi, S.; Liu, S.Q.; Lai, Z.Y. Functionalized surface layer on poplar wood fabricated by fire retardant and thermal densification. Part 1: Compression recovery and flammability. Forests 2019, 10, 955. [Google Scholar] [CrossRef]

- Bekhta, P.; Proszyk, S.A.; Krystofiak, T. Colour in short-term thermo-mechanically densified veneer of various wood species. Eur. J. Wood Prod. 2014, 72, 785–797. [Google Scholar] [CrossRef]

- Darwis, A.; Wahyudi, I.; Dwianto, W.; Cahyono, T.D. Densified wood anatomical structure and the effect of heat treatment on the recovery of set. J. Indian Acad. Wood Sci. 2017, 1–8. [Google Scholar] [CrossRef]

- Chen, A.T.; Luo, P.P.; Xu, Z.Y.; Hu, Z.J. Effects of silicon dioxide combined heat treatment on properties of rubber wood. J. For. Eng. 2016, 1, 21–25. (In Chinese) [Google Scholar] [CrossRef]

- Liu, H.L.; Shang, J.; Kamke, F.A.; Guo, K.Q. Bonding performance and mechanism of thermal-hydro-mechanical modified veneer. Wood Sci. Technol. 2018, 52, 343–363. [Google Scholar] [CrossRef]

- Pelit, H.; Budakçı, M.; Sönmez, A.; Burdurlu, E. Surface roughness and brightness of scots pine (Pinus sylvestris) applied with water-based varnish after densification and heat treatment. J. Wood Sci. 2015, 61, 586–594. [Google Scholar] [CrossRef]

- Gu, B. Study on the Effects of Properties of UF Plywood Treated with BL-Environmental-Friendly Flame Retardant. Composition Analysis of BL Environmental Protection Flame Retardant. Ph.D. Thesis, Beijing Forestry University, Beijing, China, 2007; pp. 50–56. [Google Scholar]

- Zhang, X.T.; Mu, J.; Chu, D.M.; Zhao, Y. Synthesis of fire retardants based on N and P and poly (sodium silicate aluminum dihydrogen phosphate) (PSADP) and testing the flame-retardant properties of PSADP impregnated poplar wood. Holzforschung 2015, 70, 341–350. [Google Scholar] [CrossRef]

- Chu, D.M.; Mu, J.; Zhang, L.; Li, Y.S. Promotion effect of NP fire retardant pre-treatment on heat-treated poplar wood. Part 1: Color generation, dimensional stability, and fire retardancy. Holzforschung 2017, 71, 207–215. [Google Scholar] [CrossRef]

- Chu, D.M.; Mu, J.; Zhang, L.; Li, Y.S. Promotion effect of NP fire retardant pre-treatment on heat-treated poplar wood. Part 2: Hygroscopicity, leaching resistance, and thermal stability. Holzforschung 2017, 71, 217–223. [Google Scholar] [CrossRef]

- Van Oss, C.J.; Good, R.J.; Chaudhury, M.K. Additive and nonadditive surface tension components and the interpretation of contact angles. Langmuir 1988, 4, 884–891. [Google Scholar] [CrossRef]

- Gérardin, P.; Petrič, M.; Petrissans, M.; Lambert, J.; Ehrhrardt, J.J. Evolution of wood surface free energy after heat treatment. Polym. Degrad. Stab. 2007, 92, 653–657. [Google Scholar] [CrossRef]

- Wang, W.; Zhu, Y.; Cao, J.Z.; Sun, W.J. Correlation between dynamic wetting behavior and chemical components of thermally modified wood. Appl. Surf. Sci. 2015, 324, 332–338. [Google Scholar] [CrossRef]

- Gao, X.; Zhou, F.; Fu, Z.Y.; Zhou, Y.D. Sorption isotherms characteristics of high temperature heat-treated Picea abies and Pseudotsuga menziesii. J. For. Eng. 2018, 3, 25–29. [Google Scholar] [CrossRef]

- Salca, E.; Hiziroglu, S. Evaluation of hardness and surface quality of different wood species as function of heat treatment. Mater. Des. 2014, 62, 416–423. [Google Scholar] [CrossRef]

| Liquids | Surface Free Energy (mJ m−2) | ||||

|---|---|---|---|---|---|

| γL | γLLW | γLAB | γL+ | γL− | |

| Distilled water | 72.8 | 21.8 | 51.0 | 25.5 | 25.5 |

| Diiodomethane | 50.8 | 50.8 | 0 | 0 | 0 |

| Formamide | 58.0 | 39.0 | 19.0 | 2.28 | 39.6 |

| Groups | Contact Angle (°) | Surface Free Energy (mJ m−2) | ||||||

|---|---|---|---|---|---|---|---|---|

| Diiodomethane | H2O | Formamide | γs | γsLW | γsAB | γs+ | γs− | |

| WNP–TM | 44.42 ± 2.42 | 64.98 ± 4.3 | 71.72 ± 2.68 | 55.13 | 37.32 | 17.81 | 2.15 | 36.9 |

| WTM | 35.28 ± 4.73 | 115.24 ± 3.7 | 97.55 ± 5.28 | 45.80 | 41.90 | 3.90 | 6.76 | 0.56 |

| WHT–TM | 41.21 ± 4.12 | 116.88 ± 8.7 | 73.28 ± 0.62 | 39.95 | 39.00 | 0.95 | 0.05 | 4.22 |

| WHT | 38.56 ± 3.52 | 116.56 ± 6.8 | 69.99 ± 4.30 | 42.38 | 40.32 | 2.06 | 0.20 | 5.42 |

| Wc | 38.40 ± 1.14 | 71.58 ± 1.6 | 59.30 ± 0.83 | 45.65 | 40.41 | 2.18 | 0.08 | 15.12 |

| Groups | Contact Angle Change | Absorption Ratio Change | |||||

|---|---|---|---|---|---|---|---|

| θi (Degrees) | θe (Degrees) | Kθ | R2 | Ka | R2 | SE | |

| WNP–TM | 41.92 | 26.24 | 0.019 | 0.90 | 0.153 | 0.907 | 0.034 |

| WTM | 115.94 | 0.1 * | 0.040 | 0.99 | 0.826 | 0.998 | 0.036 |

| WHT–TM | 116.36 | 109.60 | 0.004 | 0.95 | 0.076 | 0.959 | 0.013 |

| WHT | 113.79 | 105.98 | 0.002 | 0.96 | 0.099 | 0.966 | 0.014 |

| Wc | 68.73 | 3.42 | 0.174 | 0.92 | 0.227 | 0.928 | 0.039 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chu, D.; Mu, J.; Avramidis, S.; Rahimi, S.; Liu, S.; Lai, Z. Functionalized Surface Layer on Poplar Wood Fabricated by Fire Retardant and Thermal Densification. Part 2: Dynamic Wettability and Bonding Strength. Forests 2019, 10, 982. https://doi.org/10.3390/f10110982

Chu D, Mu J, Avramidis S, Rahimi S, Liu S, Lai Z. Functionalized Surface Layer on Poplar Wood Fabricated by Fire Retardant and Thermal Densification. Part 2: Dynamic Wettability and Bonding Strength. Forests. 2019; 10(11):982. https://doi.org/10.3390/f10110982

Chicago/Turabian StyleChu, Demiao, Jun Mu, Stavros Avramidis, Sohrab Rahimi, Shengquan Liu, and Zongyuan Lai. 2019. "Functionalized Surface Layer on Poplar Wood Fabricated by Fire Retardant and Thermal Densification. Part 2: Dynamic Wettability and Bonding Strength" Forests 10, no. 11: 982. https://doi.org/10.3390/f10110982

APA StyleChu, D., Mu, J., Avramidis, S., Rahimi, S., Liu, S., & Lai, Z. (2019). Functionalized Surface Layer on Poplar Wood Fabricated by Fire Retardant and Thermal Densification. Part 2: Dynamic Wettability and Bonding Strength. Forests, 10(11), 982. https://doi.org/10.3390/f10110982