Noise Reduction of Steel Cord Conveyor Belt Defect Electromagnetic Signal by Combined Use of Improved Wavelet and EMD †

Abstract

:1. Introduction

2. Basic Theory of Signal Noise Reduction Method

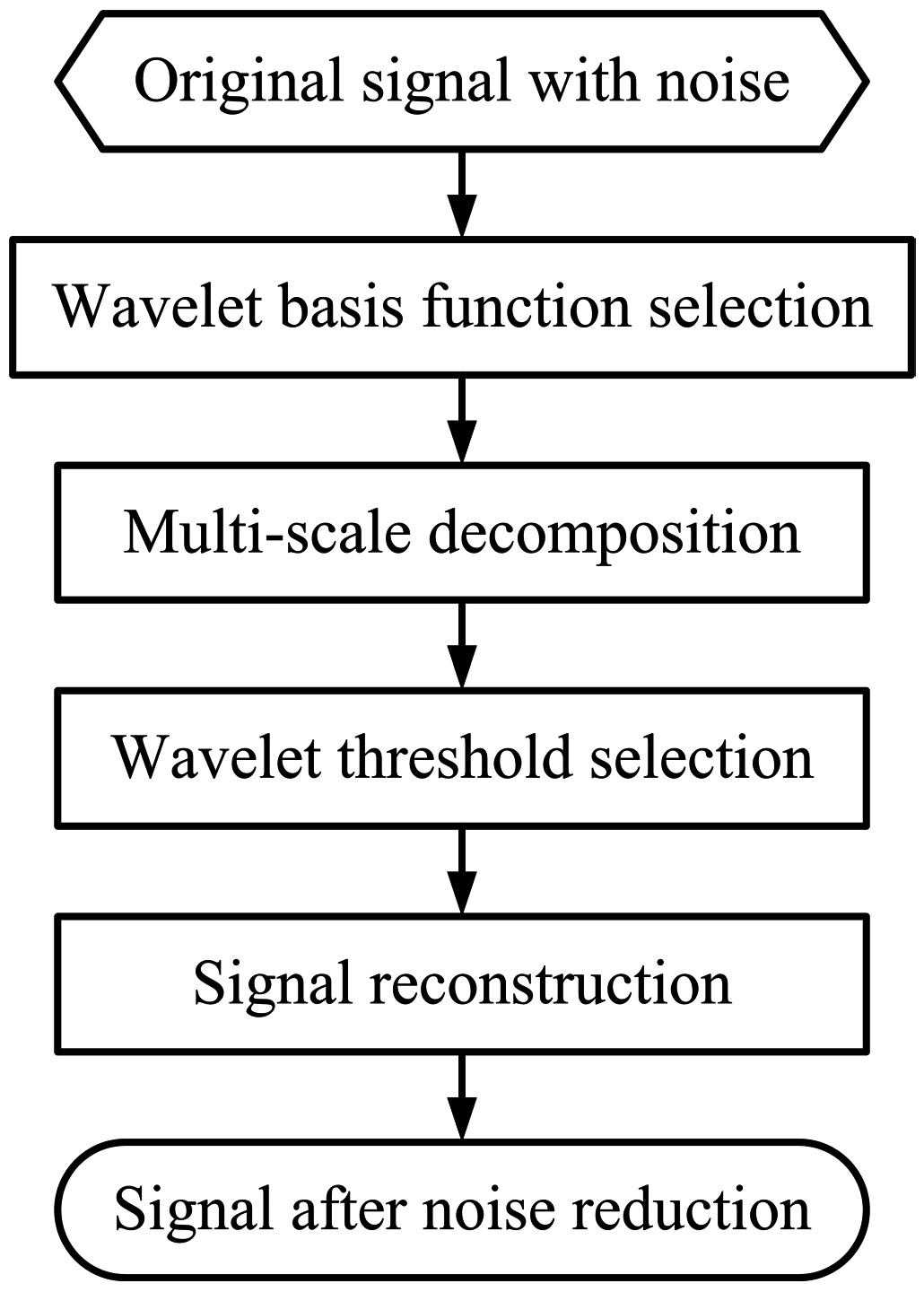

2.1. Wavelet Noise Reduction Principle

2.1.1. Wavelet Basis Function Selection

2.1.2. Wavelet Multi-Scale Decomposition

2.1.3. Wavelet Threshold Selection

2.1.4. Signal Reconstruction

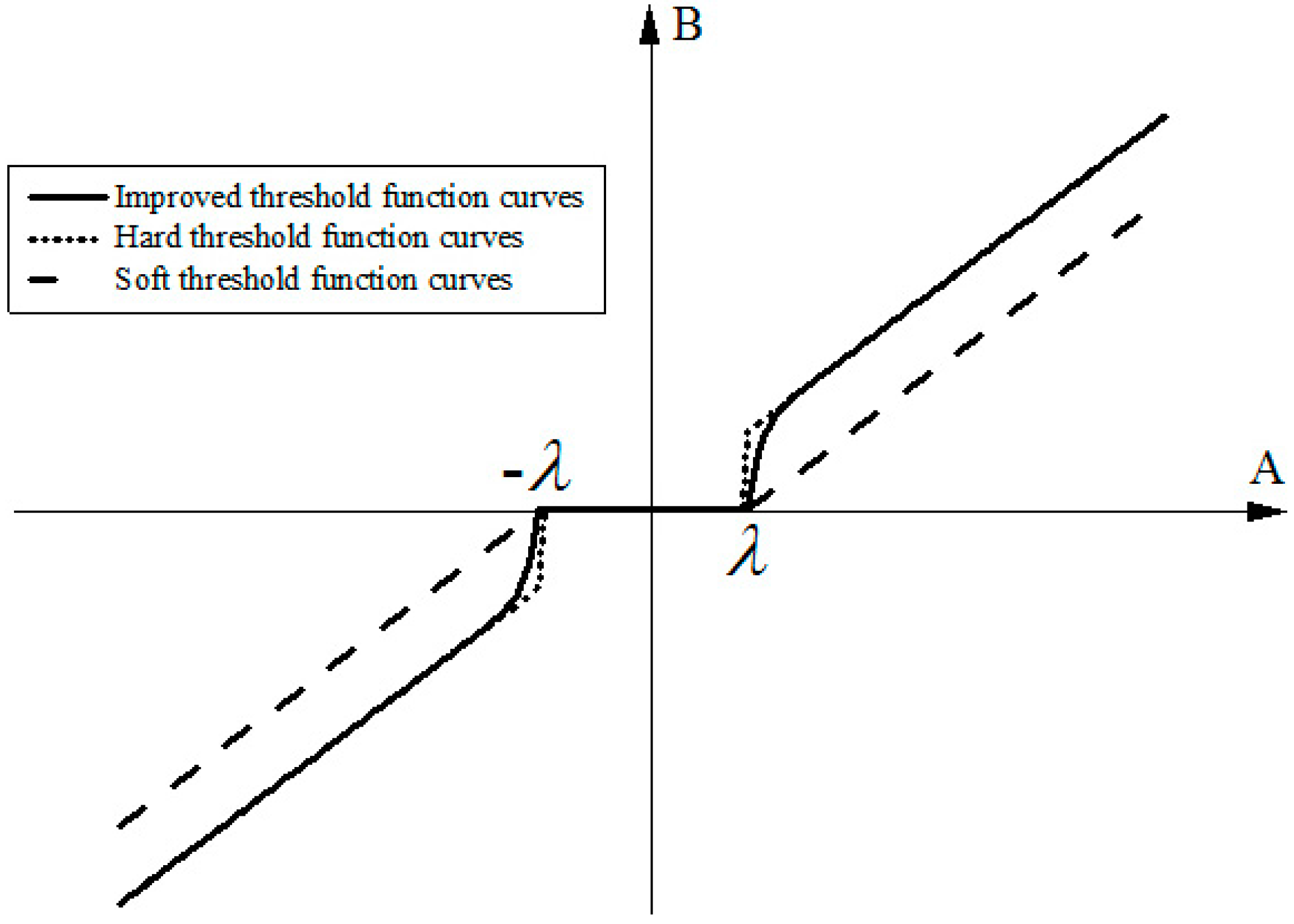

2.2. New Improved Threshold Wavelet Method

2.3. EMD Noise Reduction Method by Dominant Eigenvalues

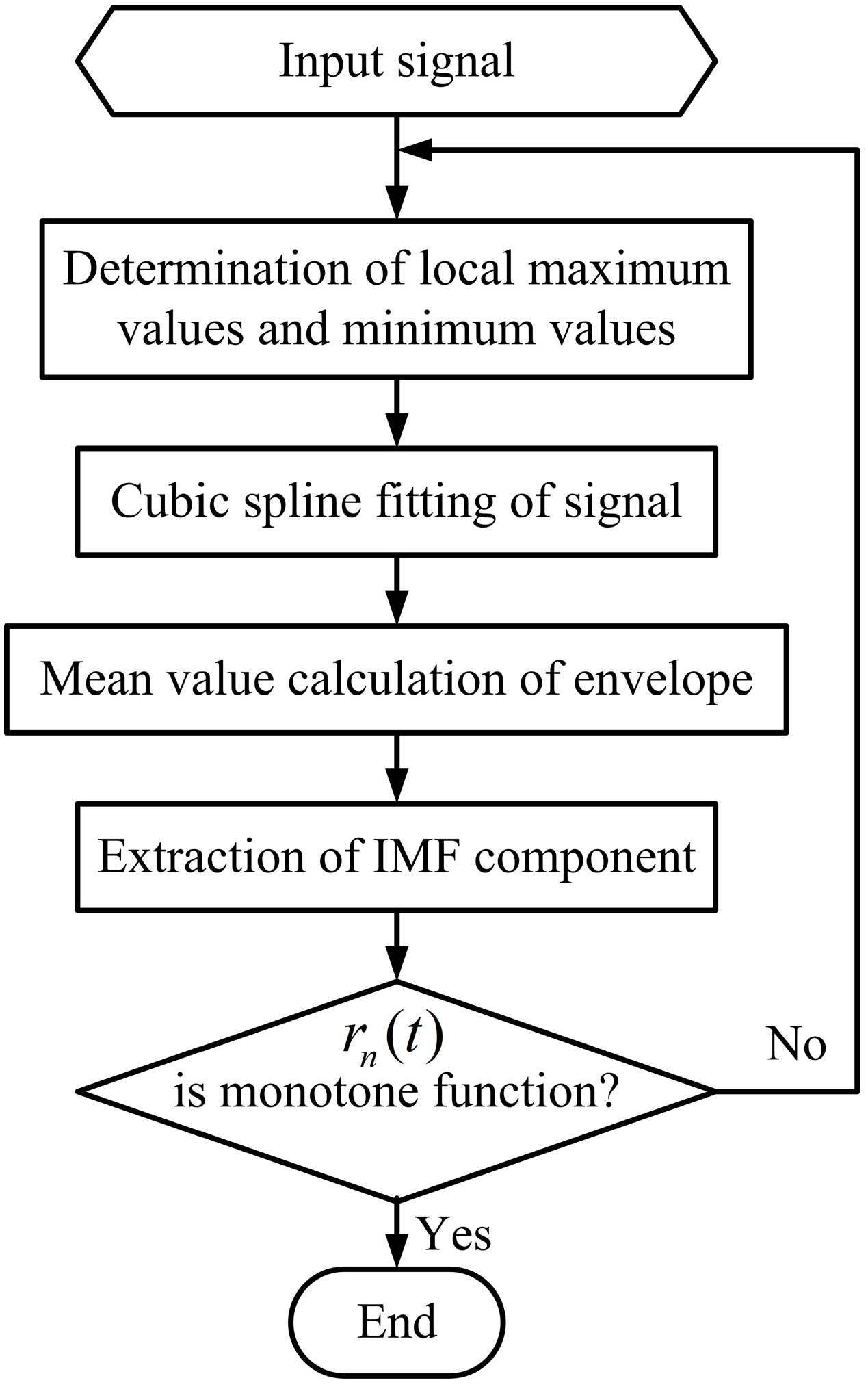

2.3.1. Noise Reduction Principle by EMD

2.3.2. New IMF Component Extraction Method by Dominant Eigenvalue

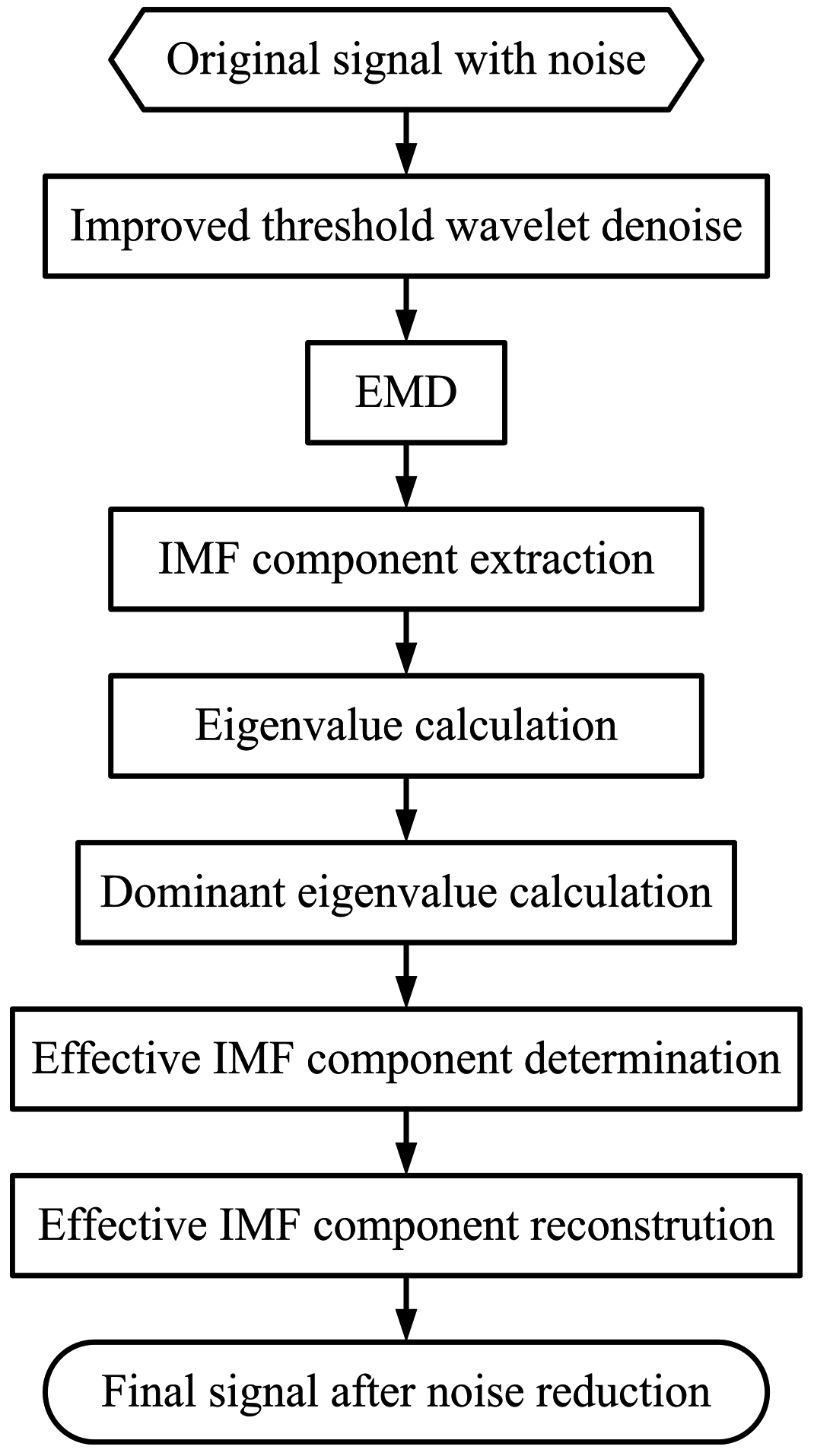

2.3.3. New Noise Reduction Method Based on the Improved Threshold Wavelet and EMD by Dominant Eigenvalue

3. Verification of Noise Reduction Method by Combined Use of Improved Wavelet and EMD

3.1. Test Rig Setup

3.2. Noise Reduction Evaluation Index

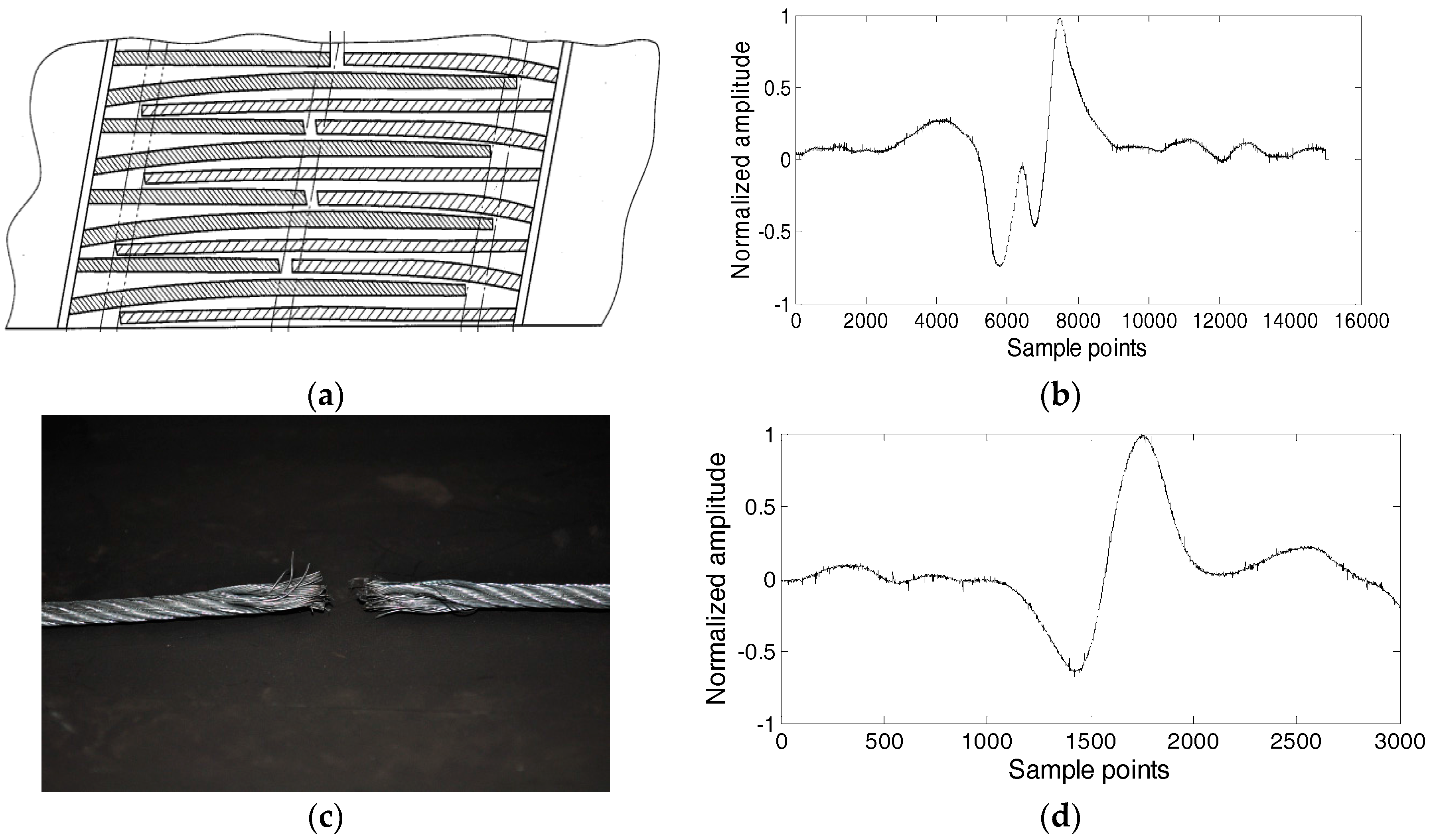

3.3. Electromagnetic Signal Collection

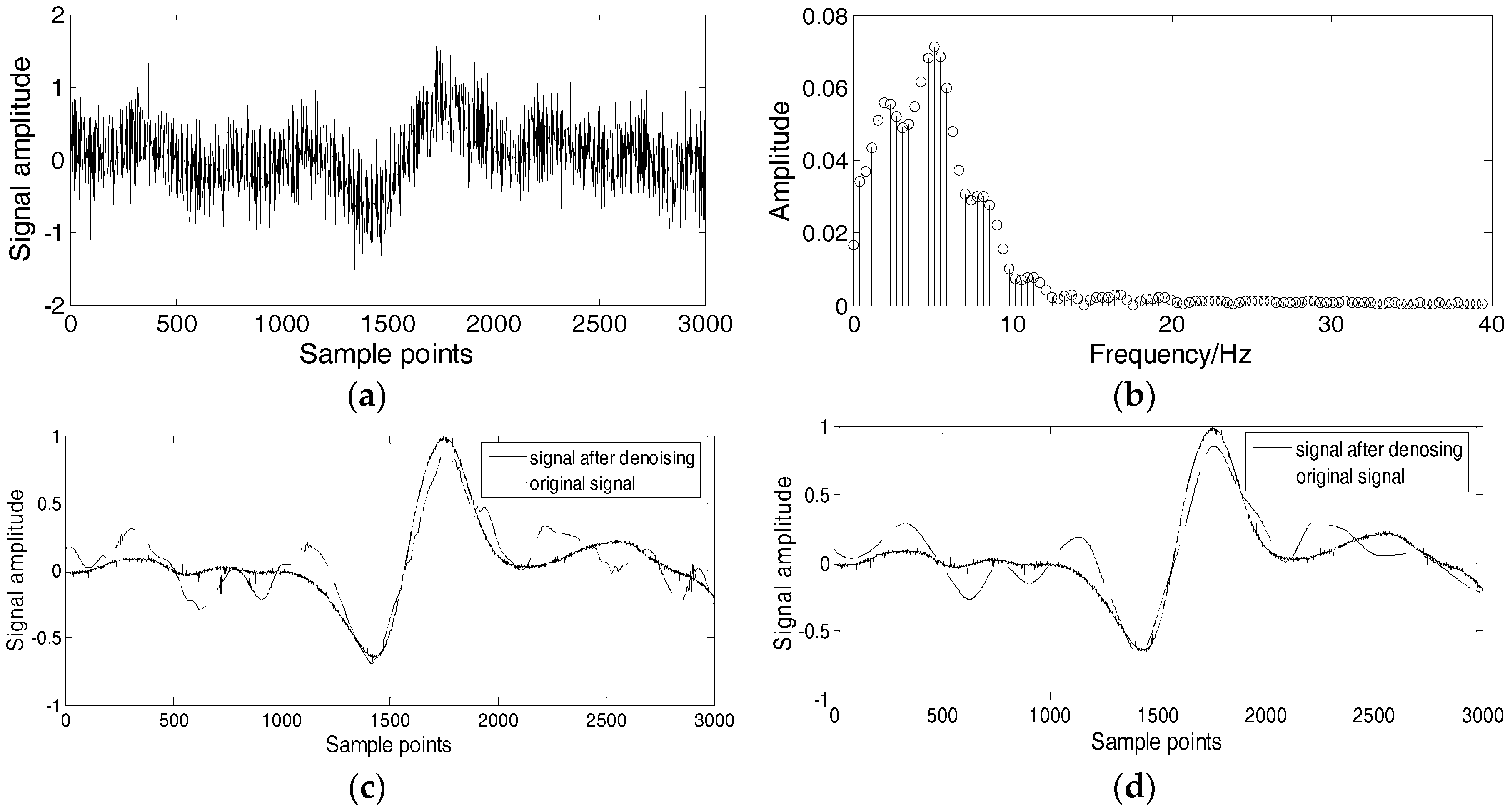

3.4. Denoising Analysis of Defect Signal

3.4.1. Noise Reduction of Joint Electromagnetic Signal

3.4.2. Noise Reduction of Electromagnetic Signal with Wire Rope Break

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Sawicki, M.; Zimroz, R.; Wylomanski, A.; Stefaniak, P.; Zak, G. An automatic procedure for multidimensional temperature signal analysis of a SCADA system with application to belt conveyor components. Procedia Earth Planet. Sci. 2015, 15, 781–790. [Google Scholar] [CrossRef]

- Huang, M.; Pan, H.S.; Hu, C.; Wei, R.Z. A system for real-time monitoring and protecting of steel-cord belt conveyors. J. China Univ. Min. Technol. 2006, 5, 673–679. (In Chinese) [Google Scholar]

- Schillaci, T.; Barraco, R.; Brai, M.; Raso, G.; Bortolotti, V.; Gombia, M.; Fantazzini, P. Noise reduction in magnetic resonance images by wavelet transforms: An application to the study of capillary water absorption in sedimentary rocks. Magn. Reson. Imaging 2007, 25, 581–582. [Google Scholar] [CrossRef]

- Zhou, Z.J.; Wen, Z.J.; Bu, Y.Y. Application study of wavelet analysis of ultrasonic echo wave noise reduction. Chin. J. Sci. Instrum. 2009, 2, 237–241. [Google Scholar]

- Jin, T.; Que, P.W. Applying wavelet theory to eliminate noise of magnetic flux leakage inspecting. J. Transduct. Technol. 2003, 1, 260–262. (In Chinese) [Google Scholar]

- Han, W.H. A new denoising algorithm for MFL data obtained from seamless pipeline inspection. Russ. J. Nondestruct. Test. 2006, 3, 184–195. [Google Scholar] [CrossRef]

- Mao, Q.H.; Ma, H.W.; Zhang, X.H. Steel cord conveyor belt defect signal noise reduction method based on a combination of wavelet packet and RLS adaptive filtering. In Proceeding of the IEEE International Symposium on Computer, Consumer and Control, Xi’an, China, 4–6 July 2016.

- Song, D.L.; Xu, D.G.; Wang, W.; Wang, Y. The application of wavelet analysis in nondestructive testing of wire ropes. Chin. J. Sci. Instrum. 1997, 2, 150–154. [Google Scholar]

- Zhang, D.L.; Xu, D.G. Data compression and feature extraction of broken wires signal based on B-wavelet. Chin. J. Sci. Instrum. 1998, 3, 249–254. [Google Scholar]

- Zhang, Q.; Zhou, X.F.; Wang, J.; Guo, Q.G. Ultrasonic signal denoising based on improved EMD. J. Nanjing Univ. Posts Telecommun. 2016, 2, 49–55. (In Chinese) [Google Scholar]

- Poornachandra, S. Wavelet-based denoising using subband dependent threshold for ECG signals. Digit. Signal Process. 2008, 1, 49–55. [Google Scholar] [CrossRef]

- Cui, H.M.; Zhao, R.M.; Hou, Y.L. Improved threshold denoising method based on wavelet transform. Phys. Procedia 2012, 33, 1354–1359. [Google Scholar]

- Guo, C.C.; Wen, Y.M.; Li, P.; Wen, J. Adaptive noise cancellation based on EMD in water-supply pipeline leak detection. Measurement 2016, 79, 188–197. [Google Scholar] [CrossRef]

- Li, L.M.; Chai, X.D.; Zheng, S.B.; Zhu, W.F. A denoising method for track state detection signal based on EMD. J. Signal Inf. Process. 2014, 4, 104–111. [Google Scholar]

- Cui, F.X.; Xu, L.L.; Zheng, X.T. A new method for noise reduction based on EMD and SVD subspaces reconstruction. J. Shaoyang Univ. 2014, 4, 12–17. (In Chinese) [Google Scholar]

- Huang, M.; Wang, C.F.; Li, H.M.; Yao, C.W. Application of EMD noise reduction and wavelet transform in bearing fault diagnosis. J. Acad. Armored Force Eng. 2013, 3, 39–43. [Google Scholar]

- Zhang, X.Y.; Xie, F.; Qiao, T.Z.; Yang, Y. Denoising algorithm for metal magnetic memory signals based on EEMD and improved semi-soft wavelet threshold. J. Taiyuan Univ. Technol. 2015, 5, 592–597. (In Chinese) [Google Scholar]

- Ghods, A.; Lee, H.H. Probabilistic frequency-domain discrete wavelet transform for better detection of bearing faults in induction motors. Neurocomputing 2016, 188, 206–216. [Google Scholar] [CrossRef]

- Shi, H.S.; Wang, Q.M. Design and experimental Mallet method based on the SURF thresholding denoisings. Compu. Digit. Eng. 2014, 4, 739–742. (In Chinese) [Google Scholar]

- Wang, G.X.; Chen, L.; Guo, S.; Peng, Y.; Guo, K. Application of a new wavelet threshold method in unconventional oil and gas reservoir seismic data denoising. Math. Probl. Eng. 2015, 2015, 969702. [Google Scholar] [CrossRef]

- Zhao, X.Z.; Ye, B.Y. Singular value decomposition packet and its application to extraction of weak fault feature. Mech. Syst. Signal Process. 2016, 70–71, 73–86. [Google Scholar] [CrossRef]

- Liu, J.C.; Wang, H.H.; Zhang, Y. New result on PID controller design of LTI systems via dominant eigenvalue assignment. Automatica 2015, 62, 93–97. [Google Scholar] [CrossRef]

| IMF Component | Eigenvalue | ||

|---|---|---|---|

| IMF1 | 29.62 | 1.68 | 1.37 |

| IMF2 | 17.61 | 1.23 | 1.04 |

| IMF3 | 14.34 | 1.18 | 1.008 |

| IMF4 | 12.19 | 1.17 | 1.04 |

| IMF5 | 10.45 | 1.12 | 1.06 |

| IMF6 | 9.36 | 1.05 | 0.30 |

| IMF7 | 8.91 | 3.50 | 0.82 |

| IMF8 | 2.55 | 4.21 | 0.38 |

| IMF9 | 0.60 | 11.21 | 0.15 |

| IMF10 | 0.054 | 73.43 | — |

| IMF11 | 0.00073 | — | — |

| Method | SNR (dB) | RSME |

|---|---|---|

| Before denoising | −2.72 | 0.36 |

| Improved threshold wavelet | 5.027 | 0.17 |

| Combined use of improved threshold wavelet and EMD | 11.63 | 0.069 |

| IMF Component | Eigenvalue | ||

|---|---|---|---|

| IMF1 | 25.28 | 1.25 | 1.045 |

| IMF2 | 20.20 | 1.20 | 1.034 |

| IMF3 | 16.87 | 1.16 | 1.035 |

| IMF4 | 14.57 | 1.12 | 1.034 |

| IMF5 | 12.99 | 1.083 | 1.025 |

| IMF6 | 11.99 | 1.056 | 0.21 |

| IMF7 | 11.36 | 4.98 | 0.28 |

| IMF8 | 2.28 | 17.54 | 0.32 |

| IMF9 | 0.13 | 54.24 | 7.27 × 10−11 |

| IMF10 | 0.0025 | 7.46 × 1011 | — |

| IMF11 | 3.35 × 10−15 | — | — |

| Method | SNR(dB) | RSME |

|---|---|---|

| Before denoising | −0.76 | 0.34 |

| Improved threshold wavelet | 6.42 | 0.14 |

| Combined use of improved threshold wavelet and EMD | 7.08 | 0.13 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, H.-W.; Fan, H.-W.; Mao, Q.-H.; Zhang, X.-H.; Xing, W. Noise Reduction of Steel Cord Conveyor Belt Defect Electromagnetic Signal by Combined Use of Improved Wavelet and EMD. Algorithms 2016, 9, 62. https://doi.org/10.3390/a9040062

Ma H-W, Fan H-W, Mao Q-H, Zhang X-H, Xing W. Noise Reduction of Steel Cord Conveyor Belt Defect Electromagnetic Signal by Combined Use of Improved Wavelet and EMD. Algorithms. 2016; 9(4):62. https://doi.org/10.3390/a9040062

Chicago/Turabian StyleMa, Hong-Wei, Hong-Wei Fan, Qing-Hua Mao, Xu-Hui Zhang, and Wang Xing. 2016. "Noise Reduction of Steel Cord Conveyor Belt Defect Electromagnetic Signal by Combined Use of Improved Wavelet and EMD" Algorithms 9, no. 4: 62. https://doi.org/10.3390/a9040062

APA StyleMa, H.-W., Fan, H.-W., Mao, Q.-H., Zhang, X.-H., & Xing, W. (2016). Noise Reduction of Steel Cord Conveyor Belt Defect Electromagnetic Signal by Combined Use of Improved Wavelet and EMD. Algorithms, 9(4), 62. https://doi.org/10.3390/a9040062