A Scheduling Solution for Robotic Arm-Based Batching Systems with Multiple Conveyor Belts †

Abstract

1. Introduction

2. Related Work

2.1. Scheduling Problems for Robotic Arms in Automated Systems

2.2. Scheduling Problems for Robotic Arms with Conveyor Belts

2.3. Solution Algorithms for Scheduling Robotic Arm-Based Batching Systems

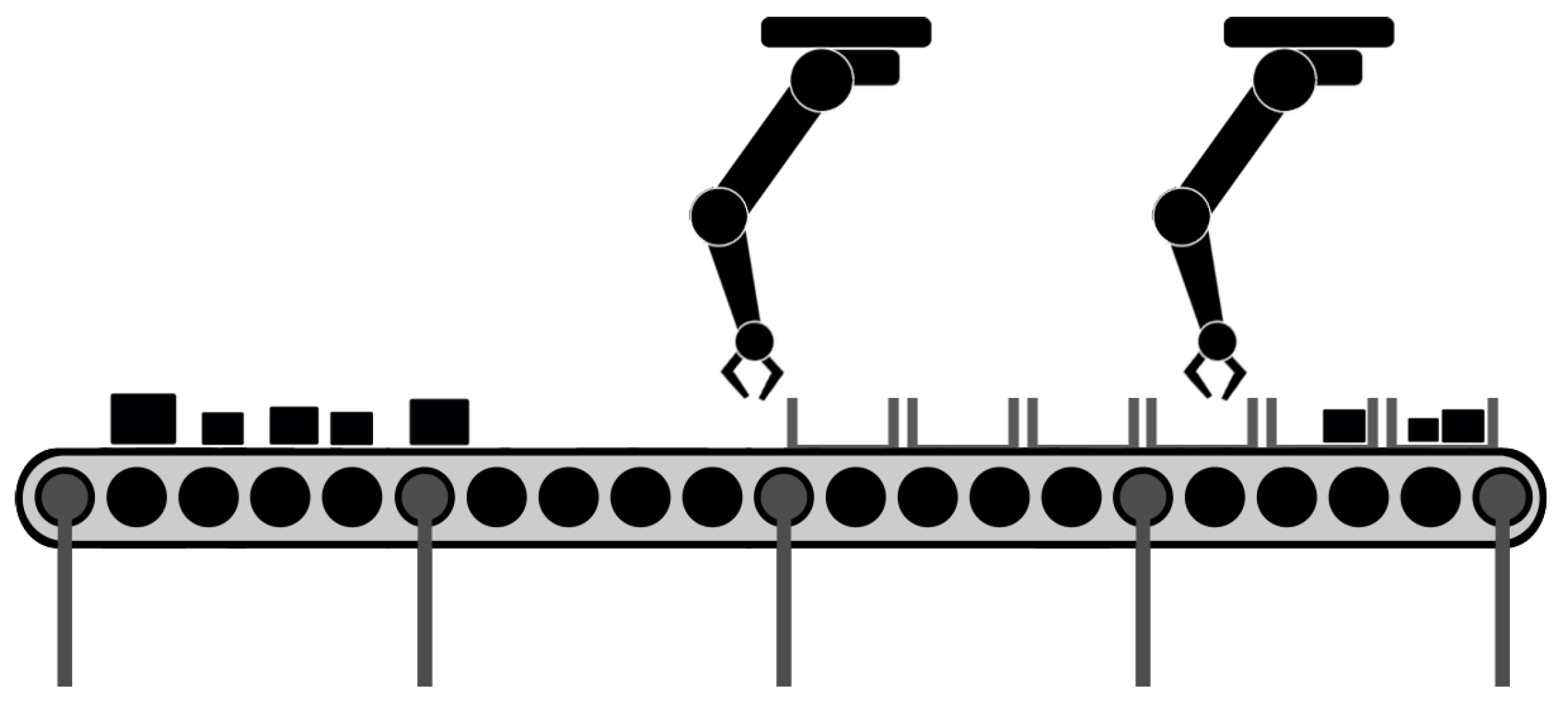

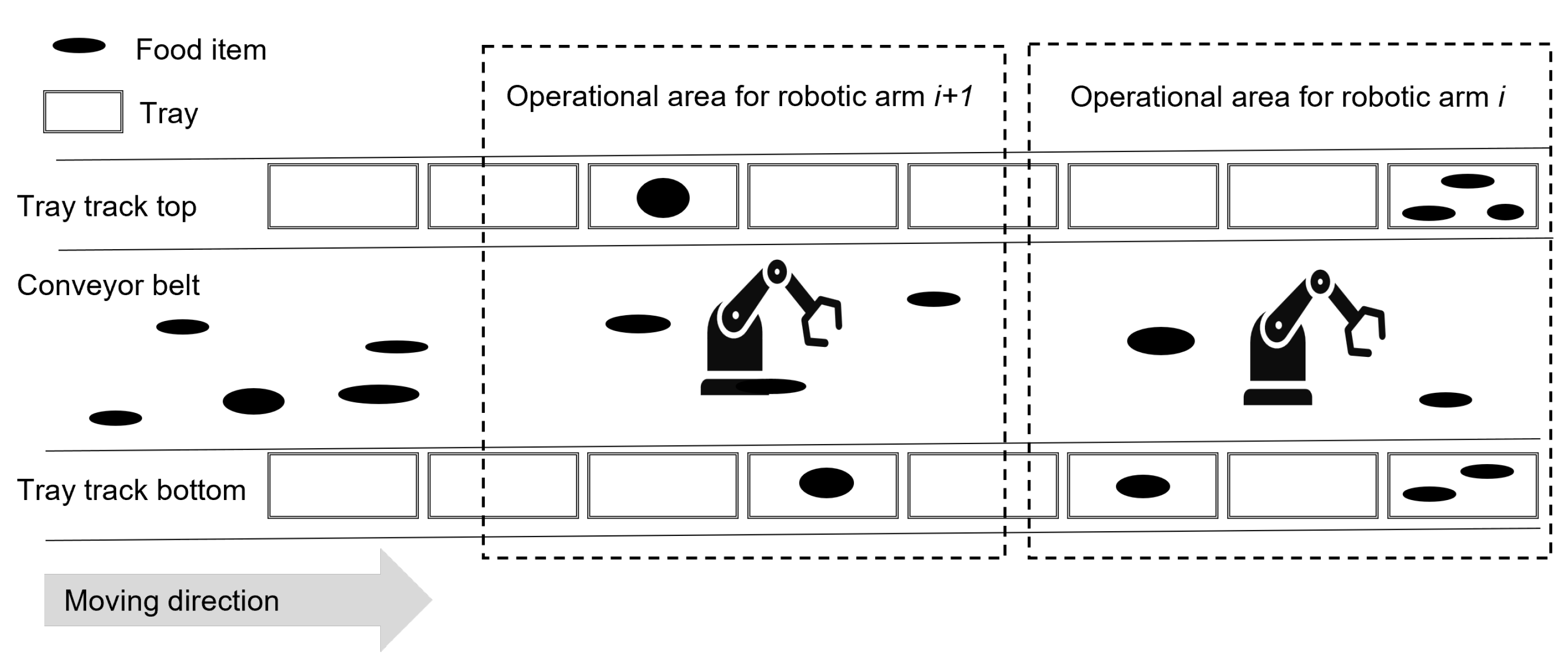

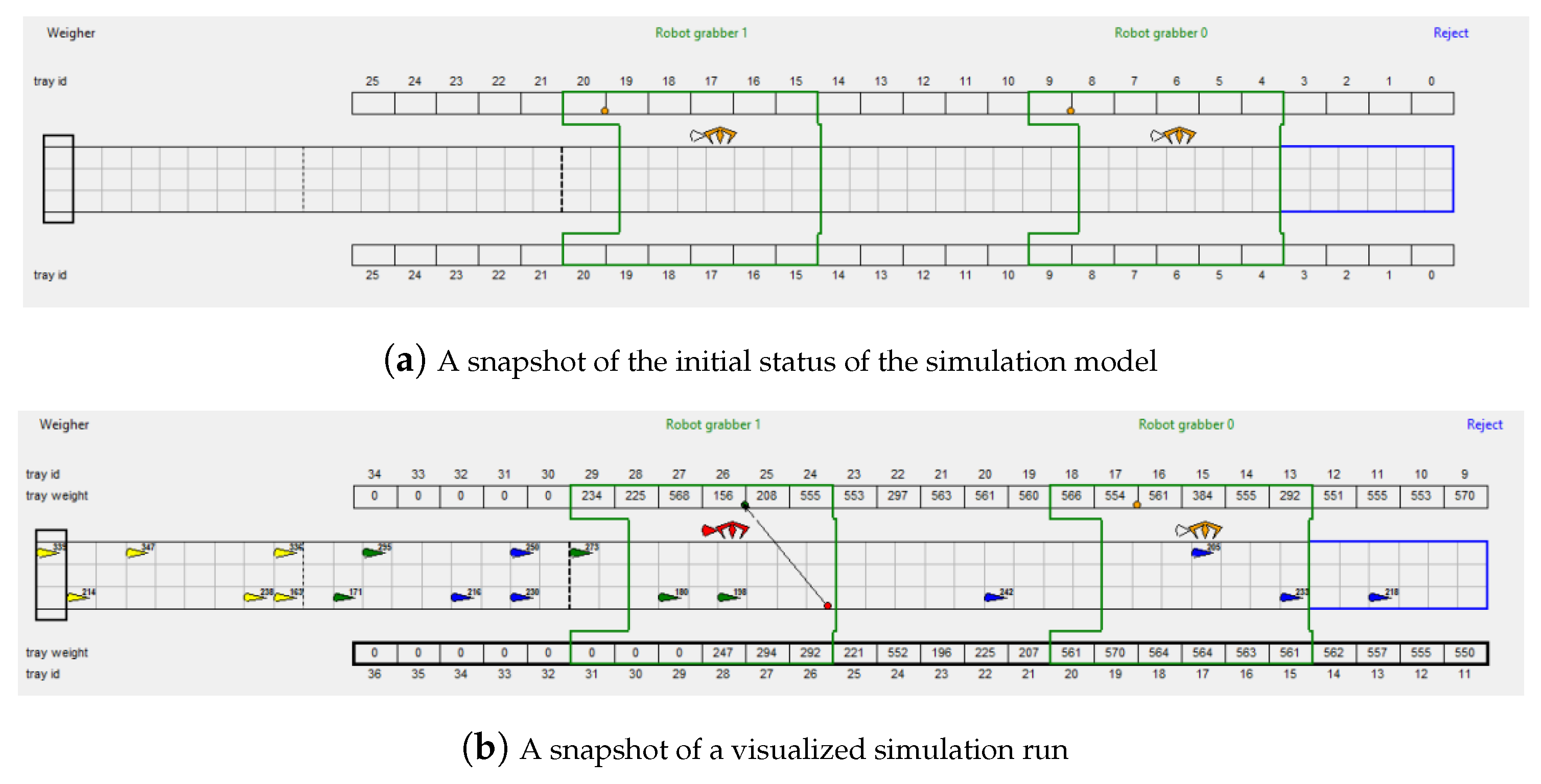

3. A Robotic Arm-Based Food Processing System

3.1. Problem Descriptions

- Which robotic arm will pick up an item;

- When and where an item on a conveyor belt will be picked up;

- On which tray on which side of the conveyor belt an item will be placed.

3.2. The Complexity of the Target Scheduling Problem

- The initial position and weight of items are unknown until they enter the conveyor belt;

- The position of an item on a conveyor belt is continuously moving;

- Processing time of a robotic arm depends on (1) the position of an item to pick up and (2) the position of the tray where the robotic arm placed the previous item picked up before the current one;

- A tray track is advanced only when the tray at the end of the track exceeds the target weight, affecting the positions of the entire trays in the system;

- Each robotic arm can handle items in a designated operational area.

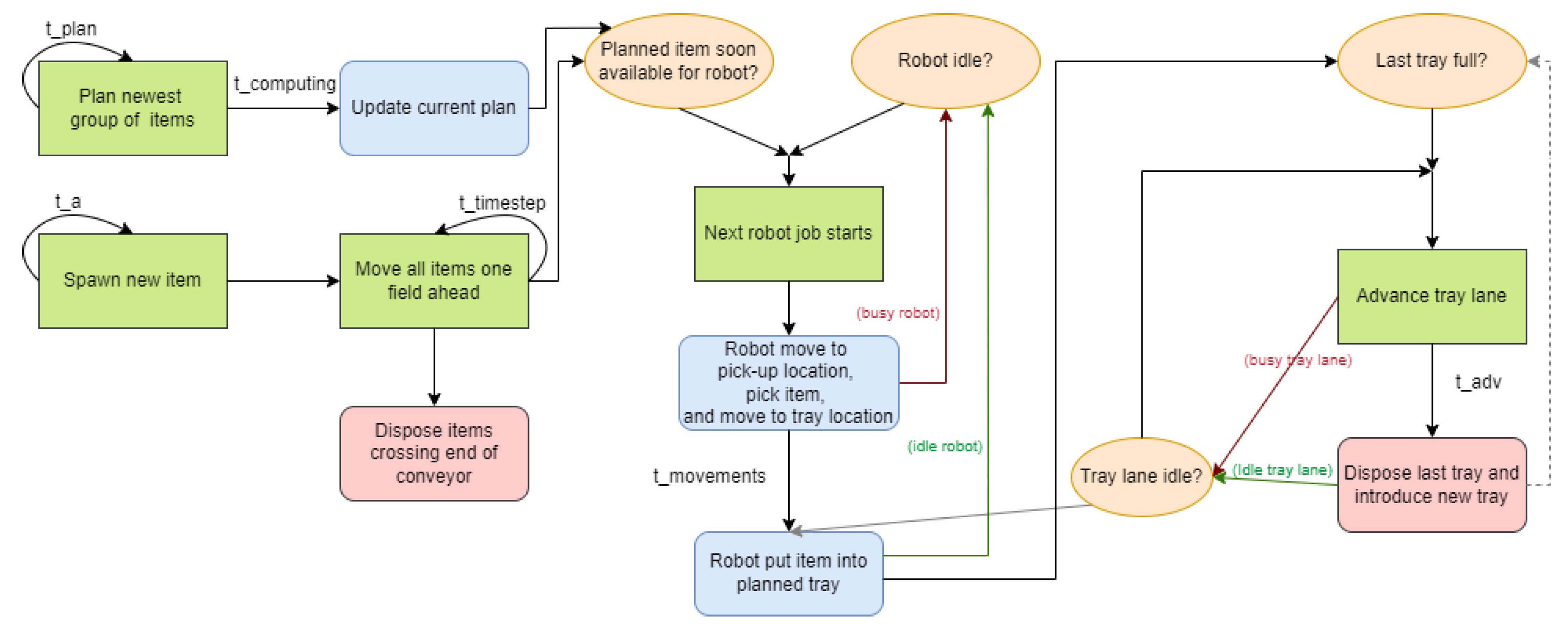

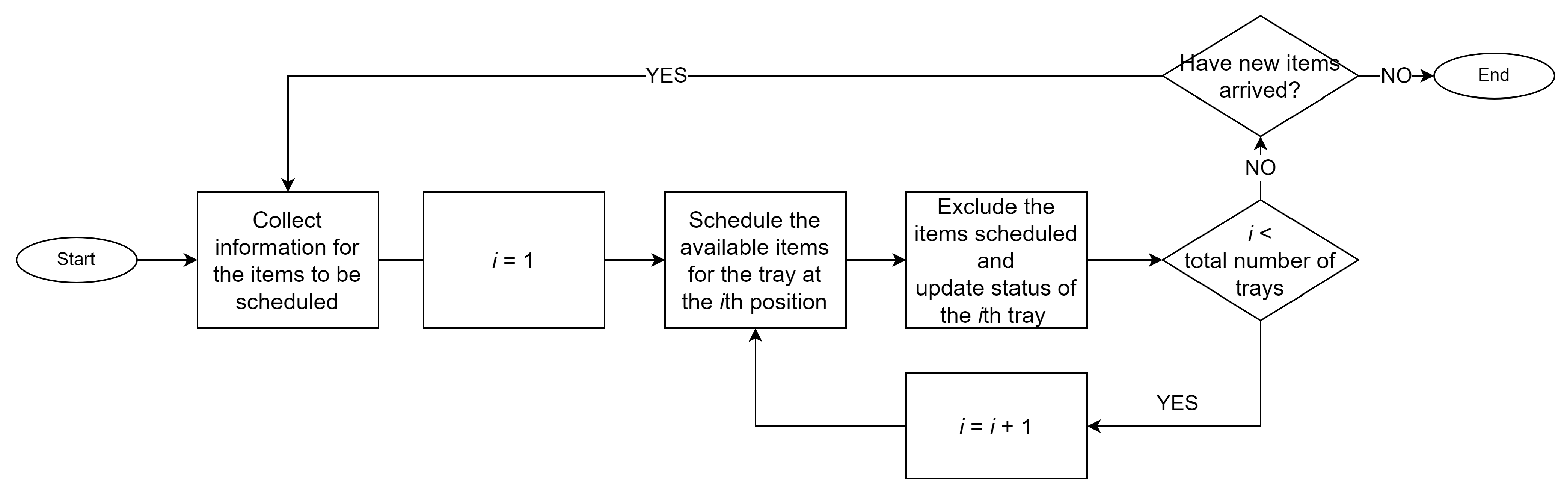

4. The Proposed Solution Approach

A Goal Program for a Sub-Problem: Scheduling Robotic Arms Only for a Single Tray

- There is enough time for a robotic arm to move to field f after completing all the tasks scheduled to be done before the time when item i arrives at field f;

- Placing item i on the tray after the nth advancement does not delay any following tasks scheduled by upstream sub-problems.

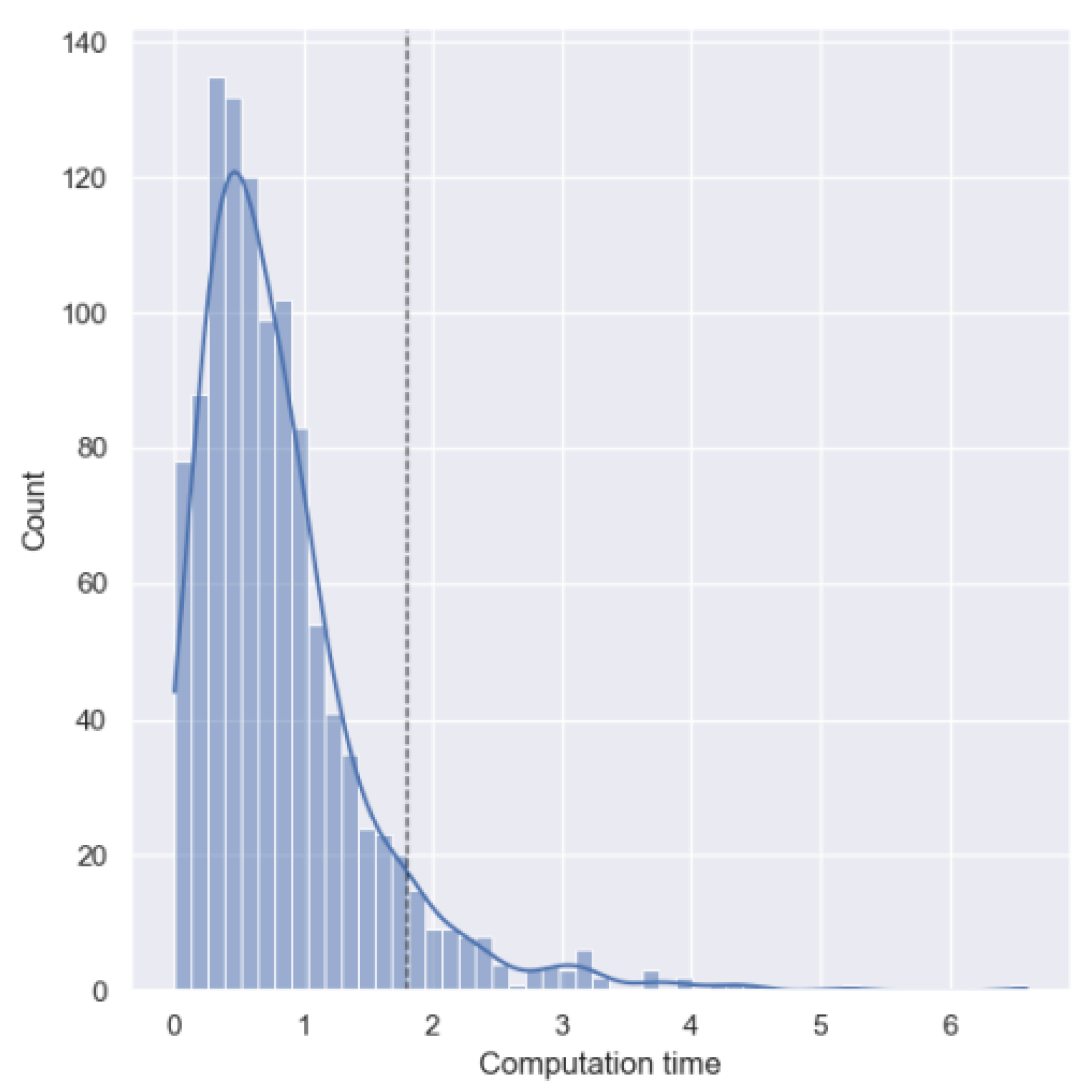

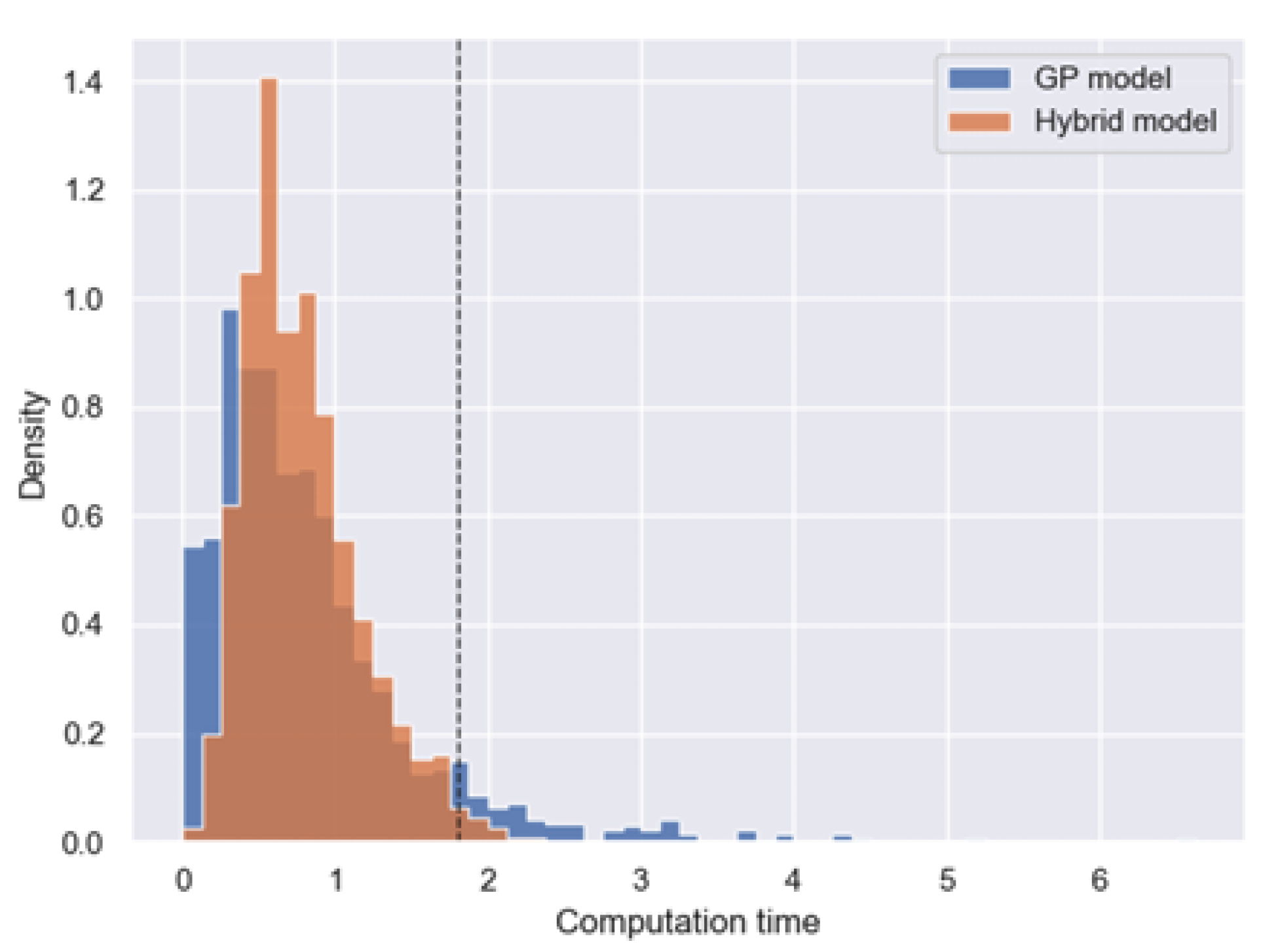

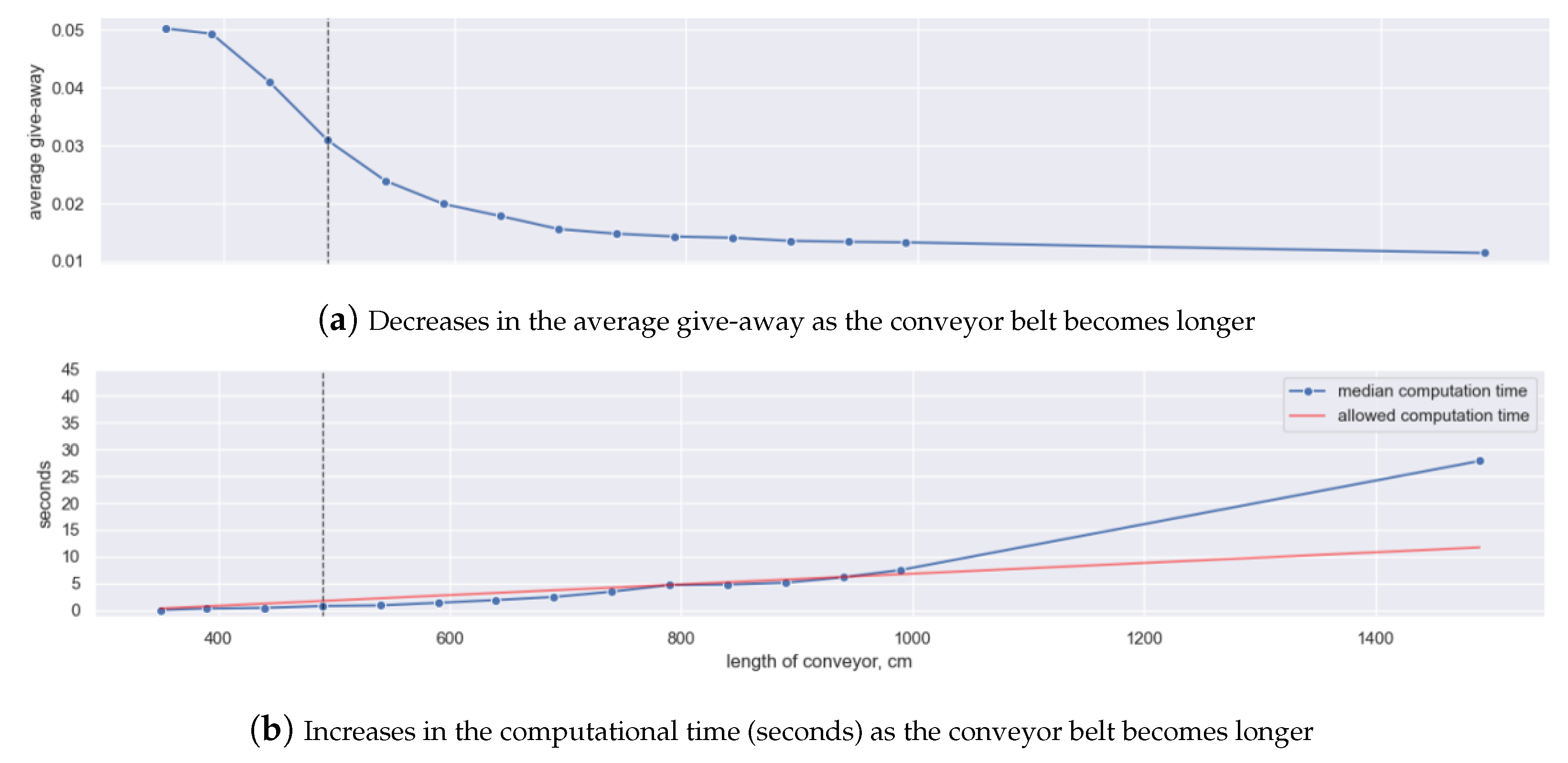

5. Computational Burden of the Proposed Solution Approach

6. Discussion

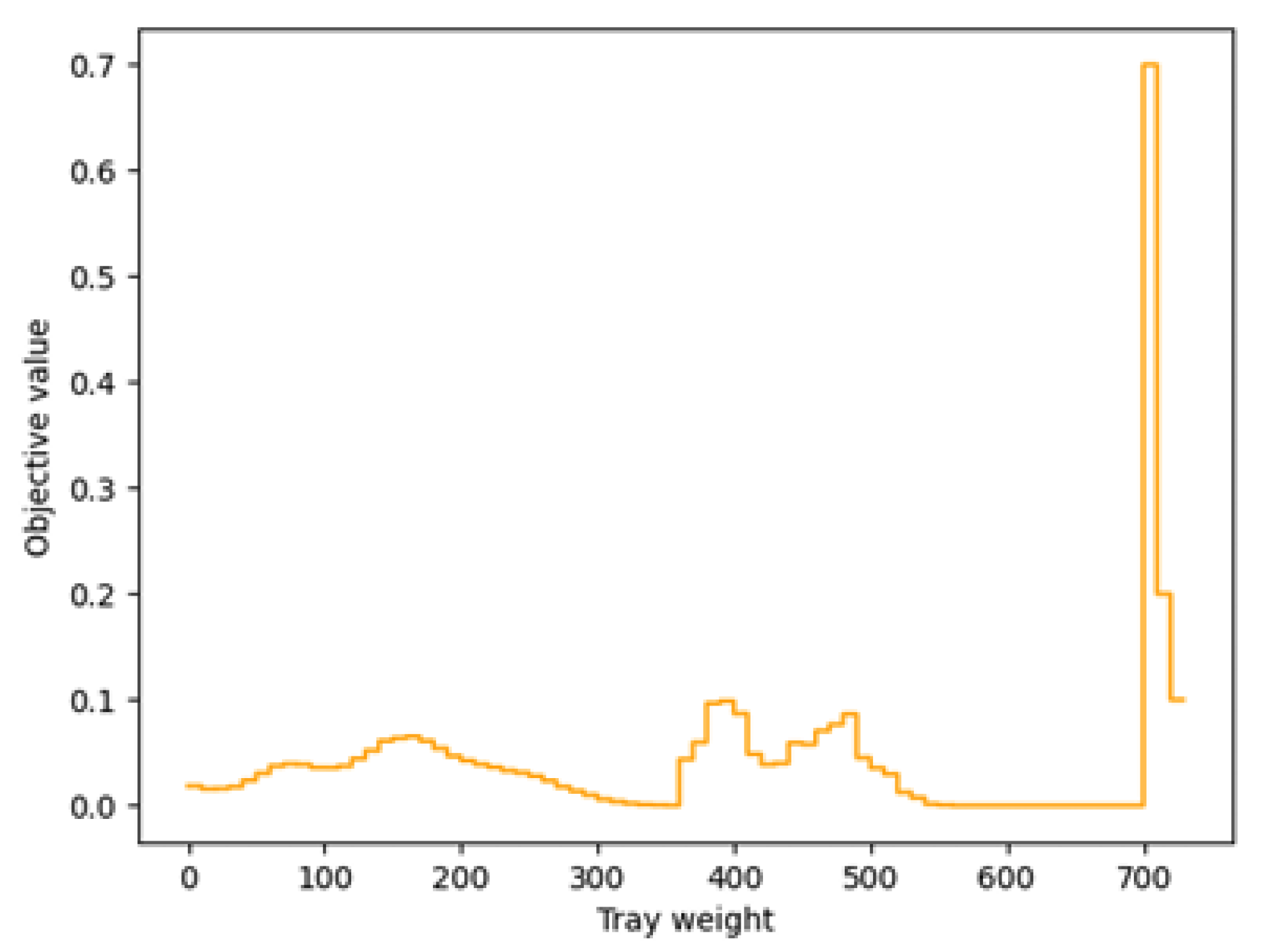

6.1. The Objective Function of the Sub-Problem

6.2. A Robotic Arm-Based Batching System Configuration

7. Concluding Remarks

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, Y.; Li, L.; Ripperger, M.; Nicho, J.; Veeraraghavan, M.; Fumagalli, A. Gilbreth: A conveyor-belt based pick-and-sort industrial robotics application. In Proceedings of the 2018 Second IEEE International Conference on Robotic Computing (IRC), Laguna Hills, CA, USA, 31 January–2 February 2018; pp. 17–24. [Google Scholar]

- Bogue, R. The role of robots in the food industry: A review. Ind. Robot. Int. J. 2009, 36, 531–536. [Google Scholar] [CrossRef]

- Iqbal, J.; Khan, Z.H.; Khalid, A. Prospects of robotics in food industry. Food Sci. Technol. 2017, 37, 159–165. [Google Scholar] [CrossRef]

- Einarsdóttir, H.; Guðmundsson, B.; Ómarsson, V. Automation in the fish industry. Anim. Front. 2022, 12, 32–39. [Google Scholar] [CrossRef] [PubMed]

- Sung, I.; Nam, H.; Lee, T. Scheduling algorithms for mobile harbor: An extended m-parallel machine problem. Int. J. Ind. Eng. Theory Appl. Pract. 2013, 20, 211–224. [Google Scholar]

- Rahman, H.; Janardhanan, M.; Nielsen, I. Real-time order acceptance and scheduling problems in a flow shop environment using hybrid Ga-PSO algorithm. IEEE Access 2019, 7, 112742–112755. [Google Scholar]

- Suárez-Ruiz, F.; Lembono, T.S.; Pham, Q.C. Robotsp—A fast solution to the robotic task sequencing problem. In Proceedings of the 2018 IEEE International Conference on Robotics and Automation (ICRA), Brisbane, Australia, 21–25 May 2018; pp. 1611–1616. [Google Scholar]

- Saha, M.; Roughgarden, T.; Latombe, J.C.; Sánchez-Ante, G. Planning tours of robotic arms among partitioned goals. Int. J. Robot. Res. 2006, 25, 207–223. [Google Scholar]

- Wurll, C.; Henrich, D. Point-to-point and multi-goal path planning for industrial robots. J. Robot. Syst. 2001, 18, 445–461. [Google Scholar]

- Alatartsev, S.; Stellmacher, S.; Ortmeier, F. Robotic task sequencing problem: A survey. J. Intell. Robot. Syst. 2015, 80, 279–298. [Google Scholar]

- Zahorán, L.; Kovács, A. ProSeqqo: A generic solver for process planning and sequencing in industrial robotics. Robot. Comput.-Integr. Manuf. 2022, 78, 102387. [Google Scholar]

- Sutdhiraksa, S.; Zurawski, R. Scheduling robotic assembly tasks using petri nets. In Proceedings of the IEEE International Symposium on Industrial Electronics, Warsaw, Poland, 17 June 1996; pp. 459–465. [Google Scholar]

- Nie, W.; Luo, J.; Fu, Y.; Sun, S.; Li, D. Schedule of flexible manufacturing systems based on petri nets and a search with a neural network heuristic function. In Proceedings of the 2020 7th International Conference on Information Science and Control Engineering (ICISCE), Changsha, China, 18–20 December 2020; pp. 1246–1250. [Google Scholar]

- Cerda, J.; Henning, G.P.; Grossmann, I.E. A mixed-integer linear programming model for short-term scheduling of single-stage multiproduct batch plants with parallel lines. Ind. Eng. Chem. Res. 1997, 36, 1695–1707. [Google Scholar] [CrossRef]

- Tika, A.; Gafur, N.; Yfantis, V.; Bajcinca, N. Optimal scheduling and model predictive control for trajectory planning of cooperative robot manipulators. IFAC-PapersOnLine 2020, 53, 9080–9086. [Google Scholar] [CrossRef]

- Gafur, N.; Yfantis, V.; Ruskowski, M. Optimal scheduling and non-cooperative distributed model predictive control for multiple robotic manipulators. In Proceedings of the 2021 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Prague, Czech Republic, 27 September–1 October 2021; pp. 390–397. [Google Scholar]

- Paape, N.; van Eekelen, J.; Reniers, M. Design of meat processing systems with agent-based production control. IFAC-PapersOnLine 2021, 54, 1112–1117. [Google Scholar] [CrossRef]

- Peeters, K.; Martagan, T.; Adan, I.; Cruysen, P. Control and design of the fillet batching process in a poultry processing plant. In Proceedings of the 2017 Winter Simulation Conference (WSC), Las Vegas, NV, USA, 3–6 December 2017; pp. 3816–3827. [Google Scholar] [CrossRef]

- Peeters, K.; Adan, I.J.B.F.; Martagan, T. Throughput control and revenue optimization of a poultry product batcher. IISE Trans. 2022, 54, 845–857. [Google Scholar] [CrossRef]

- Peeters, K.; Adan, J.; Hundscheid, B.; Martagan, T.; Adan, I. Online product allocation in poultry batchers with lookahead. Comput. Ind. Eng. 2022, 165, 107875. [Google Scholar] [CrossRef]

- Hundscheid, B.H.; Peeters, K.; Adan, J.; Martagan, T.; Adan, I.J. A Hybrid Genetic Algorithm for the K-Bounded Semi-Online Bin Covering Problem in Batching Machines. In Proceedings of the 2019 Winter Simulation Conference (WSC), National Harbor, MD, USA, 8–11 December 2019; pp. 2142–2153. [Google Scholar] [CrossRef]

- Huang, M.; Wu, J.; Tang, Y.; Shi, L. Optimal Design of a Conveyor-Based Automatic Sorting System. In Proceedings of the 2020 IEEE 16th International Conference on Control & Automation (ICCA), Sapporo, Japan, 6–9 July 2020; pp. 1124–1129. [Google Scholar] [CrossRef]

- Hildebrand, M.; Andersen, R.S.; Bøgh, S. Deep Reinforcement Learning for Robot Batching Optimization and Flow Control. Procedia Manuf. 2020, 51, 1462–1468. [Google Scholar] [CrossRef]

- Ásgeirsson, A. On-Line Algorithms for Bin-Covering Problems with Known Item Distributions. Ph.D. Thesis, Georgia Institute of Technology, Atlanta, GA, USA, 2014. [Google Scholar]

- Van Sprang, R. Condition Based Maintenance at Marel Poultry. Master’s Thesis, Eindhoven University of Technology, Eindhoven, The Netherlands, 2017. [Google Scholar]

- Raaijmakers, S. Performance Analysis of Broiler Product Batchers in Poultry Processing Plant. Master’s Thesis, Eindhoven University of Technology, Eindhoven, The Netherlands, 2018. [Google Scholar]

- Caprara, A.; Kellerer, H.; Pferschy, U. The multiple subset sum problem. SIAM J. Optim. 2000, 11, 308–319. [Google Scholar] [CrossRef]

- Csirik, J.; Johnson, D.S.; Kenyon, C. Better approximation algorithms for bin covering. In Proceedings of the SODA, Washington, DC, USA, 7–9 January 2001; Volume 1, pp. 557–566. [Google Scholar]

- El Yafrani, M.; Sung, I.; Krach, B.; Katsilieris, F.; Nielsen, P. Analysis of a local search heuristic for the generalized assignment problem with resource-independent task profits and identical resource capacity. Eng. Optim. 2022, 54, 1426–1440. [Google Scholar] [CrossRef]

- Zhu, L.; Spachos, P. Support vector machine and YOLO for a mobile food grading system. Internet Things 2021, 13, 100359. [Google Scholar] [CrossRef]

- Zhu, L.; Spachos, P.; Pensini, E.; Plataniotis, K.N. Deep learning and machine vision for food processing: A survey. Curr. Res. Food Sci. 2021, 4, 233–249. [Google Scholar] [CrossRef] [PubMed]

- Boysen, N.; Briskorn, D.; Fedtke, S.; Schmickerath, M. Automated sortation conveyors: A survey from an operational research perspective. Eur. J. Oper. Res. 2019, 276, 796–815. [Google Scholar] [CrossRef]

| Study | Target System/Problem | Decision | Tray/Bin Lane Number |

|---|---|---|---|

| [17] | A meat processing system | Batch or trim pieces? (with respect to weights) | 1 |

| [18] | A fillet batching operation in a poultry processing plant | Which tray? (with respect to weights) | 1 |

| [19] | Batching food items for a specific weight target | Which bin? (with respect to weights) | 2 |

| [20] | Poultry processing plants with batchers | Which tray? (with respect to weights) | 1 |

| [21] | Bin covering with a target weight for a poultry processing plant | Which tray? (with respect to weights) | 1 |

| [22] | Packing in a conveyor-based automatic sorting system | Which action? - Do {stay, put, pick} - For {current box, buffer} | 1 |

| [23] | A robotic arm system with multiple conveyor belts | Which tray? (with respect to weights and conveyor belt track) | 2 |

| Study | Conveyor Belt Type | Buffer | Machine Type |

|---|---|---|---|

| [17] | Two conveyor belts | Yes | Grader (diverter) |

| [18] | 4 track line conveyor belt | Yes | Grader |

| [19] | 1 track line conveyor belt | Yes | Grader |

| [20] | 1 track line conveyor belt | Yes | Batcher (drop) |

| [21] | 1 track line conveyor belt | Yes | Batcher (drop) |

| [22] | Unidirectional 1 track conveyor belt A circular conveyor for boxes | Yes (for unused product) | Robotic arm |

| [23] | 2 track line conveyor belt | Yes | Robotic arm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nielsen, K.G.; Sung, I.; El Yafrani, M.; Kılıç, D.K.; Nielsen, P. A Scheduling Solution for Robotic Arm-Based Batching Systems with Multiple Conveyor Belts. Algorithms 2023, 16, 172. https://doi.org/10.3390/a16030172

Nielsen KG, Sung I, El Yafrani M, Kılıç DK, Nielsen P. A Scheduling Solution for Robotic Arm-Based Batching Systems with Multiple Conveyor Belts. Algorithms. 2023; 16(3):172. https://doi.org/10.3390/a16030172

Chicago/Turabian StyleNielsen, Kasper Gaj, Inkyung Sung, Mohamed El Yafrani, Deniz Kenan Kılıç, and Peter Nielsen. 2023. "A Scheduling Solution for Robotic Arm-Based Batching Systems with Multiple Conveyor Belts" Algorithms 16, no. 3: 172. https://doi.org/10.3390/a16030172

APA StyleNielsen, K. G., Sung, I., El Yafrani, M., Kılıç, D. K., & Nielsen, P. (2023). A Scheduling Solution for Robotic Arm-Based Batching Systems with Multiple Conveyor Belts. Algorithms, 16(3), 172. https://doi.org/10.3390/a16030172