Optimal Cooking Procedure Presentation System for Multiple Recipes and Investigating Its Effect

Abstract

1. Introduction

2. Related Work

2.1. Scheduling of Cooking Procedures

2.2. Task Scheduling Problem

2.3. Position of This Study

3. Definition of Problem

3.1. Expanding the Task Scheduling Problem to the Optimal Cooking Procedure Search Problem

3.2. Formulation of the Optimal Cooking Procedure Search Problem

3.2.1. Recipe Information

3.2.2. Cooking Procedure

3.2.3. Definition of Washing Task

3.2.4. Objective Function

4. System Overview

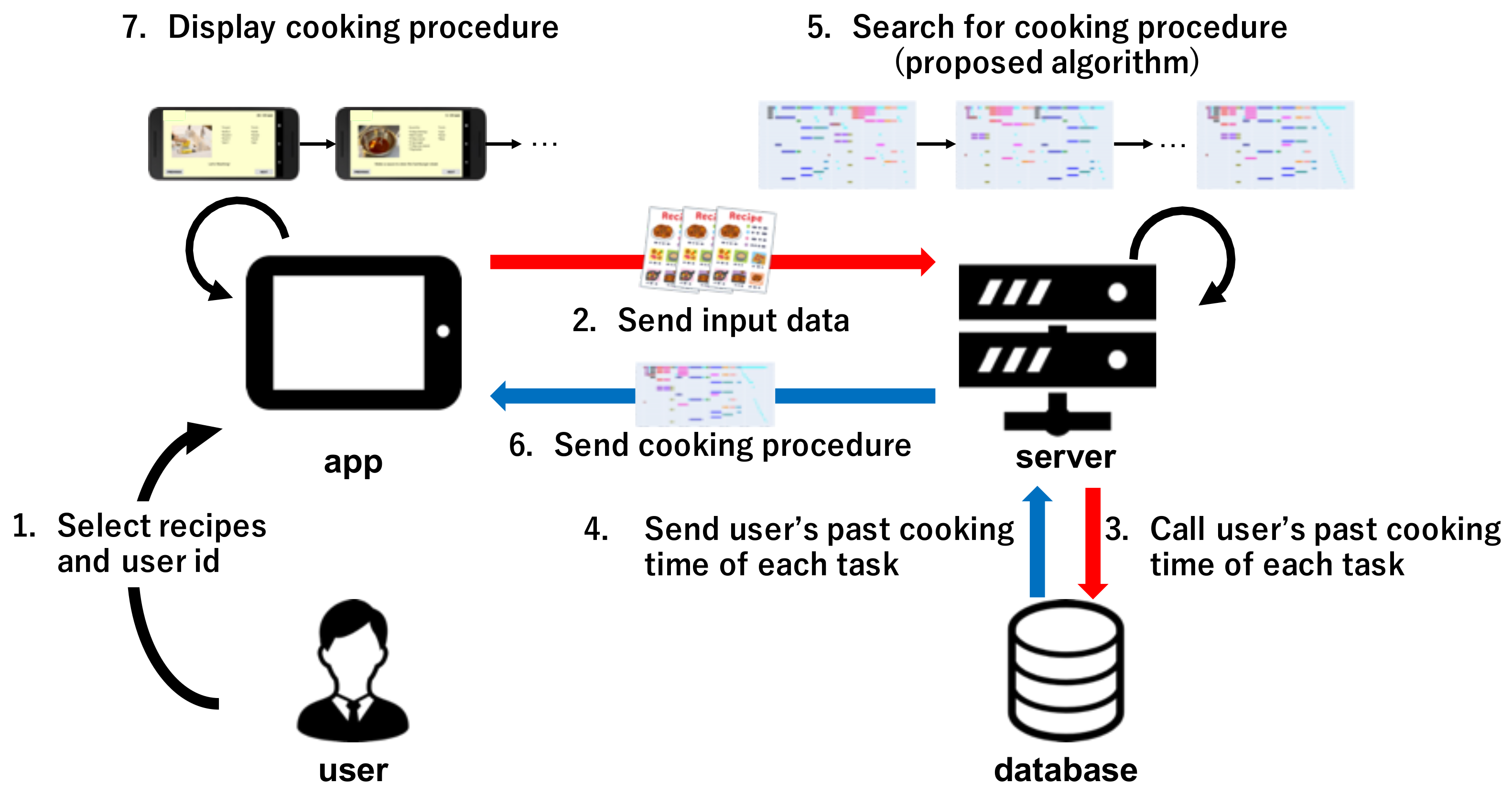

4.1. Proposed System

4.2. Optimal Cooking Procedure Search Algorithm

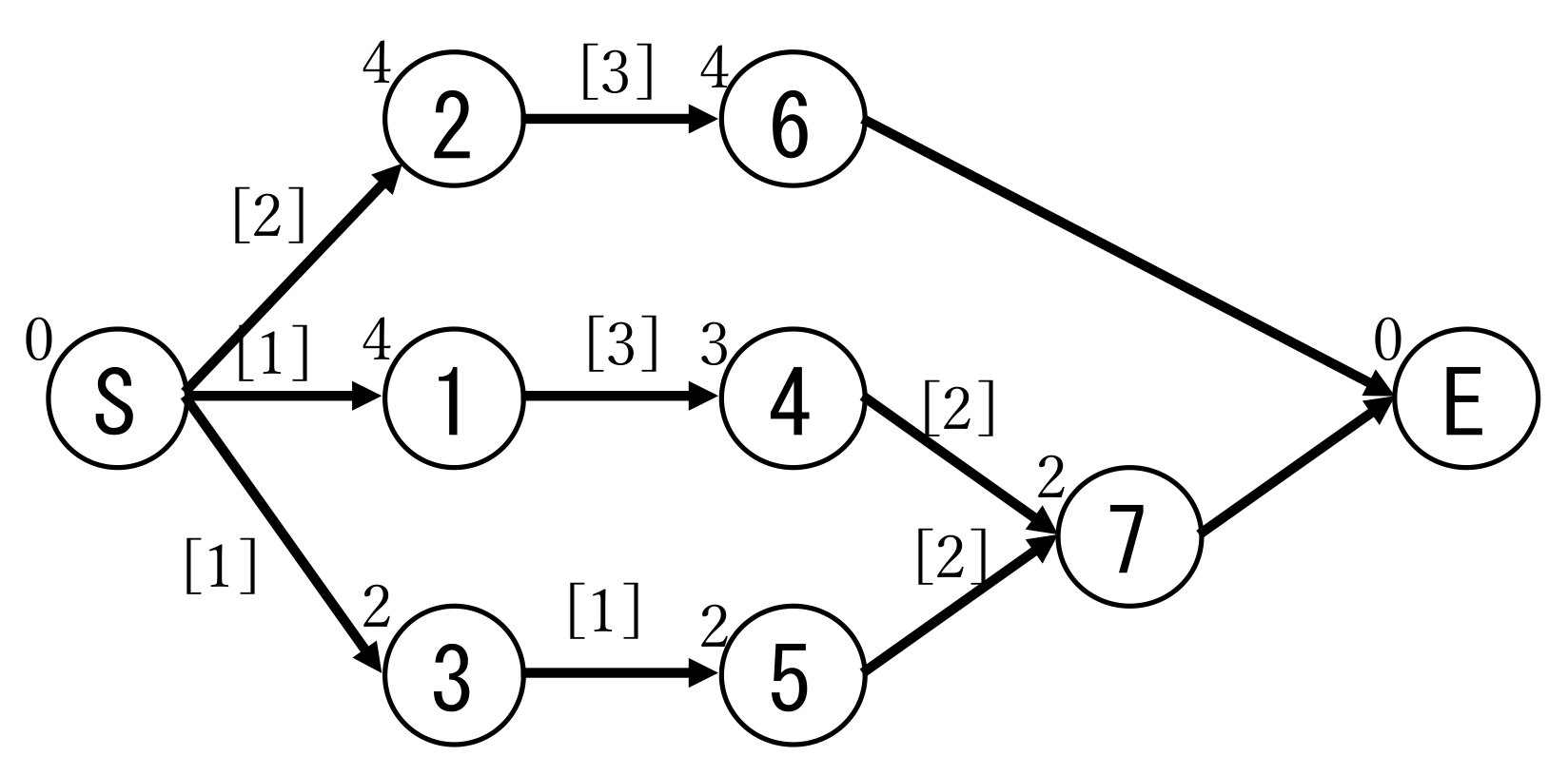

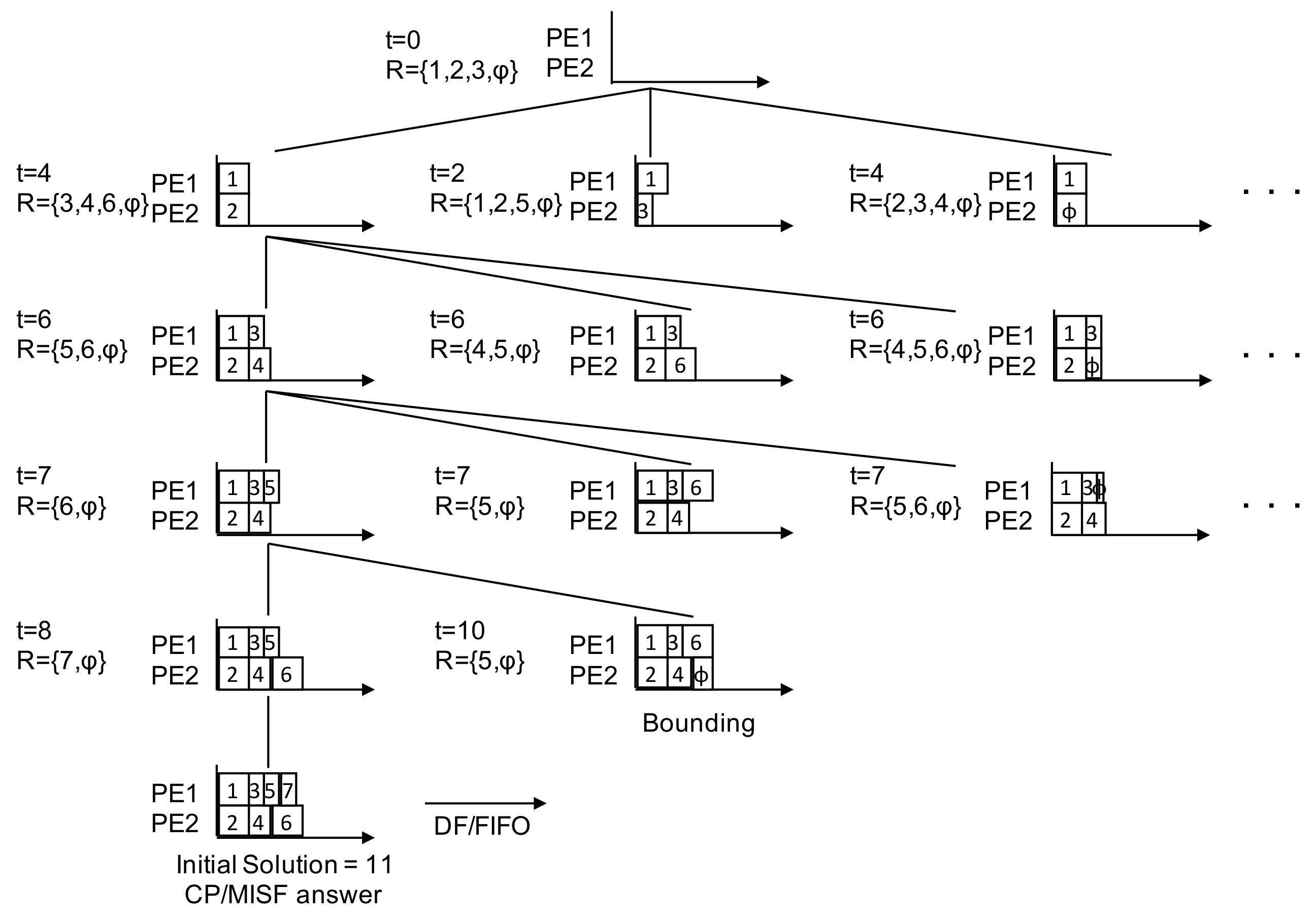

4.2.1. Base Algorithm: PDF/IHS

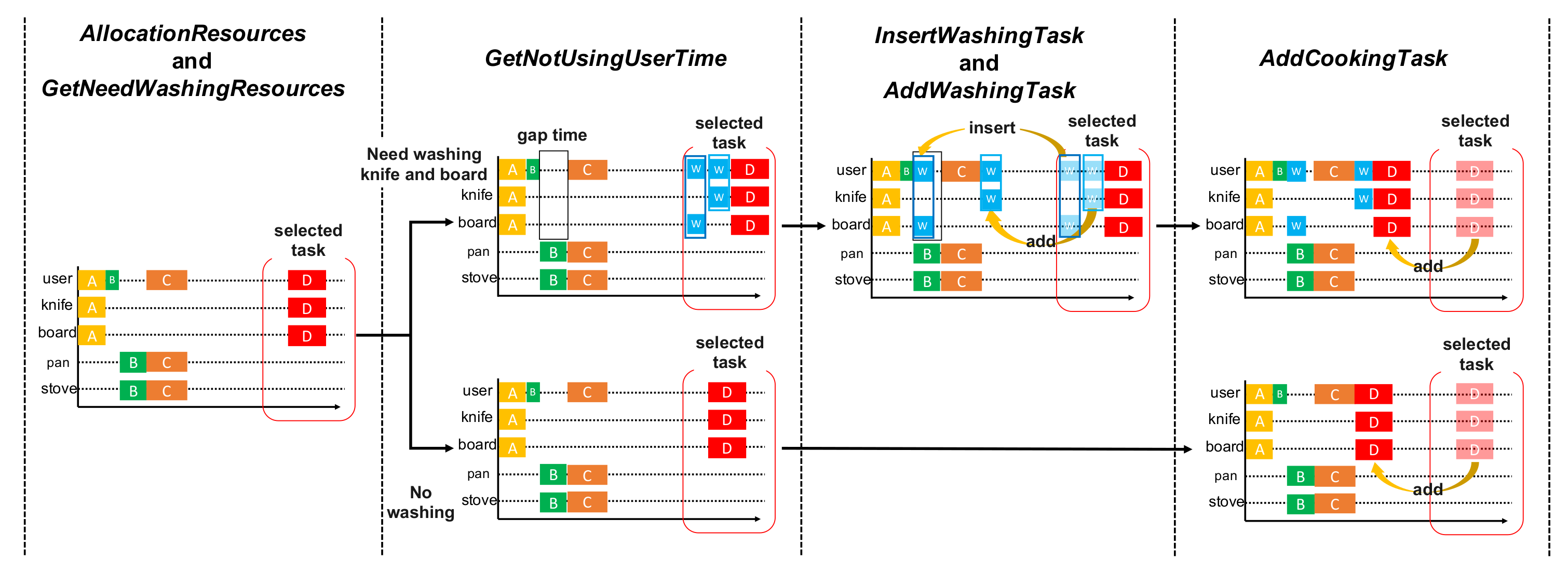

4.2.2. Overview of the Optimal Cooking Procedure Search Algorithm

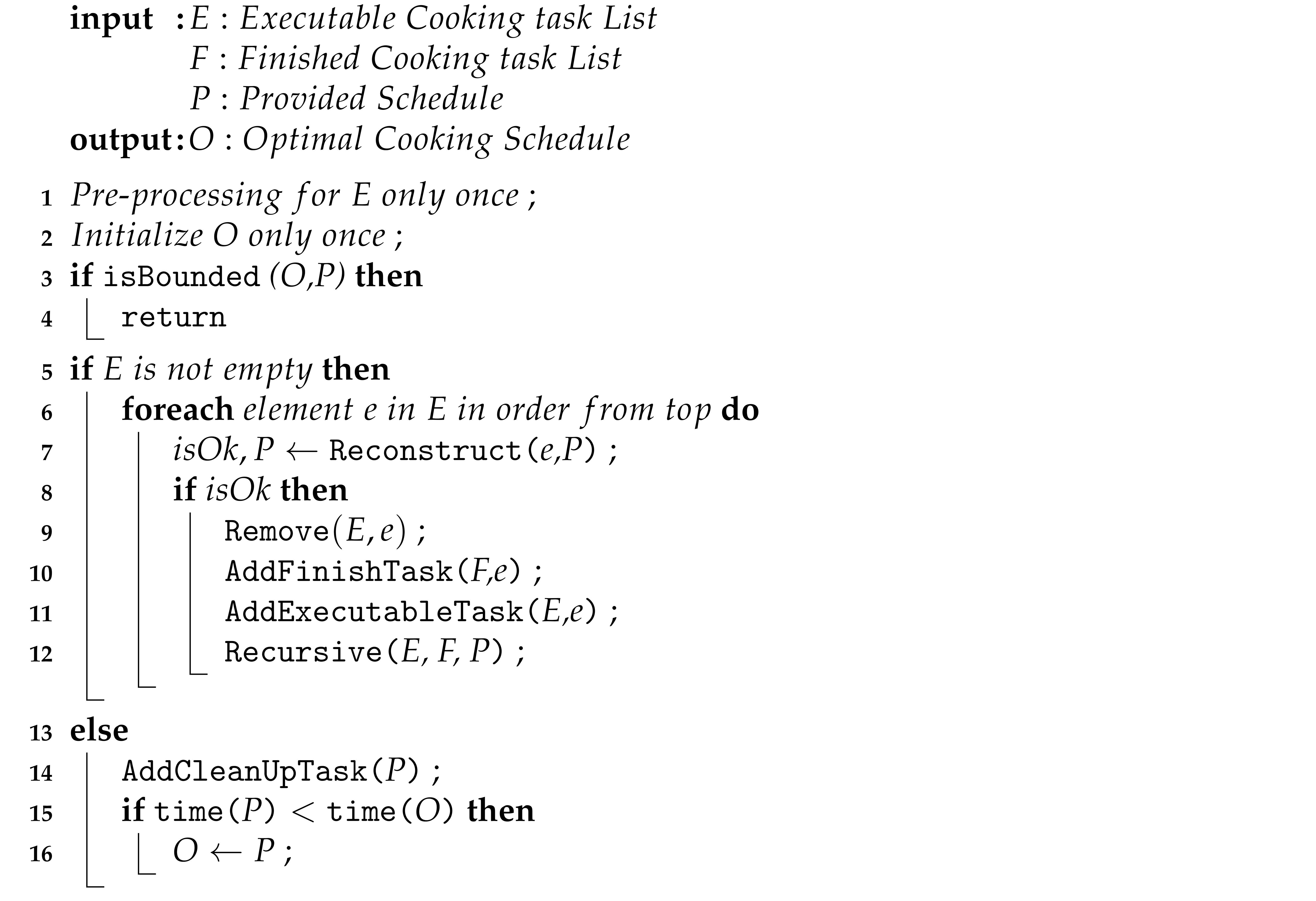

| Algorithm 1: |

|

| Algorithm 2: |

|

- A resource that is not being used and does not require a washing task

- A resource that is not being used and requires a washing task

- Earliest available resource

4.2.3. Proposed Method of Preprocessing

- Method 1: Sorting by critical path (CP)

- Method 2: Sorting by user-free time

4.2.4. Proposed Method of Bounding Operation

- Method 1: Bounding by critical path and washing task time

- Method 2: Bounding by remaining time for each resource and washing task time

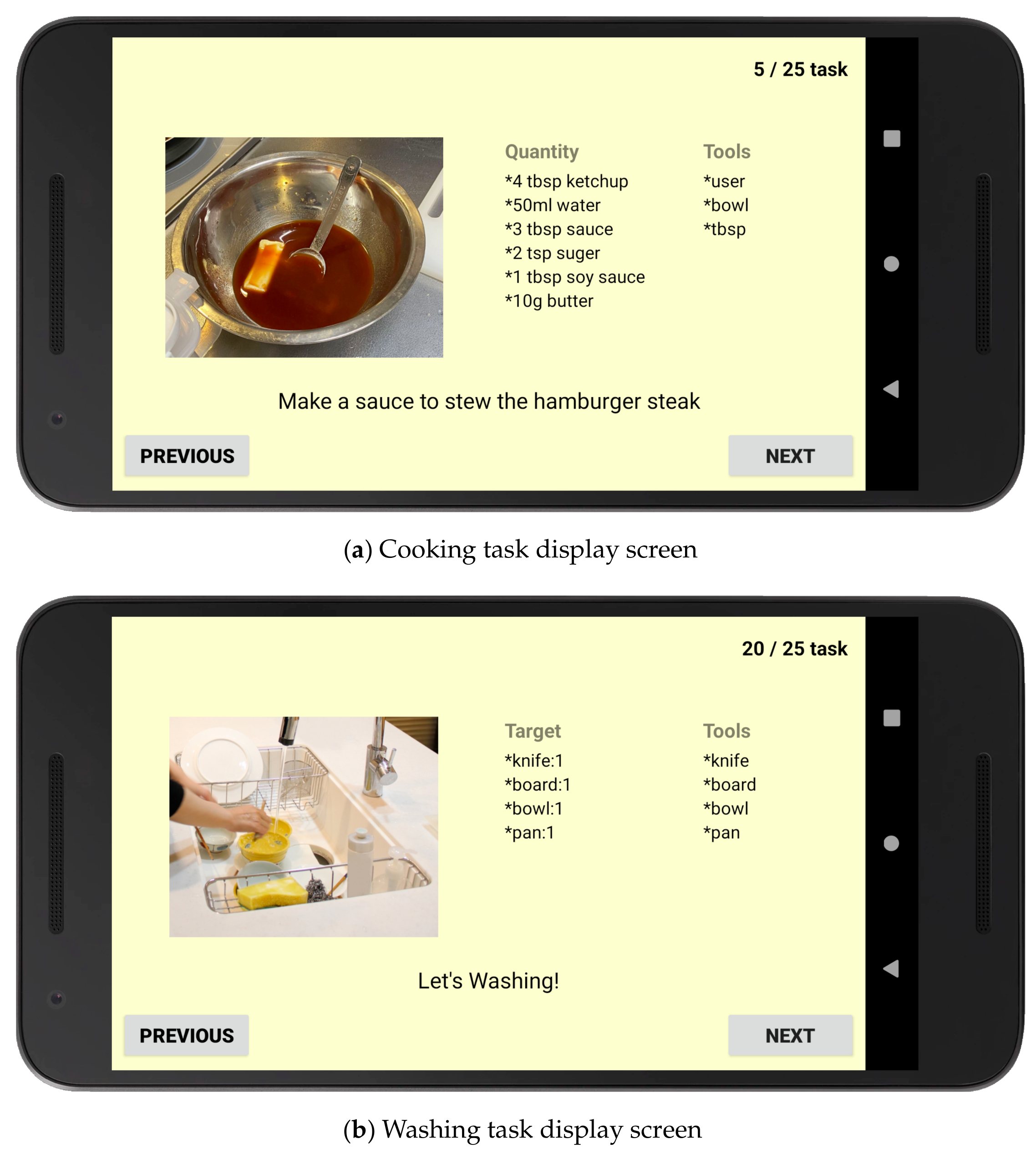

4.3. Optimal Cooking Procedure Presentation Application

5. Evaluation

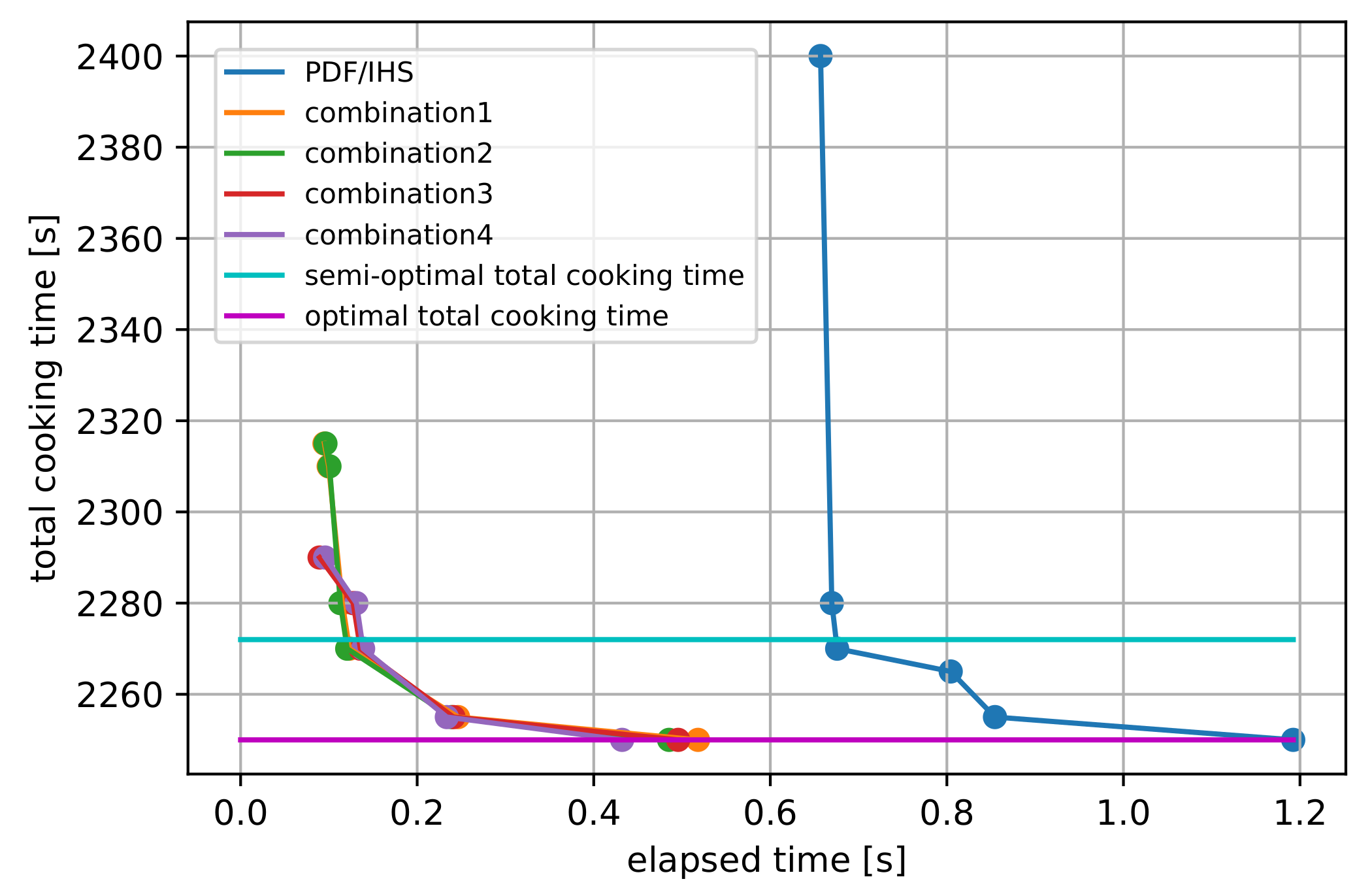

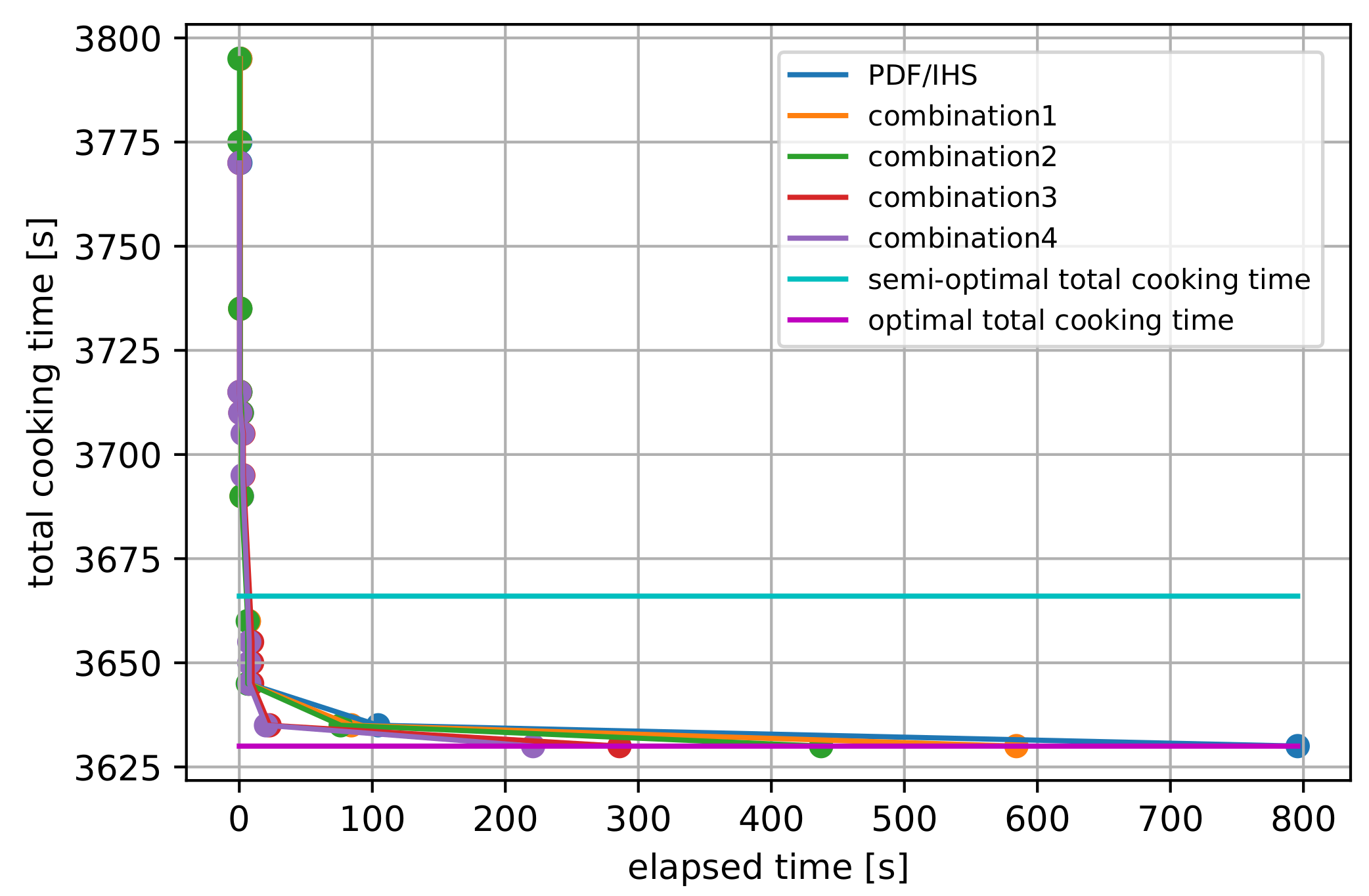

5.1. Evaluation of the Optimal Cooking Procedure Search Algorithm

5.1.1. Experiment Overview

5.1.2. Results

5.1.3. Discussion

5.2. Evaluation of Optimal Cooking Procedure Presenting Application

5.2.1. Experiment Overview

5.2.2. Results

5.2.3. Discussion

6. Conclusions

Author Contributions

Funding

Informed Consent Statement

Conflicts of Interest

References

- Cookpad Inc. Available online: https://cookpad.com/ (accessed on 19 December 2020).

- Allrecipes.com Inc. Available online: https://www.allrecipes.com/ (accessed on 19 December 2020).

- Kasahara, H.; Itoh, A.; Tanaka, H.; Itoh, K. A parallel optimization algorithm for minimum execution-time multiprocessor scheduling problem. Syst. Comput. Jpn. 1992, 23, 54–65. [Google Scholar] [CrossRef]

- Matsushima, Y.; Funabiki, N. Practices of Cooking-Step Scheduling Algorithm for Homemade Cooking. In Proceedings of the 2015 IIAI 4th International Congress on Advanced Applied Informatics, Washington, DC, USA, 12–16 July 2015; pp. 500–505. [Google Scholar]

- Van Laarhoven, P.J.; Aarts, E.H. Simulated annealing. In Simulated Annealing: Theory and Applications; Springer: Berlin/Heidelberg, Germany, 1987; pp. 7–15. [Google Scholar]

- Yamabuki, T.; Ono, N.; Nagata, Y. Modeling of the Simultaneous Table Scheduling Problem and Dynamic Scheduling for this Problem. Soc. Instrum. Control Eng. 2018, 54, 346–356. [Google Scholar] [CrossRef]

- Kimura, Y.; Shimizu, K.; Tsuboi, T.; Hasegawa, D.; Ishikawa, K.; Kimura, K.; Tanaka, M.; Ozeki, K.; Zhou, J.; Shigeno, M. An approach to cooking process scheduling for a family restaurant. J. Adv. Mech. Des. Syst. Manuf. 2018, 12, JAMDSM0076. [Google Scholar] [CrossRef]

- Zhou, J.; Tsuboi, T.; Hasegawa, D.; Ishikawa, K.; Kimura, K.; Tanaka, M.; Ozeki, K.; Shigeno, M. Design and Validation of Rules for a Cooking Process Scheduling Model. IPSJ Trans. Math. Model. Appl. 2018, 11, 63–74. [Google Scholar]

- Ishino, C.; Morimoto, N.; Yamada, T. Disjunctive Constraints Using Integer Range for Food Preparation Scheduling Considering Machine Type. Spec. Interest Group Tech. Rep. IPSJ 2020, 2020, 1–6. [Google Scholar]

- Coffman, E.G.; Bruno, J.L. Computer and Job-Shop Scheduling Theory; John Wiley & Sons: Hoboken, NJ, USA, 1976. [Google Scholar]

- Hu, T.C. Parallel sequencing and assembly line problems. Oper. Res. 1961, 9, 841–848. [Google Scholar] [CrossRef]

- Kasahara, H.; Narita, S. Practical multiprocessor scheduling algorithms for efficient parallel processing. IEEE Trans. Comput. 1984, 33, 1023–1029. [Google Scholar] [CrossRef]

- Fernandez, E.B.; Bussell, B. Bounds on the number of processors and time for multiprocessor optimal schedules. IEEE Trans. Comput. 1973, 100, 745–751. [Google Scholar] [CrossRef]

- Nakamura, A.; Maekawa, Y. A Reduction Algorithm of Branching Nodes for Solving Task Scheduling Problems. Inf. Process. Soc. Jpn. PRO 2014, 7, 1–9. [Google Scholar]

- Matsuse, H.; Nakamura, A.; Tominaga, H.; Maekawa, Y. Reducing the Number of Search Nodes in Task Scheduling Problem Using Hash Table of DF/IHS Method. In Proceedings of the 78th National Convention of IPSJ, Kanagawa, Japan, 10 March 2016; Volume 2016, pp. 197–198. [Google Scholar]

- Matsuse, H.; Nakamura, A.; Tominaga, H.; Maekawa, Y. A Sppedup Method for PDF/IHS by Reducing of Branching Nodes in Task Scheduling Problems. IPSJ Trans. Adv. Comput. Syst. 2018, 11, 17–26. [Google Scholar]

- Shibuya, T.; Kurita, K.; Kai, M. B-017 Evaluation of a Parallelized Branch and Bound Method for the Task Scheduling Problem Considering Communication Overhead. Forum Inf. Technol. 2014, 13, 149–154. [Google Scholar]

- Utsunomiya, M.; Shioda, R.; Kai, M. Heuristic search based on branch and bound method for task scheduling considering communication overhead. In Proceedings of the 2011 IEEE Pacific Rim Conference on Communications, Computers and Signal Processing, Victoria, BC, Canada, 23–26 August 2011; pp. 256–261. [Google Scholar]

- Development of Parallelized Solver for Task Scheduling Problems with Communication Delays: Improvements of Search Effectiveness Using Optimal Scheduling of Sub-Task-Graphs. Available online: http://hdl.handle.net/10928/813 (accessed on 19 December 2020).

- Detecting Hierarchically Structured Macro-Tasks within a Task Graph and Its Task Scheduling Method. Available online: http://hdl.handle.net/10928/1133 (accessed on 19 December 2020).

- Garey, M.R. Computers and Intractability: A Guide to the Theory of Np-Completeness. Rev. Esc. Enferm. Usp 1979, 44, 340. [Google Scholar]

- Ramamoorthy, C.V.; Chandy, K.M.; Gonzalez, M.J. Optimal scheduling strategies in a multiprocessor system. IEEE Trans. Comput. 1972, 100, 137–146. [Google Scholar] [CrossRef]

| Task Number | Required Resource | Holding Resource | Cooking Time | Preparing Time | Cooking Type | Holding Type | Starting Requirement | Holding Requirement | Previous Task |

|---|---|---|---|---|---|---|---|---|---|

| 1 | user, knife, board | bowl | 150 | 0 | vegetable | A | 2 | ||

| 2 | bowl, microwave | bowl | 180 | 60 | A | A | 1 | 3 | |

| 3 | user, bowl, tbsp | plate | 390 | 0 | A | A | 2 | 4 | |

| 4 | user, pan, stove, turner | pan, stove | 330 | 0 | B | B | 3 | 6 | |

| 5 | user, bowl, tbsp | bowl | 120 | 0 | C | C | 6 | ||

| 6 | pan, stove, lid | pan | 300 | 30 | B | B | 4,5 | 7 | 4 |

| 7 | user, pan, turner, spoon | 120 | 0 | B | 6 |

| Recipe Name | Task Number | Estimated Total Cooking Time | Number of Required Searches | |

|---|---|---|---|---|

| menu 1 | salt-grilled mackerel | 5 | 900 | |

| miso soup | 5 | 990 | ||

| Japanese omelet | 3 | 660 | ||

| menu 2 | hamburg steak | 7 | 1680 | |

| miso soup | 5 | 990 | ||

| potato salad | 6 | 1290 |

| Total Cooking Time [s] | |||

|---|---|---|---|

| Menu 1 | Menu 2 | ||

| Base PDF/IHS | 2250 | 3630 | |

| SA (10 times Avg.) | 2441 | 3786 | |

| Proposed Algorithm | 2250 | 3630 | |

| Execution Time [s] | Convergence Time [s] | Reached Time [s] | ||||

|---|---|---|---|---|---|---|

| Menu 1 | Menu 2 | Menu 1 | Menu 2 | Menu 1 | Menu 2 | |

| Base PDF/IHS | 1.98 | 2141 | 1.19 | 796 | 0.68 | 7.08 |

| combination 1 pre-processing 1 + bounding 1 | 1.45 | 1645 | 0.52 | 584 | 0.12 | 7.30 |

| combination 2 pre-processing 1 + bounding 2 | 1.32 | 1207 | 0.49 | 437 | 0.12 | 6.36 |

| combination 3 pre-processing 2 + bounding 1 | 1.52 | 1633 | 0.50 | 286 | 0.14 | 9.58 |

| combination 4 pre-processing 2 + bounding 2 | 1.35 | 1202 | 0.43 | 221 | 0.14 | 7.48 |

| ID | Unexpected Parallelism | No Washing | Cooking as Usual | Using App | Change in Cooking Task | Substantial Change in Cooking Time | Proportion of Substantial Change in Cooking Time |

|---|---|---|---|---|---|---|---|

| 1 | 1:29:30 | 1:18:23 | +2:06 | −13:13 | −14.8% | ||

| 3 | ✓ | ✓ | 1:04:52 | 1:03:56 | −8:46 | +9:44 | +15.0% |

| 5 | ✓ | 1:11:56 | 0:54:21 | −20:40 | +3:05 | +4.29% | |

| 6 | 1:48:08 | 1:48:25 | +10:43 | −10:26 | −9.46% | ||

| 7 | 1:52:32 | 1:35:45 | −6:13 | −10:34 | −9.39% |

| ID | Unexpected Parallelism | No Washing | Cooking as Usual | Using App | Change in Cooking Task | Substantial Change in Cooking Time | Proportion of Substantial Change in Cooking Time |

|---|---|---|---|---|---|---|---|

| 4 | ✓ | ✓ | 0:57:13 | 1:06:05 | +5:57 | +2:55 | +5.09% |

| 8 | 1:10:16 | 1:06:45 | +1:07 | −4:38 | −6.59% | ||

| 9 | ✓ | ✓ | 1:19:42 | 1:26:15 | +0:23 | +6:10 | +7.80% |

| 10 | ✓ | 1:21:11 | 1:41:27 | +16:52 | +3:24 | +4.19% | |

| 11 | 1:31:24 | 1:29:50 | +5:24 | −6:58 | −7.62% |

| Questionnaire | Cooking as Usual | Using App |

|---|---|---|

| fatigue [1:very low, 5:very high] | 3.7 | 3.0 |

| urgency and pressure [1:very low, 5:very high] | 3.1 | 1.7 |

| progress as planned [1:low satisfaction, 5:high satisfaction] | 3.1 | 4.5 |

| ease of cooking [1:very difficult, 5:very easy] | 3.4 | 4.8 |

| quality [1:low satisfaction, 5:high satisfaction] | 3.9 | 3.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nakabe, J.; Mizumoto, T.; Suwa, H.; Yasumoto, K. Optimal Cooking Procedure Presentation System for Multiple Recipes and Investigating Its Effect. Algorithms 2021, 14, 67. https://doi.org/10.3390/a14020067

Nakabe J, Mizumoto T, Suwa H, Yasumoto K. Optimal Cooking Procedure Presentation System for Multiple Recipes and Investigating Its Effect. Algorithms. 2021; 14(2):67. https://doi.org/10.3390/a14020067

Chicago/Turabian StyleNakabe, Jin, Teruhiro Mizumoto, Hirohiko Suwa, and Keiichi Yasumoto. 2021. "Optimal Cooking Procedure Presentation System for Multiple Recipes and Investigating Its Effect" Algorithms 14, no. 2: 67. https://doi.org/10.3390/a14020067

APA StyleNakabe, J., Mizumoto, T., Suwa, H., & Yasumoto, K. (2021). Optimal Cooking Procedure Presentation System for Multiple Recipes and Investigating Its Effect. Algorithms, 14(2), 67. https://doi.org/10.3390/a14020067