Abstract

Considering the increasing use of emerging technologies in industrialized construction in recent years, the primary objective of this article is to develop and validate predictive models to predict the emerging technology utilization level of industrialized construction industry practitioners. Our preliminary research results indicate that the company background and personal career profiles can significantly affect practitioners’ technology utilization level. Thus, our prediction model is based on four variables: company size, company type, working experience, and working position. The United States and China are selected as the case studies to validate the prediction model. First, a well-designed questionnaire survey is distributed to the industrialized construction industry practitioners from the two countries, which leads to 81 and 99 valid responses separately. Then, ordinal logistic regression is used to develop a set of models to predict the practitioners’ utilization level of the four main technology types. Finally, the external test dataset consisting of 16 cases indicates the prediction models have a high accuracy. The results also reflect some differences of the technology utilization status in the industrialized construction industry between the United States and China. The major contribution of this research is offering an efficient and accurate method to predict practitioners’ technology utilization level in industrialized construction. Significantly, the models are believed to have a wide application in promoting the emerging technologies in the actual industrialized construction.

1. Introduction

Industrialized construction is a method of construction that promotes the advancement of the process from design through construction by employing intelligent manufacturing and automation techniques. In recent years, industrialization has been gradually introduced into the construction industry due to benefits including less construction cost, shorter construction time, and reduced labor requirements [1,2,3]. This is also accompanied by an increase in the amount of research relevant to industrialized construction.

Some researchers have provided a holistic review of the industrialized construction-related research. The incorporation of emerging construction technologies (e.g., information technology, sensing technology, and advanced data analytics) has been identified as one of the future research directions of industrialized construction-related research [4,5]. Due to the factory-based nature of industrialized construction, the benefits of emerging technologies on off-site industrialized construction facture could be far greater than those of traditional construction [1]. The application of technology can make industrialized construction sites safer and workers more efficient, and thus achieving the expected performance improvement and benefits brought by industrialized construction. For example, the post-3D model-based ergonomic analysis proposed by [6] can significantly reduce various types of risk ratings on the industrialized construction site. [7] propose a precast production scheduling optimization model, which can reduce the construction time by around 15% to 36%.

Despite the growing academic attention, our preliminary study [8] indicated a discrepancy in the needs of emerging technology in industrialized construction between academia and industry. Specifically, the corresponding application in the actual industrialized construction industry is generally at a low level, although more works in academia are focusing on the research of emerging technologies. The promotion of the emerging technologies is impeded by many barriers, including human skepticism and resistance [9], potential work interruptions [6], the inability to afford the hardware or software [10], and increased cost [11]. Thus, it is important to design effective strategies to promote the emerging technologies into the industrialized construction industry. Some common technology promotion strategies mentioned in previous research include collaboration with research institutes and firms, implementation of market-based incentives, better enforcement of existing standards, subsidies from government, low-cost loans, and investment incentives [12]. Before applying the specific strategy, it is necessary to get the full picture of the existing technology utilization status. The specific technology promotion strategy should be designed according to the existing technology utilization level of the construction practitioners. Thus, the practitioners can determine whether new technologies can be integrated smoothly by assessing the maturity level of their current technology application. In this article, construction practitioner is defined as someone who has a career in a construction-related discipline (e.g., architect, engineer, and quantity surveyor).

However, the statistics about the current technology utilization level in the industrialized construction industry are lacking. The traditional methods include using questionnaire surveys, interviews, or focus groups to collect related data from the industry practitioners. Specifically, our preliminary research distributed a questionnaire survey to collect the practitioners’ technology utilization level [8,13]. The questionnaire introduced the concepts and scope of various technology types and then requested the practitioners to rate their utilization level. However, traditional surveying methods have limitations including inefficiency and high-cost [14,15]. This highlights the importance of developing robust prediction models based on past data to enable the detection of the industrialized construction practitioners’ technology utilization level.

Predictive analysis is commonly applied in construction-related research, such as contractor performance prediction [16], construction company failure prediction [17], and sustainability performance prediction [18]. However, similar research often requests the users to evaluate dozens of factors to obtain the prediction results, which might be too sophisticated to be understood and utilized by users [17]. In addition, some of the factors, such as organization skills or cultures, are difficult to collect and quantify. The rating process of these determinants could be affected by respondents’ selection preferences and subjectivity [17]. Without a benchmarking system, the organization or individuals cannot get a consistent evaluation of these determinants.

These limitations mentioned above might decrease the generalization of the predictive model, and a more efficient and objective method is needed. Our preliminary research [8,13,19] used Analysis of Variance (ANOVA) to find that company background and personal career profiles can significantly affect the practitioners’ technology utilization level in the industrialized construction projects. The data about company background and personal career profiles can be easier to access compared to other types of determinants that need to be evaluated subjectively by respondents. Thus, four variables—company size, company type, working experience, and working position—are regarded as viable predictors to predict the practitioners’ technology utilization level. The primary objective of this article is to describe a comprehensive effort to predict the emerging technology utilization level of industrialized industry practitioners using practitioners’ company backgrounds and career profiles. An external test dataset has been used to evaluate the efficiency of the prediction model. Correlating historical data allows the development of a model to assist the planning and implementation of emerging technologies into the industrialized construction industry and the collaboration between academia and industry. Although the scope covers any developed economy, this article uses case studies from the United States and Chinese industry. The findings of this article contribute to the body of knowledge and practice by offering an efficient and accurate method to the predict practitioners’ technology utilization level in the industrialized construction.

2. Emerging Technology Categorization

The manufacturing industry has a history of applying emerging technologies to improve efficiency and production. Recently, the manufacturing industry has been experiencing the 4th Industrial Revolution, also referred to as Industry 4.0. Industry 4.0 is used to describe the tendency towards digitization, automation of the manufacturing environment. Much research has summarized the different types of Industry 4.0 technologies that have applied in the manufacturing sector (e.g., [20,21,22]). There are also some technologies that are specific to the construction industry (e.g., BIM). This literature is focusing on the discussion of technology itself, without discussing the difference between the use in different countries. Based on the works of previous literature reviewing and the preliminary research conducted by the authors [8], this article classifies the technologies that either have already been applied or have the potential to be applied in the industrialized construction industry into four main areas: 1) business digitalization, 2) computer integrated design and planning, 3) data acquisition and analytics, and 4) robotics and automation. Each of these groups encompasses subclasses of technologies and tools that are necessary to re-engineer the industrialized construction process.

2.1. Business Digitalization

The workflows and project deliveries of the construction industry are experiencing a trend of moving away from the traditional paper-based to digital-based. Successful implementation of industrialized construction technologies requires digital collaboration among stakeholders from different fields [23]. It is also essential to design an effective method to realize data integration and interoperability between the various information systems [24]. Efficient interaction between devices and applications reduces the time and effort needed for communication and information exchange among different stakeholders during the project life cycle. The business digitalization class has two subcategories:

- Business information systems. The Cloud-based information systems are emerging in the construction industry for coordination, sharing design documents, and communication between project sectors [25]. These information systems have the ready-made software to implement. Some existing commercial information systems are enterprise resource planning (ERP), geographical information systems (GIS), manufacturing execution system (MES), and product life-cycle management (PLM).

- Self-designed system integration. Other than existing commercial business information systems, researchers also design the system integration applications by themselves. Self-designed system integration applications can be classified into two types: horizontal integration and vertical integration [25,26]. Horizontal integration refers to expanding the company by acquisition or investing in different types of off-site construction, such as precast concrete, metal frames, panelized, and modular, that address the same customer base with different but complementary products. Vertical integration aims to tie together all logical layers within the organization from the design to assembly.

2.2. Computer Integrated Design

The computer systems are often used in both the manufacturing and construction sectors to improve the process of creation, analysis, and optimization of a design. Computer-integrated design class includes:

- 3D and nD. The architecture, engineering, and construction (AEC) industry has utilized the computer-aided design (CAD) tools for creating 2D or 3D design practices [27]. Compared to 2D drawings, 3D models are more intuitive and can accelerate the product development cycle. The emergence of BIM tools also adds parametric and standard features into the 3D geometries and expands the application of 3D models. The developments in BIM now go beyond 3D and create the 4D (time), 5D (cost), or 6D (quality) models.

- Design optimization. Design optimization refers to optimizing industrialized building design and improving its one-time success rate by integrating professional knowledge and information of other stages into the design stage [28]. The parametric and standard structure of BIM facilitates providing information for various design optimization applications such as automated rule checking and constructability validation [28].

- Extended reality. Extended reality technology refers to real-and-virtual combined environments and human-machine interactions generated by computer technologies, which includes augmented reality (AR), virtual reality (VR), and mixed reality (MR) [29]. It is gradually getting attention from construction industry for its ability of visualizing design, production, and construction information.

2.3. Data Acquisition and Analytics

The operation management and scheduling in both manufacturing and construction industries conventionally rely on manual methods or outdated simulation and planning software packages. The emerging data acquisition and analytics technologies improve the process of data collection, data analysis, and the communication of process-performance results. These measures increase efficiency in controlling entire project processes such as design, engineering, planning, purchasing, as well as factory floor functions such as materials handling and quality control. The subcategories include:

- Sensing technology. Data acquisition is the process of collecting real world physical conditions and converting them into numeric values that can be manipulated by computers. Commonly applied sensing technologies include photogrammetry, digital imaging, laser scanning, GPS sensors, and industrial sensors (i.e., sensors commonly applied in industrial automation processes such as temperature sensors and pressure sensors). These sensors can be applied to collect real-time vision, kinematic, or energy data throughout the project [25].

- IoT system. IoT (Internet of things) is composed of numerous connected devices that rely on sensory, communication, networking, and information processing technologies [20,21]. The key technologies that enable the IoT network are wireless sensor networks (WSN) devices, such as RFID and Bluetooth. Other technologies that can integrate with IoT systems include barcodes, industrial sensors and actuators, location-based services, and wearables [30].

- Optimization and simulation. Various optimization algorithms are used to predict uncertainties, progress, and risks of the construction projects [21,26]. The collected information from the project can be processed by simulation software to model the behavior of machines, products, and workers [25]. The optimization and simulation results enable the problem prediction, configuration costs reduction, and quality improvement of the industrialized projects.

- Advanced data analytics. Advanced data analytics are used to extract useful information from vast amounts of data generated from interconnected systems [20]. The specific advanced data analytic techniques that can be used in the construction industry include data management techniques (e.g., data mining, data classification, and data storage) and artificial intelligence techniques (e.g., machine learning and deep learning). The appearance of third-party Cloud computing systems with friendly interfaces and high levels of security and reliability lowers the threshold to using these technologies.

2.4. Robotics and Automation

The technology developments in robotics and automation systems are transferable to the fabrication and assembly stages of the industrialized construction. The subcategories for the robotics and automation class are:

- Digital fabrication. Digital fabrication is a fabrication process where the machine is controlled by computers [20]. The ready-made control systems for managing and controlling of digital fabrication in the manufacturing factories include a computer numerical controlled (CNC) machine tool, programmable logic controller (PLC), and production control system (PCS). Researchers in the construction sector also develop the other digital fabrication systems that are designed to implement specific functions during the construction process [31].

- Autonomous machinery. Autonomous robots with interconnectivity, such as drones, can operate collaboratively to improve the production processes [26]. The new generation of autonomous machinery is capable of monitoring the physical environment and performing functions with little or no direct human control. Their most common applications in the construction industry are progress monitoring, material handling, or replacing human workers in unsafe conditions.

- Additive manufacturing. This refers to the manufacturing techniques that build 3D objects by adding a layer-upon-layer of material [29]. One of the typical examples of additive manufacturing is 3D printing. Additive manufacturing beneficial in the production system to increase flexibility and customization of construction products.

3. Research Purpose and Methodology

The main objective of this article is to develop and validate prediction models that can predict the industry practitioners’ utilization level of the four main technology classes. Despite emerging technologies are receiving increasing attention from academia, the practical application of emerging technology is still at a low level. Before implementing the specific promotion strategy, it is necessary to understand the current technology utilization level of industry practitioners.

The specific research process consists of four steps. First, a holistic literature review was conducted to establish the state of practice and research regarding emerging technologies in industrialized construction, which has been conducted in preliminary research [19]. Second, a well-designed questionnaire survey was developed and distributed to the construction industry. Third, the collected data was inputted into the ordinary logistic regression model to generate the prediction models. Fourth, the accuracy of the models will be tested through the external test dataset. Since this article selects the United States and China as the case studies, the same research flow will be applied to the two countries independently.

3.1. Questionnaire Survey

A three-part online survey was designed to collect industry practitioners’ perspectives. The first part briefly introduced the objectives of this survey, concepts of industrialized construction, and descriptions of each category of emerging technologies. The second part asked the respondents’ company background and career profiles through single-choice questions, which included their company type, company annual revenue, occupation type, and working experience. Table 1 presents the options for each question, which can be regarded as the categories for different variables. The criteria for the data grouping are based on our preliminary research [13]. Each category was given a label for facilitating further analysis and processing. This part also collected respondents’ experience on the industrialized construction projects. The third part of the survey asked the respondents to rate their current utilization levels of four technology types in the industrialized construction project separately using a four-point scale (i.e., 1 = none, 2 = low level, 3 = medium level, 4 = high level). We also clarified the specific criteria for each level: “none” means have never used this technology in the industrialized construction projects; “low” means have used this technology once or twice in the industrialized construction projects; “medium” means have used this technology in half of the industrialized projects; “high” means have used this technology in almost every industrialized project.

Table 1.

Predictor variables and corresponding groups.

The questionnaire survey was also translated into a Chinese version to overcome the language barriers in China. Finally, the survey was sent to the modular construction experts from the two countries separately to solicit feedback on the design, format, and content. The survey was then updated accordingly, and the final version was published on Qualtrics for distribution, which is a commonly used web-based survey tool.

A snowball sampling method was utilized to distribute the survey. The snowball sampling method is a non-probability sampling technique in which the samples have traits that are rare to find. This is a sampling technique where the existing research participants recruit other participants for a test or study. For the survey distribution in the United States, initial respondents included manufacturers, designers, and project managers from several modular construction companies in Florida; in China, initial respondents included the practitioners from several modular construction companies in Jiangsu. Then, they were requested to answer the survey and distribute it to other knowledgeable participants they think appropriate within their country. The respondents were sent e-mails containing the hyperlinks to access the survey. The survey distribution lasted for two months, starting from August 9 to October 9, 2019. Approximately 500 questionnaires have been distributed in the United States, and 600 questionnaires have been distributed in China.

The collected data were then preprocessed to filter out invalid responses. First, incomplete responses were removed. Then, since the questionnaire also contained questions asking the respondents’ past experiences with industrialized construction. (e.g., Have you utilized any industrialized construction strategies? Which type of projects have you utilized industrialized construction strategies?), only responses of the respondents who had utilized any industrialized construction strategies or participated in any industrialized projects were regarded as valid.

3.2. Ordinal Logistic Regression Model

Ordinal logistic regression was applied to develop the prediction model in Minitab. Ordinal logistic regression was used to predict an ordinal dependent variable given one or more independent variables [32]. For this research, the technology utilization level was regarded as the ordinal dependent variable (i.e., multi-class ordered variables), which included levels from 1 to 4; company size, company type, working position, and working experience were regarded as categorical independent variables (i.e., multi-class unordered variables), and the categories for each variable are presented in Table 1. Assuming a dependent variable has j levels, and there are M independent variables, the mathematical formulation of the ordinal logistic regression model is given below:

In Formula (1), is the logarithmic link function of the probability of occurrence of an event when dependent variable Y’s value is no larger than j. represents the intercept of the corresponding regression model. represents the regression coefficient of the corresponding independent variable . For the categorical independent variable, the first category is regarded as the reference category. Regression coefficients of the other categories indicate their influence on Y compared to the reference category. Specifically, positive coefficients indicate that the first level of the dependent variable (i.e., technology utilization level 1) is more likely to happen at this category of than at the reference category. Negative coefficients indicate that the last level of the dependent variable (i.e., technology utilization level 4) is more likely to happen at this category of than at the reference category. The four independent variables involved in this article are all unmeasurable categorical variables. Since the categorical variable cannot be directly input into the regression model like a numerical variable, it is necessary to convert the four categorical variables into a dummy variable. Each category of the independent variable is encoded in a 0/1 form, where 1 refers to presence and 0 refers to absence.

Based on Formula (1), the probability of the event when dependent variable Y’s level is no larger than j can be obtained through Formula (2). The probability of each level of Y can be obtained in Formula (3). Then, the model will assign the sample’s Y value as the level with the largest probability.

Then, it was necessary to evaluate the fitness of the model. The null hypothesis was that all independent variable coefficients were equal to zero, which implied that there was no association between the dependent variable and the independent variables. The p-value of “test of all slopes being zero” was used to determine whether at least one of the predictors in the model had a statistically significant association. A p-value equal to or less than 0.05 could reject the null hypothesis and then conclude that there was a statistically significant association between the dependent variable and at least one of the independent variables. Lower p-values provide stronger evidence against the null hypothesis. There was a total of ( = 15) combinations of the four independent variables, and the model was trained separately. The model with the lowest p-value and less than 0.05 would be selected.

3.3. Model Prediction Efficiency Evaluation

This article compared the prediction results to the actual outcomes to evaluate the performance of the models. An external test dataset was built consisting of multiple different cases. The percentage of the cases whose technology utilization levels were correctly predicted (i.e., correctness ratio) was used as the evaluation metric. In each case, the corresponding industry practitioner was asked the questions about their company background and career profiles, experience with industrialized construction, and utilization level of each technology through the questionnaire and interviews. The background of the selected practitioners should be as diverse as possible to cover different company background and occupation categories. Then, the collected practitioners’ company backgrounds and career profiles data were input into the model to obtain the predicted utilization level of each technology type. Finally, the predicted utilization levels were compared with the actual utilization level, to evaluate the accuracy of the model.

4. Results

The following subsections will present the descriptive data of the questionnaire survey results, the development, and the evaluation process of the models.

4.1. Descriptive Data

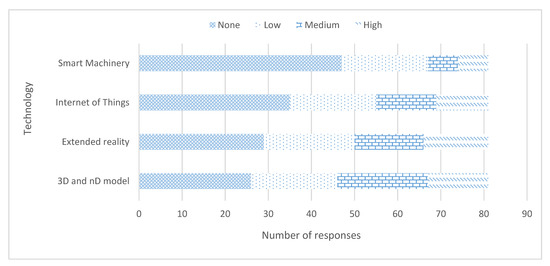

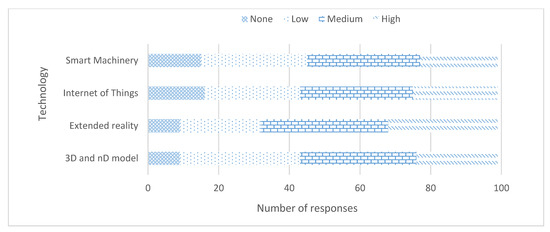

A total of 99 responses is received in the United States. Eighty-one of them (82%) are regarded as valid responses since they meet the criteria of being complete and the respondents being knowledgeable about industrialized construction. A total of 112 responses is received in China and 99 of them (88%) are regarded as valid responses. The specific company background and career profiles of the respondents are presented in Table 2. The average utilization levels of different technology types in the United States and China are presented in Figure 1 and Figure 2. It is found that the overall average utilization level of Chinese practitioners (2.70) is higher than that of United States practitioners (2.02).

Table 2.

Data distribution.

Figure 1.

Average technology utilization levels of the United States practitioners.

Figure 2.

Average technology utilization levels of the Chinese practitioners.

4.2. Model Fitting

As mentioned previously, different combinations of the four independent variables are used to train the models separately, and the model with the lowest p-value and less than 0.05 will be selected. After getting the intercepts and the regression coefficients of each independent variable, the probability of each level of technology utilization can be calculated using Formulas (2) and (3).

- United States. The ordinal logistic regression model results for the four technology types in the United States’ industrialized construction industry are presented in Table 3. values for different models are presented in Table 4. The practitioner utilization levels of 3D and nD models cannot be predicted based on the collected data since none of the models have been tested with a p-value less than 0.05. Specifically, in the United States models, company size and working experience are used in the prediction of the utilization level of extended reality; company size, working experience, and working position are used in the prediction of the utilization level of Internet of things; and company type and working experience are used in the prediction of the utilization level of smart machinery.

Table 3. Ordinal logistic regression model for the United States.

Table 3. Ordinal logistic regression model for the United States. Table 4. value of different technology types for the United States.

Table 4. value of different technology types for the United States. - China. Similarly, the ordinal logistic regression model results for the four technology types in the Chinese industrialized construction industry are presented in Table 5. values for different models are presented in Table 6. In the Chinese models, company type and company sizes are used in the prediction of the utilization level of all four technology types. The prediction of the utilization level of Internet of things and smart machinery use the working experience as the predictor.

Table 5. Ordinal logistic regression model for China.

Table 5. Ordinal logistic regression model for China. Table 6. value of different technology type for China.

Table 6. value of different technology type for China.

4.3. Model Evaluation

As presented in Table 3 and Table 5, seven models have been selected to predict the utilization level of different technology types of the practitioners in the United States and China. Then, an external test dataset consisting of 16 cases were selected to evaluate the accuracy of the developed prediction models, which included 8 from the United States and 8 from China. The specific information of the cases and the corresponding prediction results are presented in Table 7. Six out of the seven models have the correctness ratio no less than 75%. It is noticeable that the prediction model of the utilization level of smart machinery in China has a correctness ratio of 100%. Only the model to predict the utilization level of smart machinery in the United States has a correctness ratio less than 75%. For those wrong predictions, the difference between the predicted value and actual value is 1.

Table 7.

Application of the ordinal logistic regression model.

5. Discussion

By observing the models and questionnaire survey results, some insights about the differences in the technology utilization status in the industrialized construction between the United States and China are obtained. The practical application and the limitations of the models will also be discussed in the following subsections.

5.1. Comparison between the United States and China

The results show that Chinese practitioners have a higher average technology utilization level in industrialized construction than those in the United States. This reflects that, currently, the practitioners in China pay more attention to the application of emerging technologies into the industrialized construction than the United States. Recent years have witnessed a prosperous development in the Chinese construction industry. Before 2008, the U.S. had the most top 225 international construction companies in the world. However, China has now surpassed the United States. This booming development brings the increase in the level of construction technologies [33,34]. Moreover, in order to comply with increasing requirements of urbanization and housing demand, the Chinese government is proactively promoting the industrialized construction strategies [34]. It has also been confirmed by previous researchers [35,36] that China is gradually leading in the off-site related research around the world. These could potentially explain why Chinese practitioners have a higher average technology utilization level.

Moreover, the compositions of the models of the United States and China are different. These differences in the model compositions can reflect some insights about the practitioners’ technology utilization conditions in the United States and China. Specifically, working experience acts as the influencing factors in all of the models in the United States. The United States practitioners with different working experience expressed significant differences in their attitudes towards applying emerging technologies in industrialized construction. By comparison, company type and company size are the predictors in all four models in China. Working position is not included in any of the four models in China. It reflects that the practitioners from the same Chinese company may have similar mastery of the applied technologies. The size and types of companies where Chinese practitioners work can significantly affect their technology utilization level in the industrialized construction projects.

Overall, it is found that the variable company size exists in six out of the seven models. It indicates that company size can significantly affect practitioners’ utilization levels of different technology levels in both countries. As presented in Table 5, the regression coefficients of CS2 and CS3 of different models are almost negative. It means the practitioners from medium-sized and large-sized companies are more likely to have a higher technology utilization level than those from small-sized companies. This is reasonable since technology utilization in small-sized companies is often hampered by high costs of equipment, software, and technical education. By contrast, large-sized companies often have more funding to invest in the development and application of technologies.

5.2. Model Application

Four predictors, which are company type, company size, working position, and working experience, are used in this research to predict the practitioners’ technology utilization level in industrialized construction. The ordinal logistic regression models get a high predication correctness ratio through the external test dataset and it can be concluded that the developed models can accurately predict the practitioners’ technology utilization level in industrialized construction.

The other significant advantage of the model is the simple requirements on the input parameters. In previous construction-related research (e.g., [37]), users are required to evaluate dozens of factors to get the prediction results. Some of the factors are difficult to quantify and can also be affected by subjective bias. However, the model developed in this research only requires the input of the practitioners’ company background and career profiles, which are often easy to get. For the practical applications of the models, respondents’ company background, career profiles, and experience with industrialized construction can be collected in the format of a concise questionnaire or a simple telephone interview. Then, the collected company background and career profiles of the respondents who have participated in the industrialized construction projects can be input into the models to generate the predicted technology utilization level.

Knowing the practitioners’ technology utilization level in the industrialized construction is beneficial for different stakeholders: researchers can seek support from those practitioners with a high technology utilization level in the development and validation process of their research achievements; technology vendors can identify the market demand and thus promote their technological products better; and practitioners can determine whether new technologies can be integrated smoothly by assessing the maturity level of their current technology application. The models developed in this research are believed to have a wide application in the promotion of emerging technologies in the industrialized construction.

5.3. Limitation and Future Works

Even though an extensive work, this research still has some limitations, which can be categorized into following aspects:

- The data sample is not sufficient. Despite great benefits, industrialized construction technique is not the mainstream construction technique in both the United States and China. During the questionnaire survey distribution and collection process, it was found that a large proportion of practitioners have never participated in any industrialized construction projects, which made them refuse to answer the questionnaire survey. The number of respondents in some groups are not sufficient. For example, the number of Chinese practitioners whose company type is component manufacturer is only six, which is much lower than the number of respondents in other groups. Future research should enlarge the sample size, which is believed to further improve the accuracy of the prediction models.

- Other variables may affect the results. In addition to these four variables, there could be other variables that can affect the practical technology utilization level in industrialized construction, such as construction culture and research investment. Future research will focus on collecting and quantifying these factors and thus improve the prediction performance.

- This research is the first known research that focuses on the prediction of technology utilization levels in the industrialized construction, and ordinal logistic regression is used as the method considering the structure of the collected data. In future research, some other multi-class machine-learning algorithms (e.g., Naïve Bayes, Decision tree, and support vector machine) might be used to improve the accuracy of prediction.

6. Conclusions

The application of emerging technology is gradually becoming a research hotspot in the industrialized construction field. Meanwhile, a preliminary study found a discrepancy in the needs of emerging technology in industrialized construction between academia and industry. Before applying the specific promotion strategy, it is necessary to understand the existing technology utilization status. However, the statistic on the industry practitioners’ technology utilization level is lacking. This highlights the importance of a prediction model that can accurately predict the industry practitioners’ technology utilization level. This article is based on our preliminary research results that company background and personal career profiles can significantly affect practitioners’ technology utilization level. Thus, the primary objective of this article is to develop and validate predictive models to predict the emerging technology utilization level of industrialized construction industry practitioners using four variables: company size, company type, working experience, and working position. Such prediction models are based on the questionnaire survey data collected from the United States and Chinese industrialized construction industries. Using the ordinal logistic regression model, a set of models have been developed to predict the practitioners’ utilization level of the four main technology types in both the United States and China. The external validation indicates the prediction models are reliable.

Through analyzing the questionnaire survey data and the model compositions, some facts about the differences of the technology utilization in industrialized construction between the United States and China are reflected. Specifically, Chinese practitioners have a higher average technology utilization level in industrialized construction than those in the United States; working experience is influential in the United States practitioners’ technology utilization level; and company type and company size are the key determinants for the technology utilization of Chinese practitioners. The developed model is advantageous in its accuracy and the simple requirements on the input parameters, which makes it reliable and efficient to predict the technology utilization level of industrialized construction practitioners. The models developed in this research are believed to be beneficial for different stakeholders in the industrialized construction by accelerating the collaboration between industry and academia, providing an assessment benchmark for practitioners, and helping technology vendors promote the emerging technologies.

The major contribution of this research is offering an efficient and accurate method to predict practitioners’ technology utilization level in the industrialized construction. Significantly, understanding the practitioners’ utilization level of different types of the technologies is beneficial for different stakeholders including researchers, technology providers, and construction companies. The developed prediction models are believed to have a wide application in promoting the emerging technologies in industrialized construction.

Author Contributions

Conceptualization, B.Q. and S.Q; methodology, B.Q. and S.Q.; validation, B.Q.; writing—original draft preparation, B.Q.; writing—review and editing, A.C.; supervision, A.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded in part by the University of Florida College of Design, Construction, and Planning (DCP) seed funding And APC was funded by MDPI.

Acknowledgments

This study was approved by the University of Florida Institutional Review Board (IRB201801656). Any opinions, findings, and conclusions or recommendations expressed are those of the authors and do not necessarily reflect the views of others.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Abanda, F.H.; Tah, J.H.M.; Cheung, F.K.T. BIM in off-site manufacturing for buildings. J. Build. Eng. 2017, 14, 89–102. [Google Scholar] [CrossRef]

- Qi, B.; Costin, A. Challenges of Implementing Emerging Technologies in Residential Modular Construction. In Proceedings of the CIB World Building Congress, Constructing Smart Cities, Hong Kong, China, 17–21 June 2019; pp. 1166–1176. [Google Scholar]

- Yin, X.; Liu, H.; Chen, Y.; Al-Hussein, M. Building information modelling for off-site construction: Review and future directions. Autom. Constr. 2019, 101, 72–91. [Google Scholar] [CrossRef]

- Li, Z.; Shen, G.Q.; Xue, X. Critical review of the research on the management of prefabricated construction. Habitat Int. 2014, 43, 240–249. [Google Scholar] [CrossRef]

- Jin, R.; Gao, S.; Cheshmehzangi, A.; Aboagye-Nimo, E. A holistic review of off-site construction literature published between 2008 and 2018. J. Clean. Prod. 2018, 202, 1202–1219. [Google Scholar] [CrossRef]

- Li, X.; Han, S.; Gül, M.; Al-Hussein, M. Automated post-3D visualization ergonomic analysis system for rapid workplace design in modular construction. Autom. Constr. 2019, 98, 160–174. [Google Scholar] [CrossRef]

- Wang, Z.; Hu, H. Improved precast production–scheduling model considering the whole supply chain. J. Comput. Civ. Eng. 2017, 31, 04017013. [Google Scholar] [CrossRef]

- Razkenari, M.; Qi, B.; Fenner, A.; Hakim, H.; Costin, A.; Kibert, C.J. Industrialized construction: Emerging methods and technologies. In Computing in Civil Engineering, 2019: Data, Sensing, and Analytics; ASCE: Atlanta, GA, USA, 2019; pp. 352–359. [Google Scholar]

- Cantu, H.; Canal, C.; Costin, A. Modular Construction: Assessing the Challenges Faced with the Adoption of an Innovative Approach to Improve U.S. Residential Construction. In Proceedings of the CIB World Building Congress, Hong Kong, China, 17–21 June 2019. [Google Scholar]

- Xu, G.; Li, M.; Chen, C.H.; Wei, Y. Cloud asset-enabled integrated IoT platform for lean prefabricated construction. Autom. Constr. 2018, 93, 123–134. [Google Scholar] [CrossRef]

- Martinez, P.; Ahmad, R.; Al-Hussein, M. A vision-based system for pre-inspection of steel frame manufacturing. Autom. Constr. 2019, 97, 151–163. [Google Scholar] [CrossRef]

- Chan, A.P.C.; Darko, A.; Ameyaw, E.E. Strategies for promoting green building technologies adoption in the construction industry—An international study. Sustainability 2017, 9, 969. [Google Scholar] [CrossRef]

- Qi, B.; Razkenari, M.; Li, J.; Costin, A.; Kibert, C.; Qian, S. Investigating US Industry Practitioners’ Perspectives towards the Adoption of Emerging Technologies in Industrialized Construction. Buildings 2020, 10, 85. [Google Scholar] [CrossRef]

- Jiang, H.; Qiang, M.; Lin, P. Assessment of online public opinions on large infrastructure projects: A case study of the Three Gorges Project in China. Environ. Impact Assess. Rev. 2016, 1, 38–51. [Google Scholar] [CrossRef]

- Dai, H.; Hao, J. Mining social media data on marijuana use for Post Traumatic Stress Disorder. Comput. Hum. Behav. 2017, 1, 282–290. [Google Scholar] [CrossRef]

- Wong, C.H. Contractor performance prediction model for the United Kingdom construction contractor: Study of logistic regression approach. J. Constr. Eng. Manag. 2004, 130, 691–698. [Google Scholar] [CrossRef]

- Wong, J.; Thomas, N. Company Failure in the Construction Industry. A Critical Review and Future Agenda. In Proceedings of the FIG Congress, Facing the Challenges and Building Capacity, Sydney, Australia, 11–16 April 2010. [Google Scholar]

- Moon, H.; Hyun, C.; Hong, T. Prediction model of CO2 emission for residential buildings in South Korea. J. Manag. Eng. 2014, 30, 04014001. [Google Scholar] [CrossRef]

- Qian, S. Emerging Technology Utilization in Industrialized Construction: A Predictive Analysis in the United States and China. Master’s Thesis, University of Florida, Gainesville, FL, USA, 2020. [Google Scholar]

- Lu, Y. Industry 4.0: A survey on technologies, applications and open research issues. J. Ind. Inf. Integr. 2017, 6, 1–10. [Google Scholar] [CrossRef]

- Xu, L.D.; Xu, E.L.; Li, L. Industry 4.0: State of the art and future trends. Int. J. Prod. Res. 2018, 56, 2941–2962. [Google Scholar] [CrossRef]

- Oesterreich, T.D.; Teuteberg, F. Understanding the implications of digitisation and automation in the context of Industry 4.0: A triangulation approach and elements of a research agenda for the construction industry. Comput. Ind. 2016, 83, 121–139. [Google Scholar] [CrossRef]

- Zhang, W.; Lee, M.W.; Jaillon, L.; Poon, C.S. The hindrance to using prefabrication in Hong Kong’s building industry. J. Clean. Prod. 2018, 204, 70–81. [Google Scholar] [CrossRef]

- Costin, A.; Eastman, C. Need for interoperability to enable seamless information exchanges in smart and sustainable urban systems. J. Comput. Civ. Eng. 2019, 33, 04019008. [Google Scholar] [CrossRef]

- Fernández-Caramés, T.M.; Fraga-Lamas, P. A review on human-centered IoT-connected smart labels for the industry 4.0. IEEE Access 2018, 6, 25939–25957. [Google Scholar] [CrossRef]

- Rüßmann, M.; Lorenz, M.; Gerbert, P.; Waldner, M.; Justus, J.; Engel, P.; Harnisch, M. Industry 4.0: The future of productivity and growth in manufacturing industries. Boston Consult. Group 2015, 9, 54–89. [Google Scholar]

- Costin, A.; Adibfar, A.; Hu, H.; Chen, S.S. Building Information Modeling (BIM) for transportation infrastructure–Literature review, applications, challenges, and recommendations. Autom. Constr. 2018, 94, 257–281. [Google Scholar] [CrossRef]

- Yuan, Z.; Sun, C.; Wang, Y. Design for Manufacture and Assembly-oriented parametric design of prefabricated buildings. Autom. Constr. 2018, 88, 13–22. [Google Scholar] [CrossRef]

- Saucedo-Martínez, J.A.; Pérez-Lara, M.; Marmolejo-Saucedo, J.A.; Salais-Fierro, T.E.; Vasant, P. Industry 4.0 framework for management and operations: A review. J. Ambient Intell. Humaniz. Comput. 2018, 9, 789–801. [Google Scholar]

- Costin, A.; Wehle, A.; Adibfar, A. Leading indicators—A conceptual IoT-based framework to produce active leading indicators for construction safety. Safety 2019, 5, 86. [Google Scholar] [CrossRef]

- De Soto, B.G.; Agustí-Juan, I.; Hunhevicz, J.; Joss, S.; Graser, K.; Habert, G.; Adey, B.T. Productivity of digital fabrication in construction: Cost and time analysis of a robotically built wall. Autom. Constr. 2018, 92, 297–311. [Google Scholar] [CrossRef]

- Wang, Y. Ordinal logistic regression model for predicting AC overlay cracking. J. Perform. Constr. Facil. 2013, 27, 346–353. [Google Scholar] [CrossRef]

- Zhang, P.; London, K. A Comparative Analysis of Construction Industry International Performance between China and United States Using the International Advanced Index; CIB: Montreal, QC, Canada, 2012; pp. 25–36. [Google Scholar]

- Zhang, X.; Skitmore, M.; Peng, Y. Exploring the challenges to industrialized residential building in China. Habitat Int. 2014, 41, 176–184. [Google Scholar] [CrossRef]

- Qi, B.; Chen, K.; Costin, A.M. RFID and BIM-enabled prefabricated component management system in prefabricated housing production. In Proceedings of the Construction Research Congress, New Orleans, LA, USA, 2–5 April 2018; pp. 591–601. [Google Scholar]

- Hosseini, M.R.; Martek, I.; Zavadskas, E.K.; Aibinu, A.A.; Arashpour, M.; Chileshe, N. Critical evaluation of off-site construction research: A Scientometric analysis. Autom. Constr. 2018, 87, 235–247. [Google Scholar] [CrossRef]

- Tserng, H.P.; Lin, G.F.; Tsai, L.K.; Chen, P.C. An enforced support vector machine model for construction contractor default prediction. Autom. Constr. 2011, 20, 1242–1249. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).