Horizontal Bending Angle Optimization Method for Scraper Conveyor Based on Improved Bat Algorithm

Abstract

1. Introduction

2. Basic Theory

2.1. Analyze the Running Resistance of the Scraper Conveyor

Straight line running resistance

S-bending section additional resistance

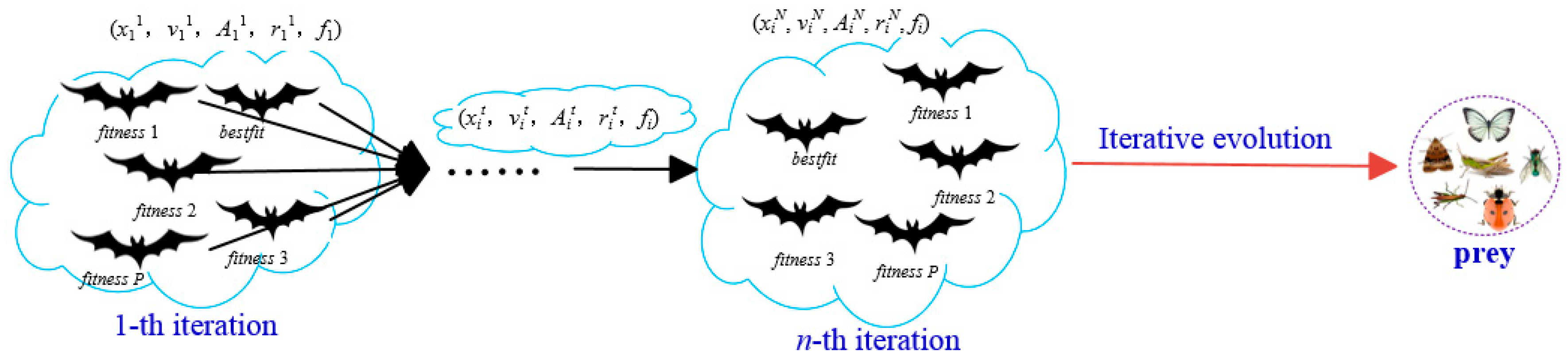

2.2. Bat Algorithm

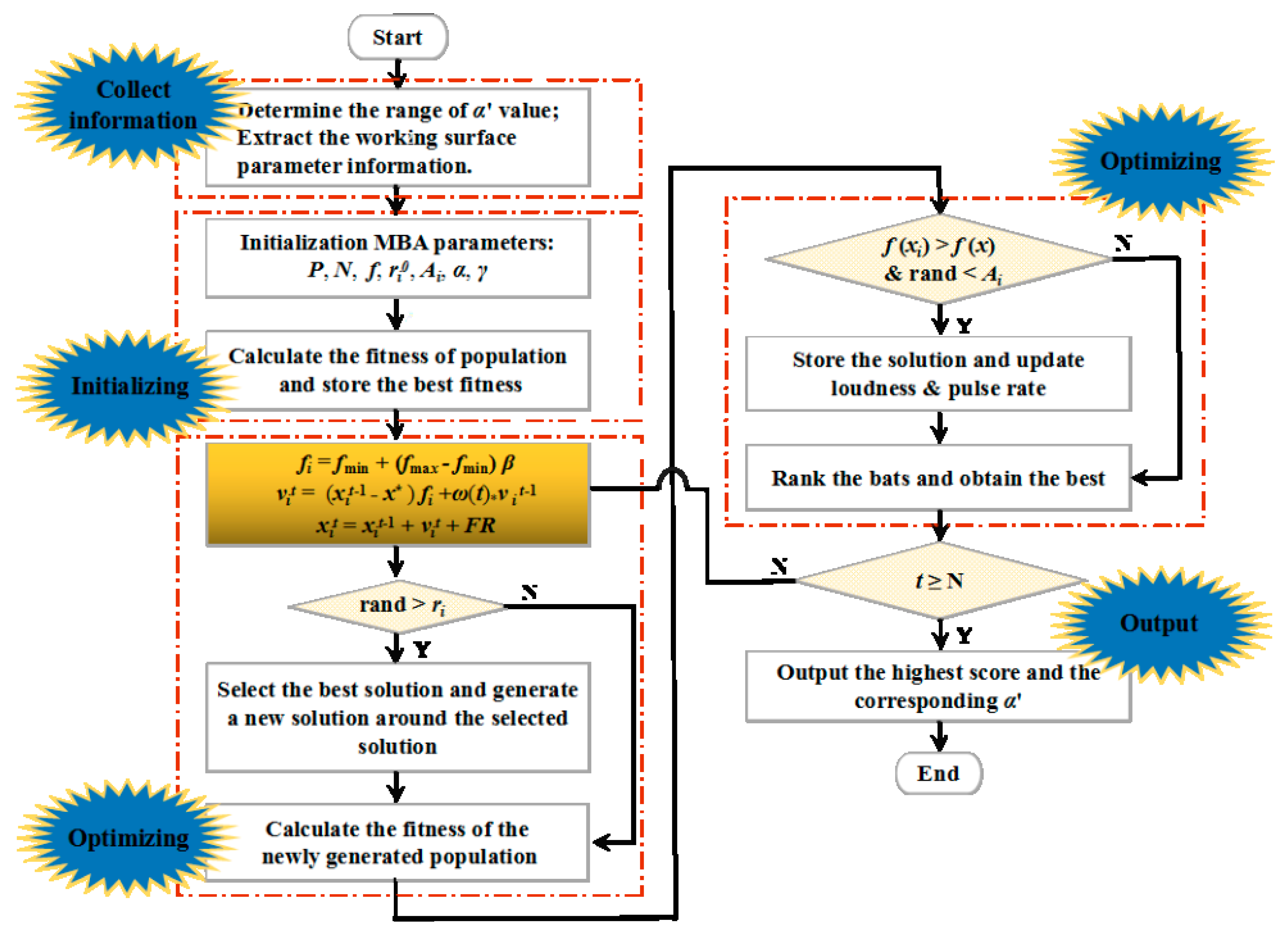

3. The Proposed Method

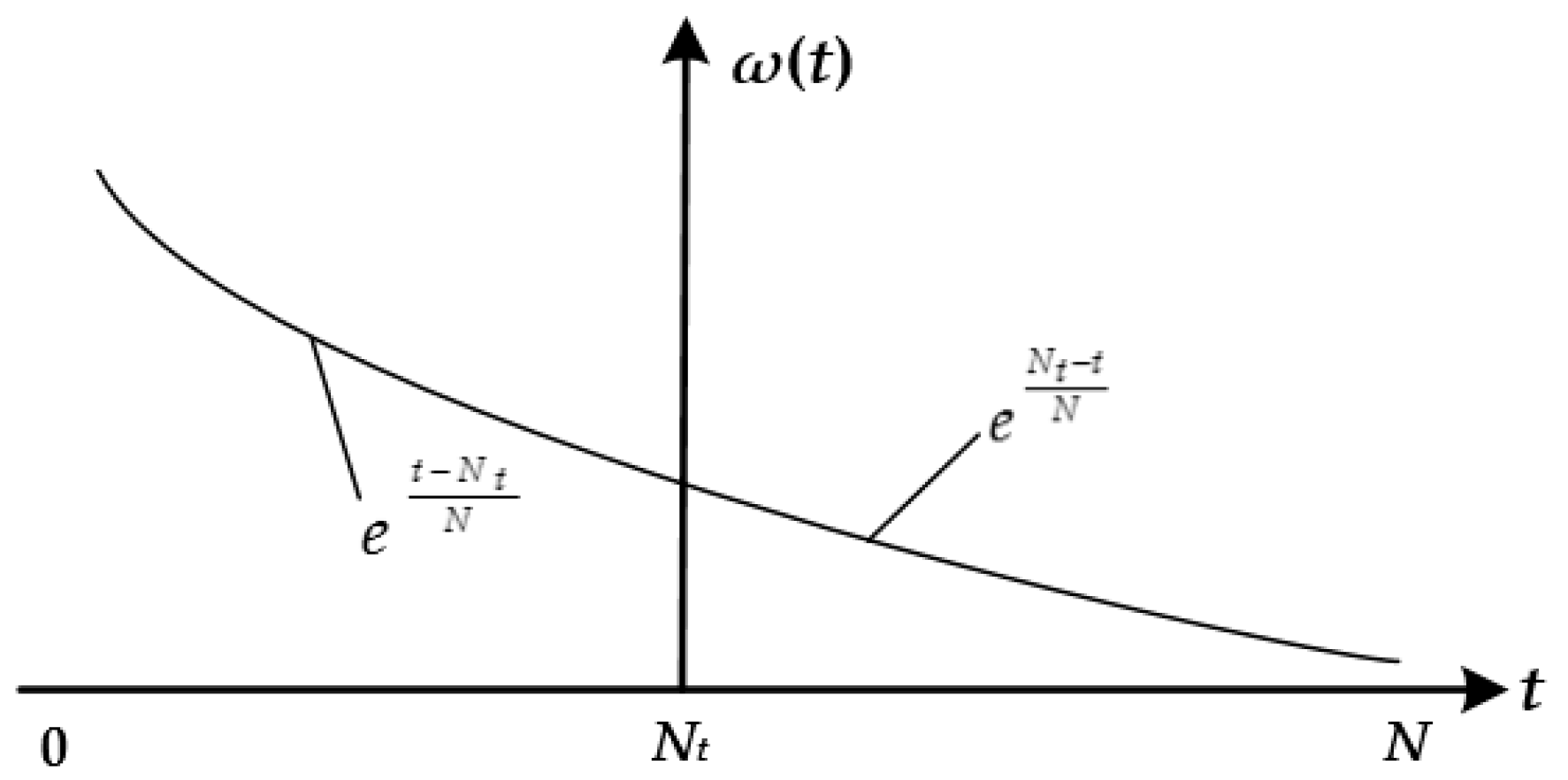

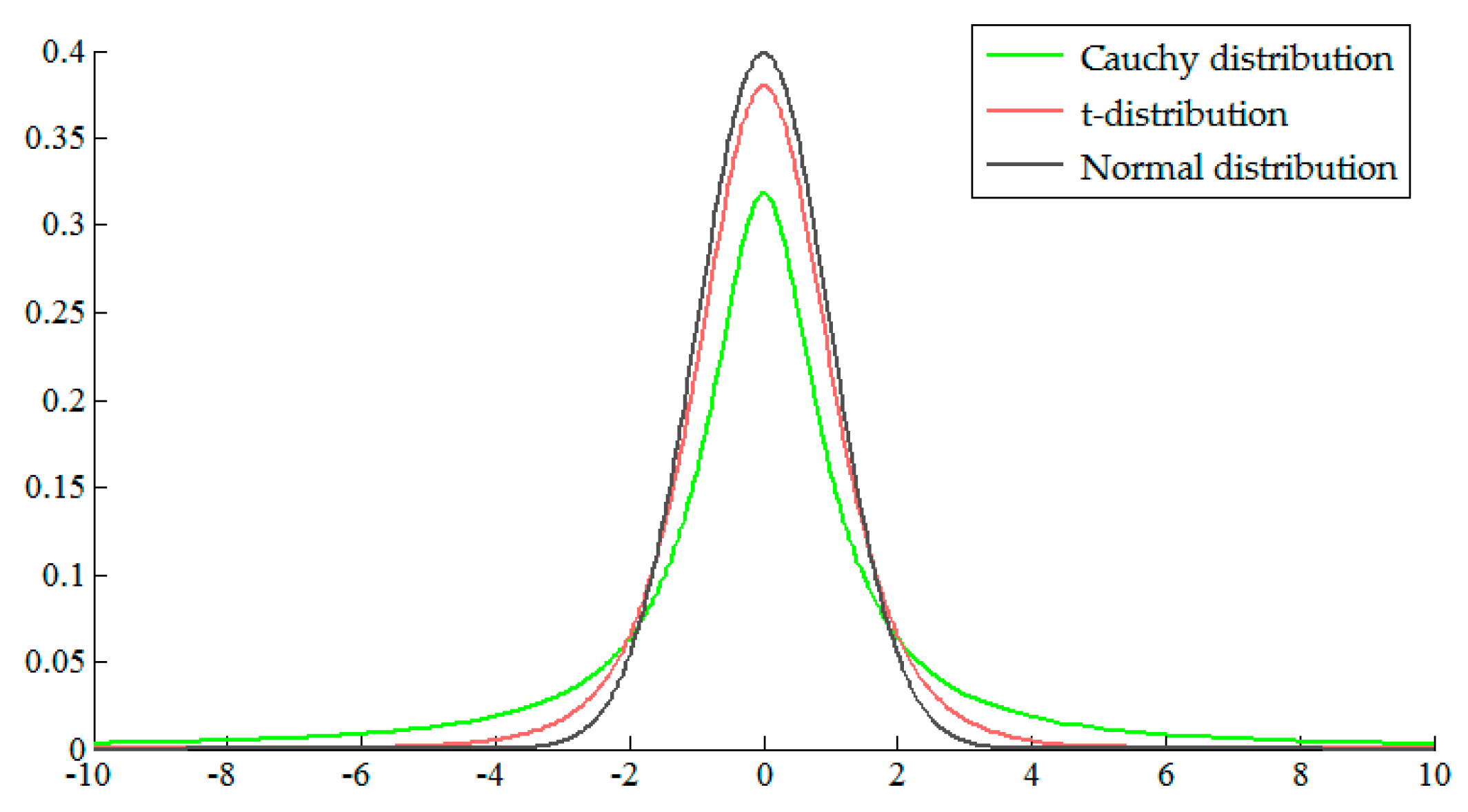

3.1. Improvement of BA

3.2. Design of the Fitness Function

3.3. Flowchart of Optimization Method for Horizontal Bending Angle

4. Simulation and Analysis

4.1. Parameter Information Acquisition

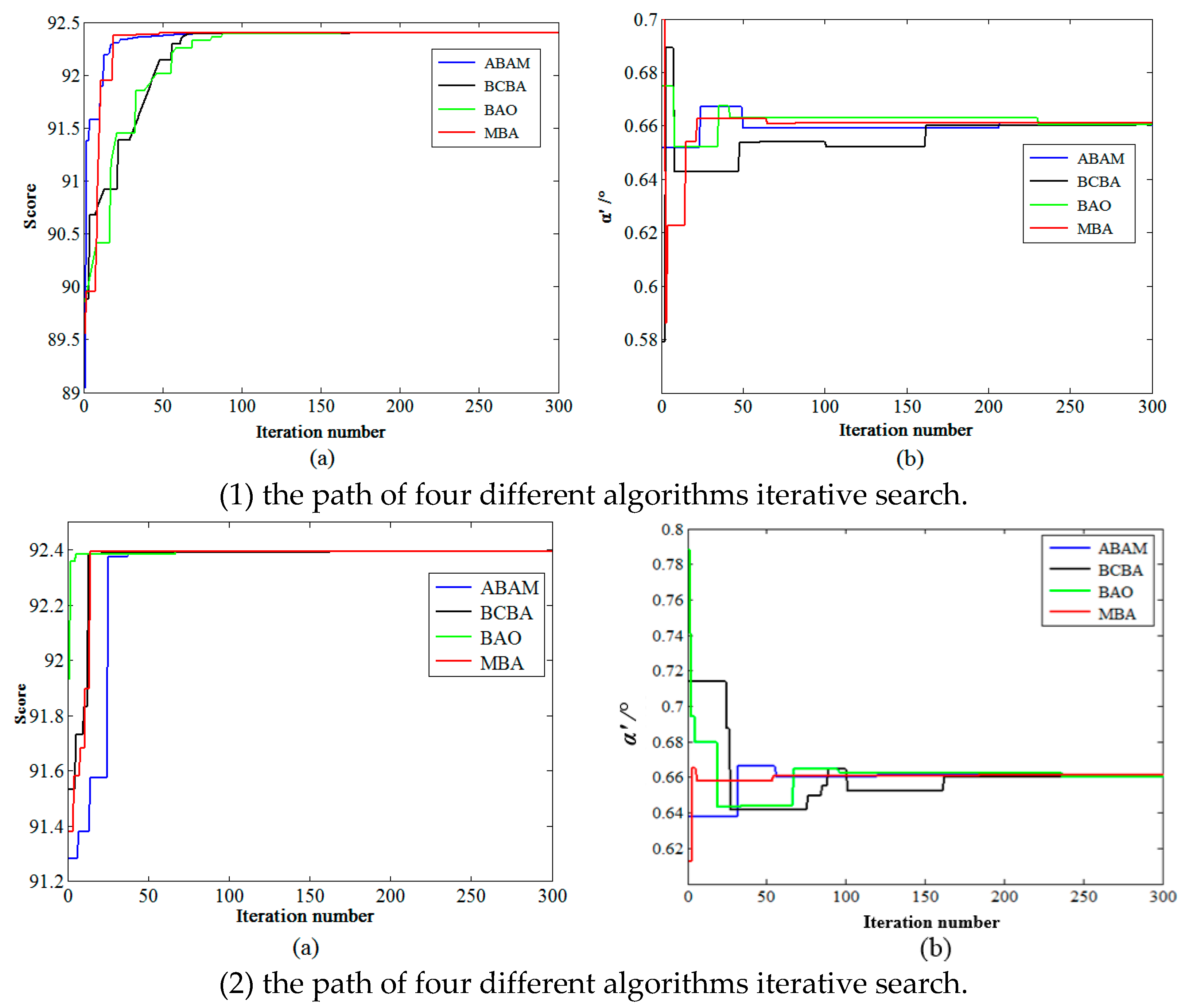

4.2. Horizontal Bending Angle Optimization Effect Analysis

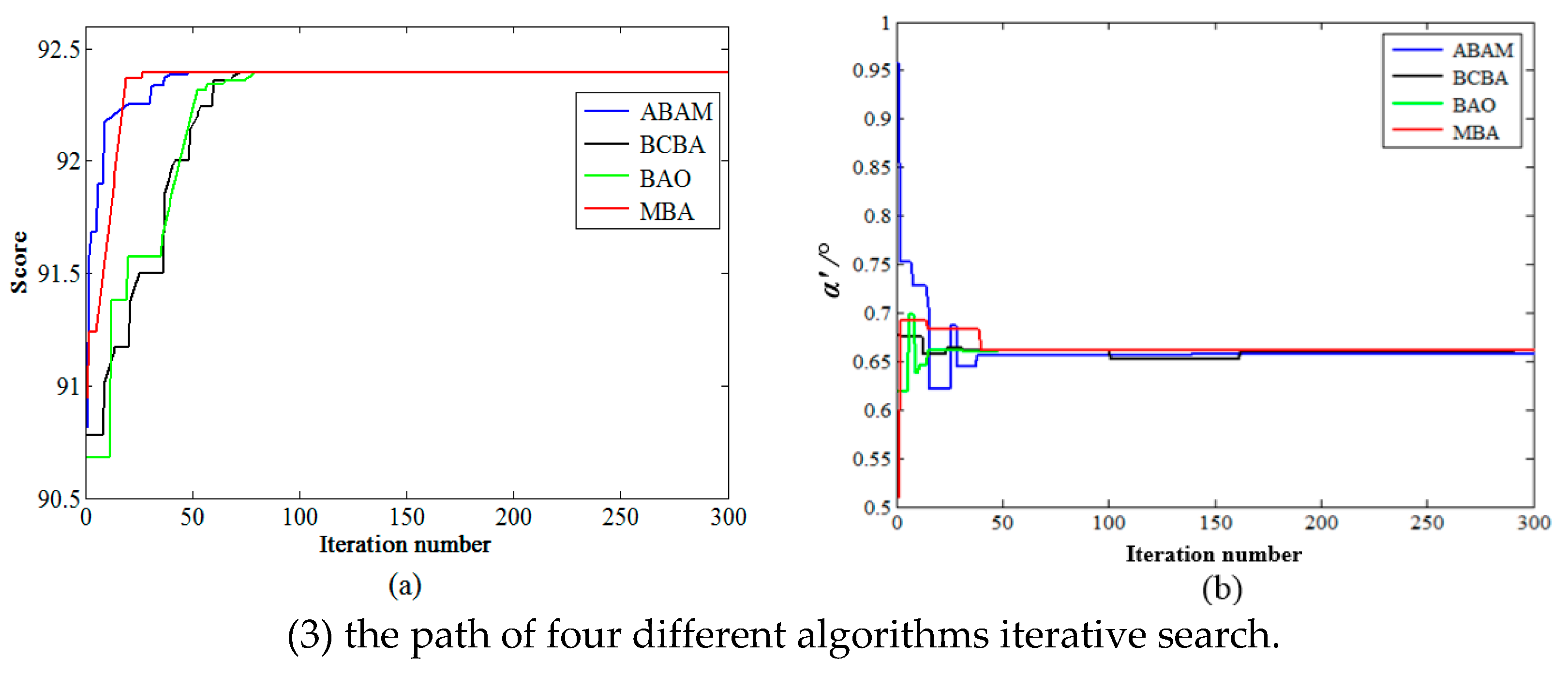

4.3. Comparison and Discussion

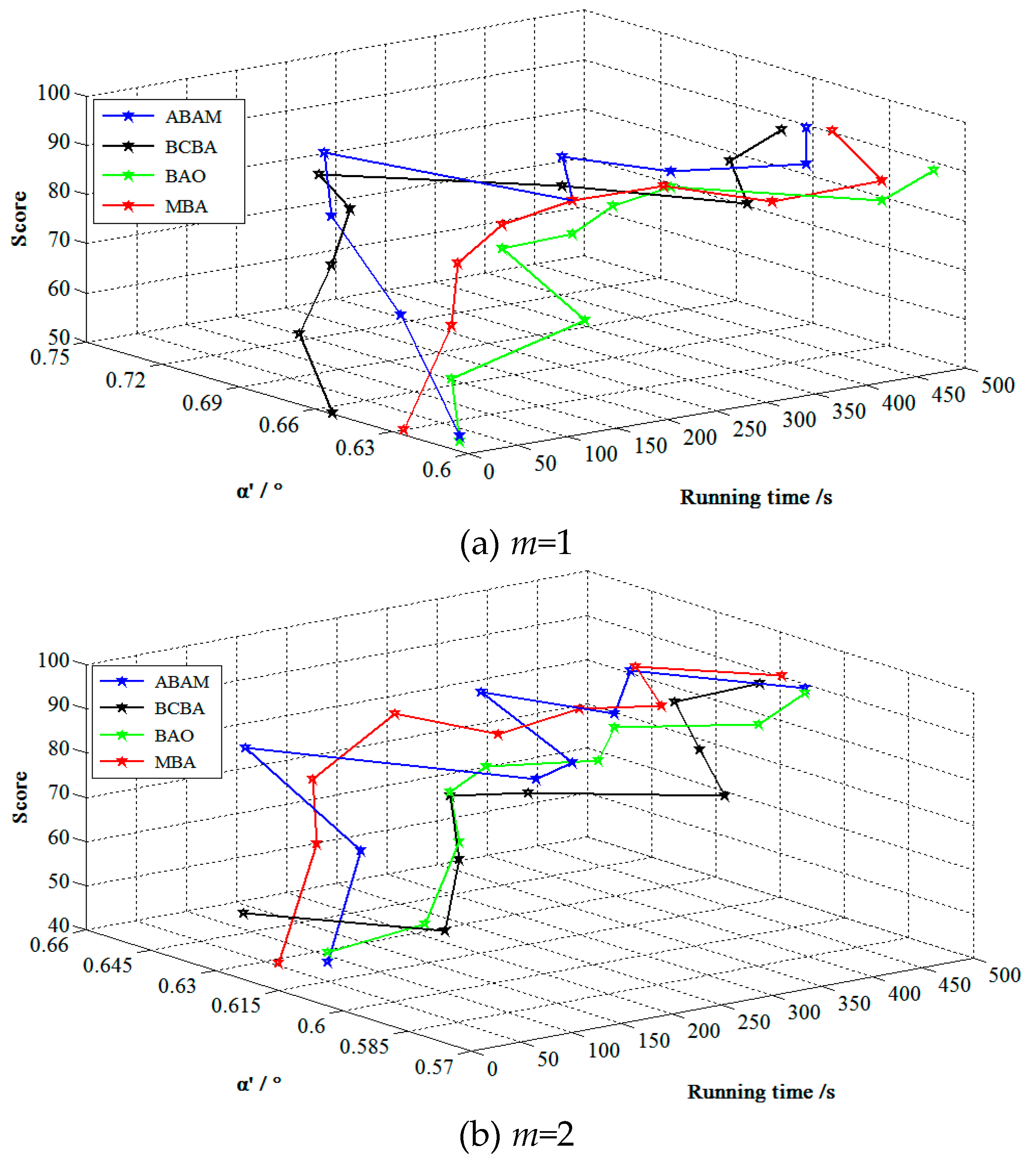

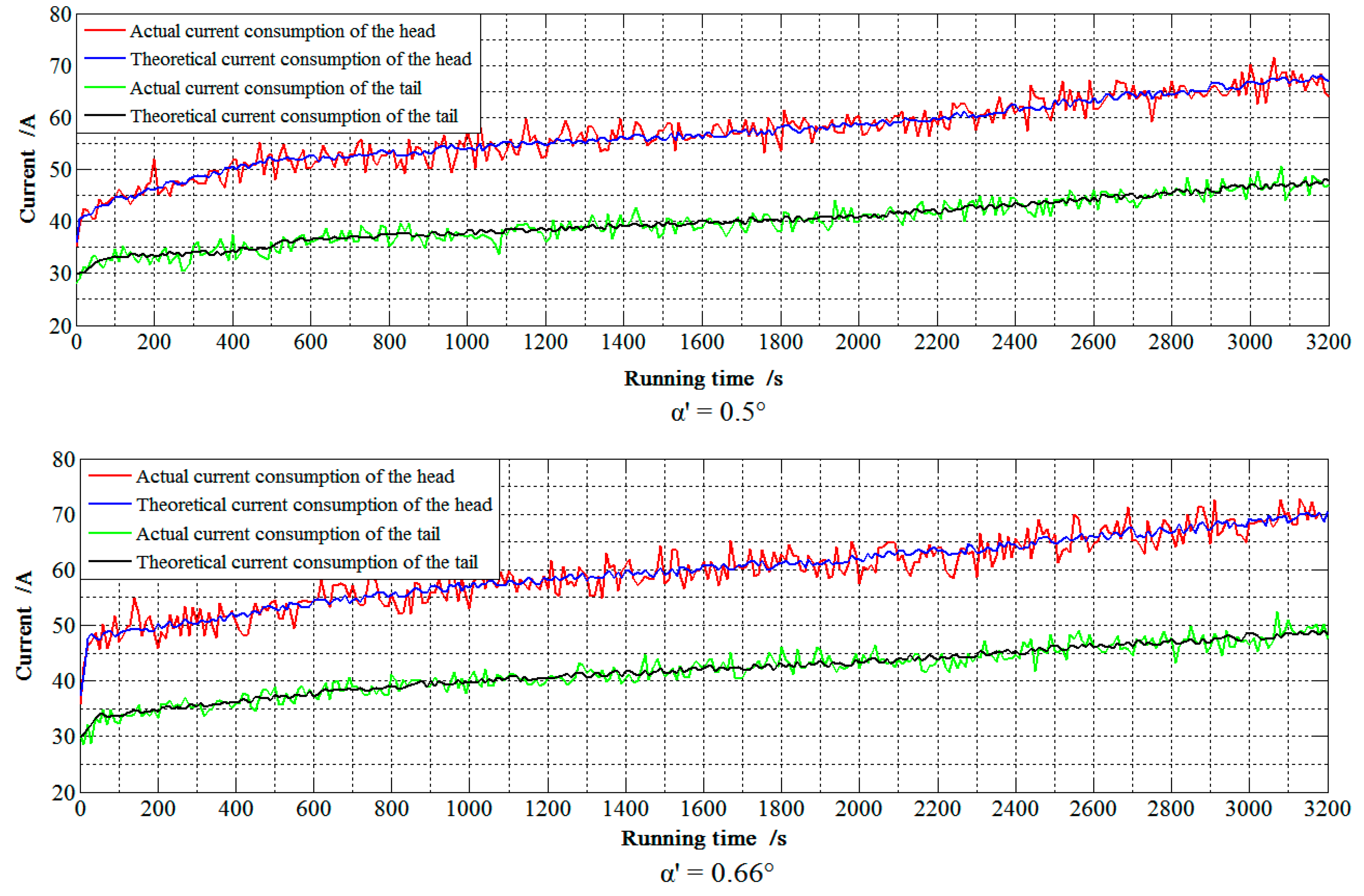

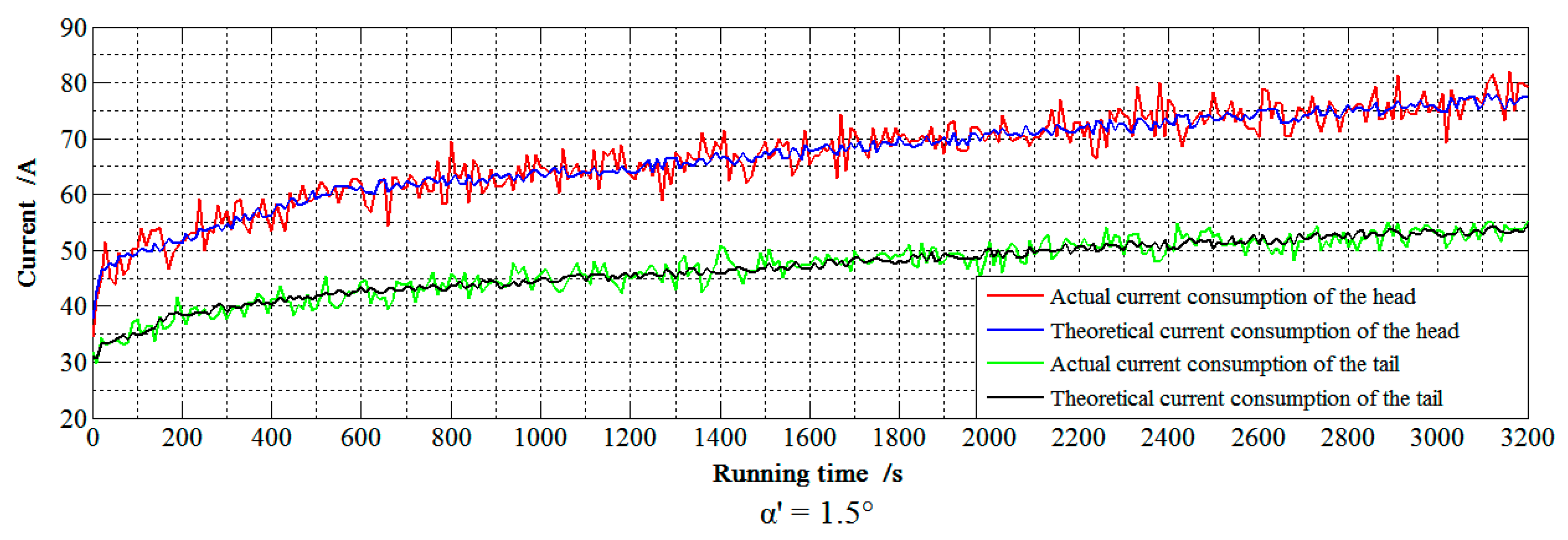

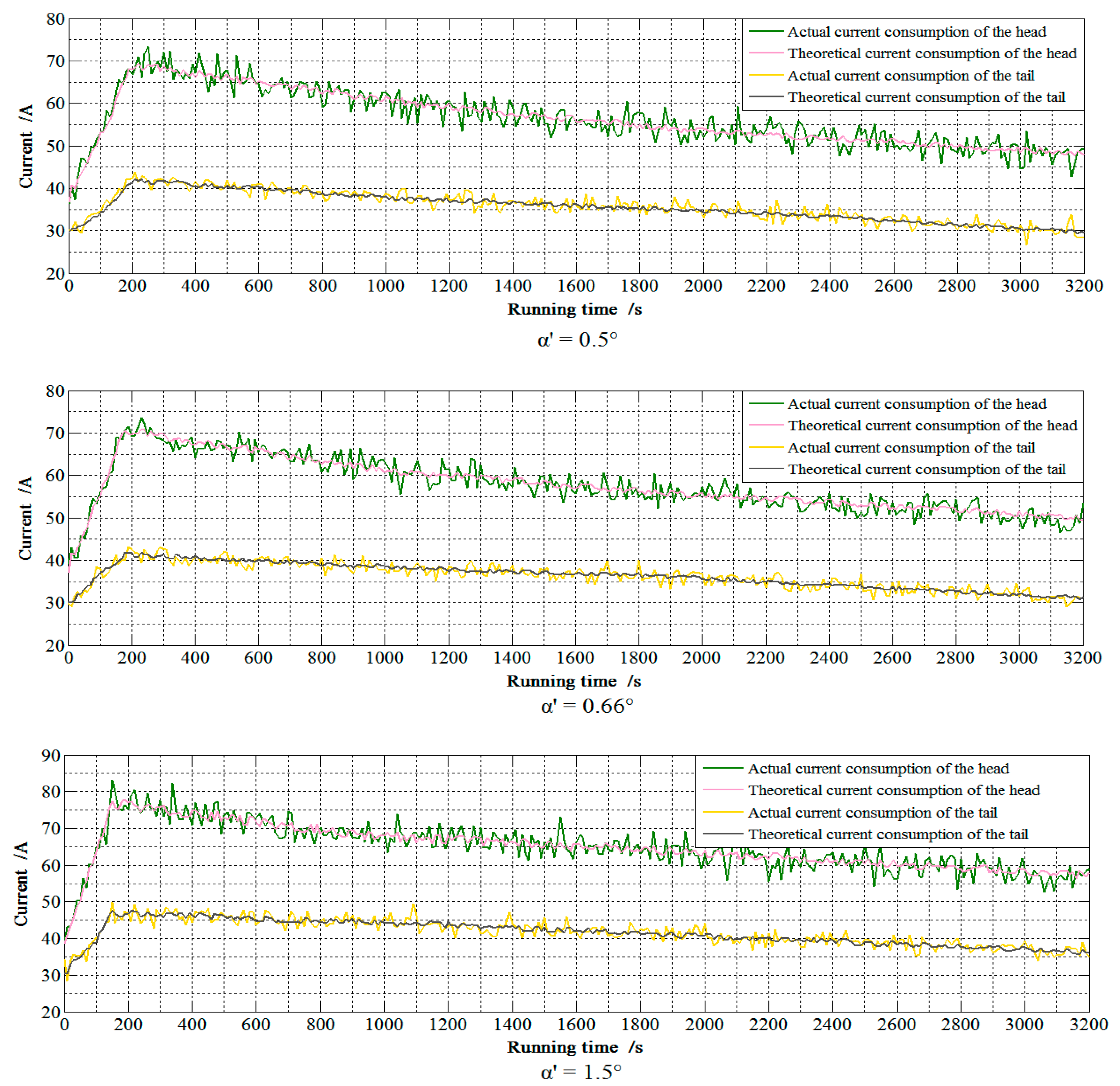

5. Experiment and Application

6. Conclusions and Future Work

- The current consumption and running resistance of three different α′ cases were compared. The results show that the average absolute error rate of theoretical calculation and measured current value was 3%. The correctness of the mathematical model was verified.

- The improved bat algorithm (MBA) had faster convergence speed and higher accuracy than AMBA, BCBA, and BAO algorithms. MBA was superior in searching for optimal horizontal bending angles.

- When α′ = 0.66° was compared with the usual bending angle, not only the current consumption and the cost per ton of coal were reduced, but the MTBF was reduced by 50%. The correctness and feasibility of the simulation results were verified by industrial application.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Shen, B.H.; Guo, Y.H. Development Status and Tendency of Technology and Equipment for Fully Mechanized Coal Mining in China. Coal Sci. Technol. 2012, 40, 1–3. [Google Scholar]

- Wang, X.W.; Wang, S.P.; Long, R.S.; Yang, Z.J.; Liu, G.P. Rigid-flexible coupled dynamic contact analysis for a chains drive system of a heavy scraper conveyer during loading start-up. J. Vib. Shock 2016, 35, 34–40. [Google Scholar]

- Ordin, A.A.; Metel’Kov, A.A. Analysis of longwall face output in screw-type cutter loader and scraper conveyor system in underground mining of flat-lying coal beds. J. Min. Sci. 2015, 51, 1173–1179. [Google Scholar] [CrossRef]

- Zhang, L. Research on Key Technologies of Autonomous Following Mining Machine for Hydraulic Support. Ph.D. Thesis, China University of Mining and Technology, Xuzhou, China, 2017. [Google Scholar]

- Crawford, K.S.; Epperly, R.A.; Murphy, H.G.; Saunders, L.A. Applying Adjustable Frequency Controllers to High-Starting-Torque Loads. In Proceedings of the Petroleum and Chemical Industry Conference, St. Louis, MO, USA, 13–15 September 1993; pp. 89–100. [Google Scholar]

- Murphy, C.J.; Bliss, R.E. Method and Apparatus for Belt Conveyor Load Tracking. U.S. Patent 5,335,777, 9 August 1994. [Google Scholar]

- Dolipski, M.; Remiorz, E.; Sobota, P. Dynamics of Non-Uniformity Loads of AFC Drives. Arch. Min. Sci. 2014, 59, 155–168. [Google Scholar] [CrossRef]

- Wang, K. Research on Shearer Speed Control Technology Based on Scraper Conveyor Load Prediction. Master’s Thesis, China University of Mining and Technology, Xuzhou, China, 2015. [Google Scholar]

- Morley, L.A.; Kohler, J.L.; Smolnikar, H.M. A model for predicting motor load for an armored face-conveyor drive. IEEE Trans. Ind. Technol. 1988, 24, 649–659. [Google Scholar] [CrossRef]

- Swider, J.; Herbus, K.; Szewerda, K. Dynamic analysis of scraper conveyor operation with external loads. In Proceedings of the 4th International Conference on Computing and Solutions in Manufacturing Engineering 2016—CoSME’16, Braşov, Romania, 3–4 November 2016; pp. 1–6. [Google Scholar]

- Dolipski, M.; Cheluszka, P.; Remiorz, E.; Sobota, P. Follow-Up Chain Tension in an Armoured Face Conveyor/Nadążne Napinanie Łańcucha Zgrzebłowego W Przenośniku Ścianowym. Arch. Min. Sci. 2015, 60, 25–38. [Google Scholar] [CrossRef]

- Sdvyzhkova, O.; Patyńska, R. Effect of increasing mining rate on longwall coal mining—Western donbass case study. Stud. Geotech. Mech. 2016, 38, 91–98. [Google Scholar] [CrossRef]

- Krawczyk, J.; Pawlowski, B. The Analysis of the Tribological Properties of the Armoured Face Conveyor Chain Race. Arch. Min. Sci. 2013, 58, 1251–1262. [Google Scholar]

- Broadfoot, A.R.; Betz, R.E. Power requirement prediction for armoured face conveyors. Min. Technol. 2014, 109, 93–101. [Google Scholar] [CrossRef]

- Shi, Z.; Zhu, Z. Case study: Wear analysis of the middle plate of a heavy-load scraper conveyor chute under a range of operating conditions. Wear 2017, 380, 36–41. [Google Scholar] [CrossRef]

- Liu, K.M. The Mechanical Study of Scraper Conveyor. Master’s Thesis, Hebei University of Technology, Tianjin, China, 2005. [Google Scholar]

- Jiao, H.Z.; Yang, Z.J.; Wang, S.P. Contact dynamics simulation analysis for sprocket transmission system of scraper conveyor. J. China Coal Soc. 2012, 37, 494–498. [Google Scholar]

- Yang, X.S. A New Metaheuristic Bat-Inspired Algorithm. Comput. Knowl. Technol. 2010, 284, 65–74. [Google Scholar]

- Yang, X.; Ah, G. Bat algorithm: A novel approach for global engineering optimization. Eng. Comput. 2012, 29, 464–483. [Google Scholar] [CrossRef]

- Altringham, J.D.; Mcowat, T.; Hammond, L. Bats: Biology and behaviour. Q. Rev. Biol. 1998, 78, 43–57. [Google Scholar]

- Chen, M.; Feng, J.; Li, Z.; Zhou, J.; Zhao, H.; Zhang, S.; Sheng, L. Echolocation sound waves, morphological features and foraging strategies in Hipposideros pratti. Chin. J. Appl. Ecol. 2002, 13, 1629–1632. [Google Scholar]

- Heraguemi, K.E.; Kamel, N.; Drias, H. Multi-swarm bat algorithm for association rule mining using multiple cooperative strategies. Appl. Intell. 2016, 45, 1–13. [Google Scholar] [CrossRef]

- Hafezi, R.; Shahrabi, J.; Hadavandi, E. A bat-neural network multi-agent system (BNNMAS) for stock price prediction: Case study of DAX stock price. Appl. Soft Comput. J. 2015, 29, 196–210. [Google Scholar] [CrossRef]

- Bento, P.M.R.; Pombo, J.A.N.; Calado, M.R.A.; Mariano, S.J.P.S. A bat optimized neural network and wavelet transform approach for short-term price forecasting. Appl. Energy 2018, 210, 88–97. [Google Scholar] [CrossRef]

- Furmanik, K.; Pracik, M. Method for evaluation of movement resistance in scraper pipe conveyors. Proc. Appl. Math. Mech. 2010, 7, 4130043–4130044. [Google Scholar] [CrossRef]

- Mao, J.; Cao, H.; Xie, M. Load characteristic analysis and simulation of scraper conveyor under stable operation. J. Liaoning Technol. Univ. 2017, 36, 1298–1302. [Google Scholar]

- Nie, R.; He, B.Y.; Yuan, P.; Zhang, L.; Li, G. Novel approach to and implementation of design and analysis of armored face conveyor power train. Sci. China Technol. Sci. 2015, 58, 2153–2168. [Google Scholar] [CrossRef]

- Yu, Y.D. Calculation of additional resistance of curved conveyor chain of scraper conveyor. J. Hunan Univ. Sci. Technol. 1995, 2, 38–42. [Google Scholar]

- Euler, L. Leonhard Euler and the Koenigsberg Bridges. Sci. Am. 1953, 189, 66–70. [Google Scholar] [CrossRef]

- Wang, C.J.; An, J.S.; Wu, X.G.; Liu, D.Y.; Zheng, Y.Z. Research and Application of Tighting Chain Device for 40T Scraper Conveyor. Colliery Mech. Electron. Technol. 2013, 767, 141–147. [Google Scholar]

- Xie, J.C.; Yang, Z.J.; Wang, X.W.; Wang, S.P.; Zhang, Q. Cooperative solving method of chute postures in the bending section of a scraper conveyor. Adv. Mech. Eng. 2018, 10, 1687814018767684. [Google Scholar] [CrossRef]

- Liao, H.Q.; Qiu, Y.; Yang, X. A Study of Weight Coefficient Method Based on AHP. Mech. Eng. 2012, 6, 22–25. [Google Scholar]

- Goyal, S.; Patterh, M.S. Modified Bat Algorithm for Localization of Wireless Sensor Network. Wirel. Pers. Commun. 2016, 86, 657–670. [Google Scholar] [CrossRef]

- Wang, C.F.; Song, W.X.; Liu, L.X. An adaptive bat algorithm with memory for global optimization. IAENG Int. J. Comput. Sci. 2018, 45, 320–327. [Google Scholar]

- Wang, Y.P. Research on Key Technology of Scraper Conveyor and Shearer Coordinated Speed Control. Master’s Thesis, China University of Mining and Technology, Xuzhou, China, 2016. [Google Scholar]

| Operating System | Windows 7 (64 bits) |

|---|---|

| CPU | Intel(R) i5-4590 (4 cores, 3.3 GHz) |

| Memory | 8 GB (DDR3) |

| Matlab version | 8.3 |

| Hard disk space | SSD (465 GB) |

| Object | Technical Parameters | Value |

|---|---|---|

| Working face | Length (m) | 270 |

| Shearer (MG300/730-WD2) | Height (m) | 2 |

| Cut depth (m) | 0.63 | |

| Haulage speed (m/min) | 4.5 | |

| Scraper conveyor (SGZ800/800) | Chain speed (m/s) | 1.31 |

| Motor | YBSD-400/200-4/8GX3 | |

| Transportation volume (t/h) | 1500 | |

| Middle slot (mm) | 1503 × 800 × 308 | |

| Scraper spacing (mm) | 1008 |

| Serial Number | 1 | 2 | 3 | |

|---|---|---|---|---|

| Compared Methods | ||||

| MBA | Sscore_max | 92.396 | 92.396 | 92.396 |

| Mean (°) | 0.660 | 0.660 | 0.664 | |

| SD (%) | 1.0 | 0.6 | 0.7 | |

| ABAM | Sscore_max | 92.395 | 92.394 | 92.396 |

| Mean (°) | 0.657 | 0.659 | 0.661 | |

| SD (%) | 2.0 | 2.5 | 1.8 | |

| BCBA | Sscore_max | 92.396 | 92.395 | 92.396 |

| Mean (°) | 0.650 | 0.660 | 0.657 | |

| SD (%) | 3.0 | 2.7 | 1.9 | |

| BAO | Sscore_max | 92.394 | 92.395 | 92.396 |

| Mean (°) | 0.640 | 0.664 | 0.662 | |

| SD (%) | 3.2 | 3.3 | 1.9 |

| α′ | 0.5° | 0.66° | 1.5° | ||||

|---|---|---|---|---|---|---|---|

| m | Head | Tail | Head | Tail | Head | Tail | |

| 1 | 2.49% | 2.40% | 2.45% | 2.11% | 3.38% | 2.96% | |

| 2 | 3.59% | 2.56% | 2.66% | 2.34% | 2.67% | 2.63% | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, T.; Tan, C.; Wang, Z.; Xu, J.; Man, Y.; Wang, T. Horizontal Bending Angle Optimization Method for Scraper Conveyor Based on Improved Bat Algorithm. Algorithms 2019, 12, 84. https://doi.org/10.3390/a12040084

Liu T, Tan C, Wang Z, Xu J, Man Y, Wang T. Horizontal Bending Angle Optimization Method for Scraper Conveyor Based on Improved Bat Algorithm. Algorithms. 2019; 12(4):84. https://doi.org/10.3390/a12040084

Chicago/Turabian StyleLiu, Ting, Chao Tan, Zhongbin Wang, Jing Xu, Yiqiao Man, and Tuo Wang. 2019. "Horizontal Bending Angle Optimization Method for Scraper Conveyor Based on Improved Bat Algorithm" Algorithms 12, no. 4: 84. https://doi.org/10.3390/a12040084

APA StyleLiu, T., Tan, C., Wang, Z., Xu, J., Man, Y., & Wang, T. (2019). Horizontal Bending Angle Optimization Method for Scraper Conveyor Based on Improved Bat Algorithm. Algorithms, 12(4), 84. https://doi.org/10.3390/a12040084