Fatigue Property of Open-Hole Steel Plates Influenced by Bolted Clamp-up and Hole Fabrication Methods

Abstract

:1. Introduction

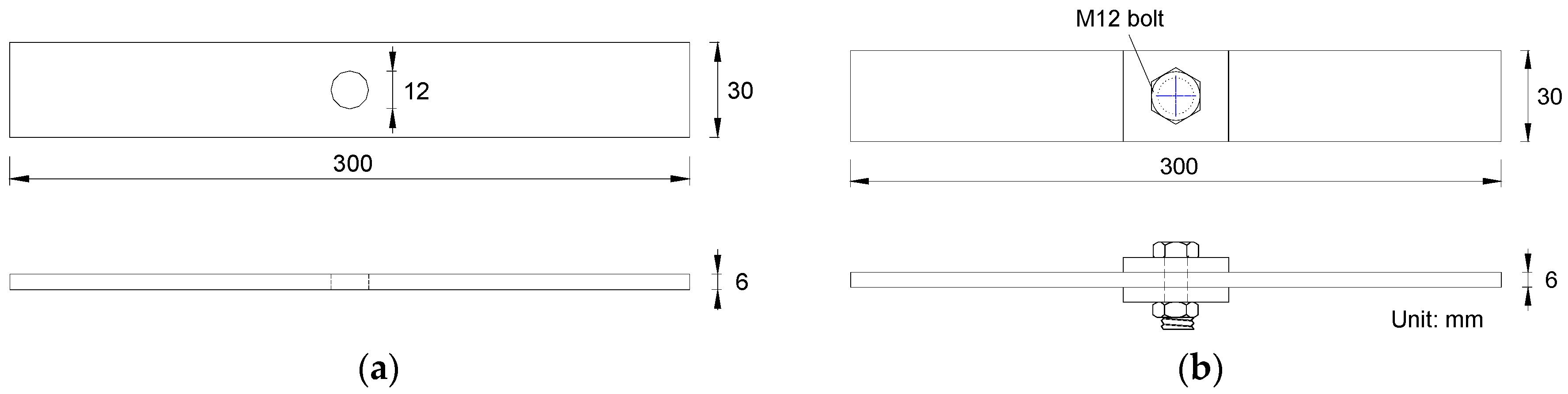

2. Material and Fatigue Test Procedures

3. Experimental Test Results

3.1. Fracture Surface Observation

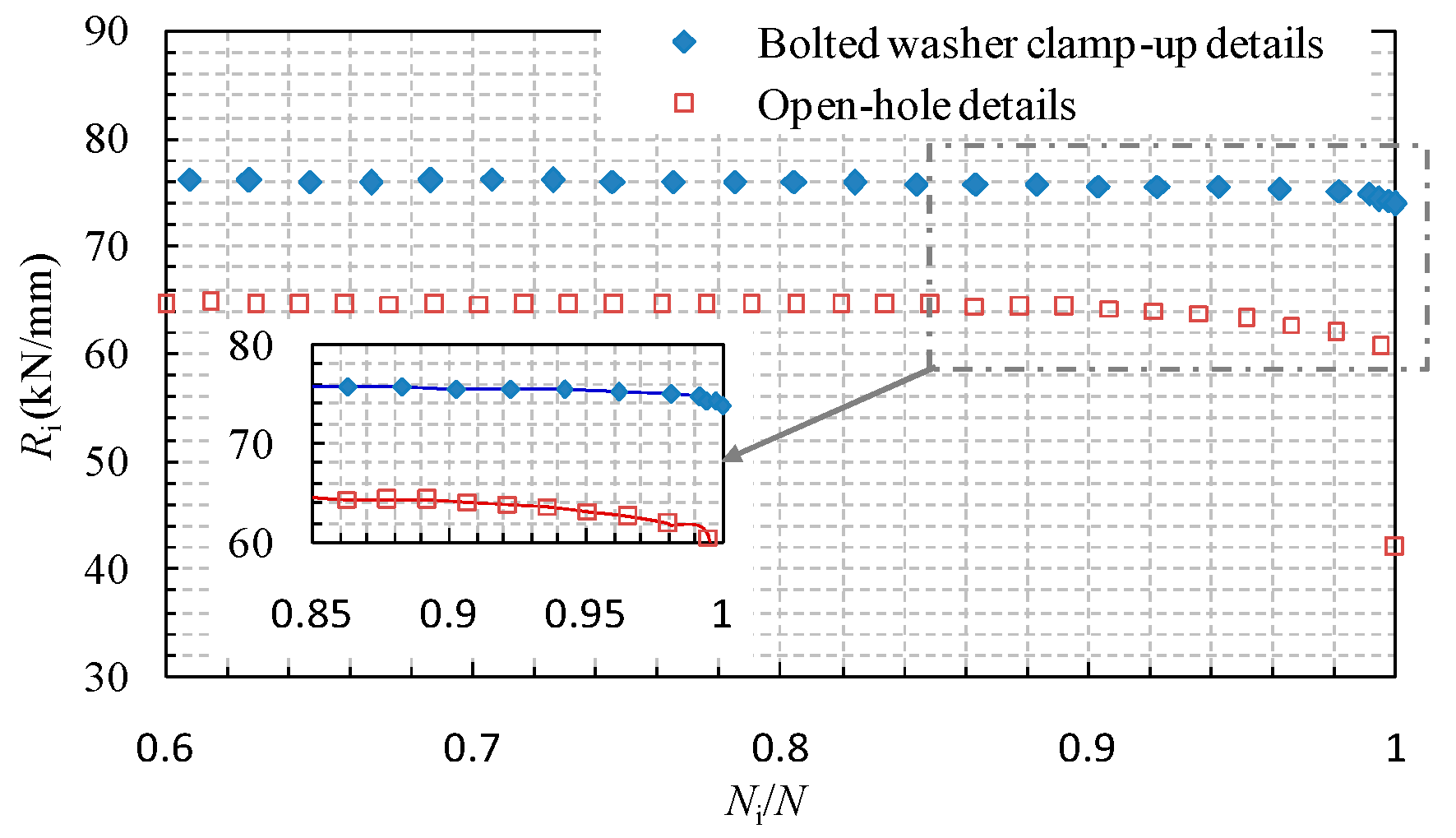

3.2. Stiffness Degradation Behaviour and Damage Progress

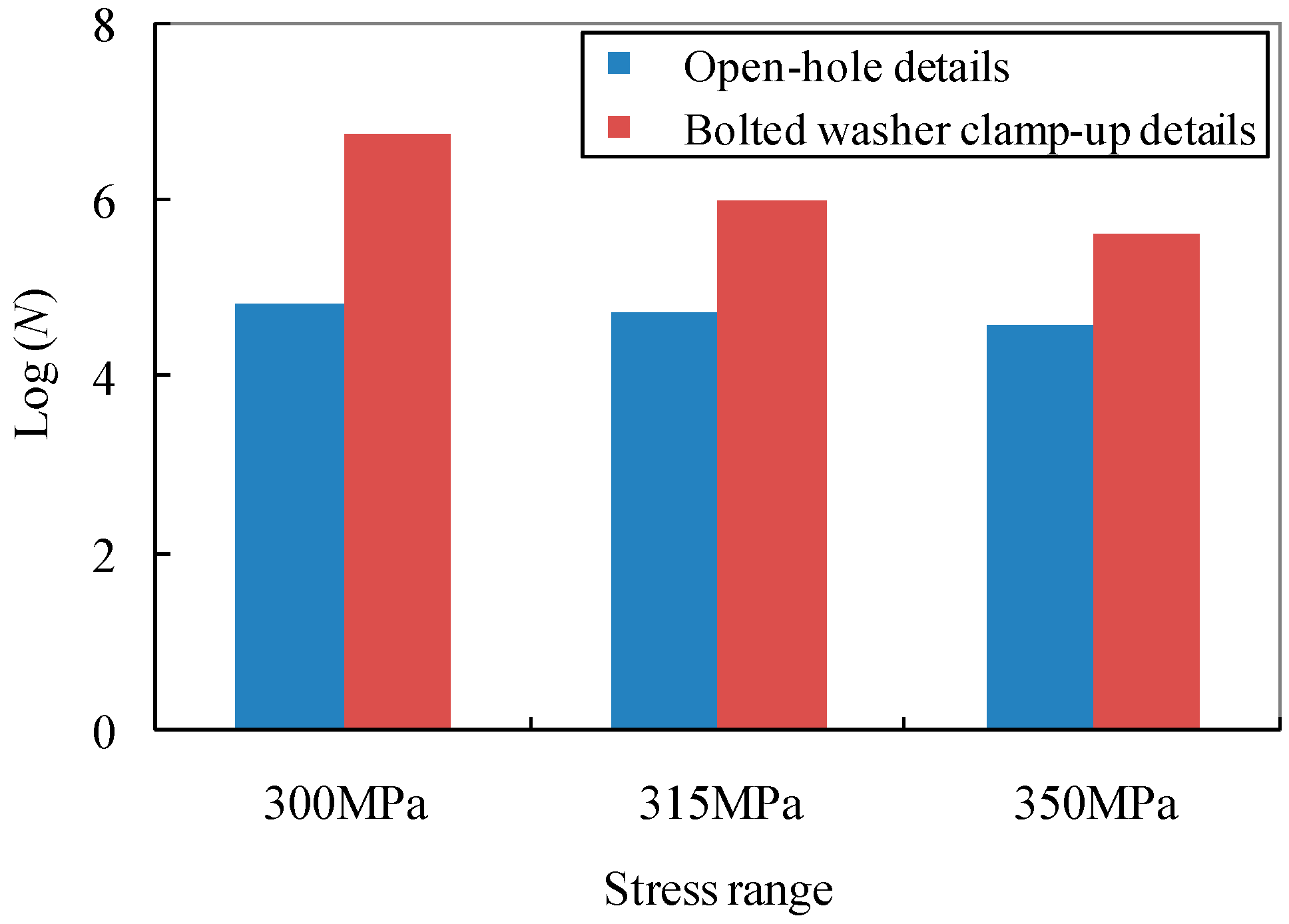

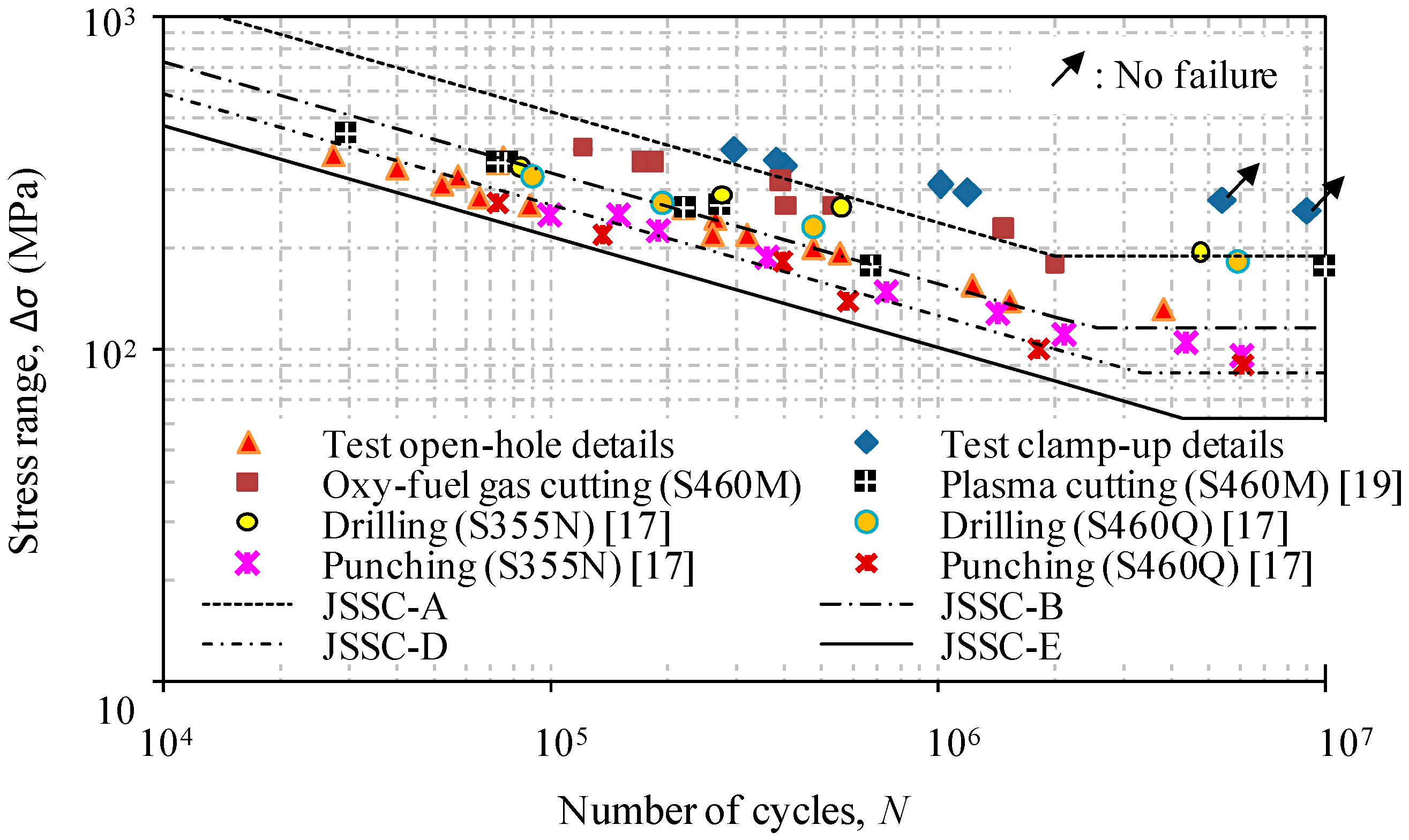

3.3. Fatigue Life Results and Analysis

- (i)

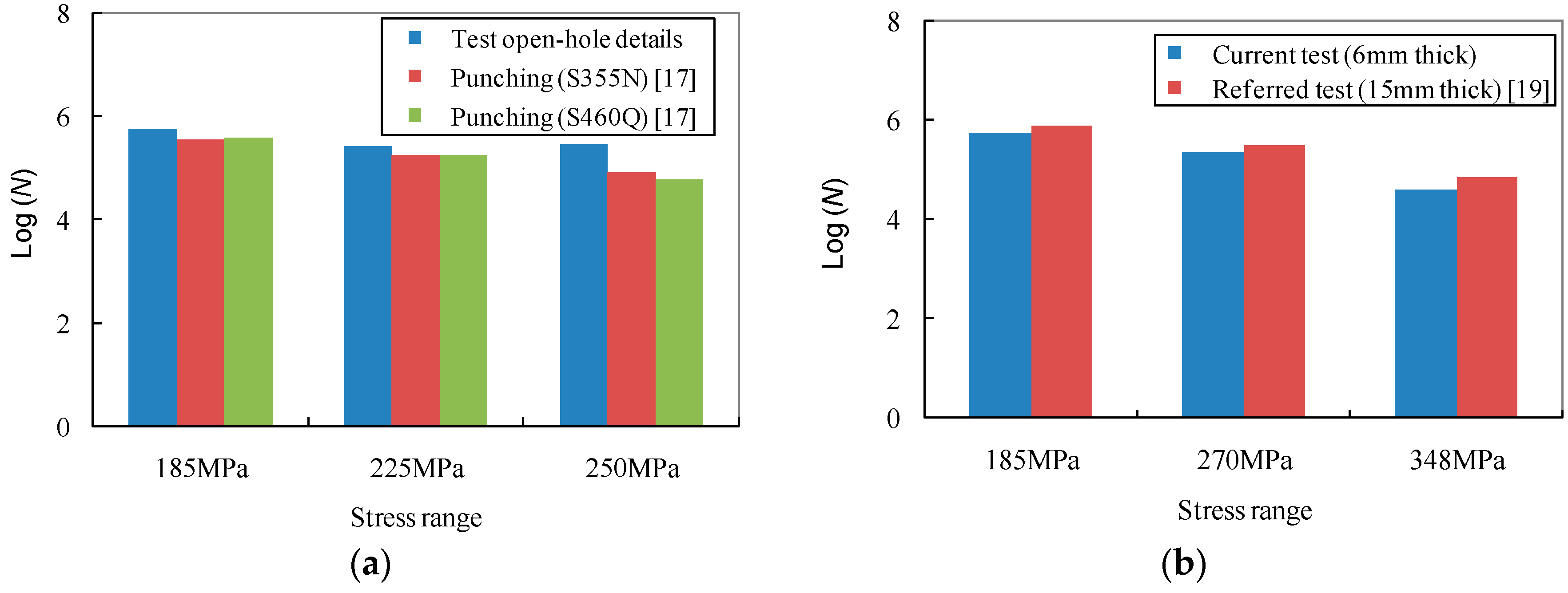

- For the specimens with open-hole details:

- (ii)

- For the specimens with bolted washer clamp-up details:

4. Discussion

5. Conclusions

- The fatigue crack of test specimens mostly initiated not only at the edge of the hole but also in the vicinity of the middle thickness of the steel plate with the presence of predominant draglines within the thickness for the laser-cut hole.

- The open-hole plate using laser cutting exhibits notable stiffness degradation in its appearing cycle and magnitude. This trend seems to be reduced to some extent when the bolted clamp-up details are introduced.

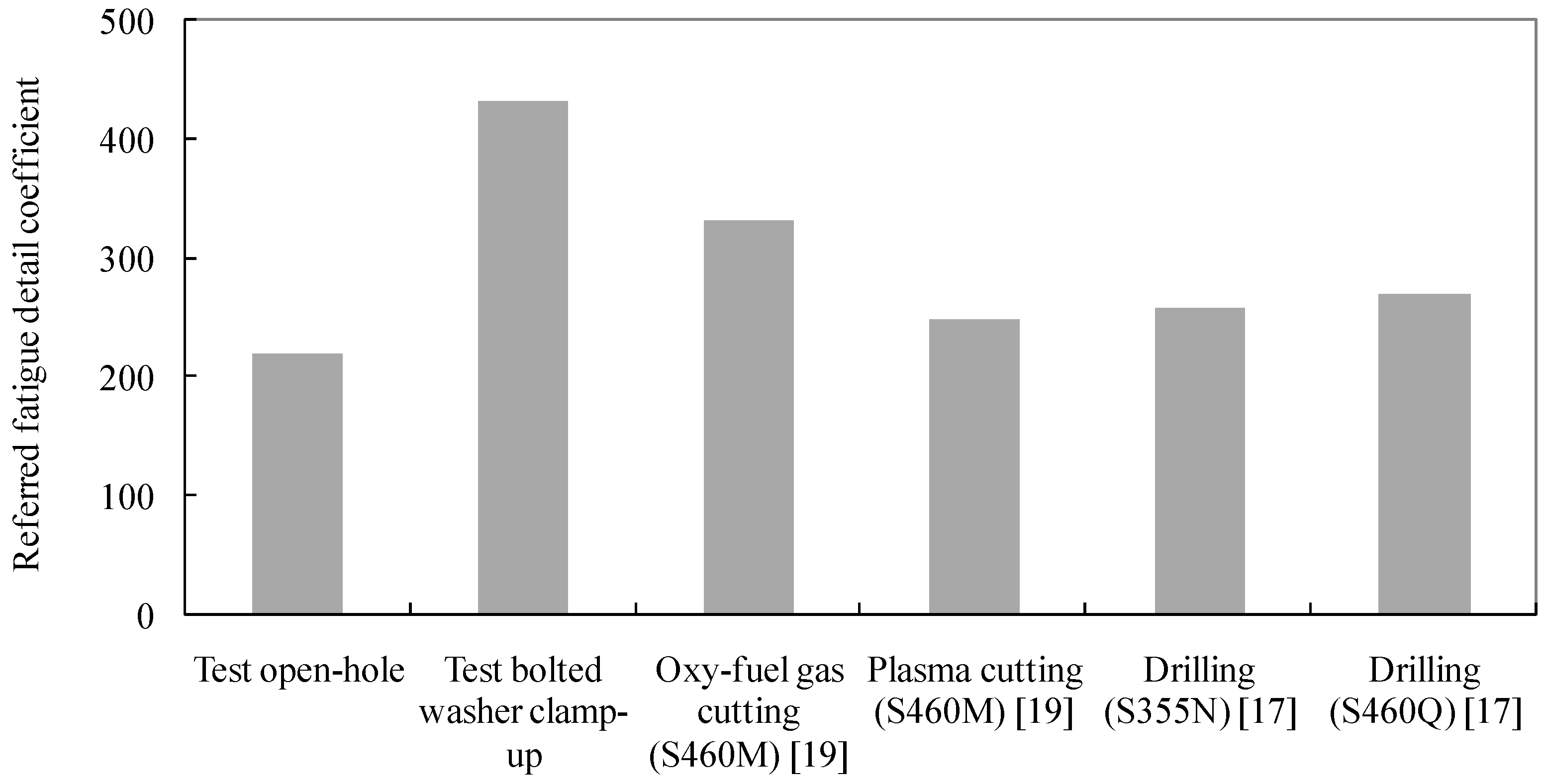

- The bolted clamp-up details greatly enhance the fatigue life of the open-hole plate from category E to approaching category A as codified in JSSC, from category B’ to approaching category A as codified in AASHTO, and from category 100 to approaching category 160 as codified in Eurocode.

- The fatigue life of open-hole details with laser cutting is greater than that with punched holes but lower than those with plasma cutting, drilling and oxy-fuel gas cutting. The introduction of bolted clamp-up details can be used to compensate for the laser cutting holes when a lower fatigue detail coefficient is concerned.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Wang, Z.Y.; Zhang, N.; Wang, Q.Y. Tensile behaviour of open-hole and bolted steel plates reinforced by CFRP strips. Compos. Part B 2016, 100, 101–113. [Google Scholar] [CrossRef]

- Wang, Z.Y.; Wang, Q.Y. Fatigue strength strengthened welded joints with corrugated steel plates. Compos. Part B 2015, 72, 30–39. [Google Scholar] [CrossRef]

- Chesson, J.E.; Munse, W.H. Riveted and bolted joints: Truss-type tensile connections. J. Struct. Eng. 1963, 89, 67–107. [Google Scholar]

- Frank, K.H. Influence of Hole Making Process upon the Tensile Strength of Steel Plates; TxDOT Research Publications: Washington, USA, 2002; Volume 5, pp. 1–9. [Google Scholar]

- Rassati, G.A.; Swanson, J.A.; Yuan, Q. Investigation of Hole Making Practices in the Fabrication of Structural Steel; AISC: Cincinnati, OH, USA, 2004. [Google Scholar]

- American Association of State Highway and Transportation Officials (AASHTO). AASHTO LRFD Bridge Design Specifications, 3rd ed.; AASHTO: Washington, DC, USA, 2005. [Google Scholar]

- O’Higgins, R.M.; McCarthy, M.A.; McCarthy, C.T. Comparison of open-hole tension characteristics of high strength glass and carbon bre-reinforced composite materials. Compos. Sci. Technol. 2008, 68, 2770–2778. [Google Scholar] [CrossRef]

- Dano, M.L.; Kamal, E.; Gendron, G. Analysis of bolted joints in composite laminates: Strains and bearing stiffness predictions. Compos. Struct. 2007, 79, 562–570. [Google Scholar] [CrossRef]

- Hallett, S.R.; Green, B.G.; Jiang, W.G.; Wisnom, M.R. An experimental and numerical investigation into the damage mechanisms in notched composites. Compos. Part A 2009, 40, 613–624. [Google Scholar] [CrossRef]

- Yun, J.H.; Choi, J.H.; Kweon, J.H. A study on the strength improvement of the multi-bolted joint. Compos. Struct. 2014, 108, 409–416. [Google Scholar] [CrossRef]

- Gamdani, F.; Boukhili, R.; Vadean, A. Tensile strength of open-hole, pin-loaded and multi-bolted single-lap joints in woven composite plates. Mater. Des. 2015, 88, 702–712. [Google Scholar] [CrossRef]

- Standard Test Method for Open-Hole Tensile Strength of Polymer Matrix Composite Laminates; ASTM-D5766/D5766M-11; ASTM International: West Conshohocken, PA, USA, 2011.

- Dubey, A.K.; Yadava, V. Laser beam machining-a review. Int. J. Mach. Tools Manuf. 2008, 48, 609–628. [Google Scholar] [CrossRef]

- Rangari, V.K.; Jeelani, M.I.; Zhou, Y.; Jeelani, S. Fabrication and characterization of MWCNT/thermoplastic microsphere nanocom-posite foams. Int. J. Nanos 2008, 7, 161–169. [Google Scholar] [CrossRef]

- Yilbas, B.S.; Akhtar, S.S.; Keles, O. Laser cutting of small diameter hole in aluminum foam. Int. J. Adv. Manuf. Technol. 2015, 79, 101–111. [Google Scholar] [CrossRef]

- Alegre, J.M.; Aragon, A.; Gutierrez-Solana, F.A. Finite element simulation methodology of the fatigue behavior of punched and drilled plate components. Eng. Fail. Anal. 2004, 11, 737–750. [Google Scholar] [CrossRef]

- Sánchez, L.; Gutierrez-Solana, F.; Pesquera, D. Fatigue behaviour of punched structural plates. Eng. Fail. Anal. 2004, 11, 751–764. [Google Scholar] [CrossRef]

- Brown, J.D.; Lubitz, D.J.; Cekov, Y.C.; Frank, K.H.; Keating, P.B. Evaluation of Influence of Hole Making upon the Performance of Structural Steel Plates and Connections; Report No. 0-4624-1; Center for Transportation Research, The University of Texas at Austin: Austin, TX, USA, 2007. [Google Scholar]

- Garcia, T.; Cicero, S.; Alvarez, J.A.; Martín-Meizoso, A.; Bannister, A.; Klimpel, A.; Aldazabal, A. Fatigue performance of thermally cut bolt holes in structural steel S460M. Proc. Eng. 2015, 133, 590–602. [Google Scholar] [CrossRef]

- Cicero, S.; Garcia, T.; Alvarez, J.A.; Martín-Meizoso, A.; Aldazabal, A.; Bannister, A.; Klimpel, A. Definition and validation of Eurocode 3 FAT classes for structural steels containing oxy-fuel, plasma and laser cut holes. Int. J. Fatigue 2016, 87, 50–58. [Google Scholar] [CrossRef]

- Wang, Z.Y.; Wang, Q.Y. Yield and ultimate strengths determination of a blind bolted endplate connection to square hollow section column. Eng. Struct. 2016, 111, 345–369. [Google Scholar] [CrossRef]

- Metallic Materials-Fatigue Testing-Axial Force Controlled Method; GB/T 3075-2008; Standards Press of China: Beijing, China, 2009.

- Wang, Z.Y.; Wang, Q.Y.; Liu, Y.J. Evaluation of fatigue strength improvement by CFRP laminates and shotpeening onto the tension flanges joining corrugated steel webs. Materials 2015, 8, 5348–5362. [Google Scholar] [CrossRef]

- Jharkhand Staff Selection Commission (JSSC). JSSC Fatigue Design Recommendations for Steel Structures; Gihodo Shuppan: Tokyo, Japan, 1993. [Google Scholar]

- Wang, Z.Y.; Wang, Q.Y. Fatigue assessment of welds joining corrugated steel webs to flange plates. Eng. Struct. 2014, 73, 1–12. [Google Scholar] [CrossRef]

- Eurocode 3: Design of Steel Structures, Part 1-9; prEN 1993-1-8: 2005; CEN: Brussels, Belgium, 2005.

- Wirsching, P.H. Probabilistic fatigue analysis. In Probabilistic Structural Mechanics Handbook; Sundararajan, C., Ed.; Chapman and Hall: New York, NY, USA, 1995. [Google Scholar]

| Steel Grade | Chemical Composition (%) | Mechanical Properties | ||||||

|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | σy (MPa) | Es (MPa) | σu (MPa) | |

| Q345B | 0.17 | 0.25 | 1.15 | 0.015 | 0.014 | 388 | 2.1 × 105 | 553 |

| S355N [17] | 0.17 | 0.30 | 1.35 | 0.02 | 0.011 | 423 | 2.0 × 105 | 602 |

| S460Q [17] | 0.08 | 0.30 | 1.31 | 0.014 | 0.003 | 619 | 2.0 × 105 | 685 |

| S460M [19] | 0.12 | 0.45 | 1.49 | 0.012 | 0.001 | 484 | 2.05 × 105 | 594 |

| Categories/Relations | Standard Deviation | Log(C) | CAFL (MPa) |

|---|---|---|---|

| JSSC-A | - | 13.13 | 190 |

| JSSC-B | - | 12.87 | 155 |

| JSSC-D | - | 12.30 | 100 |

| JSSC-E | - | 12.01 | 80 |

| AASHTO-A | - | 12.91 | 165 |

| AASHTO-B | - | 12.59 | 110 |

| AASHTO-B’ | - | 12.30 | 82.7 |

| Eurocode 3-160 | - | 12.91 | 160 |

| Eurocode 3-112 | - | 12.45 | 112 |

| Eurocode 3-100 | - | 12.30 | 100 |

| Equation (4) | 0.11 | 12.45 | 112.11 |

| Equation (5) | 0.06 | 13.36 | 225.22 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.-Y.; Li, L.; Liu, Y.-J.; Wang, Q.-Y. Fatigue Property of Open-Hole Steel Plates Influenced by Bolted Clamp-up and Hole Fabrication Methods. Materials 2016, 9, 698. https://doi.org/10.3390/ma9080698

Wang Z-Y, Li L, Liu Y-J, Wang Q-Y. Fatigue Property of Open-Hole Steel Plates Influenced by Bolted Clamp-up and Hole Fabrication Methods. Materials. 2016; 9(8):698. https://doi.org/10.3390/ma9080698

Chicago/Turabian StyleWang, Zhi-Yu, Lihui Li, Yong-Jie Liu, and Qing-Yuan Wang. 2016. "Fatigue Property of Open-Hole Steel Plates Influenced by Bolted Clamp-up and Hole Fabrication Methods" Materials 9, no. 8: 698. https://doi.org/10.3390/ma9080698

APA StyleWang, Z.-Y., Li, L., Liu, Y.-J., & Wang, Q.-Y. (2016). Fatigue Property of Open-Hole Steel Plates Influenced by Bolted Clamp-up and Hole Fabrication Methods. Materials, 9(8), 698. https://doi.org/10.3390/ma9080698