Quantification of Microstructural Features and Prediction of Mechanical Properties of a Dual-Phase Ti-6Al-4V Alloy

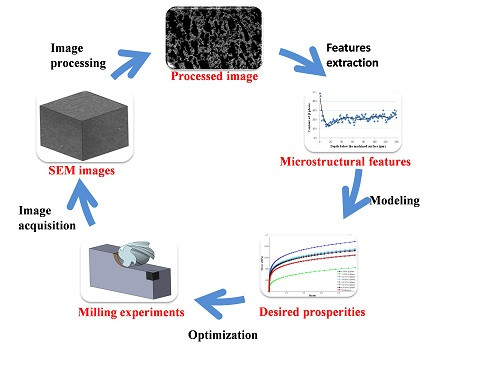

Abstract

:1. Introduction

2. Experimental Procedure

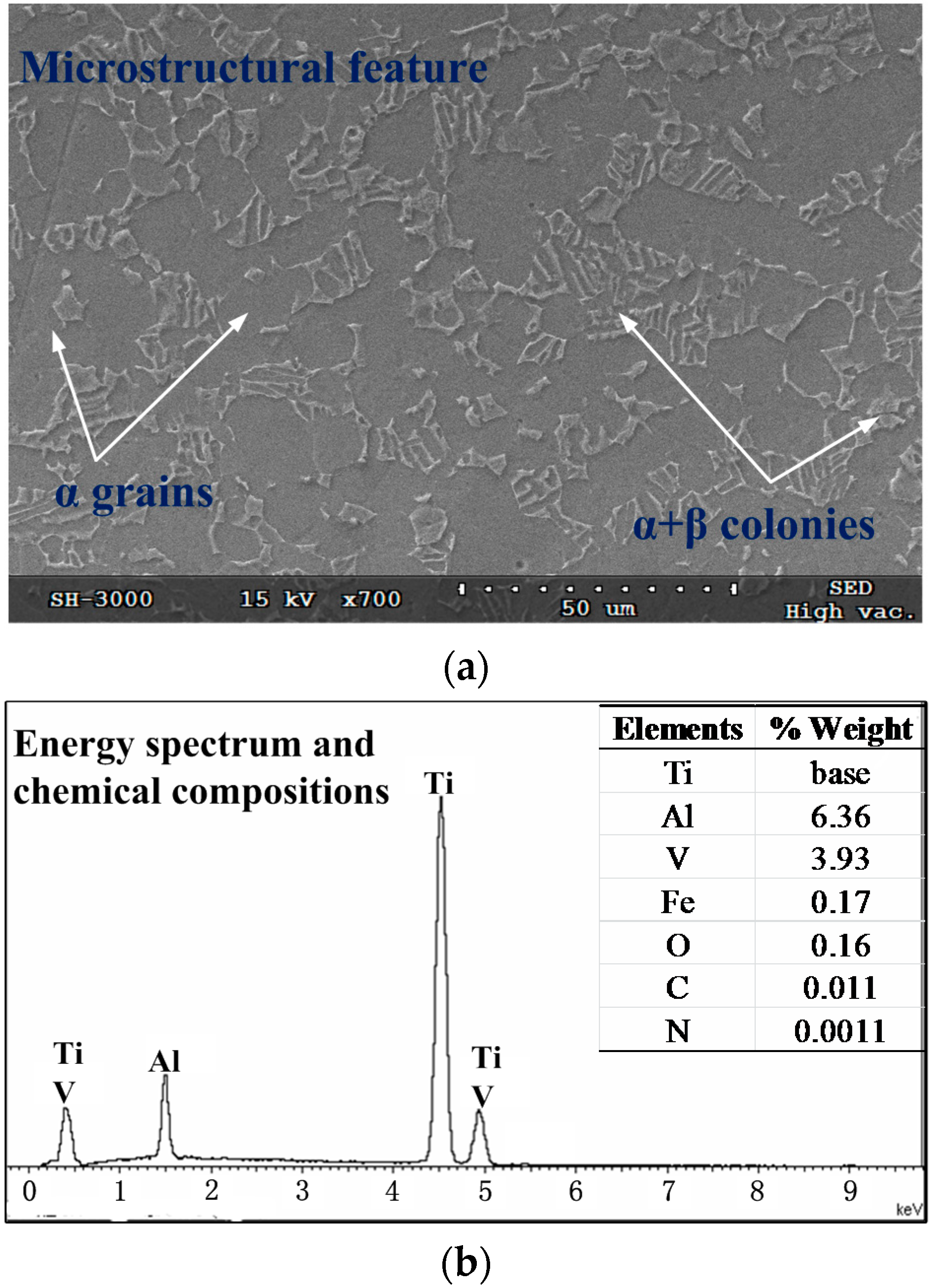

2.1. Materials

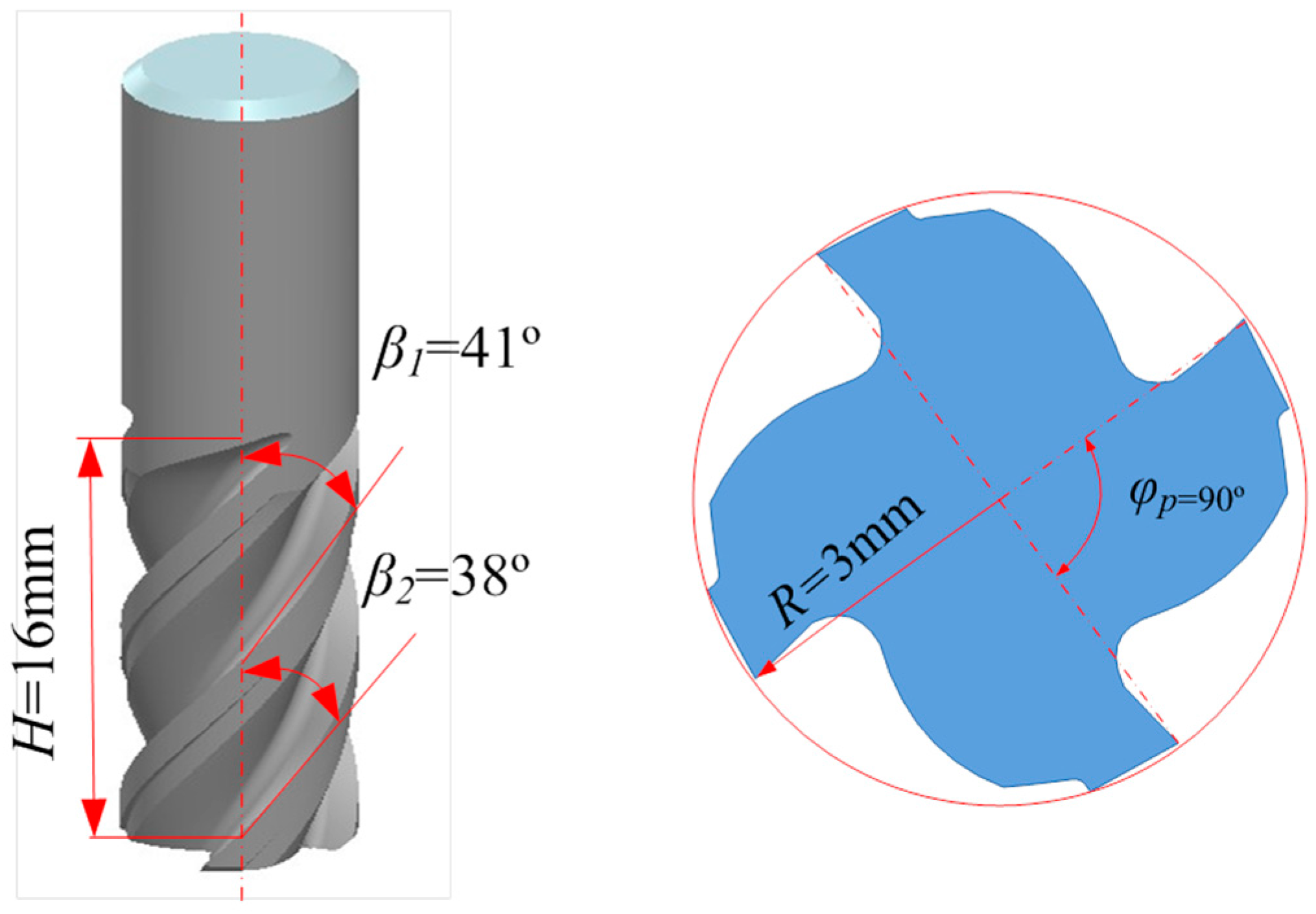

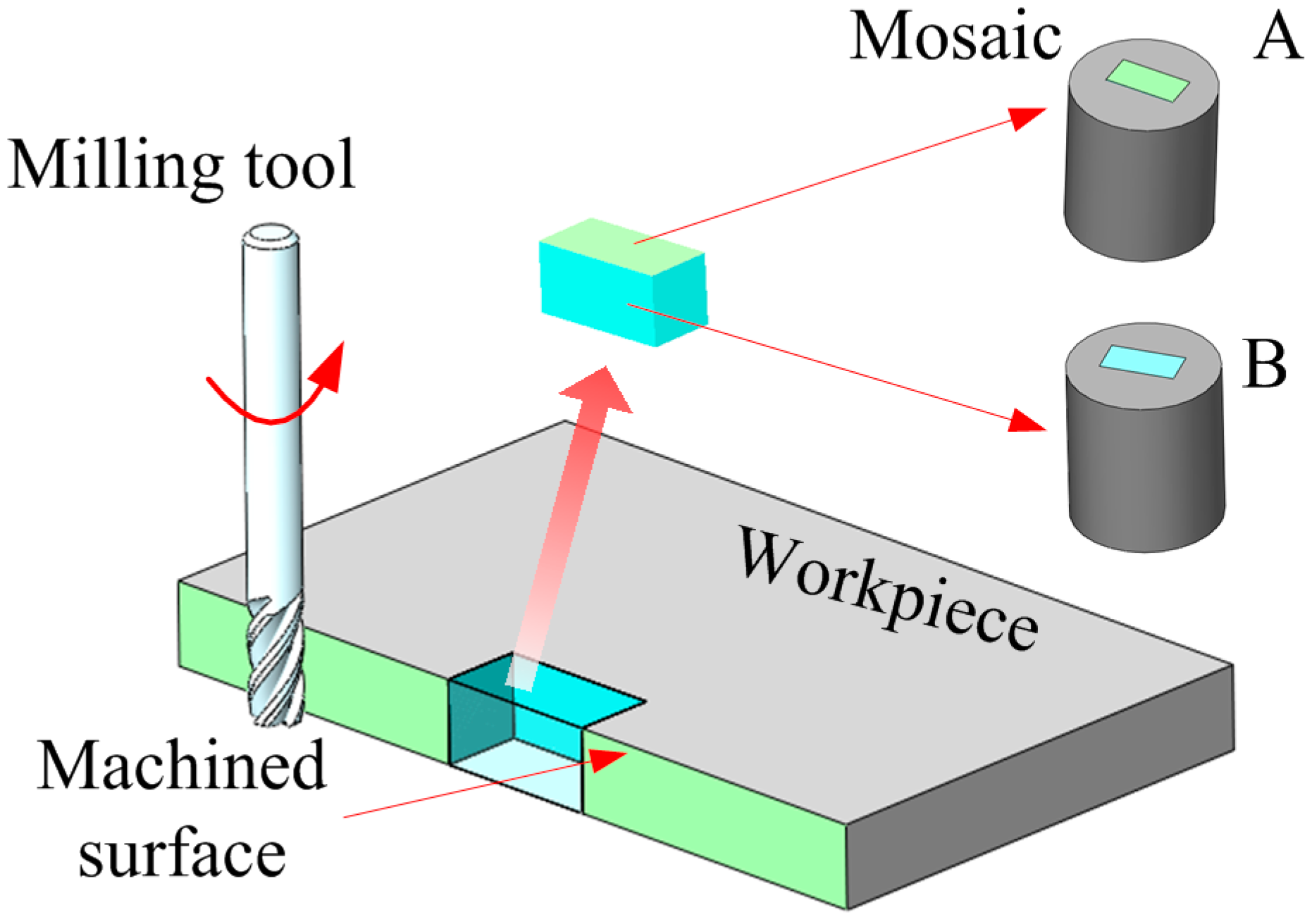

2.2. Cutting Experiments

2.3. Samples Preparation

3. Inspection of the Microstructural Features

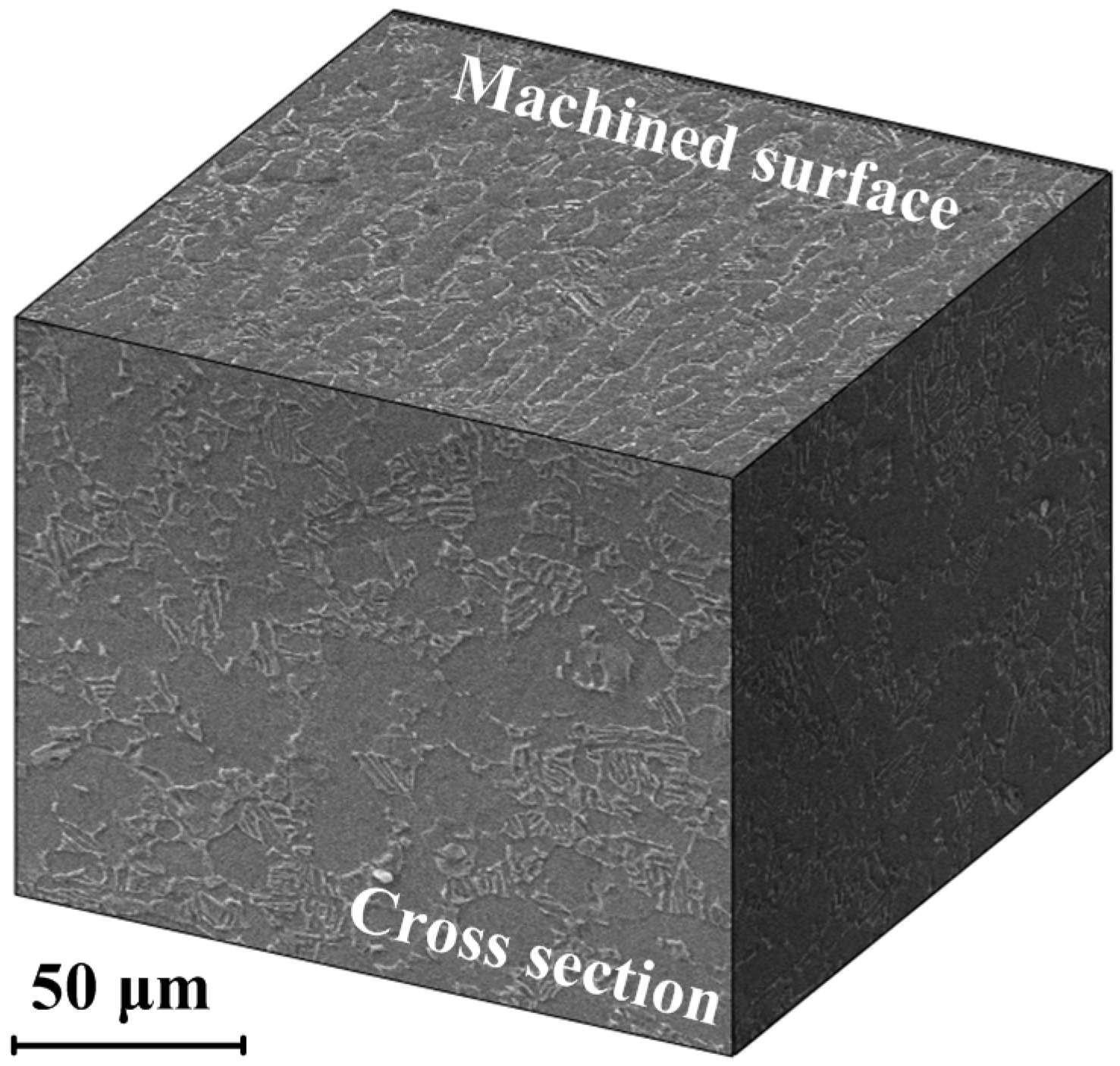

3.1. Qualitative Description

3.2. Quantitative Identification

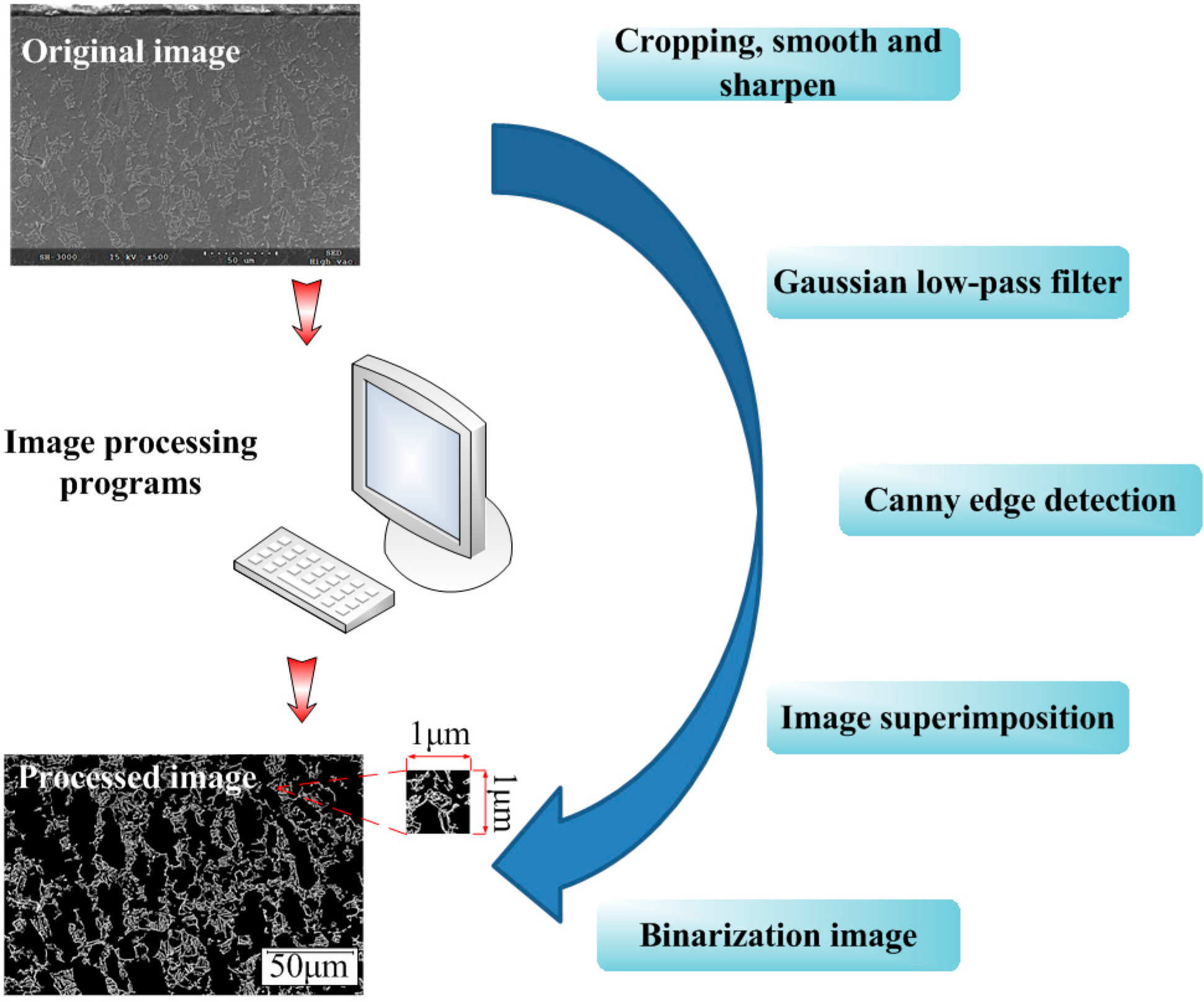

3.2.1. Proposed Method

- (1)

- The original image was entered into Matlab software with an uncompressed tagged image file format. Cropping, smoothing, and sharpening were then carried out to eliminate image defects, such as uneven brightness;

- (2)

- Noise reduction of the digital image using a Gaussian low-pass filter;

- (3)

- Implement the Canny edge detection algorithm after executing image graying;

- (4)

- Superposition of the images, which are processed by step (1) and step (3), to add contrast between the α and β phases;

- (5)

- The gray image was transformed into a binary image. The image matrix of the binary image only consists of pixel values “0” and “1”, where “1” represents the α phase, and “0” represent the β phase;

- (6)

- Extract the density of the constituent phases per square micron. The distribution gradients of the constituent phases beneath the machined surface are then obtained; and

- (7)

- Lamellar α + β colonies were regarded as a single β phase, and then profiles of the α phase were picked up. The size distribution and mean diameter of α grains were then calculated using Image-P Plus software. The statistics cover the whole SEM image with a size of 244 μm × 167 μm. The mean diameter is the average length of diameters measured at 2 degree intervals and passing through the profile centroid of the α phase.

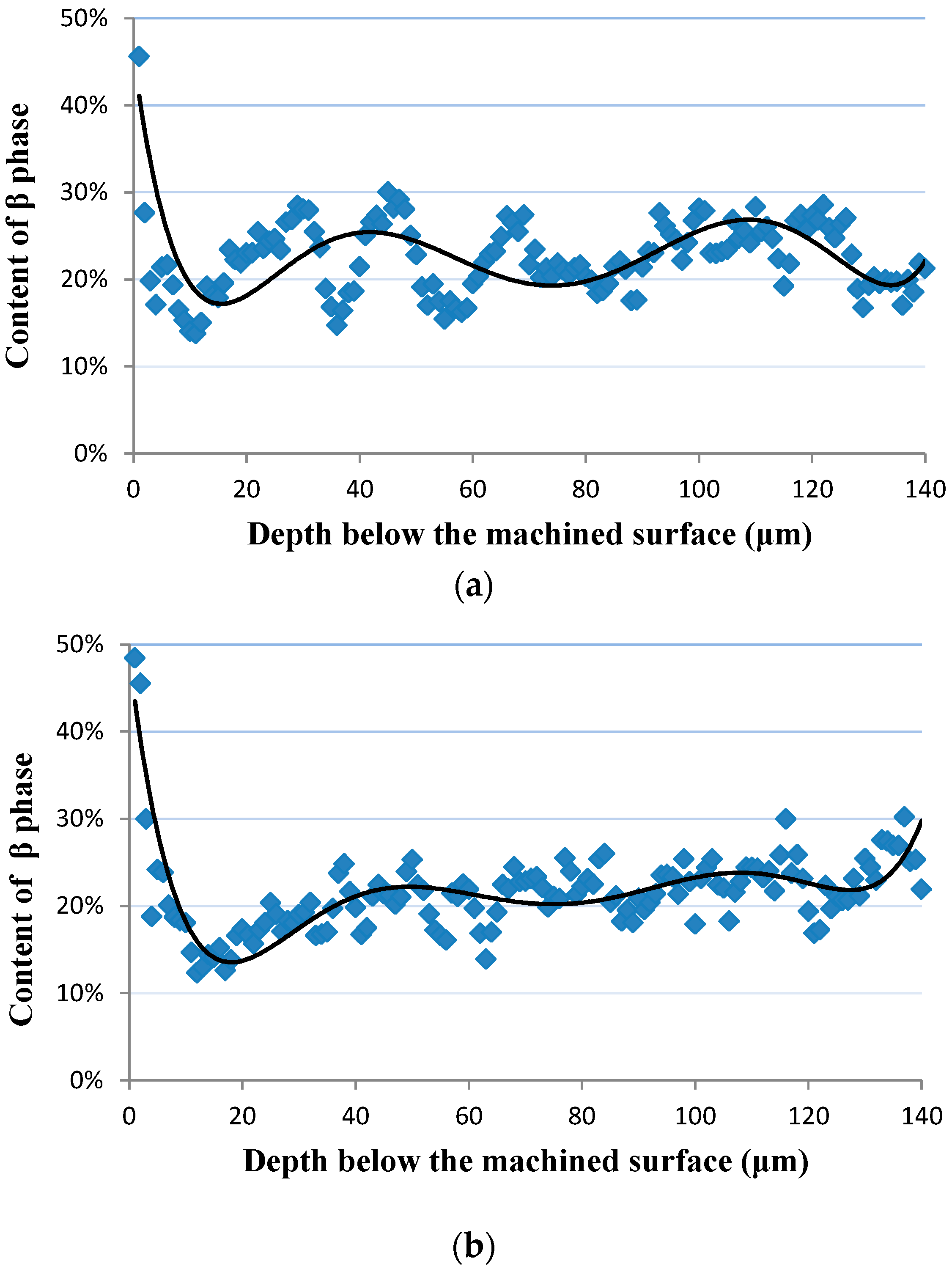

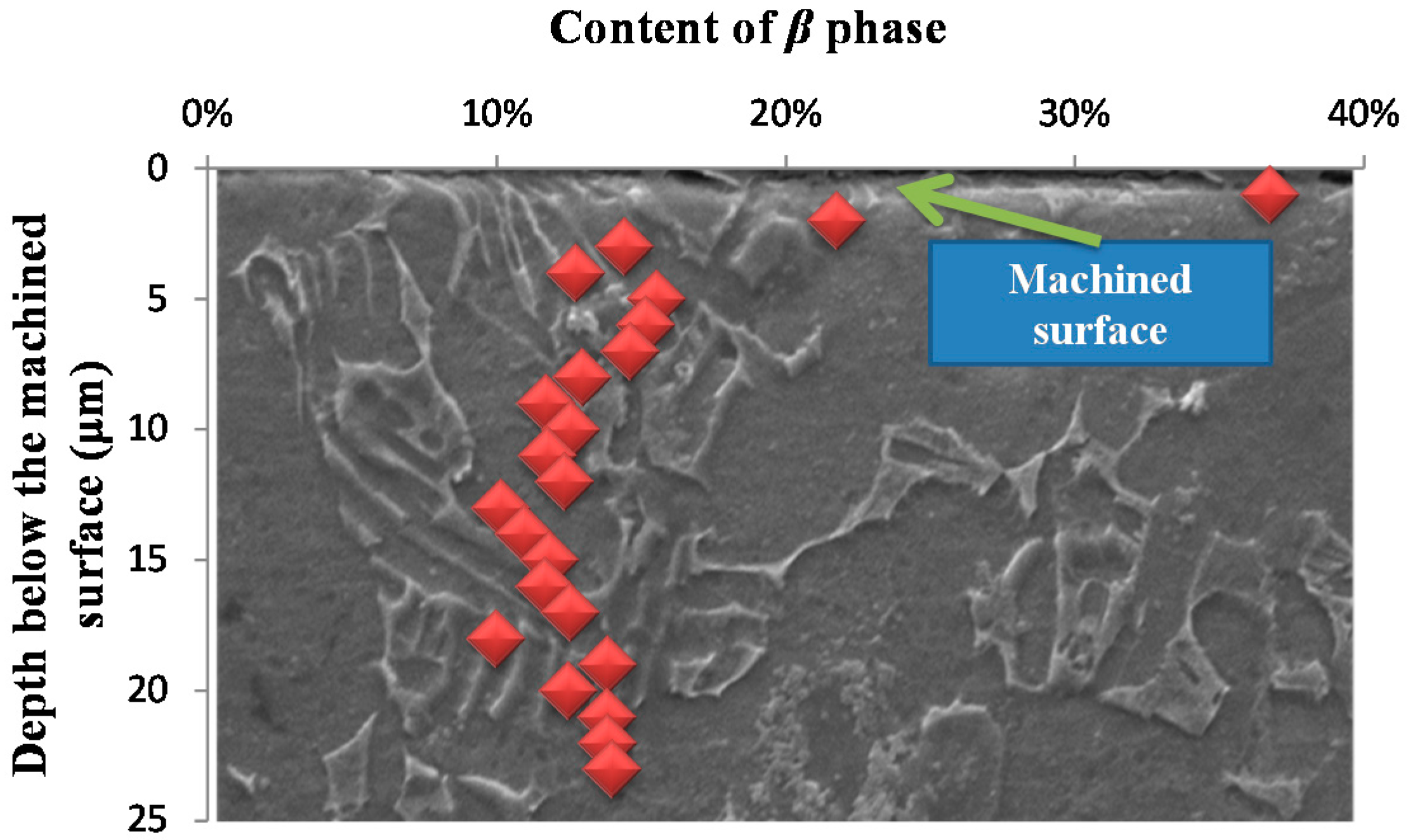

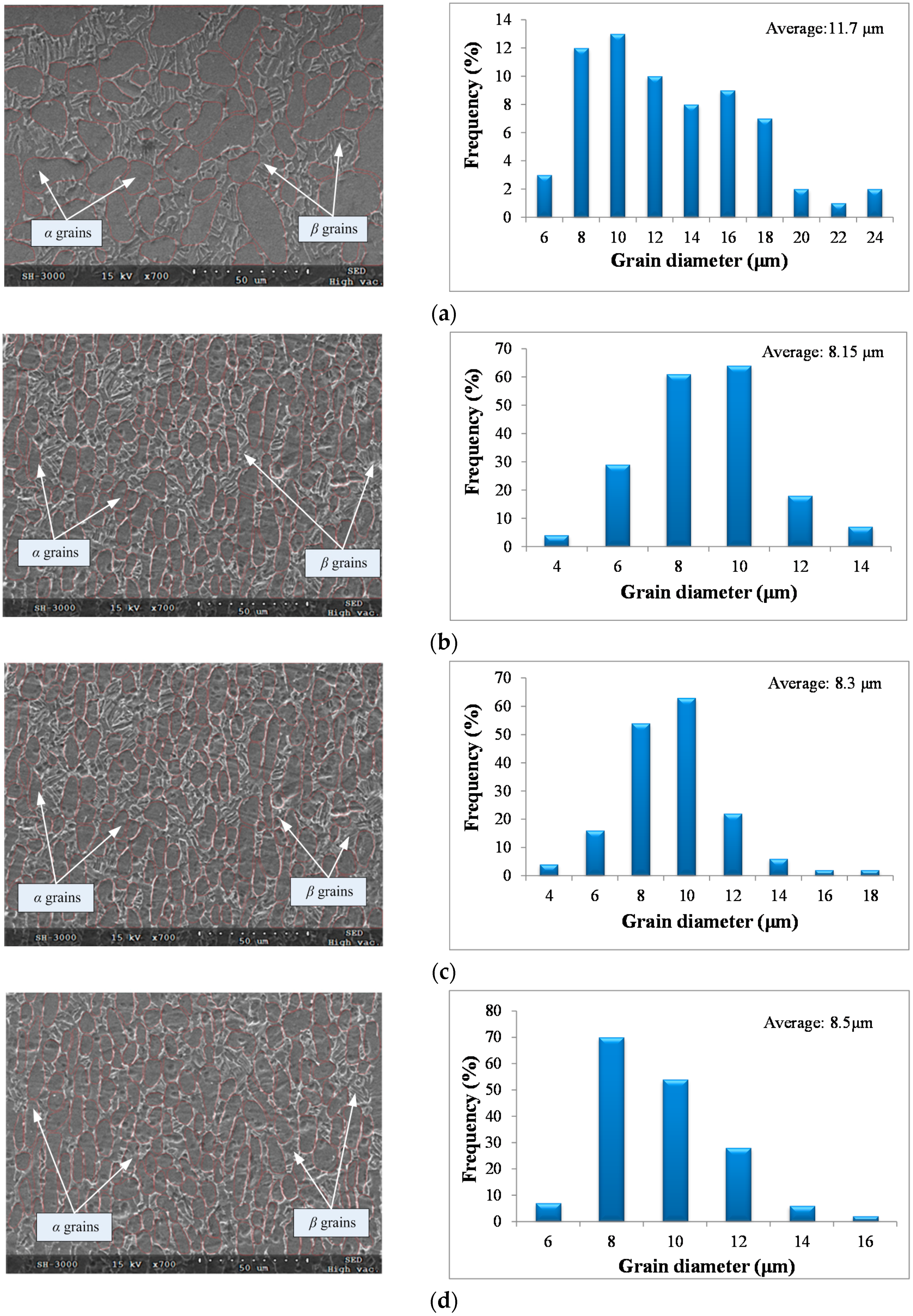

3.2.2. Identification Results

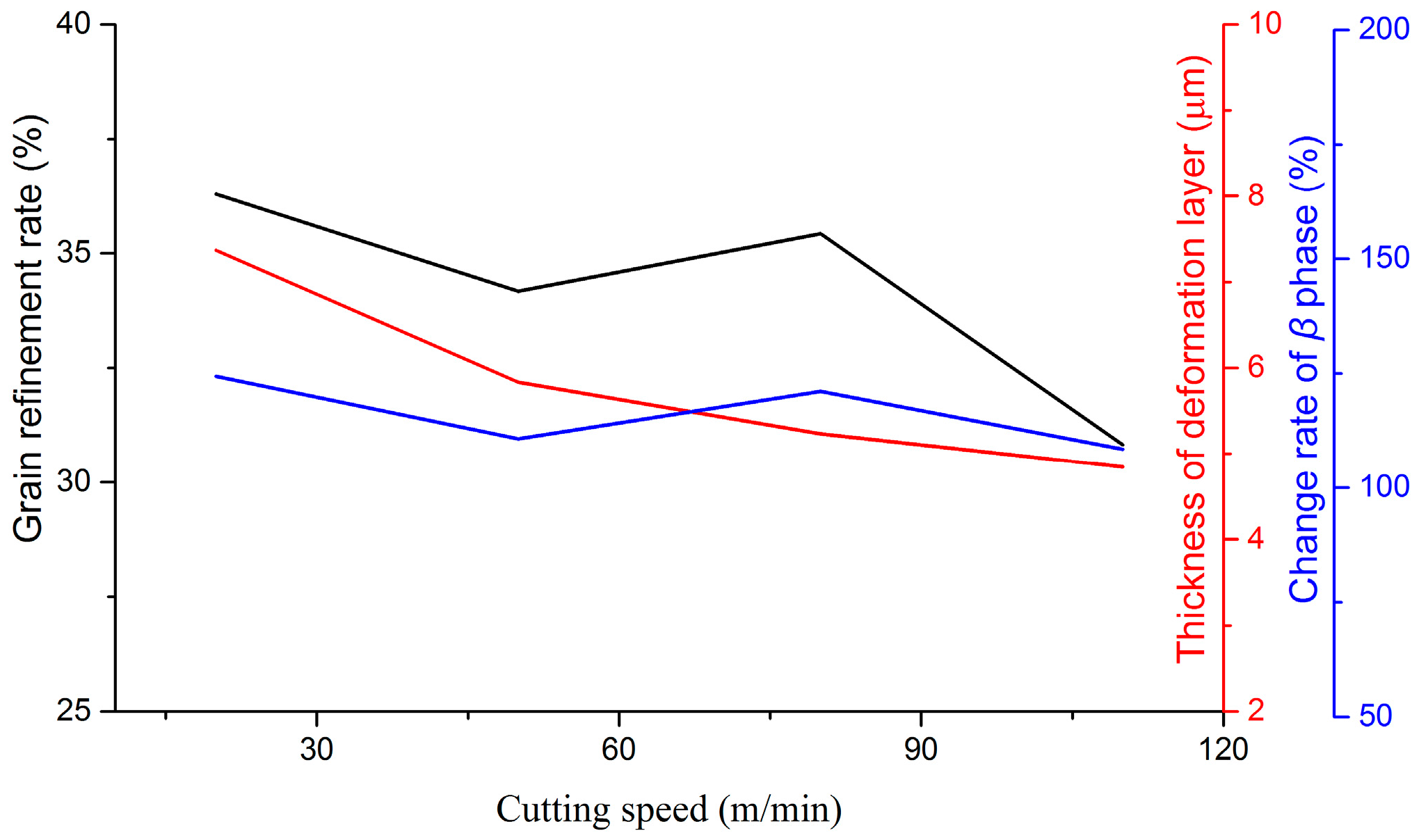

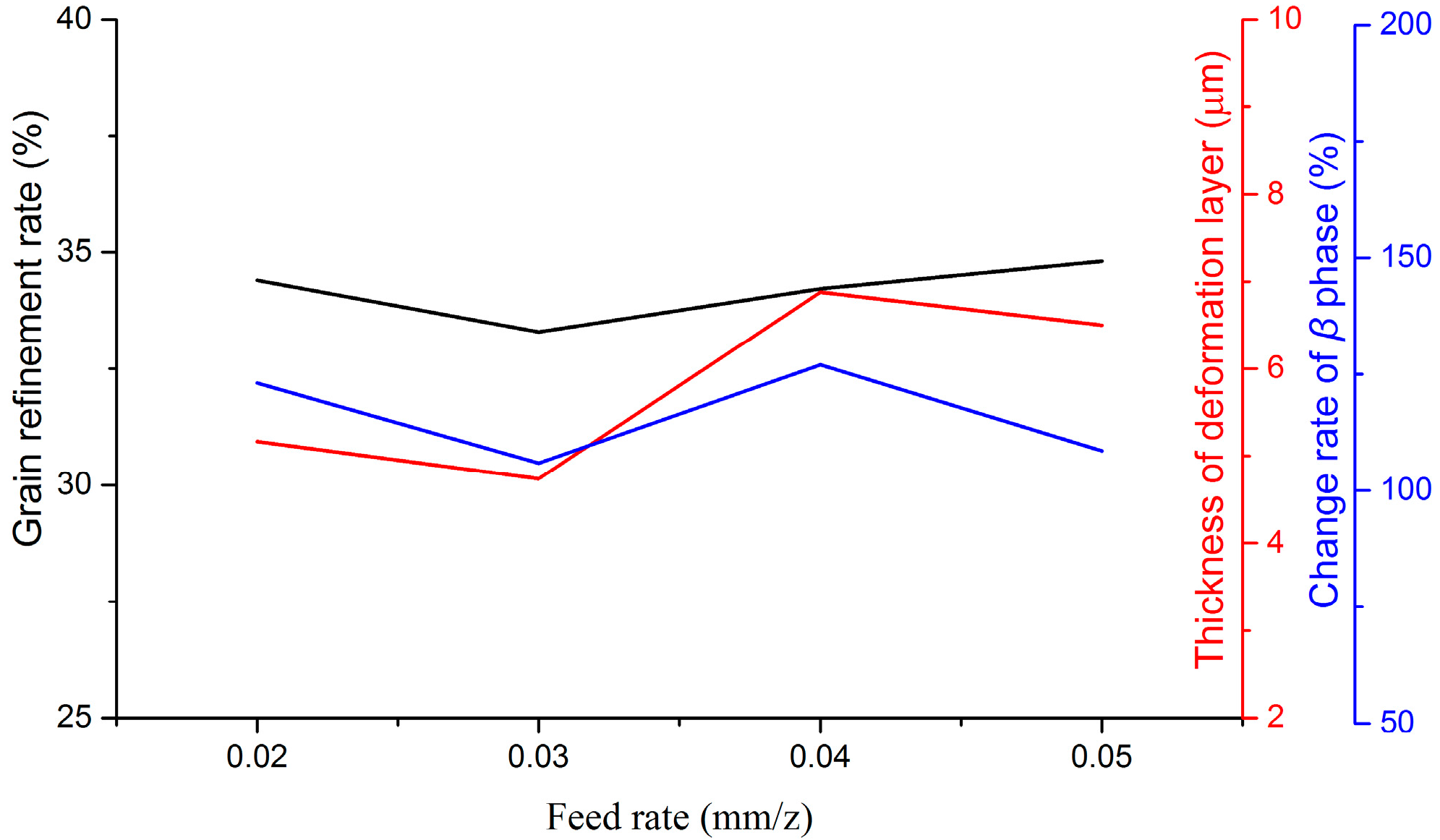

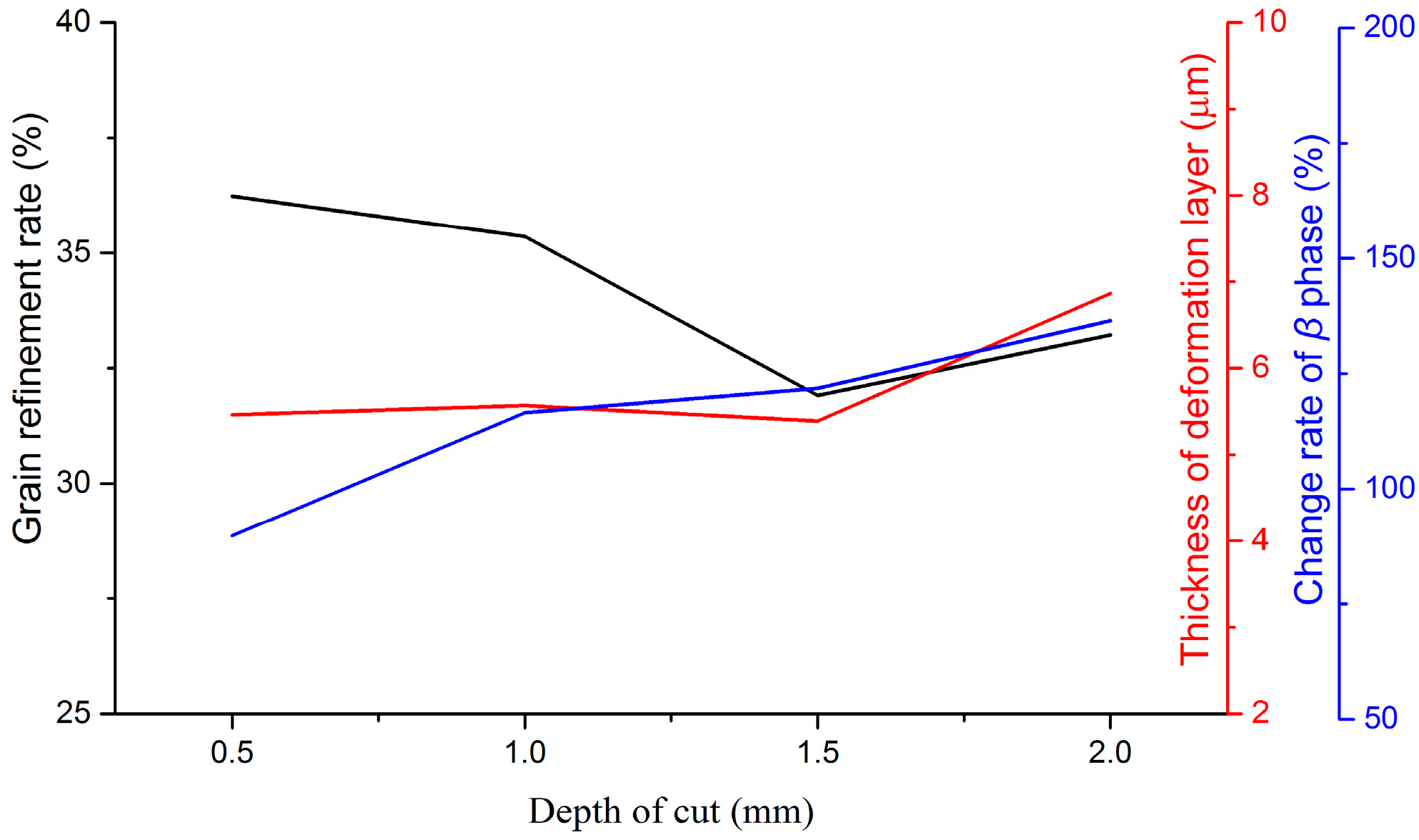

3.3. Milling Parameter Sensitivity Analysis

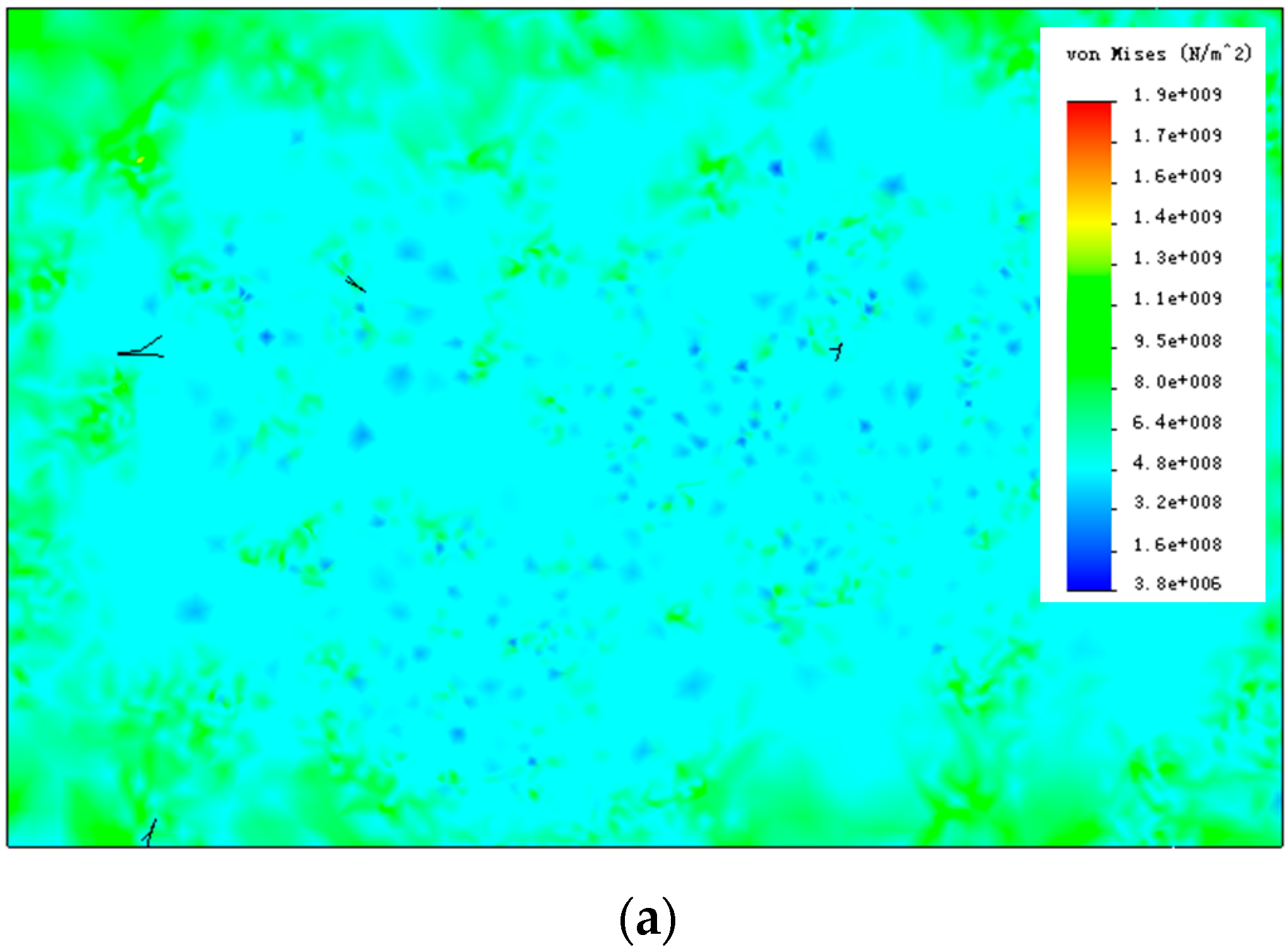

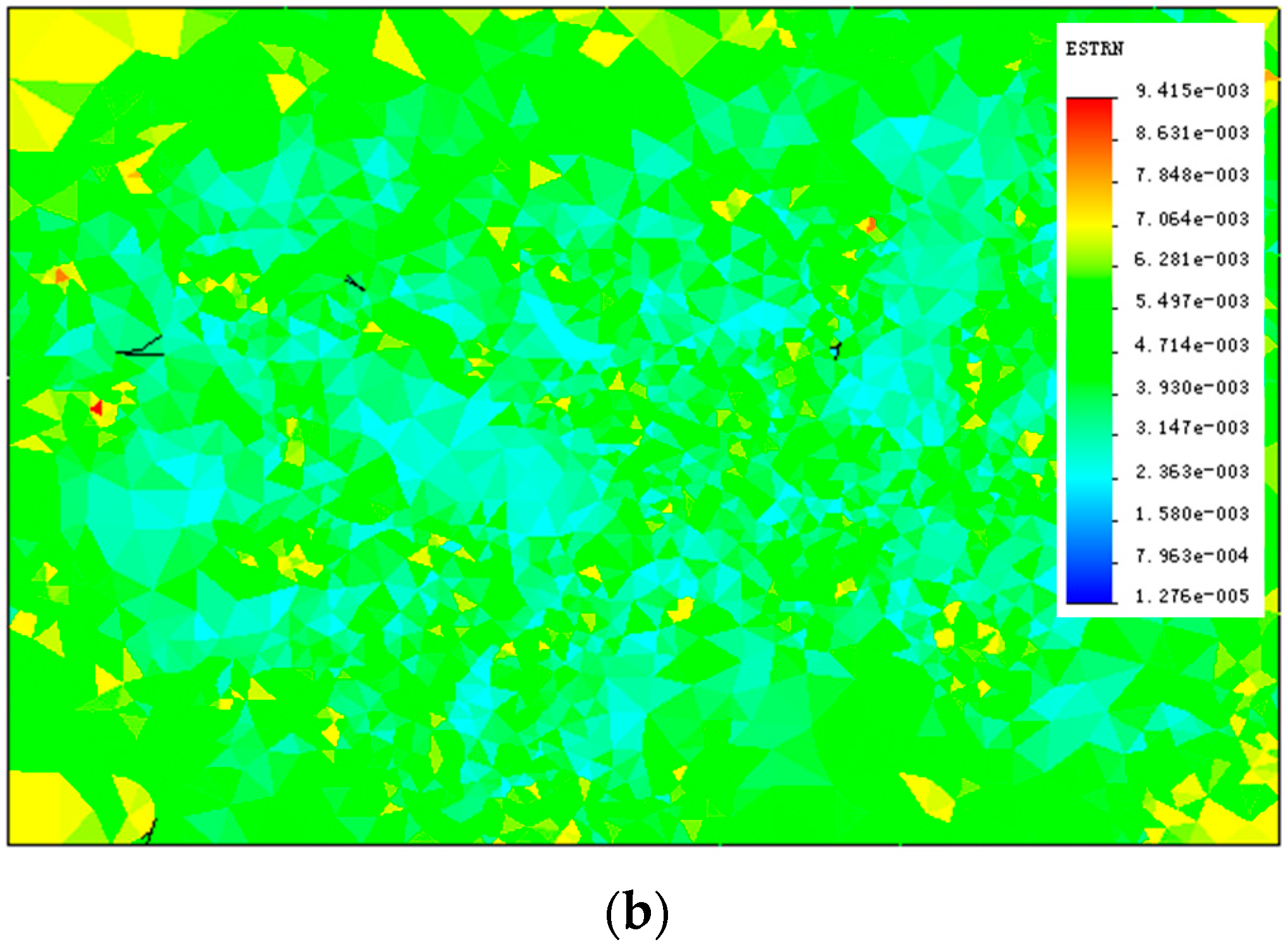

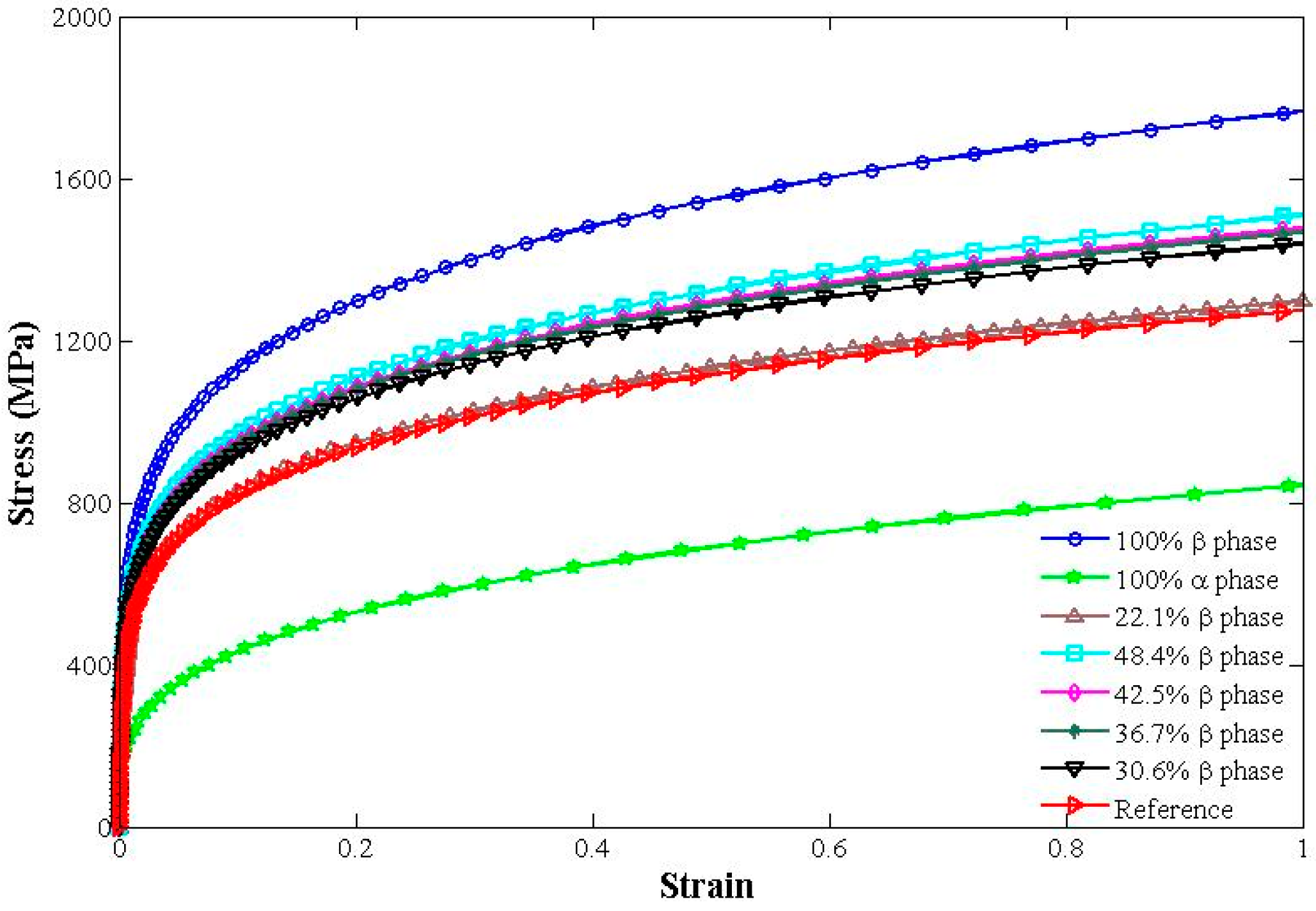

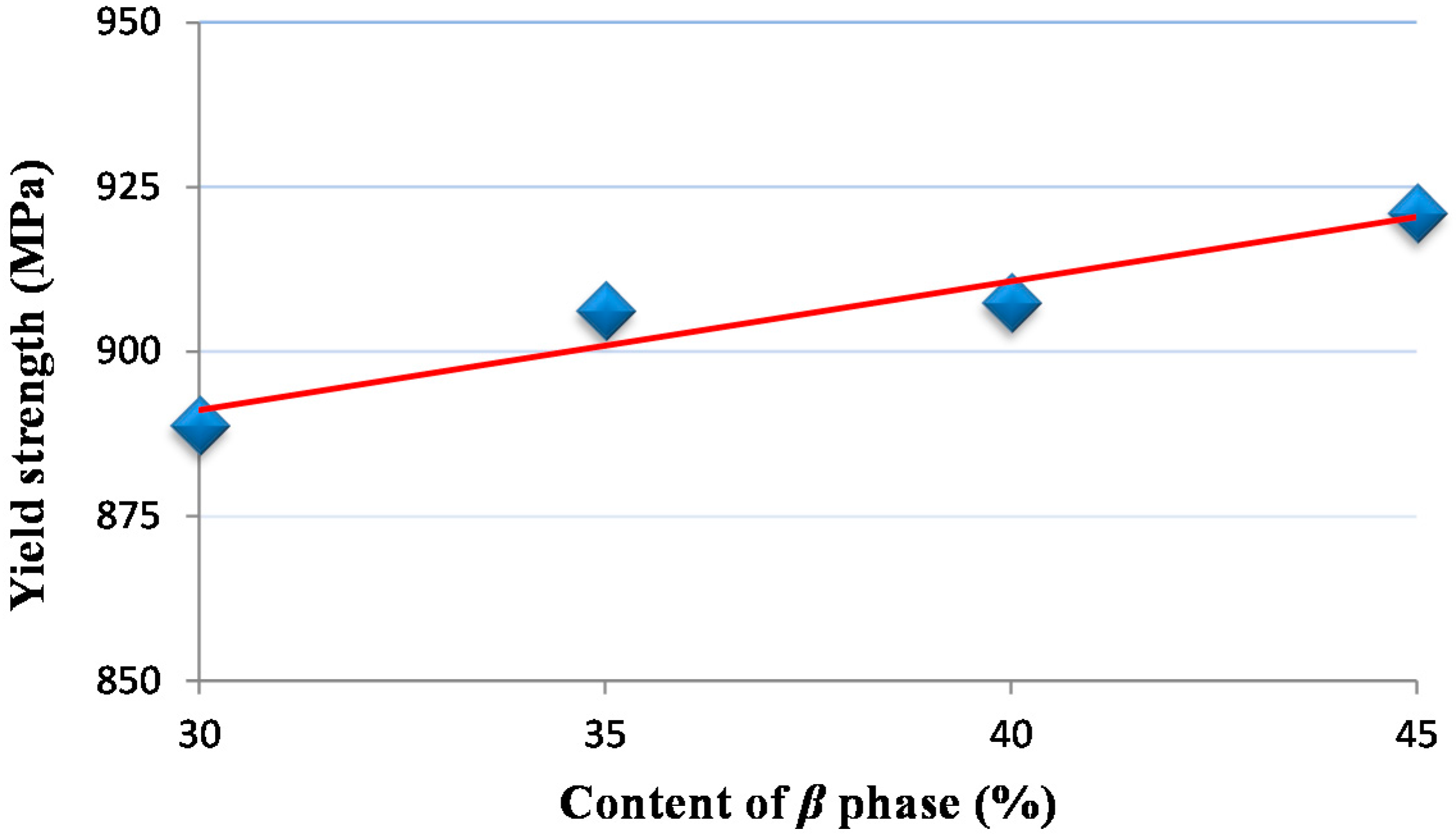

4. Mechanical Property Optimization

5. Conclusions

- A digital image processing method was proposed. The new approach is based on the fact that the constituent phases of Ti-6Al-4V titanium alloy show different gray levels in digital images. By the proposed method, microstructural features, including the content of constituent phases and grain size, were identified. A high content of the β phase and small grain size were found at the machined surface. The maximum measured values of change rate of β phase, grain refinement rate at the machined surface, and thickness of the deformation layer are 141.1%, 47.2%, and 12.3 μm, respectively.

- Sensitivity of microstructural changes to milling parameters was investigated. The thickness of the deformed layer and grain refinement rate decreased distinctly with the increase of the cutting speed, but increased with the increase of the feed rate. The parameter of the depth of cut played a positive role in increasing the thickness of the deformed layer, while opposite to the grain refinement rate. For the variation of the change rate of the β phase at the machined surface, the depth of cut is the foremost factor among the three studied parameters.

- Stress-strain behavior of two ductile phase alloys was developed using the finite element method. A high content of the β phase was found to have a high strength of materials. Values of yield strength varied from 889–921 MPa with the change of content of the β phase from 30%–45%.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ruibin, X.; Wu, H. Study on cutting mechanism of Ti6Al4V in ultra-precision machining. Int. J. Adv. Manuf. Technol. 2016. [Google Scholar] [CrossRef]

- Wu, G.Q.; Shi, C.L.; Sha, W.; Sha, A.X.; Jiang, H.R. Effect of microstructure on the fatigue properties of Ti–6Al–4V titanium alloys. Mater. Des. 2013, 46, 668–674. [Google Scholar] [CrossRef]

- Zhao, X.; Li, S.; Zhang, M.; Liu, Y.; Sercombe, T.B.; Wang, S.; Murr, L.E. Comparison of the microstructures and mechanical properties of Ti–6Al–4V fabricated by selective laser melting and electron beam melting. Mater. Des. 2006, 95, 21–31. [Google Scholar] [CrossRef]

- Fan, Y.; Tian, W.; Guo, Y.; Sun, Z.; Xu, J. Relationships among the Microstructure, Mechanical Properties, and Fatigue Behavior in Thin Ti6Al4V. Adv. Mater. Sci. Eng. 2016, 2016, 7278267. [Google Scholar] [CrossRef]

- Chan, K.S.; Lee, Y.D. Effects of deformation-induced constraint on high-cycle fatigue in Ti alloys with a duplex microstructure. Metall. Mater. Trans. 2008, 39, 1665–1675. [Google Scholar] [CrossRef]

- Che-Haron, C.H.; Jawaid, A. The effect of machining on surface integrity of titanium alloy Ti-6% Al-4% V. J. Mater. Process. Technol. 2005, 166, 188–192. [Google Scholar] [CrossRef]

- Hughes, J.I.; Sharman, A.R.C.; Ridgway, K. The effect of cutting tool material and edge geometry on tool life and workpiece surface integrity. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2006, 220, 93–107. [Google Scholar] [CrossRef]

- Cantero, J.L.; Tardio, M.M.; Canteli, J.A.; Marcos, M.; Miguélez, M.H. Dry drilling of alloy Ti-6Al-4V. Int. J. Mach. Tools Manuf. 2005, 45, 1246–1255. [Google Scholar] [CrossRef]

- Velásquez, J.P.; Tidu, A.; Bolle, B.; Chevrier, P.; Fundenberger, J.J. Sub-surface and surface analysis of high speed machined Ti-6Al-4V alloy. Mater. Sci. Eng. A 2010, 527, 2572–2578. [Google Scholar] [CrossRef]

- Hall, E.O. The deformation and ageing of mild steel: III discussion of results. Proc. Phys. Soc. Lond. Sect. B 1951, 64, 747. [Google Scholar] [CrossRef]

- Petch, N.J. The cleavage strength of polycrystals. J. Iron Steel Inst. 1953, 174, 25–28. [Google Scholar]

- Standard Test Methods for Determining Average Grain Size; ASTM E-112; ASTM: West Conshohocken, PA, USA, 2010.

- Standard Test Method for Determining Volume Fraction By systematic Manual Point Count; ASTM E562–99; ASTM: West Conshohocken, PA, USA, 1999.

- Chaharsooghi, S.; Dhokia, V.; Flynn, J.; Newman, S. Image Processing for Quantification of Machining Induced Changes in Subsurface Microstructure. In Proceedings of the 25th International Conference of Flexible Automation Integrated Faim, University of Bath, Bath, UK, 23 June 2015.

- Collins, P.C.; Welk, B.; Searles, T.; Tiley, J.; Russ, J.C.; Fraser, H.L. Development of methods for the quantification of microstructural features in α+ β-processed α/β titanium alloys. Mater. Sci. Eng. A 2009, 508, 174–182. [Google Scholar] [CrossRef]

- Tiley, J.; Searles, T.; Lee, E.; Kar, S.; Banerjee, R.; Russ, J.C.; Fraser, H.L. Quantification of microstructural features in α/β titanium alloys. Mater. Sci. Eng. A 2004, 372, 191–198. [Google Scholar] [CrossRef]

- Kar, S.; Searles, T.; Lee, E.; Viswanathan, G.B.; Fraser, H.L.; Tiley, J.; Banerjee, R. Modeling the tensile properties in β-processed α/β Ti alloys. Metall. Mater. Trans. A 2006, 37, 559–566. [Google Scholar] [CrossRef]

- Searles, T.; Tiley, J.; Tanner, A.; Williams, R.; Rollins, B.; Lee, E.; Fraser, H.L. Rapid characterization of titanium microstructural features for specific modelling of mechanical properties. Meas. Sci. Technol. 2004, 16, 60. [Google Scholar] [CrossRef]

- Sreejith, P.S.; Ngoi, B.K.A. Dry machining: machining of the future. J. Mater. Process. Technol. 2000, 101, 287–291. [Google Scholar] [CrossRef]

- Leyens, C.; Peters, M. Titanium and Titanium Alloys; Wiley-VCH: Weinheim, Germany, 2003; p. 207. [Google Scholar]

- Ankem, S.; Margolin, H. A rationalization of stress-strain behavior of two-ductile phase alloys. Metall. Trans. A 1986, 17, 2209–2226. [Google Scholar] [CrossRef]

- Li, J.C.M.; Chou, Y.T. The role of dislocations in the flow stress grain size relationships. Metall. Mater. Trans. 1970, 1, 1145–1159. [Google Scholar]

- Hansen, N. Hall–Petch relation and boundary strengthening. Scr. Mater. 2004, 51, 801–806. [Google Scholar] [CrossRef]

- Meyer, H.W.; Kleponis, D.S. Modeling the high strain rate behavior of titanium undergoing ballistic impact and penetration. Int. J. Impact Eng. 2001, 26, 509–521. [Google Scholar] [CrossRef]

| Levels/Factors | Cutting Speed vc (m/min) | Feed Rate fz (mm/z) | Radial Depth of Cut ae (mm) |

|---|---|---|---|

| Level 1 | 20 | 0.02 | 0.5 |

| Level 2 | 50 | 0.03 | 1.0 |

| Level 3 | 80 | 0.04 | 1.5 |

| Level 4 | 110 | 0.05 | 2.0 |

| Phase | σy (MPa) | E (GPa) | N | |

|---|---|---|---|---|

| α | 345 | 140 | 17.959 | 3.484 |

| β | 1000 | 170 | 8.246 | 5.305 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, D.; Liu, Z. Quantification of Microstructural Features and Prediction of Mechanical Properties of a Dual-Phase Ti-6Al-4V Alloy. Materials 2016, 9, 628. https://doi.org/10.3390/ma9080628

Yang D, Liu Z. Quantification of Microstructural Features and Prediction of Mechanical Properties of a Dual-Phase Ti-6Al-4V Alloy. Materials. 2016; 9(8):628. https://doi.org/10.3390/ma9080628

Chicago/Turabian StyleYang, Dong, and Zhanqiang Liu. 2016. "Quantification of Microstructural Features and Prediction of Mechanical Properties of a Dual-Phase Ti-6Al-4V Alloy" Materials 9, no. 8: 628. https://doi.org/10.3390/ma9080628

APA StyleYang, D., & Liu, Z. (2016). Quantification of Microstructural Features and Prediction of Mechanical Properties of a Dual-Phase Ti-6Al-4V Alloy. Materials, 9(8), 628. https://doi.org/10.3390/ma9080628