Permeability of Concrete with Recycled Concrete Aggregate and Pozzolanic Materials under Stress

Abstract

:1. Introduction

2. Experimental Program

2.1. Materials

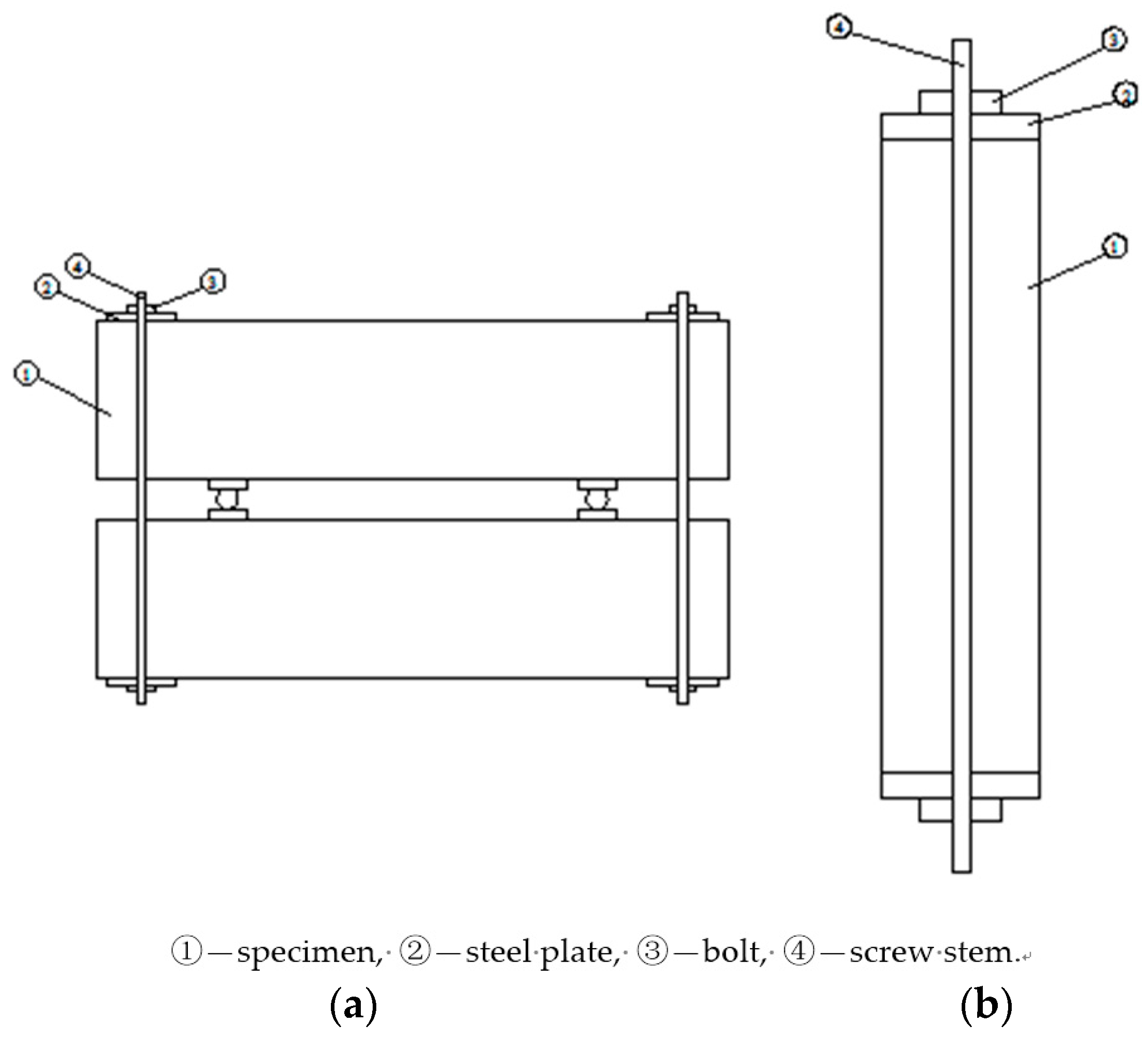

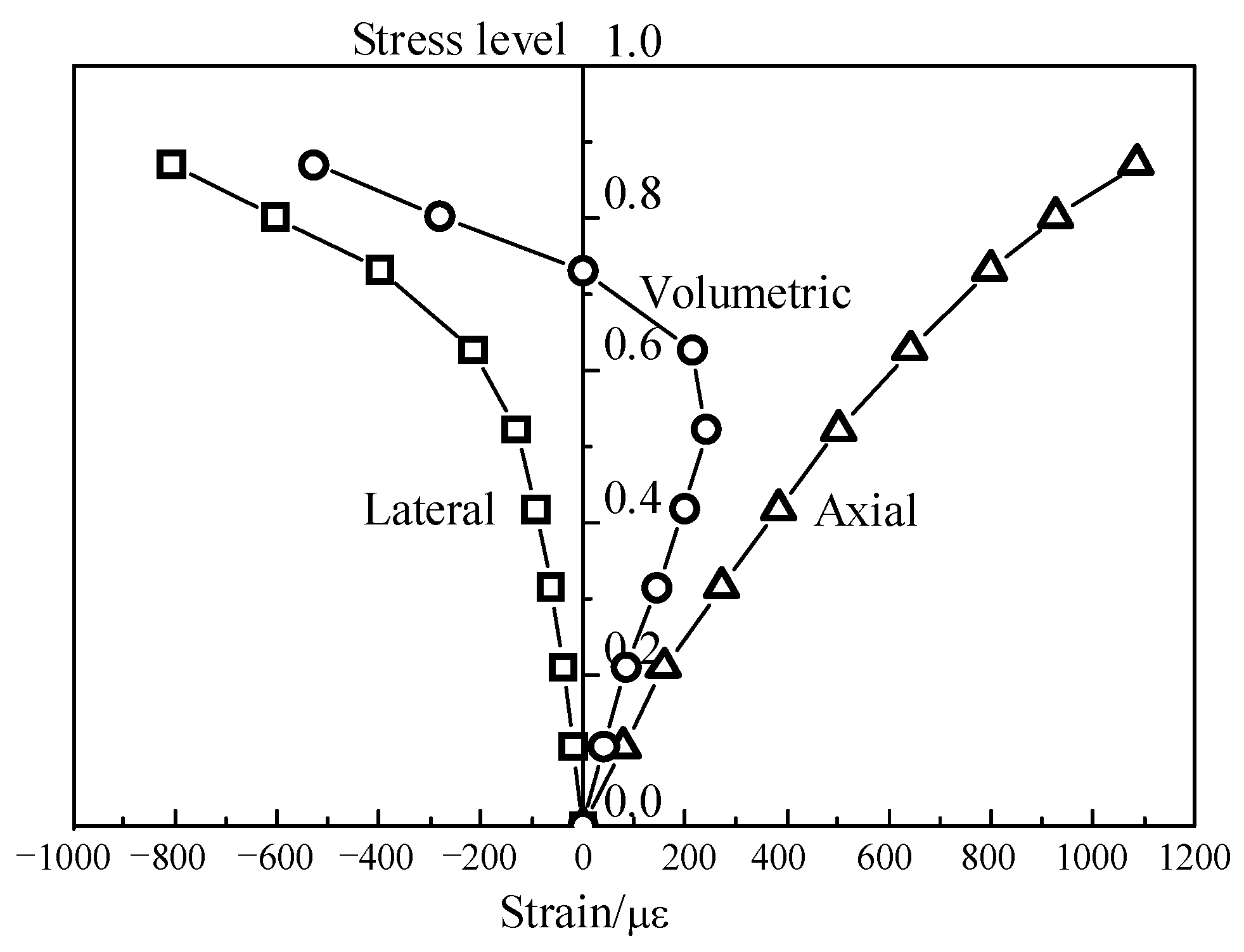

2.2. Specimens with External Loads

2.3. Experimental Environment

2.4. Chloride Transport Test

2.5. Air Permeability Test

3. Results and Discussion

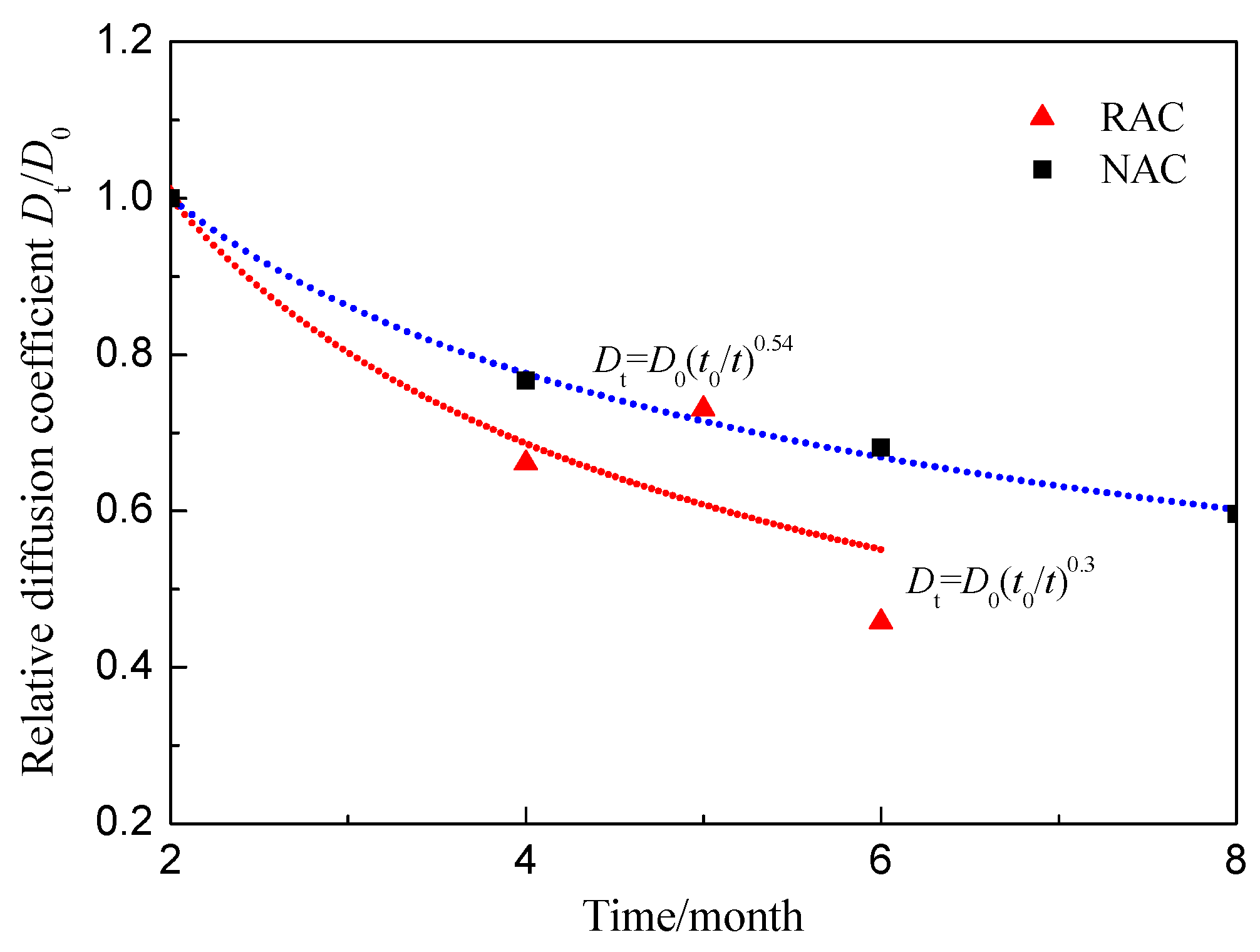

3.1. Permeability of Concrete without Stress

3.2. Chloride Permeability of RAC under Compressive Stress

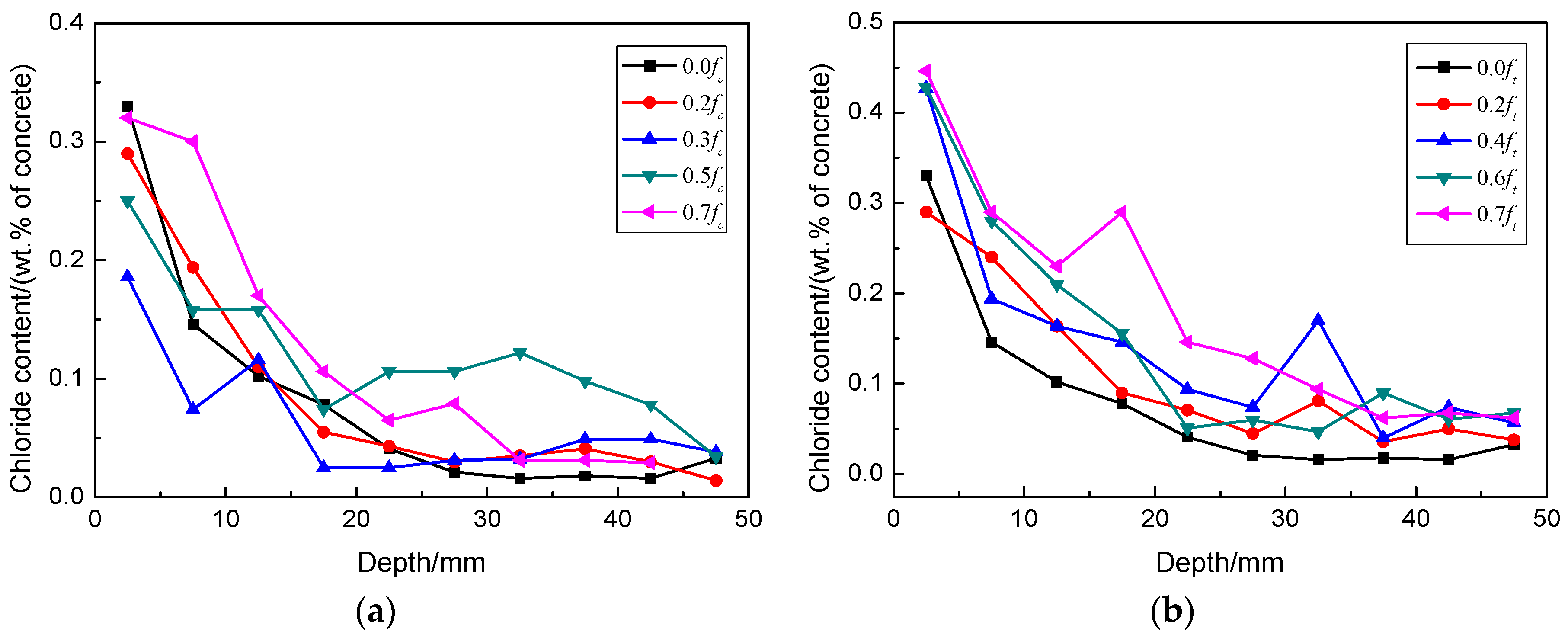

3.2.1. Chloride Profile

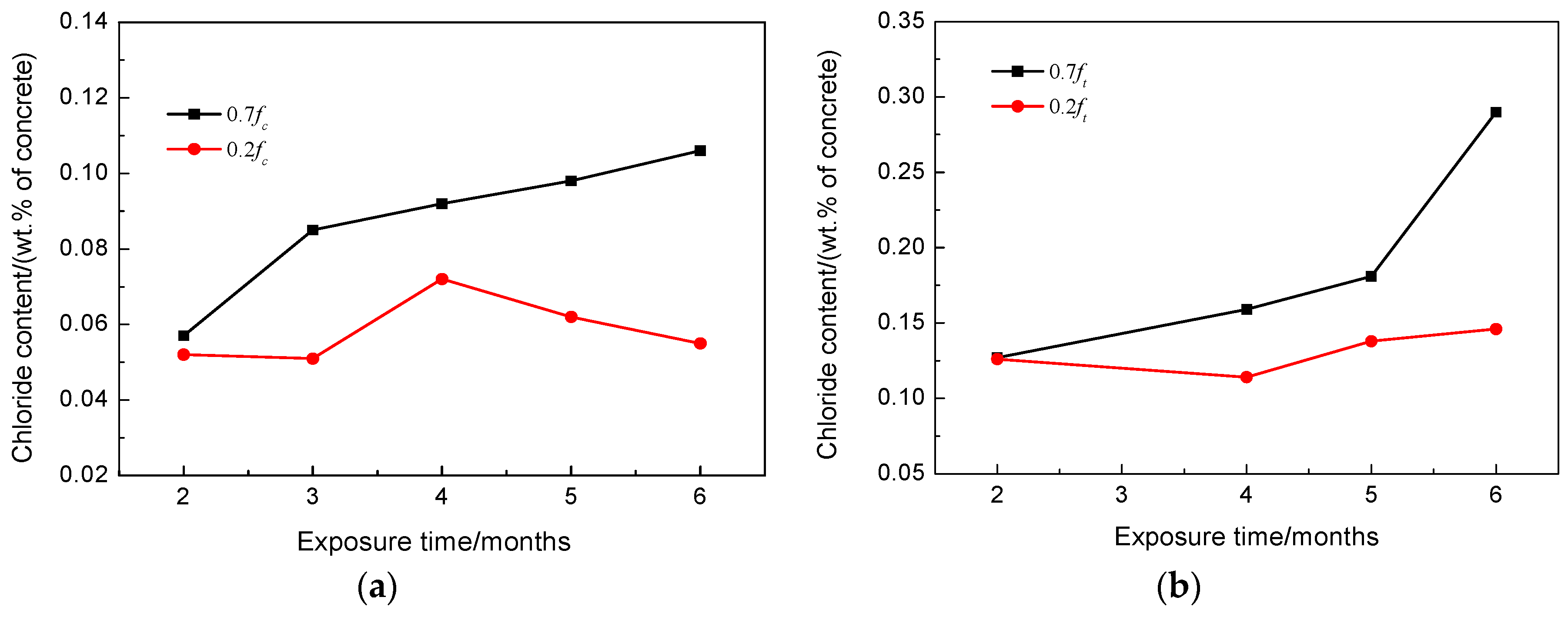

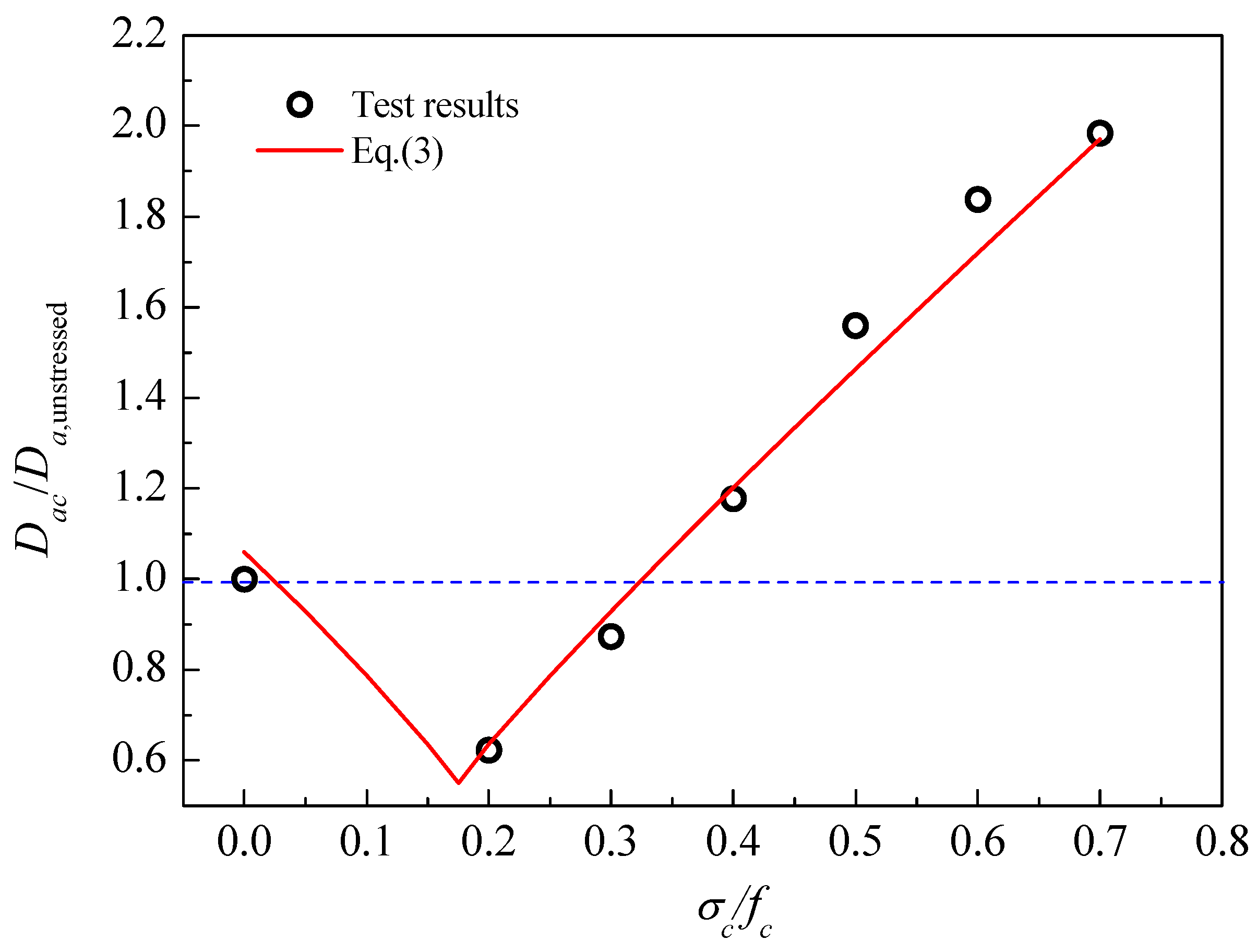

3.2.2. Chloride Diffusion Coefficient

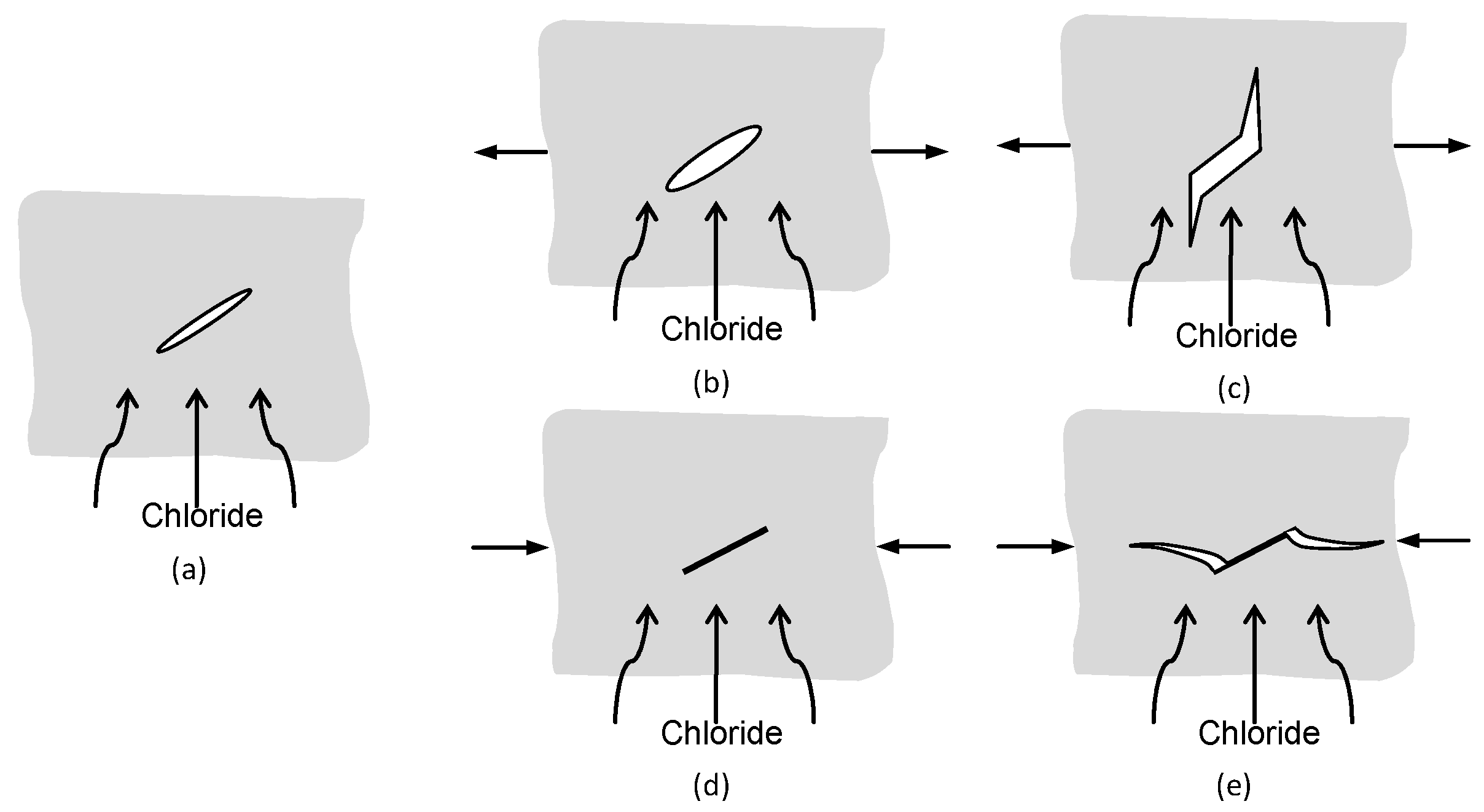

3.3. Chloride Permeability of RAC under Flexural Stress

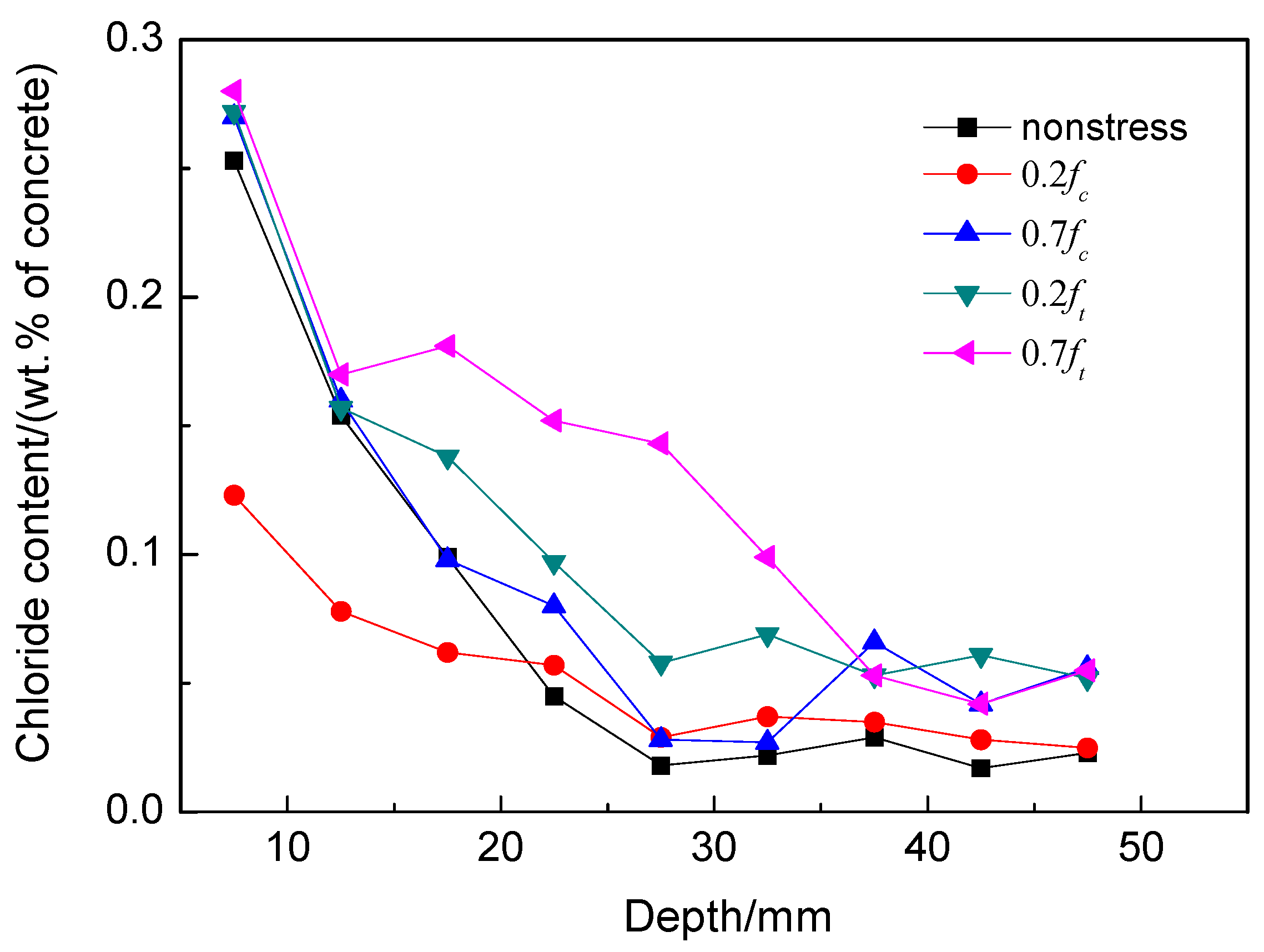

3.3.1. Chloride Profile

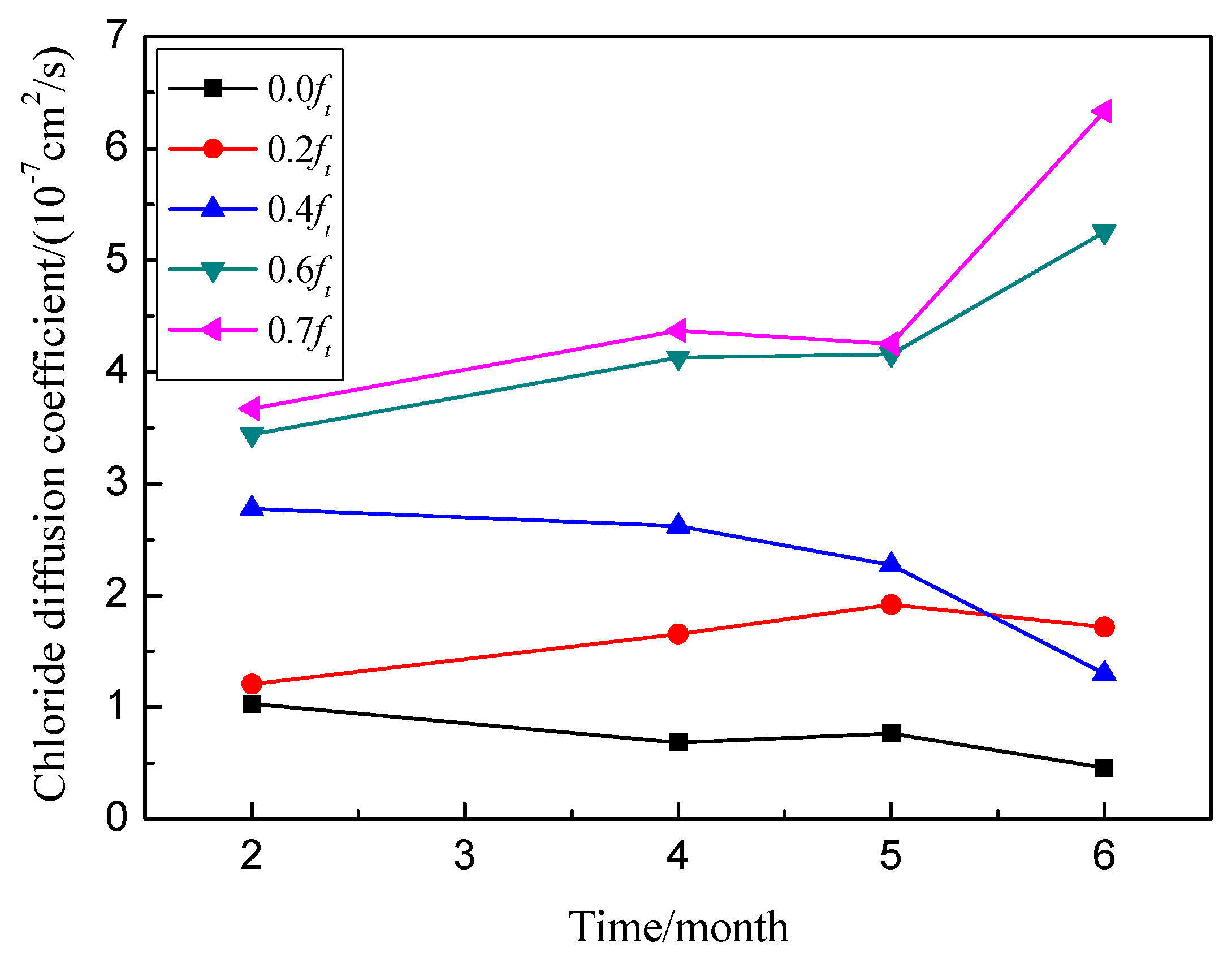

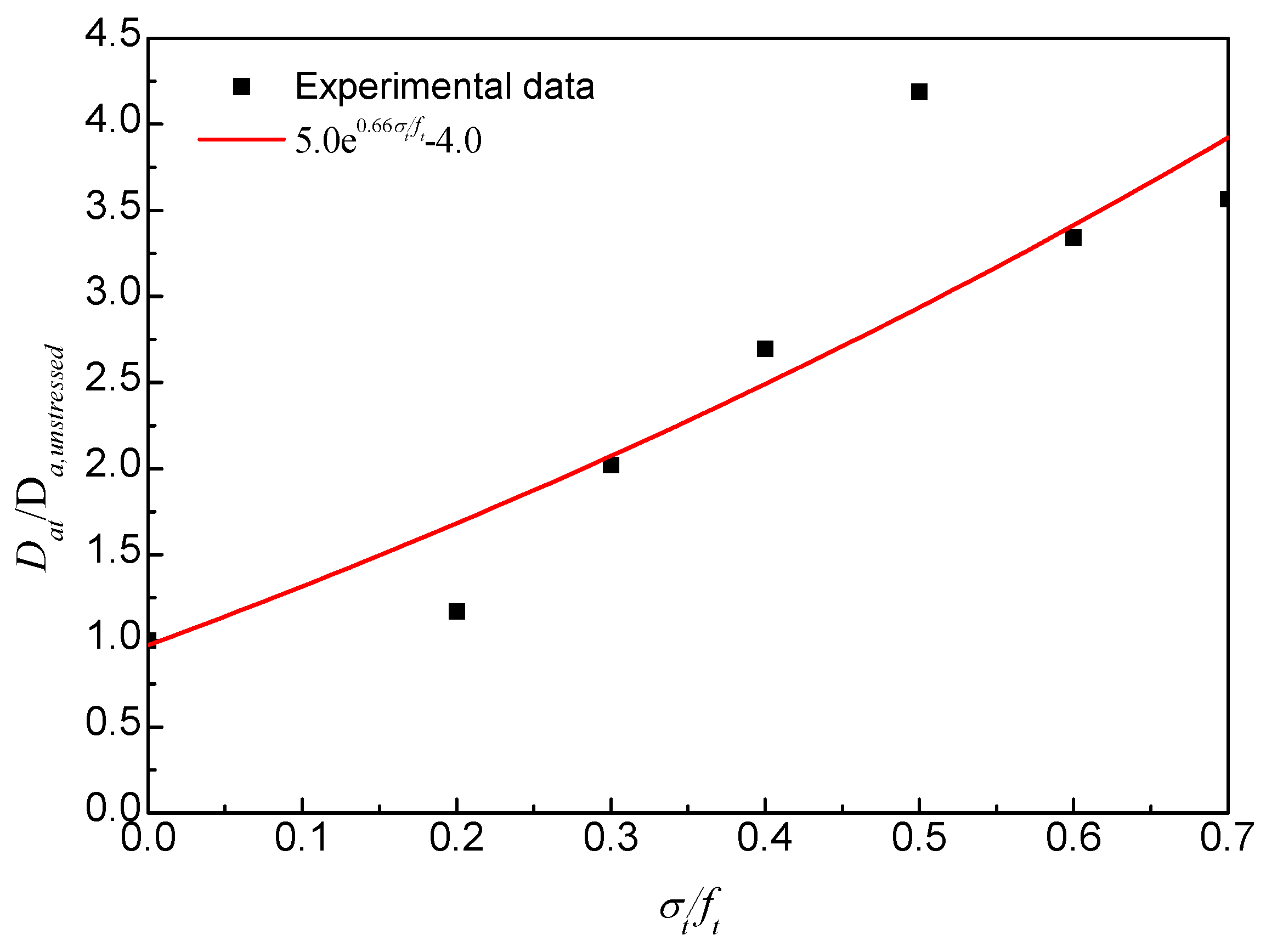

3.3.2. Chloride Diffusion Coefficient

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| RAC | Recycled aggregate concrete |

| NAC | Natural aggregate concrete |

| RA | Recycled-concrete aggregate |

| NA | Natural aggregate |

| PHS | Phosphorous slag |

| GGBS | Ground granulated blast-furnace slag |

| ITZ | Interfacial transition zone |

References

- Tabsh, S.W.; Abdelfatah, A.S. Influence of recycled concrete aggregates on strength properties of concrete. Constr. Build. Mater. 2009, 23, 1163–1167. [Google Scholar] [CrossRef]

- Thomas, C.; Setién, J.; Polanco, J.A.; Alaejos, P.; Sánchez de Juan, M. Durability of recycled aggregate concrete. Constr. Build. Mater. 2013, 40, 1054–1065. [Google Scholar] [CrossRef]

- Kwan, W.H.; Ramli, M.; Kam, K.J.; Sulieman, M.Z. Influence of the amount of recycled coarse aggregate in concrete design and durability properties. Constr. Build. Mater. 2012, 26, 565–573. [Google Scholar] [CrossRef]

- Ann, K.Y.; Moon, H.Y.; Kim, Y.B.; Ryou, J. Durability of recycled aggregate concrete using pozzolanic materials. Waste Manag. 2008, 28, 993–999. [Google Scholar] [CrossRef] [PubMed]

- Kou, S.C.; Poon, C.S. Enhancing the durability properties of concrete prepared with coarse recycled aggregate. Constr. Build. Mater. 2012, 35, 69–76. [Google Scholar] [CrossRef]

- Wang, H.L.; Wang, J.J.; Sun, X.Y.; Jin, W.L. Improving performance of recycled aggregate concrete with superfine pozzolanic powders. J. Cent. South Univ. 2013, 20, 3715–3722. [Google Scholar] [CrossRef]

- Wang, H.L.; Lu, C.H.; Jin, W.L.; Bai, Y. Effect of external loads on chloride transport in concrete. J. Mater. Civ. Eng. 2011, 23, 1043–1049. [Google Scholar] [CrossRef]

- Hoseini, M.; Bindiganavile, V.; Banthia, N. The effect of mechanical stress on permeability of concrete: A review. Cem. Concr. Compos. 2009, 31, 213–220. [Google Scholar] [CrossRef]

- Aldea, C.M.; Ghandehari, M.; Shah, S.P.; Karr, A. Estimation of water flow through cracked concrete under load. ACI Mater. J. 2000, 97, 567–575. [Google Scholar]

- Li, H.M.; Jin, W.; Song, Y.J.; Zhe, W. Effect of external loads on chloride diffusion coefficient of concrete with fly ash and blast furnace slag. J. Mater. Civ. Eng. 2014, 26, 04014053:1–04014053:6. [Google Scholar]

- Banthia, N.; Biparva, A.; Mindess, S. Permeability of concrete under stress. Cem. Concr. Res. 2005, 35, 1651–1655. [Google Scholar] [CrossRef]

- Shi, C. Effect of mixing proportions of concrete on its electrical conductivity and the rapid chloride permeability test (ASTM C1202 or ASSHTO T277) results. Cem. Concr. Res. 2004, 34, 537–545. [Google Scholar] [CrossRef]

- Djerbi, T.A.; Bonnet, S.; Khelidj, A.; Baroghel-Bouny, V. Effect of uniaxial compressive loading on gas permeability and chloride diffusion coefficient of concrete and their relationship. Cem. Concr. Res. 2013, 52, 131–139. [Google Scholar] [CrossRef]

- Costa, A.; Appleton, J. Chloride penetration into concrete in marine environment Part I: Main parameters affecting chloride penetration. Mater. Struct. 1999, 32, 252–259. [Google Scholar] [CrossRef]

- Poulsen, E.; Mejlbro, L. Diffusion of Chloride in Concrete: Theory and Application; Taylor and Francis: London, UK, 2006; p. 84. [Google Scholar]

- Mehta, P.K.; Monteiro, P.J.M. Concrete: Microstructure, Properties and Materials, 3rd ed.; McGraw-Hill: New York, NY, USA, 2006. [Google Scholar]

- Carneiro, J.A.; Lima, P.R.L.; Leite, M.B. Compressive stress-strain behavior of steel fiber reinforced-recycled aggregate concrete. Cem. Concr. Compos. 2014, 46, 65–72. [Google Scholar] [CrossRef]

- Wang, H.L.; Dai, J.G.; Sun, X.Y.; Zhang, X.L. Characteristics of concrete cracks and their influence on chloride penetration. Constr. Build. Mater. 2016, 107, 216–225. [Google Scholar] [CrossRef]

- Wang, H.L.; Jin, W.L.; Li, Q.B. Saturation effect on dynamic tensile and compressive strength of concrete. Adv. Struct. Eng. 2009, 12, 279–286. [Google Scholar] [CrossRef]

| Material | CaO | SiO2 | MgO | P2O5 | Al2O3 | Na2O | Fe2O3 | F |

|---|---|---|---|---|---|---|---|---|

| PHS | 47.91 | 36.81 | 2.56 | 2.73 | 4.47 | 0.49 | 2.27 | 2.65 |

| GGBS | 40.15 | 33.42 | 8.35 | 0 | 14.69 | 0.24 | 0.93 | 0 |

| Ingredients | RAC (Quantity: kg/m3) | NAC (Quantity: kg/m3) |

|---|---|---|

| Cement | 276 | 345 |

| Phosphorous slag | 34.5 | 0 |

| Ground granulated blast-furnace slag | 34.5 | 0 |

| 5–20 mm natural aggregate | 778.5 | 1038 |

| 5–20 mm recycled aggregate | 259.5 | 0 |

| Sand | 677 | 677 |

| FDN superplasticizer | 15.33 | 0 |

| Water | 171 | 171 |

| Permeability Index | RAC | NAC | RAC/NAC |

|---|---|---|---|

| Chloride permeability (10–11 m2/s) | 1.03 | 2.88 | 35.8% |

| Air permeability (Ln(bar)/min) | 0.0240 | 0.0476 | 50.4% |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Sun, X.; Wang, J.; Monteiro, P.J.M. Permeability of Concrete with Recycled Concrete Aggregate and Pozzolanic Materials under Stress. Materials 2016, 9, 252. https://doi.org/10.3390/ma9040252

Wang H, Sun X, Wang J, Monteiro PJM. Permeability of Concrete with Recycled Concrete Aggregate and Pozzolanic Materials under Stress. Materials. 2016; 9(4):252. https://doi.org/10.3390/ma9040252

Chicago/Turabian StyleWang, Hailong, Xiaoyan Sun, Junjie Wang, and Paulo J.M. Monteiro. 2016. "Permeability of Concrete with Recycled Concrete Aggregate and Pozzolanic Materials under Stress" Materials 9, no. 4: 252. https://doi.org/10.3390/ma9040252

APA StyleWang, H., Sun, X., Wang, J., & Monteiro, P. J. M. (2016). Permeability of Concrete with Recycled Concrete Aggregate and Pozzolanic Materials under Stress. Materials, 9(4), 252. https://doi.org/10.3390/ma9040252