RETRACTED: Porosity Defect Remodeling and Tensile Analysis of Cast Steel

Abstract

:1. Introduction

2. Mathematical Model Analysis

3. Experiments and Simulation Model

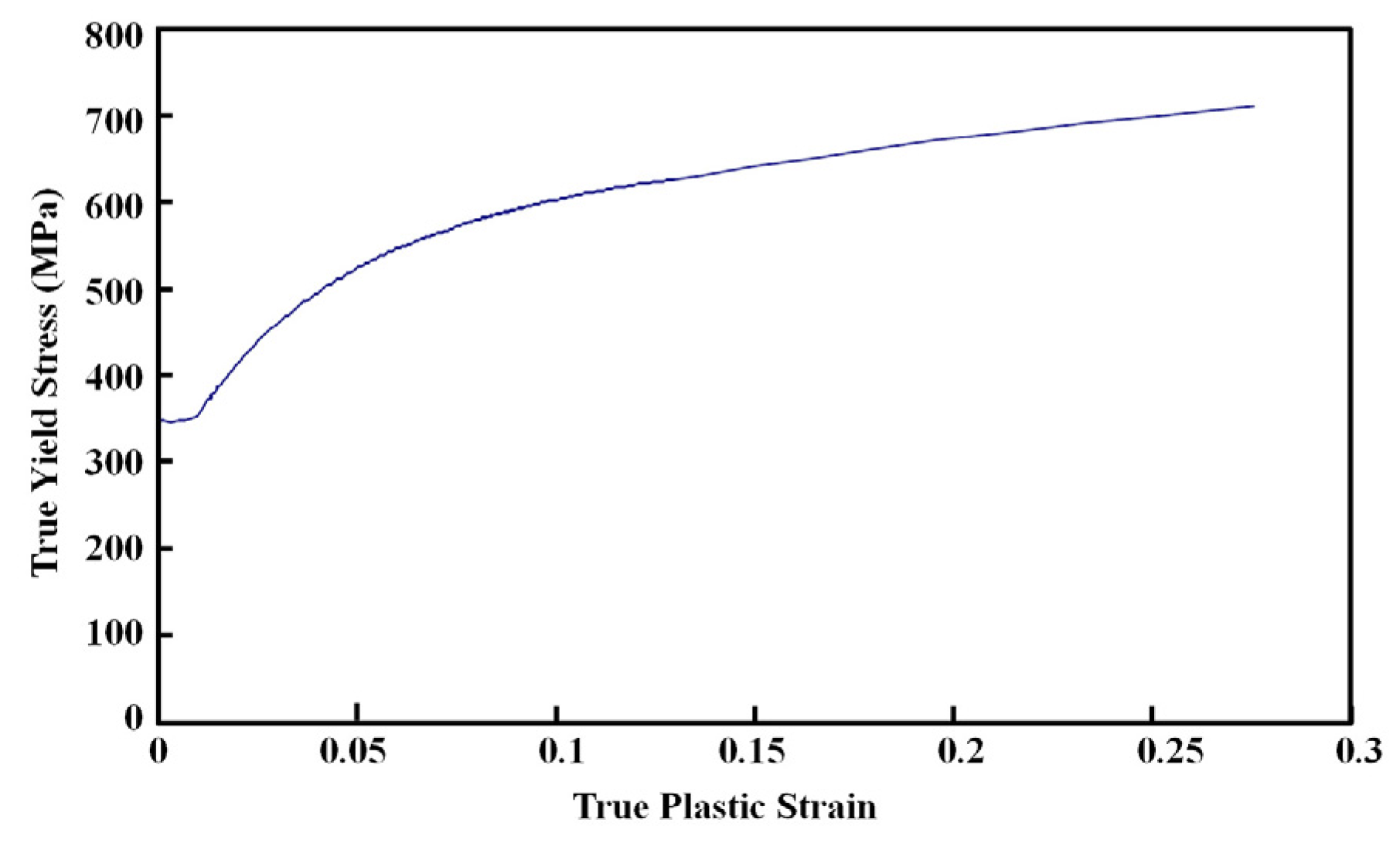

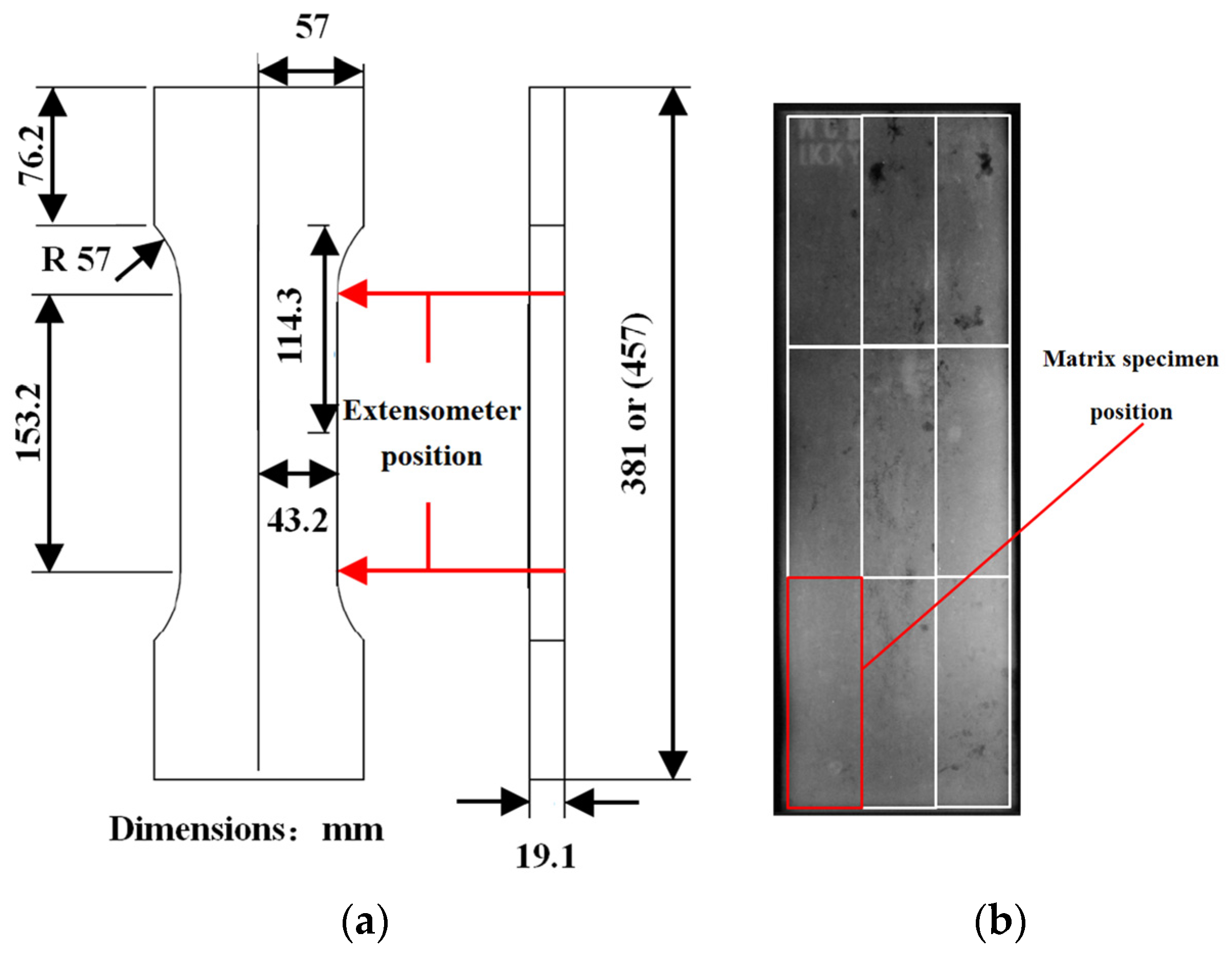

3.1. Selection of Specimen Structure and Material

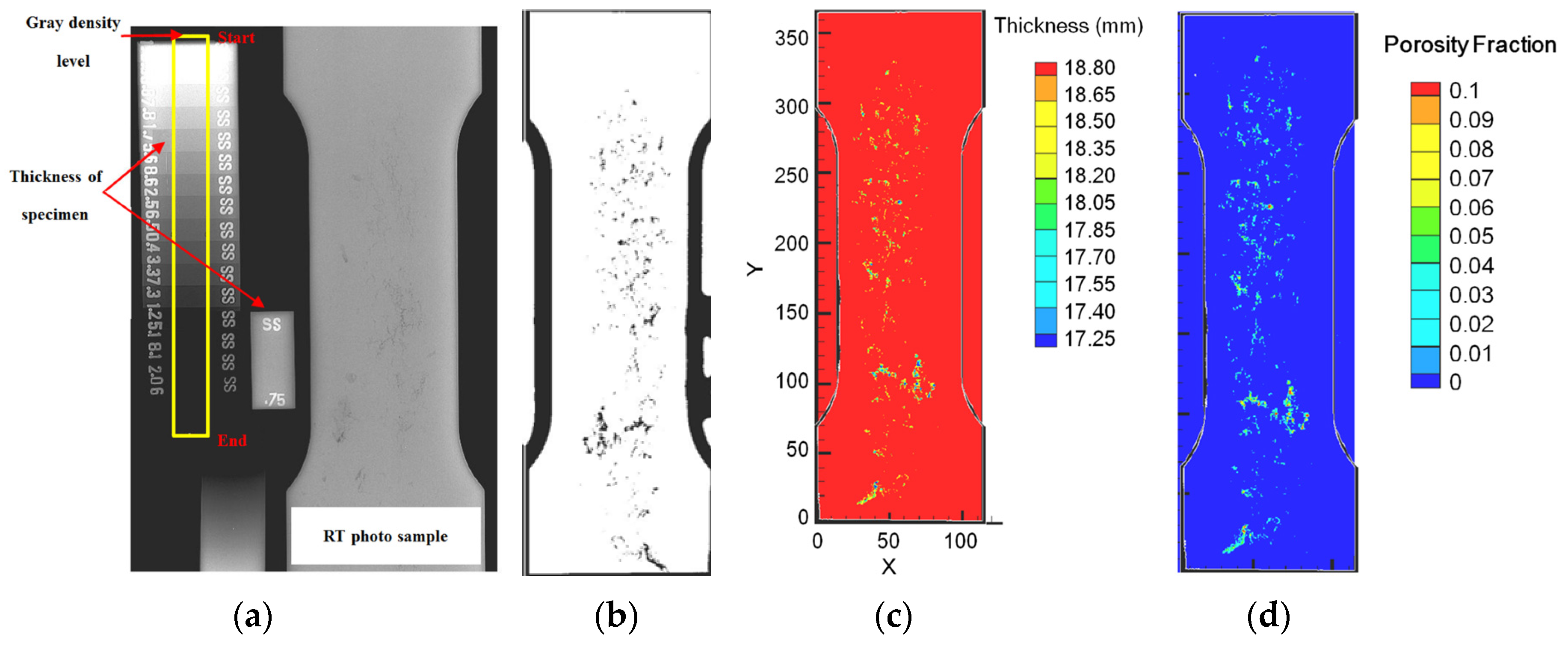

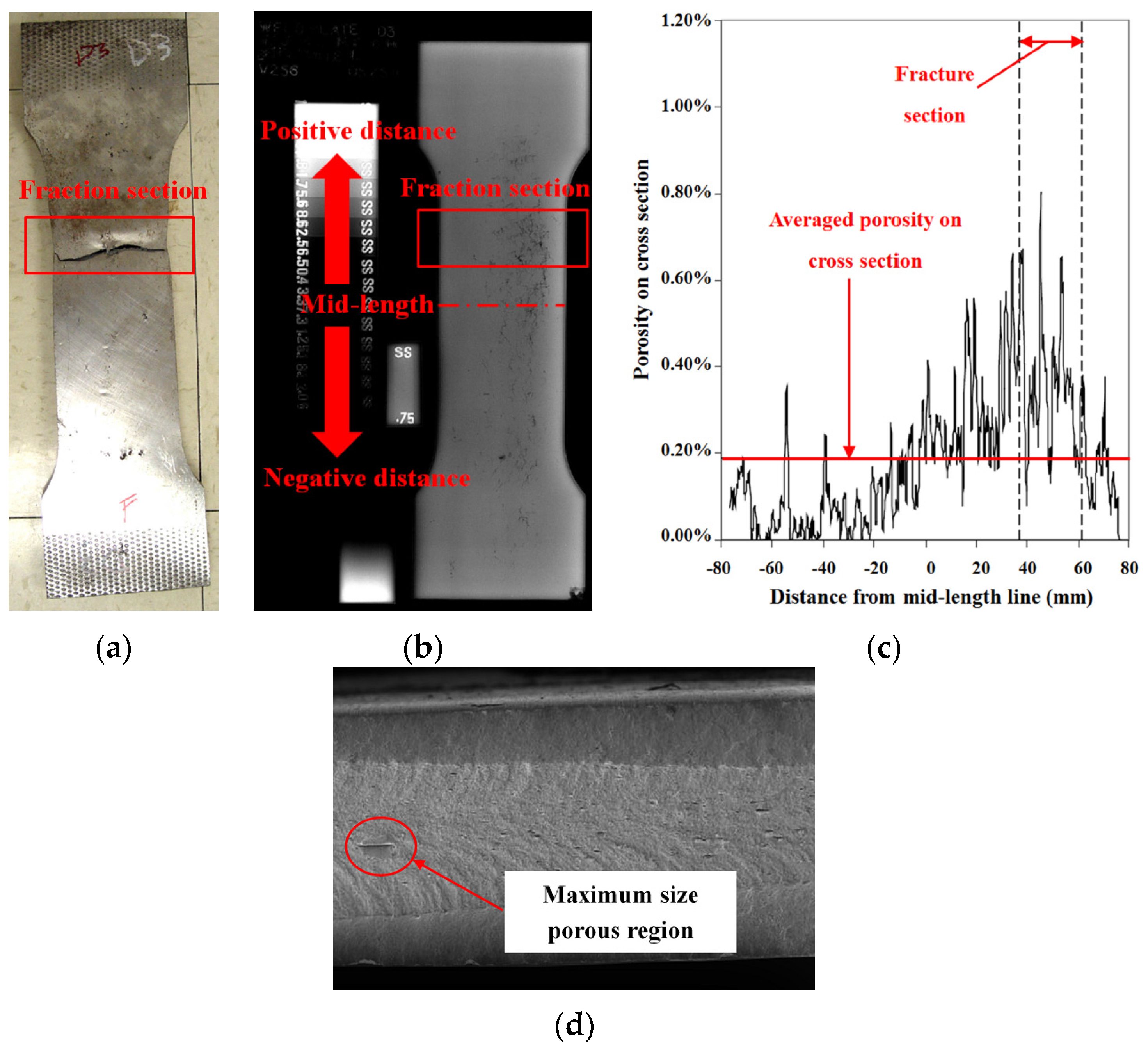

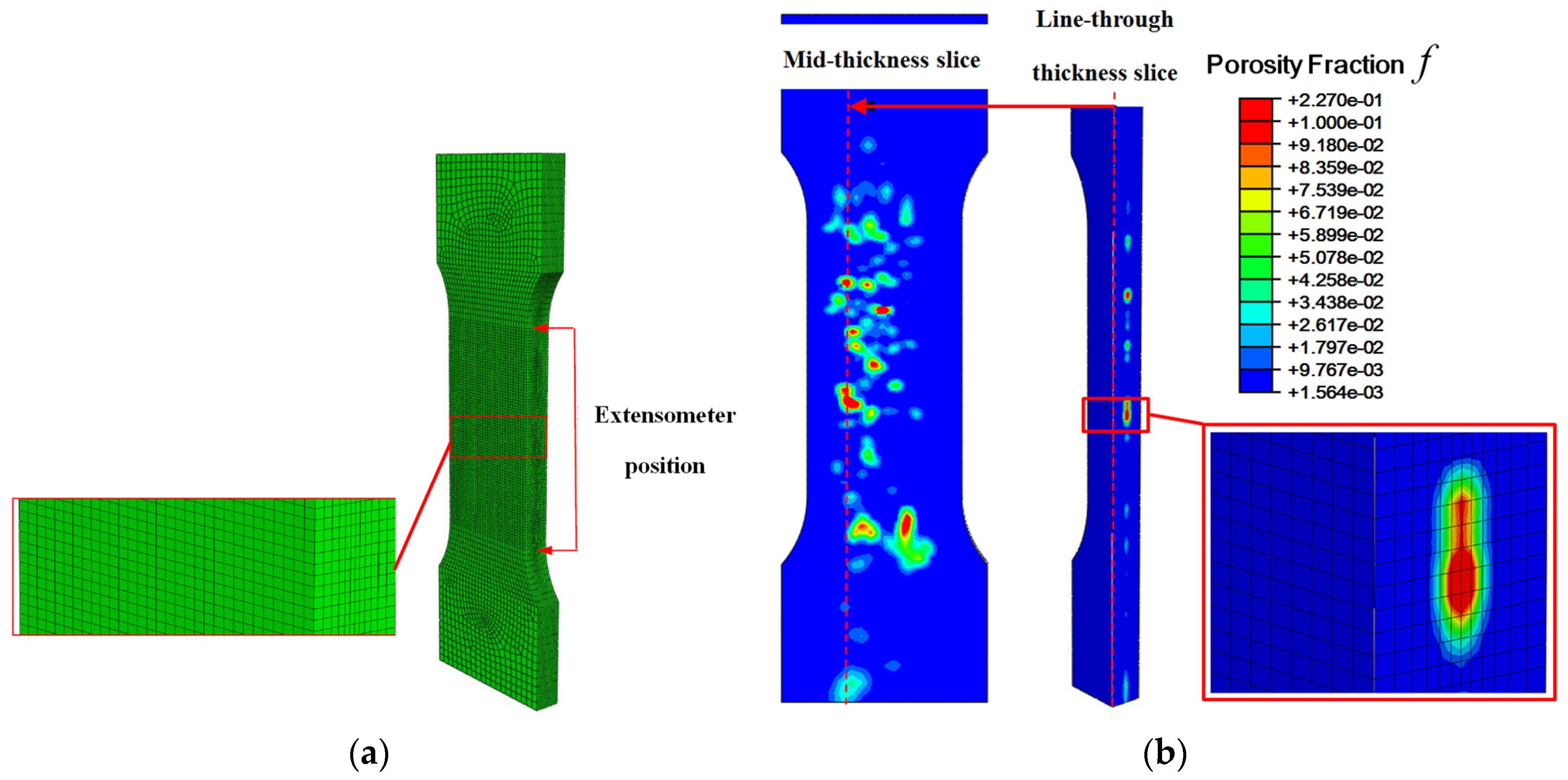

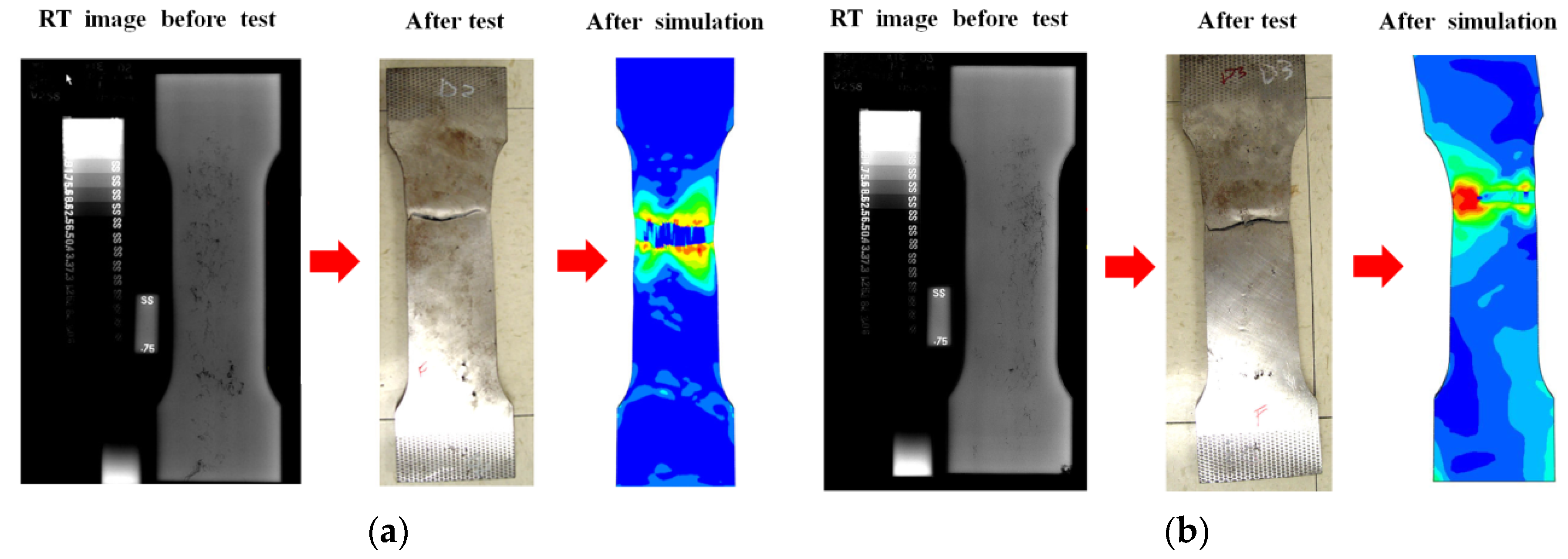

3.2. Radiograph Analysis and Finite Element Remodeling

4. Experimental and Simulation Results and Comparison

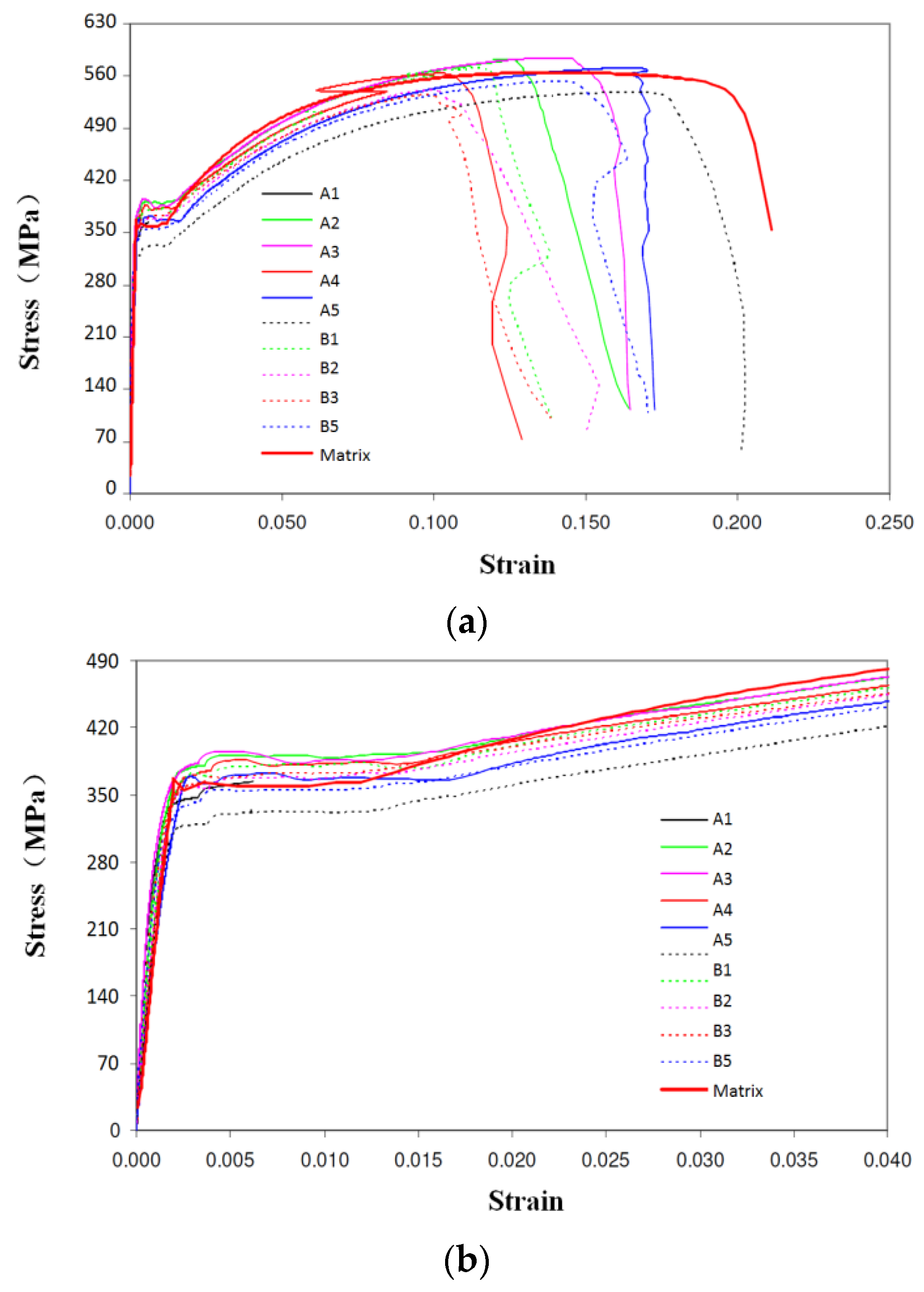

4.1. Experimental Results of Tensile Tests

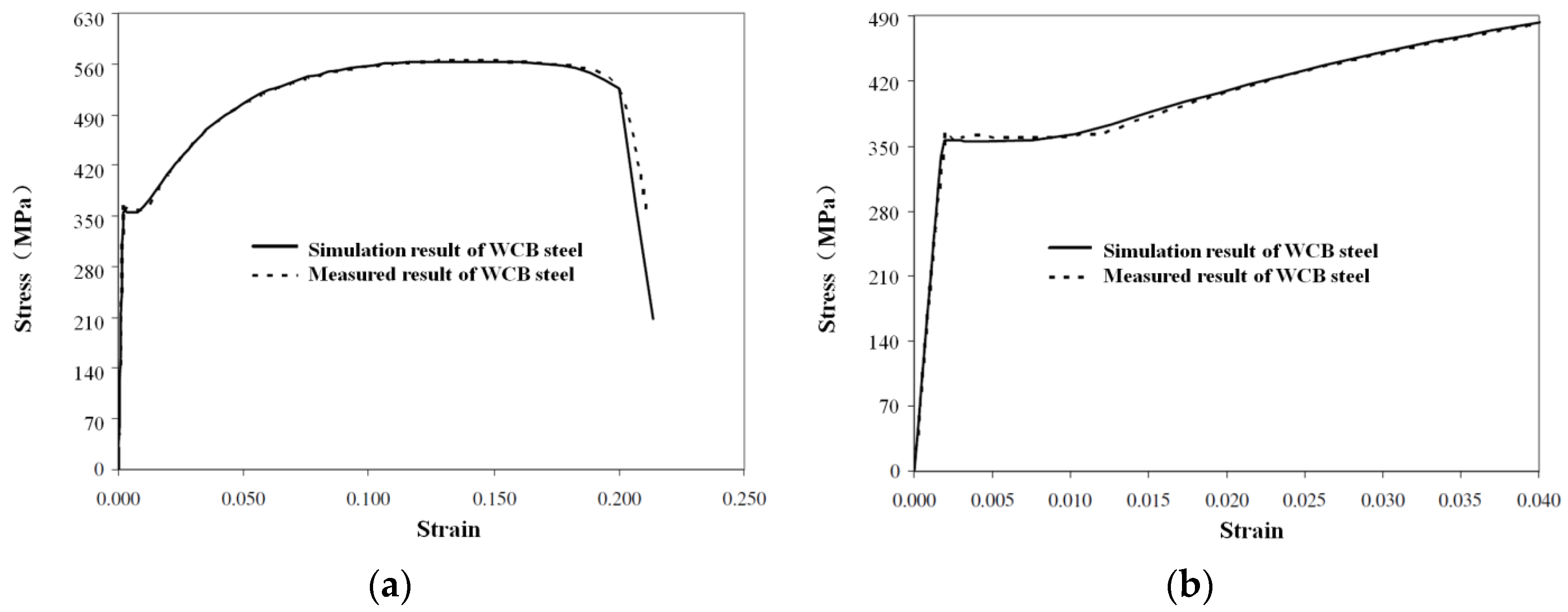

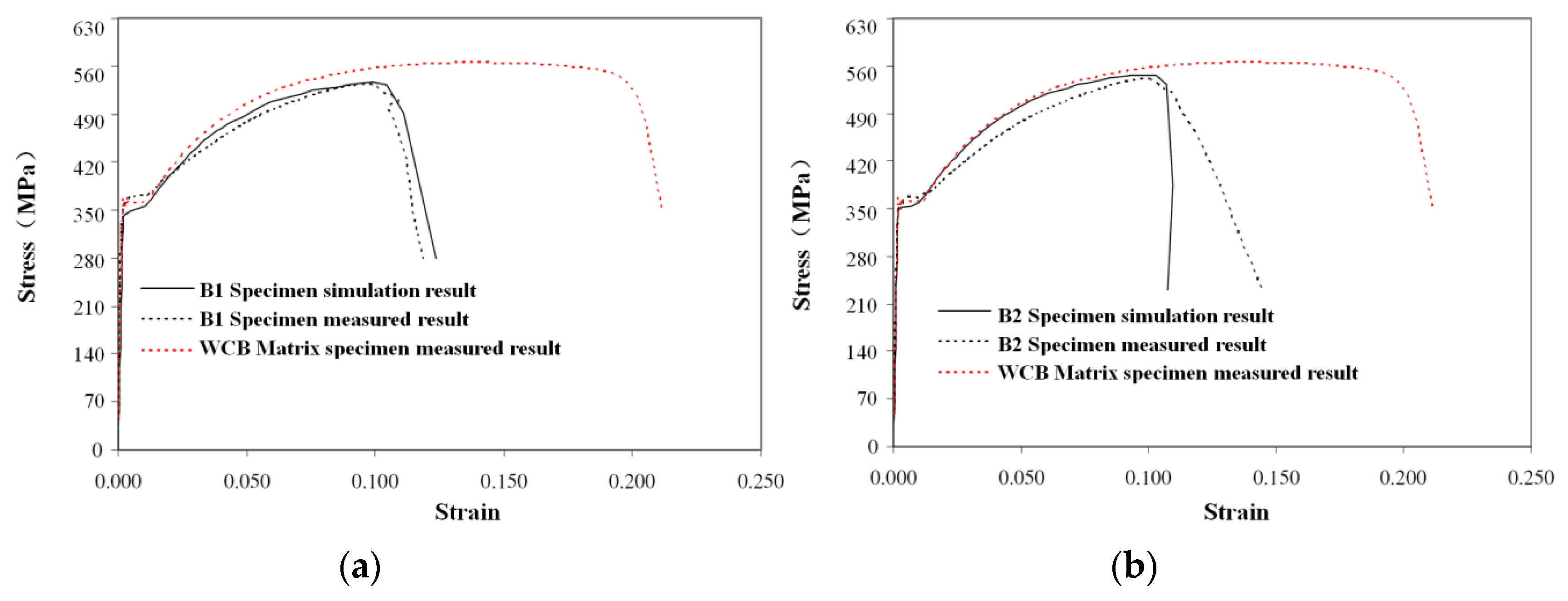

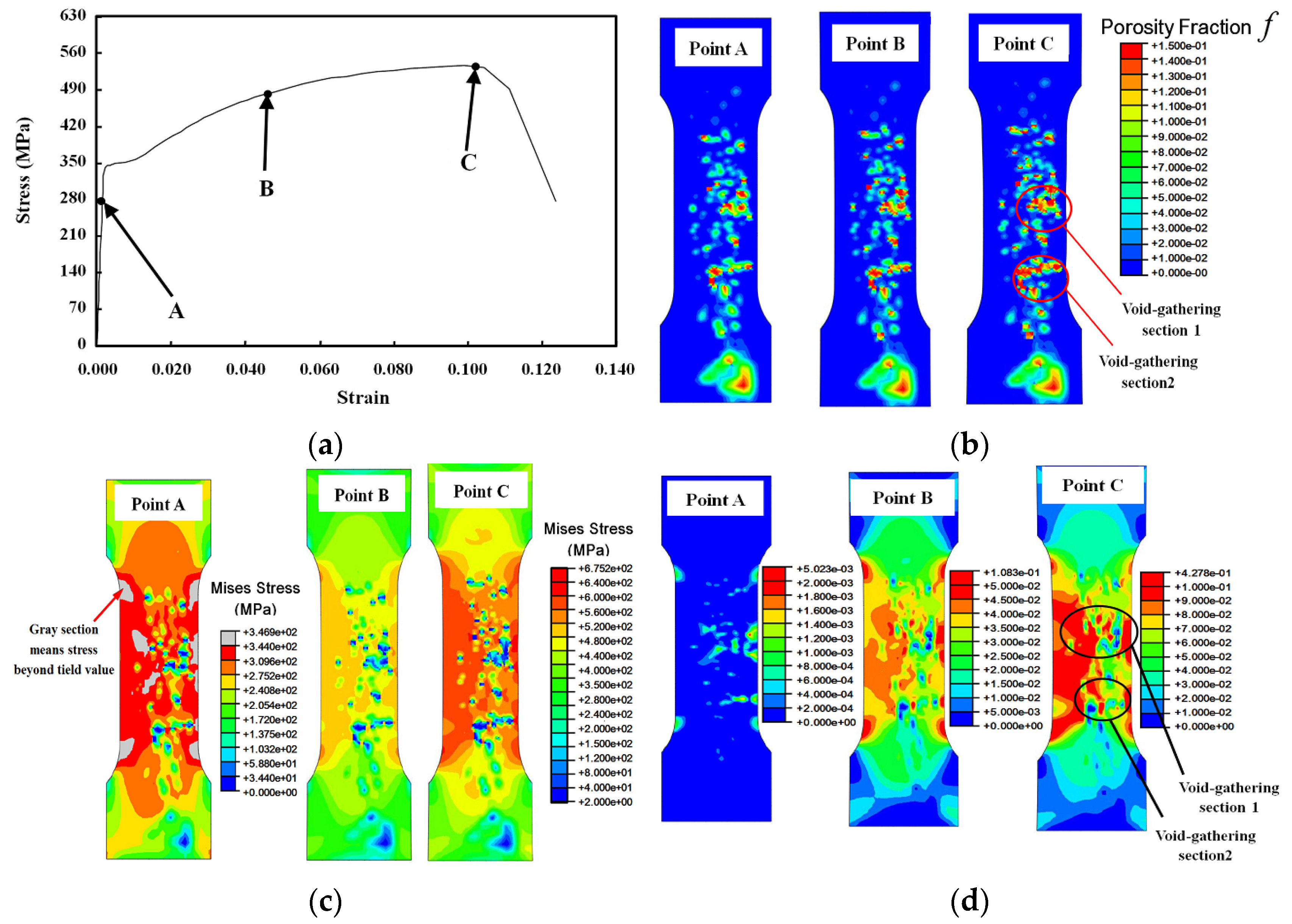

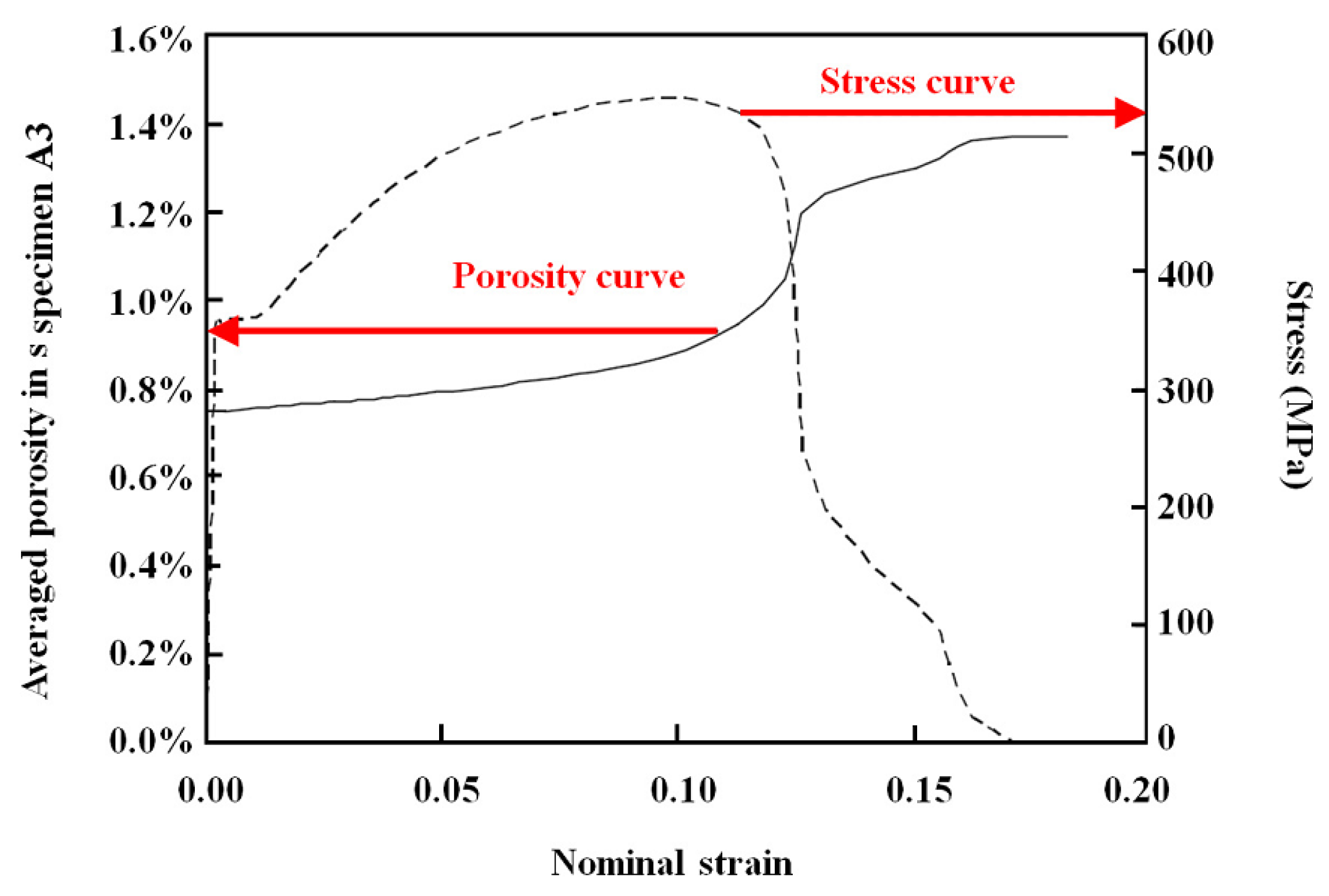

4.2. Simulation Results of Tensile Tests

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Heuler, P.; Berger, C.; Motz, J. Fatigue Behavior of Steel Castings Containing Near-Surface Defects. Fatigue Fract. Eng. Mater. Struct. 1992, 16, 115–136. [Google Scholar] [CrossRef]

- Sigl, K.M.; Hardin, R.; Stephens, R.I.; Beckermann, C. Fatigue of 8630 cast steel in the presence of porosity. Int. J. Cast Met. Res. 2004, 17, 130–146. [Google Scholar] [CrossRef]

- Herakovich, C.T.; Baxter, S.C. Influence of Pore Geometry on the Effective Response of Porous Media. J. Mater. Sci. 1999, 34, 1595–1609. [Google Scholar] [CrossRef]

- Roberts, A.P.; Garboczi, E.J. Elastic Properties of Model Porous Ceramics. J. Am. Ceram. Soc. 2000, 83, 3041–3048. [Google Scholar] [CrossRef]

- Zhang, E.; Wang, B. On the Compressive Behavior of Sintered Porous Coppers with Low to Medium Porosities Part I: Experimental Study. Int. J. Mech. Sci. 2005, 47, 744–756. [Google Scholar] [CrossRef]

- Hangai, Y.; Kamada, H.; Utsunomiya, T.; Kitahara, S.; Kuwazuru, O.; Yoshikawa, N. Tensile Properties and Fracture Behavior of Aluminum Alloy Foam Fabricated from Die Castings without Using Blowing Agent by Friction Stir Processing Route. Materials 2014, 7, 2382–2394. [Google Scholar] [CrossRef]

- Dewey, J.M. The Elastic Constants of Materials Loaded with Non-rigid Fillers. J. Appl. Phys. 1947, 18, 578–581. [Google Scholar] [CrossRef]

- Tvergaard, V. Influence of Voids on Shear Band Instabilities under Plane Strain Condition. Int. J. Fract. 1981, 17, 389–407. [Google Scholar] [CrossRef]

- Ramakrishnan, N.; Arunachalam, V.S. Effective Elastic Moduli of Porous Ceramic Materials. J. Am. Ceram. Soc. 1993, 76, 2745–2752. [Google Scholar] [CrossRef]

- Taxer, T.; Schwarz, C.; Smarsly, W.; Werner, E. A finite element approach to study the influence of cast pores on the mechanical properties of Ni-base alloy MAR-M247. Mater. Sci. Eng. A 2013, 575, 144–151. [Google Scholar] [CrossRef]

- Ghosh, S.; Moorthy, S. Three dimensional Voronoi cell finite element model for microstructures with ellipsoidal heterogeneities. Comput. Mech. 2004, 34, 510–531. [Google Scholar] [CrossRef]

- Hangai, Y.; Kitahara, S. Quantitative evaluation of porosity in aluminum die castings by fractal analysis of perimeter. Mater. Trans. 2008, 49, 782–786. [Google Scholar] [CrossRef]

- Ries, M.; Krempaszky, C.; Hadler, B.; Werner, E. The influence of porosity on the elastoplastic behavior of high performance cast alloys. Proc. Appl. Math. Mech. 2007, 7. [Google Scholar] [CrossRef]

- ASTM A216 Grade WCB Cast Steel. Available online: http://www.makeitfrom.com/material-properties/ASTM-A216-Grade-WCB-Cast-Steel/ (accessed on 11 June 2015).

- Rice, R.W. Use of normalized porosity in models for the porosity dependence of mechanical properties. J. Mater. Sci. 2005, 40, 983–989. [Google Scholar] [CrossRef]

- Bert, C.W. Prediction of elastic moduli of solids with oriented porosity. J. Mater. Sci. 1985, 20, 2220–2224. [Google Scholar] [CrossRef]

- Gurson, A.L. Continuum theory of ductile rupture by void nucleation and growth: Part I—Yield criteria and flow rules for porous ductile media. J. Eng. Mater. Tech. 1977, 99, 2–15. [Google Scholar] [CrossRef]

- Dassault Systèmes. ABAQUS Theory Manual. Version 6.10, Section 4.3.6 Porous Metal Plasticity. Available online: http://abaqusdoc.ucalgary.ca/books/stm/default.htm (accessed on 11 June 2015).

- Needleman, A.; Tvergaard, V. An Analysis of Ductile Rupture in Notched Bar. J. Mech. Phys. Solids 1984, 32, 461–490. [Google Scholar] [CrossRef]

- American Society for Testing Materials. Standard Test Methods for Tension Testing of Metallic Materials; ASTM E8/E8M-08; ASTM International: West Conshohocken, PA, USA, 2008. [Google Scholar]

- Davis, J.R. Tensile Testing, 2nd ed.; ASM International: Materials Park, OH, USA, 2004. [Google Scholar]

| Specimen | Elastic Modulus (MPa) | Yield Stress (MPa) | Ultimate Strength (MPa) | Elongation (%) |

|---|---|---|---|---|

| A1 | 179,931.92 | 351.71 | 573.65 | 16.11 |

| A2 | 179,649.23 | 388.53 | 575.66 | 16.30 |

| A3 | 178,766.67 | 362.13 | 525.68 | 13.80 |

| A4 | 174,167.70 | 375.02 | 554.43 | 12.80 |

| A5 | 173,126.56 | 383.71 | 572.63 | 16.00 |

| B1 | 172,175.05 | 355.30 | 532.09 | 15.00 |

| B2 | 169,051.61 | 349.23 | 543.88 | 17.00 |

| B3 | 162,625.47 | 368.06 | 562.08 | 13.80 |

| B4 | 157,178.42 | 329.24 | 542.02 | 19.60 |

| B5 | 137,258.77 | 373.36 | 575.80 | 17.10 |

| Matrix | 190,302.00 | 356.89 | 556.08 | 22.00 |

| 1.5 | 1 | 2.25 | 0.002 | 0.05 | 0.15 | 0.3 | 0.1 | 0.04 |

| Specimen | Yield Stress (MPa) | Ultimate Strength (MPa) | Elongation (%) |

|---|---|---|---|

| A1 | 359.22 | 568.97 | 16.23 |

| A2 | 380.37 | 565.19 | 16.15 |

| A3 | 339.23 | 524.02 | 12.30 |

| A4 | 380.30 | 535.33 | 11.89 |

| A5 | 375.27 | 560.91 | 16.10 |

| B1 | 352.33 | 538.50 | 10.70 |

| B2 | 337.17 | 533.67 | 16.20 |

| B3 | 356.37 | 533.67 | 13.90 |

| B4 | 346.82 | 536.43 | 11.80 |

| B5 | 355.82 | 555.74 | 17.00 |

| Matrix | 350.27 | 555.74 | 21.50 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, L.; Liao, R.; Lu, W.; Fu, S. RETRACTED: Porosity Defect Remodeling and Tensile Analysis of Cast Steel. Materials 2016, 9, 119. https://doi.org/10.3390/ma9020119

Sun L, Liao R, Lu W, Fu S. RETRACTED: Porosity Defect Remodeling and Tensile Analysis of Cast Steel. Materials. 2016; 9(2):119. https://doi.org/10.3390/ma9020119

Chicago/Turabian StyleSun, Linfeng, Ridong Liao, Wei Lu, and Sibo Fu. 2016. "RETRACTED: Porosity Defect Remodeling and Tensile Analysis of Cast Steel" Materials 9, no. 2: 119. https://doi.org/10.3390/ma9020119

APA StyleSun, L., Liao, R., Lu, W., & Fu, S. (2016). RETRACTED: Porosity Defect Remodeling and Tensile Analysis of Cast Steel. Materials, 9(2), 119. https://doi.org/10.3390/ma9020119