Performance of High Layer Thickness in Selective Laser Melting of Ti6Al4V

Abstract

:1. Introduction

2. Experimental Procedures

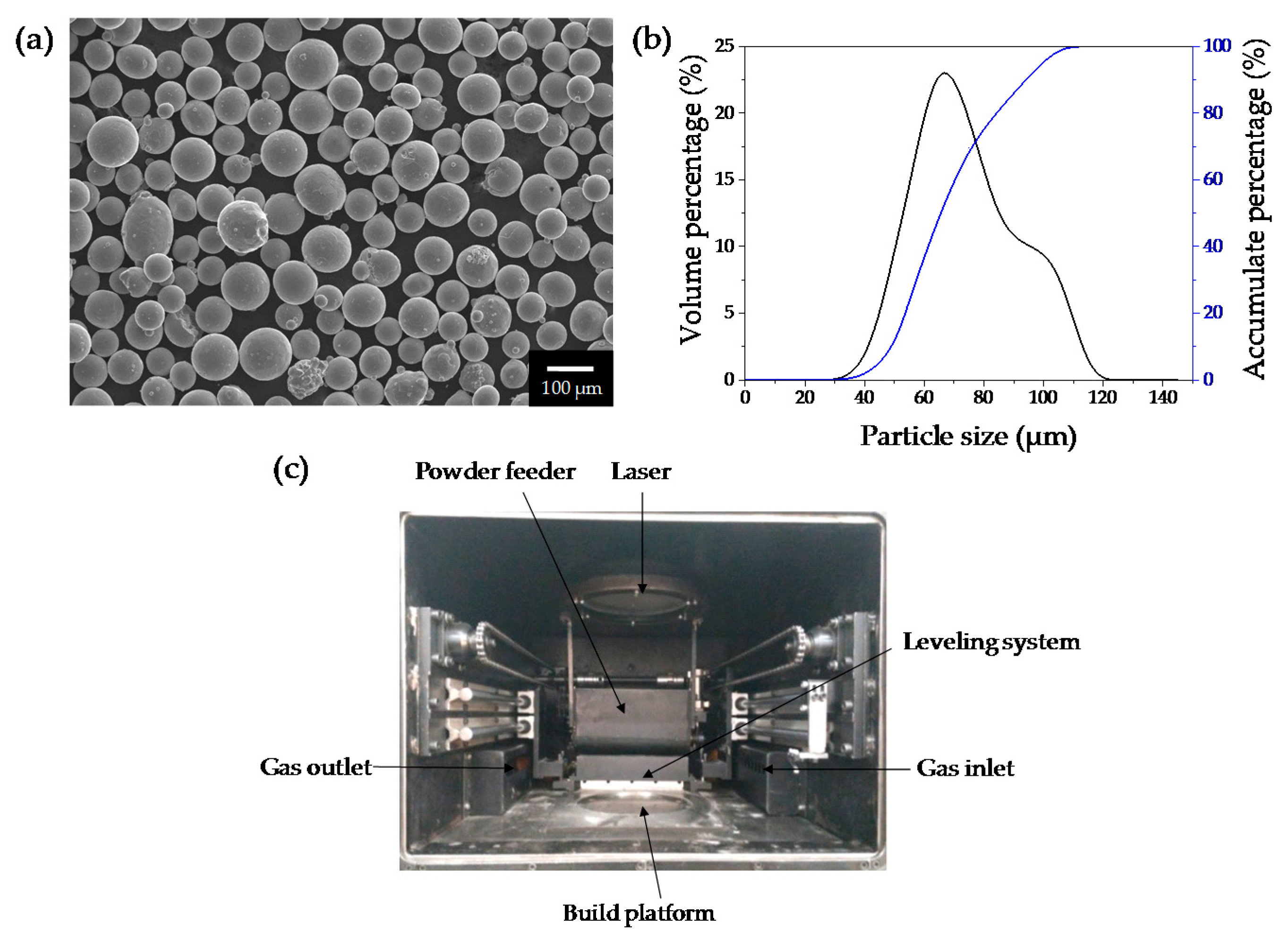

2.1. Materials

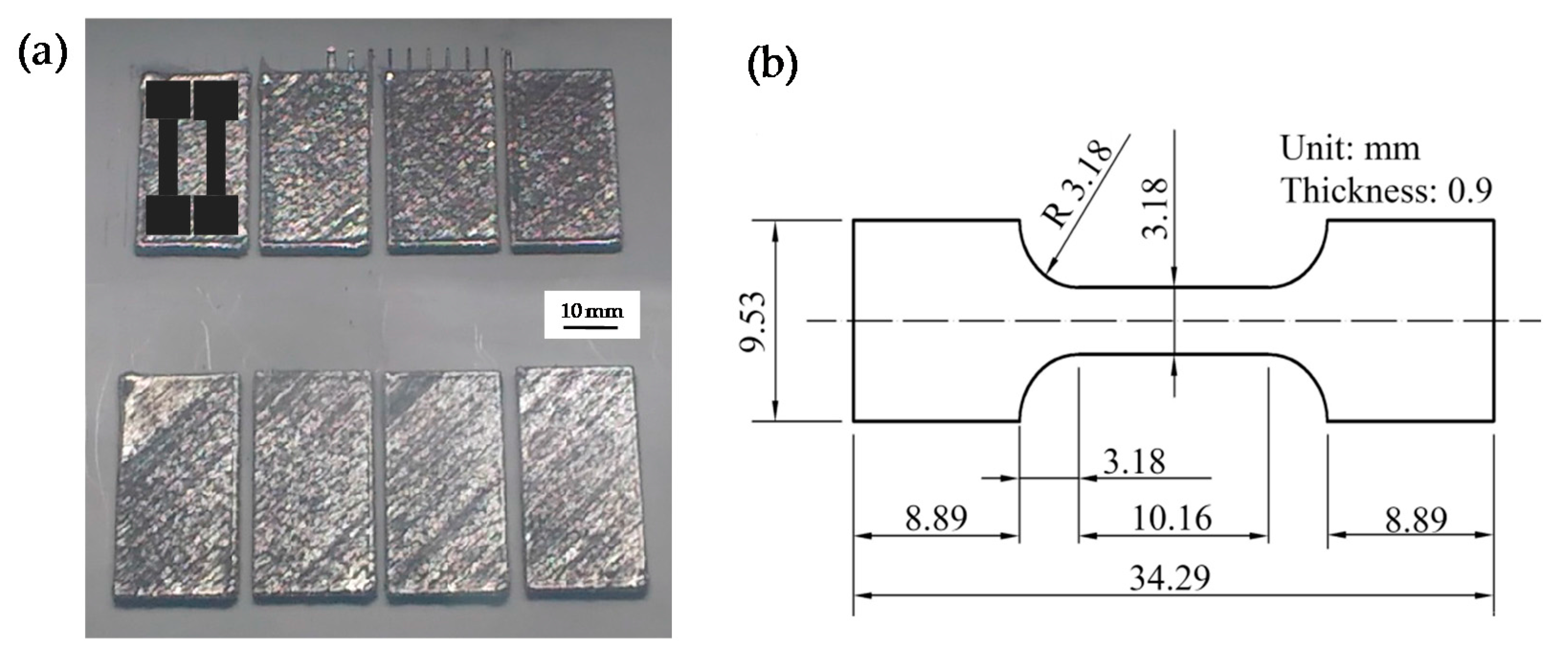

2.2. Experimental Setup and Manufacturing Process

2.3. Characterization

3. Results and Discussion

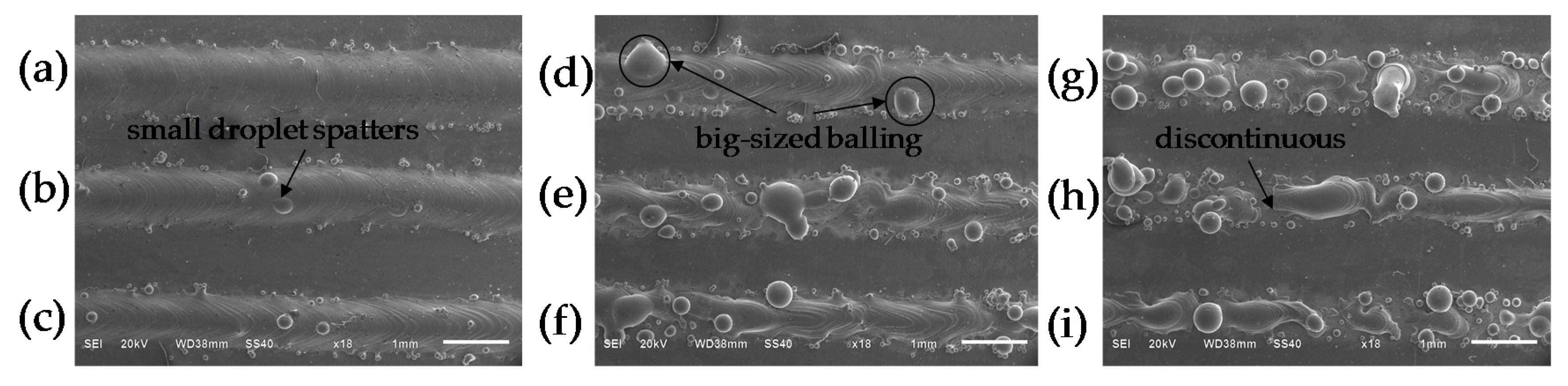

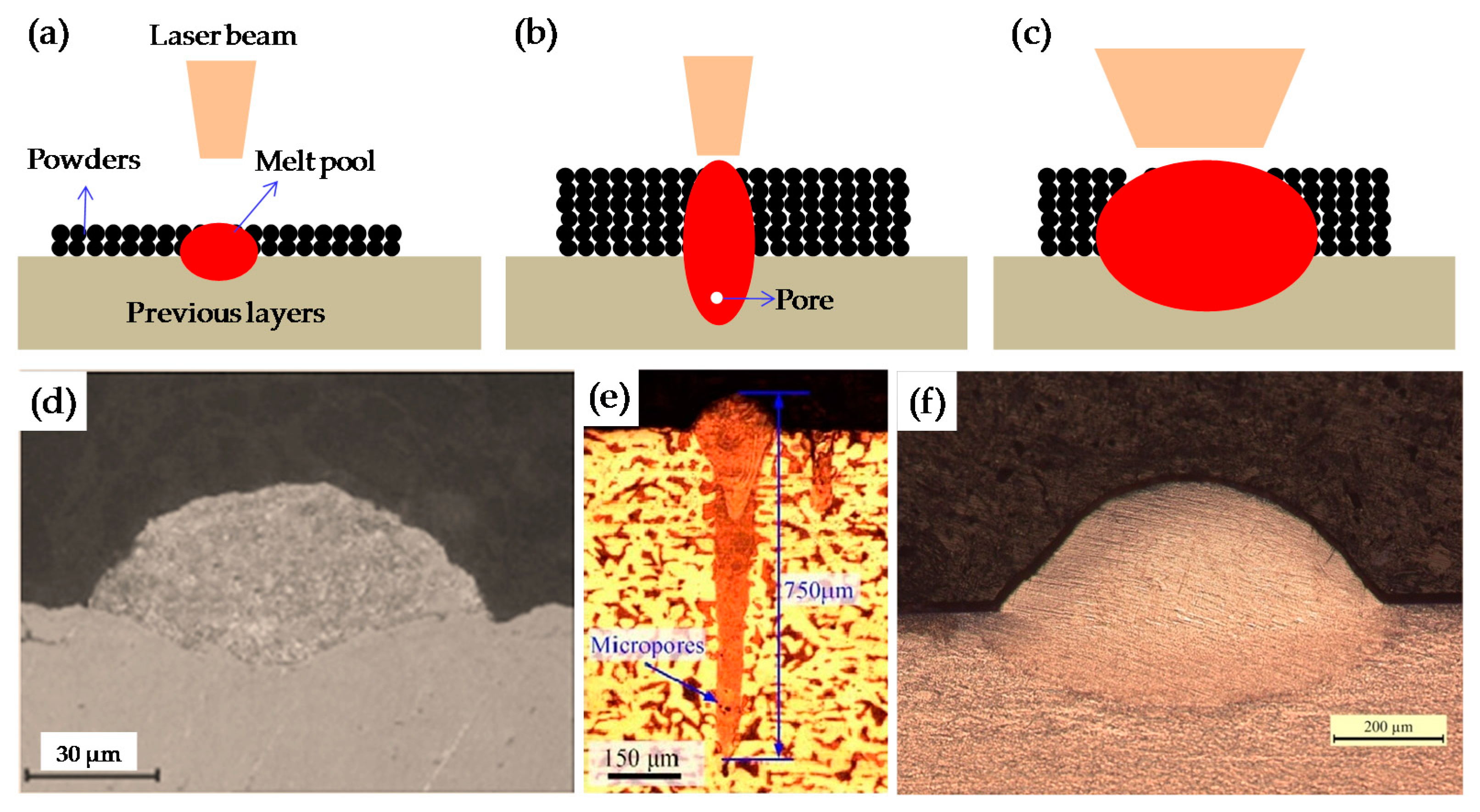

3.1. Single Scan Tracks

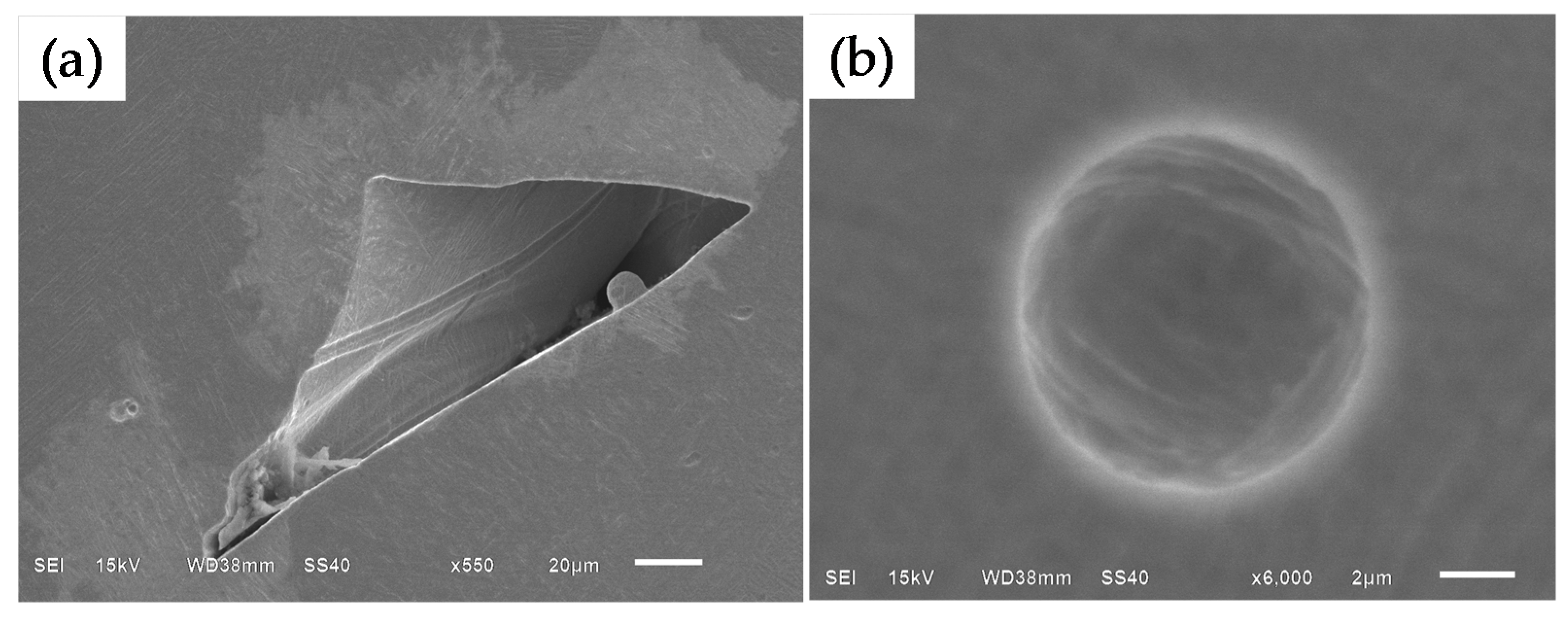

3.1.1. Surface Morphologies

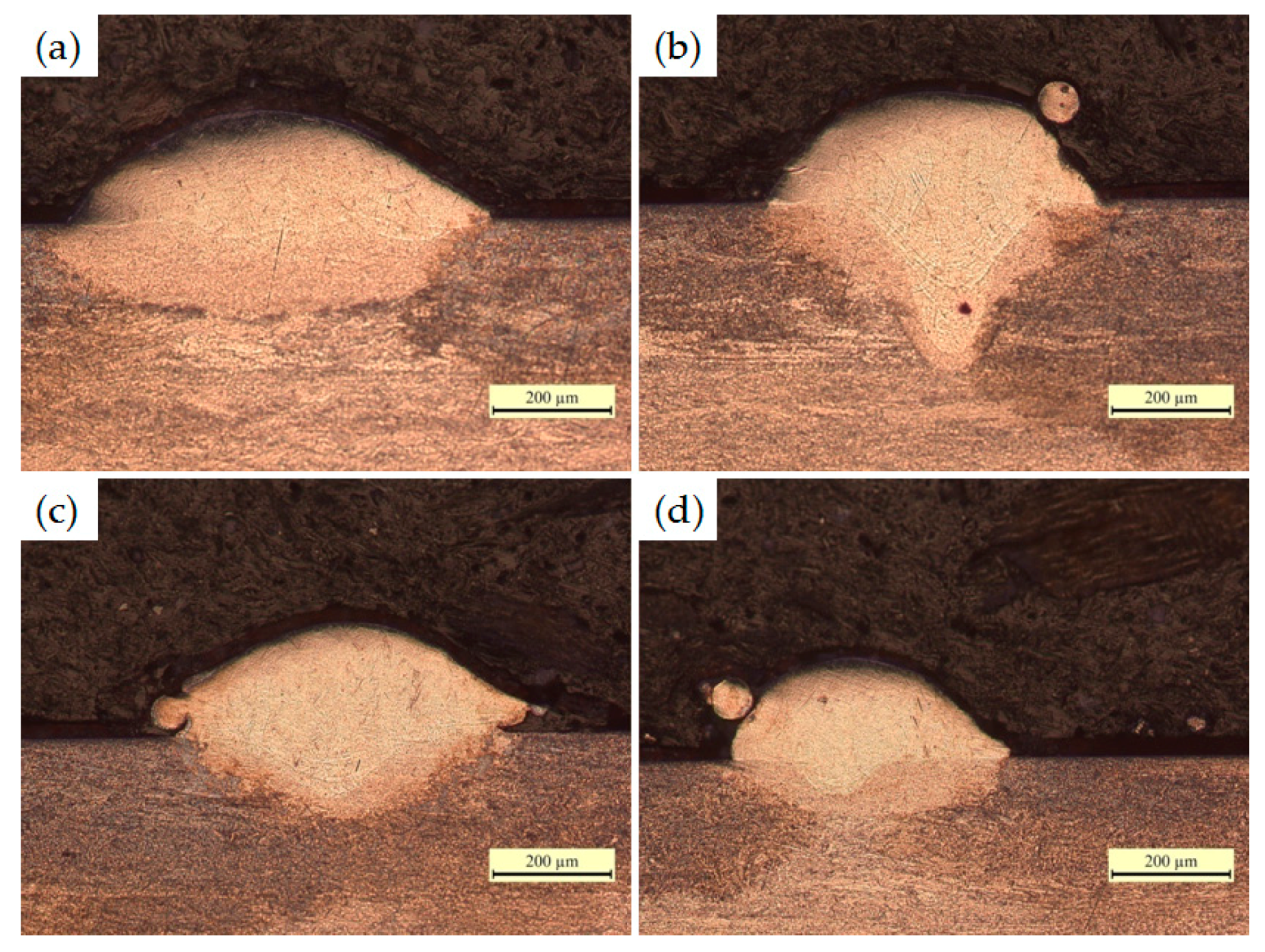

3.1.2. Geometrical Characteristics

3.2. Multi-Layer Fabrication

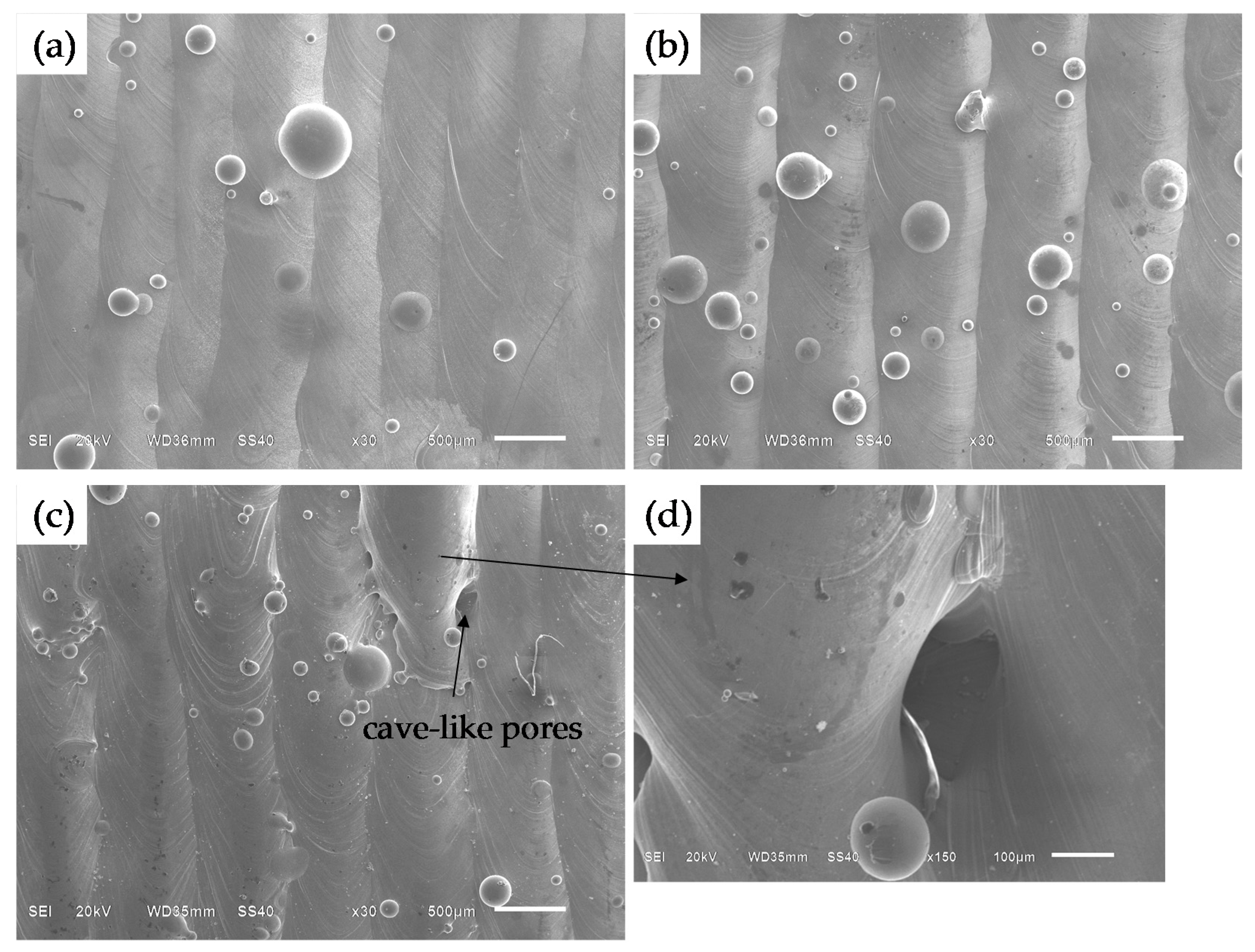

3.2.1. Density Behavior

3.2.2. Building Rate

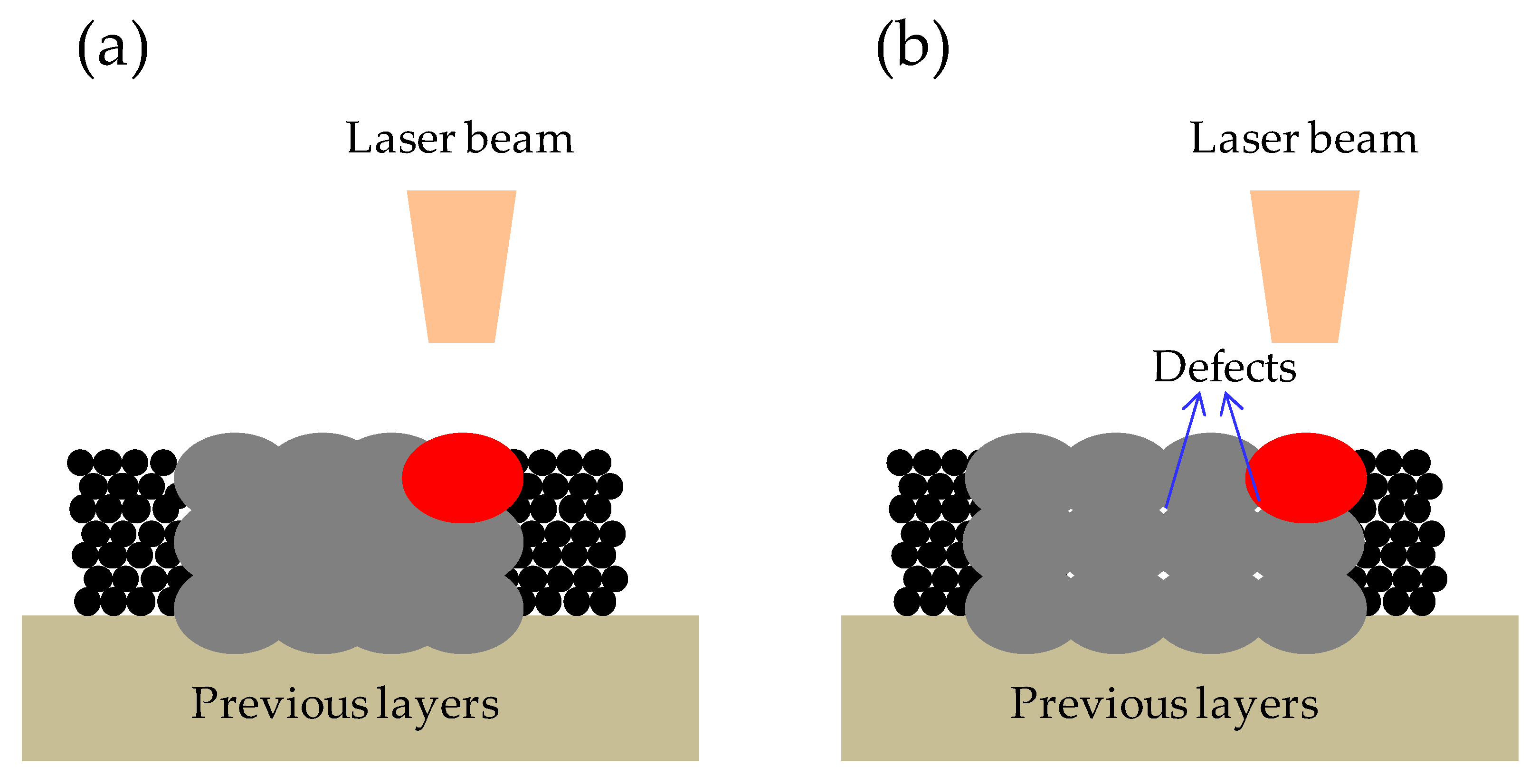

3.2.3. Mechanisms of Defects Forming

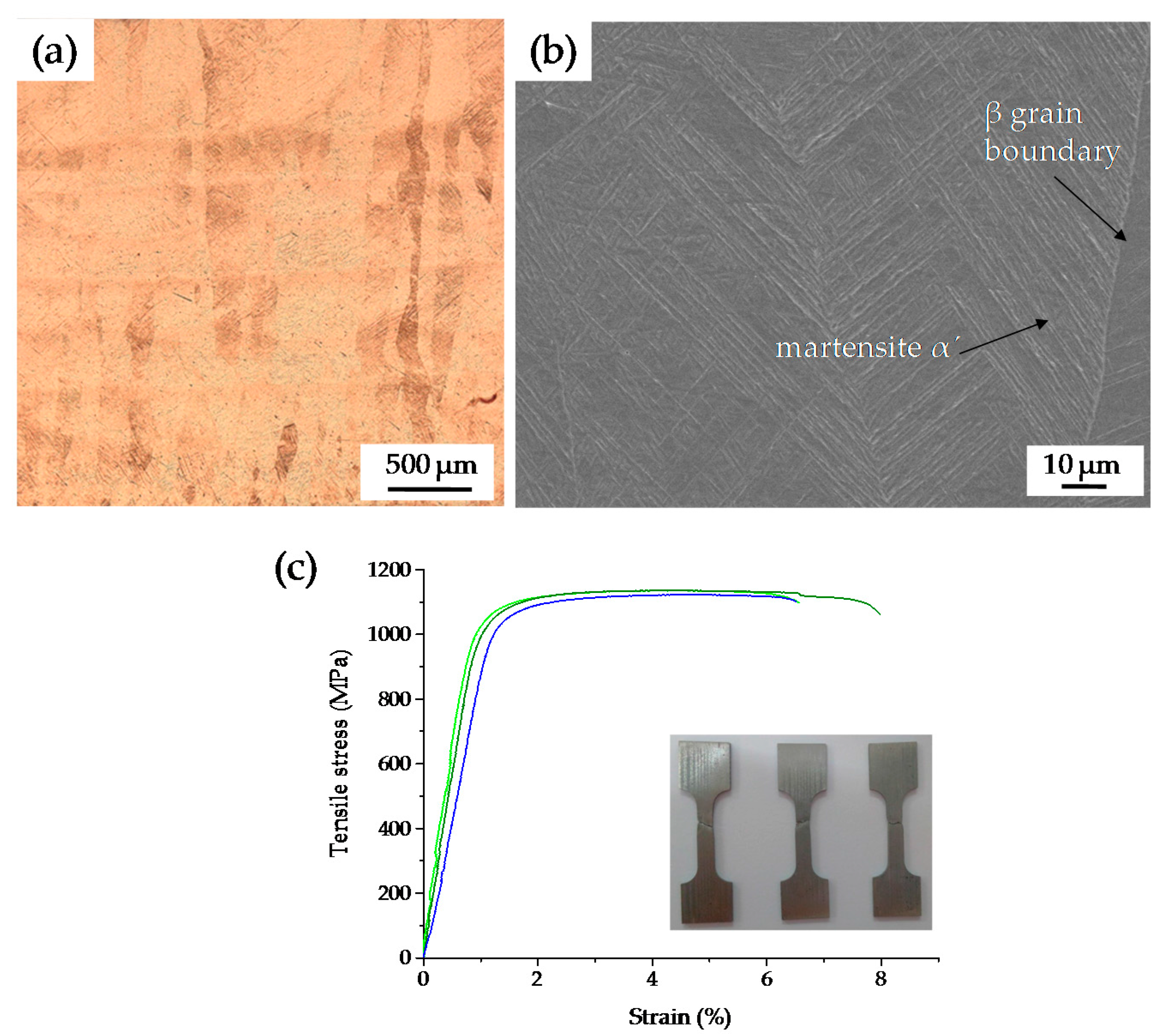

3.2.4. Microstructure and Tensile Properties

4. Conclusions

- (1)

- The series of single track experiments showed that a stable and proper melt pool can be obtained at lower scanning speeds from 40 mm/s to 80 mm/s combined with a laser power of 400 W and a laser beam diameter of 200 μm.

- (2)

- All the fabricated samples were very close to full density ranging from 99.73% to 99.99%. The building rate was up to 7.2 mm3/s, which is about 2 times–9 times that of the commercial equipment.

- (3)

- There are two different defect morphologies in the specimens’ interior, the large un-melted defects and the small spherical micropores. The formation of the un-melted defects was mainly attributed to the inappropriate overlap rates and the unstable scanning tracks, which can be eliminated by adjusting the processing parameters. Nevertheless, the micropores cannot be completely eliminated.

- (4)

- The microstructure of SLM samples consisted of a mixture of α and β phases. The coarse β columnar grains grew along the building direction of the SLM samples. The majority of acicular martensite α′ originate from the prior β grain boundaries and filled the columnar grains.

- (5)

- The high layer thickness played a key role on surface roughness rather than tensile properties during the SLM process. Although a sample with a relatively coarse surface was generated, the average values of yield strength, ultimate tensile strength, and elongation were 1050 MPa, 1140 MPa, and 7.03%, respectively, which are not obviously different than those of the thin layer thickness in the previous research; this is due to the similar metallurgical bonding and microstructure.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Strantza, M.; Vafadari, R.; de Baere, D.; Vrancken, B.; van Paepegem, W.; Vandendael, I.; Terryn, H.; Guillaume, P.; van Hemelrijck, D. Fatigue of Ti6Al4V structural health monitoring systems produced by selective laser melting. Materials 2016, 9, 106. [Google Scholar] [CrossRef]

- Campanelli, S.; Contuzzi, N.; Ludovico, A.; Caiazzo, F.; Cardaropoli, F.; Sergi, V. Manufacturing and characterization of Ti6Al4V lattice components manufactured by selective laser melting. Materials 2014, 7, 4803–4822. [Google Scholar] [CrossRef]

- Murr, L.E.; Quinones, S.A.; Gaytan, S.M.; Lopez, M.I.; Rodela, A.; Martinez, E.Y.; Hernandez, D.H.; Martinez, E.; Medina, F.; Wicker, R.B. Microstructure and mechanical behavior of Ti–6Al–4V produced by rapid-layer manufacturing, for biomedical applications. J. Mech. Behav. Biomed. Mater. 2009, 2, 20–32. [Google Scholar] [CrossRef] [PubMed]

- Maskery, I.; Aremu, A.O.; Simonelli, M.; Tuck, C.; Wildman, R.D.; Ashcroft, I.A.; Hague, R.J.M. Mechanical properties of Ti–6Al–4V selectively laser melted parts with body-centred-cubic lattices of varying cell size. Exp. Mech. 2015, 55, 1261–1272. [Google Scholar] [CrossRef]

- Rafi, H.K.; Karthik, N.V.; Gong, H.; Starr, T.L.; Stucker, B.E. Microstructures and mechanical properties of Ti6Al4V parts fabricated by selective laser melting and electron beam melting. J. Mater. Eng. Perform. 2013, 22, 3872–3883. [Google Scholar] [CrossRef]

- Zhang, S.; Wei, Q.; Cheng, L.; Li, S.; Shi, Y. Effects of scan line spacing on pore characteristics and mechanical properties of porous ti6al4v implants fabricated by selective laser melting. Mater. Des. 2014, 63, 185–193. [Google Scholar] [CrossRef]

- Song, B.; Dong, S.; Zhang, B.; Liao, H.; Coddet, C. Effects of processing parameters on microstructure and mechanical property of selective laser melted Ti6Al4V. Mater. Des. 2012, 35, 120–125. [Google Scholar] [CrossRef]

- Sun, J.; Yang, Y.; Wang, D. Mechanical properties of a ti6al4v porous structure produced by selective laser melting. Mater. Des. 2013, 49, 545–552. [Google Scholar] [CrossRef]

- Wang, F.; Williams, S.; Colegrove, P.; Antonysamy, A.A. Microstructure and mechanical properties of wire and arc additive manufactured Ti-6Al-4V. Metall. Mater. Trans. A 2012, 44, 968–977. [Google Scholar] [CrossRef]

- Ma, M.; Wang, Z.; Gao, M.; Zeng, X. Layer thickness dependence of performance in high-power selective laser melting of 1Cr18Ni9Ti stainless steel. J. Mater. Process. Technol. 2015, 215, 142–150. [Google Scholar] [CrossRef]

- Bremen, S.; Wilhelm, M.; Andrei, D. Selective laser melting-a manufacturing technology for the future? Laser Tech. J. 2012, 9, 33–38. [Google Scholar] [CrossRef]

- Li, R.; Liu, J.; Shi, Y.; Wang, L.; Jiang, W. Balling behavior of stainless steel and nickel powder during selective laser melting process. Int. J. Adv. Manuf. Technol. 2011, 59, 1025–1035. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Smurov, I. Selective laser melting technology: From the single laser melted track stability to 3d parts of complex shape. Phys. Proced. 2010, 5, 551–560. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Gusarov, A.; Yadroitsava, I.; Smurov, I. Single track formation in selective laser melting of metal powders. J. Mater. Process. Technol. 2010, 210, 1624–1631. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Yadroitsava, I.; Bertrand, P.; Smurov, I. Factor analysis of selective laser melting process parameters and geometrical characteristics of synthesized single tracks. Rapid Prototyp. J. 2012, 18, 201–208. [Google Scholar] [CrossRef]

- Gu, D.; Hagedorn, Y.-C.; Meiners, W.; Meng, G.; Batista, R.J.S.; Wissenbach, K.; Poprawe, R. Densification behavior, microstructure evolution, and wear performance of selective laser melting processed commercially pure titanium. Acta Mater. 2012, 60, 3849–3860. [Google Scholar] [CrossRef]

- Hu, Z.; Zhu, H.; Zhang, H.; Zeng, X. Experimental investigation on selective laser melting of 17-4ph stainless steel. Opt. Laser Technol. 2017, 87, 17–25. [Google Scholar] [CrossRef]

- Dadbakhsh, S.; Hao, L. Effect of layer thickness in selective laser melting on microstructure of Al/5 wt.% Fe2O3 powder consolidated parts. Sci. World J. 2014, 2014, 106129. [Google Scholar] [CrossRef] [PubMed]

- Gong, H.; Gu, H.; Zeng, K.; Dilip, J.J.S.; Pal, D.; Stucker, B. Melt pool characterization for selective laser melting of Ti-6Al-4V pre-alloyed powder. In Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, 4–6 August 2014; pp. 256–267.

- Qiu, C.; Panwisawas, C.; Ward, M.; Basoalto, H.C.; Brooks, J.W.; Attallah, M.M. On the role of melt flow into the surface structure and porosity development during selective laser melting. Acta Mater. 2015, 96, 72–79. [Google Scholar] [CrossRef]

- Schleifenbaum, H.; Diatlov, A.; Hinke, C.; Bültmann, J.; Voswinckel, H. Direct photonic production: Towards high speed additive manufacturing of individualized goods. Prod. Eng. 2011, 5, 359–371. [Google Scholar] [CrossRef]

- Gong, H.; Rafi, K.; Gu, H.; Ram, G.D.J.; Starr, T.; Stucker, B. Influence of defects on mechanical properties of Ti–6Al–4V components produced by selective laser melting and electron beam melting. Mater. Des. 2015, 86, 545–554. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Krakhmalev, P.; Yadroitsava, I. Hierarchical design principles of selective laser melting for high quality metallic objects. Addit Manuf. 2015, 7, 45–56. [Google Scholar] [CrossRef]

- Simonelli, M.; Tse, Y.Y.; Tuck, C. Further understanding of Ti-6Al-4V selective laser melting using texture analysis. In Proceedings of the 23rd Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 6–8 August 2012; pp. 480–491.

- Thijs, L.; Verhaeghe, F.; Craeghs, T.; Humbeeck, J.V.; Kruth, J.-P. A study of the microstructural evolution during selective laser melting of Ti–6Al–4V. Acta Mater. 2010, 58, 3303–3312. [Google Scholar] [CrossRef]

- Vilaro, T.; Colin, C.; Bartout, J.D. As-fabricated and heat-treated microstructures of the Ti-6Al-4V alloy processed by selective laser melting. Metall. Mater. Trans. A 2011, 42, 3190–3199. [Google Scholar] [CrossRef]

- Gong, H. The effects of processing parameters on defect regularity in Ti-6Al-4V parts fabricated by selective laser melting and electron beam melting. In Proceedings of the 24th Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, Austin, TX, USA, 12–14 August 2013; pp. 424–439.

- Li, Y.; Gu, D. Parametric analysis of thermal behavior during selective laser melting additive manufacturing of aluminum alloy powder. Mater. Des. 2014, 63, 856–867. [Google Scholar] [CrossRef]

- Brandl, E.; Heckenberger, U.; Holzinger, V.; Buchbinder, D. Additive manufactured AlSi10Mg samples using selective laser melting (slm): Microstructure, high cycle fatigue, and fracture behavior. Mater. Des. 2012, 34, 159–169. [Google Scholar] [CrossRef]

- Löber, L.; Schimansky, F.P.; Kühn, U.; Pyczak, F.; Eckert, J. Selective laser melting of a beta-solidifying TNM-B1 titanium aluminide alloy. J. Mater. Process. Technol. 2014, 214, 1852–1860. [Google Scholar] [CrossRef]

- Li, L. Repair of directionally solidified superalloy gtd-111 by laser-engineered net shaping. J. Mater. Sci. 2006, 41, 7886–7893. [Google Scholar] [CrossRef]

- Ackelid, U.; Svensson, M. Additive manufacturing of dense metal parts by electron beam melting. In Proceedings of the Materials Science and Technology Conference, Pittsburgh, PA, USA, 25–29 October 2009; pp. 2711–2719.

- Hrabe, N.; Kircher, R.; Quinn, T. Effects of processing on microstructure and mechanical properties of Ti–6Al–4V fabricated using electron beam melting (EBM): Orientation and location. In Proceedings of the 23rd Solid Freeform Fabrication Symposium, Austin, TX, USA, 6–8 August 2012; pp. 1045–1058.

- Vrancken, B.; Thijs, L.; Kruth, J.-P.; van Humbeeck, J. Heat treatment of Ti6Al4V produced by selective laser melting: Microstructure and mechanical properties. J. Alloys Compd. 2012, 541, 177–185. [Google Scholar] [CrossRef]

- Squillace, A.; Prisco, U.; Ciliberto, S.; Astarita, A. Effect of welding parameters on morphology and mechanical properties of Ti–6Al–4V laser beam welded butt joints. J. Mater. Process. Technol. 2012, 212, 427–436. [Google Scholar] [CrossRef]

- Mertens, A.; Reginster, S.; Paydas, H.; Contrepois, Q.; Dormal, T.; Lemaire, O.; Lecomte-Beckers, J. Mechanical properties of alloy Ti–6Al–4V and of stainless steel 316l processed by selective laser melting: Influence of out-of-equilibrium microstructures. Powder Metall. 2014, 57, 184–189. [Google Scholar] [CrossRef]

- Facchini, L.; Magalini, E.; Robotti, P.; Molinari, A.; Höges, S.; Wissenbach, K. Ductility of a Ti-6Al-4V alloy produced by selective laser melting of prealloyed powders. Rapid Prototyp. J. 2010, 16, 450–459. [Google Scholar] [CrossRef]

- Guan, K.; Wang, Z.; Gao, M.; Li, X.; Zeng, X. Effects of processing parameters on tensile properties of selective laser melted 304 stainless steel. Mater. Des. 2013, 50, 581–586. [Google Scholar] [CrossRef]

| Scanning Speed v (mm/s) | Hatch Spacing s (mm) | |||

|---|---|---|---|---|

| 40 | 0.5 | 0.6 | 0.7 | 0.8 |

| 60 | 0.4 | 0.5 | 0.6 | 0.7 |

| 80 | 0.3 | 0.4 | 0.5 | 0.6 |

| 100 | 0.2 | 0.3 | 0.4 | 0.5 |

| Particle Size (µm) | Layer Thickness (µm) | Hatch Spacing (µm) | Scanning Speed (mm/s) | Building Rate (mm3/s) | References |

|---|---|---|---|---|---|

| d50 = 32 | 50 | 150 | 600 | 4.5 | [4] |

| d50 = 35 | 50 | 40 | 400 | 0.8 | [7] |

| d50 = 38 | 30 | 100 | 800 | 2.4 | [19] |

| d50 = 30 | 30 | 100 | 540 | 2.88 | [22] |

| d50 < 50 | 50 | 100 | 227 | 1.135 | [24] |

| d50 = 34 | 30 | 75 | 200 | 0.45 | [25] |

| d50 = 35 | 30 | 200 | 500 | 3 | [26] |

| d50 = 68 | 200 | 600 | 60 | 7.2 | In this study |

| Layer Thickness (μm) | Yield Stress (Offset 0.2%) (MPa) | Ultimate Tensile Stress (MPa) | Elongation (%) | References |

|---|---|---|---|---|

| <50 | 1333 | 1407 | 4.54 | [3] |

| <50 | 1195 | 1269 | 5 | [5] |

| <50 | 1098 | 1237 | 8.8 | [22] |

| 30 | 1110 | 1267 | 7.28 | [34] |

| 30 | 1140 | 1214 | 3.2 | [36] |

| <50 | 990 | 1095 | 8.1 | [37] |

| 200 | 1050 | 1140 | 7.03 | In this study |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, X.; Ma, S.; Liu, C.; Chen, C.; Wu, Q.; Chen, X.; Lu, J. Performance of High Layer Thickness in Selective Laser Melting of Ti6Al4V. Materials 2016, 9, 975. https://doi.org/10.3390/ma9120975

Shi X, Ma S, Liu C, Chen C, Wu Q, Chen X, Lu J. Performance of High Layer Thickness in Selective Laser Melting of Ti6Al4V. Materials. 2016; 9(12):975. https://doi.org/10.3390/ma9120975

Chicago/Turabian StyleShi, Xuezhi, Shuyuan Ma, Changmeng Liu, Cheng Chen, Qianru Wu, Xianping Chen, and Jiping Lu. 2016. "Performance of High Layer Thickness in Selective Laser Melting of Ti6Al4V" Materials 9, no. 12: 975. https://doi.org/10.3390/ma9120975

APA StyleShi, X., Ma, S., Liu, C., Chen, C., Wu, Q., Chen, X., & Lu, J. (2016). Performance of High Layer Thickness in Selective Laser Melting of Ti6Al4V. Materials, 9(12), 975. https://doi.org/10.3390/ma9120975