Impact Behavior of Three Notched All-Ceramic Restorations after Soaking in Artificial Saliva

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

| Brand | Lot No. | Crystal Phase | Sintering/Crystallization Temperature (°C) | Application |

|---|---|---|---|---|

| ProCAD | G17661 | Leucite | 625 | inlay, onlay, single crown, veneer |

| IPS e.max CAD | J07273 | lithium disilicate | 850 | inlay, onlay, veneer, single crown, bridge |

| IPS e.max ZirCAD | J20390 | Zirconia | 1500 | inlay, onlay, single crown, three unit bridge |

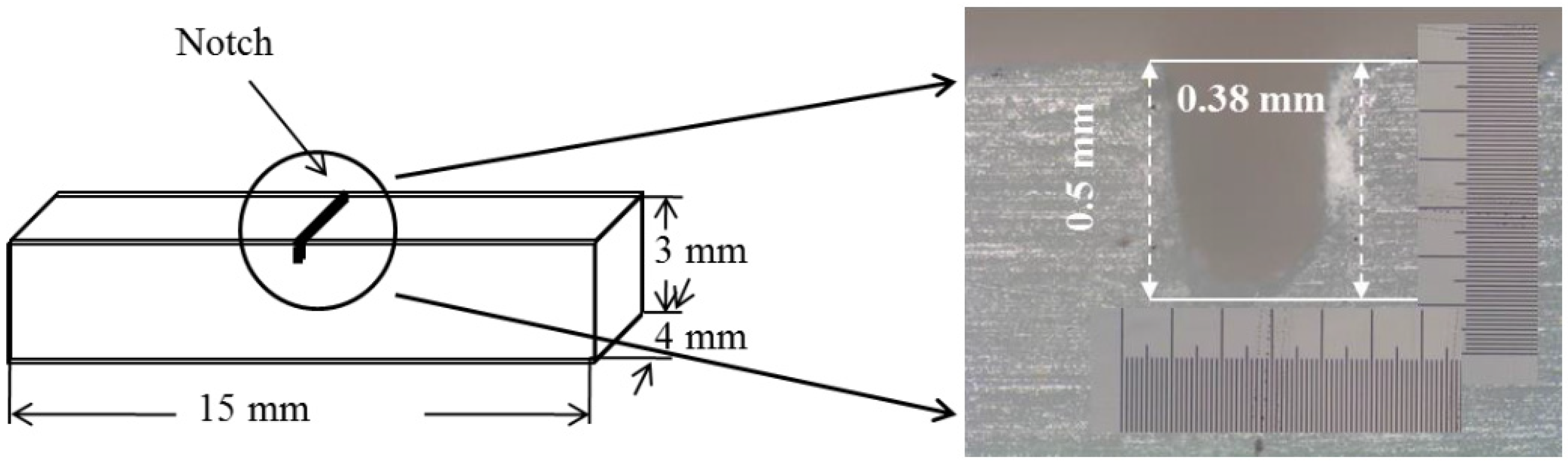

2.2. Sample Preparation

2.3. Impact Test

2.4. Surface Morphology

2.5. Statistical Analysis

3. Results

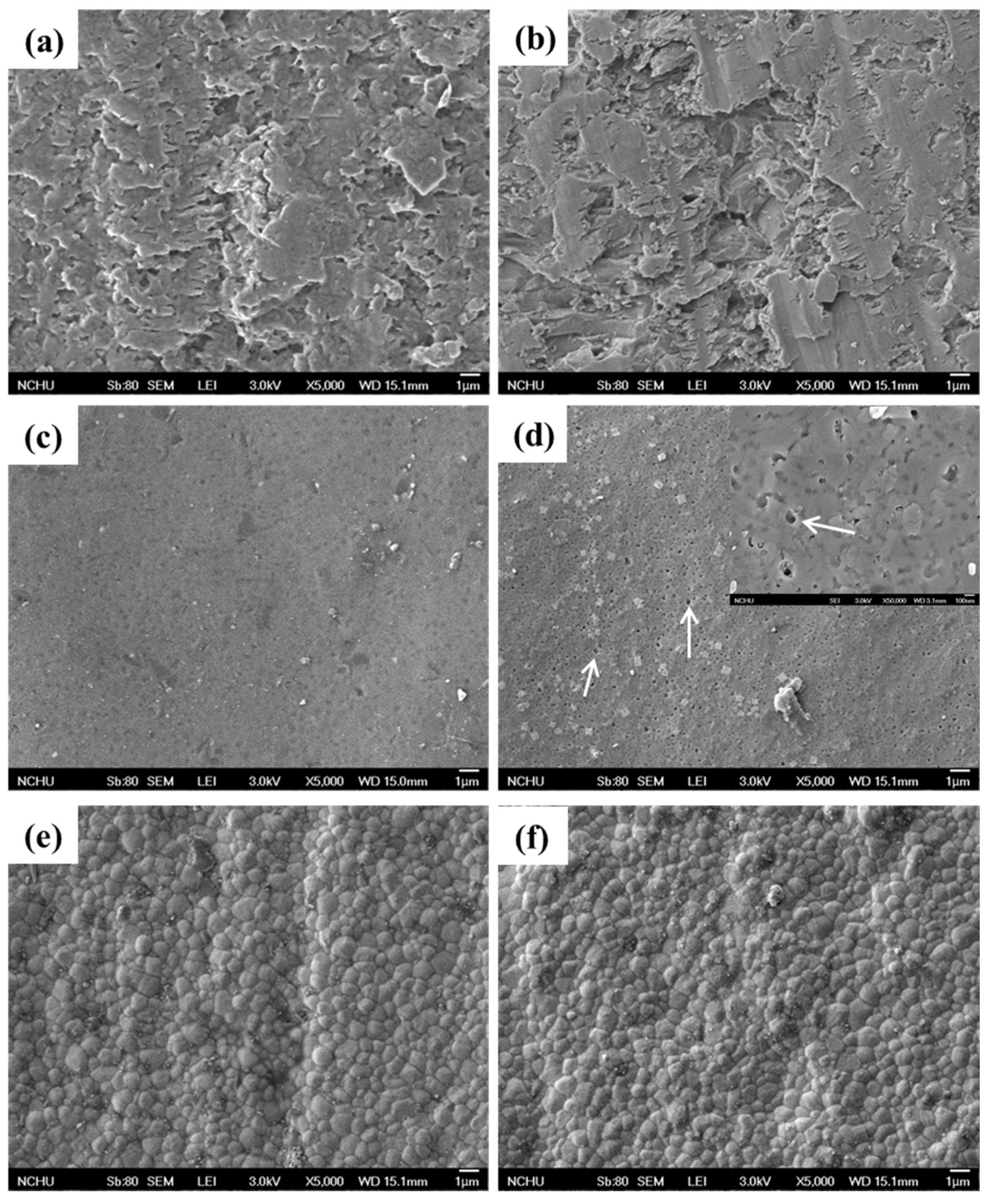

3.1. Surface Morphology

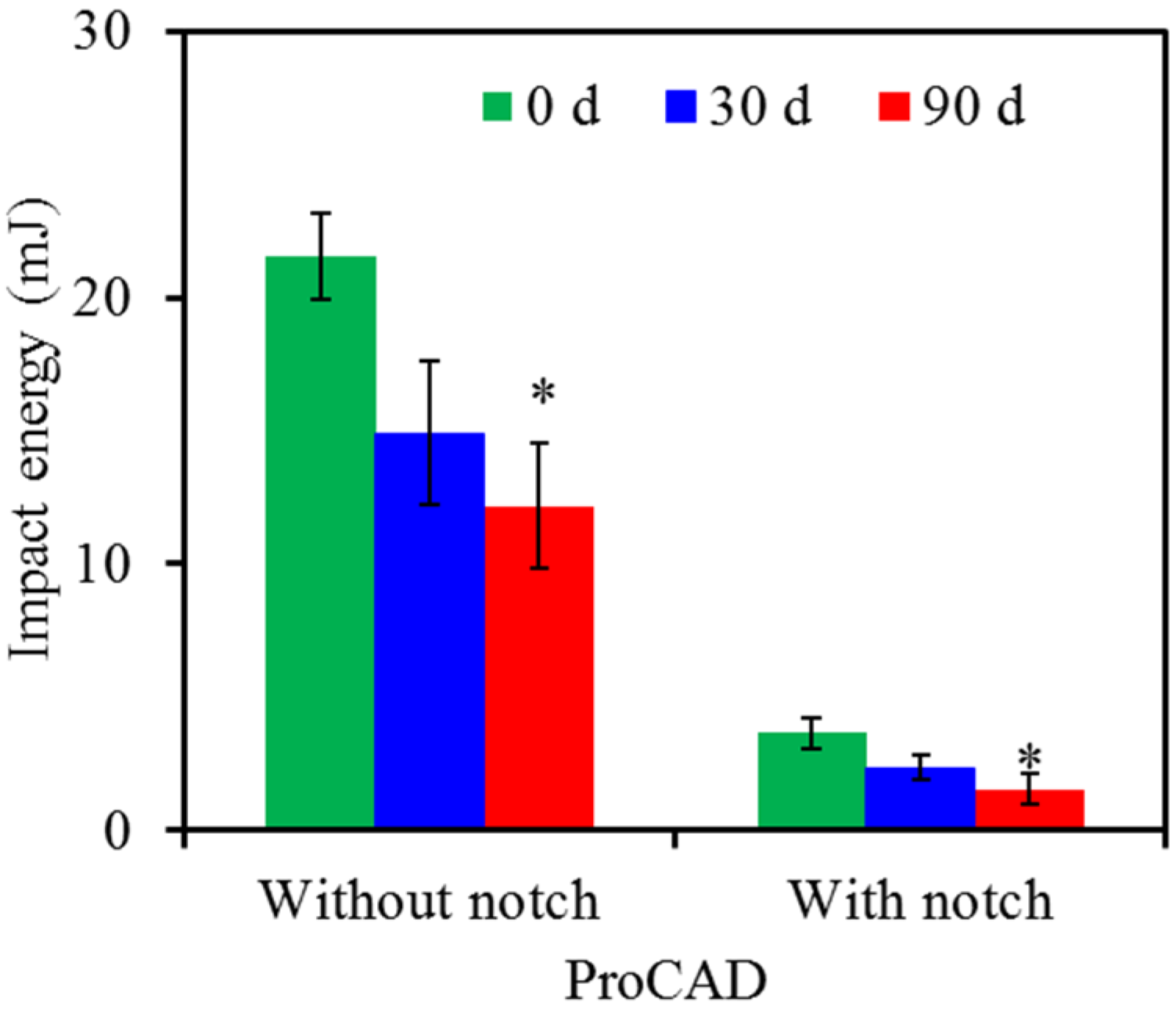

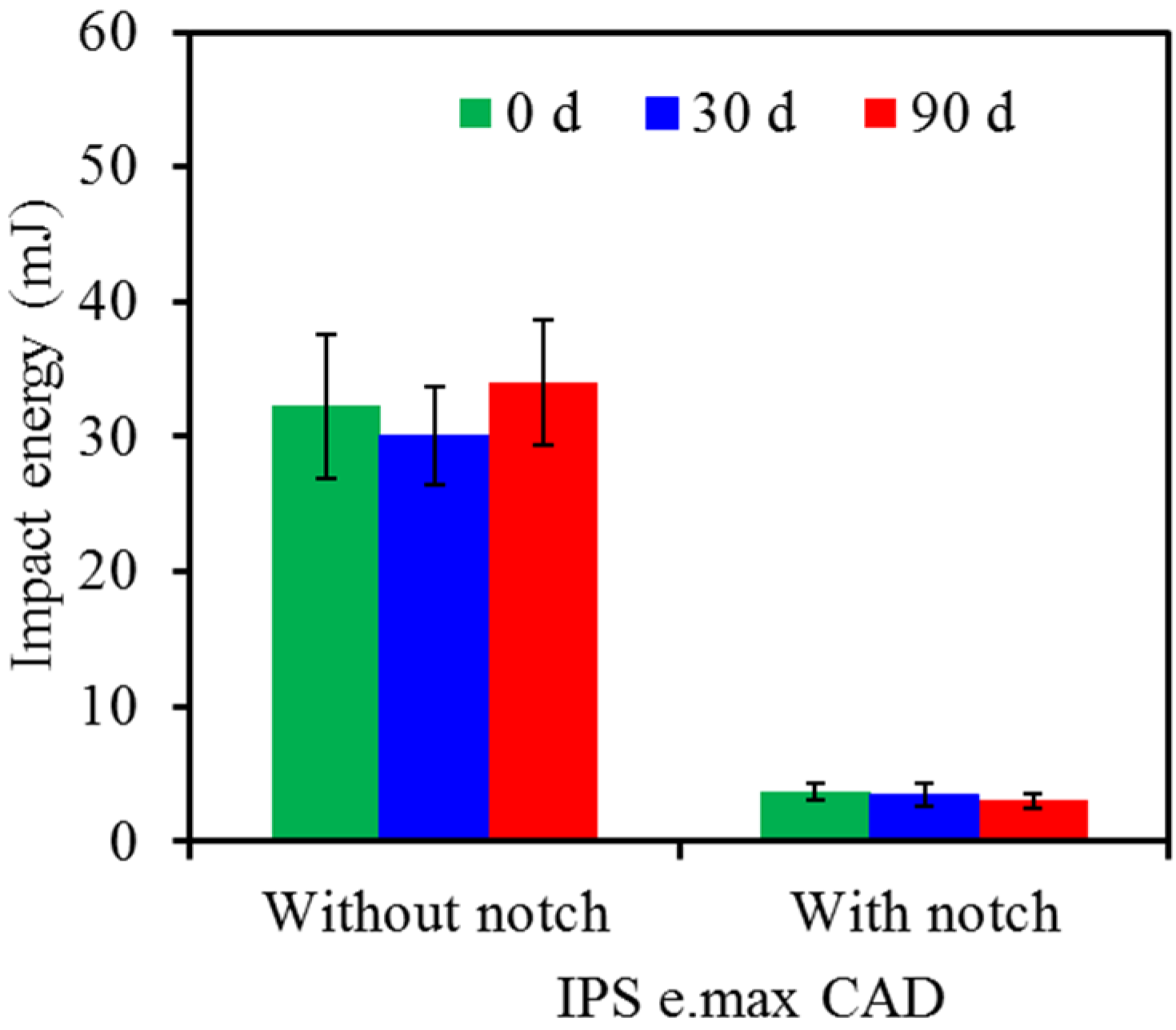

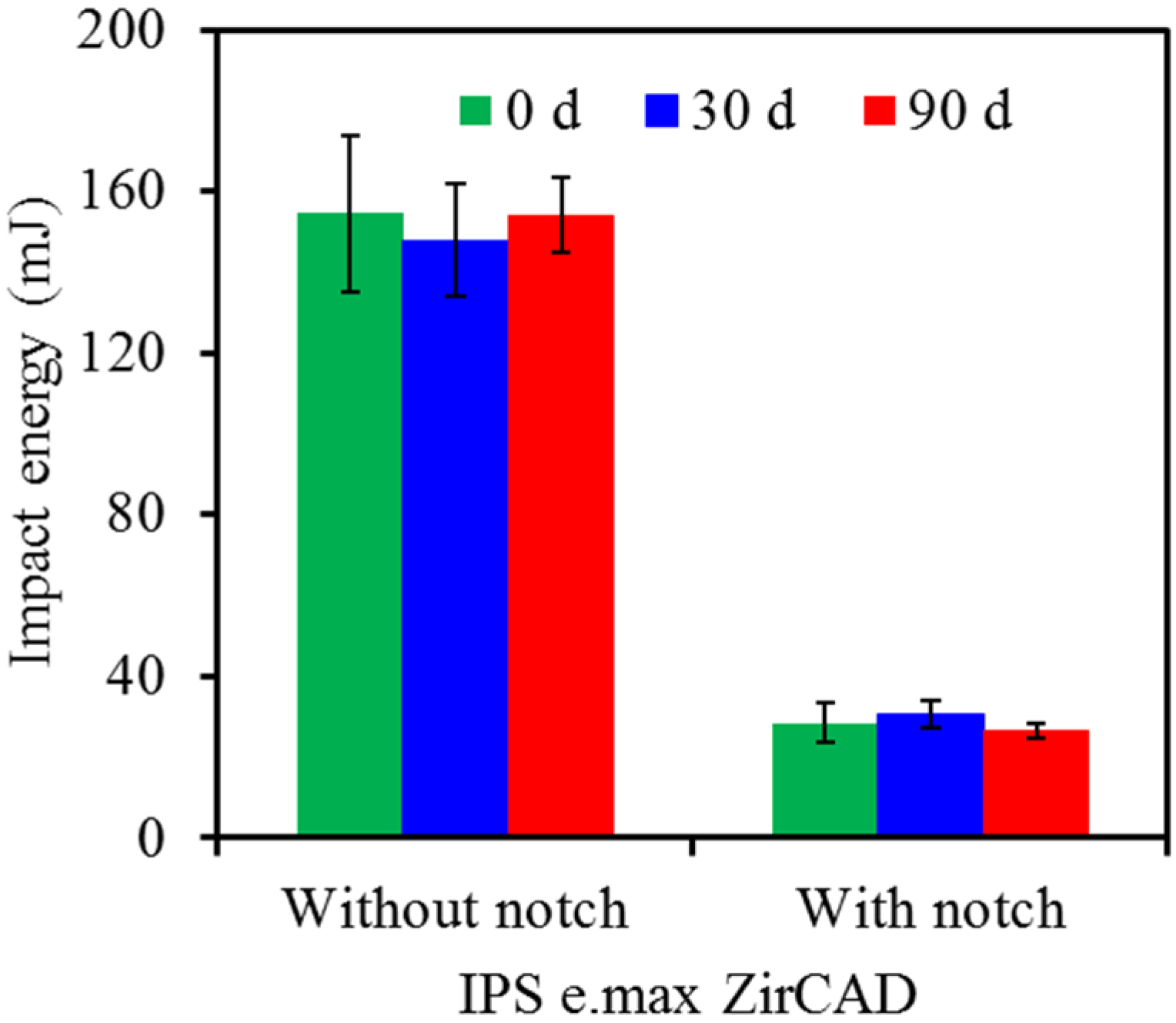

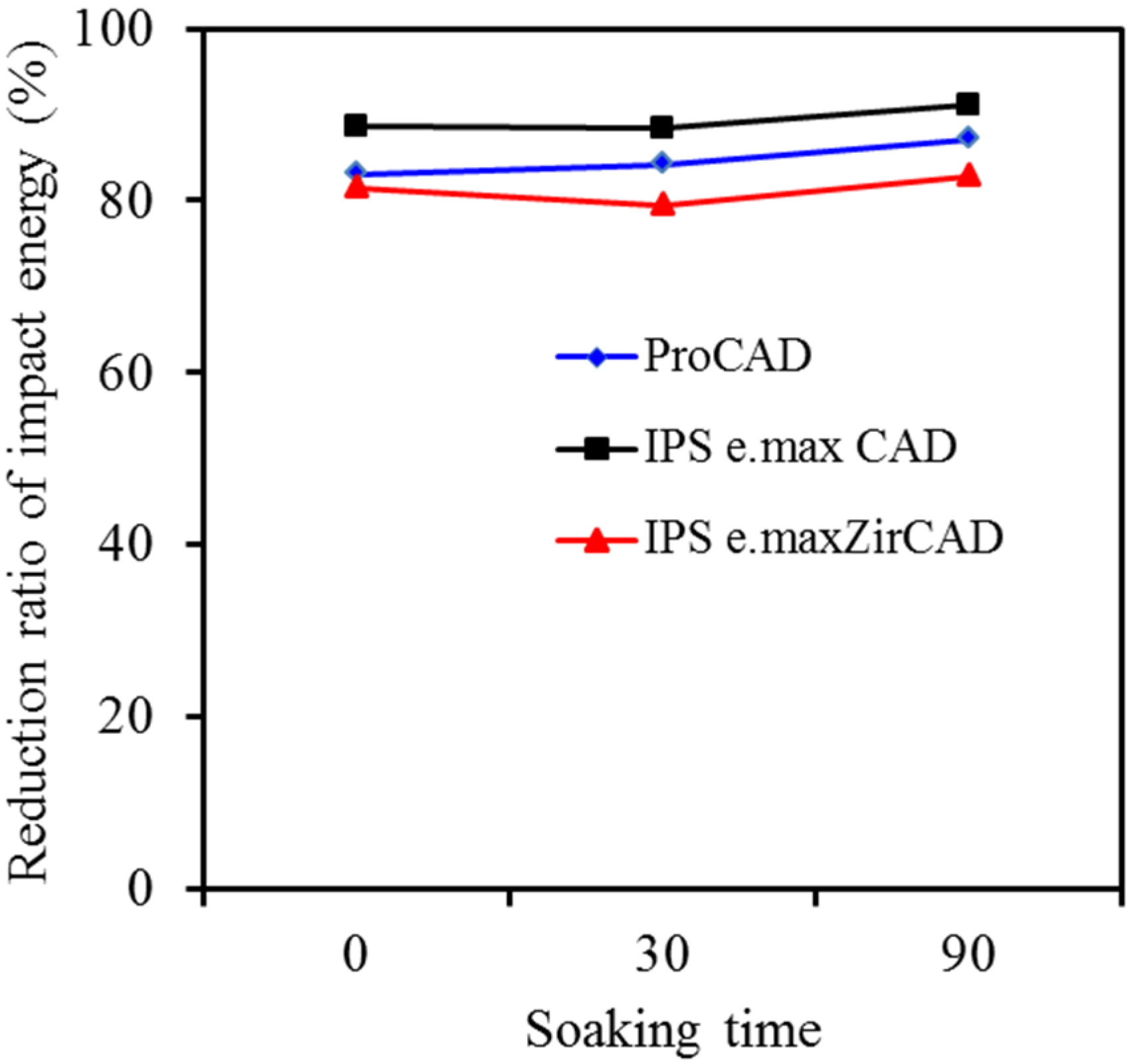

3.2. Soaking and Notch Effects

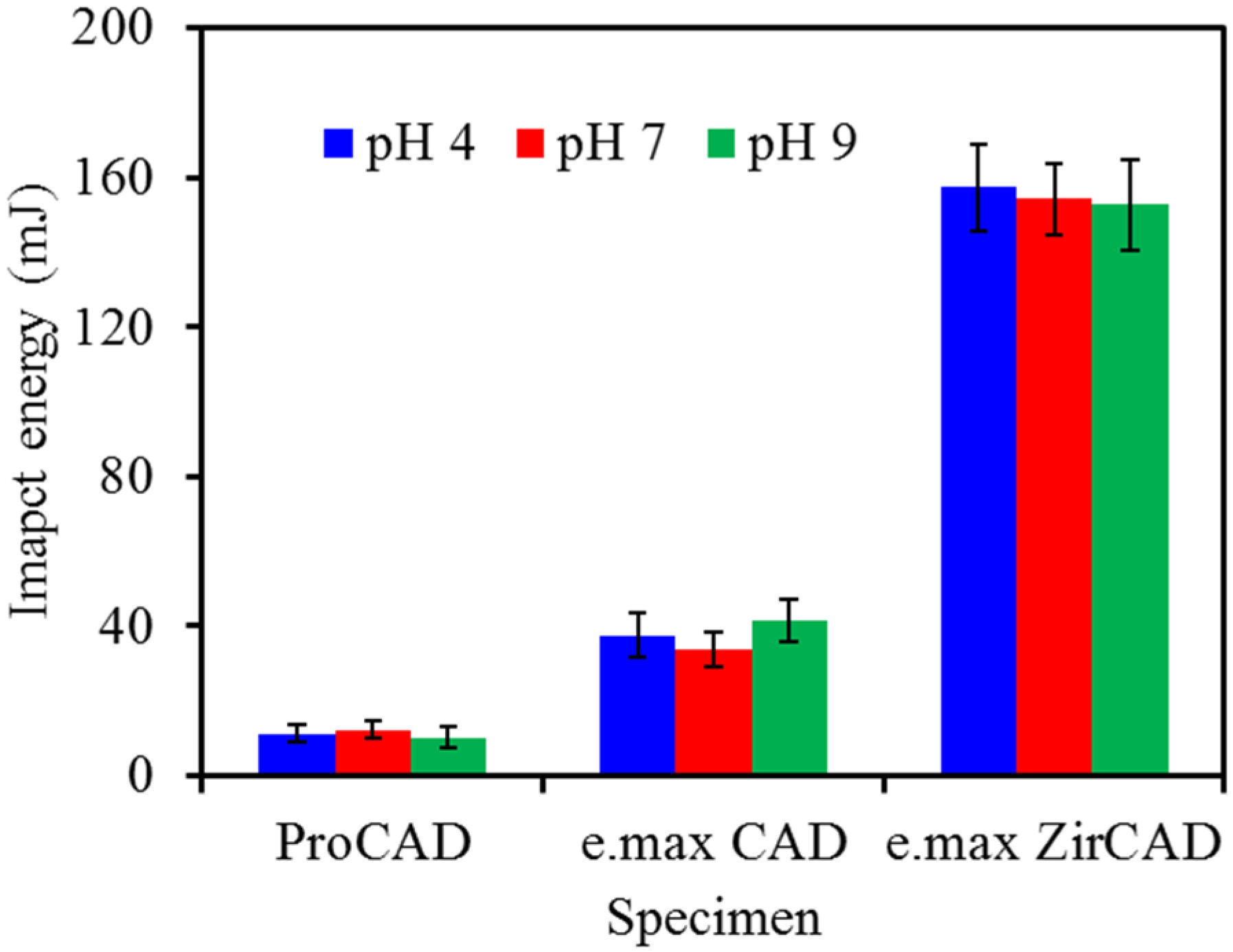

3.3. pH Effect

4. Discussion

5. Conclusions

Author Contributions

Conflicts of Interest

References

- Conrad, H.J.; Seong, W.J.; Pesun, I.J. Current ceramic materials and systems with clinical recommendations: A systematic review. J. Prosthet. Dent. 2007, 98, 389–404. [Google Scholar] [CrossRef]

- Höland, W.; Rheinberger, V.; Apel, E.; van’t Hoen, C.; Höland, M.; Dommann, A.; Obrecht, M.; Mauth, C.; Graf-Hausner, U. Clinical applications of glass-ceramics in dentistry. J. Mater. Sci. Mater. Med. 2006, 17, 1037–1042. [Google Scholar] [CrossRef] [PubMed]

- Ritzberger, C.; Apel, E.; Höland, W.; Peschke, A.; Rheinberger, V.M. Properties and clinical application of three types of dental glass-ceramics and ceramics for CAD-CAM technologies. Materials 2010, 3, 3700–3713. [Google Scholar] [CrossRef]

- Wu, C.C.; Wei, C.K.; Ho, C.C.; Ding, S.J. Enhanced hydrophilicity and biocompatibility of dental zirconia ceramics by oxygen plasma treatment. Materials 2015, 8, 684–699. [Google Scholar] [CrossRef]

- Kohal, R.F.; Kilian, J.B.; Stampf, S.; Spies, B.C. All-ceramic single crown restauration of zirconia oral implants and its influence on fracture resistance: An investigation in the artificial mouth. Materials 2015, 8, 1577–1589. [Google Scholar] [CrossRef]

- Denry, I.; Holloway, J.A. Ceramics for dental applications: A review. Materials 2010, 3, 351–368. [Google Scholar] [CrossRef]

- Sundh, A.; Sjogren, G. A comparison of fracture strength of yttrium-oxide-partially-stabilized zirconia ceramic crowns with varying core thickness, shapes and veneer ceramics. J. Oral Rehabil. 2004, 31, 682–688. [Google Scholar] [CrossRef] [PubMed]

- Raigrodski, A.J.; Chiche, G.J.; Potiket, N.; Hochstedler, J.L.; Mohamed, S.E.; Billiot, S.; Mercante, D.E. The efficacy of posterior three-unit zirconiumoxide-based ceramic fixed partial dental prostheses: A prospective clinical pilot study. J. Prosthet. Dent. 2006, 96, 237–244. [Google Scholar] [CrossRef] [PubMed]

- Vult von Steyern, P.; Jonsson, O.; Nilner, K. Five-year evaluation of posterior all-ceramic three-unit (in-ceram) FPDs. Int. J. Prosthodont. 2001, 14, 379–384. [Google Scholar] [PubMed]

- Esquivel-Upshaw, J.F.; Anusavice, K.J.; Young, H.; Jones, J.; Gibbs, C. Clinical performance of a lithia disilicate-based core ceramic for three-unit posterior FPDs. Int. J. Prosthodont. 2004, 17, 469–475. [Google Scholar] [PubMed]

- Sindel, J.; Petschelt, A.; Grellner, F.; Dierken, C.; Greil, P. Evaluation of subsurface damage in CAD/CAM machined dental ceramics. J. Mater. Sci. Mater. Med. 1998, 9, 291–295. [Google Scholar] [CrossRef] [PubMed]

- Nakamura, T.; Wakabayashi, K.; Kawamura, Y.; Kinuta, S.; Mutobe, Y.; Yatani, H. Analysis of dental defects in all-ceramic crown using micro-focus X-ray computed tomography. Dent. Mater. J. 2007, 26, 598–601. [Google Scholar] [CrossRef] [PubMed]

- Guazzato, M.; Albakry, M.; Ringer, S.P.; Swain, M.V. Strength, fracture toughness and microstructure of a selection of all-ceramic materials. Part I. Pressable and alumina glass-infiltrated ceramics. Dent. Mater. 2004, 20, 441–448. [Google Scholar] [CrossRef] [PubMed]

- Drummond, J.L.; King, T.J.; Bapna, M.S.; Koperski, R.D. Mechanical property evaluation of pressable restorative ceramics. Dent. Mater. 2000, 16, 226–233. [Google Scholar] [CrossRef]

- Aboushelib, M.N.; Jager, N.D.; Kleverlaan, C.J.; Feilzer, A.J. Effect of loading method on the fracture mechanics of two layered all-ceramic restorative systems. Dent. Mater. 2007, 23, 952–959. [Google Scholar] [CrossRef] [PubMed]

- Anusavice, K.J.; Zhang, N.Z. Chemical durability of Dicor and lithia-based glass-ceramics. Dent. Mater. 1997, 13, 13–19. [Google Scholar] [CrossRef]

- ASTM E23:2004 Standard Test Methods for Notched Bar Impact Testing of Metallic Materials; American Society for Testing and Materials: Philadelphia, PA, USA, 2004.

- Zappini, G.; Kammann, A.; Wachtera, W. Comparison of fracture tests of denture base materials. J. Prosthet. Dent. 2003, 90, 578–585. [Google Scholar] [CrossRef] [PubMed]

- ISO 179-1:2000 Plastics—Determination of Charpy Impact Properties—Part 1: Non-Instrumented Test; International Organization for Standardization: Geneva, Switzerland, 2000.

- Huang, M.S.; Li, M.T.; Huang, F.M.; Ding, S.J. The effect of thermocycling and dentine pre-treatment on the durability of the bond between composite resin and dentine. J. Oral. Rehabil. 2004, 31, 492–499. [Google Scholar] [CrossRef] [PubMed]

- Robinson, J.G.; McCabe, J.F. Impact strength of acrylic resin denture base materials with surface defects. Dent. Mater. 1993, 9, 355–360. [Google Scholar] [CrossRef]

- ISO 13802:1999 Plastics—Verification of Pendulum Impact-Testing Machines—Charpy, Lzod and Tensile Impact-Testing; International Organization Standardization: Geneva, Switzerland, 1999.

- Øilo, M.; Gjerdet, N.R. Fractographic analyses of all-ceramic crowns: A study of 27 clinically fractured crowns. Dent. Mater. 2013, 29, E78–E84. [Google Scholar] [CrossRef] [PubMed]

- White, W.B. Theory of corrosion of glass and ceramics. In Corrosion of Glass Ceramics and Superconductors; Clarke, D.E., Zoitos, B.K., Eds.; Noyes: Park Ridge, NJ, USA, 1992; pp. 2–28. [Google Scholar]

- Borchers, L.; Stiesch, M.; Bach, F.W.; Buhl, J.C.; Hübsch, C.; Kellner, T.; Kohorst, P.; Jendras, M. Influence of hydrothermal and mechanical conditions on the strength of zirconia. Acta Biomater. 2010, 6, 4547–4552. [Google Scholar] [CrossRef] [PubMed]

- Pinto, M.M.; Cesar, P.F.; Rosa, V.; Yoshimura, H.N. Influence of pH on slow crack growth of dental porcelains. Dent. Mater. 2008, 24, 814–823. [Google Scholar] [CrossRef] [PubMed]

- Esquivel-Upshaw, J.F.; Dieng, F.Y.; Clark, A.E.; Neal, D.; Anusavice, K.J. Surface degradation of dental ceramics as a function of environmental pH. J. Dent. Res. 2013, 92, 467–471. [Google Scholar] [CrossRef] [PubMed]

- Cattani-Lorente, M.; Scherrer, S.S.; Ammann, P.; Jobin, M.; Wiskott, H.W.A. Low temperature degradation of a Y-TZP dental ceramic. Acta Biomater. 2011, 7, 858–865. [Google Scholar] [CrossRef] [PubMed]

- Milleding, P.; Haraldsson, C.; Karlssom, S. Ion leaching from dental ceramics during static in vitro corrosion testing. J. Biomed. Mater. Res. 2002, 62, 541–550. [Google Scholar] [CrossRef] [PubMed]

- Craig, R.; Powers, J.M. Restorative Dental Materials, 11th ed.; Elsevier: St. Louis, MO, USA, 2002; pp. 640–645. [Google Scholar]

- Christel, P.; Meunier, A.; Heller, M.; Torre, J.P.; Peille, C.N. Mechanical properties and short-term in vivo evaluation of yttrium-oxide-partially-stabilized zirconia. J. Biomed. Mater. Res. 1989, 23, 45–61. [Google Scholar] [CrossRef] [PubMed]

- Raigrodski, A.J. Contemporary all-ceramic fixed partial dentures: A review. Dent. Clin. N. Am. 2004, 48, 531–544. [Google Scholar] [CrossRef] [PubMed]

- Goodacre, C.J.; Campagni, W.V.; Aquilino, S.A. Tooth preparations for complete crowns: An art form based on scientific principles. J. Prosthet. Dent. 2001, 85, 363–376. [Google Scholar] [CrossRef] [PubMed]

- Wolfart, S.; Bohlsen, F.; Wegner, S.M.; Kern, M. A preliminary prospective evaluation of allceramic crown-retained and inlay-retained fixed partial dentures. Int. J. Prosthodont. 2005, 18, 497–505. [Google Scholar] [PubMed]

- Thompson, J.Y.; Anusavice, K.J.; Naman, A.; Morris, H.F. Fracture surface characterization of clinically failed all-ceramic crowns. J. Dent. Res. 1994, 73, 1824–1832. [Google Scholar] [PubMed]

- Tomozawa, M.; Oka, Y.; Wahl, M.J. Glass surface cracks caused by alkaline solution containing an alkaline-earth element. J. Am. Ceram. Soc. 1981, 64, 32–33. [Google Scholar] [CrossRef]

- Simmons, C.; Freiman, S. Effect of corrosion processes on subcritical crack-growth in glass. J. Am. Ceram. Soc. 1981, 64, 683–686. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, M.; Wei, C.-K.; Lin, Y.-Y.; Hu, S.-W.; Ding, S.-J. Impact Behavior of Three Notched All-Ceramic Restorations after Soaking in Artificial Saliva. Materials 2015, 8, 4479-4490. https://doi.org/10.3390/ma8074479

Yan M, Wei C-K, Lin Y-Y, Hu S-W, Ding S-J. Impact Behavior of Three Notched All-Ceramic Restorations after Soaking in Artificial Saliva. Materials. 2015; 8(7):4479-4490. https://doi.org/10.3390/ma8074479

Chicago/Turabian StyleYan, Min, Chung-Kai Wei, Yuh-Yih Lin, Suh-Woan Hu, and Shinn-Jyh Ding. 2015. "Impact Behavior of Three Notched All-Ceramic Restorations after Soaking in Artificial Saliva" Materials 8, no. 7: 4479-4490. https://doi.org/10.3390/ma8074479

APA StyleYan, M., Wei, C.-K., Lin, Y.-Y., Hu, S.-W., & Ding, S.-J. (2015). Impact Behavior of Three Notched All-Ceramic Restorations after Soaking in Artificial Saliva. Materials, 8(7), 4479-4490. https://doi.org/10.3390/ma8074479