Development of Self-Consolidating High Strength Concrete Incorporating Treated Palm Oil Fuel Ash

Abstract

:1. Introduction

2. Experimental Programe

2.1. Materials

2.1.1. Cement

| Property | Coarse Aggregate | Fine Aggregate | OPC | Ground POFA | Treated POFA |

|---|---|---|---|---|---|

| Maximum size (mm) | 12.5 | 4.76 | – | – | – |

| Water absorption (%) | 0.43 | 1.13 | – | – | – |

| Specific gravity | 2.62 | 2.56 | – | – | – |

| Fineness modulus | 6.3 | 2.88 | – | – | – |

| Colour | – | – | Grey | Dark grey | Grey |

| Passed on a 45-µm (No. 325) sieve (%) | – | – | 92 | 96 | 100 |

| Surface area, BET (m2/g) | – | – | – | 104 | – |

| Relative density | – | – | 3.16 | 2.04 | 2.20 |

| Oxide Composition | OPC | Ground POFA | Treated POFA |

|---|---|---|---|

| Silicon dioxide (SiO2) | 17.60 | 59.17 | 69.02 |

| Aluminum trioxide (Al2O3) | 4.02 | 3.73 | 3.9 |

| Iron oxide (Fe2O3) | 4.47 | 6.33 | 4.33 |

| Calcium oxide (CaO) | 67.43 | 5.80 | 5.01 |

| Magnesium oxide (MgO) | 1.33 | 4.87 | 5.18 |

| Sodium oxide (Na2O) | 0.03 | 0.18 | 0.18 |

| Potassium oxide (K2O) | 0.39 | 8.25 | 6.9 |

| Sulfur trioxide (SO3) | 4.18 | 0.72 | 0.41 |

| SiO2 + Al2O3 + Fe2O3 | – | 69.23 | 77.25 |

| Loss on ignition (LOI) | 2.4 | 16.1 | 1.8 |

2.1.2. Aggregate

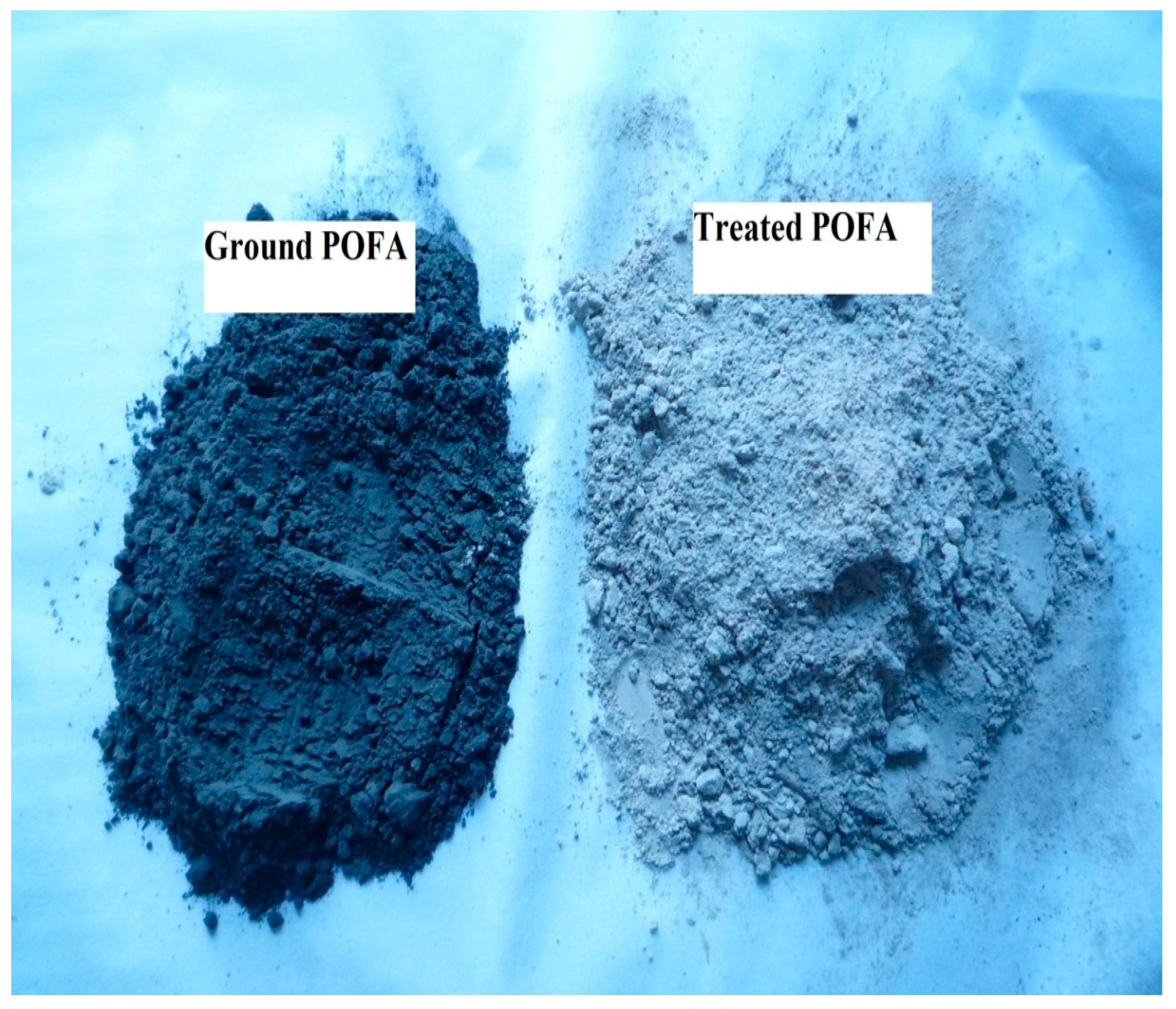

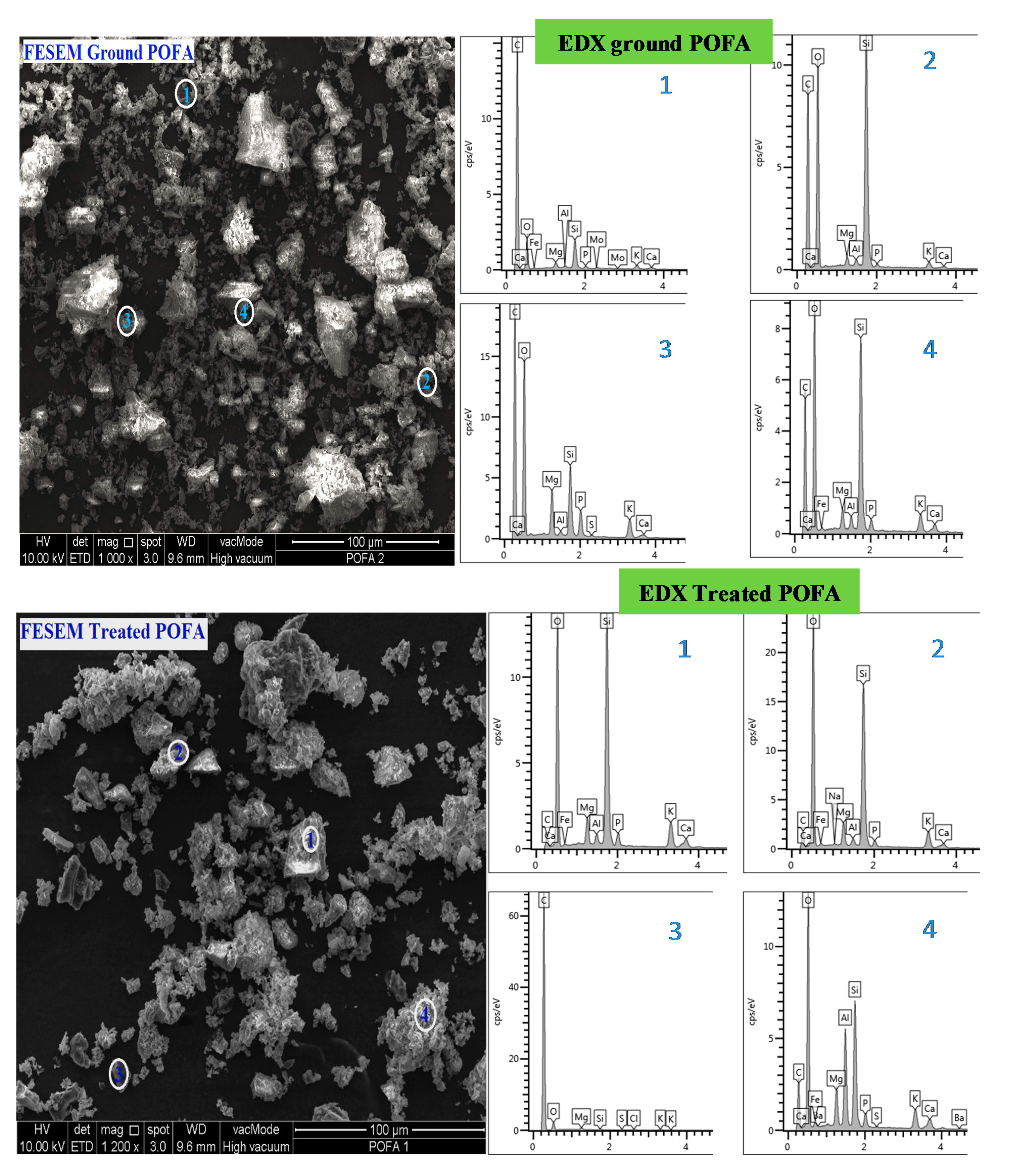

2.1.3. Preparation of Palm Oil Fuel Ash

2.2. Mix Proportions and Testing Methods

| Mix No. | Cement (kg/m3) | Water (kg/m3) | W/C Ratio | POFA (kg/m3) | POFA (%) | Fine Aggregate (kg/m3) | Coarse Aggregate (kg/m3) | Superplasticizer (S.P) (% B) |

|---|---|---|---|---|---|---|---|---|

| SCHSC0 | 480 | 168 | 0.35 | 0 | 0 | 925 | 758.2 | 1.3 |

| SCHSC10 | 432 | 168 | 0.35 | 48 | 10 | 923 | 752 | 1.3 |

| SCHSC20 | 384 | 168 | 0.35 | 96 | 20 | 948 | 772 | 1.3 |

| SCHSC30 | 336 | 168 | 0.35 | 144 | 30 | 944 | 772 | 1.3 |

| SCHSC50 | 240 | 168 | 0.35 | 240 | 50 | 896 | 728 | 1.3 |

3. Results and Discussion

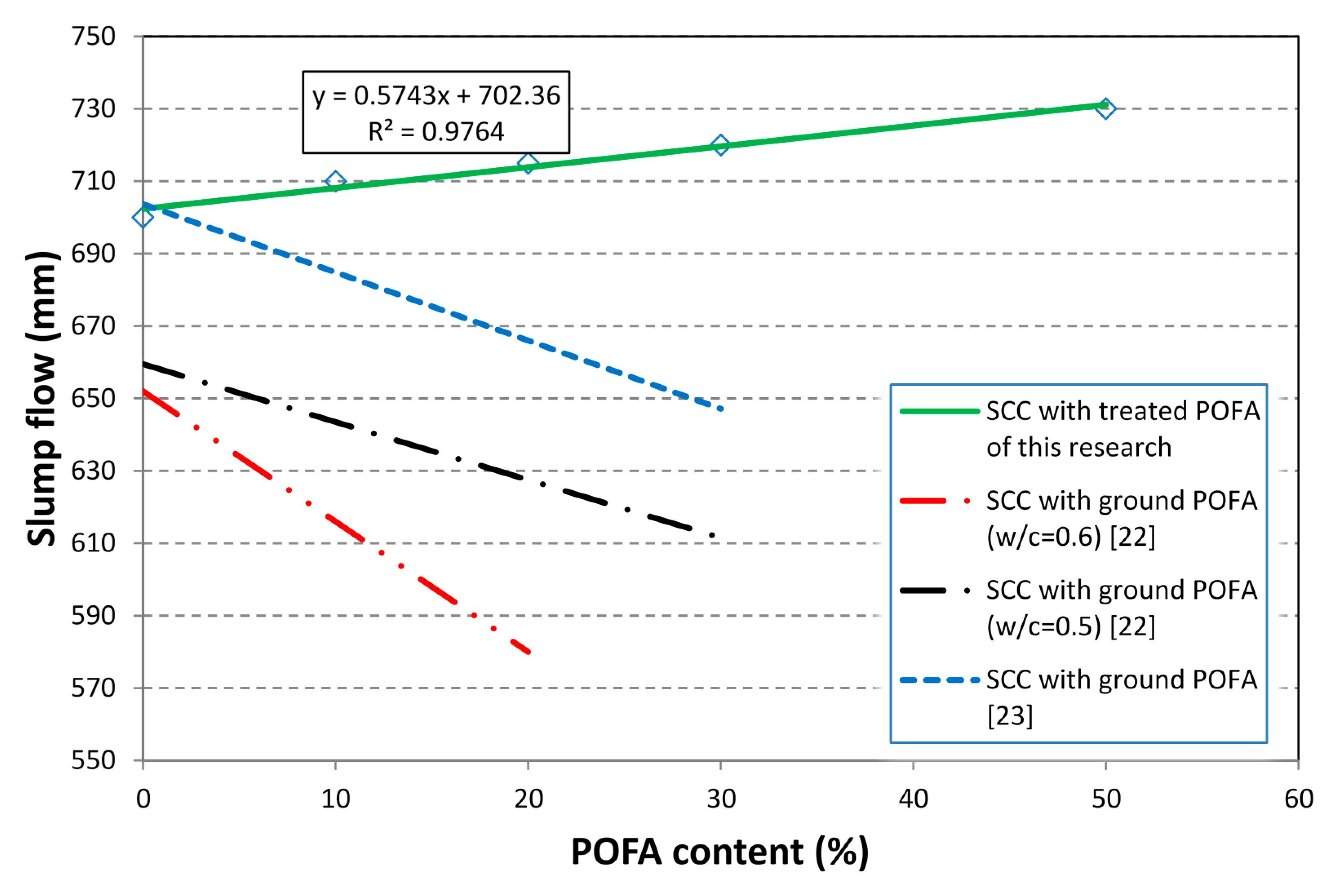

3.1. Physical Characteristics and Chemical Compositions of Treated POFA

3.2. Fresh Properties

3.2.1. Filling Ability

Slump Flow and T50cm Spread Time

| Mix No. | Filling Ability | Passing Ability | Segregation Resistance | ||||

|---|---|---|---|---|---|---|---|

| Slump Flow (mm) | T50 Spread Time (s) | V-Funnel Time (s) | J-Ring (mm) | L-Box | Segregation Index (%) | ||

| Difference in Heights (mm) | Flow (mm) | ||||||

| SCHSC0 | 700 | 3.5 | 6.6 | 9 | 690 | 94.0 | 6.7 |

| SCHSC10 | 710 | 3.4 | 6.4 | 8 | 690 | 95.0 | 6.9 |

| SCHSC20 | 715 | 3.2 | 6.0 | 7 | 695 | 97.0 | 7.3 |

| SCHSC30 | 720 | 3.0 | 5.9 | 7 | 700 | 1.0 | 7.8 |

| SCHSC50 | 730 | 2.9 | 5.8 | 5 | 710 | 1.0 | 8.2 |

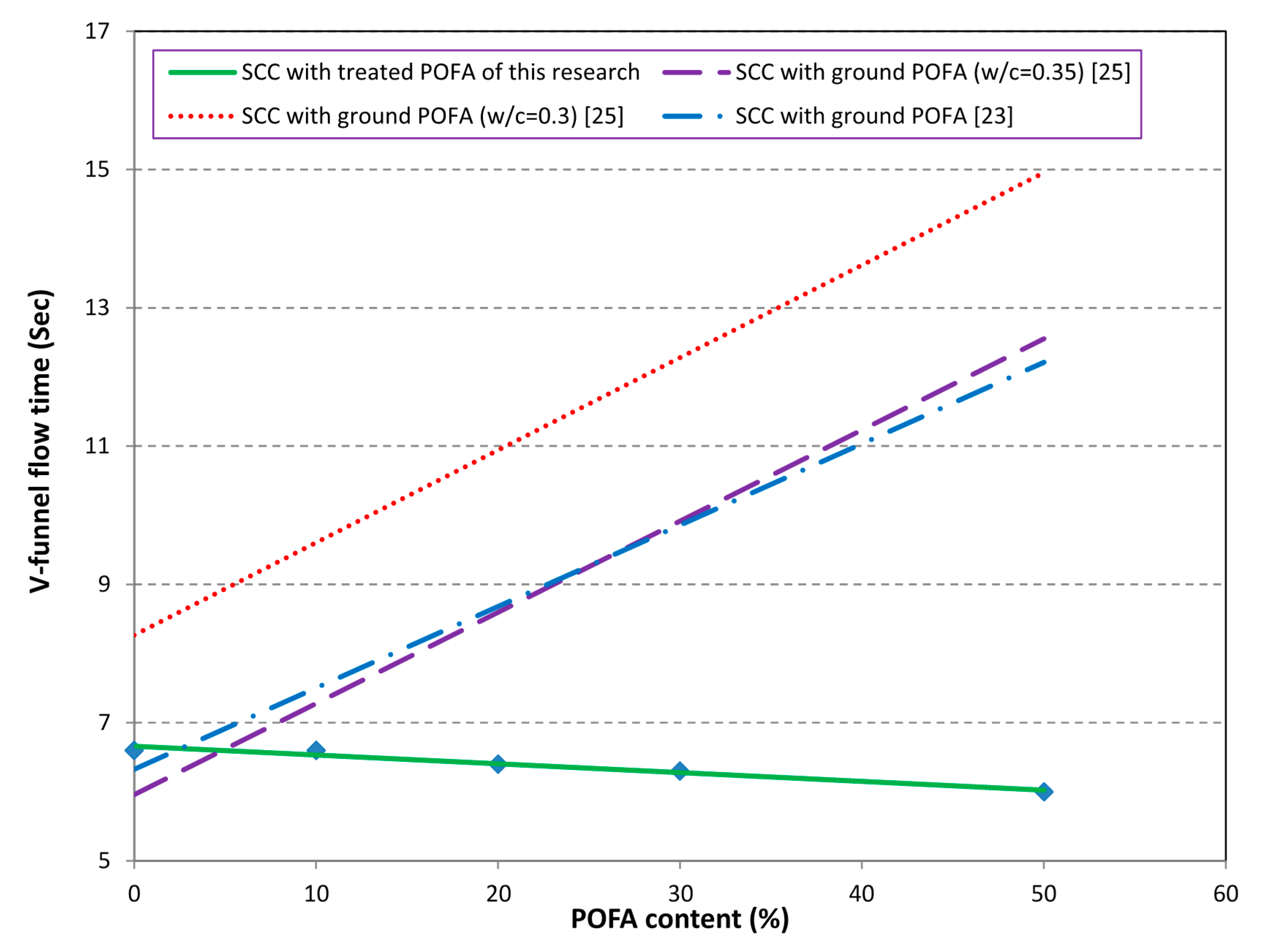

V-Funnel Test

3.2.2. Passing Ability

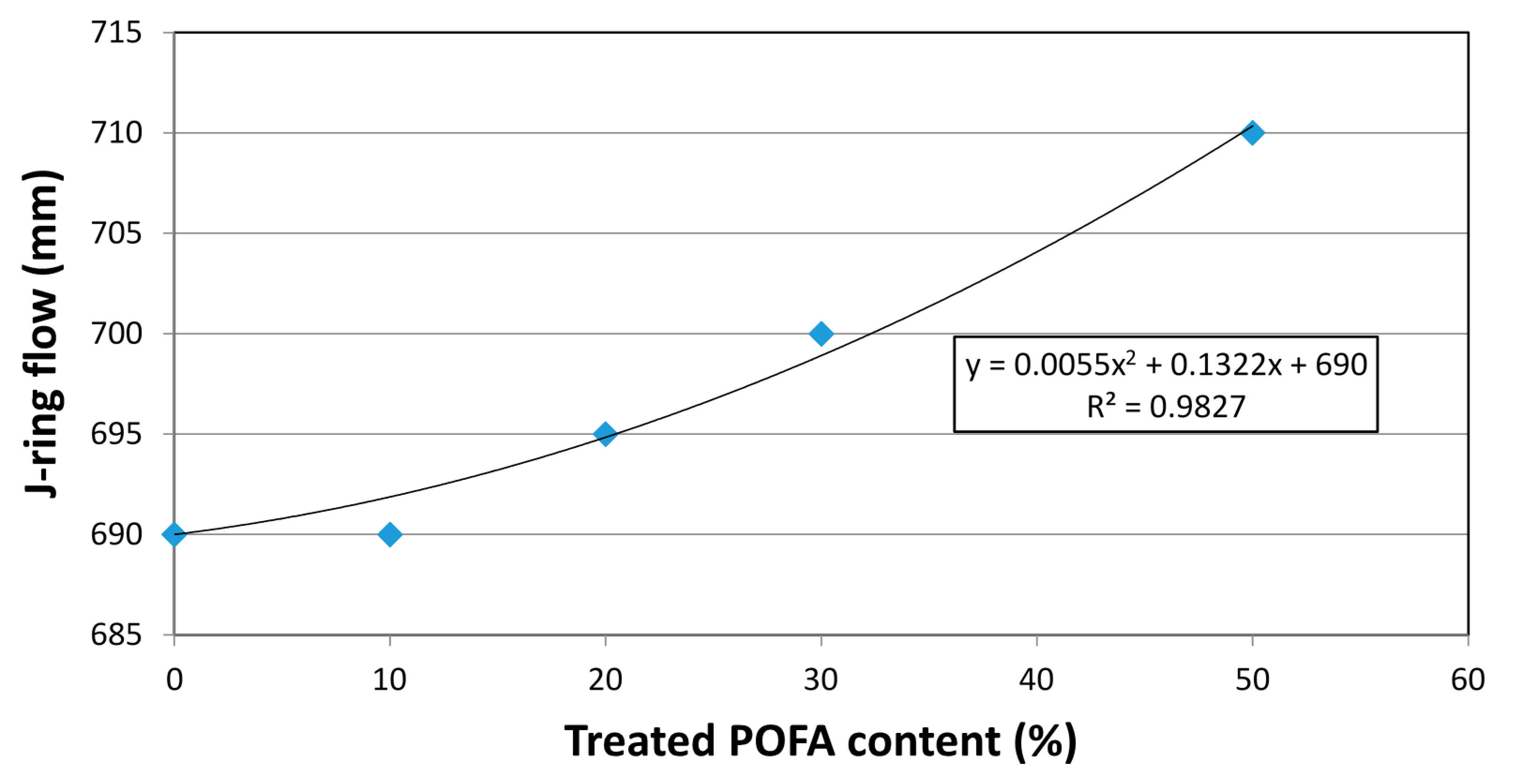

J-Ring Test

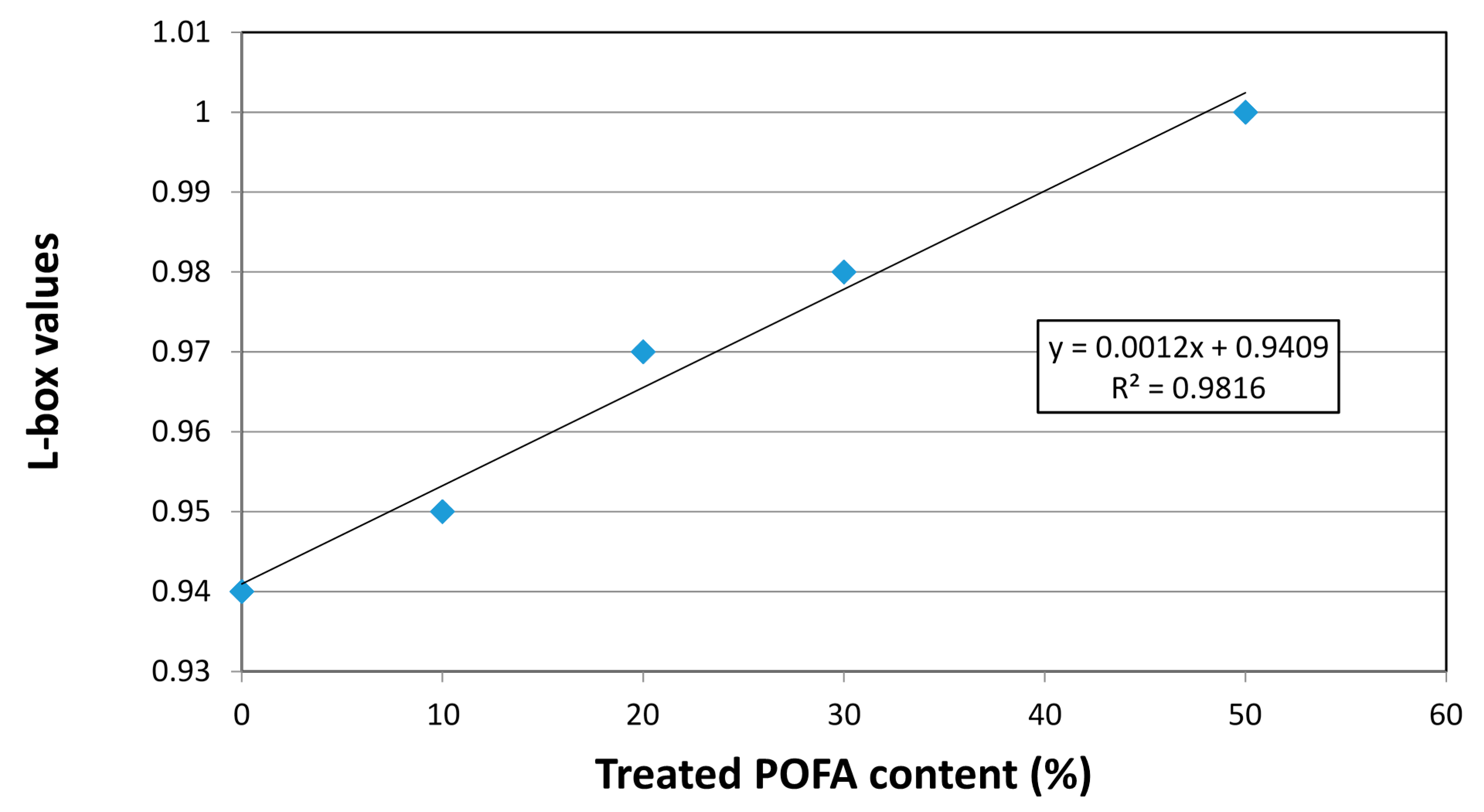

L-Box

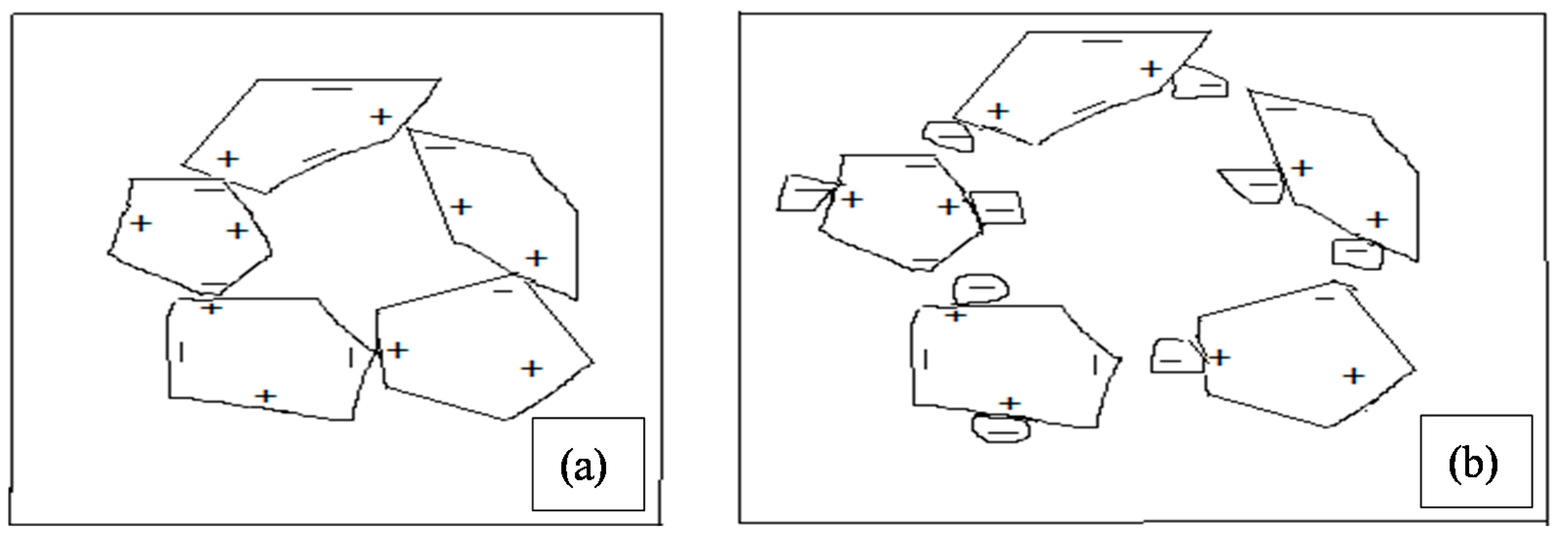

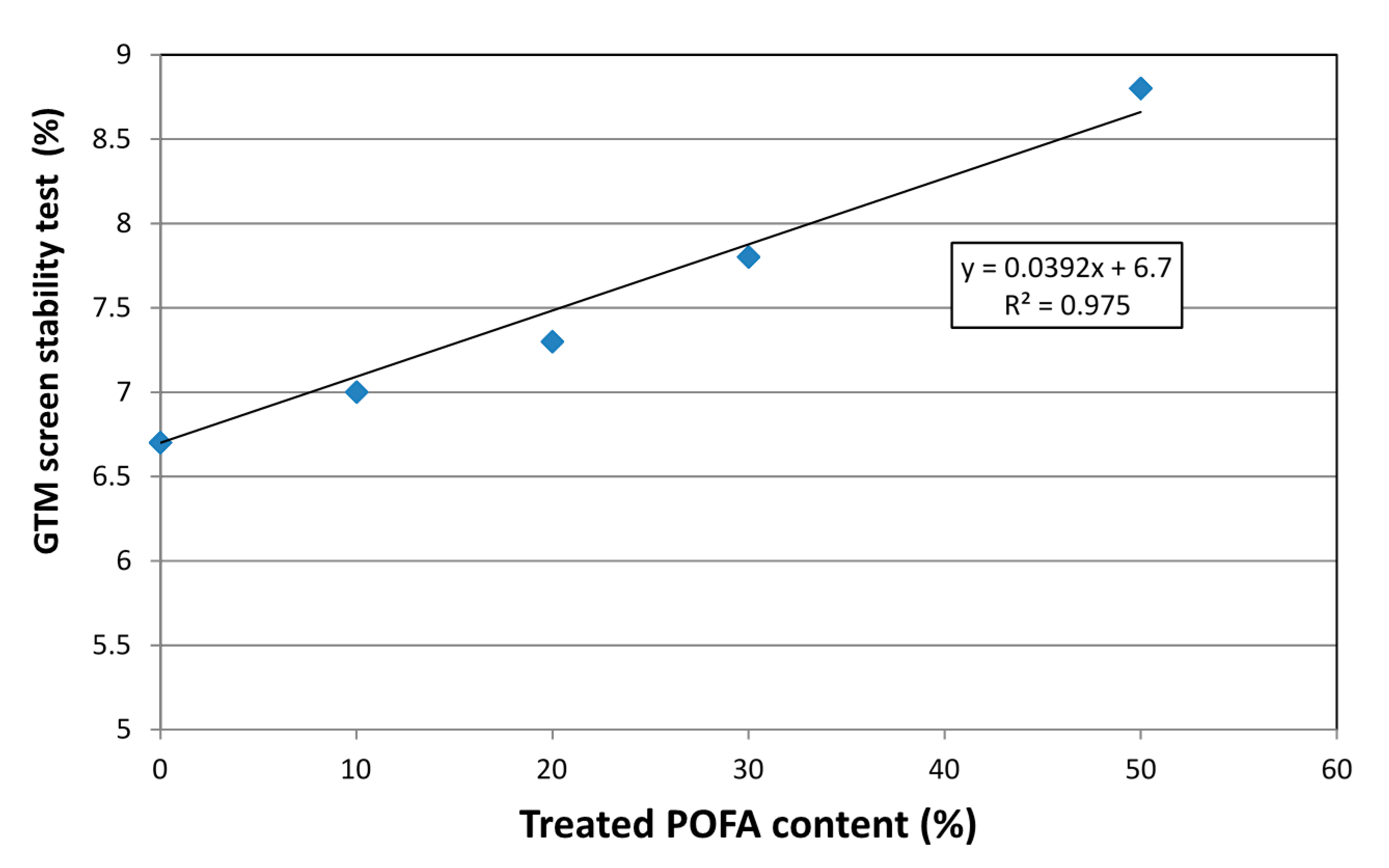

3.2.3. Segregation Resistance

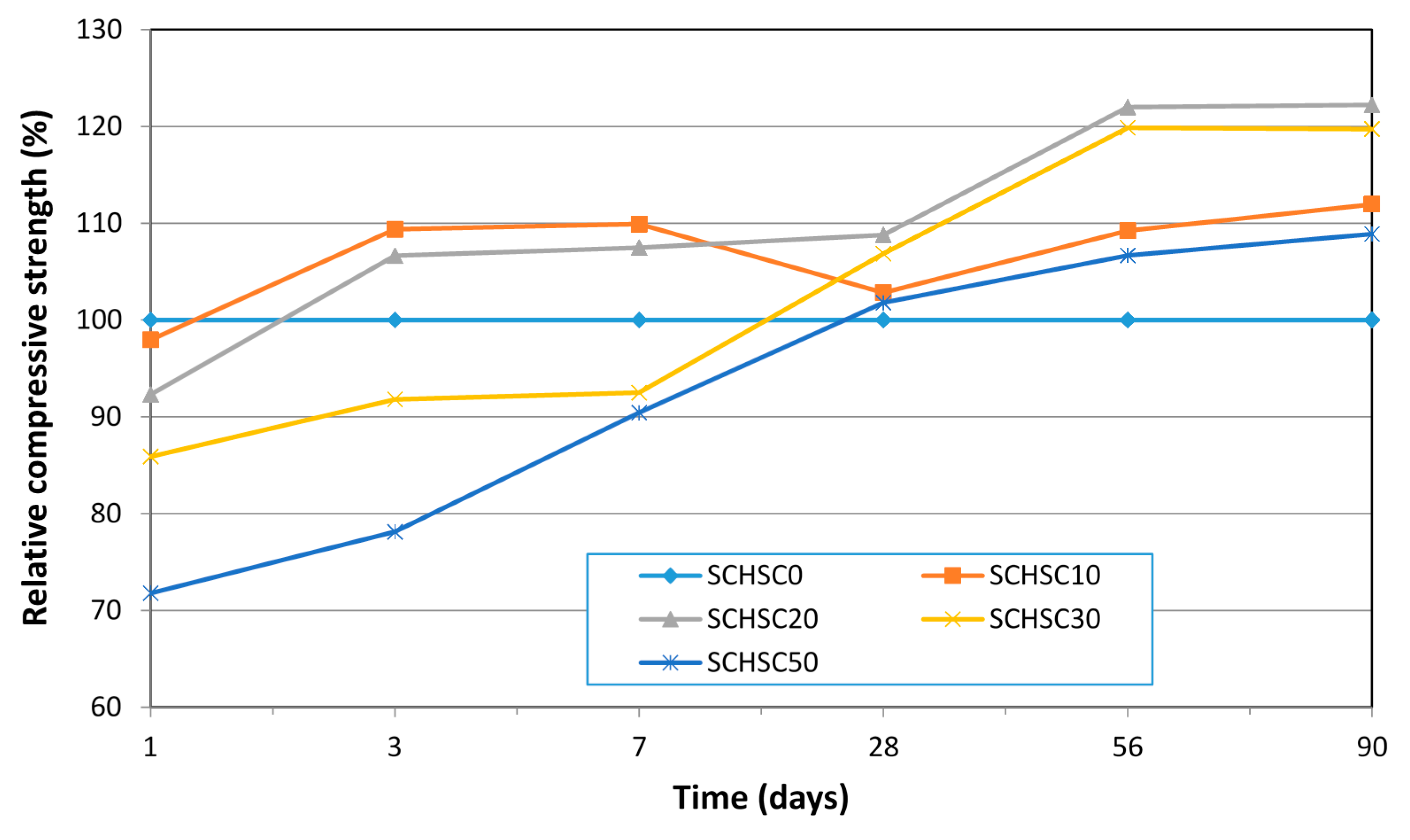

3.3. Compressive Strength

| Sample No. | 1 Day | 3 Days | 7 Days | 28 Days | 56 Days | 90 Days | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (MPa) | R1/28c * (%) | (MPa) | R3/28c * (%) | (MPa) | R7/28c (%) | (MPa) | R28/28c (%) | (MPa) | R56/28c (%) | (MPa) | R90/28c (%) | |

| SCHSC0 | 39.0 | 0.58 | 51.2 | 0.76 | 57.5 | 0.85 | 67.1 | 1.00 | 70.5 | 1.04 | 72.0 | 1.07 |

| SCHSC10 | 38.2 | 0.56 | 56.0 | 0.83 | 63.2 | 0.94 | 69.0 | 1.02 | 77.0 | 1.15 | 80.6 | 1.20 |

| SCHSC20 | 36.0 | 0.53 | 54.6 | 0.80 | 61.8 | 0.91 | 73.0 | 1.09 | 86.0 | 1.28 | 88.0 | 1.31 |

| SCHSC30 | 33.5 | 0.49 | 47.0 | 0.70 | 53.2 | 0.80 | 71.7 | 1.07 | 84.5 | 1.25 | 86.2 | 1.28 |

| SCHSC50 | 28.0 | 0.41 | 40.0 | 0.60 | 52.0 | 0.78 | 68.3 | 1.01 | 75.2 | 1.12 | 78.4 | 1.16 |

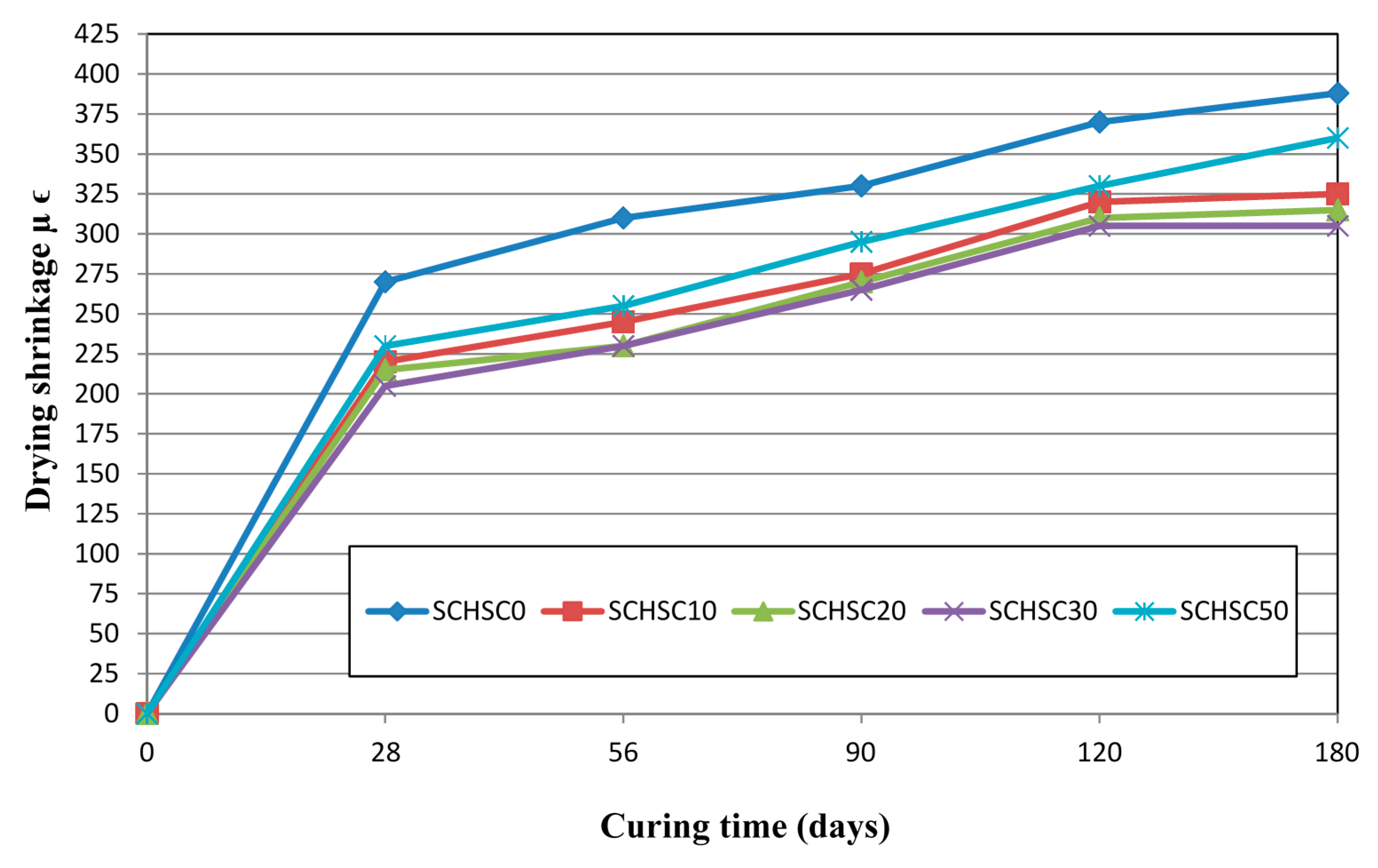

3.4. Drying Shrinkage Strain

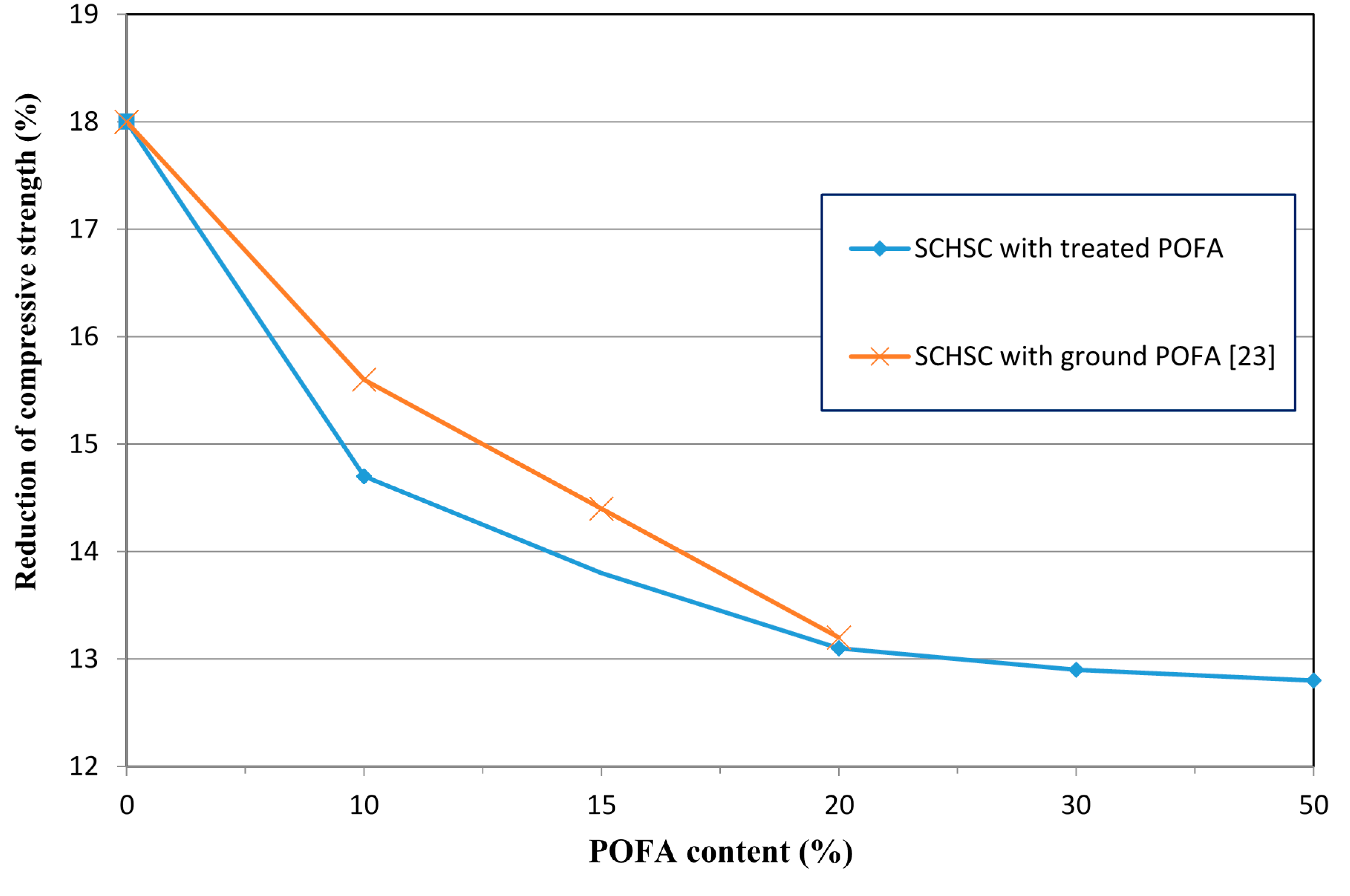

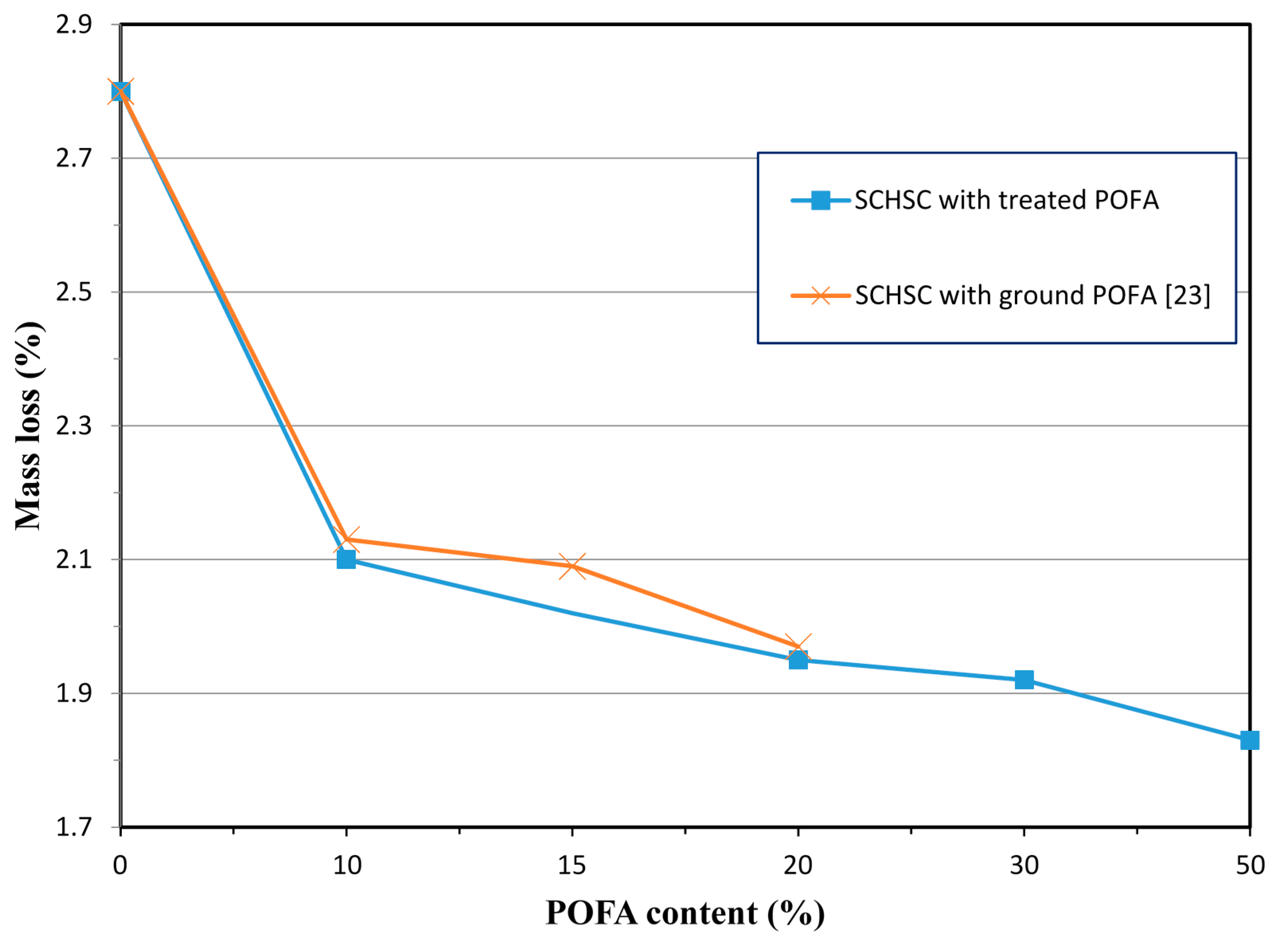

3.5. Acid Attack

3.5.1. Reduction in Compressive Strength

3.5.2. Mass Loss

3.5.3. Visual Inspections

4. Conclusions

- The physical properties and the chemical compositions of POFA were significantly improved via heat treatment and the grinding process.

- Treated POFA can be utilized in higher percentage (up to 50%) with an improvement in the concrete properties compared to ground POFA.

- SCHSCs containing treated POFA exhibited better fresh properties than the control mix.

- Incorporating treated POFA up to 50% cement replacement in SCHSCs showed higher compressive strength compared to concrete made with OPC at 28 days of water curing.

- Incorporating treated POFA caused a reduction in the drying shrinkage strain of all the mixes containing treated POFA compared to concrete just made with OPC.

- The specimens containing treated POFA showed better resistance against hydrochloric acid solution compared to SCHSC only made with OPC.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Safiuddin, M.; West, J.; Soudki, K. Durability performance of self-consolidating concrete. J. Appl. Sci. Res. 2008, 4, 1834–1840. [Google Scholar]

- Sabet, F.A.; Libre, N.A.; Shekarchi, M. Mechanical and durability properties of self consolidating high performance concrete incorporating natural zeolite, silica fume and fly ash. Constr. Build. Mater. 2013, 44, 175–184. [Google Scholar] [CrossRef]

- Tangchirapat, W.; Jaturapitakkul, C.; Chindaprasirt, P. Use of palm oil fuel ash as a supplementary cementitious material for producing high-strength concrete. Constr. Build. Mater. 2009, 23, 2641–2646. [Google Scholar] [CrossRef]

- Nehdi, M.L. Only tall things cast shadows: Opportunities, challenges and research needs of self-consolidating concrete in super-tall buildings. Constr. Build. Mater. 2013, 48, 80–90. [Google Scholar] [CrossRef]

- Barragán, B.; Gettu, R.; Pintado, X.; Bravo, M. Design of high strength self-compacting concrete for tunnel linings. In Measuring, Monitoring and Modeling Concrete Properties; Springer: Berlin, Germany, 2006; pp. 485–491. [Google Scholar]

- Salam, M.; Safiuddin, M.; Jumaat, M. Microstructure of self-consolidating high strength concrete incorporating palm oil fuel ash. Phys. Rev. Res. Int. 2013, 3, 674–687. [Google Scholar]

- Naik, T.R.; Kumar, R.; Ramme, B.W.; Canpolat, F. Development of high-strength, economical self-consolidating concrete. Constr. Build. Mater. 2012, 30, 463–469. [Google Scholar] [CrossRef]

- Hoenig, V.; Hoppe, H.; Emberger, B. Carbon Capture Technology-Options and Potentials for the Cement Industry; Tannenstrasse: European Cement Research Academy, Duesseldorf, Germany, 2007. [Google Scholar]

- Hoveidi, H.; Pazoki, M.; Hadizadeh, H.; Nasri, A. Appropriate measures to reduce greenhouse gases emissions from Iran’s cement industry. J. Earth Sci. Clim. Chang. 2013, 4. [Google Scholar] [CrossRef]

- Mohammed Owaid, H.; Hamid, R.B.; Taha, M.R. A review of sustainable supplementary cementitious materials as an alternative to all-portland cement mortar and concrete. Aust. J. Basic Appl. Sci. 2012, 6, 287–303. [Google Scholar]

- Malhotra, V. High-performance high-volume fly ash concrete. Concr. Int. 2002, 24, 30–34. [Google Scholar]

- Abdullah, K.; Hussin, M.; Zakaria, F.; Muhamad, R.; Abdul Hamid, Z. POFA: A potential partial cement replacement material in aerated concrete. In Proceedings of the 6th Asia-Pacific Structural Engineering and Construction Conference, Kuala Lumpur, Malaysia, 5–6 September 2006.

- Tangchirapat, W.; Saeting, T.; Jaturapitakkul, C.; Kiattikomol, K.; Siripanichgorn, A. Use of waste ash from palm oil industry in concrete. Waste Manag. 2007, 27, 81–88. [Google Scholar] [CrossRef] [PubMed]

- Johari, M.; Zeyad, A.; Muhamad Bunnori, N.; Ariffin, K. Engineering and transport properties of high-strength green concrete containing high volume of ultrafine palm oil fuel ash. Constr. Build. Mater. 2012, 30, 281–288. [Google Scholar] [CrossRef]

- Safiuddin, M.; Abdus Salam, M.; Jumaat, M.Z. Utilization of palm oil fuel ash in concrete: A review. J. Civil Eng. Manag. 2011, 17, 234–247. [Google Scholar] [CrossRef]

- Tay, J.-H. Ash from oil-palm waste as a concrete material. J. Mater. Civil Eng. 1990, 2, 94–105. [Google Scholar] [CrossRef]

- Specification and Guidelines for Self-Compacting Concrete; EFNARC, Association House: London, UK, 2002; pp. 1–32.

- Testing Hardened Concrete, Part 3: Compressive Strength of Test Specimens; BS EN 12390-3; British Standards Institution: London, UK, 2002.

- Sata, V.; Jaturapitakkul, C.; Kiattikomol, K. Influence of pozzolan from various by-product materials on mechanical properties of high-strength concrete. Constr. Build. Mater. 2007, 21, 1589–1598. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Homwuttiwong, S.; Jaturapitakkul, C. Strength and water permeability of concrete containing palm oil fuel ash and rice husk–bark ash. Constr. Build. Mater. 2007, 21, 1492–1499. [Google Scholar] [CrossRef]

- Tay, J.-H.; Show, K.-Y. Use of ash derived from oil-palm waste incineration as a cement replacement material. Resour. Conserv. Recycl. 1995, 13, 27–36. [Google Scholar] [CrossRef]

- Safiuddin, M.; Jumaat, M. Fresh properties of self-consolidating concrete incorporating palm oil fuel ash as a supplementary cementing material. Chiang Mai J. Sci. 2011, 38, 389–404. [Google Scholar]

- Alsubari, B.; Shafigh, P.; Jumaat, M.Z.; Alengaram, U.J. Palm oil fuel ash as a partial cement replacement for producing durable self-consolidating high-strength concrete. Arab. J. Sci. Eng. 2014, 39, 8507–8516. [Google Scholar] [CrossRef]

- Chandara, C.; Sakai, E.; Azizli, K.A.M.; Ahmad, Z.A.; Hashim, S.F.S. The effect of unburned carbon in palm oil fuel ash on fluidity of cement pastes containing superplasticizer. Constr. Build. Mater. 2010, 24, 1590–1593. [Google Scholar] [CrossRef]

- Safiuddin, M.; Salam, M.A.; Jumaat, M.Z. Key fresh properties of self-consolidating high-strength POFA concrete. J. Mater. Civil Eng. 2013, 26, 134–142. [Google Scholar] [CrossRef]

- Dhiyaneshwaran, S.; Ramanathan, P.; Baskar, I.; Venkatasubramani, R. Study on durability characteristics of self-compacting concrete with fly ash. Jordan J. Civil Eng. 2013, 7, 342–353. [Google Scholar]

- Long, W.-J.; Khayat, K.H.; Lemieux, G.; Hwang, S.-D.; Xing, F. Pull-out strength and bond behavior of prestressing strands in prestressed self-consolidating concrete. Materials 2014, 7, 6930–6946. [Google Scholar] [CrossRef]

- Bui, V.; Montgomery, D.; Hinczak, I.; Turner, K. Rapid testing method for segregation resistance of self-compacting concrete. Cement Concr. Res. 2002, 32, 1489–1496. [Google Scholar] [CrossRef]

- Obla, K.H.; Hill, R.L.; Thomas, M.D.; Shashiprakash, S.G.; Perebatova, O. Properties of concrete containing ultra-fine fly ash. ACI Mater. J. 2003, 100, 426–433. [Google Scholar]

- Galau, D.; Ismail, M. Characterization of Palm Oil Fuel Ash (POFA) from Different Mill as Cement Replacement Material. 2010. Available online: http://www.efka.utm.my/thesis/IMAGES/3PSM/2010/JSB-6/dominicgalauaa060049d10ttp.pdf (accessed on 6 March 2015).

- Habeeb, G.A.; Mahmud, H.B. Study on properties of rice husk ash and its use as cement replacement material. Mater. Res. 2010, 13, 185–190. [Google Scholar] [CrossRef]

- Tonnayopas, D.; Tonnayopas, F.; Putto, K.; Tantiwitayawanich, J. Effect of oil palm fiber fuel ash on compressive strength of hardening concrete. In Proceedings of the 4th Thailand Materials Science and Technology Conference, Pathumthani, Thailand, 31 March–1 April 2006; pp. 1–3.

- Sata, V.; Jaturapitakkul, C.; Rattanashotinunt, C. Compressive strength and heat evolution of concretes containing palm oil fuel ash. J. Mater. Civil Eng. 2010, 22, 1033–1038. [Google Scholar] [CrossRef]

- Awal, A.; Abubakar, S.I. Properties of concrete containing high volume palm oil fuel ash: Ashort-term investigation. Malays. J. Civil Eng. 2011, 23, 164–176. [Google Scholar]

- Haque, M.; Kayali, O. Properties of high-strength concrete using a fine fly ash. Cement Concr. Res. 1998, 28, 1445–1452. [Google Scholar] [CrossRef]

- Mahmud, H.B.; Malik, M.F.A.; Kahar, R.A.; Zain, M.F.M.; Raman, S.N. Mechanical properties and durability of normal and water reduced high strength grade 60 concrete containing rice husk ash. J. Adv. Concr. Technol. 2009, 7, 21–30. [Google Scholar] [CrossRef]

- Budiea, A.; Hussin, M.; Muthusamy, K.; Ismail, M. Performance of high strength POFA concrete in acidic environment. Concr. Res. Lett. 2010, 1, 14–18. [Google Scholar]

- Hussin, M.; Ismail, M.A.; Budiea, A.; Muthusamy, K. Durability of high strength concrete containing palm oil fuel ash of different fineness. Malays. J. Civil Eng. 2009, 21, 180–194. [Google Scholar]

- Verma, A.; Shukla, M.; Sahu, A.K. Influence of aggressive chemical environment on high volume fly ash concrete. Concr. Res. Lett. 2013, 4, 550–556. [Google Scholar]

- Dinakar, P.; Babu, K.; Santhanam, M. Durability properties of high volume fly ash self compacting concretes. Cement Concr. Compos. 2008, 30, 880–886. [Google Scholar] [CrossRef]

- Siad, H.; Mesbah, H.A.; Khelafi, H.; Kamali Bernard, S.; Mouli, M. Influence of natural pozzolan on the behavior of self-compacting concrete under sulphuric and hydrochloric acid attacks, comparative study. Arab. J. Sci. Eng. 2010, 35, 183. [Google Scholar]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alsubari, B.; Shafigh, P.; Jumaat, M.Z. Development of Self-Consolidating High Strength Concrete Incorporating Treated Palm Oil Fuel Ash. Materials 2015, 8, 2154-2173. https://doi.org/10.3390/ma8052154

Alsubari B, Shafigh P, Jumaat MZ. Development of Self-Consolidating High Strength Concrete Incorporating Treated Palm Oil Fuel Ash. Materials. 2015; 8(5):2154-2173. https://doi.org/10.3390/ma8052154

Chicago/Turabian StyleAlsubari, Belal, Payam Shafigh, and Mohd Zamin Jumaat. 2015. "Development of Self-Consolidating High Strength Concrete Incorporating Treated Palm Oil Fuel Ash" Materials 8, no. 5: 2154-2173. https://doi.org/10.3390/ma8052154

APA StyleAlsubari, B., Shafigh, P., & Jumaat, M. Z. (2015). Development of Self-Consolidating High Strength Concrete Incorporating Treated Palm Oil Fuel Ash. Materials, 8(5), 2154-2173. https://doi.org/10.3390/ma8052154