Development of Composite PCMs by Incorporation of Paraffin into Various Building Materials

Abstract

:1. Introduction

- (a)

- (b)

2. Experimental Investigation

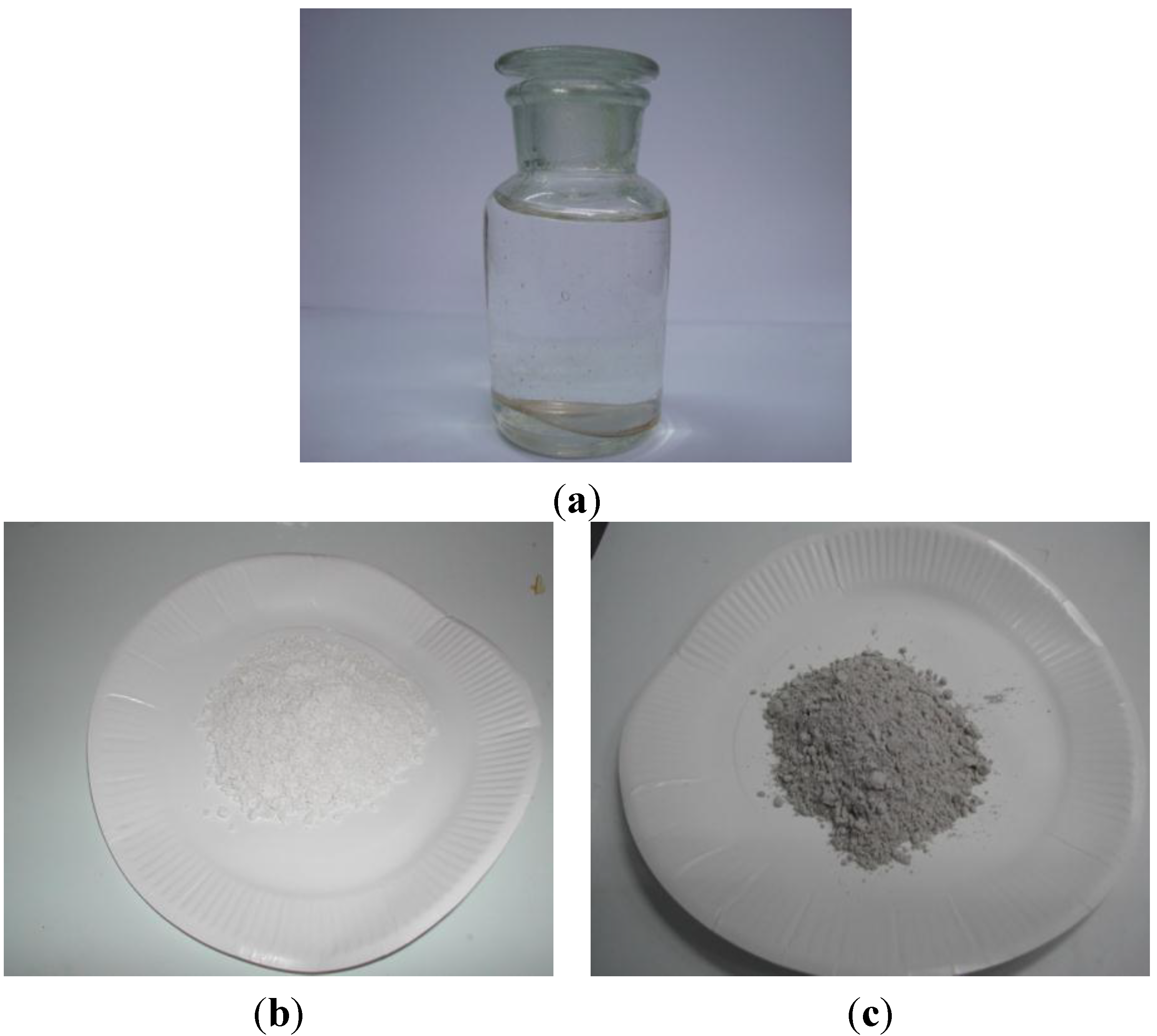

2.1. Materials and Preparation of the CPCMs

| Chemical Composition | Kaolin (%) | GGBS (%) |

|---|---|---|

| Silicon dioxide (SiO2) | 46 | 31.7 |

| Aluminum oxide (Al2O3) | 38 | 14.5 |

| Ferric oxide (Fe2O3) | 0.73 | 1.37 |

| Titanium dioxide (TiO2) | 0.19 | - |

| Calcium oxide (CaO) | 0.02 | 38.5 |

| Magnesium oxide (MgO) | 0.06 | 8.13 |

| Sodium oxide (Na2O) | 0.03 | - |

| Potassium oxide (K2O) | 0.65 | - |

| Sulfate as SO3 | - | 2.61 |

| Loss on ignition | 13.7 | - |

| Others | 3.19 |

2.2. Test Methods for Characterization of the CPCMs

2.2.1. Environmental Scanning Electron Microscopy (ESEM)

2.2.2. Chemical Compatibility of the CPCMs

2.2.3. Thermal Properties of the CPCMs

- (a)

- Equilibrate at 0.00 °C

- (b)

- Isothermal for 3.00 min

- (c)

- Ramp 5.00 °C/min to 40.00 °C

- (d)

- Isothermal for 2.00 min

- (e)

- Ramp 5.00 °C/min to 0.00 °C

- (f)

- End of method

2.2.4. Thermal Stability of the CPCMs

2.2.5. Thermal Reliability of the CPCMs

- (a)

- 1–8 h: the temperature was maintained at 26 °C.

- (b)

- 8–12 h: the temperature was decreased to 18 °C at a rate of 2 °C/h.

- (c)

- 12–20 h: the temperature was maintained at 18 °C.

- (d)

- 20–24 h: the temperature was increased to 26 °C at a rate of 2 °C/h.

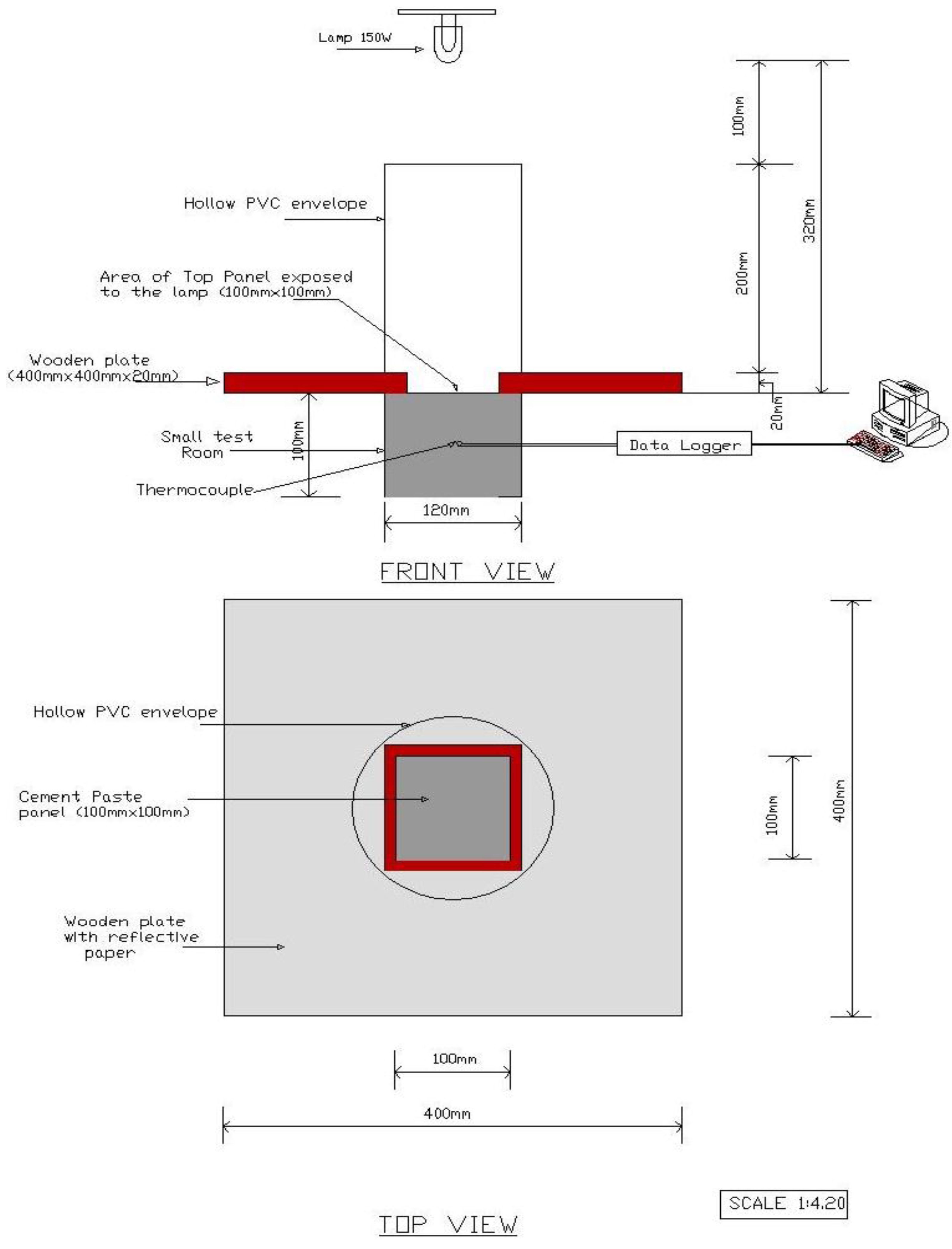

2.2.6. Thermal Performance of Cement-Paste Panels

| Sample Number | Thermal Conductivity Coefficient (W/mK) (Test temperature 22–30 °C) | Density (kg/m3) | Specific Heat Capacity (J/kg·K) (Test Temperature 5 °C/35 °C) | Enthalpy (J/kg) |

|---|---|---|---|---|

| Cement paste | 0.91 | 2230 | 1033/1033 | / |

| Cement paste with KO-CPCM | 0.77 | 1980 | 1180/1228 | 7842 |

| Cement paste with GGBS-CPCM | 0.82 | 2050 | 1061/1132 | 4038 |

3. Test Results and Discussion

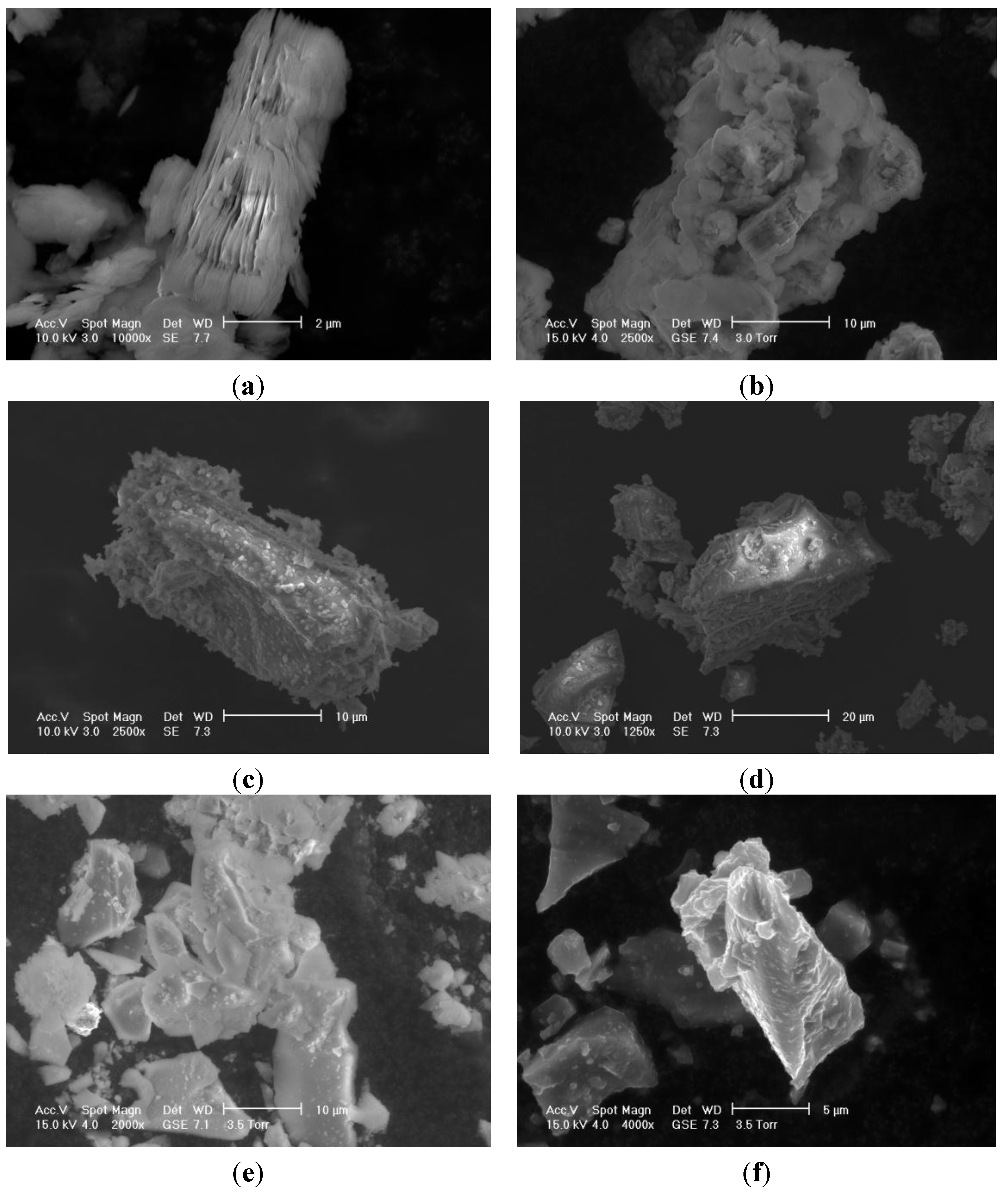

3.1. Morphology and Optimum Percentage Retained by CPCMs

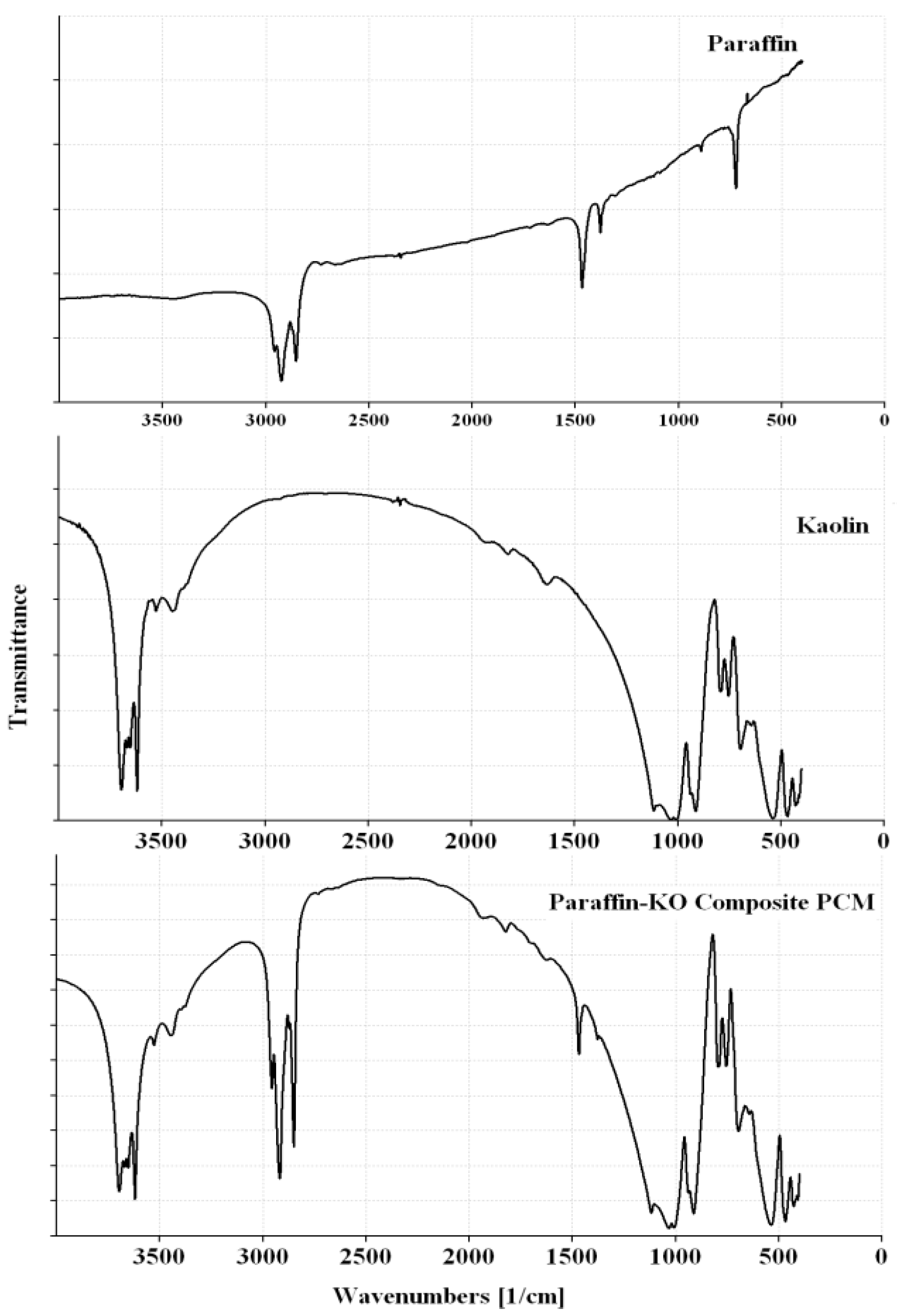

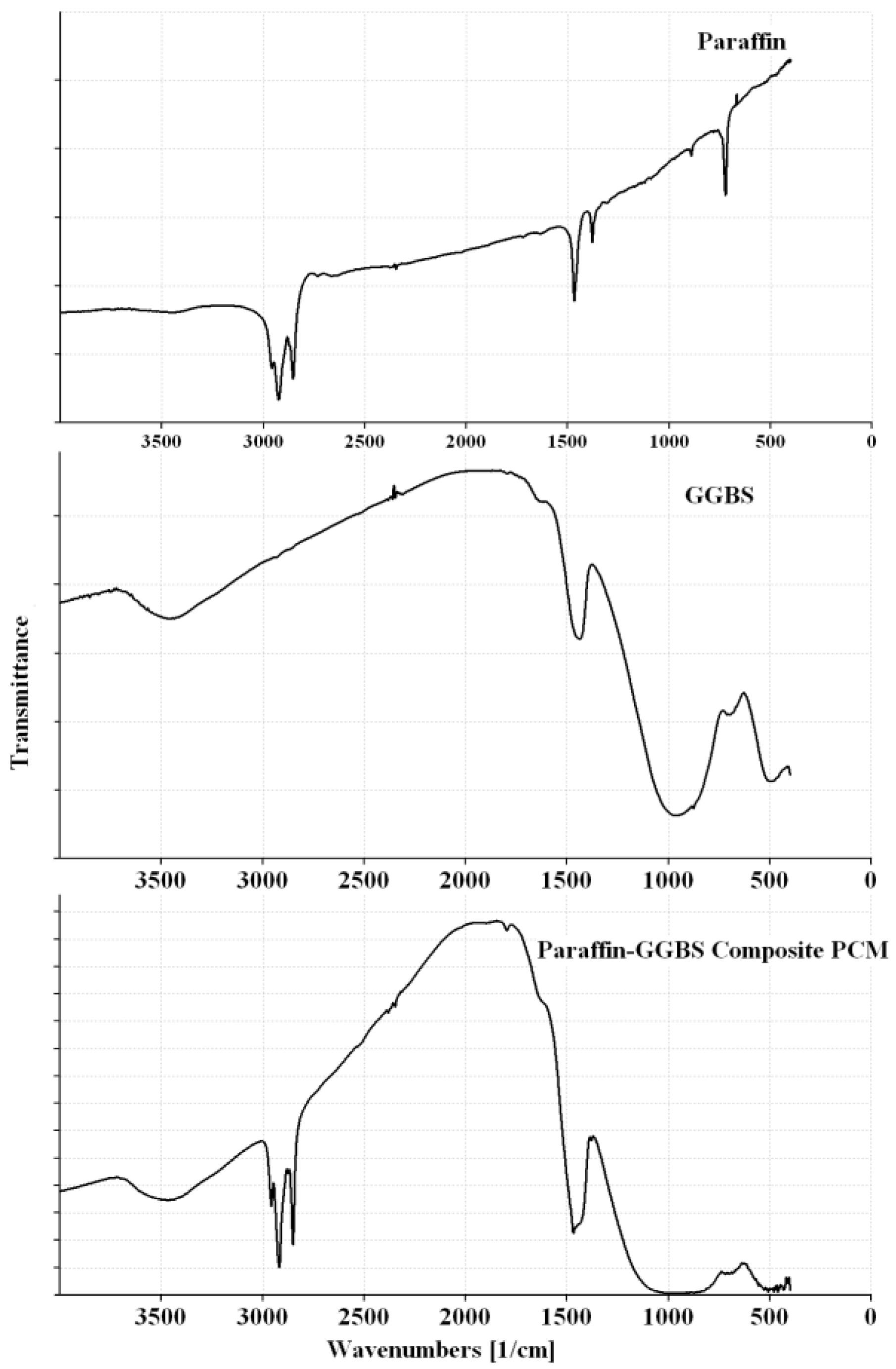

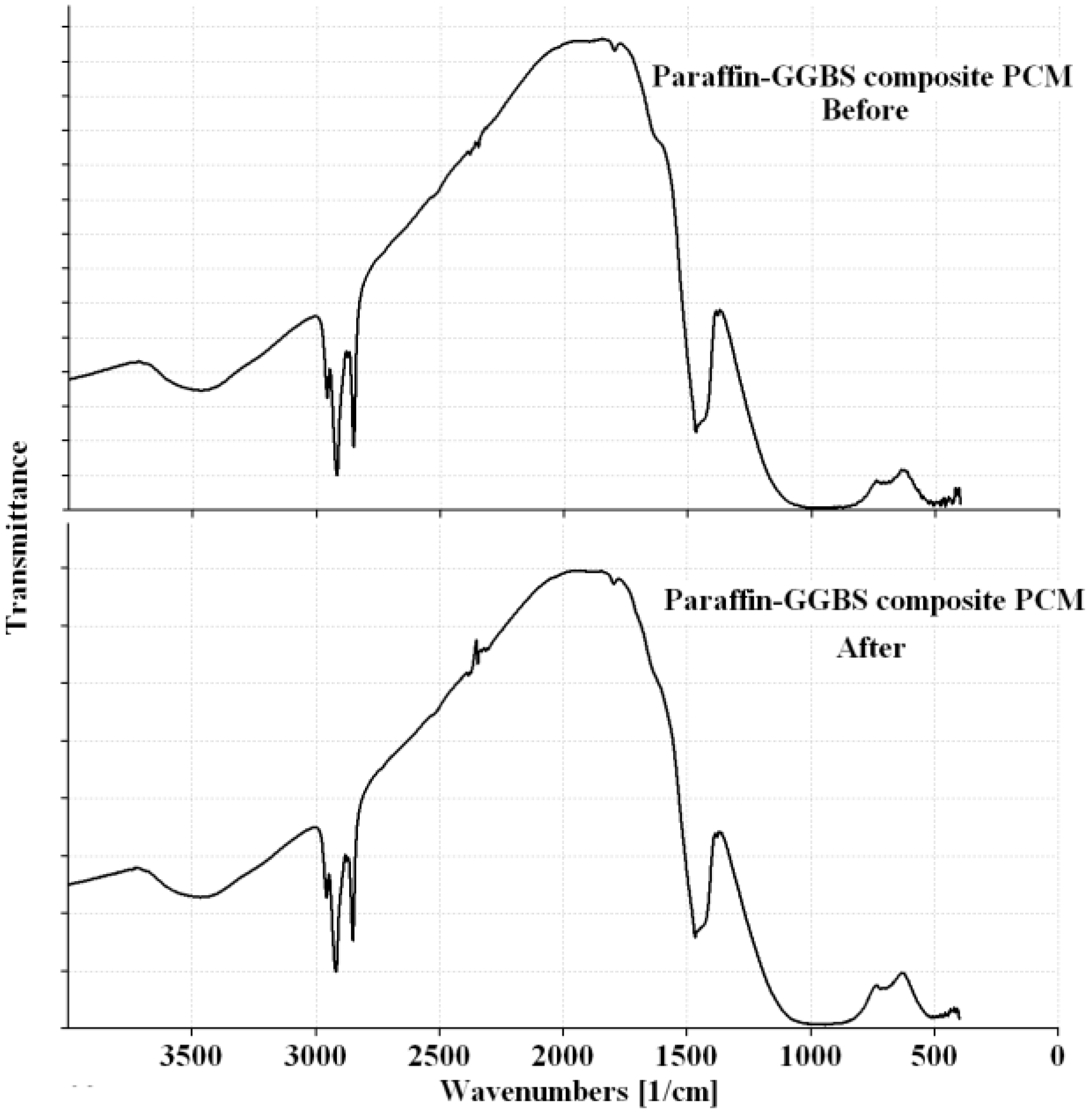

3.2. FT-IR Spectroscopy of the CPCMs

| Band (cm−1) | Assignment | Reference |

|---|---|---|

| Paraffin | ||

| 2924 | Methylene C–H stretching | [21,22,23] |

| 2853 | Methylene C–H stretching | [23,24,25] |

| 1467 | Methylene/Methyl C–H bending | [23] |

| 1378 | Methyl C–H bending | [23,26,27] |

| 721 | Rocking Methylene | [23] |

| Kaolin | ||

| 3696, 3669, 3653, 3620 | Al–O–H stretching | [28,29,30,31] |

| 3449 | H–O–H stretching | [28,29] |

| 1631 | H–O–H bending | [28,32,33] |

| 1115, 1031, 1007 | Si–O stretching | [28,29,34,35] |

| GGBS | ||

| 937, 912 | Al–OH bending | [29,32,34] |

| 754 | Si–O–Al stretching | [29,34,35] |

| 535 | Si–O–Al stretching | [32] |

| 467 | Si–O–Si bending | [29,32] |

| 3468 | H–O–H stretching | [36,37] |

| 1437 | O–C–O stretching | [38,39] |

| 963 | Si(Al)–O stretching | [40,41] |

| 711 | Si–O–Si (Al) stretching | [41] |

| 494 | O–Si–O bending | [40,41] |

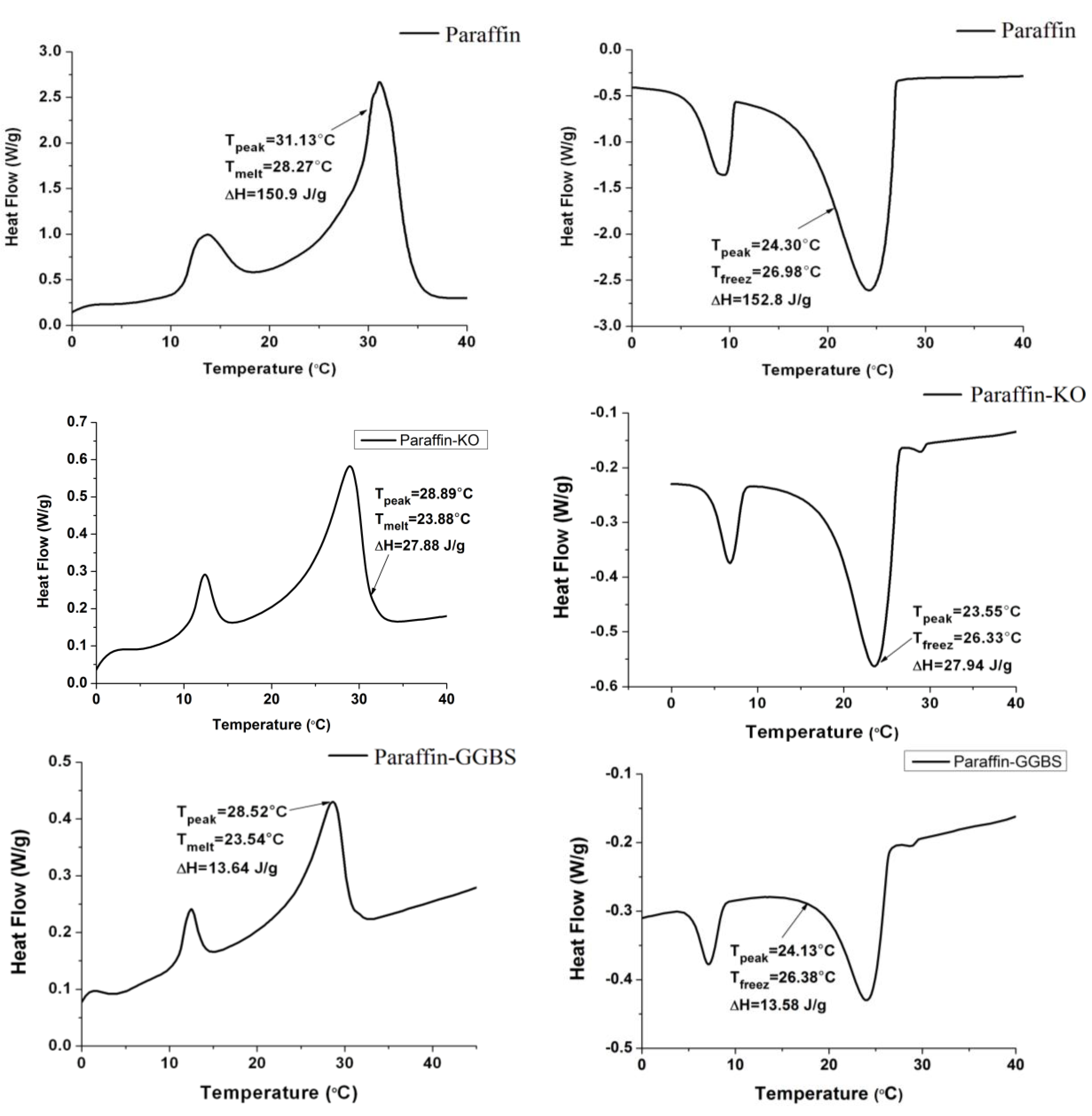

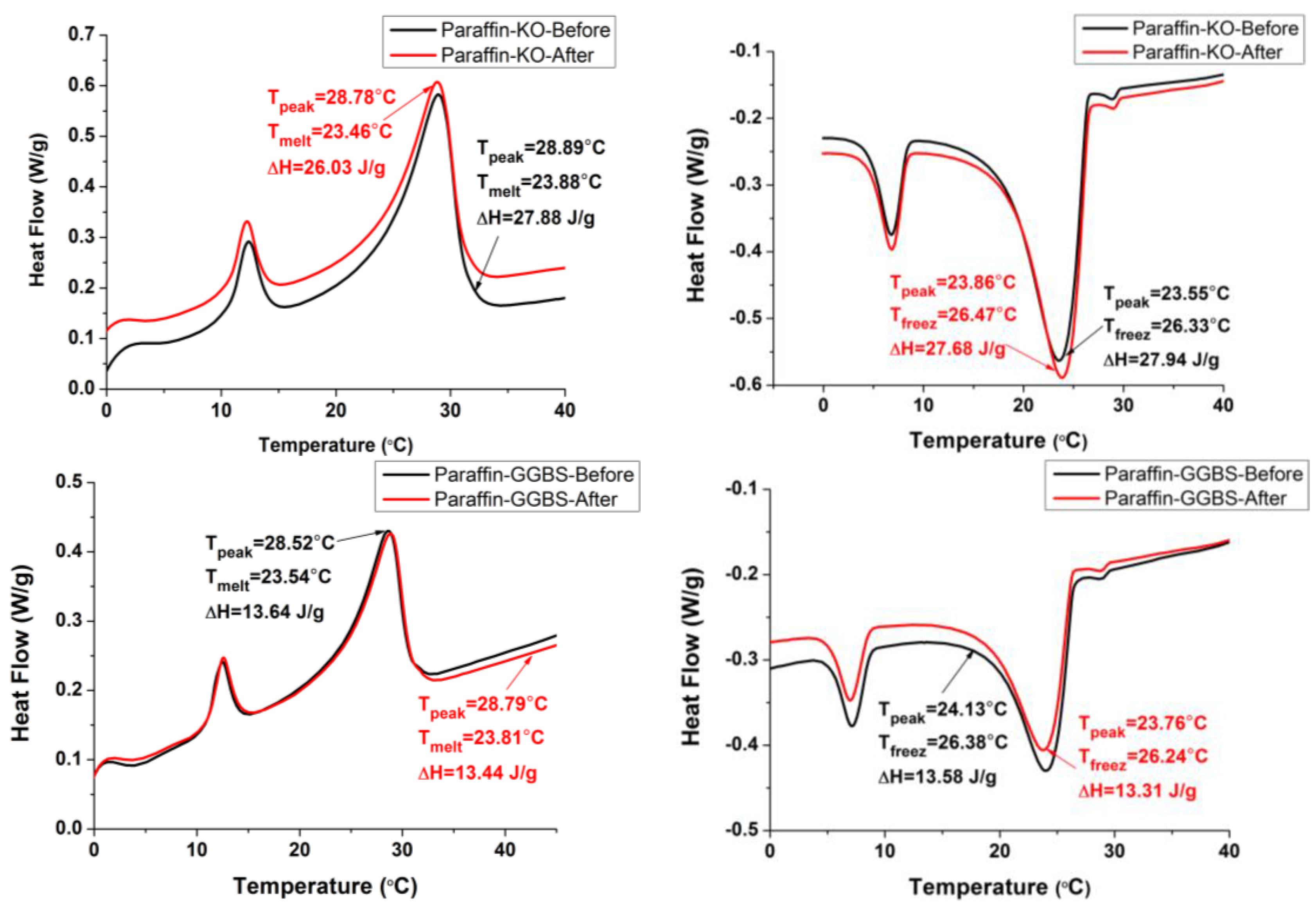

3.3. Thermal Properties of the CPCMs

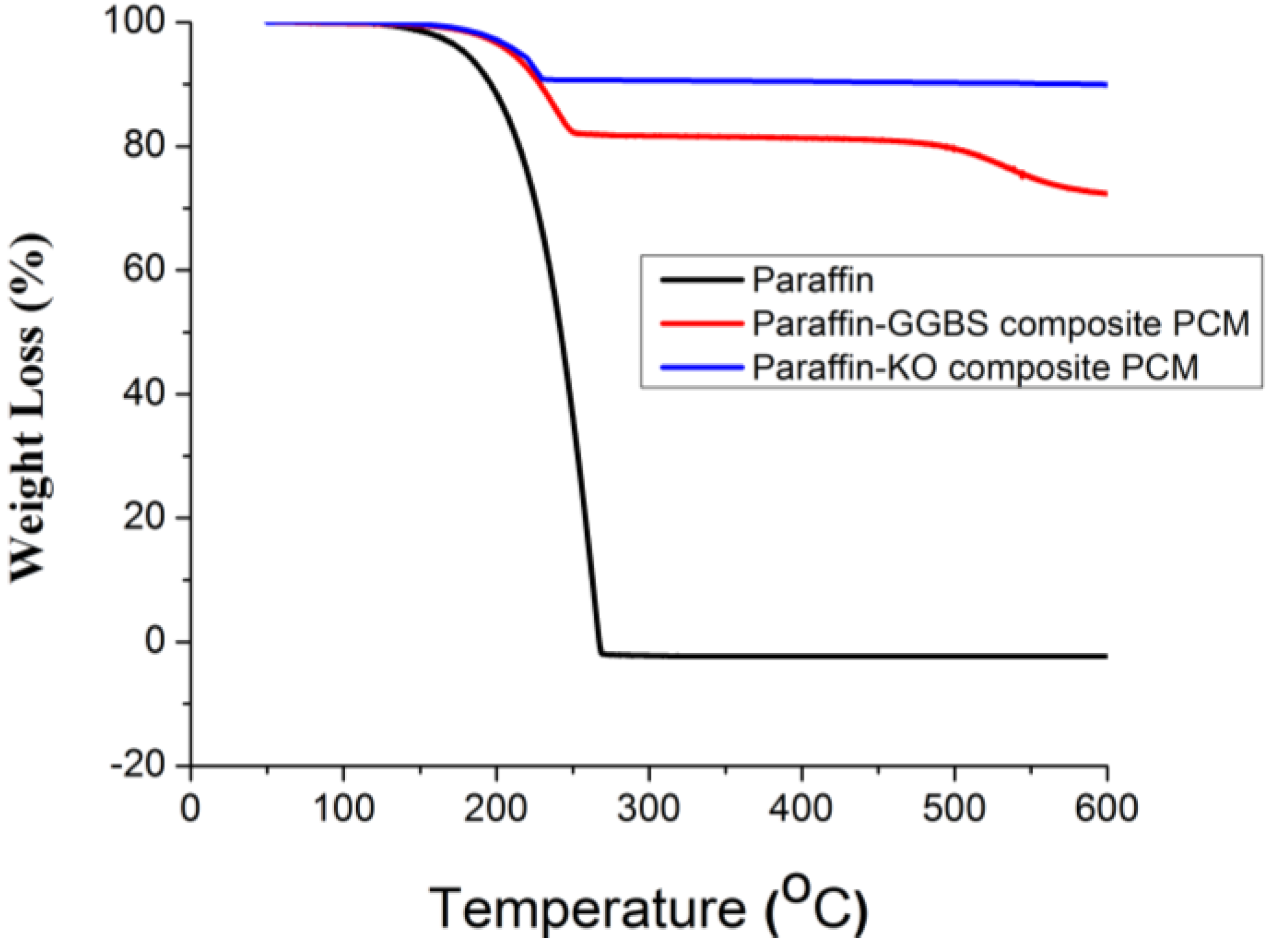

3.4. Thermal Stability of the CPCMs

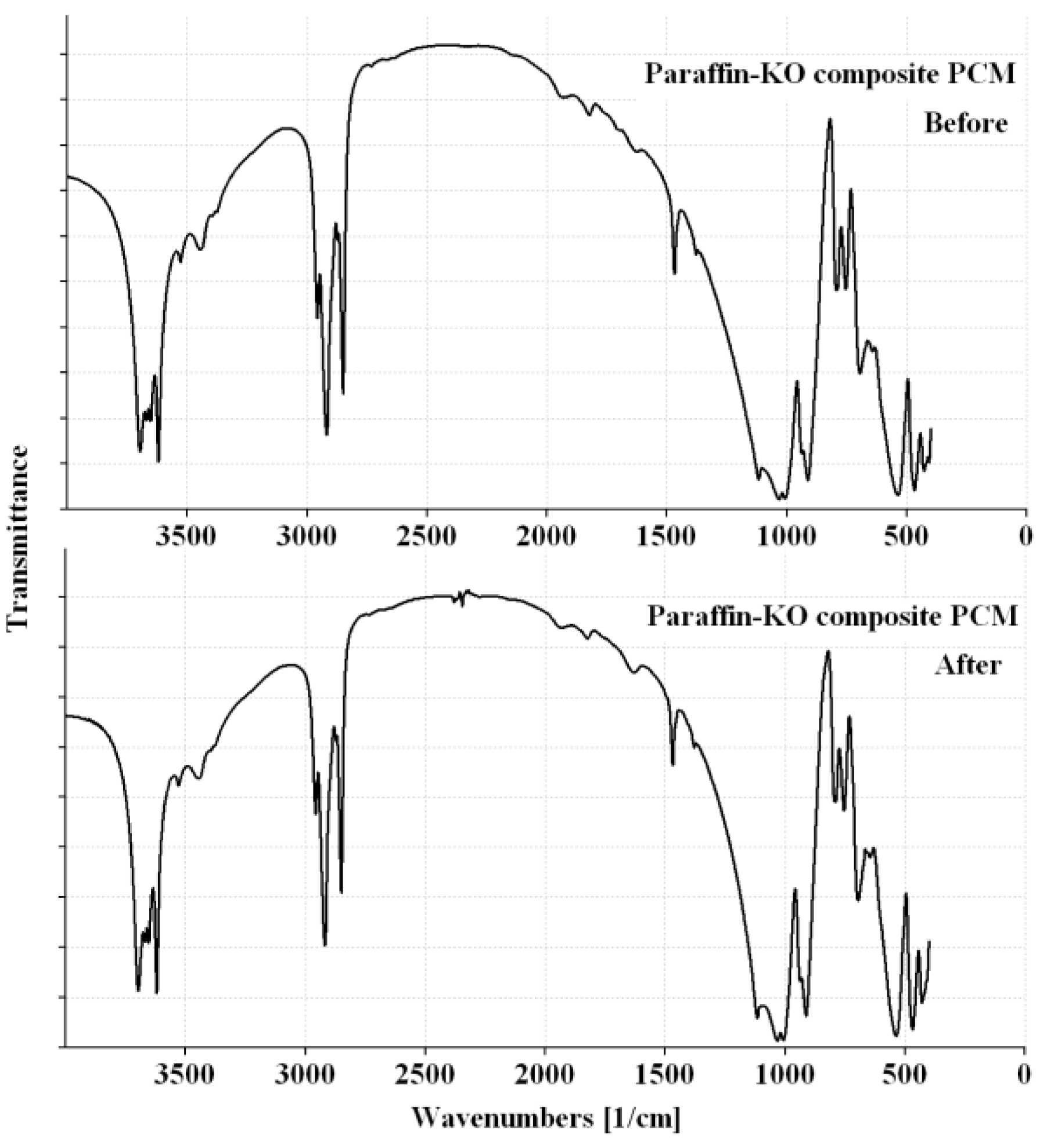

3.5. Thermal Reliability of the CPCMs

3.6. Thermal Performance of CPCMs

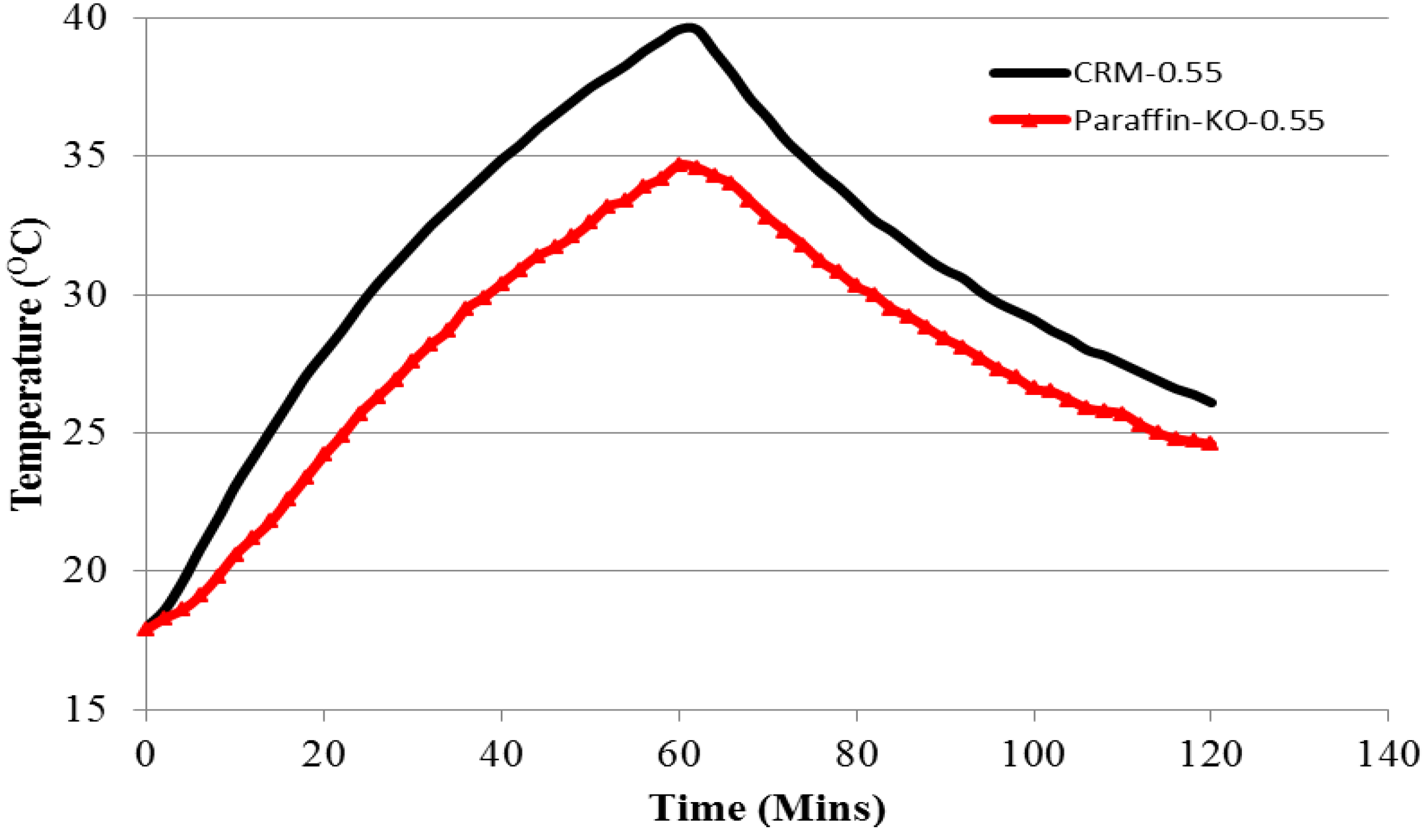

3.6.1. Thermal Performance of Paraffin-Kaolin Composite

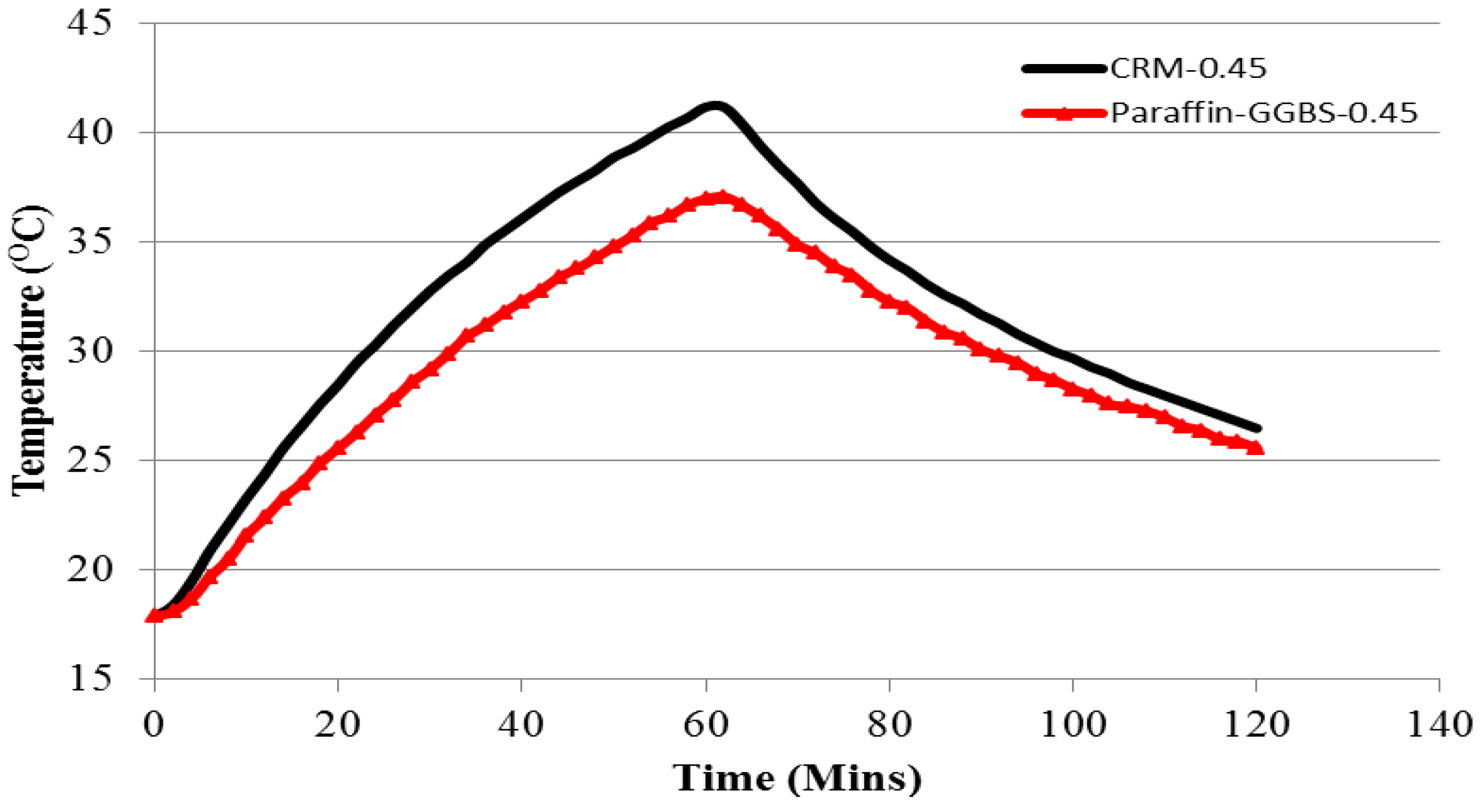

3.6.2. Thermal Performance of Paraffin-GGBS Composite

4. Conclusions

- (1)

- Through vacuum impregnation, the maximum percentage of paraffin retained by Kaolin and GGBS was found to be 18% and 9%, respectively. ESEM micrographs showed that paraffin was well confined in the pores of Kaolin and GGBS through capillary forces and surface tension which, in turn, prevented the seepage of the melted PCM.

- (2)

- FT-IR results showed that the interaction between the components of composite PCM are physical in nature and were also responsible for preventing the leakage of paraffin during its phase transition from solid to liquid. It can therefore be concluded that the components of the prepared CPCMs are chemically compatible with each other.

- (3)

- From DSC analysis, it was found that the phase-change temperatures of the developed CPCMs are in the proper temperature range for human comfort. Therefore, it can be used in building applications as a thermal energy-storage material where it can moderate the fluctuations in indoor temperatures and improve the indoor thermal environment. Moreover, the prepared CPCMs have considerable energy-storage potential; therefore, they can be used to decrease cooling, heating, and air-conditioning loads in buildings.

- (4)

- From TGA results, it was found that none of the prepared CPCMs showed signs of degradation below 150 °C, and almost no weight loss was observed, indicating that the prepared CPCMs are very stable in the working temperature region. Therefore, it can be concluded that the CPCMs have good thermal stability and can be used in thermal energy-storage applications.

- (5)

- The chemical structure of prepared CPCMs was not affected by thermal cycling. Moreover, the changes observed in the phase-change temperature and latent heat storage of the prepared CPCMs after repeated thermal cycling were smaller. Therefore, the prepared CPCMs have good thermal reliability.

- (6)

- From the self-designed thermal performance setup, it was found that the prepared CPCMs are effective in reducing the indoor temperature. Additionally, the temperature curves for the room model with CPCMs were right-shifted. Therefore, it can be concluded that CPCMs may be helpful in reducing the energy consumption by decreasing the indoor temperature and hence can be a potential candidate for applications in building facades.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Sharma, A.; Tyagi, V.V.; Chen, C.R.; Buddhi, D. Review on thermal energy storage with phase change materials and applications. Renew. Sustain. Energy Rev. 2009, 13, 318–345. [Google Scholar] [CrossRef]

- Zhang, D.; Tian, S.L.; Xiao, D.Y. Experimental study on the phase change behavior of phase change material confined in pores. Sol. Energy 2007, 81, 653–660. [Google Scholar] [CrossRef]

- Ling, T.C.; Poon, C.S. Use of phase change materials for thermal energy storage in concrete: An overview. Constr. Build. Mater. 2013, 46, 55–62. [Google Scholar] [CrossRef]

- Meshgin, P.; Xi, Y. Effect of phase-change materials on properties of concrete. ACI Mater. J. 2012, 109, 71–80. [Google Scholar]

- Ma, B.; Adhikari, S.; Chang, Y.; Ren, J.; Liu, J.; You, Z. Preparation of composite shape-stabilized phase change materials for highway pavements. Constr. Build. Mater. 2013, 42, 114–121. [Google Scholar] [CrossRef]

- Sarı, A.; Karaipekli, A. Preparation, thermal properties and thermal reliability of palmitic acid/expanded graphite composite as form-stable pcm for thermal energy storage. Sol. Energy Mater. Sol. Cells 2009, 93, 571–576. [Google Scholar] [CrossRef]

- Sarı, A.; Karaipekli, A. Fatty acid esters-based composite phase change materials for thermal energy storage in buildings. Appl. Therm. Eng. 2012, 37, 208–216. [Google Scholar] [CrossRef]

- Zuo, J.; Li, W.; Weng, L. Thermal performance of caprylic acid/1-dodecanol eutectic mixture as phase change material (PCM). Energy Build. 2011, 43, 207–210. [Google Scholar] [CrossRef]

- Wang, W.; Yang, X.; Fang, Y.; Ding, J.; Yan, J. Preparation and thermal properties of polyethylene glycol/expanded graphite blends for energy storage. Appl. Energy 2009, 86, 1479–1483. [Google Scholar] [CrossRef]

- Karaipekli, A.; Sari, A. Preparation and characterization of fatty acid ester/building material composites for thermal energy storage in buildings. Energy Build. 2011, 43, 1952–1959. [Google Scholar] [CrossRef]

- Karaipekli, A.; Sarı, A. Capric–myristic acid/vermiculite composite as form-stable phase change material for thermal energy storage. Sol. Energy 2009, 83, 323–332. [Google Scholar] [CrossRef]

- Wang, Y.; Xia, T.D.; Zheng, H.; Feng, H.X. Stearic acid/silica fume composite as form-stable phase change material for thermal energy storage. Energy Build. 2011, 43, 2365–2370. [Google Scholar] [CrossRef]

- Sarı, A.; Karaipekli, A.; Alkan, C. Preparation, characterization and thermal properties of lauric acid/expanded perlite as novel form-stable composite phase change material. Chem. Eng. J. 2009, 155, 899–904. [Google Scholar] [CrossRef]

- Li, H.; Liu, X.; Fang, G. Preparation and characteristics of n-nonadecane/cement composites as thermal energy storage materials in buildings. Energy Build. 2010, 42, 1661–1665. [Google Scholar] [CrossRef]

- Babu, G.K.; Kumar, V.S.R. Efficiency of GGBS in concrete. Cem. Concr. Res. 2000, 30, 1031–1036. [Google Scholar] [CrossRef]

- Sabir, B.; Wild, S.; Bai, J. Metakaolin and calcined clays as pozzolans for concrete: A review. Cem. Concr. Compos. 2001, 23, 441–454. [Google Scholar] [CrossRef]

- Siddique, R.; Klaus, J. Influence of metakaolin on the properties of mortar and concrete: A review. Appl. Clay Sci. 2009, 43, 392–400. [Google Scholar] [CrossRef]

- TA Instruments. Available online: http://www.tainstruments.com (accessed on 30 January 2015).

- Zhang, D.; Zhou, J.; Wu, K.; Li, Z. Granular phase changing composites for thermal energy storage. Sol. Energy 2005, 78, 471–480. [Google Scholar] [CrossRef]

- Kheradmand, M.; Azenha, M.; de Aguiar, J.L.B.; Krakowiak, K.J. Thermal behavior of cement based plastering mortar containing hybrid microencapsulated phase change materials. Energy Build. 2014, 84, 526–536. [Google Scholar] [CrossRef]

- Severcan, F.; Toyran, N.; Kaptan, N.; Turan, B. Fourier transform infrared study of the effect of diabetes on rat liver and heart tissues in the C–H region. Talanta 2000, 53, 55–59. [Google Scholar] [CrossRef] [PubMed]

- Gokulakumar, B.; Narayanasyamy, R. Fourier transform-infrared spectra (FT-IR) analysis of root rod disease in sesame (Sesamum indicum). Rom. J. Biophys. 2008, 18, 217–223. [Google Scholar]

- Coates, J. Intrepretation of infrared spectra, a practical approach. In Encyclopedia of Analytical Chemistry; Meyers, R.A., Ed.; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2000. [Google Scholar]

- Memon, S.A.; Lo, T.Y.; Barbhuiya, S.A.; Xu, W. Development of form-stable composite phase change material by incorporation of dodecyl alcohol into ground granulated blast furnace slag. Energy Build. 2013, 62, 360–367. [Google Scholar] [CrossRef]

- Hamizi, N.A.; Johan, M.R. Optical and ftir studies of cdse quantum dots. In Proceedings of the 3rd International Nanoelectronics Conference (INEC), Hong Kong, China, 3–8 January 2010.

- Su, Y.L.; Wang, J.; Liu, H.Z. FTIR spectroscopic study on effects of temperature and polymer composition on the structural properties of PEO-PPO-PEO block copolymer micelles. Langmuir 2002, 18, 5370–5374. [Google Scholar] [CrossRef]

- Litvinov, V.M.; De, P. Spectroscopy of Rubbers and Rubbery Materials; Rapra Technology Limited: Telford, UK, 2002. [Google Scholar]

- Madejová, J. FTIR techniques in clay mineral studies. Vib. Spectrosc. 2003, 31, 1–10. [Google Scholar] [CrossRef]

- Belver, C.; Muñoz, M.A.B.; Vicente, M.A. Chemical activation of a kaolinite under acid and alkaline conditions. Chem. Mater. 2002, 14, 2033–2043. [Google Scholar] [CrossRef]

- Ryan, P.C.; Huertas, F.J. The temporal evolution of pedogenic Fe-smectite to Fe-kaolin via interstratified kaolin-smectite in a moist tropical soil chronosequence. Geoderma 2009, 151, 1–15. [Google Scholar] [CrossRef]

- Ekosse, G.I.E. Fourier transform infrared spectrophotometry and X-ray powder diffractometry as complementary techniques in characterizing clay size fraction of kaolin. J. Appl. Sci. Environ. Manag. 2005, 9, 43–48. [Google Scholar]

- Saikia, B.J.; Parthasarathy, G. Fourier transform infrared spectroscopic characterization of kaolinite from assam and meghalaya, northeastern india. J. Mod. Phys. 2010, 1, 206–210. [Google Scholar] [CrossRef]

- Al-Alawi, A.; Voort, F.R.V.D.; Sedman, J.; Ghetler, A. Automated Ftir Analysis of Free Fatty Acids or Moisture in Edible Oils; McGill University: Quebec, QC, Canada, 2006. [Google Scholar]

- Vaculikova, L.; Pelvova, E.; Vallova, S.; Koutnik, I. Characterization and differentiation of kaolinites from selected czech deposits using infrared spectroscopy and differential thermal analysis. Acta Geodyn. Geomater. 2011, 8, 59–67. [Google Scholar]

- Panda, A.K.; Mishra, B.G.; Mishra, D.K.; Singh, R.K. Effect of sulphuric acid treatment on the physico-chemical characteristics of kaolin clay. Colloids Surf. A Physicochem. Eng. Asp. 2010, 363, 98–104. [Google Scholar] [CrossRef]

- Sugama, T.; Ecker, L.; Butcher, T. Carbonation of Rock Minerals by Supercritical Carbon Dioxide at 250 °C; Brookhaven National Laboratory: Upton, NY, USA, 2010; p. 25.

- Manríquez, M.E.; López, T.; Gomez, R.; Picquart, M.; Hernández-Cortez, J.G. Sol-gel silica modified with phosphate and sulfate ions. J. Non-Cryst. Solids 2004, 345–346, 643–646. [Google Scholar] [CrossRef]

- Bernal, S.A.; Provis, J.L.; Rose, V.; Mejía de Gutierrez, R. Evolution of binder structure in sodium silicate-activated slag-metakaolin blends. Cem. Concr. Compos. 2011, 33, 46–54. [Google Scholar] [CrossRef]

- Liu, Z.; Qian, G.; Zhou, J.; Li, C.; Xu, Y.; Qin, Z. Improvement of ground granulated blast furnace slag on stabilization/solidification of simulated mercury-doped wastes in chemically bonded phosphate ceramics. J. Hazard. Mater. 2008, 157, 146–153. [Google Scholar] [CrossRef] [PubMed]

- Handke, M.; Harrick, N.J. A new accessory for infrared emission spectroscopy measurements. Appl. Spectrosc. 1986, 40, 401–405. [Google Scholar] [CrossRef]

- El-Didamony, H.; Amer, A.A.; Ela-ziz, H.A. Properties and durability of alkali-activated slag pastes immersed in sea water. Ceram. Int. 2012, 38, 3773–3780. [Google Scholar] [CrossRef]

- Karaipekli, A.; Sari, A. Preparation, thermal properties and thermal reliability of eutectic mixtures of fatty acids/expanded vermiculite as novel form-stable composites for energy storage. J. Ind. Eng. Chem. 2010, 16, 767–773. [Google Scholar] [CrossRef]

- Fang, X.; Zhang, Z.; Chen, Z. Study on preparation of montmorillonite-based composite phase change materials and their applications in thermal storage building materials. Energy Convers. Manag. 2008, 49, 718–723. [Google Scholar] [CrossRef]

- Radhakrishnan, R.; Gubbins, K.E.; Watanabe, A.; Kaneko, K. Freezing of simple fluids in microporous activated carbon fibers: Comparison of simulation and experiment. J. Chem. Phys. 1999, 111, 9058–9067. [Google Scholar] [CrossRef]

- Radhakrishnan, R.; Gubbins, K.E. Free energy studies of freezing in slit pores: An order-parameter approach using monte carlo simulation. Mol. Phys. 1999, 96, 1249–1267. [Google Scholar] [CrossRef]

- Zhang, Z.; Shi, G.; Wang, S.; Fang, X.; Liu, X. Thermal energy storage cement mortar containing n-octadecane/expanded graphite composite phase change material. Renew. Energy 2013, 50, 670–675. [Google Scholar] [CrossRef]

- Hunger, M.; Entrop, A.G.; Mandilaras, I.; Brouwers, H.J.H.; Founti, M. The behavior of self-compacting concrete containing micro-encapsulated phase change materials. Cem. Concr. Compos. 2009, 31, 731–743. [Google Scholar] [CrossRef]

- Xu, B.; Li, Z. Paraffin/diatomite composite phase change material incorporated cement-based composite for thermal energy storage. Appl. Energy 2013, 105, 229–237. [Google Scholar] [CrossRef]

- Chinese National Standard. Uniform Technical Code for Wall Materials Used in Buildings; GB 50574-2010; Chinese National Standard: Beijing, China, 2010. (In Chinese) [Google Scholar]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Memon, S.A.; Liao, W.; Yang, S.; Cui, H.; Shah, S.F.A. Development of Composite PCMs by Incorporation of Paraffin into Various Building Materials. Materials 2015, 8, 499-518. https://doi.org/10.3390/ma8020499

Memon SA, Liao W, Yang S, Cui H, Shah SFA. Development of Composite PCMs by Incorporation of Paraffin into Various Building Materials. Materials. 2015; 8(2):499-518. https://doi.org/10.3390/ma8020499

Chicago/Turabian StyleMemon, Shazim Ali, Wenyu Liao, Shuqing Yang, Hongzhi Cui, and Syed Farasat Ali Shah. 2015. "Development of Composite PCMs by Incorporation of Paraffin into Various Building Materials" Materials 8, no. 2: 499-518. https://doi.org/10.3390/ma8020499

APA StyleMemon, S. A., Liao, W., Yang, S., Cui, H., & Shah, S. F. A. (2015). Development of Composite PCMs by Incorporation of Paraffin into Various Building Materials. Materials, 8(2), 499-518. https://doi.org/10.3390/ma8020499