Modeling and Measurement of Sustained Loading and Temperature-Dependent Deformation of Carbon Fiber-Reinforced Polymer Bonded to Concrete

Abstract

:1. Introduction

2. Experimental Investigation

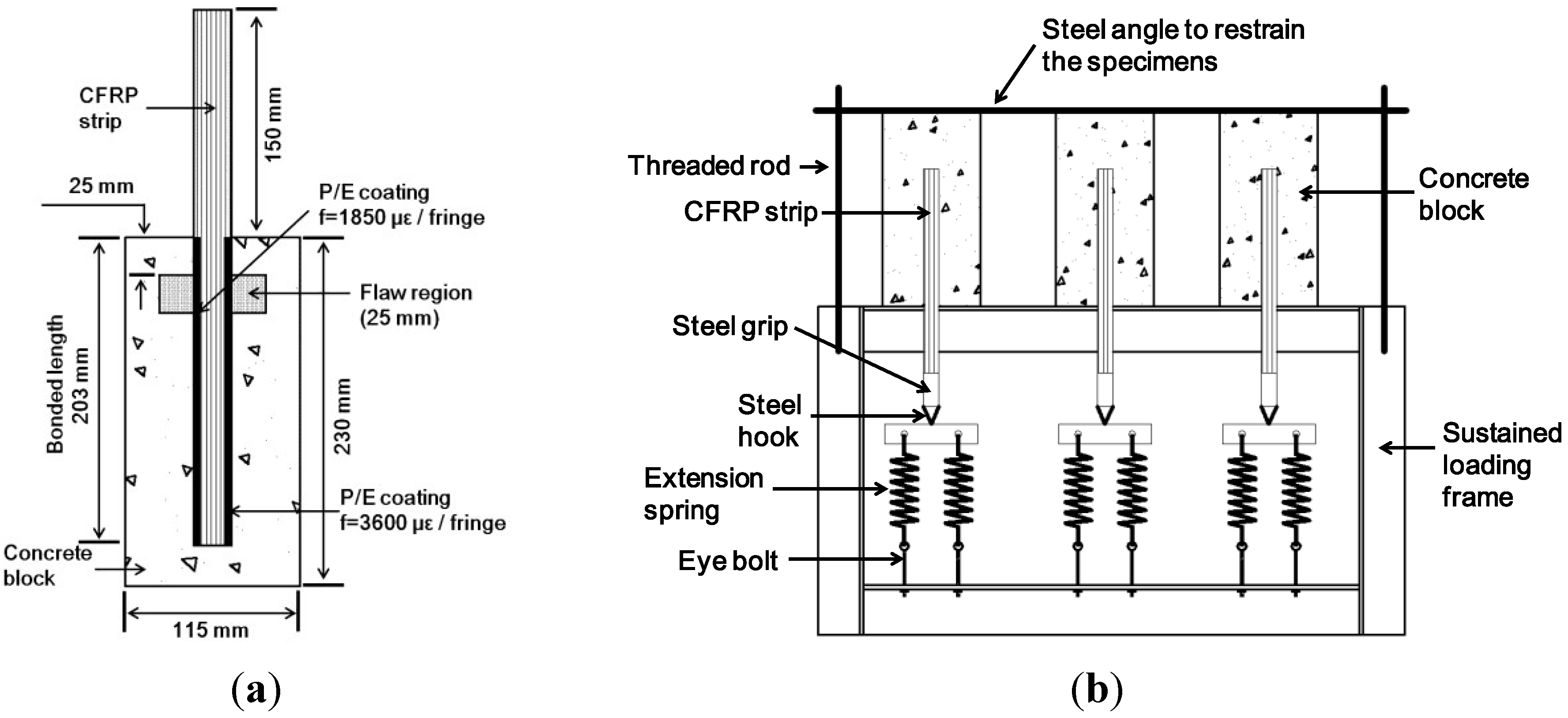

2.1. Single-Lap Shear Test

| Material Properties | Plain Concrete | Epoxy | CFRP * | |

|---|---|---|---|---|

| 23 °C | 40 °C | |||

| Modulus of elasticity, GPa | 22 | 3.46 | 2.99 | 95.8 |

| Poisson’s Ratio | 0.2 | 0.36 | 0.36 | 0.2 |

| Tensile strength, MPa | 3.2 | 71.2 | – | 986 |

| Compressive strength, MPa | 32 | – | – | – |

| Ultimate strain, % | – | – | – | 1 |

| Thickness, mm | – | – | – | 1 |

| Specimen ID | Samples | Flaw (Yes/No) | Temperature at Sustained Loading (°C) | Sustained Loading Period (h) |

|---|---|---|---|---|

| NF-HT-SL | 2 | No | 40 | 87 |

| NF-HT-C | 2 | – | ||

| NF-RT-SL | 2 | No | 23 | 87 |

| NF-RT-C | 2 | – | ||

| F-HT-SL | 2 | Yes | 40 | 87 |

| F-HT-C | 2 | – | ||

| F-RT-SL | 2 | Yes | 23 | 87 |

| F-RT-C | 2 | – |

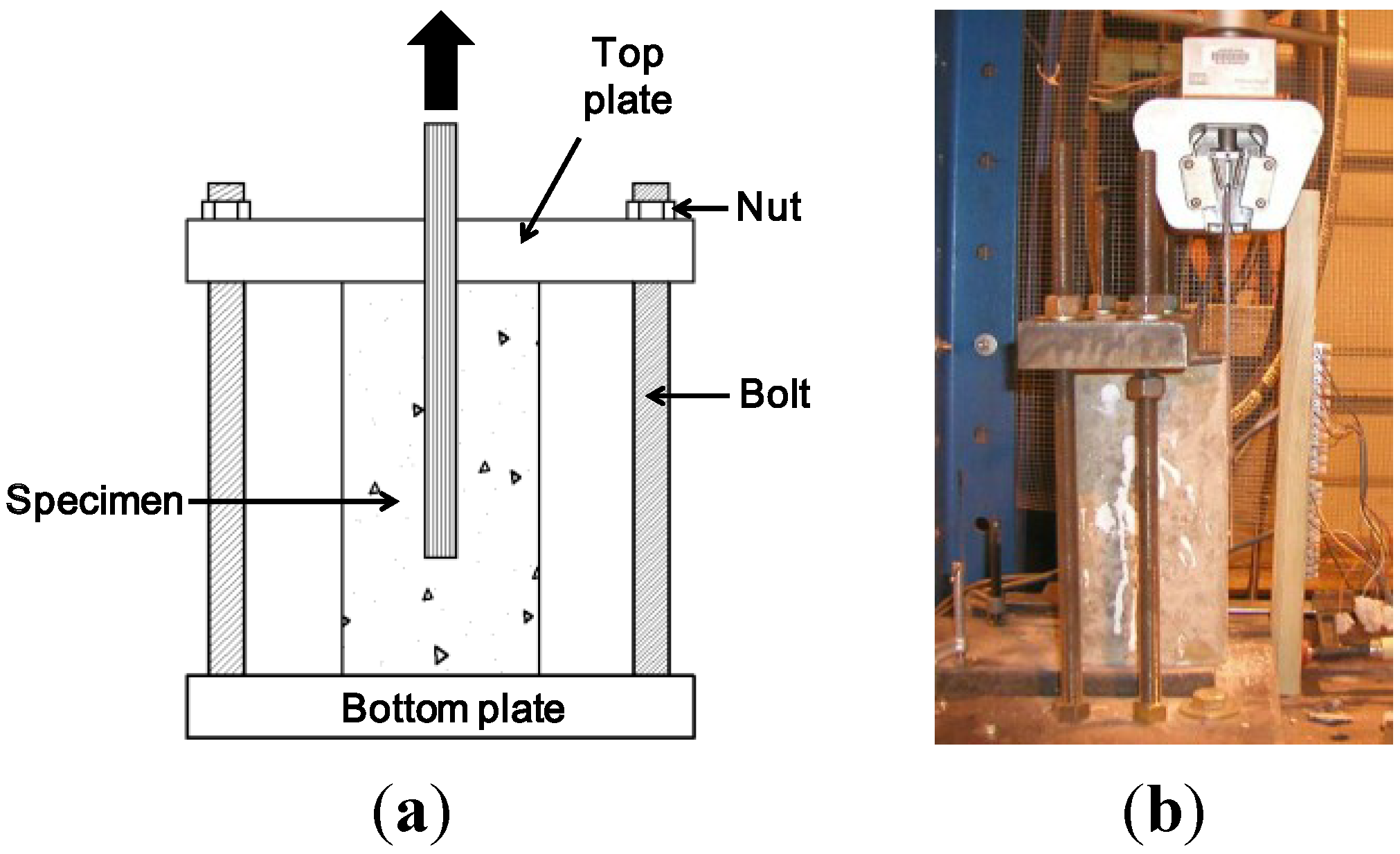

2.2. Epoxy Creep Test

| Specimen ID | P1 | τ1 (min) | P2 | τ2 (min) | P3 | τ3 (min) |

|---|---|---|---|---|---|---|

| Epoxy-HT | 0.43 | 6.45 | 0.25 | 353 | 0.00065 | 3500 |

| Epoxy-RT | 0.11 | 95 | 0.16 | 646 | 0.41 | 4196 |

3. Numerical Investigation

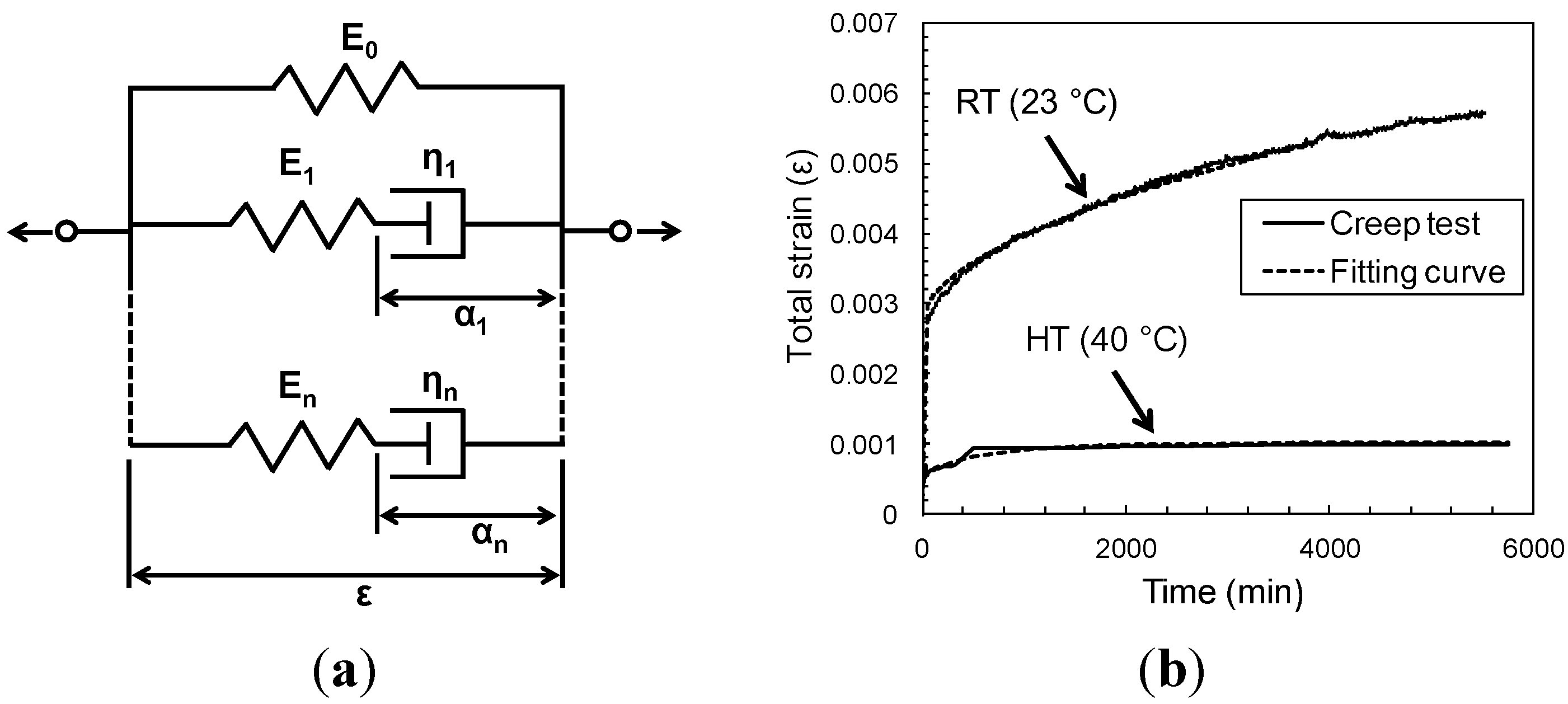

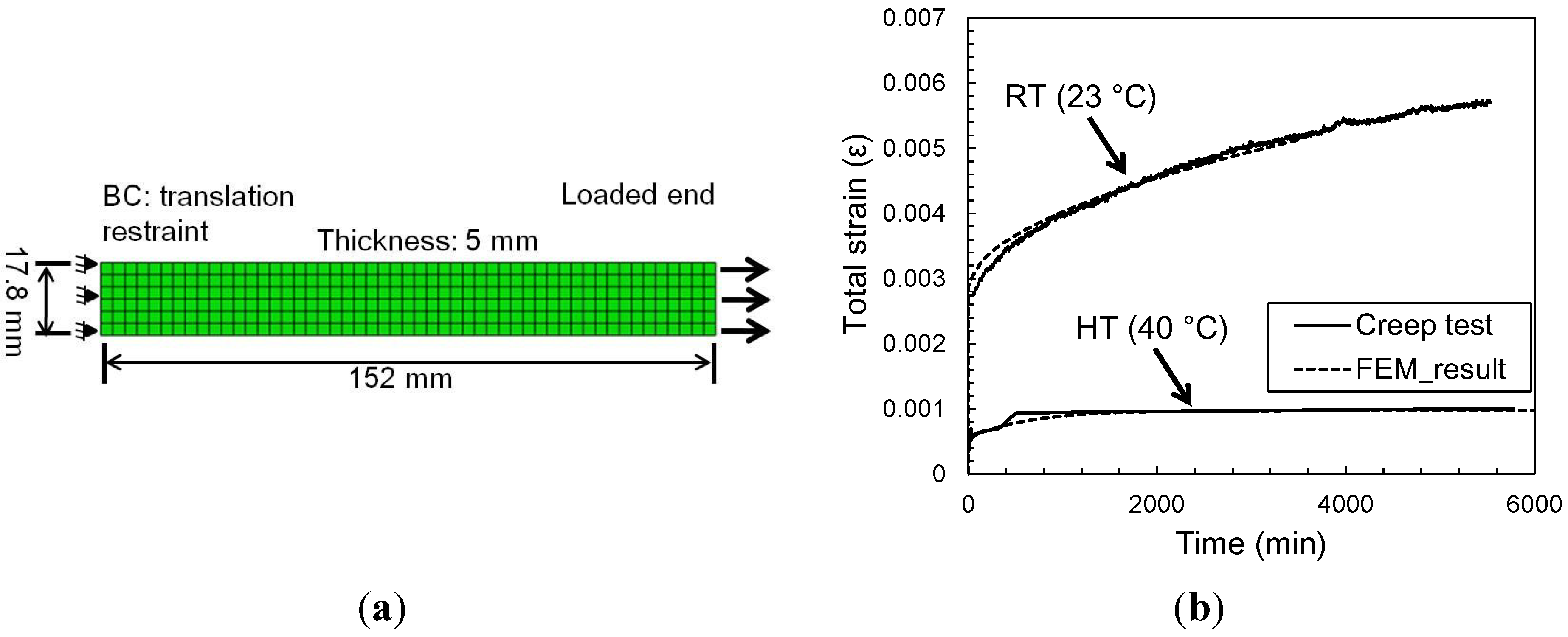

3.1. Finite Element Model of Epoxy Creep Test

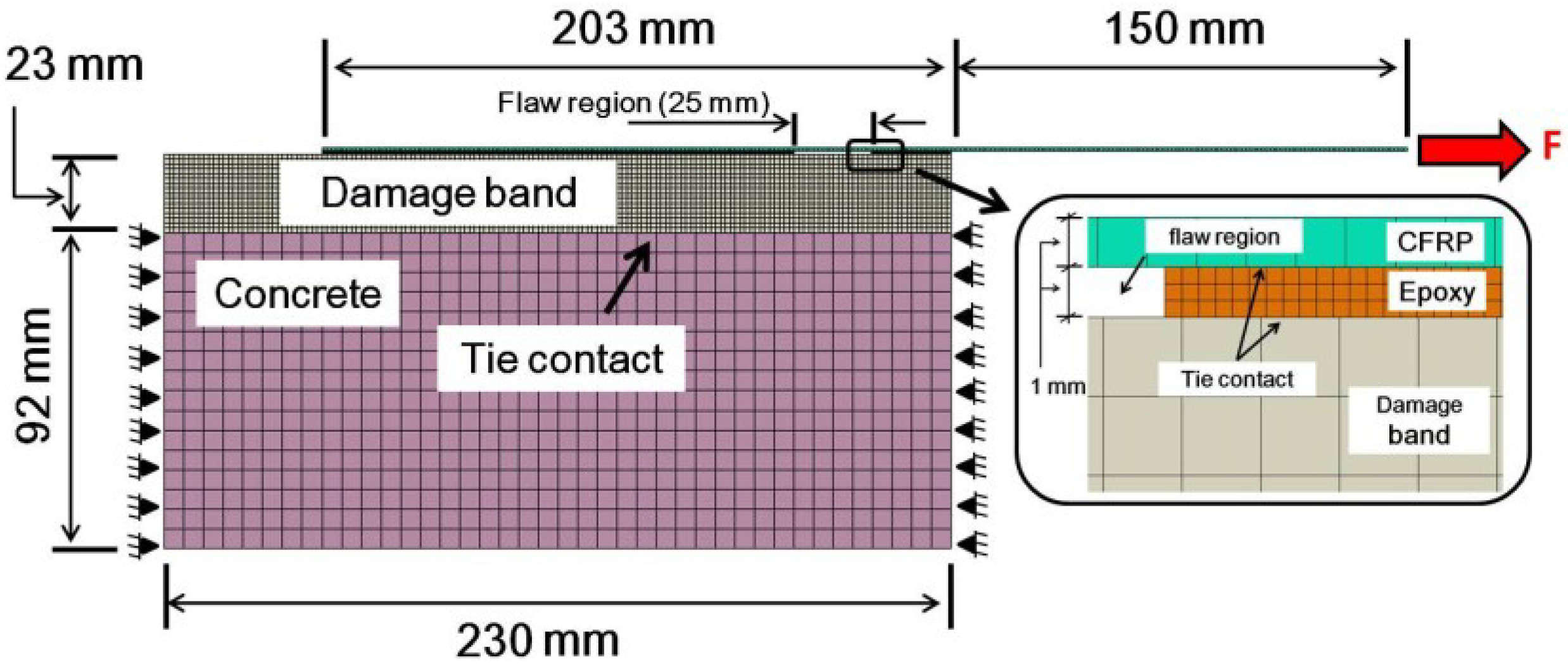

3.2. Finite Element Model of Single-Lap Shear Test

3.3. Material Constitutive Behavior

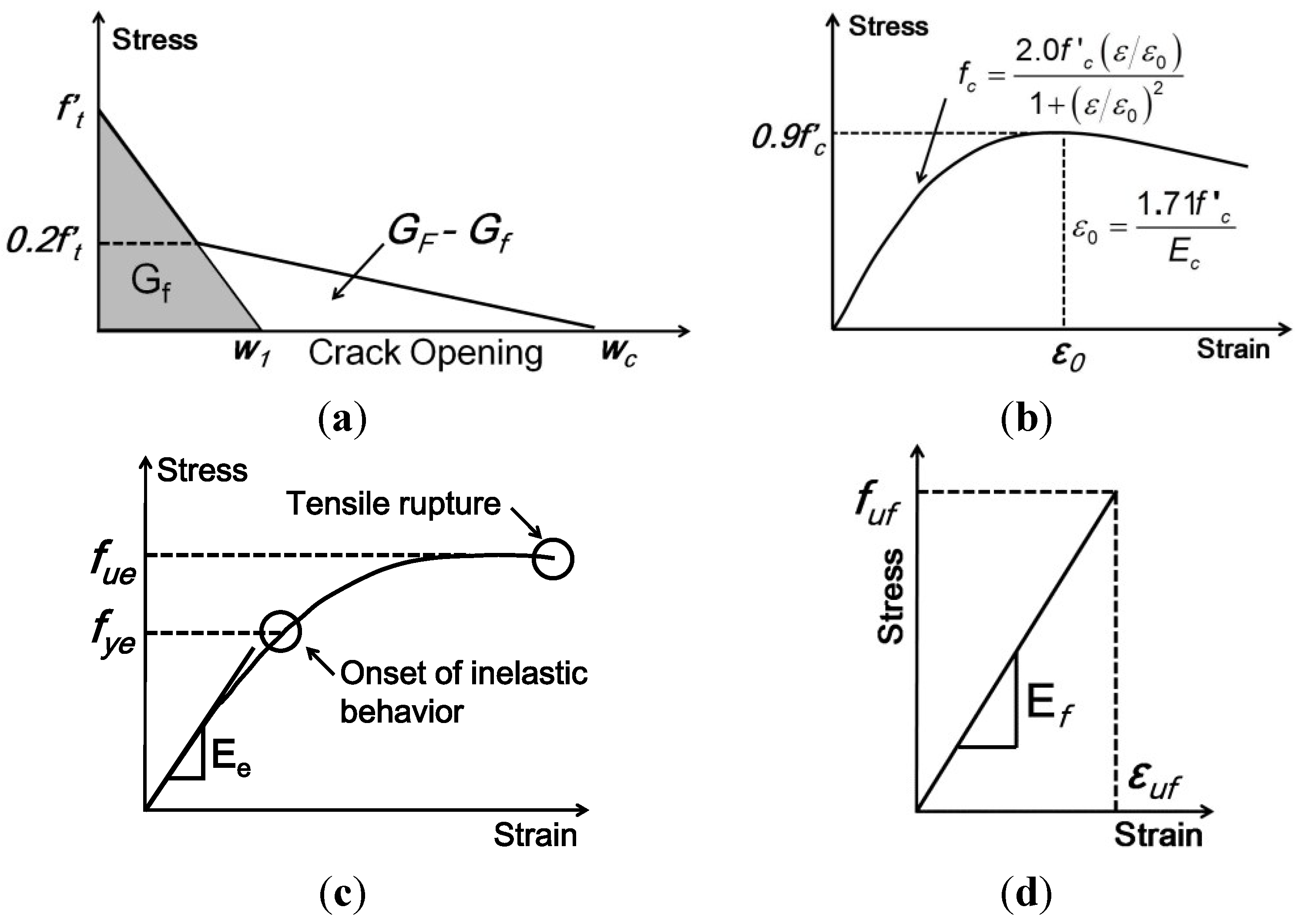

3.3.1. Model for the Concrete and Damage Band

| f't (MPa) | w1 (μm) | Gf (N/m) | GF (N/m) | wc (mm) |

|---|---|---|---|---|

| 2.62 | 58.04 | 76.13 | 190.32 | 0.073 |

3.3.2. Epoxy Model

3.3.3. CFRP Model

3.4. Comparison of Predictions and Experimental Results

3.4.1. Epoxy Creep Test

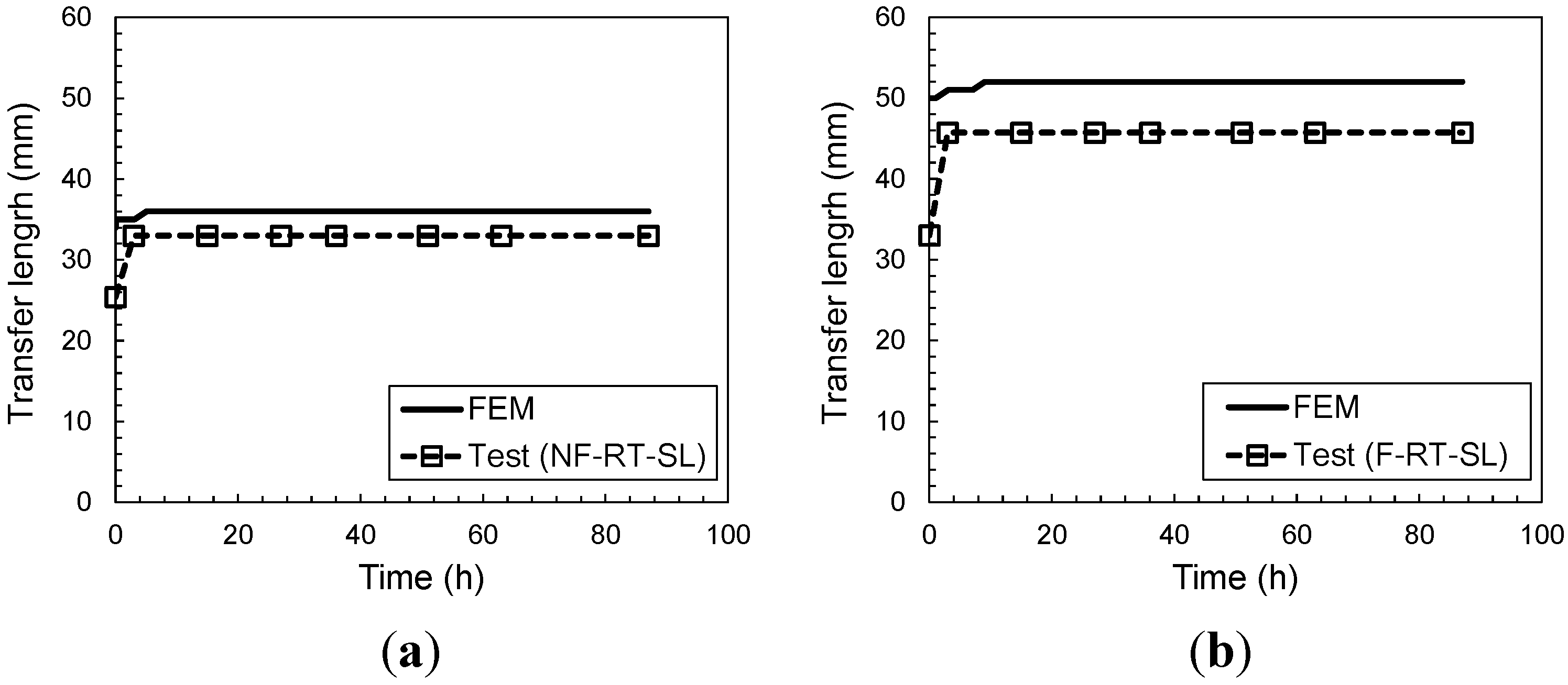

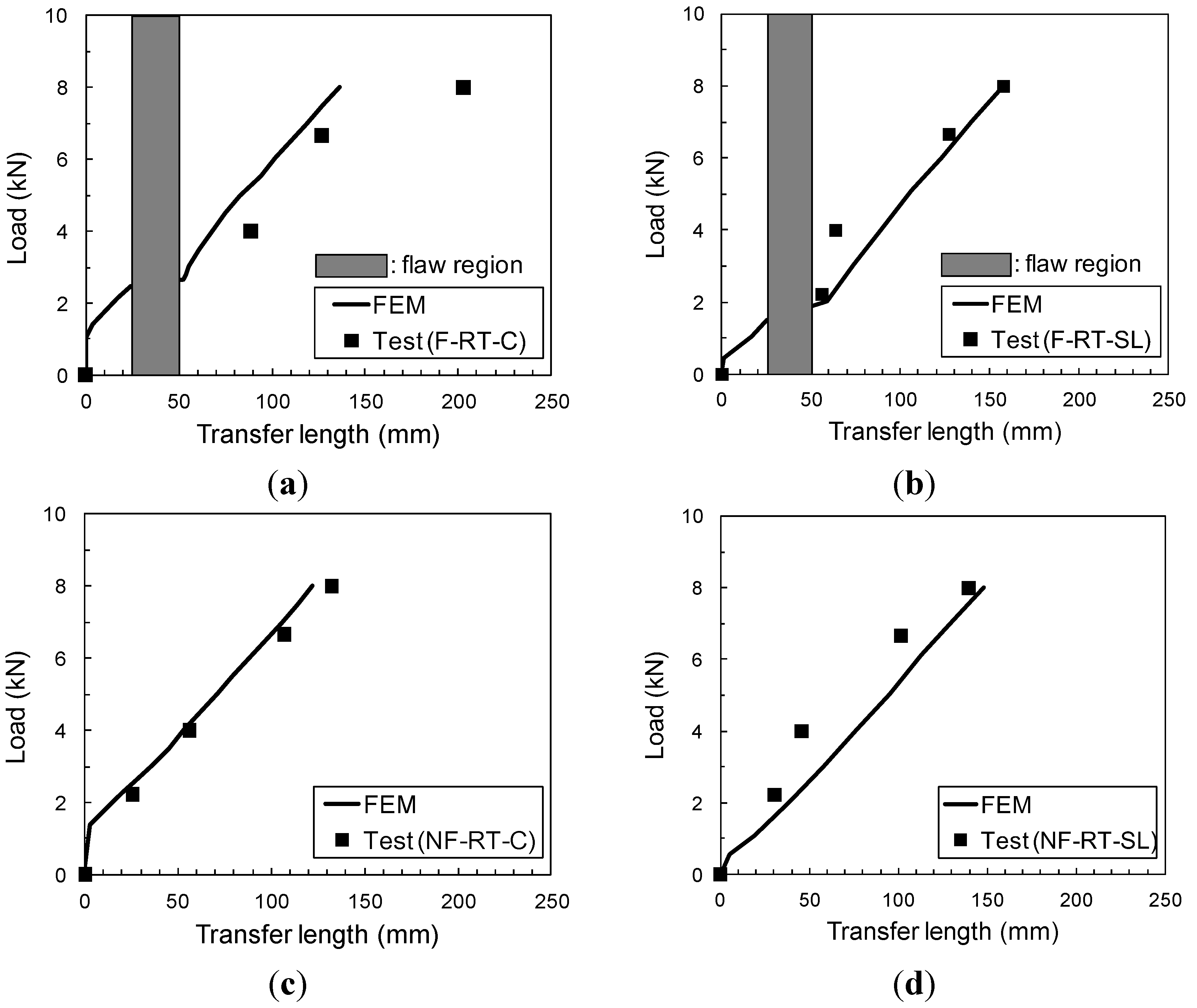

3.4.2. Single-Lap Shear Test

Sustained Loading Period

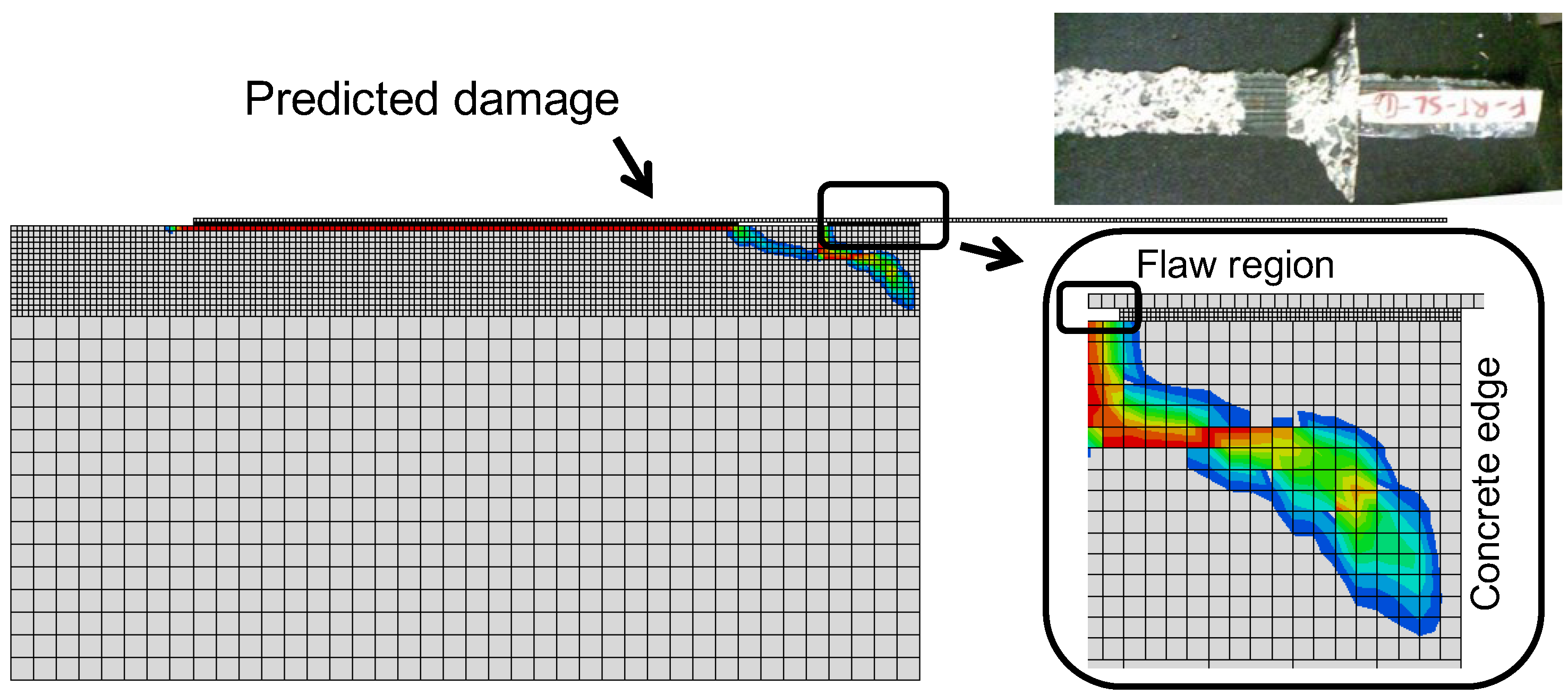

Pull-Off Loading Period

| Specimen Identification | Pnum (kN) | Pexp (kN) | Pnum/Pexp | Effect of Flaw | Effect of Sustained Load | ||

|---|---|---|---|---|---|---|---|

| NUM | EXP | NUM | EXP | ||||

| NF_RT_C (a) | 9.66 | 8.54 | 1.13 | – | – | – | – |

| F_RT_C (b) | 9.79 | 8.80 | 1.11 | 1% (b/a) * | 3% (b/a) | – | – |

| NF_RT_SL (c) | 9.03 | 8.27 | 1.09 | – | – | −6% (c/a) | −3% (c/a) |

| F_RT_SL (d) | 9.93 | 9.16 | 1.08 | 10% (d/c) | 10% (d/c) | 1% (d/b) | 4% (d/b) |

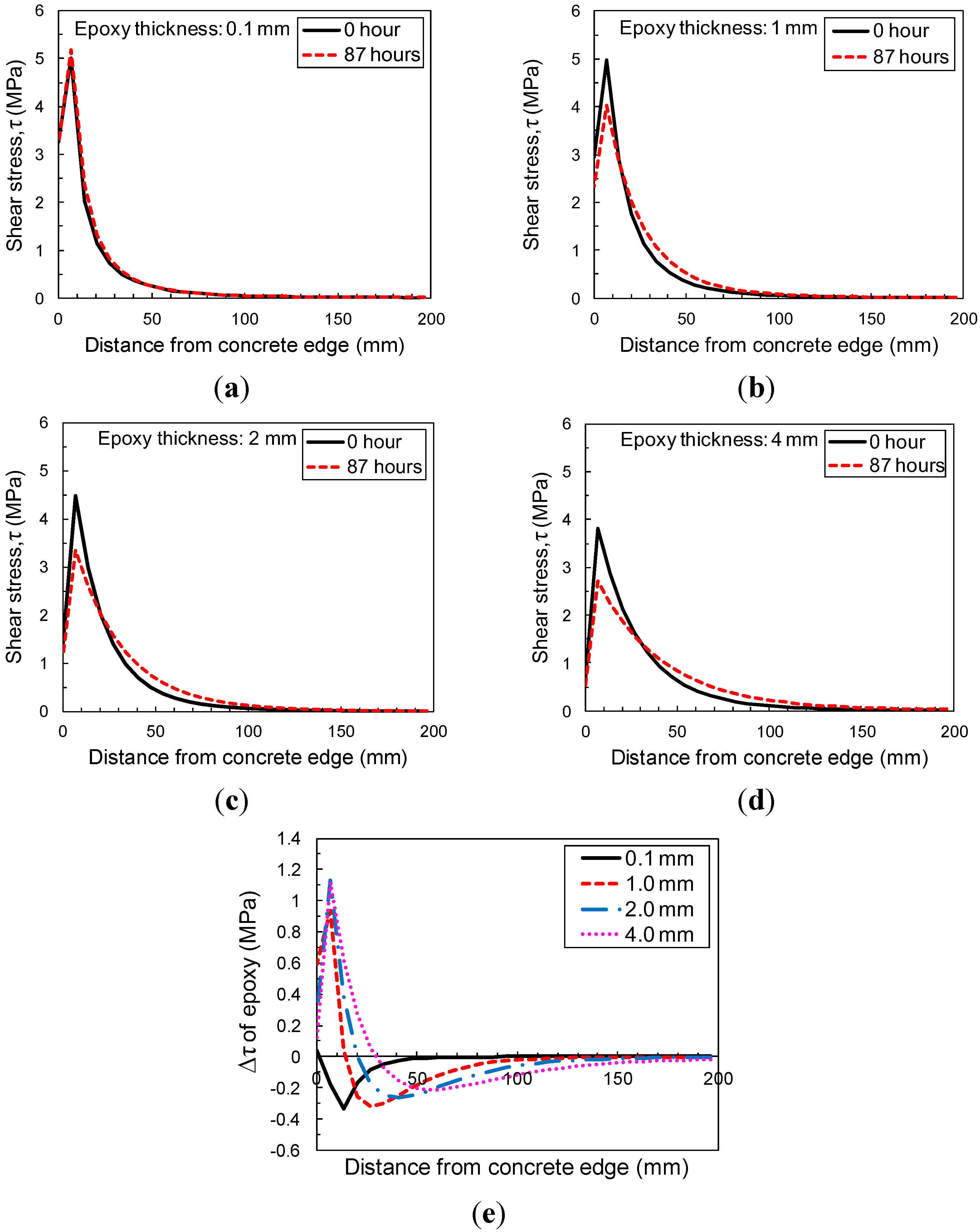

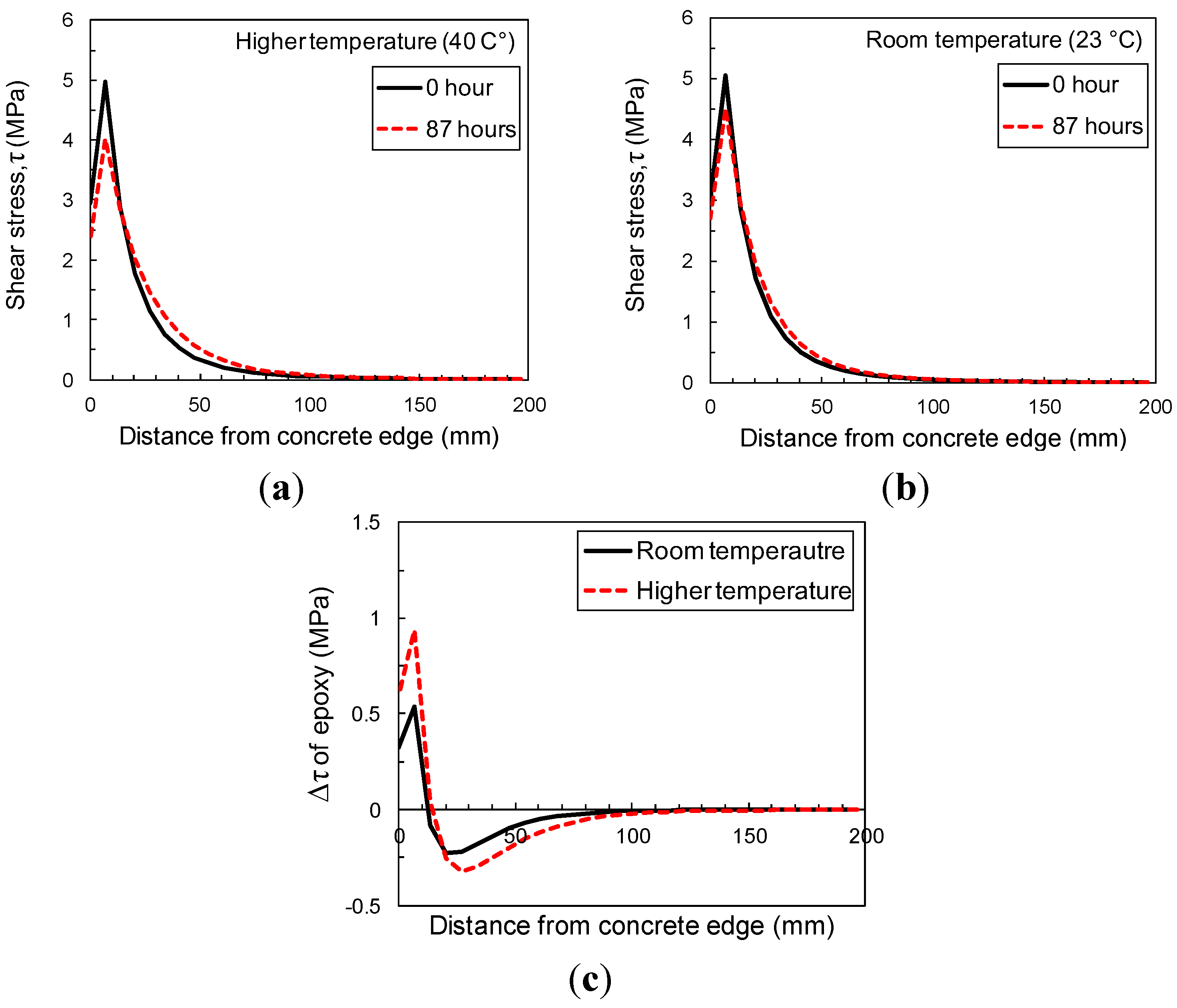

3.5. Sensitivity Study

3.5.1. Sensitivity to Thickness of Epoxy

3.5.2. Sensitivity to Temperature

4. Conclusions

- Based on the experimental data, the proposed model has the ability to estimate the effects of flaws and sustained loading in terms of the pull-off strength.

- The presence of a manufactured flaw in the specimen under sustained loading extends the transfer length, which also increased the pull-off strength. It appears that existing flaws in the specimens in this study engage a larger transfer length, which also demands greater participation from the concrete substrate.

- Following the sustained loading period, the pull-off strength of the single-lap shear specimen decreased, when compared to the specimens not subjected to sustained loading.

- The numerical model used in this study predicts, with good correlation with experimental results, the failure mode and pull-off behavior of the specimen after experiencing sustained loading.

- The results of sensitivity studies confirm that the specimen’s creep response is sensitive to geometric and temperature-dependent material parameters. While the parameters of the proposed model, which are obtained based on creep tests, can be acceptable to estimate the pull-off behavior of the specimens experiencing sustained loading, more experimental studies are needed to confirm the validity of these parameters in single-lap specimens during sustained loading at different temperatures and in pull-off tests to failure following such conditioning.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Klamer, E.L.; Hordijk, D.A.; Hermes, M.C.J. The influence of temperature on RC beams strengthened with externally bonded CFRP reinforcement. Heron 2008, 53, 157–185. [Google Scholar]

- Lopez, M.M.; Krishnaswamy, R. Time performance of concrete-CFRP bond under effects of freeze-thaw cycles and sustained loading. In Proceedings of the Transportation Research Board 85th Annual Meeting, Washington, DC, USA, 23 January 2006.

- Wan, B.; Ouyang, Z. Experimental and numerical study of moisture effects on the bond fracture energy of FRP/concrete joints. J. Reinf. Plast. Compos. 2008, 27, 205–223. [Google Scholar]

- Jia, J.; Boothby, T.; Bakis, C.; Brown, T. Durability evaluation of glass fiber reinforced-polymer-concrete bonded interfaces. J. Compos. Constr. 2005, 9, 348–359. [Google Scholar] [CrossRef]

- Dai, J.; Yokota, H.; Iwanami, M.; Kato, E. Experimental investigation of the influence of moisture on the bond behavior of FRP to concrete interfaces. J. Compos. Constr. 2010, 14, 834–844. [Google Scholar] [CrossRef]

- Tuakta, C.; Büyüköztürk, O. Deterioration of FRP/concrete bond system under variable moisture conditions quantified by fracture mechanics. Compos. B Eng. 2011, 42, 145–154. [Google Scholar] [CrossRef]

- Yoseok, J. Effects of Temperature and Sustained Loading on the Response of FRP-Strengthened Concrete Elements. Ph.D. Dissertation, Pennsylvania State University, University Park, PA, USA, 20 December 2014. [Google Scholar]

- Dai, J.; Gao, W.Y.; Teng, J.G. Bond-slip model for FRP laminates externally bonded to concrete at elevated temperature. J. Compos. Constr. 2013, 17, 217–228. [Google Scholar] [CrossRef]

- Gao, W.Y.; Teng, J.G.; Dai, J.-G. Effect of temperature variation on the full-range behavior of FRP-to-concrete bonded joints. J. Compos. Constr. 2012, 16, 671–683. [Google Scholar] [CrossRef]

- Meshgin, P.; Choi, K.-K.; Reda Taha, M.M. Experimental and analytical investigations of creep of epoxy adhesive at the concrete-FRP interfaces. Int. J. Adhes. Adhes. 2009, 29, 56–66. [Google Scholar] [CrossRef]

- Mazzotti, C.; Savoia, M. The effect of long-term loading on the CFRP-concrete bonding strength. In Proceedings of the 4th International Conference on Durability & Sustainability of Fiber Reinforced Polymer Composites for Construction and Rehabilitation, CDCC-11, University of Sherbrooke, Quebec City, QC, Canada, 20–22 July 2011.

- Plevris, N.; Triantafillou, T. Time-dependent behavior of RC members strengthened with FRP laminates. J. Struct. Eng. 1994, 120, 1016–1042. [Google Scholar] [CrossRef]

- Gullapalli, A.; Lee, J.H.; Lopez, M.M.; Bakis, C.E. Sustained loading and temperature response of fiber-reinforced polymer-concrete bond. J. Transp. Res. Board 2009, 2131, 155–162. [Google Scholar] [CrossRef]

- SCH-41S Composite Using Tyfo S Epoxy; Fyfe Co., LLC: San Diego, CA, USA, 2007.

- Bazant, Z.P. Viscoelasticity of solidifying porous material-concrete. ASCE J. Eng. Mech. 1977, 103, 1049–1067. [Google Scholar]

- Brinson, H.F. The viscoelastic constitutive modelling of adhesives. Composites 1982, 13, 377–382. [Google Scholar] [CrossRef]

- Savoia, M.; Ferracuti, B.; Mazzotti, C. Creep deformation of fiber reinforced plastics-plated reinforced concrete tensile members. J. Compos. Constr. 2005, 9, 63–72. [Google Scholar] [CrossRef]

- Ferrier, E.; Michel, L.; Jurkiewiez, B.; Hamelin, P. Creep behavior of adhesives used for external FRP strengthening of RC structures. Constr. Build. Mater. 2011, 25, 461–467. [Google Scholar] [CrossRef]

- Bazant, Z.P. Mathematical Modeling of Creep and Shrinkage of Concrete; Wiley: New York, NY, USA, 1988. [Google Scholar]

- Ferry, J.D. Viscoelastic Properties of Polymers; Wiley: New York, NY, USA, 1980. [Google Scholar]

- Park, S.W.; Schapery, R.A. Methods of interconversion between linear viscoelastic material functions. Part I—A numerical method based on Prony series. Int. J. Solids Struct. 1999, 36, 1653–1675. [Google Scholar] [CrossRef]

- ABAQUS. Standard User’s Manual Version 6.11–1; Hibbitt, Karlsson and Sorensen, Inc.: Pawtucket, RI, USA, 2011. [Google Scholar]

- Anderson, T. Fracture Mechanics: Fundamentals and Applications; CRC: Boca Raton, FL, USA, 1994. [Google Scholar]

- Bazant, Z.P.; Planas, J. Fracture and Size Effect in Concrete and Other Quasibrittle Materials; CRC Press: Boca Raton, FL, USA, 1998. [Google Scholar]

- Coronado, C.A.; Lopez, M.M. Damage approach for the prediction of debonding failure on concrete elements strengthened with FRP. J. Compos. Constr. 2007, 11, 391–400. [Google Scholar] [CrossRef]

- Lubliner, J.; Oliver, J.; Oller, S.; Oñate, E. A plastic-damage model for concrete. Int. J. Solids Struct. 1989, 25, 299–326. [Google Scholar] [CrossRef]

- Lee, J.; Fenves, G.L. A plastic-damage concrete model for earthquake analysis of dams. Earthq. Eng. Struct. D 1998, 27, 937–956. [Google Scholar] [CrossRef]

- Todeschini, C.E.; Bianchini, A.C.; Kesler, C.E. Behavior of concrete columns reinforced with high strength steels. ACI J. Proc. 1964, 61, 701–716. [Google Scholar]

- Coronado, C.A. Characterization, Modeling and Size Effect of Concrete Epoxy Interfaces. Ph.D. Dissertation, Pennsylvania State University, University Park, PA, USA, 12 August 2006. [Google Scholar]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeong, Y.; Lee, J.; Kim, W. Modeling and Measurement of Sustained Loading and Temperature-Dependent Deformation of Carbon Fiber-Reinforced Polymer Bonded to Concrete. Materials 2015, 8, 435-450. https://doi.org/10.3390/ma8020435

Jeong Y, Lee J, Kim W. Modeling and Measurement of Sustained Loading and Temperature-Dependent Deformation of Carbon Fiber-Reinforced Polymer Bonded to Concrete. Materials. 2015; 8(2):435-450. https://doi.org/10.3390/ma8020435

Chicago/Turabian StyleJeong, Yoseok, Jaeha Lee, and WooSeok Kim. 2015. "Modeling and Measurement of Sustained Loading and Temperature-Dependent Deformation of Carbon Fiber-Reinforced Polymer Bonded to Concrete" Materials 8, no. 2: 435-450. https://doi.org/10.3390/ma8020435

APA StyleJeong, Y., Lee, J., & Kim, W. (2015). Modeling and Measurement of Sustained Loading and Temperature-Dependent Deformation of Carbon Fiber-Reinforced Polymer Bonded to Concrete. Materials, 8(2), 435-450. https://doi.org/10.3390/ma8020435