Performance-Enhanced Textured Silicon Solar Cells Based on Plasmonic Light Scattering Using Silver and Indium Nanoparticles

Abstract

:1. Introduction

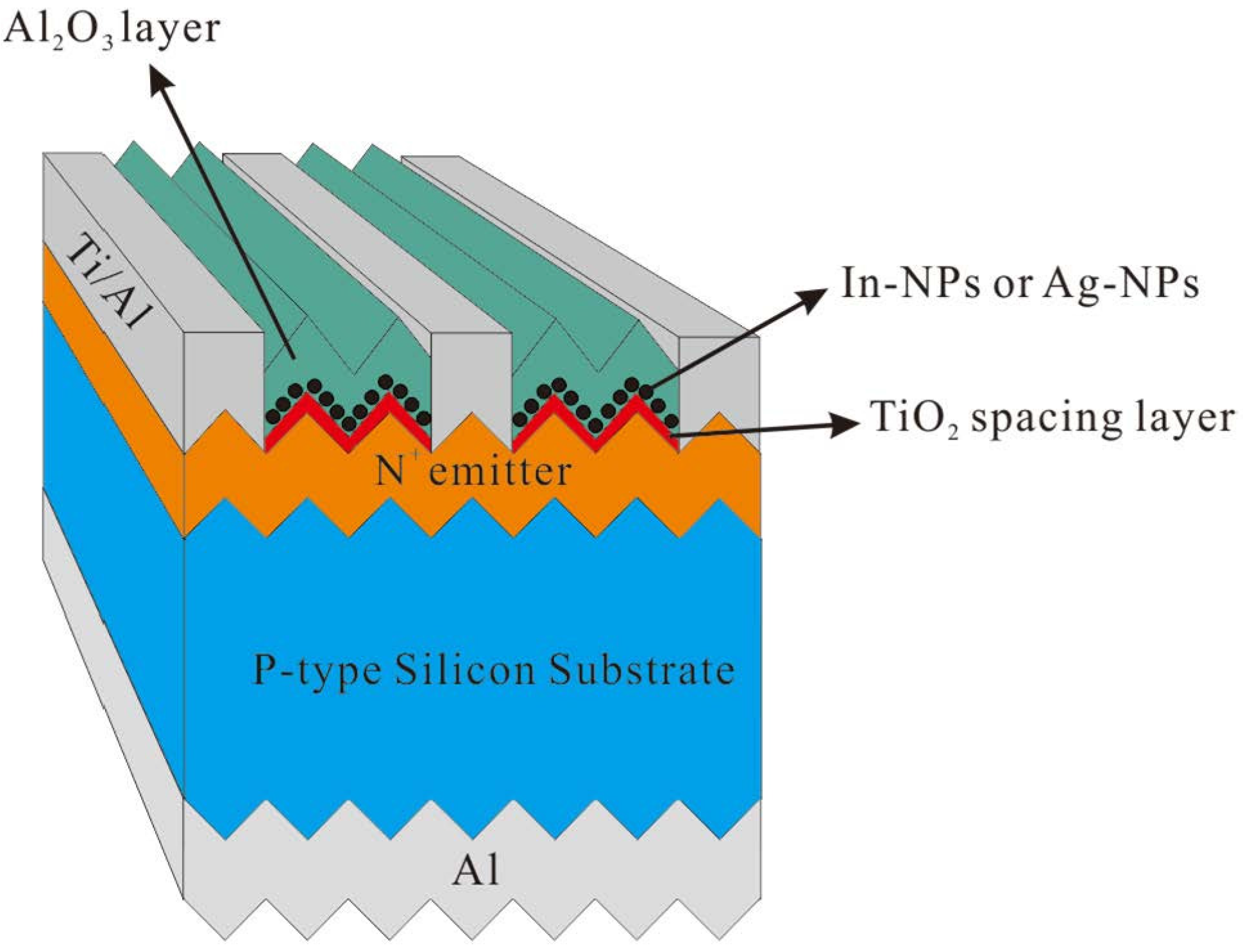

2. Experiment

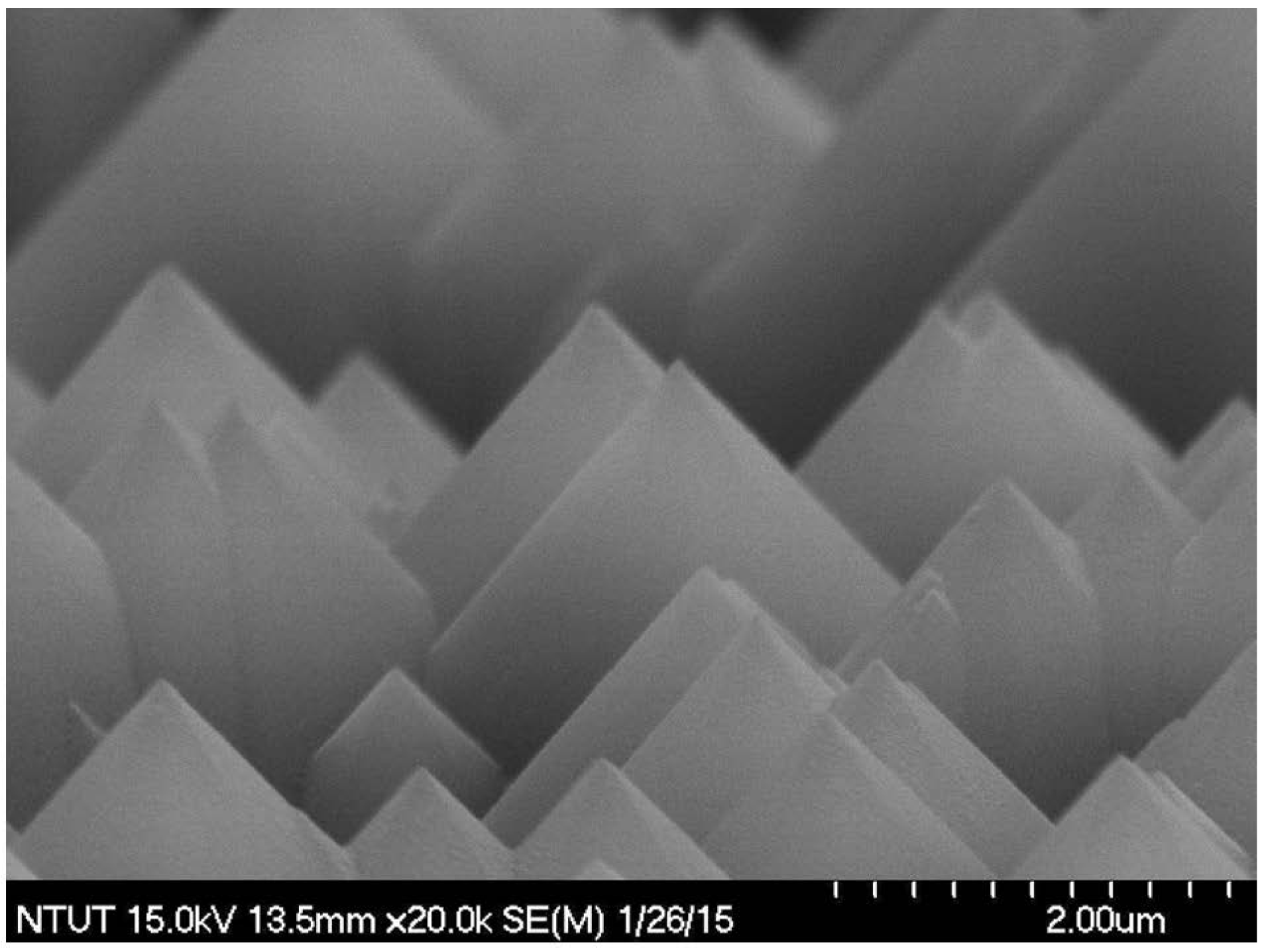

2.1. Fabrication of Textured Crystalline-Silicon (c-Si) Solar Cells

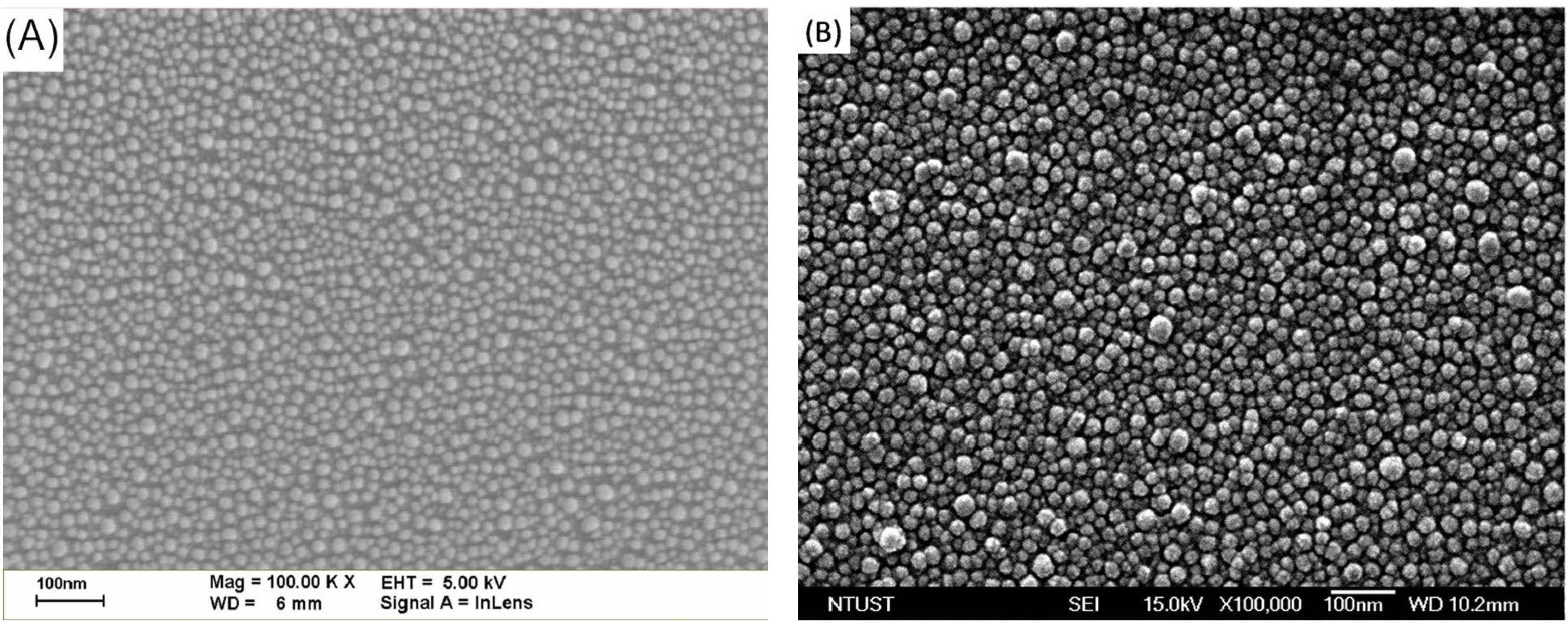

2.2. Characterization of Textured c-Si Solar Cells with In-NPs and Ag-NPs

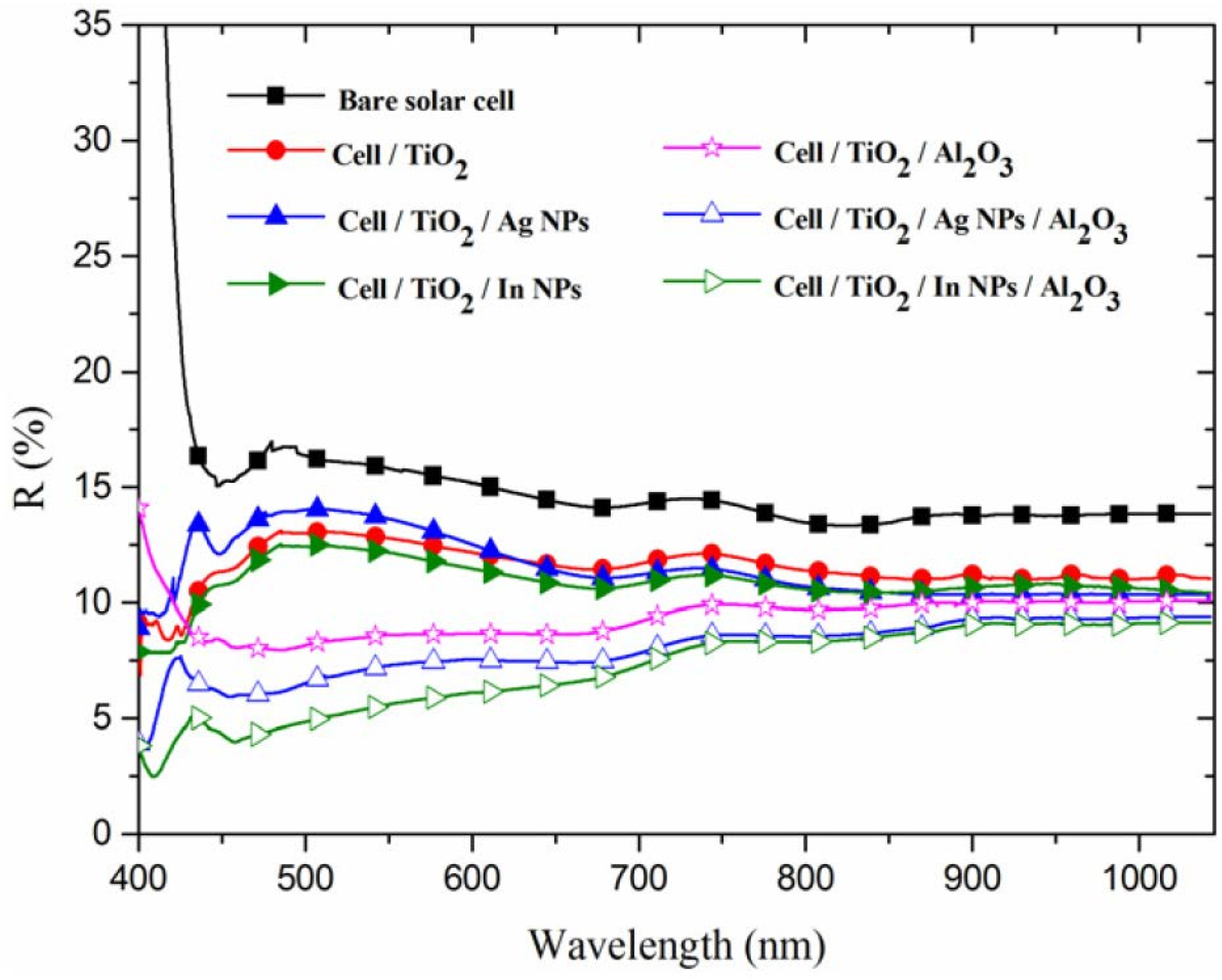

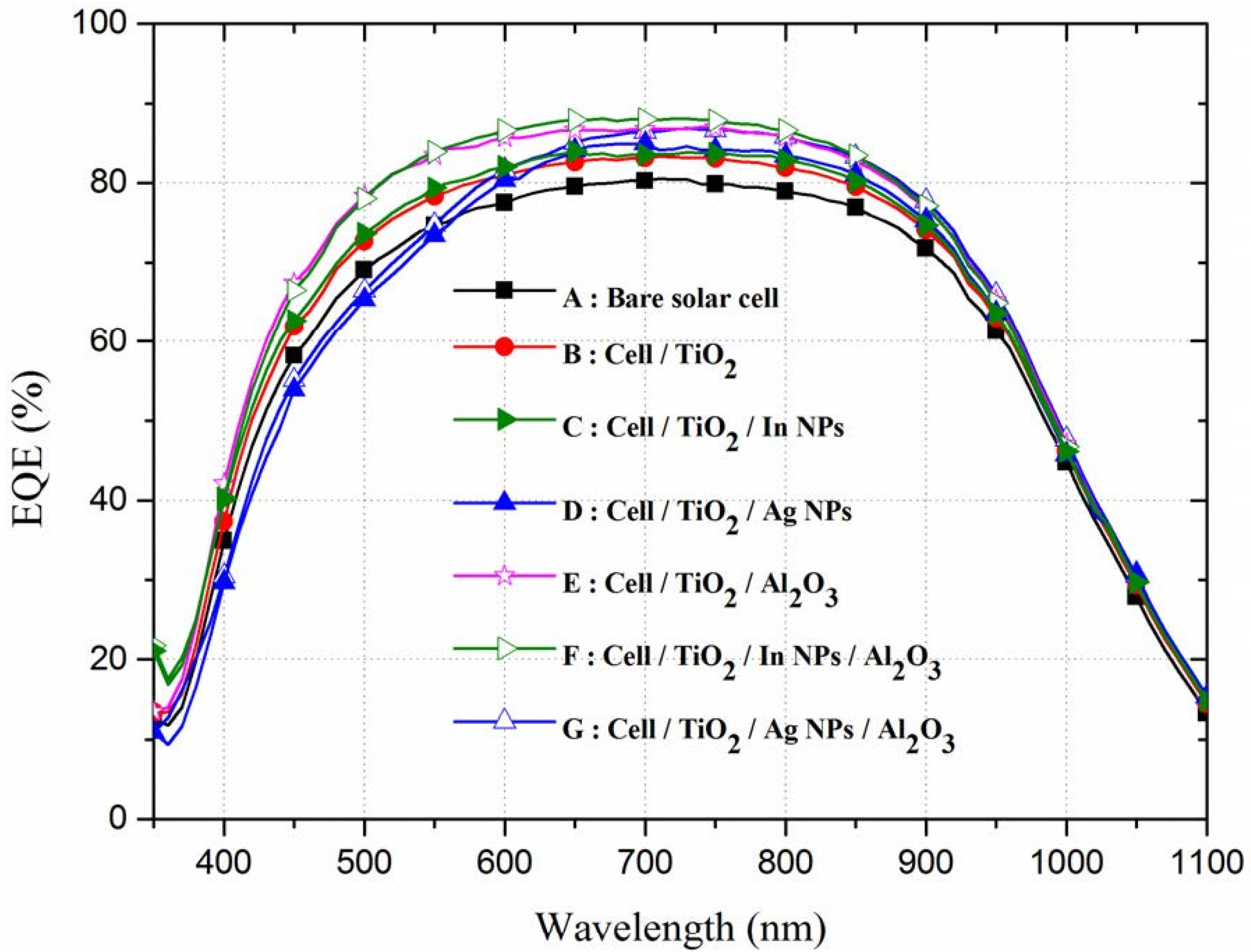

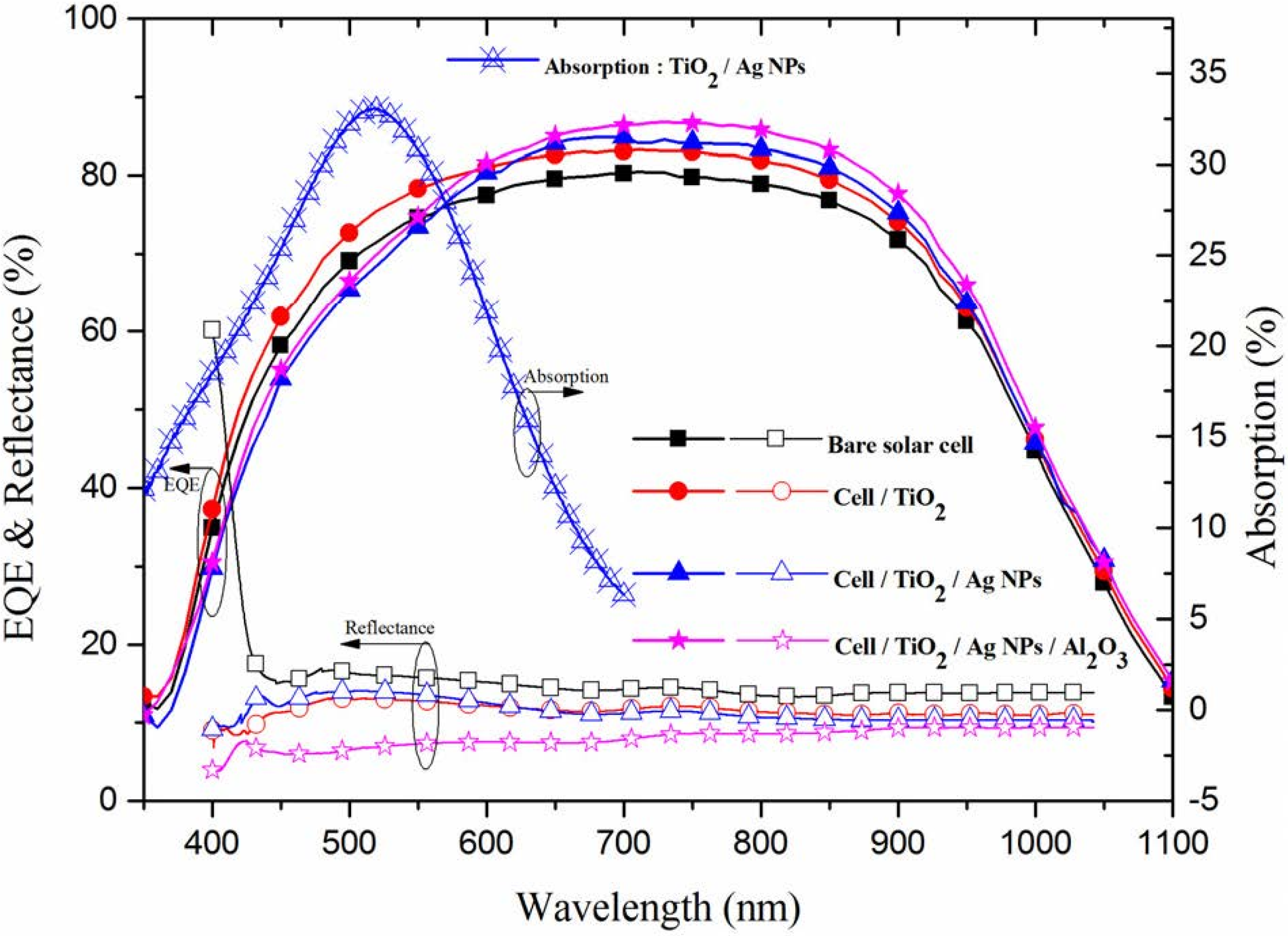

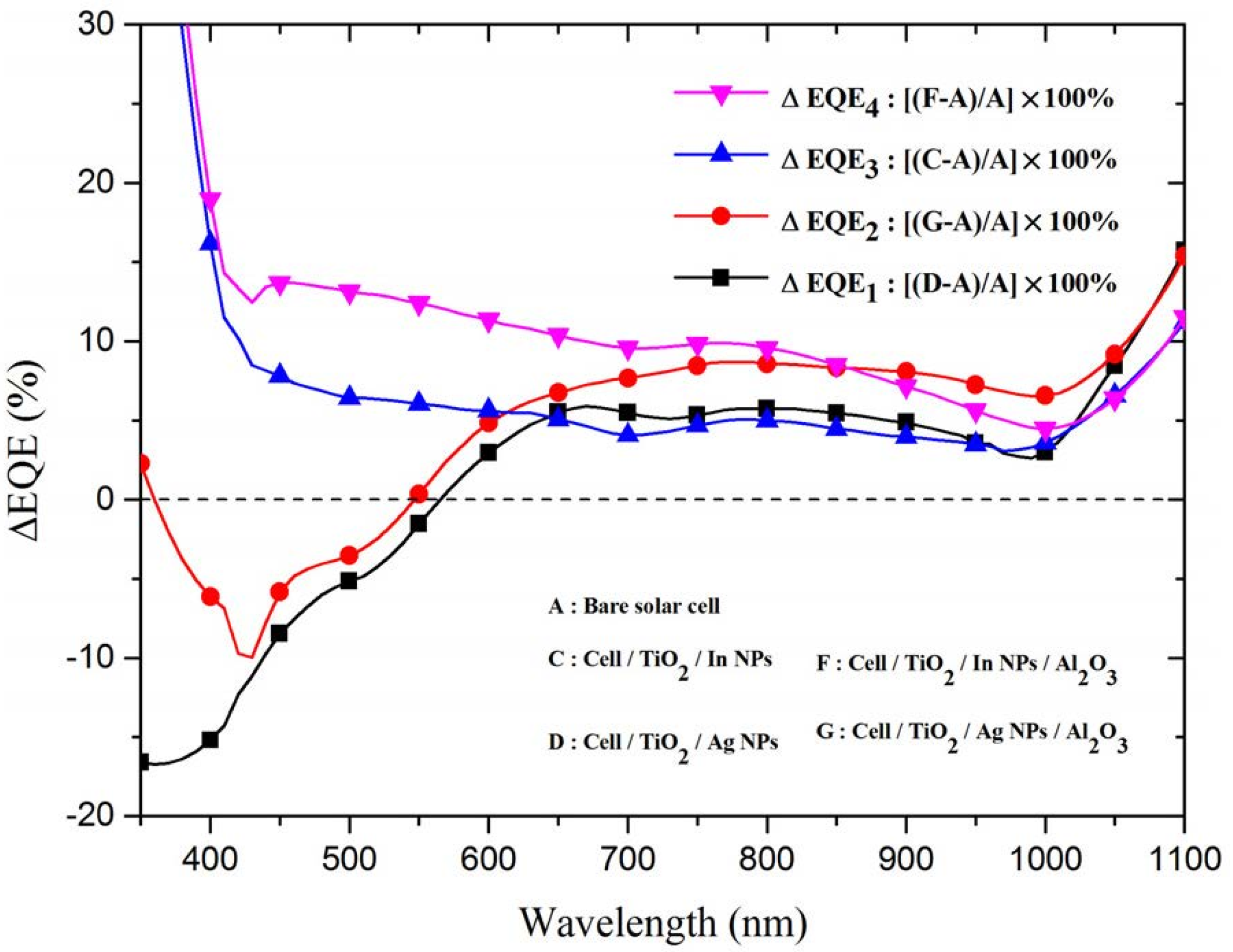

3. Results and Discussion

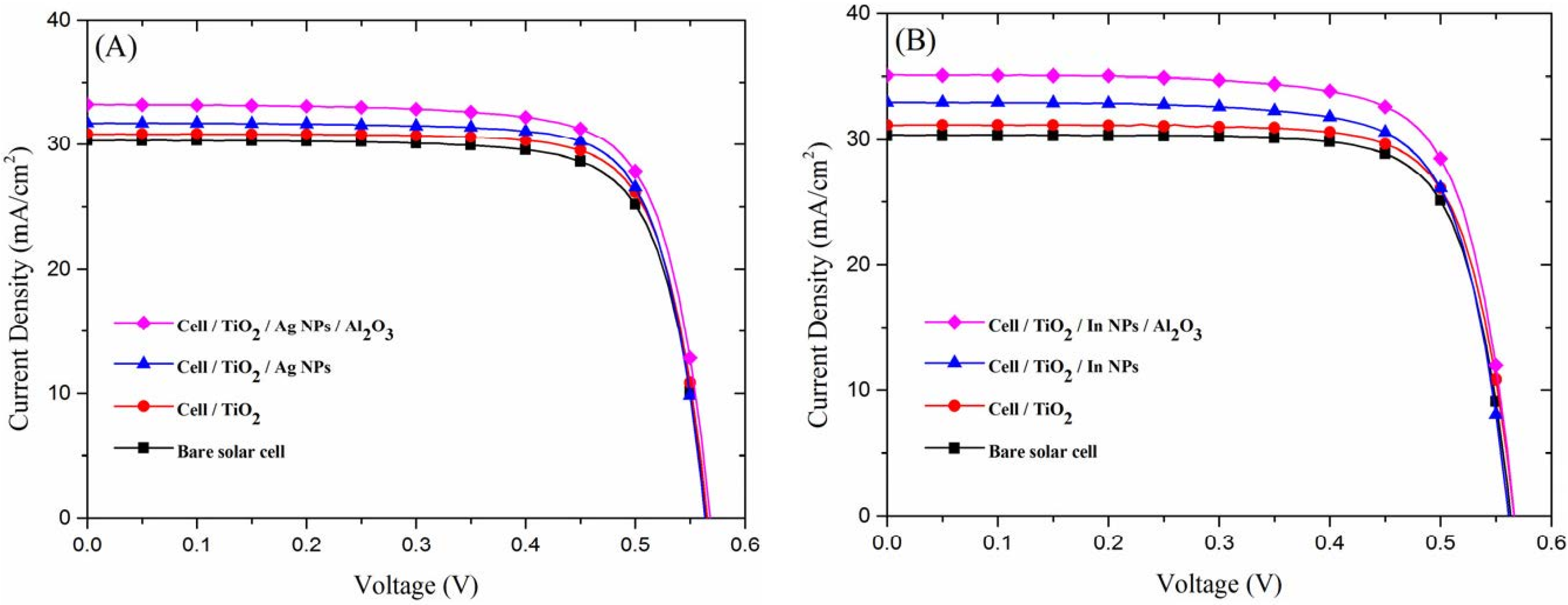

| Parameters | Cell # | Bare Solar Cell | Cell/TiO2 | Cell/TiO2/Ag-NPs | Cell/TiO2/Ag-NPs/Al2O3 |

|---|---|---|---|---|---|

| Voc (mV) | Cell-1 | 562.5 | 564.4 | 561.8 | 565.5 |

| Cell-2 | 567.1 | 566.8 | 563.7 | 566.5 | |

| Cell-3 | 565.9 | 566.0 | 563.4 | 567.8 | |

| Cell-4 * | 564.9 | 565.6 | 563.5 | 568.4 | |

| Average | 565.1 | 565.7 | 563.1 | 567.1 | |

| Jsc (mA/cm2) | Cell-1 | 30.11 | 30.45 | 30.64 | 32.41 |

| Cell-2 | 30.16 | 30.65 | 31.25 | 33.26 | |

| Cell-3 | 30.12 | 30.89 | 32.51 | 33.04 | |

| Cell-4 * | 30.32 | 30.86 | 31.75 | 33.27 | |

| Average | 30.18 | 30.71 | 31.54 | 33.00 | |

| η (%) | Cell-1 | 12.71 | 12.91 | 13.10 | 13.63 |

| Cell-2 | 13.17 | 13.30 | 13.36 | 13.73 | |

| Cell-3 | 13.18 | 13.50 | 13.80 | 14.08 | |

| Cell-4 * | 13.07 | 13.50 | 13.82 | 14.32 | |

| Average | 13.03 | 13.30 | 13.52 | 13.94 |

| Parameters | Cell # | Bare Solar Cell | Cell/TiO2 | Cell/TiO2/In-NPs | Cell/TiO2/In-NPs/Al2O3 |

|---|---|---|---|---|---|

| Voc (mV) | Cell-1 * | 563.3 | 566.4 | 561.3 | 566.6 |

| Cell-2 | 564.9 | 566.4 | 564.1 | 567.3 | |

| Cell-3 | 564.6 | 566.0 | 564.2 | 567.5 | |

| Cell-4 | X | X | X | X | |

| Average | 564.3 | 566.3 | 563.2 | 567.1 | |

| Jsc (mA/cm2) | Cell-1 * | 30.32 | 31.14 | 32.94 | 35.09 |

| Cell-2 | 30.25 | 31.26 | 32.74 | 35.14 | |

| Cell-3 | 30.48 | 31.20 | 32.43 | 35.20 | |

| Cell-4 | X | X | X | X | |

| Average | 30.35 | 31.20 | 32.70 | 35.14 | |

| η (%) | Cell-1 * | 13.14 | 13.54 | 13.84 | 13.85 |

| Cell-2 | 13.18 | 13.39 | 14.14 | 14.87 | |

| Cell-3 | 13.35 | 13.55 | 14.18 | 15.00 | |

| Cell-4 | X | X | X | X | |

| Average | 13.22 | 13.49 | 14.05 | 14.57 |

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Green, M.A. Recent progress in crystalline and polycrys-talline silicon solar cells. Solar Energy Mater. 1991, 23, 111–116. [Google Scholar] [CrossRef]

- Dimitrova, D.Z.; Dua, C.H. Crystalline silicon solar cells with micro/nano texture. Appl. Surf. Sci. 2013, 266, 1–4. [Google Scholar] [CrossRef]

- Dimitrov, D.Z.C.; Lin, C.H.; Du, C.H.; Lan, C.W. Nanotextured crystalline silicon solar cells. Phys. Status Solidi A 2011, 208, 2926–2933. [Google Scholar] [CrossRef]

- Park, H.; Kwon, S.; Lee, J.S.; Lim, H.J.; Yoon, S.; Kim, D. Improvement on surface texturing of single crystalline silicon for solar cells by saw-damage etching using an acidic solution. Sol. Energy Mater. Sol. Cells 2009, 93, 1773–1778. [Google Scholar] [CrossRef]

- Xi, Z.; Yang, D.; Dan, W.; Jun, C.; Li, X.; Que, D. Investigation of texturization for monocrystalline silicon solar cells with different kinds of alkaline. Renew. Energy 2004, 29, 2101–2107. [Google Scholar] [CrossRef]

- Das, N.C. Tunable infrared plasmonic absorption by metallic nanoparticles. J. Appl. Phys. 2011, 110, 046101. [Google Scholar] [CrossRef]

- Foslia, C.H.; Thøgersena, A.; Karazhanova, S.; Marsteina, E.S. Plasmonics for light trapping in silicon solar cells. Energy Procedia 2011, 10, 287–291. [Google Scholar] [CrossRef]

- Fahim, N.F.; Ouyang, Z.; Jia, B.; Zhang, Y.; Shi, Z.; Gu, M. Enhanced photocurrent in crystalline silicon solar cells by hybrid plasminic antireflection coating. Appl. Phys. Lett. 2012, 101, 261102. [Google Scholar] [CrossRef]

- Zhang, Y.; Jia, B.; Ouyang, Z.; Gu, M. Influence of rear local silver nanoparticle induced light losses in the light trapping of silicon wafer-based solar cells. J. Appl. Phys. 2014, 116, 124303. [Google Scholar] [CrossRef]

- Anno, E.; Tianimoto, M. Size-dependent change in interband absorption and broadening of optical plasma-resonance absorption of indium particles. J. Appl. Rhys. 2005, 98, 053510. [Google Scholar] [CrossRef]

- Atwater, H.A.; Polman, A. Plasmonics for improved photovoltaic devices. Nat. Mater. 2010, 9, 205–213. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.N.; Ouyang, Z.; Stokes, N.; Jia, B.H.; Shi, Z.R. Low cost and high performance Al nanoparticles for broadband light trapping in Si wafer solar cells. Appl. Phys. Lett. 2012, 100, 121101. [Google Scholar] [CrossRef]

- Temp, T.L.; Bagnall, D.M. Broadband scattering of the solar spectrum by spherical metal nanoparticles. Prog. Photovolt. Res. Appl. 2013, 21, 600–611. [Google Scholar]

- Dai, H.; Li, M.; Li, Y.; Yu, H.; Bai, F.; Ren, X. Effective light trapping enhancement by plasmonic Ag nanoparticles on silicon pyramid surface. Opt. Express 2012, 20, A502–A509. [Google Scholar] [CrossRef]

- Chen, X.; Jia, B.; Zhang, Y.; Gu, M. Exceeding the limit of plasmonic light trapping in textured screen-printed solar cells using Al nanoparticles and wrinkle-like graphene sheets. Light Scie. Appl. 2013, 2, e92. [Google Scholar] [CrossRef]

- Kelly, K.L.; Coronado, E.; Zhao, L.L.; Schatz, G.C. The optical properties of metal nanoparticles: The influence of size, shape, and dielectric environment. J. Phys. Chem. B 2003, 107, 668–677. [Google Scholar] [CrossRef]

- Kobayashi, Y.; Correa-Duarte, M.A.; Liz-Marzán, L.M. Sol-gel processing of silica-coated gold nanoparticles. Langmuir 2001, 17, 6375–6379. [Google Scholar]

- Liu, D.Y.; Ding, S.Y.; Lin, H.X.; Liu, B.J.; Ye, Z.Z.; Fan, F.R.; Ren, B.; Tian, Z.Q. Distinctive enhanced and tunable plasmon resonant absorption from controllable Au@Cu2O nanoparticles: Experimental and theoretical modeling. J. Phys. Chem. C 2012, 116, 4477–4483. [Google Scholar] [CrossRef]

- Cortés-Juan, F.; Ramos, C.C.; Connolly, J.P.; David, C.; García de Abajo, F.J.; Hurtado, J.; Mihailetchi, V.D.; Ponce-Alcántara, S.; Sánchez, G. Effect of Ag nanoparticles integrated within antireflection coatings for solar cells. J. Renew. Sustain. Energy 2013, 5, 033116. [Google Scholar] [CrossRef]

- Beck, F.J.; Polman, A.; Catchpole, K.R. Tunable light trapping for solar cells using localized surface plasmons. J. Appl. Phys. 2009, 105, 114310. [Google Scholar] [CrossRef]

- Ouyang, Z.; Zhao, X.; Varlamov, S.; Tao, Y.; Wong, J.; Pillai, S. Nanoparticle-enhanced light trapping in thin-film silicon solar cells. Prog. Photovolt. Res. Appl. 2011, 19, 917–926. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ho, W.-J.; Su, S.-Y.; Lee, Y.-Y.; Syu, H.-J.; Lin, C.-F. Performance-Enhanced Textured Silicon Solar Cells Based on Plasmonic Light Scattering Using Silver and Indium Nanoparticles. Materials 2015, 8, 6668-6676. https://doi.org/10.3390/ma8105330

Ho W-J, Su S-Y, Lee Y-Y, Syu H-J, Lin C-F. Performance-Enhanced Textured Silicon Solar Cells Based on Plasmonic Light Scattering Using Silver and Indium Nanoparticles. Materials. 2015; 8(10):6668-6676. https://doi.org/10.3390/ma8105330

Chicago/Turabian StyleHo, Wen-Jeng, Shih-Ya Su, Yi-Yu Lee, Hong-Jhang Syu, and Ching-Fuh Lin. 2015. "Performance-Enhanced Textured Silicon Solar Cells Based on Plasmonic Light Scattering Using Silver and Indium Nanoparticles" Materials 8, no. 10: 6668-6676. https://doi.org/10.3390/ma8105330

APA StyleHo, W.-J., Su, S.-Y., Lee, Y.-Y., Syu, H.-J., & Lin, C.-F. (2015). Performance-Enhanced Textured Silicon Solar Cells Based on Plasmonic Light Scattering Using Silver and Indium Nanoparticles. Materials, 8(10), 6668-6676. https://doi.org/10.3390/ma8105330