Single-Crystal Y2O3 Epitaxially on GaAs(001) and (111) Using Atomic Layer Deposition

Abstract

:1. Introduction

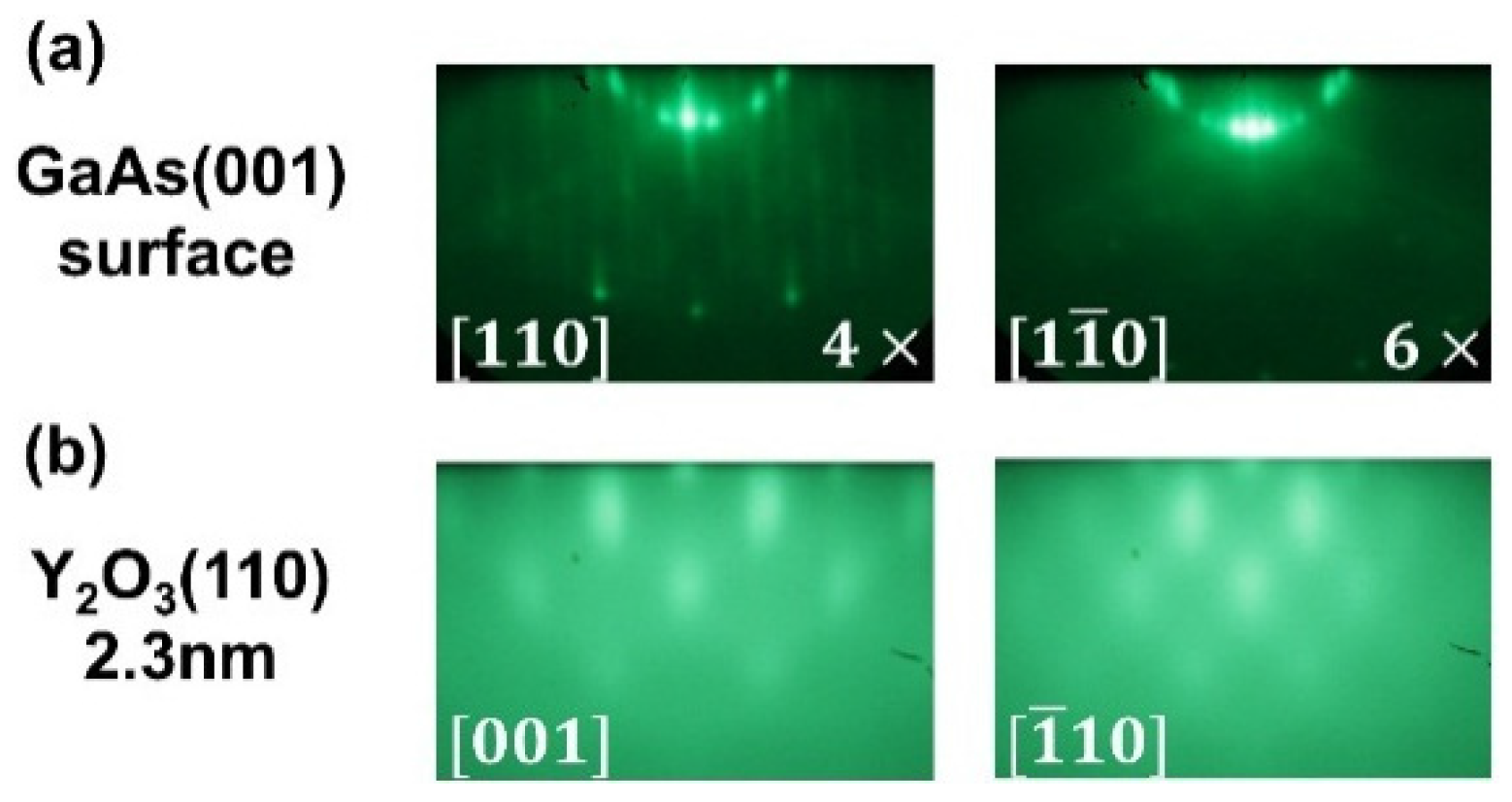

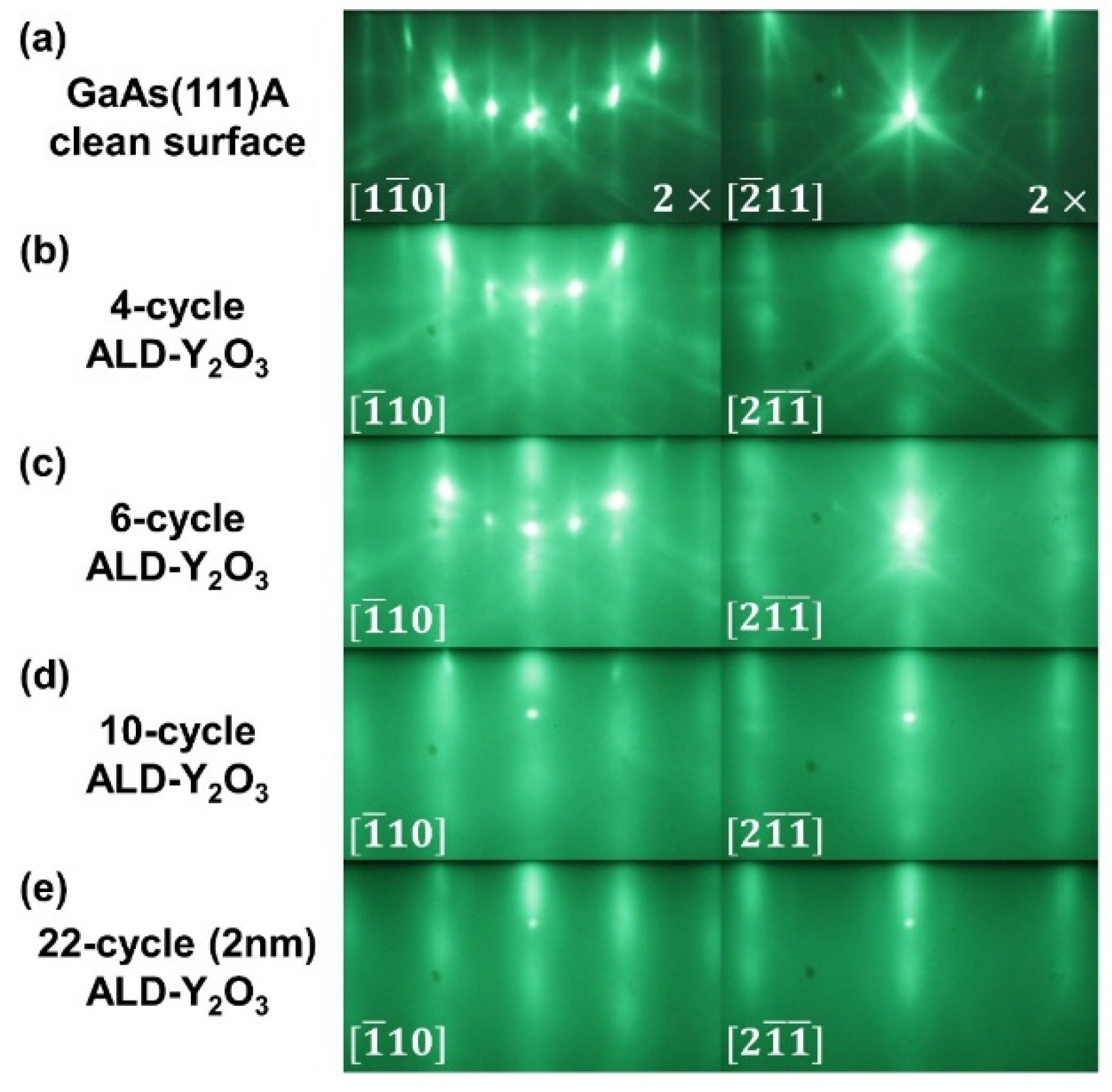

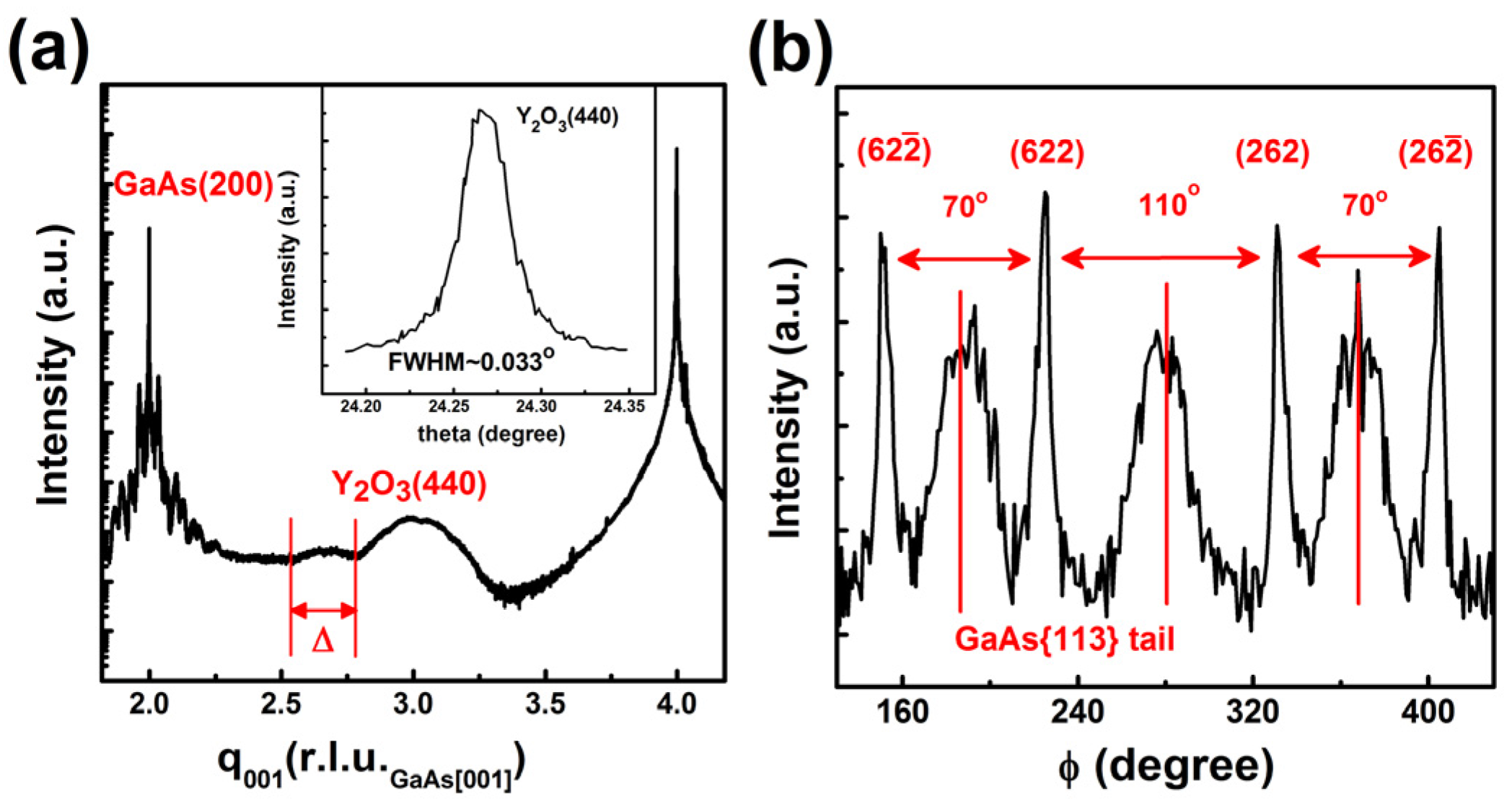

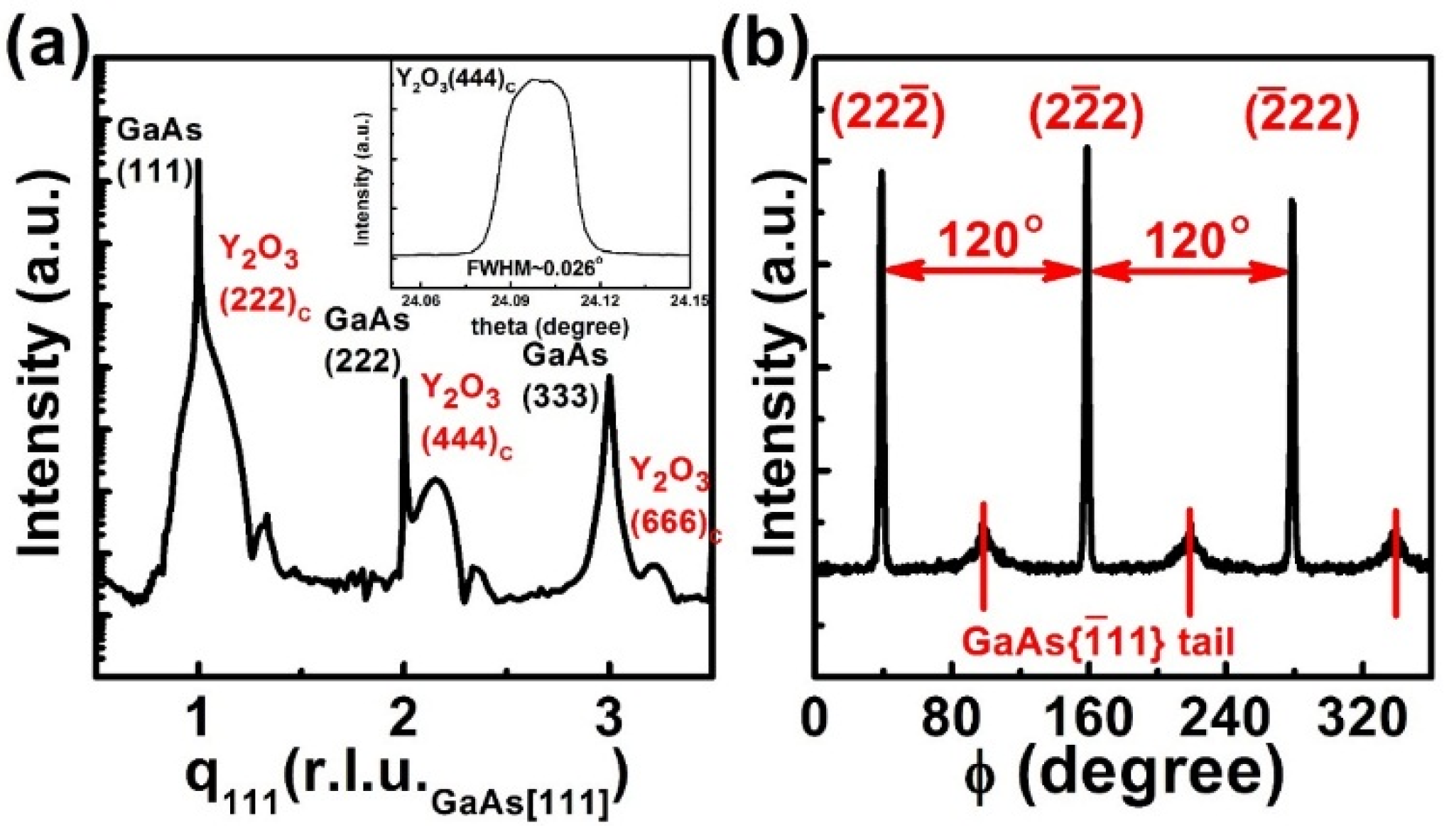

2. Results and Discussion

3. Experimental Section

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Hong, M.; Kwo, J.; Kortan, A.R.; Mannaerts, J.P.; Sergent, A.M. Epitaxial cubic gadolinium oxide as a dielectric for gallium arsenide passivation. Science 1999, 283, 1897–1900. [Google Scholar] [CrossRef] [PubMed]

- Hong, M.; Lu, Z.H.; Kwo, J.; Kortan, A.R.; Mannaerts, J.P.; Krajewski, J.J.; Hsieh, K.C.; Chou, L.J.; Cheng, K.Y. Initial growth of Ga2O3(Gd2O3) on GaAs: Key to the attainment of a low interfacial density of states. Appl. Phys. Lett. 2000, 76, 312–314. [Google Scholar] [CrossRef]

- Wang, X.; Dong, L.; Zhang, J.; Liu, Y.; Ye, P.D.; Gordon, R.G. Heteroepitaxy of La2O3 and La(2−x)O(x)O3 on GaAs (111)A by atomic layer deposition: Achieving low interface trap density. Nano Lett. 2013, 13, 594–599. [Google Scholar] [CrossRef] [PubMed]

- Kwo, J.; Hong, M.; Kortan, A.R.; Queeney, K.T.; Chabal, Y.J.; Mannaerts, J.P.; Boone, T.; Krajewski, J.J.; Sergent, A.M.; Rosamilia, J.M. High ε gate dielectrics Gd2O3 and Y2O3 for silicon. Appl. Phys. Lett. 2000, 77, 130–132. [Google Scholar] [CrossRef]

- Sitaputra, W.; Tsu, R. Defect induced mobility enhancement: Gadolinium oxide (100) on Si(100). Appl. Phys. Lett. 2012, 101. [Google Scholar] [CrossRef]

- Chaudhuri, A.R.; Fissel, A.; Osten, H.J. Superior dielectric properties for template assisted grown (100) oriented Gd2O3 thin films on Si(100). Appl. Phys. Lett. 2014, 104. [Google Scholar] [CrossRef]

- Gupta, J.A.; Landheer, D.; Sproule, G.I.; McCaffrey, J.P.; Graham, M.J.; Yang, K.C.; Lu, Z.H.; Lennard, W.N. Interfacial layer formation in Gd2O3 films deposited directly on Si(001). Appl. Surf. Sci. 2001, 173, 318–326. [Google Scholar] [CrossRef]

- Chang, W.H.; Lee, C.H.; Chang, Y.C.; Chang, P.; Huang, M.L.; Lee, Y.J.; Hsu, C.H.; Hong, J.M.; Tsai, C.C.; Kwo, J.R.; et al. Nanometer-thick single-crystal hexagonal Gd2O3 on GaN for advanced complementary metal-oxide-semiconductor technology. Adv. Mater. 2009, 21, 4970–4974. [Google Scholar] [CrossRef] [PubMed]

- Ihlefeld, J.F.; Brumbach, M.; Allerman, A.A.; Wheeler, D.R.; Atcitty, S. Algan composition dependence of the band offsets for epitaxial Gd2O3/AlxGa1−xN (0 ≤ x ≤ 0.67) heterostructures. Appl. Phys. Lett. 2014, 105. [Google Scholar] [CrossRef]

- Hong, M.; Passlack, M.; Mannaerts, J.P.; Kwo, J.; Chu, S.N.G.; Moriya, N.; Hou, S.Y.; Fratello, V.J. Low interface state density oxide-GaAs structures fabricated by in situ molecular beam epitaxy. J. Vac. Sci. Technol. 1996, B14. [Google Scholar] [CrossRef]

- Huang, Y.L.; Chang, P.; Yang, Z.K.; Lee, Y.J.; Lee, H.Y.; Liu, H.J.; Kwo, J.; Mannaerts, J.P.; Hong, M. Thermodynamic stability of Ga2O3(Gd2O3)/GaAs interface. Appl. Phys. Lett. 2005, 86. [Google Scholar] [CrossRef]

- Ren, F.; Hong, M.W.; Hobson, W.S.; Kuo, J.M.; Lothian, J.R.; Mannaerts, J.P.; Kwo, J.; Chen, Y.K.; Cho, A.Y. Enhancement-Mode p-Channel GaAs Mosfets on Semi-Insulating Substrates. In Proceedings of the 1996 IEEE International Electron Devices Meeting (IEDM 1996), San Francisco, CA, USA, 8–11 December 1996; pp. 943–945.

- Wang, Y.C.; Hong, M.; Kuo, J.M.; Mannaerts, J.P.; Kwo, J.; Tsai, H.S.; Krajewski, J.J.; Weiner, J.S.; Chen, Y.K.; Cho, A.Y. Advances in GaAs mosfet’s using Ga2O3(Gd2O3) as gate oxide. MRS Online Proc. Lib. 1999, 573. [Google Scholar] [CrossRef]

- Ye, P.D.; Wilk, G.D.; Yang, B.; Kwo, J.; Gossmann, H.J.L.; Hong, M.; Ng, K.K.; Bude, J. Depletion-mode InGaAs metal-oxide-semiconductor field-effect transistor with oxide gate dielectric grown by atomic-layer deposition. Appl. Phys. Lett. 2004, 84, 434–436. [Google Scholar] [CrossRef]

- Huang, M.L.; Chang, Y.C.; Chang, C.H.; Lee, Y.J.; Chang, P.; Kwo, J.; Wu, T.B.; Hong, M. Surface passivation of III-V compound semiconductors using atomic-layer-deposition-grown Al2O3. Appl. Phys. Lett. 2005, 87. [Google Scholar] [CrossRef]

- Frank, M.M.; Wilk, G.D.; Starodub, D.; Gustafsson, T.; Garfunkel, E.; Chabal, Y.J.; Grazul, J.; Muller, D.A. HfO2 and Al2O3 gate dielectrics on GaAs grown by atomic layer deposition. Appl. Phys. Lett. 2005, 86. [Google Scholar] [CrossRef]

- Brammertz, G.; Lin, H.C.; Martens, K.; Mercier, D.; Sioncke, S.; Delabie, A.; Wang, W.E.; Caymax, M.; Meuris, M.; Heyns, M. Capacitance-voltage characterization of GaAs–Al2O3 interfaces. Appl. Phys. Lett. 2008, 93. [Google Scholar] [CrossRef]

- Cheng, C.-W.; Hennessy, J.; Antoniadis, D.; Fitzgerald, E.A. Self-cleaning and surface recovery with arsine pretreatment in ex situ atomic-layer-deposition of Al2O3 on GaAs. Appl. Phys. Lett. 2009, 95. [Google Scholar] [CrossRef]

- Hinkle, C.L.; Milojevic, M.; Brennan, B.; Sonnet, A.M.; Aguirre-Tostado, F.S.; Hughes, G.J.; Vogel, E.M.; Wallace, R.M. Detection of Ga suboxides and their impact on III-V passivation and fermi-level pinning. Appl. Phys. Lett. 2009, 94. [Google Scholar] [CrossRef]

- Suri, R.; Lichtenwalner, D.J.; Misra, V. Impact of elemental arsenic on electrical characteristics of metal-oxide-semiconductor capacitors on GaAs using atomic-layer deposited HfO2 gate dielectric. Appl. Phys. Lett. 2008, 92. [Google Scholar] [CrossRef]

- Oktyabrsky, S.; Koveshnikov, S.; Tokranov, V.; Yakimov, M.; Kambhampati, R.; Bakhru, H.; Zhu, F.; Lee, J.; Tsai, W. InGaAs and GaAs/InGaAs Channel Enhancement Mode n-MOSFETs with HfO2 Gate Oxide and a-Si Interface Passivation Layer. In Proceedings of the 2007 65th Annual Device Research Conference, the University of Notre Dame, South Bend, IN, USA, 18–20 June 2007; pp. 203–204.

- Chang, Y.H.; Lin, C.A.; Liu, Y.T.; Chiang, T.H.; Lin, H.Y.; Huang, M.L.; Lin, T.D.; Pi, T.W.; Kwo, J.; Hong, M. Effective passivation of In0.2Ga0.8As by HfO2 surpassing Al2O3 via in-situ atomic layer deposition. Appl. Phys. Lett. 2012, 101. [Google Scholar] [CrossRef]

- Guo, Y.; Lin, L.; Robertson, J. Nitrogen passivation at GaAs:Al2O3 interfaces. Appl. Phys. Lett. 2013, 102. [Google Scholar] [CrossRef]

- Aoki, T.; Fukuhara, N.; Osada, T.; Sazawa, H.; Hata, M.; Inoue, T. Nitride passivation reduces interfacial traps in atomic-layer-deposited Al2O3/GaAs (001) metal-oxide-semiconductor capacitors using atmospheric metal-organic chemical vapor deposition. Appl. Phys. Lett. 2014, 105. [Google Scholar] [CrossRef]

- Liu, Y.; Xu, M.; Heo, J.; Ye, P.D.; Gordon, R.G. Heteroepitaxy of single-crystal LaLuO3 on GaAs(111)A by atomic layer deposition. Appl. Phys. Lett. 2010, 97. [Google Scholar] [CrossRef]

- Riel, H.; Wernersson, L.-E.; Hong, M.; del Alamo, J.A. III-V compound semiconductor transistors—From planar to nanowire structures. MRS Bull. 2014, 39, 668–677. [Google Scholar] [CrossRef]

- Lin, T.D.; Chang, W.H.; Chu, R.L.; Chang, Y.C.; Chang, Y.H.; Lee, M.Y.; Hong, P.F.; Chen, M.-C.; Kwo, J.; Hong, M. High-performance self-aligned inversion-channel In0.53Ga0.47As metal-oxide-semiconductor field-effect-transistors by in-situ atomic-layer-deposited HfO2. Appl. Phys. Lett. 2013, 103. [Google Scholar] [CrossRef]

- Gu, J.J.; Liu, Y.Q.; Wu, Y.Q.; Colby, R.; Gordon, R.G.; Ye, P.D. First Experimental Demonstration of Gate-All-Around III-V MOSFETs by Top-Down Approach. In Proceedings of the 2011 IEEE International Electron Devices Meeting (IEDM 2011), Washington, DC, USA, 5–7 December 2011; pp. 33.2.1–33.2.4.

- Xue, F.; Jiang, A.; Chen, Y.-T.; Wang, Y.; Zhou, F.; Chang, Y.-F.; Lee, J. Excellent Device Performance of 3d In0.53Ga0.47As Gate-Wrap-Around Field-Effect-Transistors with High-k Gate Dielectrics. In Proceedings of the 2012 IEEE International Electron Devices Meeting (IEDM 2012), San Francisco, CA, USA, 10–13 December 2012; pp. 27.5.1–27.5.4.

- Chu, R.L.; Chiang, T.H.; Hsueh, W.J.; Chen, K.H.; Lin, K.Y.; Chyi, J.I.; Kwo, J.; Hong, M. Passivation of GaSb using molecular beam epitaxy Y2O3 to achieve low interfacial trap density and high-performance self-aligned inversion-channel p-metal-oxide-semiconductor field-effect-transistors. Appl. Phys. Lett. 2014, 105. [Google Scholar] [CrossRef]

- Min, X.; Runsheng, W.; Ye, P.D. GaSb inversion-mode PMOSFETs with atomic-layer-deposited Al2O3 as gate dielectric. IEEE Electron Dev. Lett. 2011, 32, 883–885. [Google Scholar]

- Wong, I.H.; Chen, Y.-T.; Huang, S.-H.; Tu, W.-H.; Chen, Y.-S.; Shieh, T.-C.; Lin, T.-Y.; Lan, H.-S.; Liu, C.W. In-Situ Doped and Tensily Stained Ge Junctionless Gate-All-Around Nfets on soi Featuring Ion = 828 µA/µm, Ion/Ioff ∼ 1 × 105, DIBL= 16–54 mV/V, and 1.4X External Strain Enhancement. In Proceedings of the 2014 IEEE International Electron Devices Meeting (IEDM 2014), San Francisco, CA, USA, 15–17 December 2014; pp. 9.6.1–9.6.4.

- Lee, C.H.; Lu, C.; Tabata, T.; Zhang, W.F.; Nishimura, T.; Nagashio, K.; Toriumi, A. Oxygen Potential Engineering of Interfacial Layer for Deep Sub-nm EOT High-k Gate Stacks on Ge. In Proceedings of the 2013 IEEE International Electron Devices Meeting (IEDM 2013), Washington, DC, USA, 9–11 December 2013; pp. 2.5.1–2.5.4.

- Chu, L.K.; Chu, R.L.; Lin, T.D.; Lee, W.C.; Lin, C.A.; Huang, M.L.; Lee, Y.J.; Kwo, J.; Hong, M. Effective passivation and high-performance metal–oxide–semiconductor devices using ultra-high-vacuum deposited high-κ dielectrics on Ge without interfacial layers. Solid-State Electron. 2010, 54, 965–971. [Google Scholar] [CrossRef]

- Wu, S.Y.; Chen, K.H.; Lin, Y.H.; Cheng, C.K.; Hsu, C.H.; Kwo, J.; Hong, M. Single-crystal atomic layer deposited Y2O3 on GaAs(001)—Growth, structural, and electrical characterization. Microelectron. Eng. 2015, 147, 310–313. [Google Scholar] [CrossRef]

- Chang, W.H.; Wu, S.Y.; Lee, C.H.; Lai, T.Y.; Lee, Y.J.; Chang, P.; Hsu, C.H.; Huang, T.S.; Kwo, J.R.; Hong, M. Phase transformation of molecular beam epitaxy-grown nanometer-thick Gd2O3 and Y2O3 on GaN. ACS Appl. Mater. Interfaces 2013, 5. [Google Scholar] [CrossRef] [PubMed]

- Tung, R.T. The physics and chemistry of the schottky barrier height. Appl. Phys. Rev. 2014, 1. [Google Scholar] [CrossRef]

- Nakamura, S. The roles of structural imperfections in InGaN-based blue light-emitting diodes and laser diodes. Science 1998, 281, 956–961. [Google Scholar] [CrossRef]

- Kwo, J.; Hong, M.; Nakahara, S. Growth of rare-earth single crystals by molecular beam epitaxy: The epitaxial relationship between hcp rare earth and bcc niobium. Appl. Phys. Lett. 1986, 49. [Google Scholar] [CrossRef]

- Chen, X.; Ma, X.-C.; He, K.; Jia, J.-F.; Xue, Q.-K. Molecular beam epitaxial growth of topological insulators. Adv. Mater. 2011, 23, 1162–1165. [Google Scholar] [CrossRef] [PubMed]

- Fu, C.H.; Lin, Y.H.; Chen, K.H.; Chang, T.W.; Kwo, J.; Hong, M. unpublished results. 2015.

- Chang, Y.H.; Huang, M.L.; Chang, P.; Lin, C.A.; Chu, Y.J.; Chen, B.R.; Hsu, C.L.; Kwo, J.; Pi, T.W.; Hong, M. Electrical properties and interfacial chemical environments of in situ atomic layer deposited Al2O3 on freshly molecular beam epitaxy grown GaAs. Microelectron. Eng. 2011, 88, 440–443. [Google Scholar] [CrossRef]

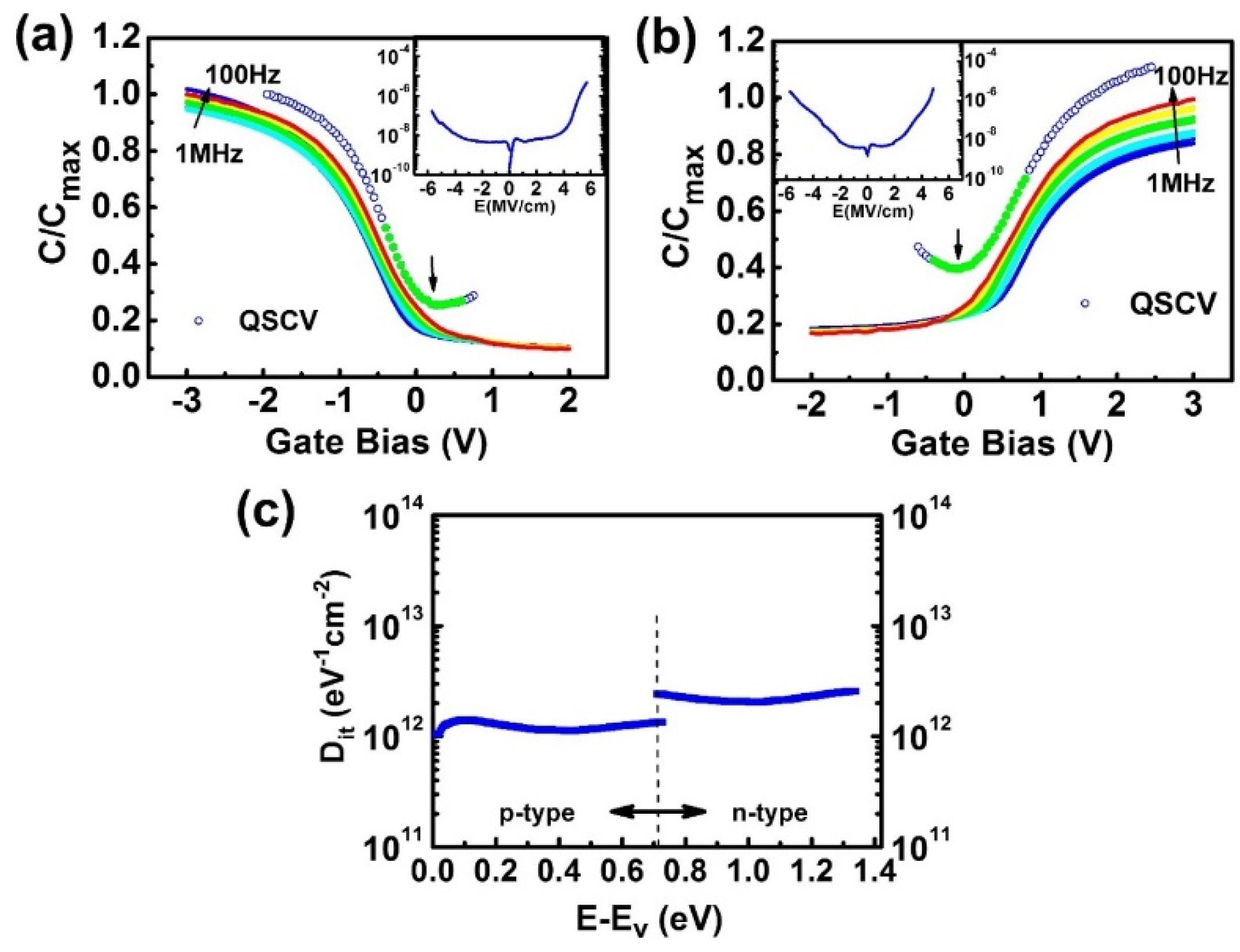

- Nicollian, E.H.; Brews, J.R. MOS (Metal Oxide Semiconductor) Physics and Technology; Wiley: New York, NY, USA, 1982. [Google Scholar]

- Berglund, C.N. Surface states at steam-grown silicon-silicon dioxide interfaces. IEEE Trans. Electron Devices 1966, ED13, 701–705. [Google Scholar] [CrossRef]

- Pi, T.-W.; Chen, B.-R.; Huang, M.-L.; Chiang, T.-H.; Wertheim, G.K.; Hong, M.; Kwo, J. Surface-atom core-level shift in GaAs(111)A-2 × 2. J. Phys. Soc. Jpn. 2012, 81. [Google Scholar] [CrossRef]

- Pi, T.W.; Lin, Y.H.; Fanchiang, Y.T.; Chiang, T.H.; Wei, C.H.; Lin, Y.C.; Wertheim, G.K.; Kwo, J.; Hong, M. In-situ atomic layer deposition of tri-methylaluminum and water on pristine single-crystal (In)GaAs surfaces: Electronic and electric structures. Nanotechnology 2015, 26. [Google Scholar] [CrossRef] [PubMed]

- Majumder, P.; Jursich, G.; Kueltzo, A.; Takoudis, C. Atomic Layer Deposition of Y2O3 Films on Silicon Using Tris(ethylcyclopentadienyl) Yttrium Precursor and Water Vapor. J. Electrochem. Soc. 2008, 158, 152–158. [Google Scholar]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, Y.H.; Cheng, C.K.; Chen, K.H.; Fu, C.H.; Chang, T.W.; Hsu, C.H.; Kwo, J.; Hong, M. Single-Crystal Y2O3 Epitaxially on GaAs(001) and (111) Using Atomic Layer Deposition. Materials 2015, 8, 7084-7093. https://doi.org/10.3390/ma8105364

Lin YH, Cheng CK, Chen KH, Fu CH, Chang TW, Hsu CH, Kwo J, Hong M. Single-Crystal Y2O3 Epitaxially on GaAs(001) and (111) Using Atomic Layer Deposition. Materials. 2015; 8(10):7084-7093. https://doi.org/10.3390/ma8105364

Chicago/Turabian StyleLin, Y. H., C. K. Cheng, K. H. Chen, C. H. Fu, T. W. Chang, C. H. Hsu, J. Kwo, and M. Hong. 2015. "Single-Crystal Y2O3 Epitaxially on GaAs(001) and (111) Using Atomic Layer Deposition" Materials 8, no. 10: 7084-7093. https://doi.org/10.3390/ma8105364

APA StyleLin, Y. H., Cheng, C. K., Chen, K. H., Fu, C. H., Chang, T. W., Hsu, C. H., Kwo, J., & Hong, M. (2015). Single-Crystal Y2O3 Epitaxially on GaAs(001) and (111) Using Atomic Layer Deposition. Materials, 8(10), 7084-7093. https://doi.org/10.3390/ma8105364