A Comparative Analysis of the Corrosive Effect of Artificial Saliva of Variable pH on DMLS and Cast Co-Cr-Mo Dental Alloy

Abstract

:1. Introduction

2. Materials and Method

2.1. Specimen Fabrication

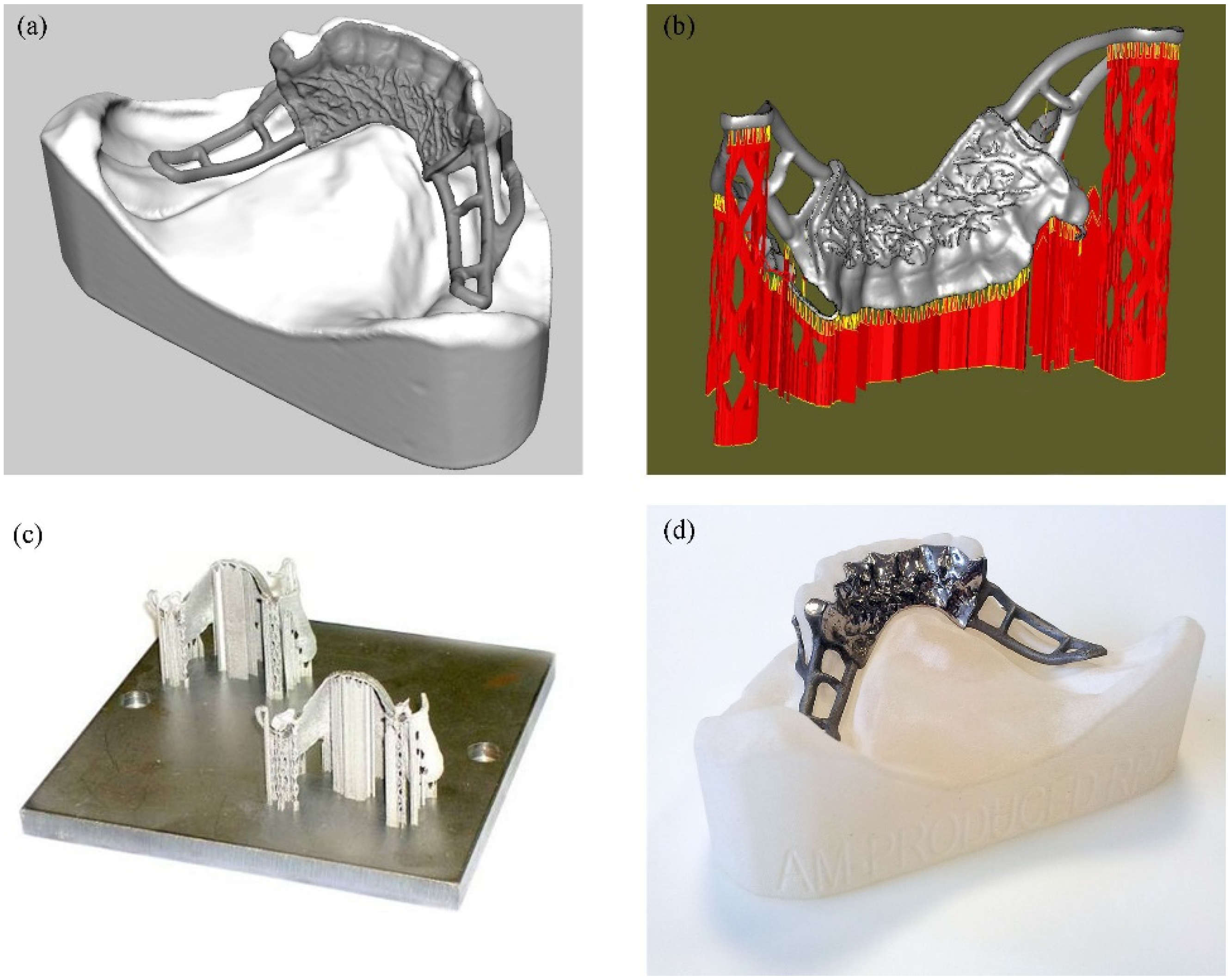

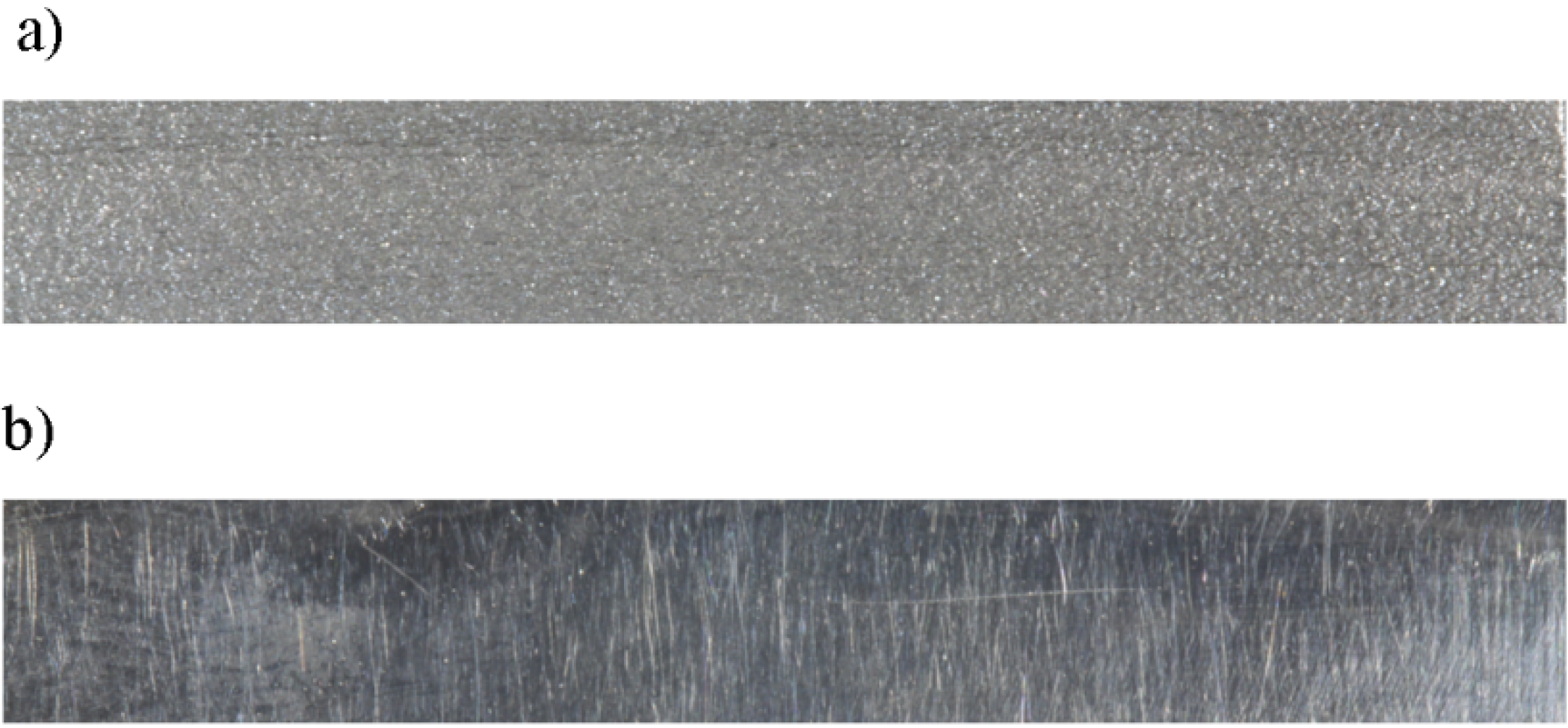

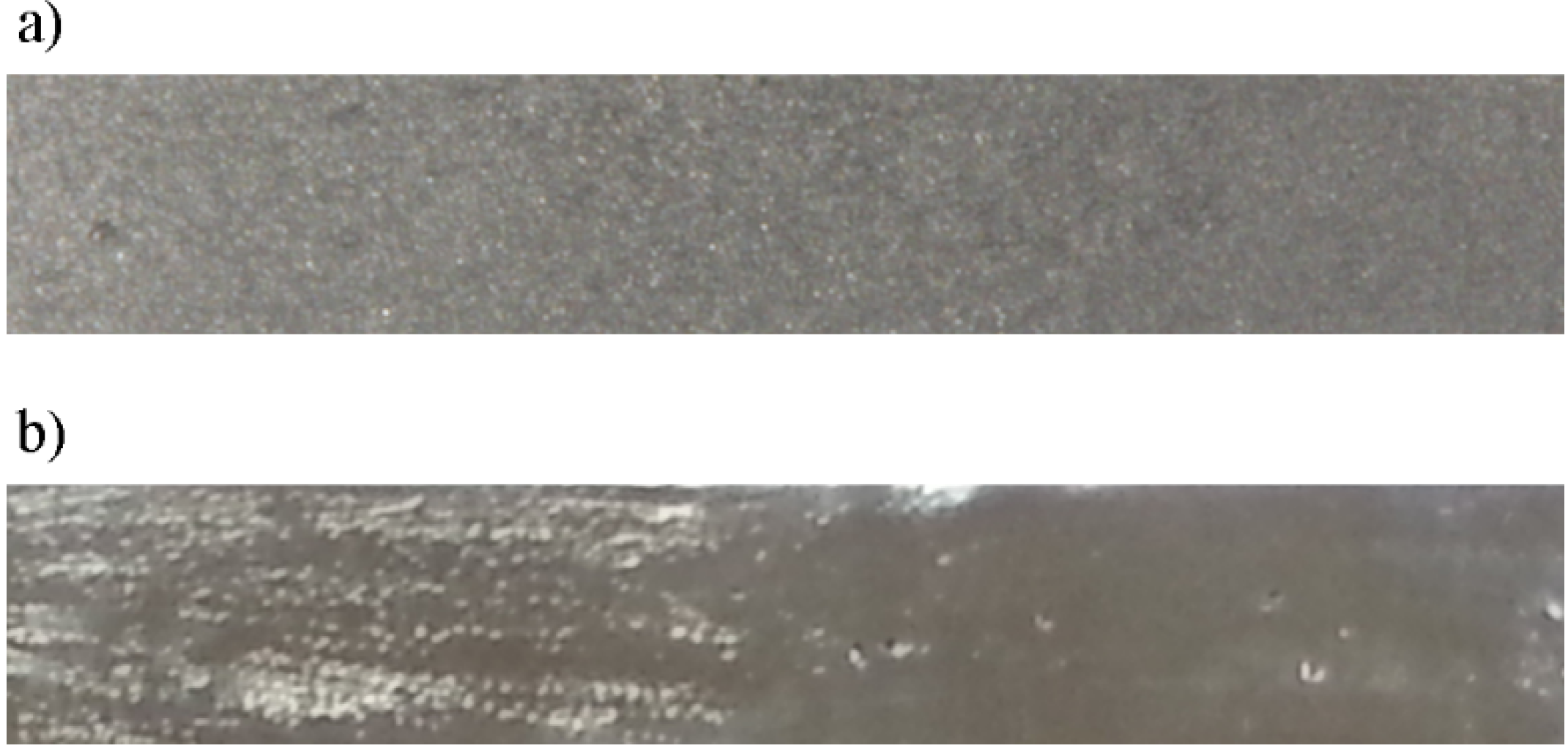

2.1.1. DMLS Specimen Production

| Processing parameter | Part border | Part hatch (core) |

|---|---|---|

| Laser power (W) | 200 | 200 |

| Laser point distance (μm) | 70 | 85 |

| Laser exposure time (ns) | 50 | 80 |

| Laser beam spot compensation (mm) | 0.079 | 0.079 |

2.1.2. Cast Specimen Production

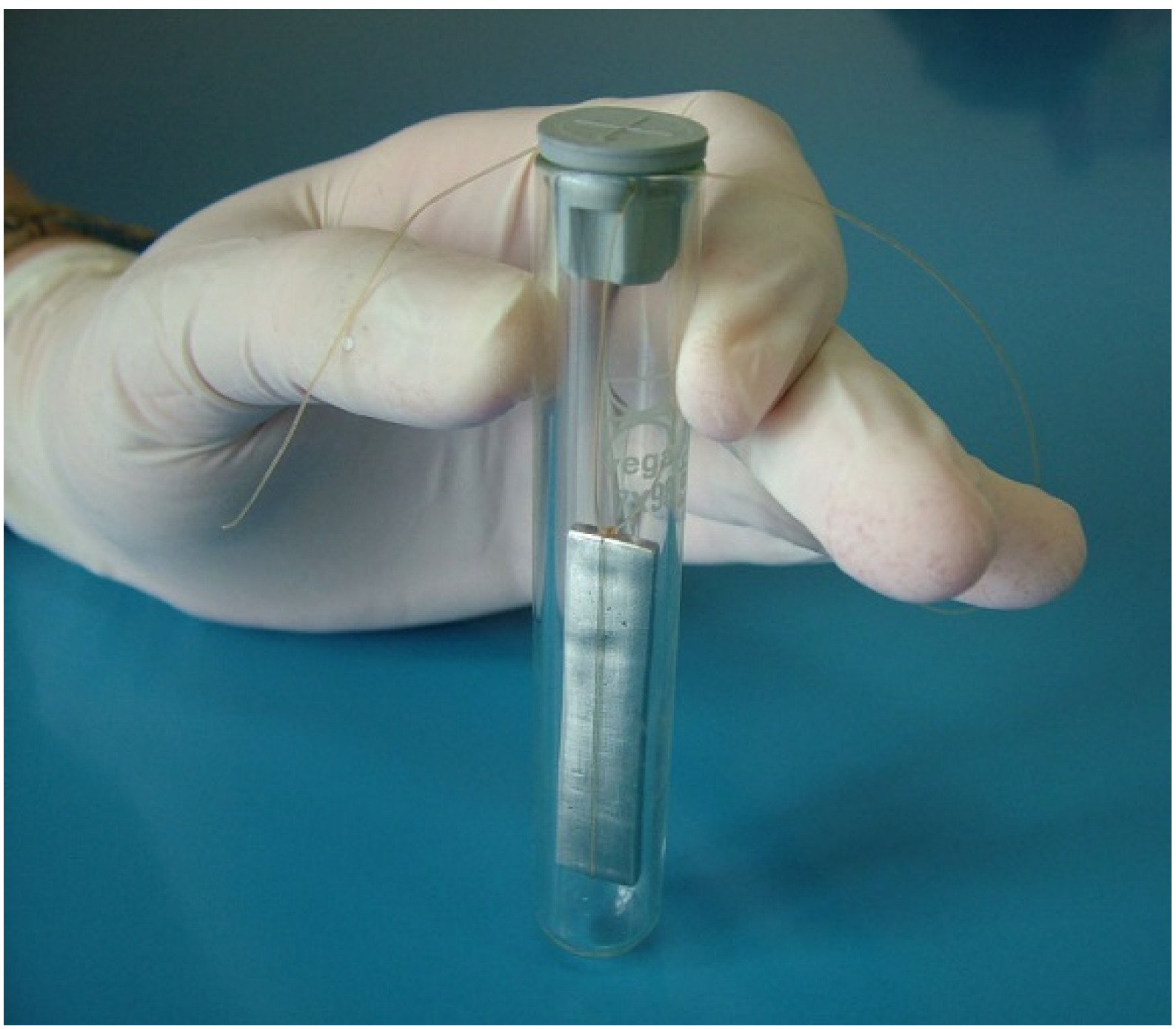

2.2. Test Procedure of the Dissolution of Metals

2.3. Density Measurement

2.4. Microstructure Analyses

3. Results and Discussion

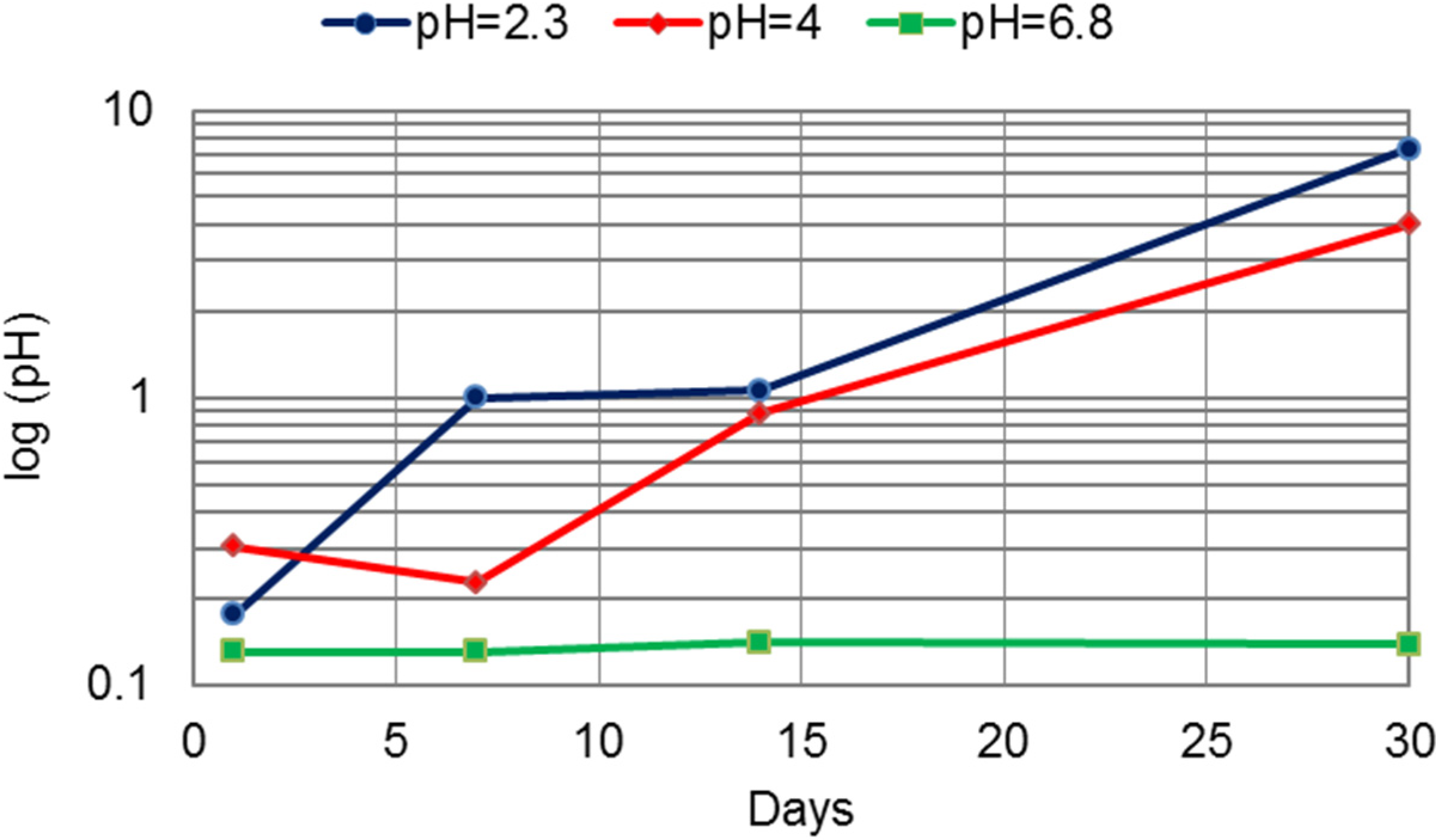

| pH | Sample | Time of the Exposure | |||

|---|---|---|---|---|---|

| 1 Day | 7 Days | 14 Days | 30 Days | ||

| 2.3 | CM | 0.500 | 1.685 | 1.819 | 8.244 |

| DMLS | 0.324 | 0.685 | 0.759 | 0.881 | |

| 4 | CM | 0.605 | 0.620 | 1.781 | 5.297 |

| DMLS | 0.302 | 0.392 | 0.897 | 1.297 | |

| 6.8 | CM | 0.162 | 0.166 | 0.179 | 0.183 |

| DMLS | 0.031 | 0.035 | 0.038 | 0.044 | |

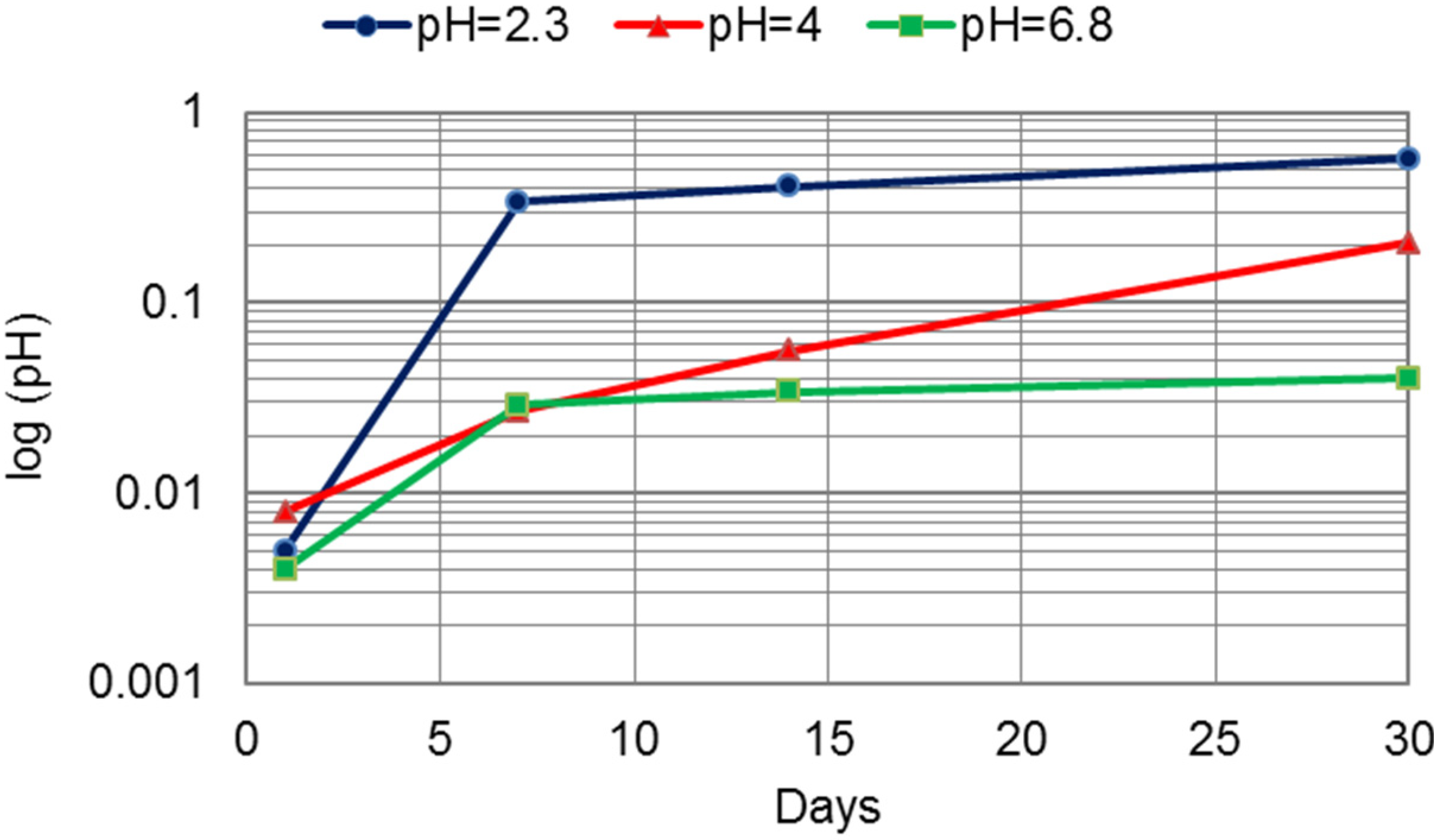

| pH | Sample | Time of the Exposure | |||

|---|---|---|---|---|---|

| 1 Day | 7 Days | 14 Days | 30 Days | ||

| 2.3 | CM | 0.012 | 0.363 | 0.437 | 0.606 |

| DMLS | 0.007 | 0.026 | 0.031 | 0.036 | |

| 4 | CM | 0.011 | 0.033 | 0.061 | 0.209 |

| DMLS | 0.003 | 0.006 | 0.005 | 0.002 | |

| 6.8 | CM | 0.004 | 0.029 | 0.034 | 0.041 |

| DMLS | 0.000 | 0.000 | 0.000 | 0.001 | |

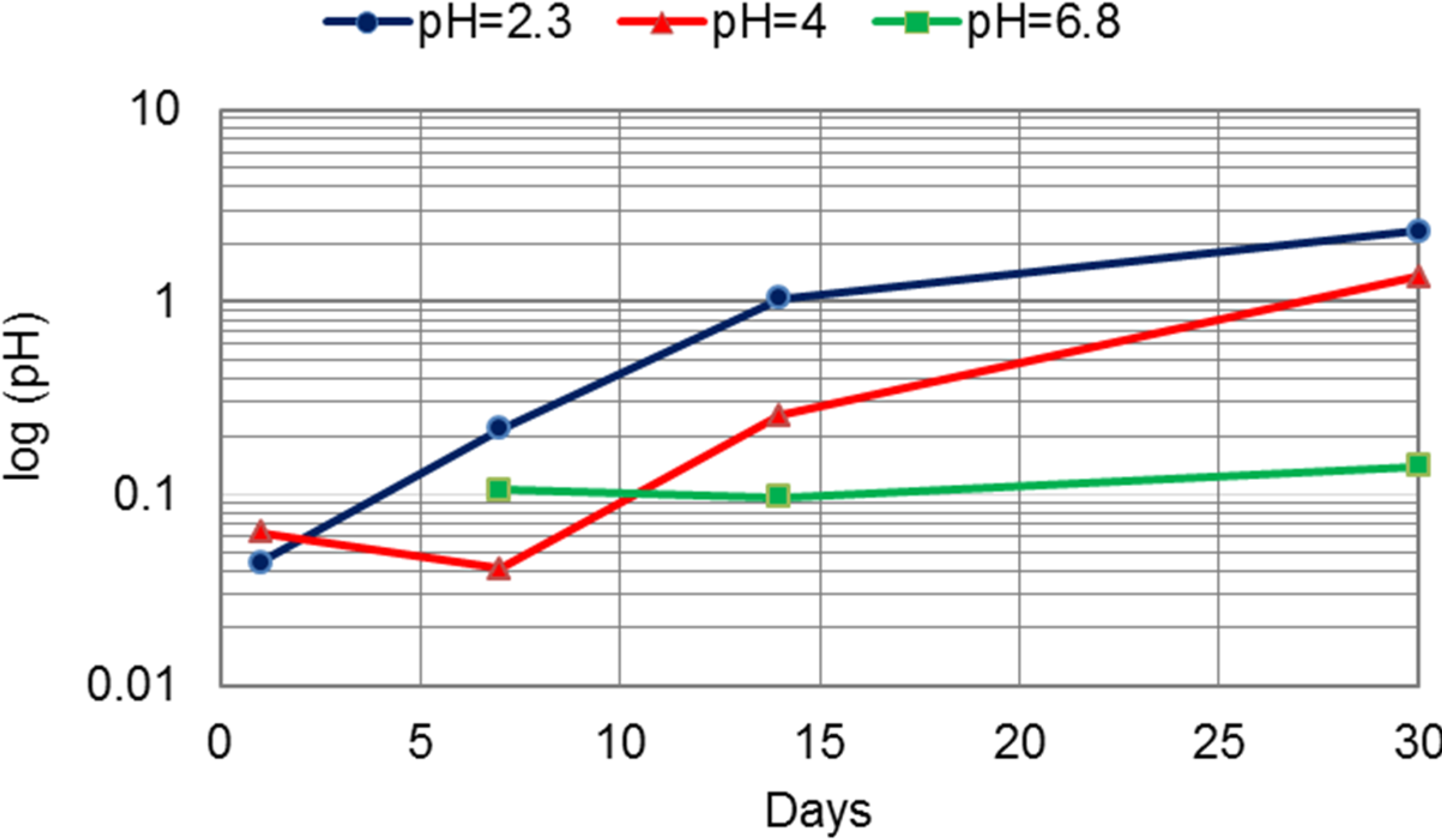

| pH | Sample | Time of the Exposure | |||

|---|---|---|---|---|---|

| 1 Day | 7 Days | 14 Days | 30 Days | ||

| 2.3 | CM | 0.059 | 0.279 | 1.133 | 2.431 |

| DMLS | 0.015 | 0.061 | 0.093 | 0.113 | |

| 4 | CM | 0.077 | 0.092 | 0.330 | 1.417 |

| DMLS | 0.014 | 0.051 | 0.073 | 0.073 | |

| 6.8 | CM | 0.092 | 0.113 | 0.130 | 0.179 |

| DMLS | 0.092 | 0.008 | 0.034 | 0.039 | |

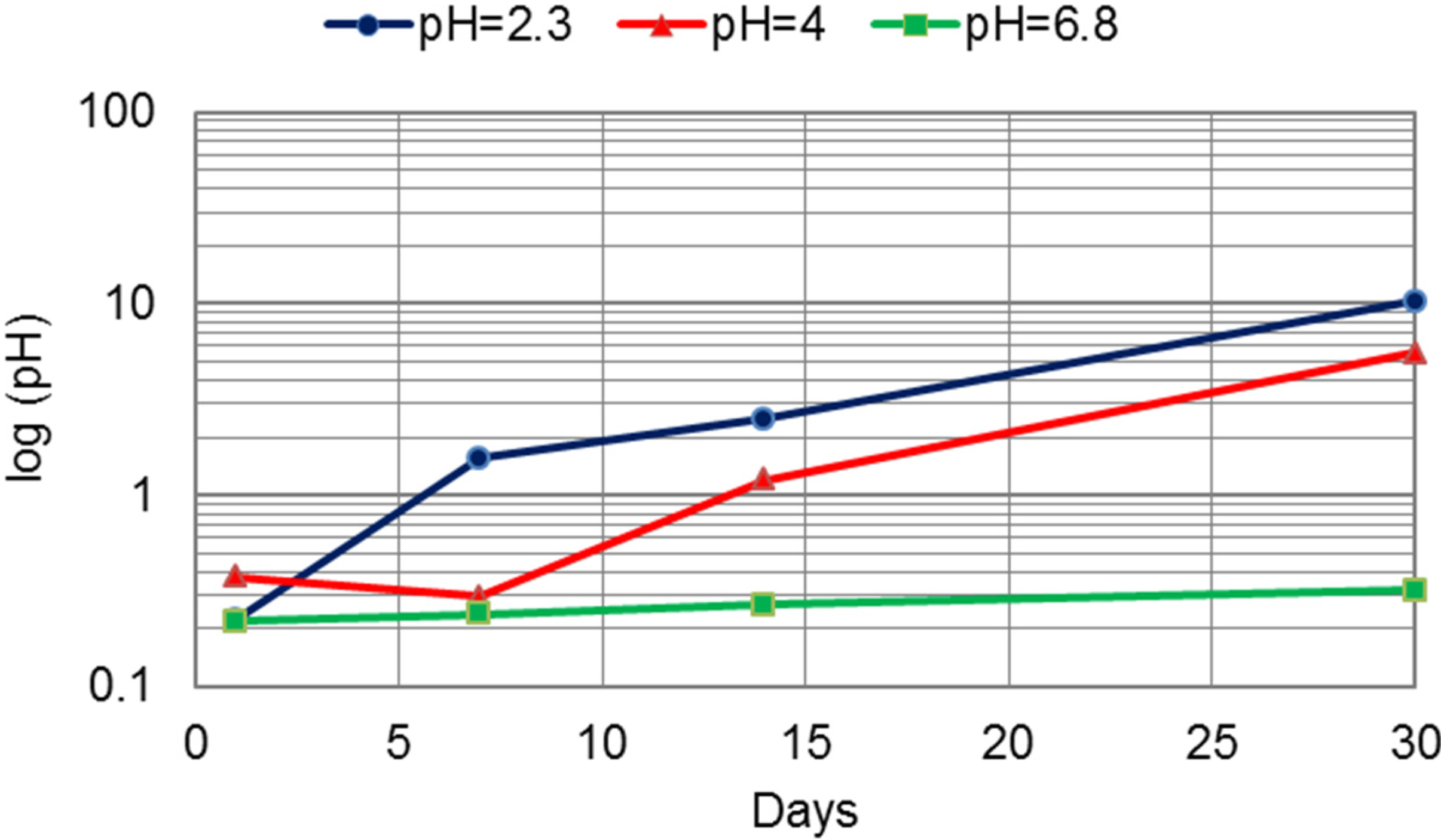

| pH | Sample | Time of the exposure | |||

|---|---|---|---|---|---|

| 1 Day | 7 Days | 14 Days | 30 Days | ||

| 2.3 | CM | 0.571 | 2.327 | 3.389 | 11.281 |

| DMLS | 0.346 | 0.772 | 0.883 | 1.030 | |

| 4 | CM | 0.693 | 0.745 | 2.172 | 6.923 |

| DMLS | 0.319 | 0.449 | 0.975 | 1.372 | |

| 6.8 | CM | 0.258 | 0.308 | 0.343 | 0.403 |

| DMLS | 0.039 | 0.069 | 0.077 | 0.085 | |

| Sample | Density ρ (g/cm3) | ||||

|---|---|---|---|---|---|

| ρaverage | ρmedian | ρstdev | ρmin. | ρmax. | |

| CM | 8.22 | 8.22 | 0.02 | 8.20 | 8.24 |

| DMLS | 8.60 | 8.59 | 0.03 | 8.52 | 8.66 |

4. Conclusions

- Metal elution in artificial saliva from the DMLS alloy was lower than the elution from the cast alloy;

- Cobalt produced the greatest release of ions;

- Acidity influenced the elution;

- The greatest elution occurred in the most acidic environment, i.e., 2.3 pH;

- The longer the investigated period, the higher the difference between the total metal ion release from the CM and DMLS alloys;

- Both alloys (CM and DMLS) showed a safe level of elution according to the ISO definition in all investigated acidic environments.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Anusavice, K. Phillips’ Science of Dental Materials, 11th ed.; Elsevier Health Sciences: St. Louis, MO, USA, 2003. [Google Scholar]

- Rosenstiel, F.S.; Land, F.M.; Fujimoto, J. Contemporary Fixed Prosthodontics, 4th ed.; Mosby, Elsevier Health Sciences: St. Louis, MO, USA, 2006. [Google Scholar]

- Akova, T.; Ucar, Y.; Tukay, A.; Balkaya, M.C.; Brantley, W.A. Comparison of the bond strength of laser-sintered and cast base metal dental alloys to porcelain. Dent. Mater. 2008, 24, 1400–1404. [Google Scholar] [CrossRef]

- Amanov, A.; Sasaki, S.; Cho, I.S.; Suzuki, Y.; Kim, H.J.; Kim, D.U. An investigation of the tribological and nano-scratch behaviours of Fe-Ni-Cr alloy sintered by direct metal laser sintering. Mater. Des. 2013, 47, 386–394. [Google Scholar] [CrossRef]

- Manfredi, D.; Calignano, F.; Krishnan, M.; Canali, R.; Ambrosio, E.P.; Atzeni, E. From powders to dense metal parts: Characterization of a commercial AlSiMg alloy processed through direct metal laser sintering. Materials 2013, 6, 856–869. [Google Scholar] [CrossRef]

- Cooper, E.D.; Stanford, M.; Kibble, A.K.; Gibbons, J.G. Additive manufacturing for product improvement at red bull technology. Mater. Des. 2012, 41, 226–230. [Google Scholar] [CrossRef]

- Bogue, R. 3D printing: The dawn of a new era in manufacturing. Assem. Autom. 2013, 33, 307–311. [Google Scholar] [CrossRef]

- ISO 13485:2012. Medical Devices-Quality Management Systems-Requirements for Regulatory Purposes; International Organization for Standardization (ISO): Geneva, Switzerland.

- Jevremovic, D.; Puskar, T.; Kosec, B.; Vukelic, D.; Budak, I.; Aleksandrovic, S.; Egbeer, D.; Williams, R. The analysis of the mechanical properties of F75 Co-Cr alloy for use in selective laser melting (SLM) manufacturing of removable partial dentures (RPD). Metalurgija 2012, 51, 171–174. [Google Scholar]

- Jevremovic, D.; Puskar, T.; Budak, I.; Vukelic, D.; Kojic, V.; Eggbeer, D.; Williams, R. An RE/RM approach to the design and manufacture of removable partial dentures with a biocompatibility analysis of the F75 Co-Cr SLM alloy. Mater. Tehnol. 2012, 46, 123–129. [Google Scholar]

- Wataha, J.C. Biocompatibility of dental casting alloys: A review. J. Prosthet. Dent. 2000, 83, 223–234. [Google Scholar] [CrossRef]

- Takaichi, A.; Suyalatu; Nakamoto, T.; Joko, N.; Nomura, N.; Tsutsumi, Y.; Migita, S.; Doi, H.; Kurosu, S.; Chiba, A.; et al. Microstructures and mechanical properties of Co-29Cr-6Mo alloy fabricated by selective laser melting process for dental applications. J. Mech. Behav. Biomed. Mater. 2013, 21, 67–76. [Google Scholar] [CrossRef]

- Ortorp, A.; Jonnson, D.; Mouhsen, A.; vult von Steyern, P. The fit of cobalt-chromium three-unit fixed dental prostheses fabricated with four different techniques: A comparative in vitro study. Dent. Mater. 2011, 27, 356–363. [Google Scholar] [CrossRef]

- Lee, J.C.; Son, Y.O.; Pratheeshkumar, P.; Shi, X. Oxidative stress and metal carcinogenesis. Free. Radic. Biol. Med. 2012, 53, 742–757. [Google Scholar] [CrossRef]

- Costa, M.; Klein, C.B. Toxicity and carcinogenicity of chromium compounds in humans. Crit. Rev. Toxicol. 2006, 36, 155–163. [Google Scholar] [CrossRef]

- Huang, J.; Hu, X.; Zhang, J.; Li, K.; Yan, Y.; Xu, X. The application of inductively coupled plasma mass spectrometry in pharmaceutical and biomedical analysis. J. Pharm. Biomed. Anal. 2006, 40, 227–234. [Google Scholar] [CrossRef]

- Alifui-Segbaya, F.; Foley, P.; Williams, R.J. The corrosive effects of artificial saliva on cast and rapid manufacture-produced cobalt chromium alloys. Rapid Prototyp. J. 2013, 19, 95–99. [Google Scholar] [CrossRef]

- Zhang, B.; Huang, Q.; Gao, Y.; Luo, P.; Zhao, C. Preliminary study on some properties of Co-Cr dental alloy formed by selective laser melting technique. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2012, 27, 665–668. [Google Scholar] [CrossRef]

- Castillo-Oyague, R.; Lynch, D.C.; Turrion, S.A.; Lopez-Lozano, F.J.; Torres-Lagares, D.; Suarez-Garcia, J.M. Misfit and microleakage of implant-supported crown copings obtained by laser sintering and casting techniques, luted with glass-ionomer, resin cements and acrylic/urethane-based agents. J. Dent. 2013, 41, 90–96. [Google Scholar] [CrossRef]

- Bhaskaran, E.; Azhagarasan, S.N.; Miglani, S.; Ilango, T.; Phani Krishna, G.; Gajapathi, B. Comparative evaluation of marginal and internal gap of co-cr copings fabricated from conventional wax pattern, 3D printed resin pattern and dmls tech: An in vitro study. J. Indian Prosthodont. Soc. 2013, 13, 189–195. [Google Scholar]

- Ucar, Y.; Akova, T.; Akyil, M.S.; Brantley, W.A. Internal fit evaluation of crowns prepared using a new dental crown fabrication technique: Laser-sintered Co-Cr crowns. J. Prosthet. Dent. 2009, 102, 253–259. [Google Scholar] [CrossRef]

- Kim, K.B.; Kim, W.C.; Kim, H.J.; Kim, J.H. An evaluation of marginal fit of three-unit fixed dental prostheses fabricated by direct metal laser sintering system. Dent. Mater. 2013, 29, 91–96. [Google Scholar]

- Rodrigues, D.C.; Valderrama, P.; Wilson, T.G., Jr.; Palmer, K.; Thomas, A.; Sridhar, S.; Adapalli, A.; Burbano, M.; Wadhwani, C. Titanium corrosion mechanisms in the oral environment: A retrieval study. Materials 2013, 6, 5258–5274. [Google Scholar] [CrossRef]

- Bardow, A.; Lynge Peterson, A.M.; Nauntofte, B. Saliva. In Clinical Oral Physiology; Miles, S.T., Nauntofte, B., Svensson, P., Eds.; Quintessence: Copenhagen, Denmark, 2004; pp. 17–18, 30–33. [Google Scholar]

- Aframian, D.J.; Davidowitz, T.; Benoliel, R. The distribution of oral mucosal pH values in healthy saliva secretors. Oral Dis. 2006, 12, 420–423. [Google Scholar] [CrossRef]

- Lavrenko, A.V.; Shvets, A.V.; Makarenko, N.G. Comparative study of the chemical resistance of titanium nitride and stainless steel in media of the oral cavity. Powder Metall. Met. Ceram. 2001, 40, 630–636. [Google Scholar] [CrossRef]

- ISO 10271:2011. Dentistry-Corrosion Test Methods for Metallic Materials; International Organization for Standardization (ISO): Geneva, Switzerland.

- ISO 22674:2006. Dentistry-Metallic Materials for Fixed and Removable Restorations and Appliances; International Organization for Standardization (ISO): Geneva, Switzerland.

- McGinley, E.L.; Fleming, G.J.P.; Moran, G.P. Development of a discriminatory biocompatibility testing model for non-precious dental casting alloys. Dent. Mater. 2011, 27, 1295–1306. [Google Scholar] [CrossRef]

- McGinley, E.L.; Moran, G.P.; Fleming, G.J.P. Base-metal dental casting alloy biocompatibility assessment using a human-derived three-dimensional oral mucosal model. Acta Biomater. 2012, 8, 432–438. [Google Scholar] [CrossRef]

- Vandenbroucke, B.; Kruth, J.P. Selective laser melting of biocompatible metals for rapid manufacturing of medical parts. Rapid Prototyp. J. 2007, 13, 196–203. [Google Scholar] [CrossRef]

- Monroy, K.; Delgado, J.; Ciurana, J. Study of the pore formation on Co-Cr-Mo alloys by selective laser melting manufacturing process. Procedia Eng. 2013, 63, 361–369. [Google Scholar] [CrossRef]

- Gu, D.; Hagedorn, Y.C.; Meiners, W.; Meng, G.; Santos Batista, R.J.; Wissenbach, K.; Poprawe, R. Densification behavior, microstructure evolution, and wear performance of selective laser melting processed commercially pure titanium. Acta Mater. 2012, 60, 3849–3860. [Google Scholar] [CrossRef]

- Smith, D.C.; Pilliar, R.M.; Metson, J.B.; Mcintyre, N.S. Dental implant materials. II. Preparative procedures and surface spectroscopic studies. J. Biomed. Mater. Res. 1991, 25, 1069–1084. [Google Scholar] [CrossRef]

- Roach, M. Base metal alloys used for dental restorations and implants. Dent. Clin. North Am. 2007, 51, 603–627. [Google Scholar] [CrossRef]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Puskar, T.; Jevremovic, D.; Williams, R.J.; Eggbeer, D.; Vukelic, D.; Budak, I. A Comparative Analysis of the Corrosive Effect of Artificial Saliva of Variable pH on DMLS and Cast Co-Cr-Mo Dental Alloy. Materials 2014, 7, 6486-6501. https://doi.org/10.3390/ma7096486

Puskar T, Jevremovic D, Williams RJ, Eggbeer D, Vukelic D, Budak I. A Comparative Analysis of the Corrosive Effect of Artificial Saliva of Variable pH on DMLS and Cast Co-Cr-Mo Dental Alloy. Materials. 2014; 7(9):6486-6501. https://doi.org/10.3390/ma7096486

Chicago/Turabian StylePuskar, Tatjana, Danimir Jevremovic, Robert J. Williams, Dominic Eggbeer, Djordje Vukelic, and Igor Budak. 2014. "A Comparative Analysis of the Corrosive Effect of Artificial Saliva of Variable pH on DMLS and Cast Co-Cr-Mo Dental Alloy" Materials 7, no. 9: 6486-6501. https://doi.org/10.3390/ma7096486

APA StylePuskar, T., Jevremovic, D., Williams, R. J., Eggbeer, D., Vukelic, D., & Budak, I. (2014). A Comparative Analysis of the Corrosive Effect of Artificial Saliva of Variable pH on DMLS and Cast Co-Cr-Mo Dental Alloy. Materials, 7(9), 6486-6501. https://doi.org/10.3390/ma7096486