Chloride Permeability of Damaged High-Performance Fiber-Reinforced Cement Composite by Repeated Compressive Loads

Abstract

:1. Introduction

2. Experimental Method

2.1. Experimental Plan

2.2. Materials and Mixture Design

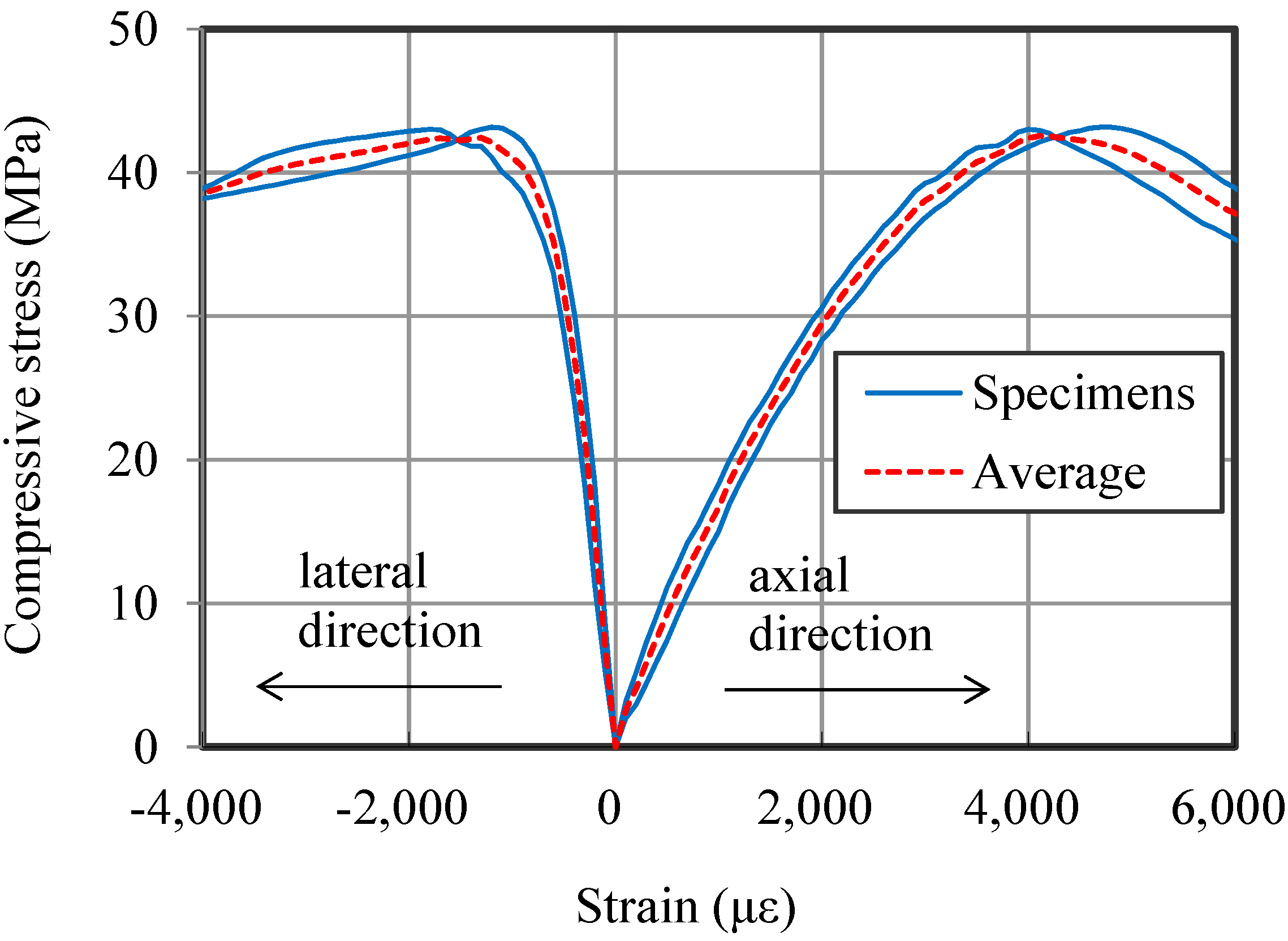

2.3. Compressive Test

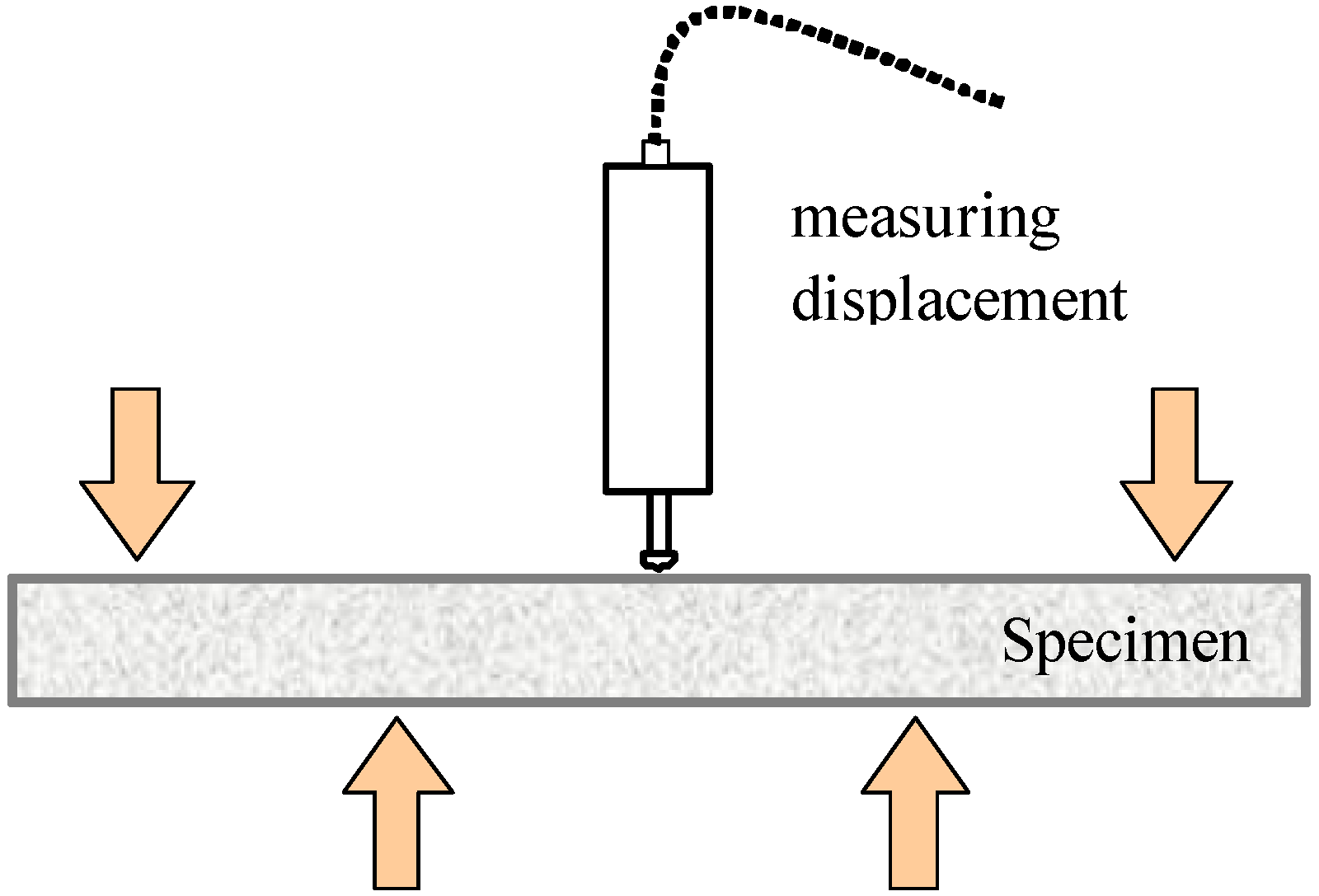

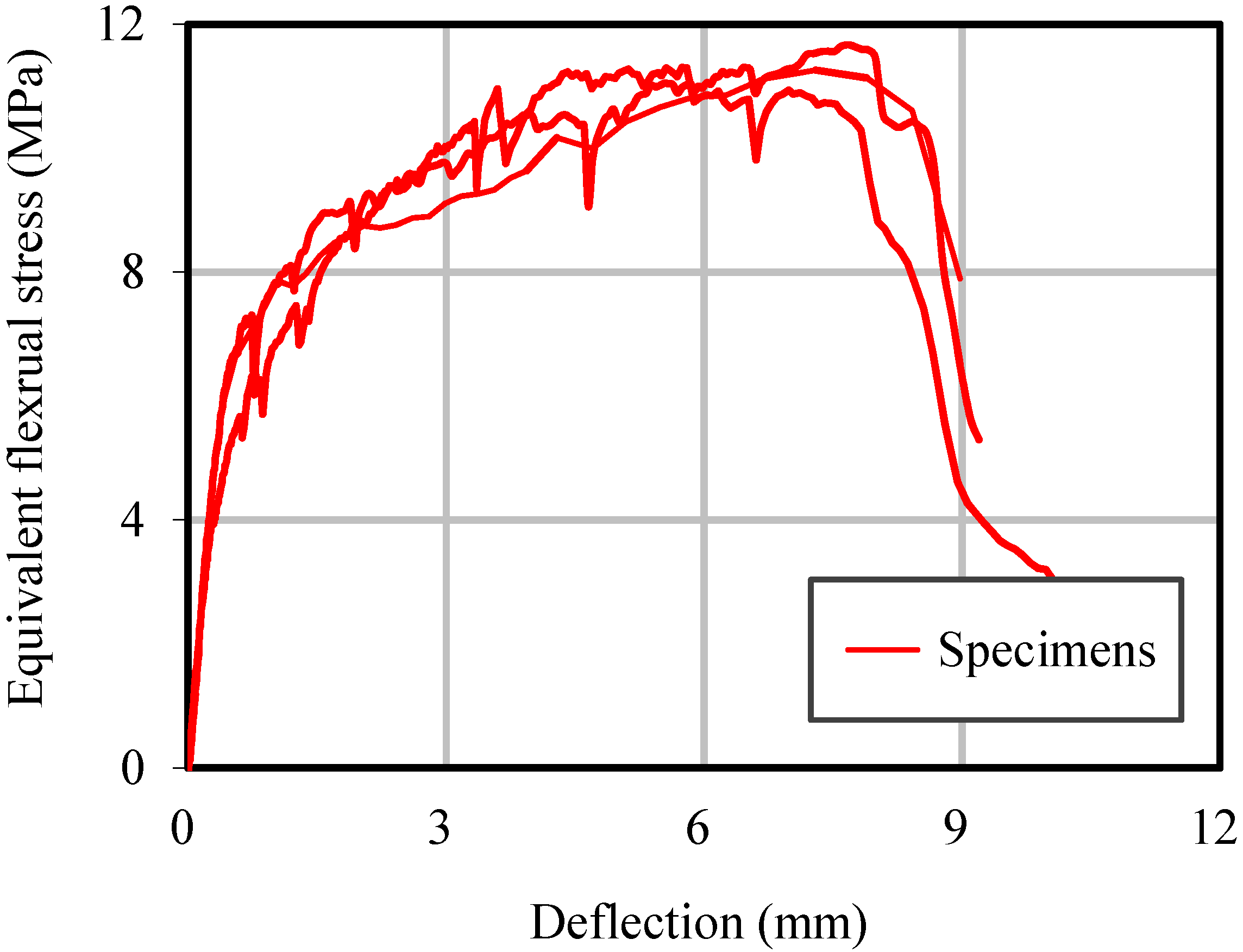

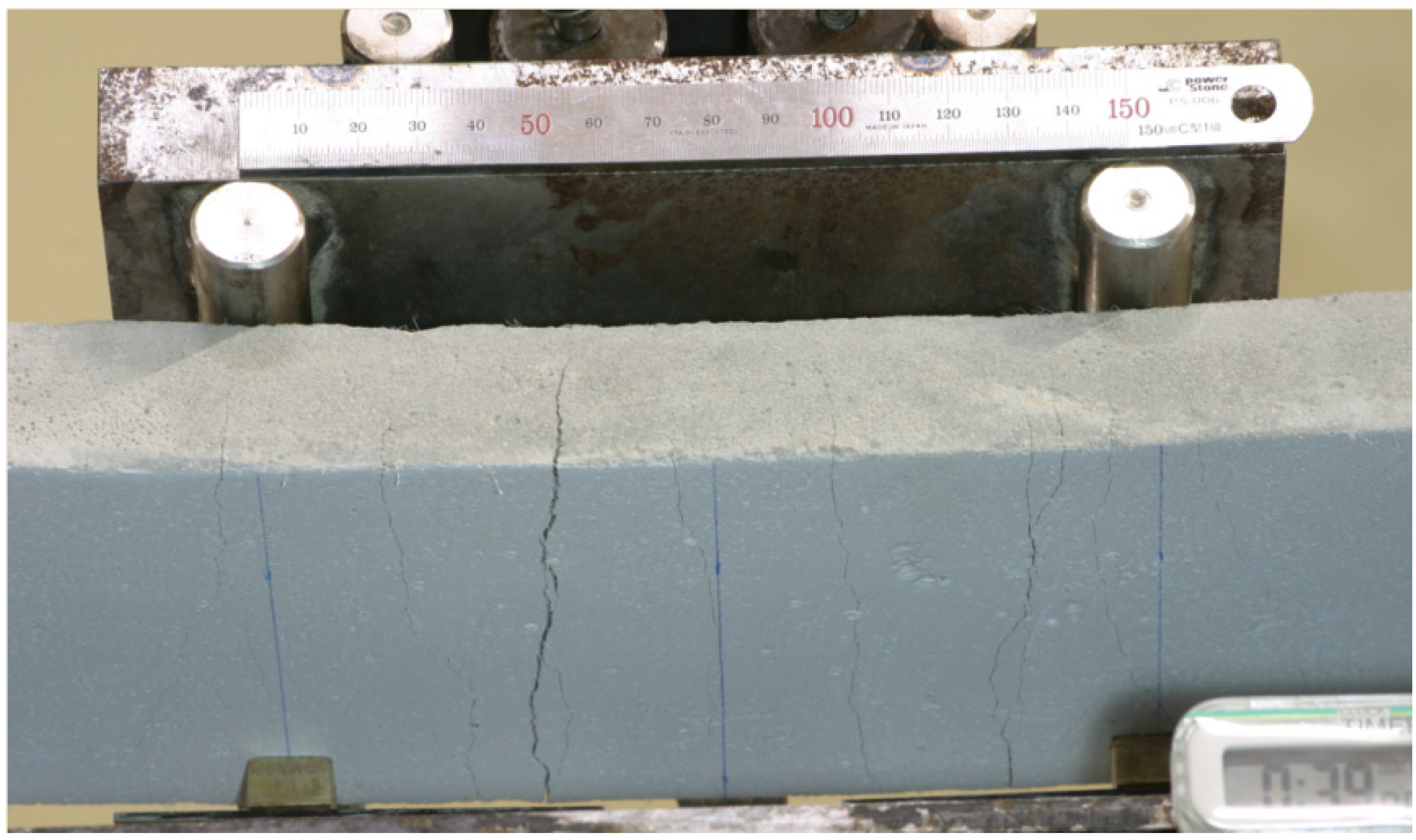

2.4. Flexural Test

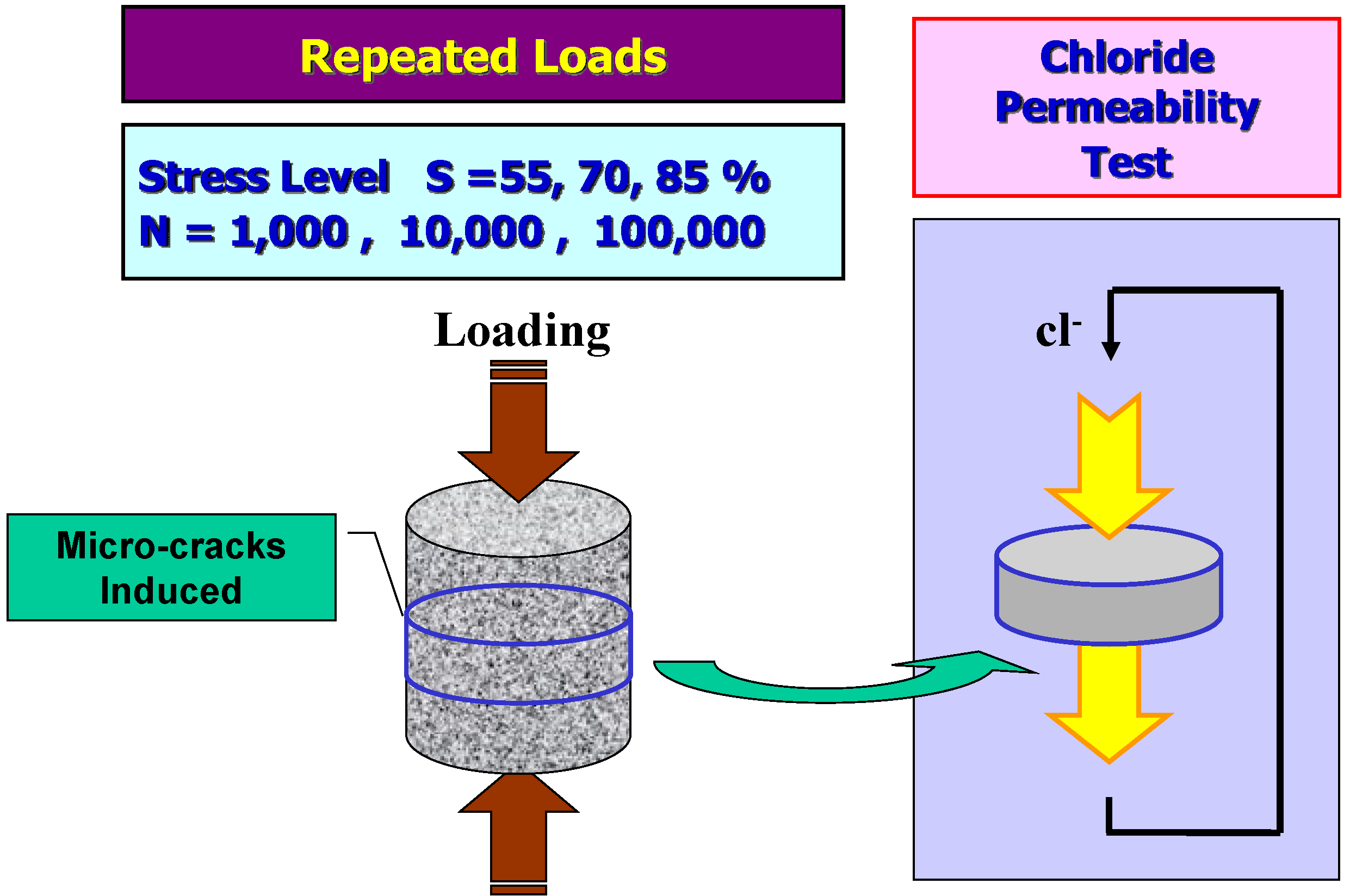

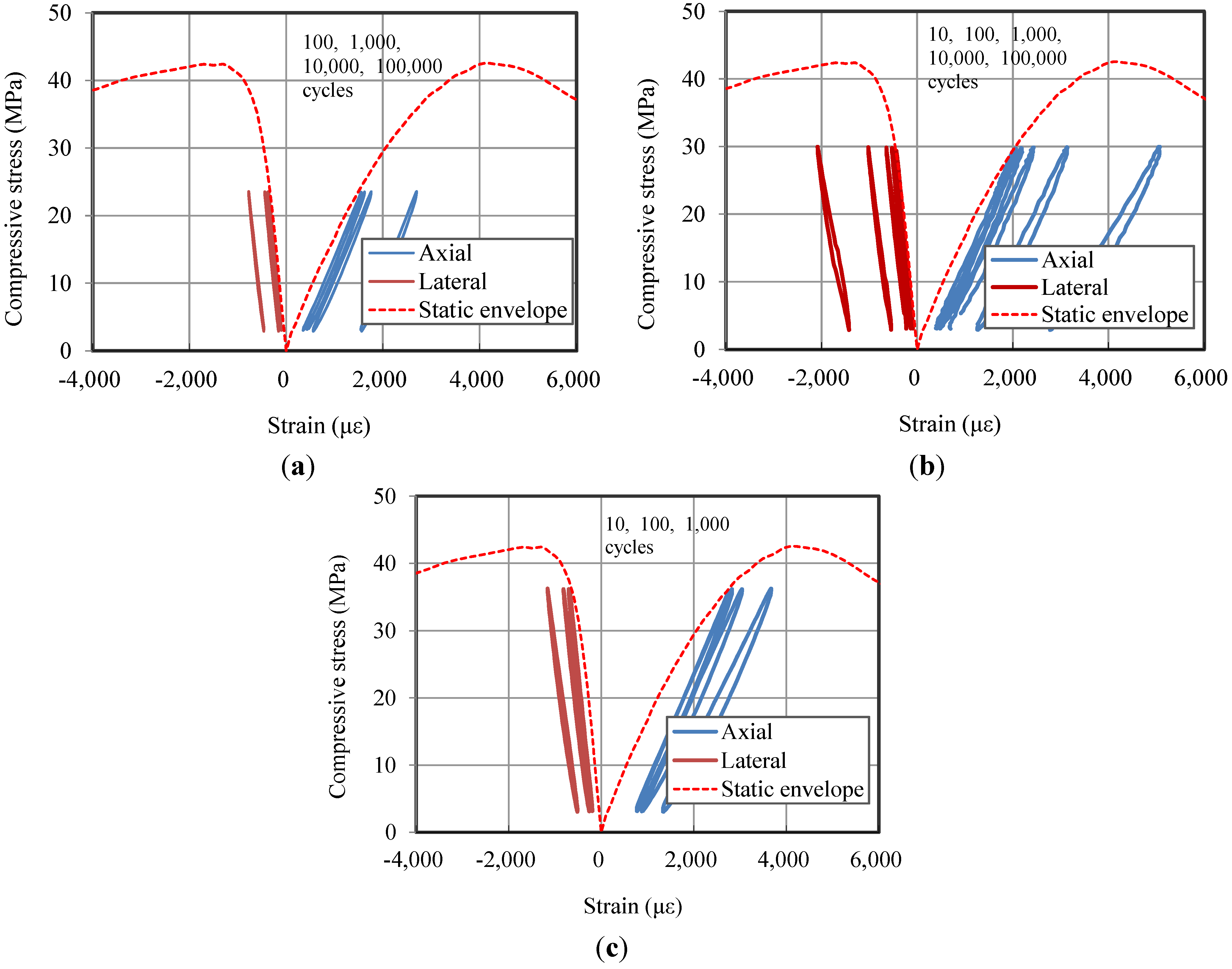

2.5. Specimens Damaged by Repeated Loads

2.6. Damage Evaluation

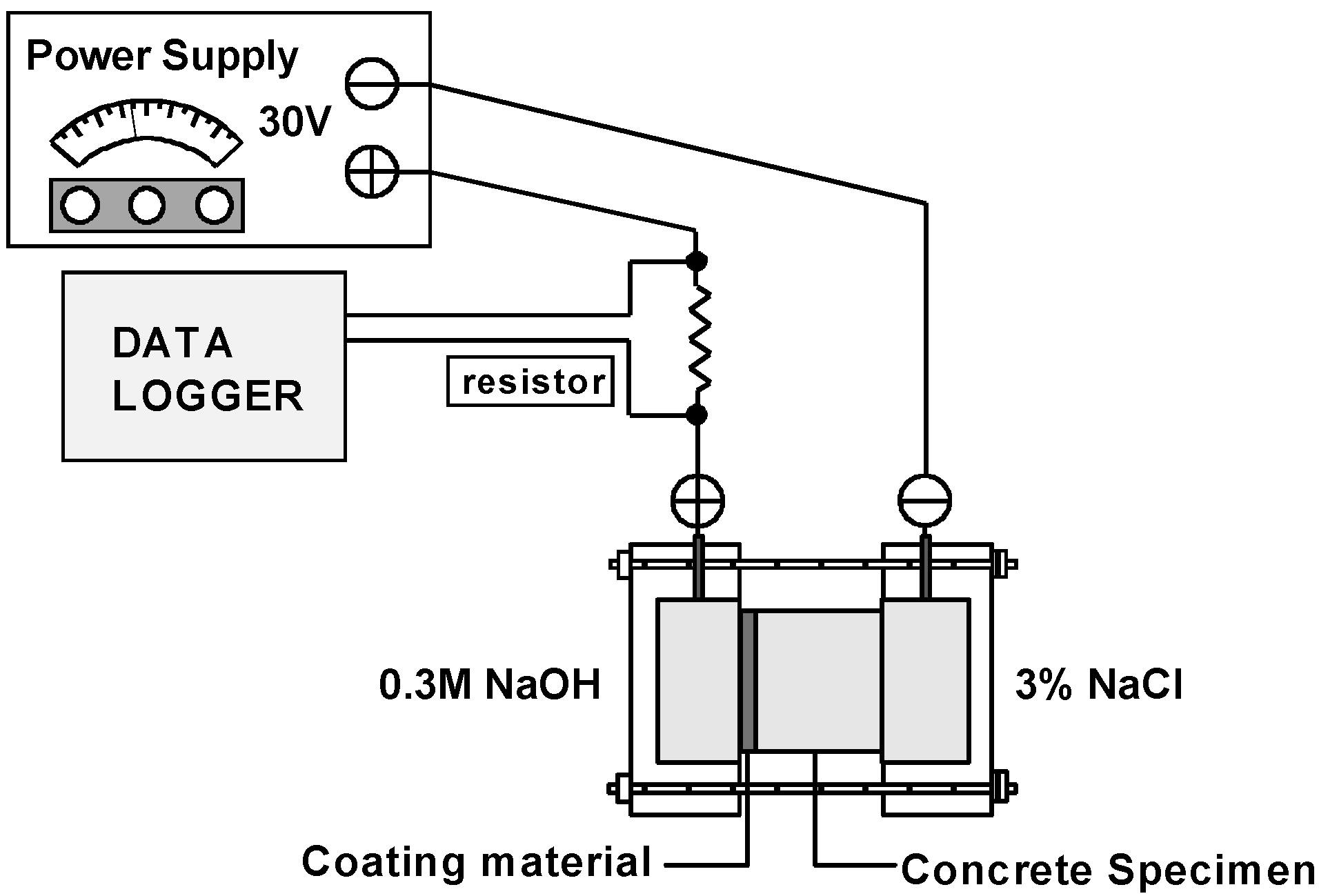

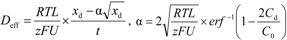

2.7. Chloride Permeability Tests

3. Results and Discussion

3.1. Static Behaviors

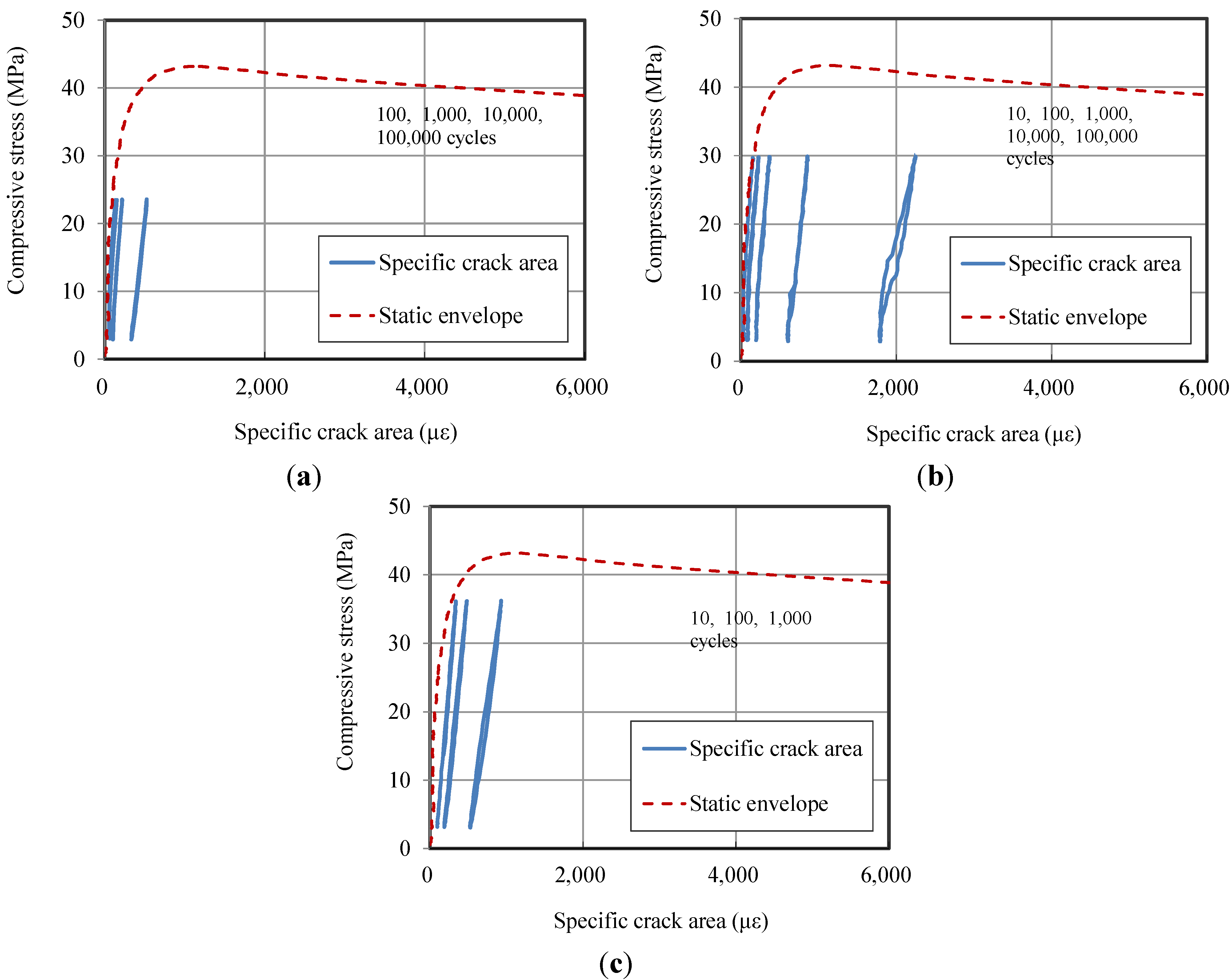

3.2. Cyclic Behaviors

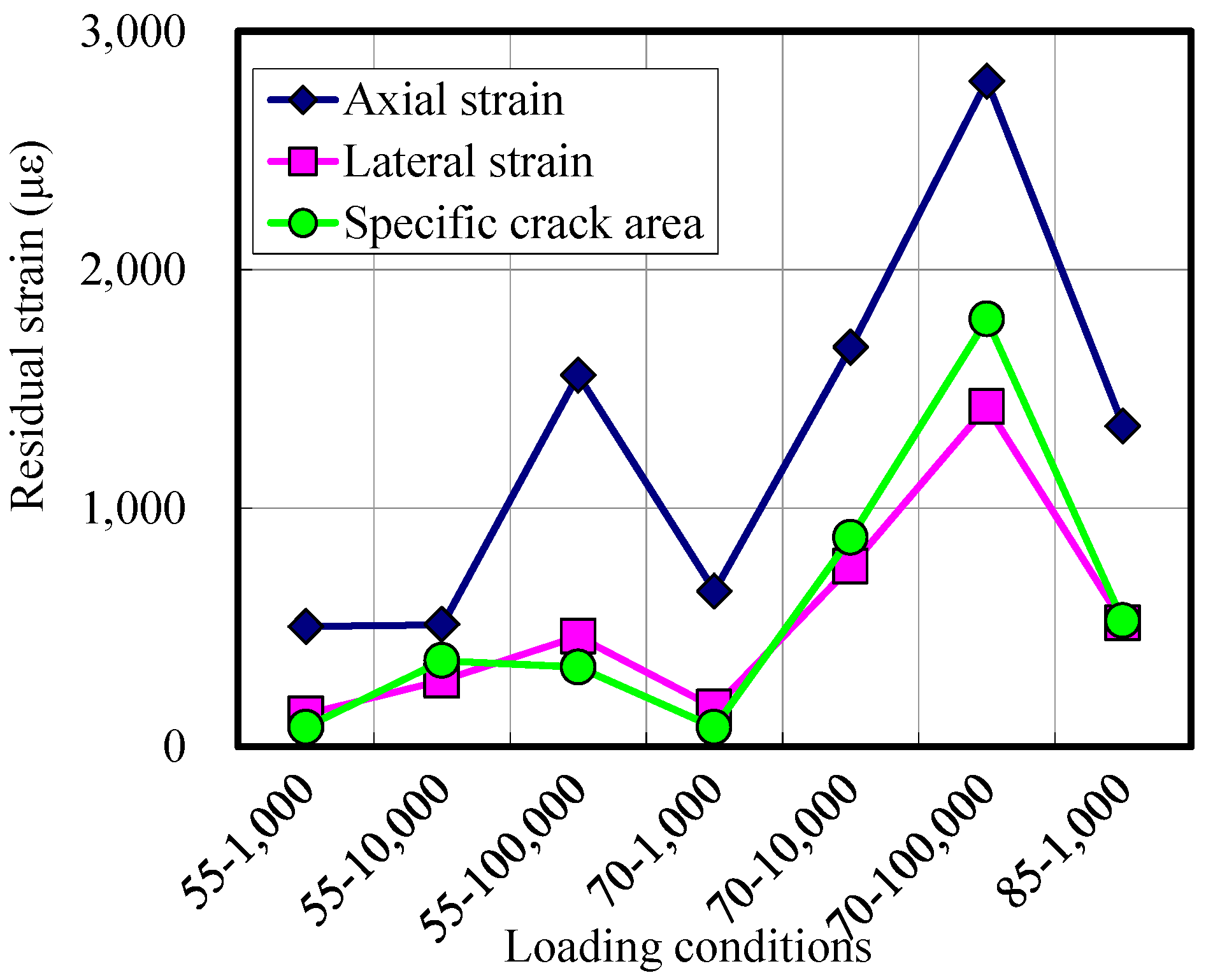

3.3. Damage Induced

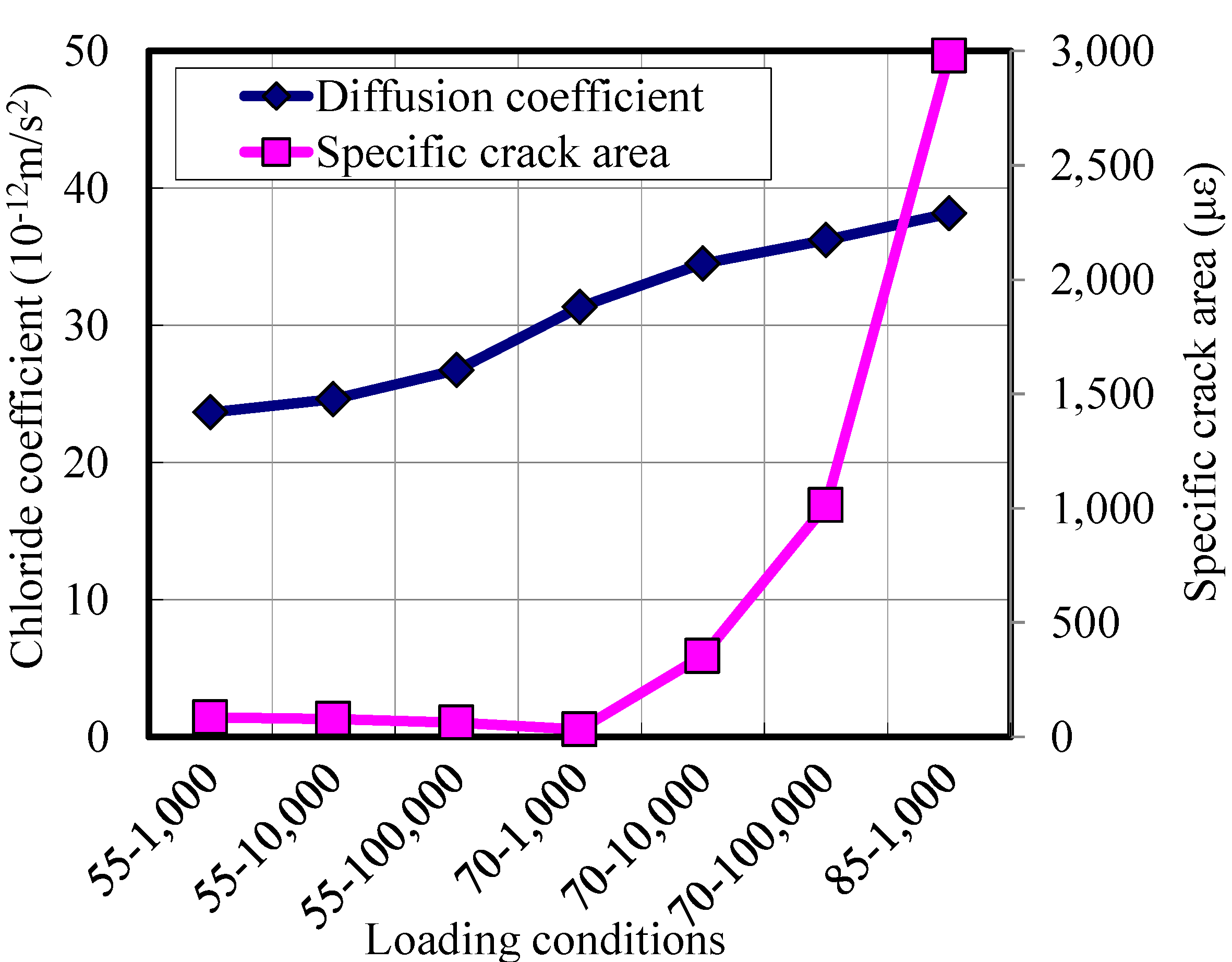

3.4. Chloride Permeability

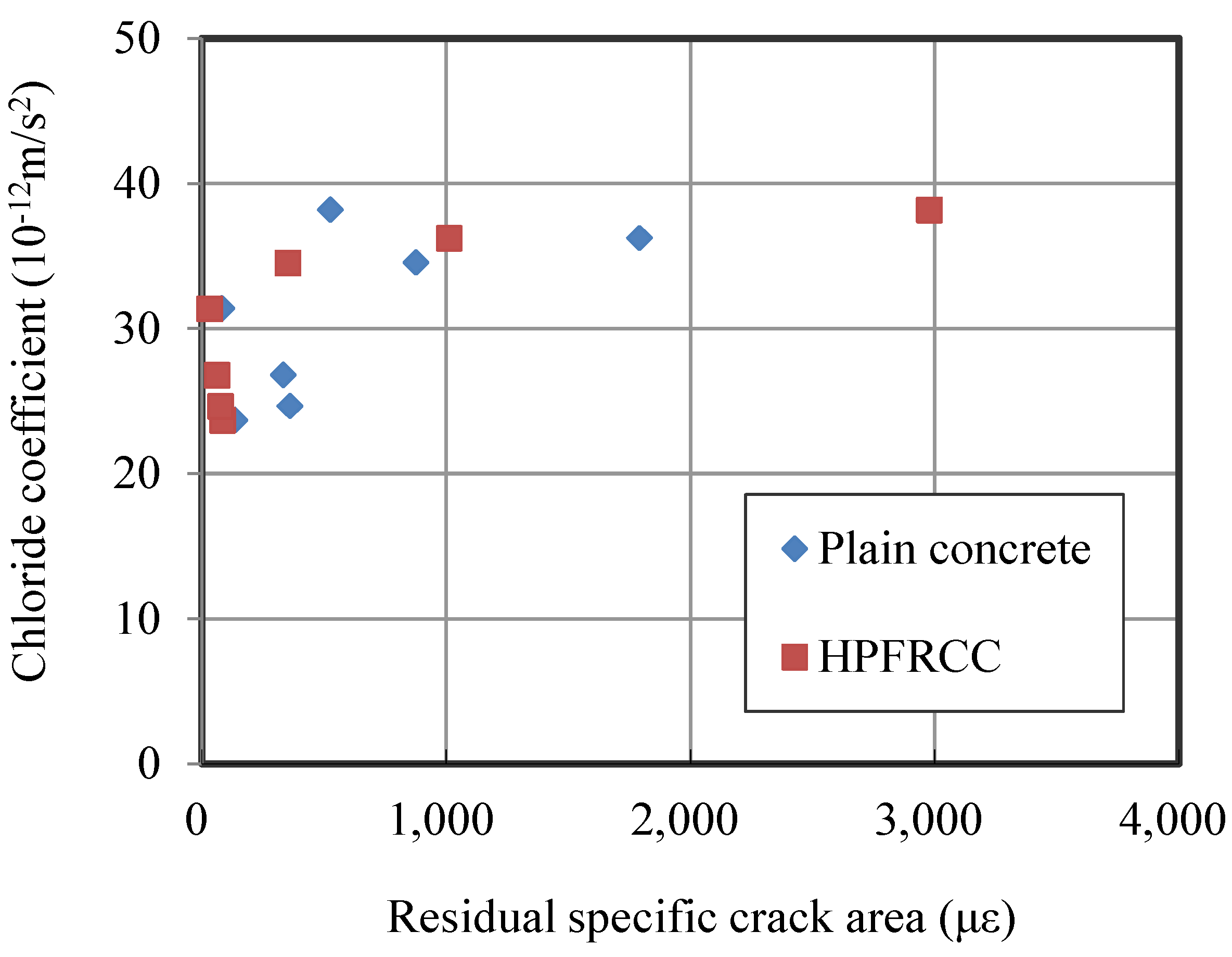

3.5. Comparison with Plain Concrete Specimens

4. Conclusions

- (1)

- Static mechanical tests show that the material used in this study has the typical characteristics of ductile HPFRCC. In the flexural test, specimens sustained the load continuously, even after peak load, and strain hardening behavior was observed, with finely-distributed microcracks.

- (2)

- Artificial damage was induced by applying repeated loads on the specimen. The results of HPFRCC specimen tests show that the residual axial strain, lateral strain and specific crack area increase due to the damage induced by repeated loads. However, the chloride diffusion coefficient does not increase significantly. The chloride diffusion coefficient increases up to 1.5-times, whereas the specific crack area increases up to 3-times with an increase of damage. Plain concrete specimens also show the same trends as the HPFRCC specimens. This is due to the fact that the repeated compressive loads applied in this test induce only microcracks that cannot cause any dramatic increase of permeability, regardless of the material type.

- (3)

- When a large deformation, causing a large amount of cracks, is applied to the specimen, finely-distributed cracks of HPFRCC can be a benefit in terms of the restriction of the crack width and reducing chloride permeability. However, for a moderate compressive load, which was below 85% of the static strength, the benefit of HPFRCC on the chloride diffusion coefficient is not significant. Because the compressive load does not induce dominant wide cracks in a stress level below 85% of the static strength, only small-scale damage is induced, even for plain concrete. Therefore, HPFRCC and plain concrete do not show significant differences in crack areas and chloride diffusion coefficients.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Balaguru, P.; Shah, S.P. Fiber-Reinforced Cement Composites; Elsevier: Amsterdam, The Netherlands, 1992. [Google Scholar]

- Mehta, P.; Monteiro, J.M. Concrete: Microstructure,Properties, and Materials; McGraw-Hill: New York, NY, USA, 2005. [Google Scholar]

- Bentur, A.; Mindess, S. Fiber Reinforced Cementitious Composites; McGraw-Hill: New York, NY, USA, 1990. [Google Scholar]

- Rapoport, J.; Aldea, C.-M.; Shah, S.P.; Ankenman, B.; Karr, A.F. Permeability of Cracked Steel Fiber-Reinforced Concrete; National Institute of Statistical Sciences (NISS) Technical Report Number 115; NISS: Research Triangle Park, NC, USA, 2001. [Google Scholar]

- Naaman, A.E.; Reinhardt, H.W. High Performance Fiber Reinforced Cement Composites 2 (HPFRCC2); E&FN Spon: London, UK, 1995. [Google Scholar]

- Li, V.C.; Wang, S.; Wu, C. Tensile strain-hardening behavior of polyvinyl alcohol engineered cementitious composite (PVA-ECC). ACI Mater. J. 2001, 98, 483–492. [Google Scholar]

- Herbert, E.N.; Li, V.C. Self-Healing of microcracks in engineered cementitious composite(ECC) under a natural environment. Materials 2013, 6, 2831–2845. [Google Scholar]

- Kim, Y.Y.; Kong, H.J.; Li, V.C. Design of engineered cementitious composite (ECC) suitable for wet-mix shotcreting. ACI Mater. J. 2003, 100, 511–518. [Google Scholar]

- Guerrini, G.L. Applications of high-performance fiber-reinforced cement-based composites. Appl. Compos. Mater 2000, 7, 195–207. [Google Scholar]

- Ann, K.Y.; Cho, C.G. Corrosion resistance of calcium aluminate cement concrete exposed to a chloride environment. Materials 2014, 7, 887–898. [Google Scholar]

- Sahmaran, M.; Li, M.; Li, V.C. Transport properties of engineered cementitious composites under chloride exposure. ACI Mater. J 2007, 104, 303–310. [Google Scholar]

- Lepech, M.D.; Li, V.C. Water permeability in engineered cementitious composites. Cem. Concr. Compos 2009, 31, 744–753. [Google Scholar]

- Charron, J.-P.; Denarié, E.; Brühwiler, E. Transport properties of water and glycol in an ultra high performance fiber reinforced concrete (UHPFRC) under high tension deformation. Cem. Concr. Res 2008, 38, 689–698. [Google Scholar]

- Banthia, N.; Bhargava, A. Permeability of stressed concrete and role of fiber reinforcement. ACI Mater. J 2007, 104, 70–76. [Google Scholar]

- Saito, M.; Ishimori, H. Chloride permeability of concrete under static and repeated compressive loading. Cem. Concr. Res 1995, 25, 803–808. [Google Scholar]

- Djerbi, A.; Bonnet, S.; Khelidj, A.; Baroghel-bouny, V. Influence of traversing crack on chloride diffusion into concrete. Cem. Concr. Res 2008, 38, 877–883. [Google Scholar]

- Djerbi, A.; Bonnet, S.; Khelidj, A.; Baroghel-Bouny, V. Effect of uniaxial compressive loading on gas permeability and chloride diffusion coefficient of concrete and their relationship. Cem. Concr. Res 2013, 52, 131–139. [Google Scholar]

- Li, V.C.; Mishra, D.K.; Wu, H.C. Matrix design for pseudo-strain-hardening fibre reinforced cementitious composites. Mater. Struct 1995, 28, 586–595. [Google Scholar]

- Naaman, A.E.; Reinhardt, H.W. Setting the stage: Toward performance based classification of FRC composites. In High Performance Fiber Reinforced Cement Composites 4; RILEM Publications: Bagneux, France, 2003; pp. 1–4. [Google Scholar]

- Loo, Y.H. A new method for microcrack evaluation in concrete under compression. Mater. Struct 1992, 25, 573–578. [Google Scholar]

- Tang, L.P.; Nilsson, L.O. Chloride binding capacity, penetration and pore structures of blended cement pastes with slag and fly ash, blended cements in construction. In Proceedings of the International Conference on Blended Cements in Construction, Sheffield, UK, 9–12 September 1991; University of Sheffield; pp. 377–388.

- Hsu, T.T.C.; Slate, F.O.; Sturman, G.M.; Winter, G. Microcracking of plain concrete and the shape of the stress-strain curve. ACI Mater. J 1963, 60, 209–224. [Google Scholar]

- Samaha, H.R.; Hover, K.C. Influence of microcracking on the mass transport properties of concrete. ACI Mater. J. 1992, 89, 416–424. [Google Scholar]

- Ludirdja, D.; Berger, R.L.; Young, J.F. Simple method for measuring water permeability of concrete. ACI Mater. J. 1989, 86, 433–439. [Google Scholar]

- Güneyisi, E.; Gesoğlu, M.; Özturan, T.; Özbay, E. Estimation of chloride permeability of concretes by empirical modeling: Considering effects of cement type, curing condition and age. Constr. Build. Mater 2009, 23, 469–481. [Google Scholar] [CrossRef]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Lee, B.J.; Hyun, J.H.; Kim, Y.Y.; Shin, K.J. Chloride Permeability of Damaged High-Performance Fiber-Reinforced Cement Composite by Repeated Compressive Loads. Materials 2014, 7, 5802-5815. https://doi.org/10.3390/ma7085802

Lee BJ, Hyun JH, Kim YY, Shin KJ. Chloride Permeability of Damaged High-Performance Fiber-Reinforced Cement Composite by Repeated Compressive Loads. Materials. 2014; 7(8):5802-5815. https://doi.org/10.3390/ma7085802

Chicago/Turabian StyleLee, Byung Jae, Jung Hwan Hyun, Yun Yong Kim, and Kyung Joon Shin. 2014. "Chloride Permeability of Damaged High-Performance Fiber-Reinforced Cement Composite by Repeated Compressive Loads" Materials 7, no. 8: 5802-5815. https://doi.org/10.3390/ma7085802

APA StyleLee, B. J., Hyun, J. H., Kim, Y. Y., & Shin, K. J. (2014). Chloride Permeability of Damaged High-Performance Fiber-Reinforced Cement Composite by Repeated Compressive Loads. Materials, 7(8), 5802-5815. https://doi.org/10.3390/ma7085802