Surface Coating of Oxide Powders: A New Synthesis Method to Process Biomedical Grade Nano-Composites

Abstract

:1. Introduction: A Brief History from Pure Monolithic to Composite Bioceramics

- (i)

- High mechanical properties (in terms of flexural strength, elastic modulus, fracture toughness, and fatigue resistance). It should be kept in mind that the loads in the body can vary from three times the body weight (~3 kN) for normal walking to eight times the body weight (~8 kN) for jogging or stumbling;

- (ii)

- High corrosion resistance and biocompatibility in vivo;

- (iii)

- High hardness and good surface finish, for ensuring long term wear resistance;

- (iv)

- Good wetting, for providing good lubrication between the implant surface and the synovial fluids.

| Property | Alumina: 1970s | Alumina: 1980s | Alumina: 1990s | ISO Alumina Standard 6474 |

|---|---|---|---|---|

| Density (g/cm3) | 3.94 | 3.96 | 3.98 | >3.90 |

| Mean grain size (μm) | 4.5 | 3.2 | 1.8 | <7 |

| Bending strength (MPa) | 400 | 500 | 580 | >400 (in Ringer’s solution) |

| Vickers Hardness (HV) | 1800 | 1900 | 2000 | >2000 |

| Hot Isostatic pressed | No | No | Yes | – |

2. Microstructure-Properties Relationship in Composite Bioceramics

3. Synthesis Methods to Produce Biomedical-Grade Ceramic Composites: A Focus on the Surface-Coating Strategy

4. Case Studies

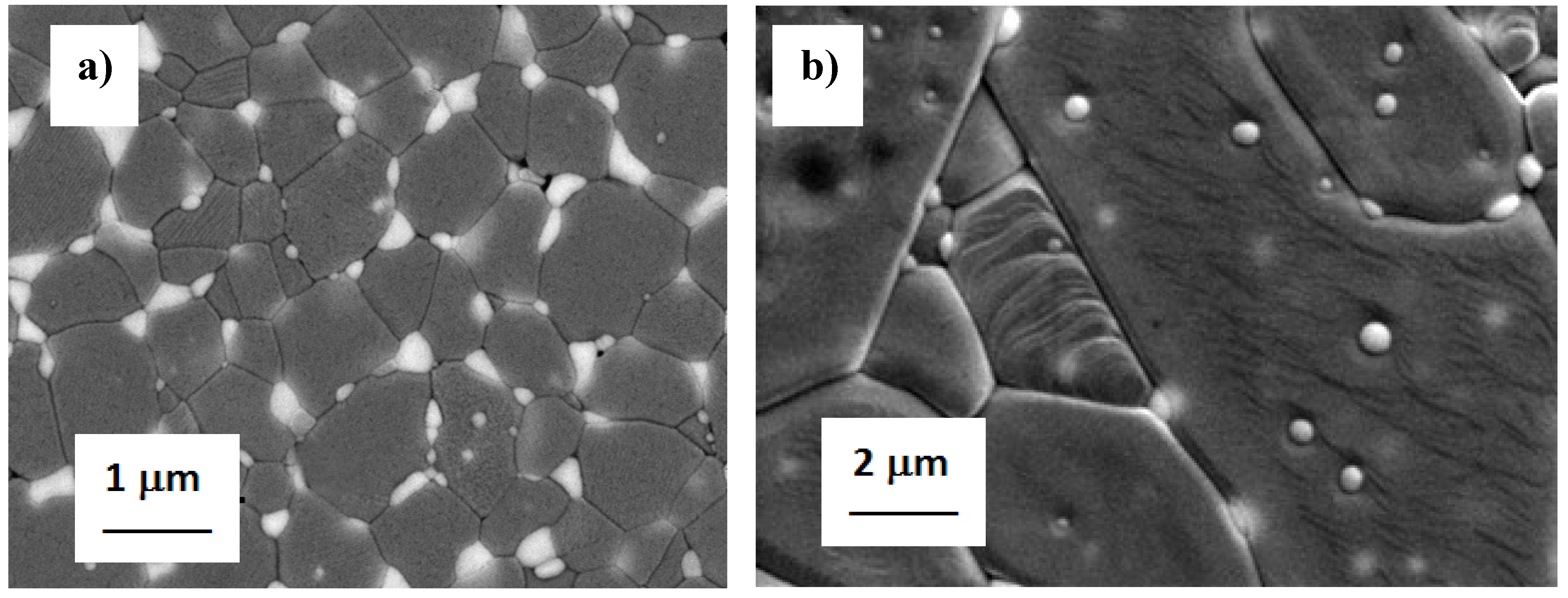

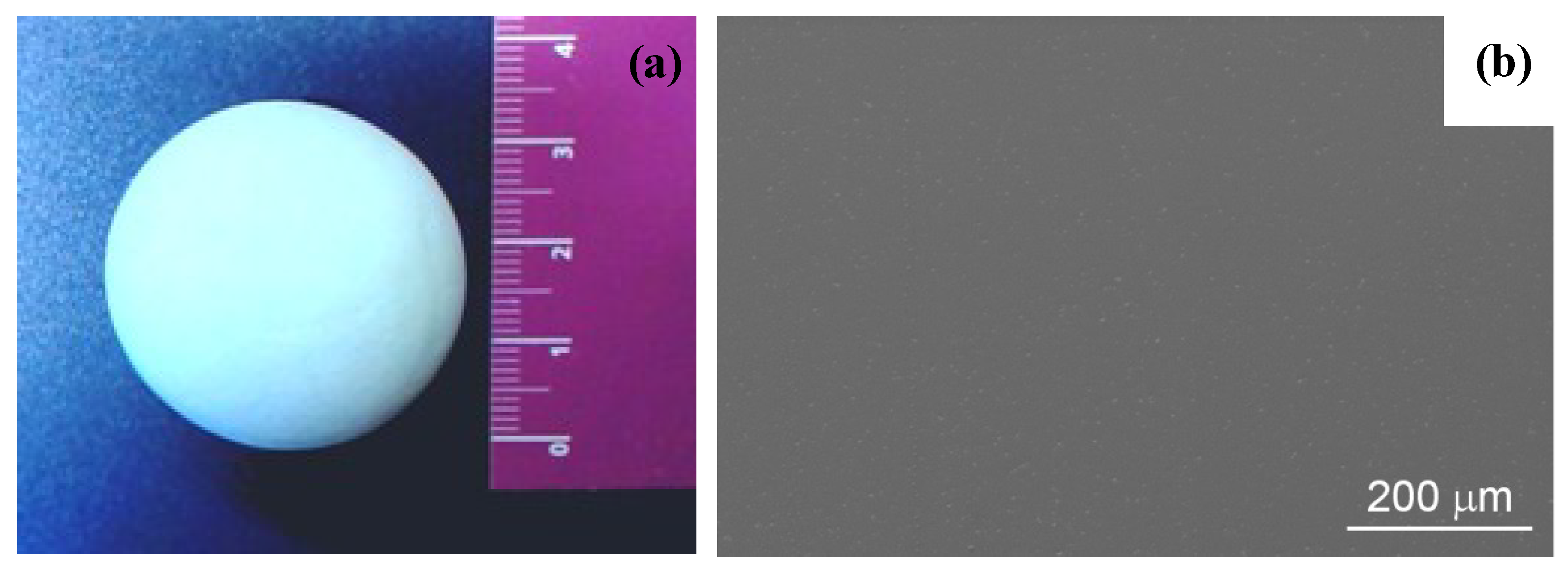

4.1. ZTA for Orthopedic Applications

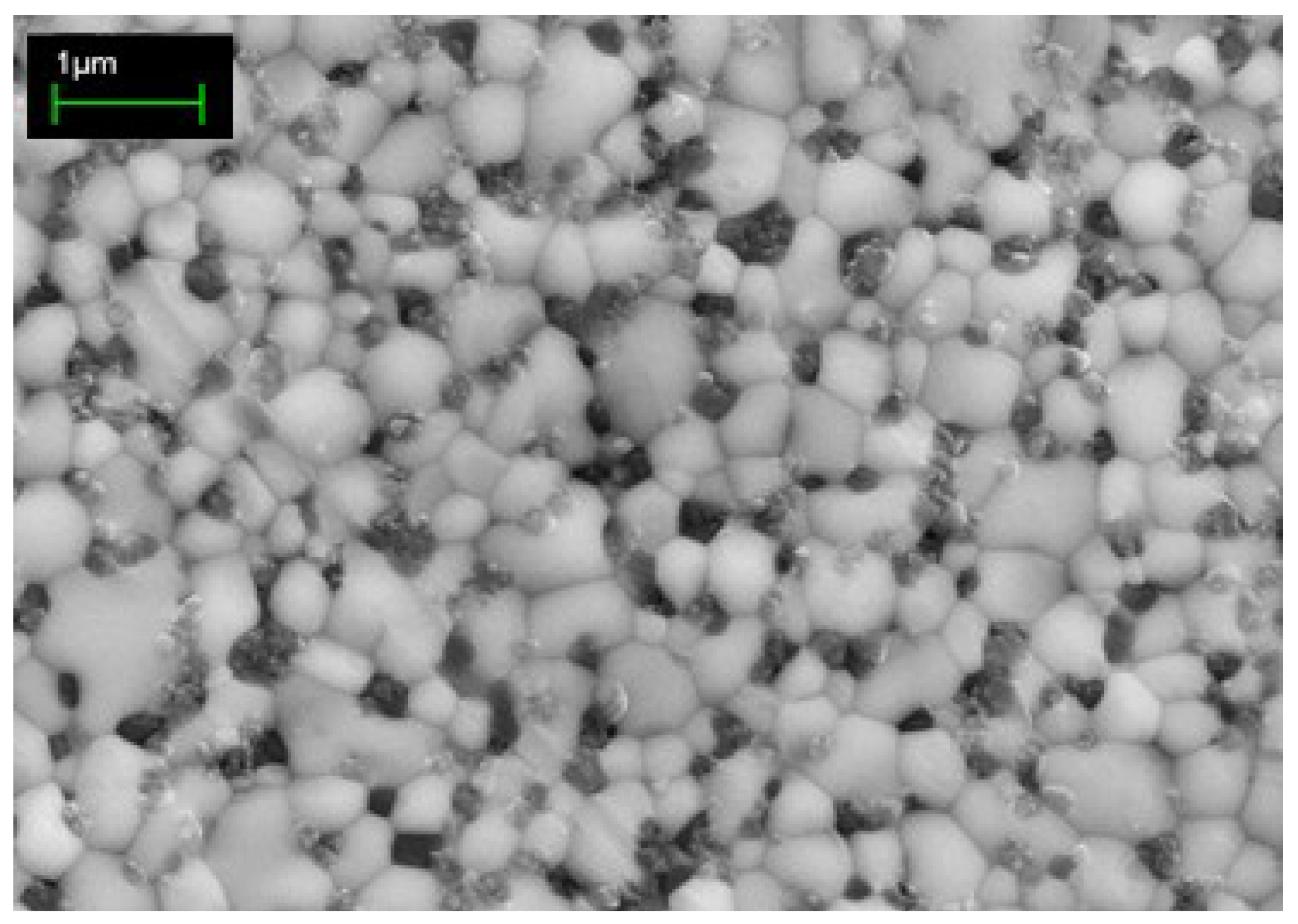

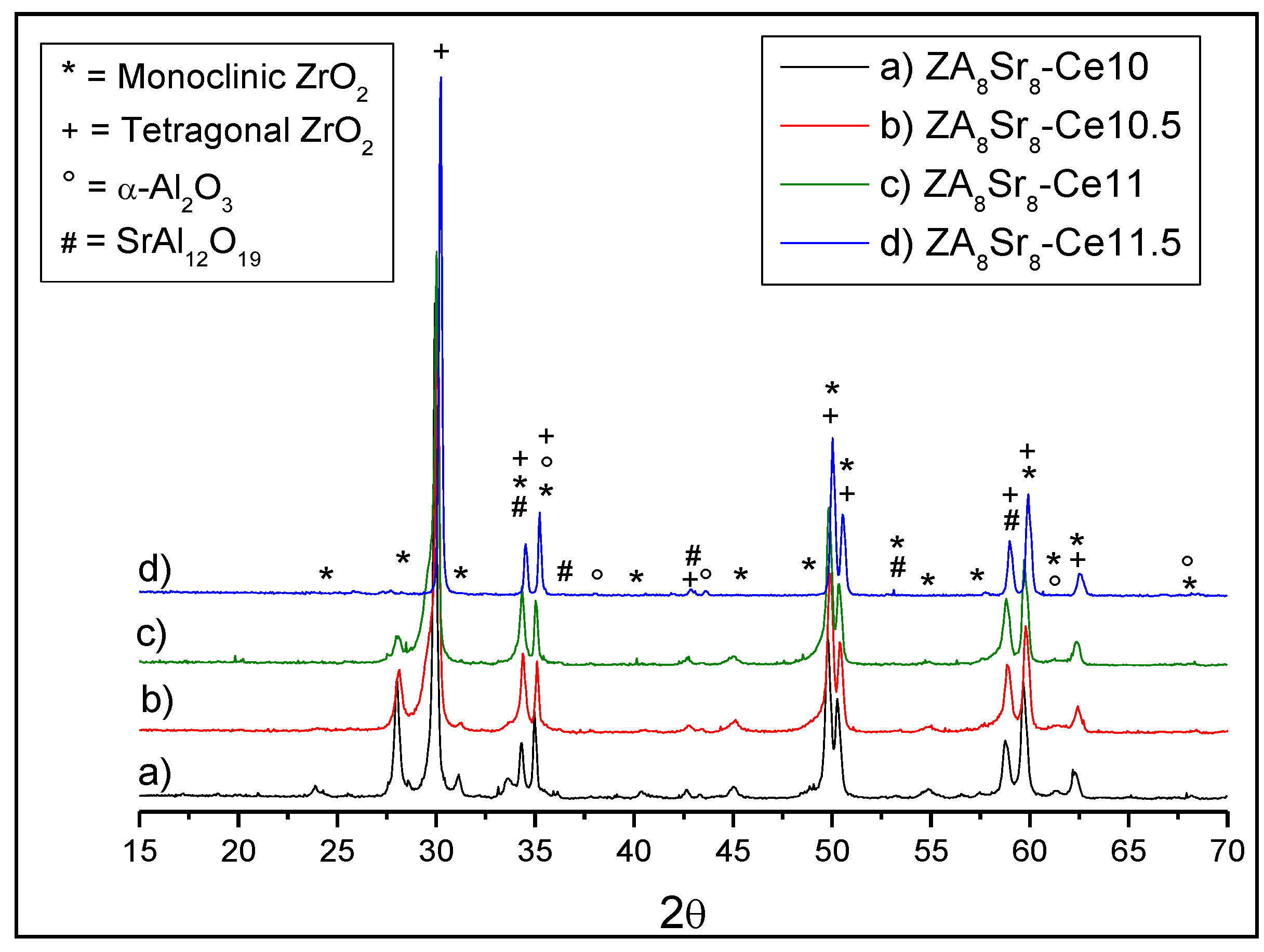

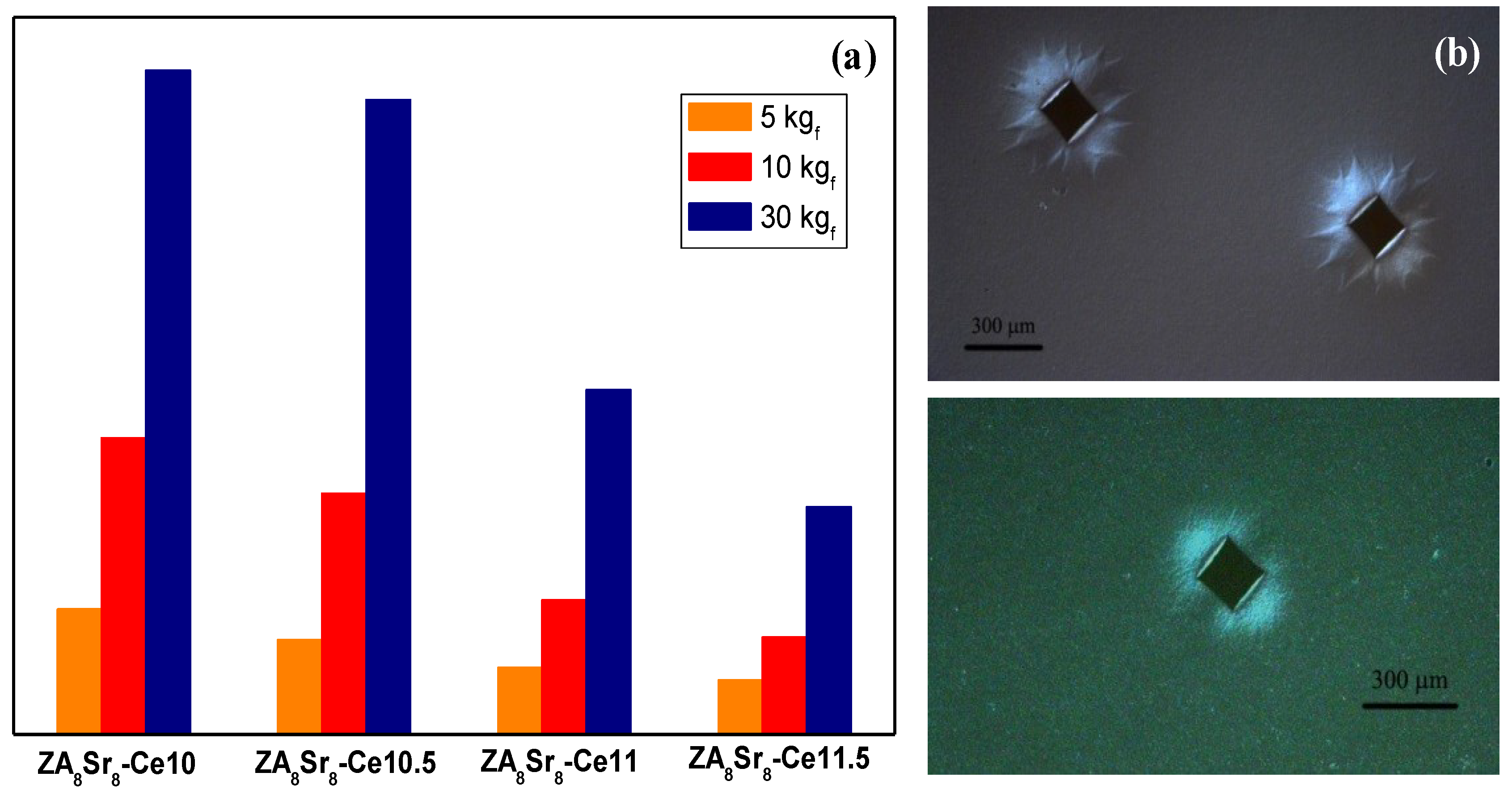

4.2. Zirconia-Based Composites for Dental Applications

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Hench, L.L. Bioceramics. J. Am. Ceram. Soc. 1998, 81, 1705–1728. [Google Scholar] [CrossRef]

- Rahaman, M.N.; Yao, A.; Bal, B.S.; Garino, J.P.; Ries, M.D. Ceramics for prosthetic hip and knee joint replacement. J. Am. Ceram. Soc. 2007, 90, 1965–1988. [Google Scholar] [CrossRef]

- Willmann, G. Ceramic femoral head retrieval data. Clin. Orthop. Relat. R. 2000, 379, 22–28. [Google Scholar] [CrossRef]

- Willmann, G. Development in medical-grade alumina during the past two decades. J. Mater. Process. Technol. 1996, 56, 168–176. [Google Scholar] [CrossRef]

- Piconi, C.; Condo, S.C.; Kosmač, T. Chapter 11. Alumina and zirconia-based ceramics for load-bearing applications. In Advanced Ceramic for Dentistry; Shen, J., Kosmač, T., Eds.; Butterworth-Heinemann (Elsevier): Wathmann, MA, USA, 2014; pp. 219–253. [Google Scholar]

- Rieger, W. Ceramics in orthopedics. 30 years of evolution and experience. In World Tribology Forum in Arthoplasty; Rieker, C., Oberjolzer, S., Wyss, U., Eds.; Verlag Hans Huber: Bern, Germany, 2001; pp. 1–13. [Google Scholar]

- Piconi, C.; Maccauro, G. Zirconia as a ceramic biomaterial. Biomaterials 1999, 20, 1–25. [Google Scholar] [CrossRef]

- Marshall, D.B.; Ritter, J.E. Reliability of advanced structural ceramics and ceramic matrix composites. A review. Ceram. Bull. 1987, 66, 309–317. [Google Scholar]

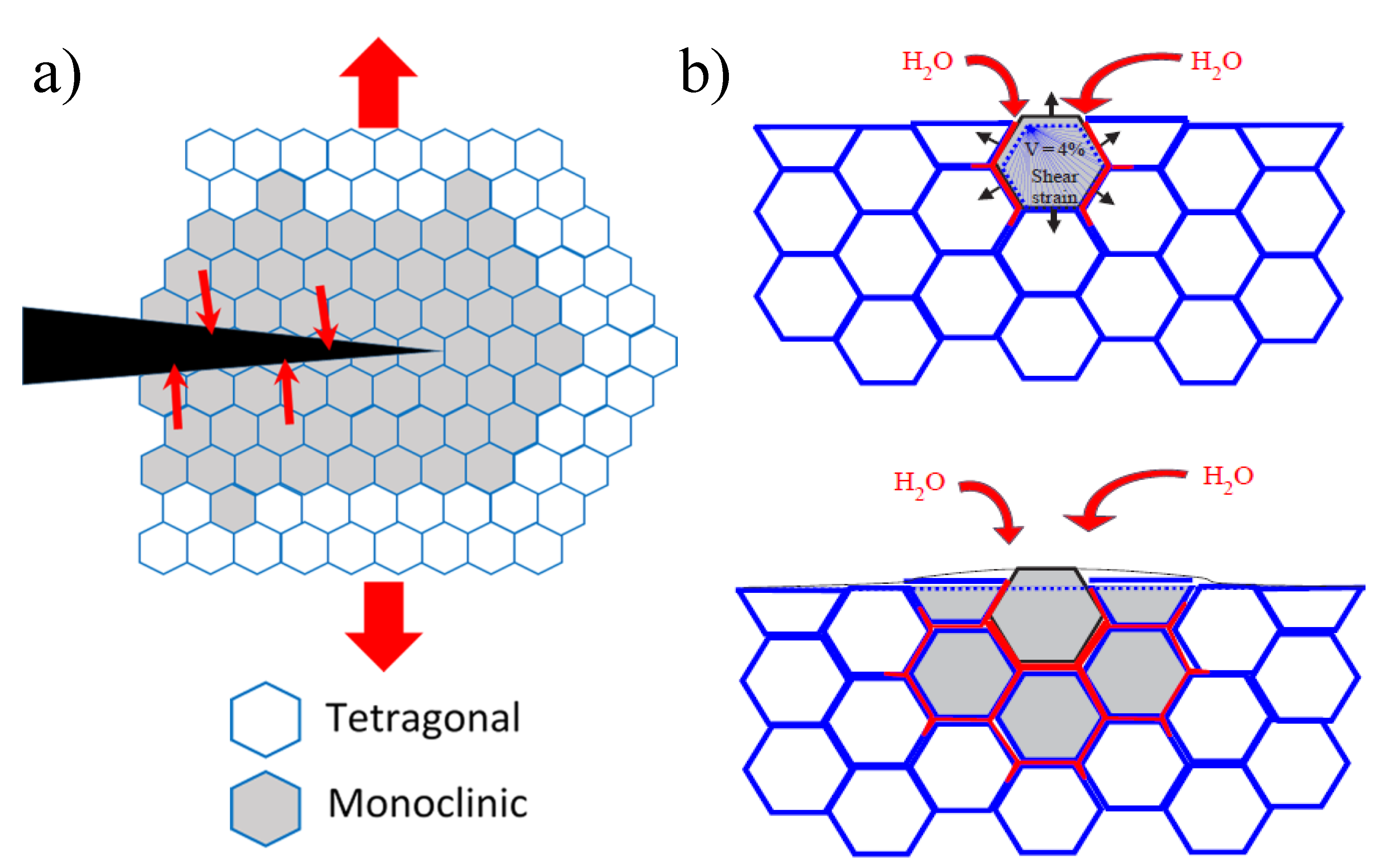

- Chevalier, J.; Gremillard, L.; Virkar, A.V.; Clarke, D.R. The Tetragonal-monoclinic transformation in zirconia: Lesson learned and future trends. J. Am. Ceram. Soc. 2009, 92, 1901–1920. [Google Scholar]

- Lawson, S. Environmental degradation of zirconia ceramics. J. Eur. Ceram. Soc. 1995, 15, 485–502. [Google Scholar] [CrossRef]

- Lughi, V.; Sergo, V. Low temperature degradation—aging—of zirconia. A critical review of the relevant aspects in dentistry. Dent. Mater. 2010, 26, 807–820. [Google Scholar] [CrossRef]

- Chevalier, J.; Gremillard, L. Ceramics for medical applications: A picture for the next 20 years. J. Eur. Ceram. Soc. 2009, 29, 1245–1255. [Google Scholar] [CrossRef]

- Schubert, H.; Frey, F. Stability of Y-TZP during hydrothermal treatment: Neutron experiments and stability considerations. J. Eur. Ceram. Soc. 2005, 25, 1597–1602. [Google Scholar] [CrossRef]

- Lange, F.F.; Dunlop, G.L.; Davis, B.L. Degradation during aging of transformation-toughened ZrO2-Y2O3 materials at 250 °C. J. Am. Ceram. Soc. 1986, 69, 237–240. [Google Scholar] [CrossRef]

- Chevalier, J.; Cales, B.; Drouin, J.M. Low-temperature ageing of Y-TZP ceramics. J. Am. Ceram. Soc. 1999, 82, 2150–2154. [Google Scholar] [CrossRef]

- Chevalier, J. What future for zirconia as a biomaterial? Biomaterials 2006, 27, 535–543. [Google Scholar] [CrossRef]

- Chevalier, J.; Gremillard, L. Zirconia as a biomaterial. In Comprehensive Biomaterials; Ducheyne, P., Ed.; Elsevier: Amsterdam, The Netherlands, 2011; volume 1, pp. 95–108. [Google Scholar]

- Guazzato, M.; Albakry, M.; Ringer, S.P.; Swain, M.V. Strength, fracture toughness and microstructure of a selection of all-ceramic materials. Part II. Zirconia-based dental ceramics. Dent. Mater. 2004, 20, 449–456. [Google Scholar] [CrossRef]

- Denry, I.; Holloway, J.A. Ceramics for dental applications: A review. Materials 2010, 3, 351–368. [Google Scholar] [CrossRef]

- Rieger, W.; Kobel, S.; Weber, W. Processing and Properties of Zirconia Ceramics for Dental Applications. Spectrum Dialogue, Reprint, March 2008. Available online: http://www.lastruttura.it/Contents/Documents/3%20Premium%20HT/Letteratura%20zirconia%20dentale.pdf (accessed on 26 June 2014).

- Cattani-Lorente, M.; Scherrer, S.S.; Ammann, P.; Jobin, M.; Wiskott, A. Low temperature degradation of a Y-TZP dental ceramic. Acta Biomater. 2011, 7, 858–865. [Google Scholar] [CrossRef]

- Kohorst, P.; Borchers, L.; Strempel, J.; Stiesch, M.; Hassel, T. Low-temperature degradation of different zirconia ceramics for dental applications. Acta Biomater. 2012, 8, 1213–1220. [Google Scholar]

- Denry, I.; Kelly, J.R. State of art of zirconia for dental applications. Dent. Mater. 2008, 24, 299–307. [Google Scholar] [CrossRef]

- Kurtz, S.M.; Kocagöz, S.; Arnholt, C.; Huet, R.; Ueno, M.; Walter, W.L. Advances in zirconia toughened alumina biomaterials for total joint replacement. J. Mech. Behav. Biomed. 2014, 31, 107–116. [Google Scholar] [CrossRef]

- Evans, A.G.; Burlingame, N.; Drory, M.; Kriven, W.M. Martensitic transformations in zirconia—Particle size effects and toughening. Acta Metall. 1981, 29, 447–456. [Google Scholar] [CrossRef]

- Heuer, A.H.; Claussen, N.; Kriven, W.M.; Rühle, M. Stability of tetragonal ZrO2 particles in ceramic matrices. J. Am. Ceram. Soc. 1982, 65, 642–650. [Google Scholar] [CrossRef]

- Pecharroman, C.; Bartolomé, J.F.; Requena, J.; Moya, J.S.; Deville, S.; Chevalier, J.; Fantozzi, G.; Torrecillas, R. Percolative mechanism of ageing in zirconia containing ceramics for medical applications. Adv. Mater. 2003, 15, 507–511. [Google Scholar] [CrossRef]

- Stewart, T.D.; Tipper, J.L.; Insley, G.; Streicher, R.M.; Ingham, E.; Fisher, J. Long-term wear of ceramic matrix composite materials for hip prostheses under severe swing phase microseparation. J. Biomed. Mater. Res. B. 2003, 66B, 567–573. [Google Scholar]

- Guo, R.; Guo, D.; Chen, Y.; Yang, Z.; Yuan, Q. In situ formation of LaAl11O18 rodlike particles in ZTA ceramics and effect on the mechanical properties. Ceram. Int. 2001, 28, 699–704. [Google Scholar]

- Liu, X.Q.; Chen, X.M. Effects of Sr2Nb2O7 additive on microstructure and mechanical properties of 3Y-TZP/Al2O3 ceramics. Ceram. Int. 2002, 28, 209–215. [Google Scholar] [CrossRef]

- Sktania, Z.D.I.; Azharb, A.Z.A.; Ratnamc, M.M.; Ahmada, Z.A. The influence of in-situ formation of hibonite on the properties of zirconia toughened alumina (ZTA) composites. Ceram. Int. 2014, 40, 6211–6217. [Google Scholar] [CrossRef]

- Jin, X.; Gao, L. Effects of powder preparation method on the microstructure and mechanical performance of ZTA/LaAl11O18 composites. J. Eur. Ceram. Soc. 2004, 24, 653–659. [Google Scholar] [CrossRef]

- Chen, Z.; Chawla, K.K.; Koopman, M. Microstructure and mechanical properties of in situ synthesized alumina/Ba-β-alumina/zirconia composites. Mater. Sci. Eng. A 2004, 367, 24–32. [Google Scholar] [CrossRef]

- Sato, T.; Endo, T.; Shimada, M. Postsintering hot isostatic pressing of ceria-doped tetragonal zirconia/alumina composites in an argon oxygen gas atmosphere. J. Am. Ceram. Soc. 1989, 72, 761–764. [Google Scholar] [CrossRef]

- Nawa, M. Tough and strong Ce-TZP/alumina nanocomposites doped with titania. Ceram. Int. 1998, 24, 497–506. [Google Scholar] [CrossRef]

- Nawa, M. The effect of TiO2 addition on strength and toughening in intragranular type 12Ce-TZP/Al2O3 nanocomposites. J. Eur. Ceram. Soc. 1998, 18, 209–219. [Google Scholar] [CrossRef]

- Panasonic Biomedical. Available online: http://www.die-modellmacher.de/wp-content/uploads/Nano-ZR-brochure.pdf (accessed on 26 June 2014).

- Apel, E.; Ritzberger, C.; Courtois, N.; Reveron, H.; Chevalier, J.; Schweiger, M.; Rothbrust, F.; Rheinberger, V.M.; Höland, W. Introduction to a tough, strong and stable Ce-TZP/MgAl2O4 composite for biomedical applications. J. Eur. Ceram. Soc. 2012, 32, 2697–2703. [Google Scholar] [CrossRef]

- Maschio, S.; Pezzotti, G.; Sbaizero, O. Effect of LaNbO4 addition on the mechanical properties of ceria-tetragonal zirconia polycrystal matrices. J. Eur. Ceram. Soc. 1998, 18, 1779–1785. [Google Scholar] [CrossRef]

- Cutler, R.A.; Lindemann, J.M.; Ulvensoen, J.H.; Lange, H.I. Damage-resistant SrO-doped Ce-TZP/Al2O3 composites. Mater. Des. 1994, 15, 123–133. [Google Scholar] [CrossRef]

- Ori, S.; Kojima, T.; Hara, T.; Uekawa, N.; Kakegawa, K. Fabrication of Ce-TZP/β-hexaaluminate composites using amorphous precursor of the second phase. J. Ceram. Soc. Jpn. 2012, 120, 111–115. [Google Scholar] [CrossRef]

- Miura, M.; Hongoh, H.; Yogo, T.; Hirano, S.; Fujll, T. Formation of plate-like lanthanum-β-aluminate crystal in Ce-TZP matrix. J. Mater. Sci. 1994, 29, 262–268. [Google Scholar] [CrossRef]

- Kern, F. A Comparison of microstructure and mechanical properties of 12Ce-TZP reinforced with alumina and in situ formed strontium- or lanthanum-hexaaluminate precipitates. J. Eur. Ceram. Soc. 2014, 34, 413–423. [Google Scholar] [CrossRef]

- Yamaguchi, T.; Sakamoto, W.; Yogo, T.; Fujii, T.; Hirano, S. In situ formation of Ce-TZP/Ba-hexaaluminate composites. J. Ceram. Soc. Jpn. 1999, 107, 814–916. [Google Scholar] [CrossRef]

- Tsai, O.F.; Chon, U.; Ramachandran, N.; Shetty, D.K. Transformation plasticity and toughening in CeO2-partially-stabilized zirconia–alumina (Ce-TZP/Al2O3) composites doped with MnO. J. Am. Ceram. Soc. 1992, 75, 1229–1238. [Google Scholar] [CrossRef]

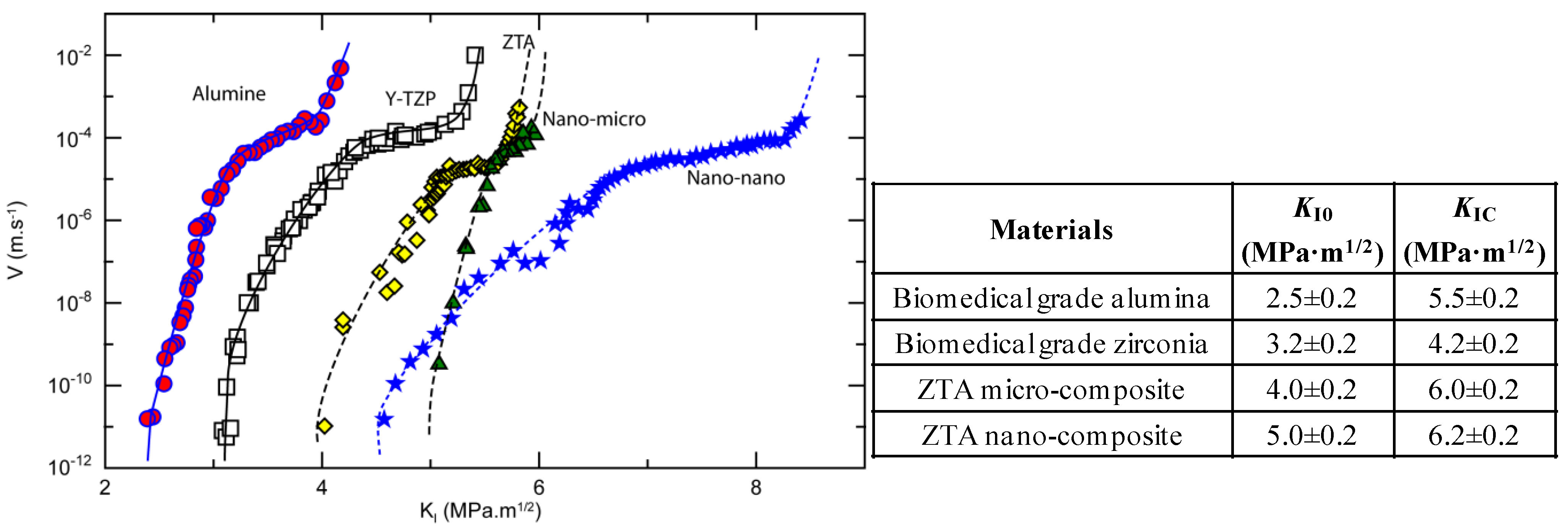

- De Aza, A.H.; Chevalier, J.; Fantozzi, G.; Schehl, M.; Torrecillas, R. Crack growth resistance of alumina, zirconia and zirconia toughened alumina ceramics for joint prostheses. Biomaterials 2002, 23, 937–945. [Google Scholar] [CrossRef]

- Chevalier, J.; Taddei, P.; Gremillard, L.; Deville, S.; Fantozzi, G.; Bartolomé, J.F.; Pecharroman, C.; Moya, J.S.; Diaz, L.A.; Torrecillas, R.; et al. Reliability assessment in advanced nanocomposite materials for orthopaedic applications. J. Mech. Behav. Biomed. 2011, 4, 303–314. [Google Scholar] [CrossRef]

- Gutknecht, D.; Chevalier, J.; Garnier, V.; Fantozzi, G. Key role of processing to avoid low temperature ageing in alumina zirconia composites for orthopaedic application. J. Eur. Ceram. Soc. 2007, 27, 1547–1552. [Google Scholar] [CrossRef]

- Deville, S.; Chevalier, J.; Fantozzi, G.; Bartolomé, J.F.; Requena, J.; Moya, J.S.; Torrecillas, R.; Díaz, L.C. Low-temperature ageing of zirconia-toughened alumina ceramics and its implication in biomedical Implants. J. Eur. Ceram. Soc. 2003, 23, 2975–2982. [Google Scholar] [CrossRef]

- Claussen, N. Fracture toughness of Al2O3 with an unstabilized ZrO2 dispersed phase. J. Am. Ceram. Soc. 1976, 59, 49–51. [Google Scholar] [CrossRef]

- Lange, F.F. Transformation toughening, Part 4: Fabrication, fracture toughness and strength of Al2O3-ZrO2 composites. J. Mater. Sci. 1982, 17, 247–254. [Google Scholar] [CrossRef]

- Szutkowska, M. Fracture resistance behaviour of alumina-zirconia composites. J. Mater. Process. Technol. 2004, 153–154, 868–874. [Google Scholar] [CrossRef]

- Shin, Y.S.; Rhee, Y.W.; Kang, S.J. Experimental evaluation of toughening mechanism in alumina-zirconia composites. J. Am. Ceram. Soc. 1999, 82, 1229–1232. [Google Scholar] [CrossRef]

- Thuan, W.H.; Chen, Z.; Wang, T.C.; Cheng, C.H.; Kuo, P.S. Mechanical properties of Al2O3/ZrO2 composites. J. Eur. Ceram. Soc. 2002, 22, 2827–2833. [Google Scholar] [CrossRef]

- Schehl, M.; Diaz, J.A.; Torrecillas, R. Alumina nanocomposites form powder-alkoxide mixtures. Acta Mater. 2002, 50, 1125–1139. [Google Scholar] [CrossRef]

- Sarkar, D.; Mohapatra, D.; Ray, S.; Bhattacharyya, S.; Adak, S.; Mitra, N. Nanostructured Al2O3/ZrO2 composite synthesized by sol-gel technique: Powder processing and microstructure. J. Mater. Sci. 2007, 42, 1847–1855. [Google Scholar] [CrossRef]

- Jayaseelan, D.D.; Rani, D.A.; Nishikawa, T.; Awaji, H.; Gnanam, F.D. Powder characteristics, sintering behavior and microstructure of sol-gel derived ZTA composites. J. Eur. Ceram. Soc. 2000, 20, 267–275. [Google Scholar] [CrossRef]

- Lee, B.T.; Han, J.K.; Saito, F. Microstructure of sol-gel synthesized Al2O3-ZrO2(Y2O3) nano-composites studied by transmission electron microscopy. Mater. Lett. 2005, 59, 355–360. [Google Scholar] [CrossRef]

- Naga, S.M.; Abdelbary, E.M.; Awaad, M.; El-Shaer, Y.I.; Abd-Elwaha, H.S. Effect of the preparation route on the mechanical properties of yttria–ceria doped tetragonal zirconia/alumina composites. Ceram. Int. 2013, 39, 1835–1840. [Google Scholar] [CrossRef]

- Boulle, A.; Oudjedi, Z.; Guinebretière, R.; Soulestine, B.; Dauger, A. Ceramic nanocomposites obtained by sol-gel coating of submicron powders. Acta Mater. 2001, 49, 811–816. [Google Scholar] [CrossRef]

- Matsumoto, Y.; Hirota, K.; Yamaguchi, O.; Inamura, S.; Miyamoto, H.; Shiokawa, N.; Tsuji, K. Mechanical properties of isostatically pressed zirconia-toughened alumina ceramics prepared from coprecipitated powders. J. Am. Ceram. Soc. 1993, 76, 2677–2680. [Google Scholar] [CrossRef]

- Rana, R.P.; Pratihar, S.K.; Bhattacharyya, S. Powder processing and densification behaviour of alumina–high zirconia nanocomposites using chloride precursors. J. Mater. Sci. Process. 2007, 190, 350–357. [Google Scholar] [CrossRef]

- Prete, F.; Rizzuti, A.; Esposito, L.; Tucci, A.; Leonelli, C. Highly homogeneous Al2O3–ZrO2 nanopowder via microwave-assisted hydro- and solvothermal synthesis. J. Am. Ceram. Soc. 2011, 94, 3587–3590. [Google Scholar] [CrossRef]

- Freim, J.; McKittrick, J. Modeling and fabrication of fine-grain alumina–zirconia composites produced from nanocrystalline precursors. J. Am. Ceram. Soc. 1998, 81, 1773–1780. [Google Scholar] [CrossRef]

- Claussen, N.; Ruhle, M. Design of transformation-toughened ceramics. In Advances in Ceramics, Vol. 3, Science and Technology of Zirconia; Heuer, A.H., Hobbs, W.L., Eds.; The American Ceramics Society: Columbus, OH, USA, 1981; pp. 137–163. [Google Scholar]

- Tsukuma, K.; Shimada, M. Strength, fracture toughness and vickers hardness of CeO2-stabilized tetragonal ZrO2 polycrystals (Ce-TZP). J. Mater. Sci. 1985, 20, 1178–1184. [Google Scholar] [CrossRef]

- Groza, J.R. Nanosintering. Nanostruct. Mater. 1999, 12, 987–992. [Google Scholar] [CrossRef]

- Groza, J.R.; Jhwding, R.J. Nanoparticulate materials densification. Nanostruct. Mater. 1996, 7, 749–768. [Google Scholar] [CrossRef]

- Wang, J.; Stevens, R. Review. Zirconia-toughened alumina (ZTA) ceramics. J. Mater. Sci. 1989, 24, 3421–3440. [Google Scholar] [CrossRef]

- Lee, M.-H.; Tai, C.Y.; Lu, C.-H. Synthesis of spherical zirconia by precipitation between two water/oil emulsions. J. Eur. Ceram. Soc. 1999, 19, 2593–2603. [Google Scholar] [CrossRef]

- Hu, M.Z.-C.; Hunt, R.D.; Payzant, E.A.; Hubbard, C.R. Nanocrystallization and phase transformation in monodispersed ultrafine zirconia particles from various homogeneous precipitation methods. J. Am. Ceram. Soc. 1999, 82, 2313–2320. [Google Scholar] [CrossRef]

- Upadhyaya, D.D.; Ghosh, A.; Gurumurthy, K.R.; Prasad, R. Microwave sintering of cubic zirconia. Ceram. Int. 2001, 27, 415–418. [Google Scholar] [CrossRef]

- Chen, I.W.; Chiao, Y.H. Martensitic transformation in ZrO2 and HfO2—An assessment of small-particles experiments with metals and ceramic matrices. In Advances in Ceramics; Heuer, A.H., Hobbs, W.L., Eds.; The American Ceramics Society: Columbus, OH, USA, 1984; volume 12, pp. 23–40. [Google Scholar]

- Yuan, Z.; Vleugels, J.; van Der Biest, O. Synthesis and characterization of CeO2-coated ZrO2 powder-based TZP. Mater. Lett. 2000, 46, 249–254. [Google Scholar]

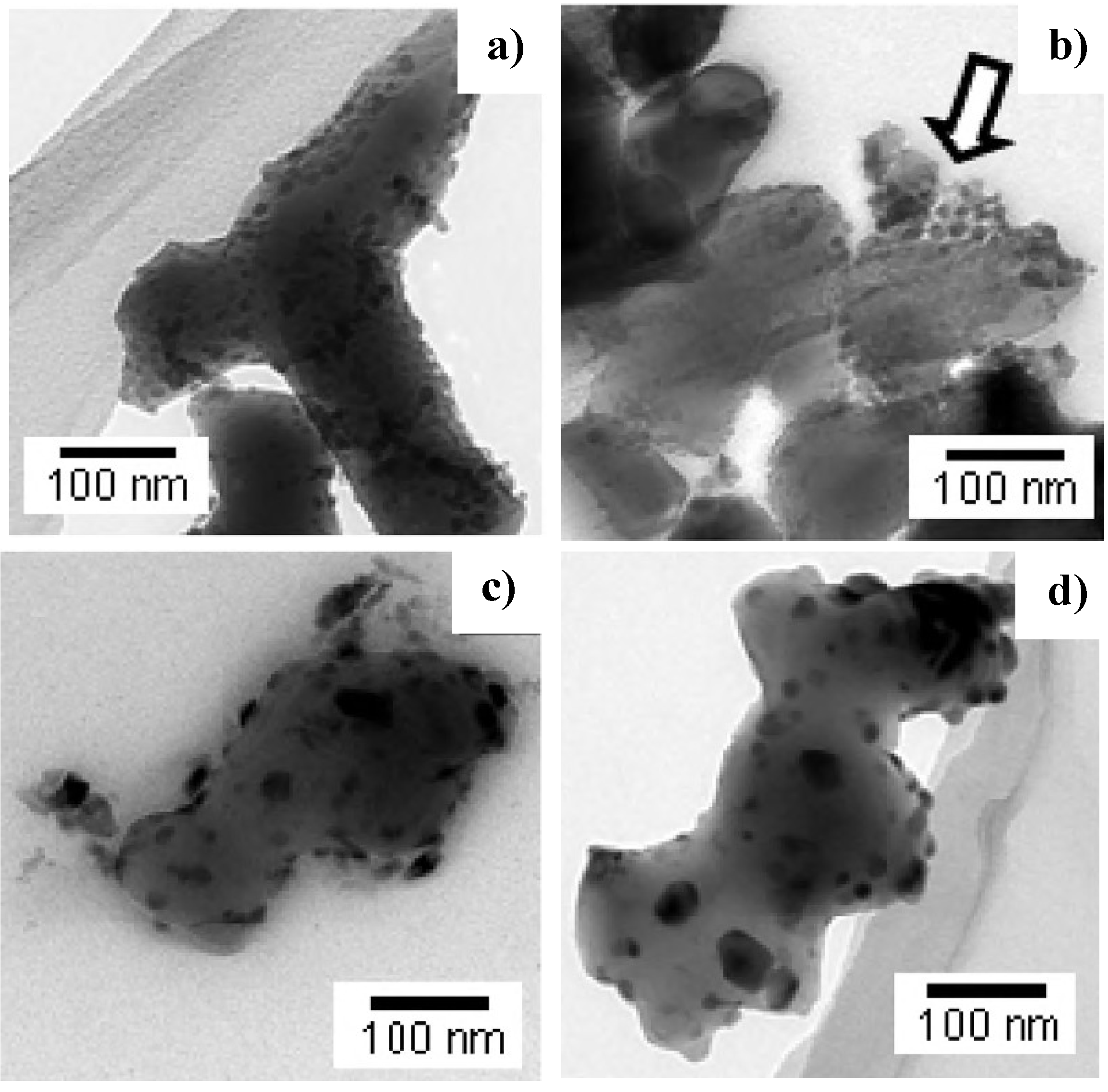

- Palmero, P.; Naglieri, V.; Chevalier, J.; Fantozzi, G.; Montanaro, L. Alumina-based nanocomposites obtained by doping with inorganic salt solutions: Application to immiscible and reactive systems. J. Eur. Ceram. Soc. 2009, 29, 59–66. [Google Scholar] [CrossRef]

- Naglieri, V.; Palmero, P.; Montanaro, L. Preparation and characterization of alumina-doped powders for the design of multi-phasic nano-microcomposites. J. Therm. Anal. Calorim. 2009, 97, 231–237. [Google Scholar] [CrossRef]

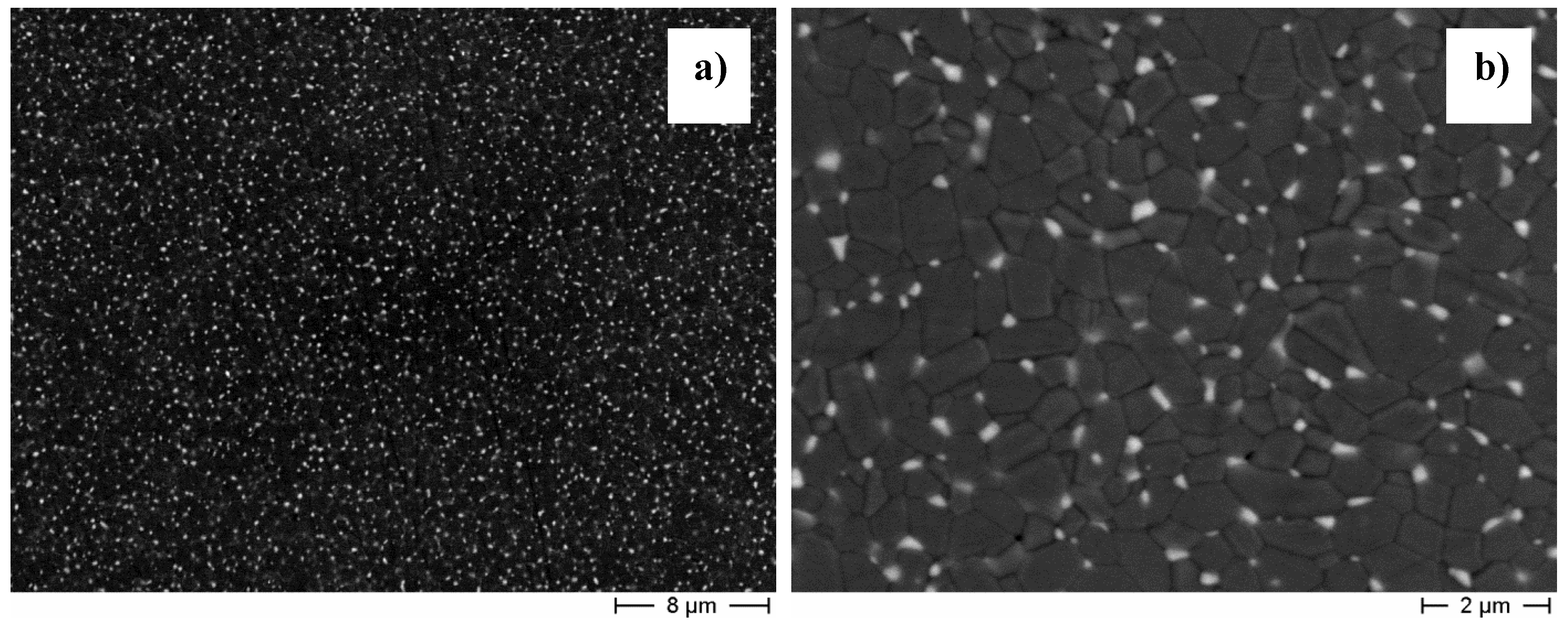

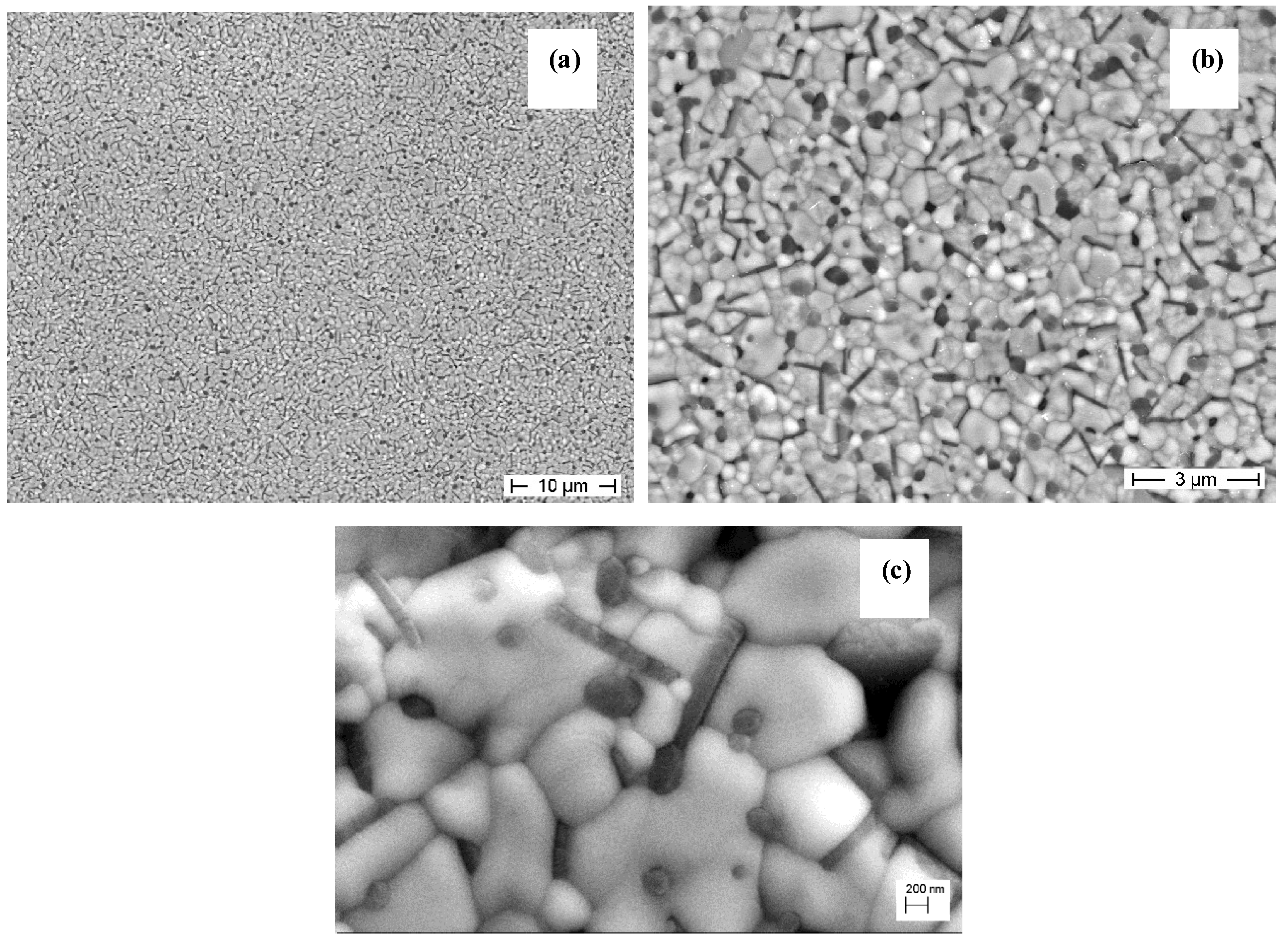

- Kern, F.; Palmero, P. Microstructure and mechanical properties of alumina 5 vol% zirconia nanocomposites prepared by powder coating and powder mixing routes. Ceram. Int. 2013, 39, 673–682. [Google Scholar] [CrossRef]

- Naglieri, V.; Palmero, P.; Montanaro, L.; Chevalier, J. Elaboration of alumina-zirconia composites: Role of the zirconia content on the microstructure and mechanical properties. Materials 2013, 6, 2090–2102. [Google Scholar] [CrossRef]

- Palmero, P.; Esnouf, C. Phase and microstructural evolution of yttrium-doped nanocrystalline alumina: A contribution of advanced microscopy techniques. J. Eur. Ceram. Soc. 2011, 31, 507–516. [Google Scholar] [CrossRef]

- Palmero, P.; Naglieri, V.; Spina, G.; Lombardi, M. Microstructural design and elaboration of multiphase ultra-fine ceramics. Ceram. Int. 2011, 37, 139–144. [Google Scholar] [CrossRef]

- Palmero, P.; Sola, A.; Naglieri, V.; Bellucci, D.; Lombardi, M.; Cannillo, V. Elaboration and mechanical characterization of multi-phase alumina-based ultra-fine composites. J. Mater. Sci. 2012, 47, 1077–1084. [Google Scholar] [CrossRef]

- Gizowska, M.; Konopka, K.; Szafran, M. Properties of water-based slurries for fabrication of ceramic-metal composites by slip casting method. Arch. Metall. Mater. 2011, 56, 1105–1110. [Google Scholar]

- Naglieri, V. Alumina-Zirconia Composites: Elaboration and Characterization in View of the Orthopaedic Applications. Ph.D. Thesis, Politecnico di Torino, Italy, INSA of Lyon, France, 11 February 2010. [Google Scholar]

- Chuah, G.K.; Jaenicke, S.; Cheong, S.A.; Chan, K.S. The influence of preparation conditions on the surface area of zirconia. Appl. Catal. A Gen. 1996, 145, 267–284. [Google Scholar] [CrossRef]

- Naglieri, V.; Joly-Pottuz, L.; Chevalier, J.; Lombardi, M.; Montanaro, L. Follow-up of zirconia crystallization on a surface modified alumina powder. J. Eur. Ceram. Soc. 2010, 30, 3377–3387. [Google Scholar]

- Naglieri, V.; Gutknecht, D.; Garnier, V.; Palmero, P.; Chevalier, J.; Montanaro, L. Optimized slurries for spray drying: Different approaches to obtain homogeneous and deformable alumina-zirconia granules. Materials 2013, 3, 5382–5397. [Google Scholar]

- Greenwood, R.; Bergstriim, L. Electroacoustic and rheological properties of aqueous Ce-ZrO2 (Ce-TZP) suspensions. J. Eur. Ceram. Soc. 1997, 17, 537–548. [Google Scholar] [CrossRef]

- Douy, A.; Capron, M. Crystallisation of spray-dried amorphous precursors in the SrO–Al2O3 system: A DSC study. J. Eur. Ceram. Soc. 2003, 23, 2075–2081. [Google Scholar] [CrossRef]

- Vishista, K.; Gnanam, F.D. Microstructural development of SrAl12O19 in alumina–strontia composites. J. Eur. Ceram. Soc. 2009, 29, 77–83. [Google Scholar] [CrossRef]

- Garvie, R.C.; Nicholson, P.S. Phase analysis in zirconia systems. J. Am. Ceram. Soc. 1972, 55, 303–305. [Google Scholar]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Palmero, P.; Montanaro, L.; Reveron, H.; Chevalier, J. Surface Coating of Oxide Powders: A New Synthesis Method to Process Biomedical Grade Nano-Composites. Materials 2014, 7, 5012-5037. https://doi.org/10.3390/ma7075012

Palmero P, Montanaro L, Reveron H, Chevalier J. Surface Coating of Oxide Powders: A New Synthesis Method to Process Biomedical Grade Nano-Composites. Materials. 2014; 7(7):5012-5037. https://doi.org/10.3390/ma7075012

Chicago/Turabian StylePalmero, Paola, Laura Montanaro, Helen Reveron, and Jérôme Chevalier. 2014. "Surface Coating of Oxide Powders: A New Synthesis Method to Process Biomedical Grade Nano-Composites" Materials 7, no. 7: 5012-5037. https://doi.org/10.3390/ma7075012

APA StylePalmero, P., Montanaro, L., Reveron, H., & Chevalier, J. (2014). Surface Coating of Oxide Powders: A New Synthesis Method to Process Biomedical Grade Nano-Composites. Materials, 7(7), 5012-5037. https://doi.org/10.3390/ma7075012