Recent Advances in Creep Modelling of the Nickel Base Superalloy, Alloy 720Li

Abstract

:1. Introduction

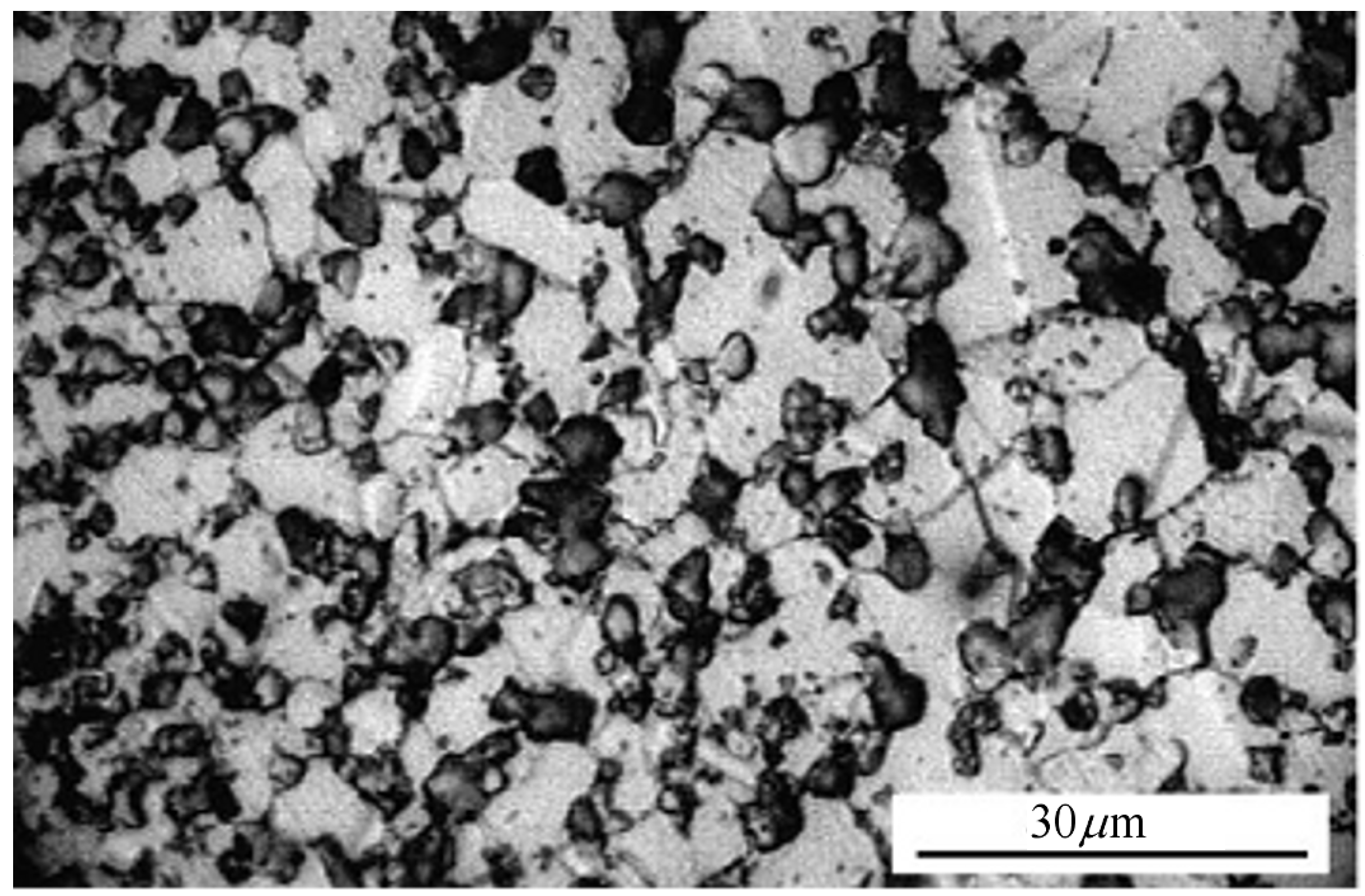

2. Experimental Data

3. Results and Discussion

| Temperature (°C) | (MPa) | (MPa) |

|---|---|---|

| 550 | 1500 | 1088 |

| 600 | 1468 | 1067 |

| 650 | 1420 | 1017 |

| 700 | 1254 | 927 |

| 750 | 1084 | 787 |

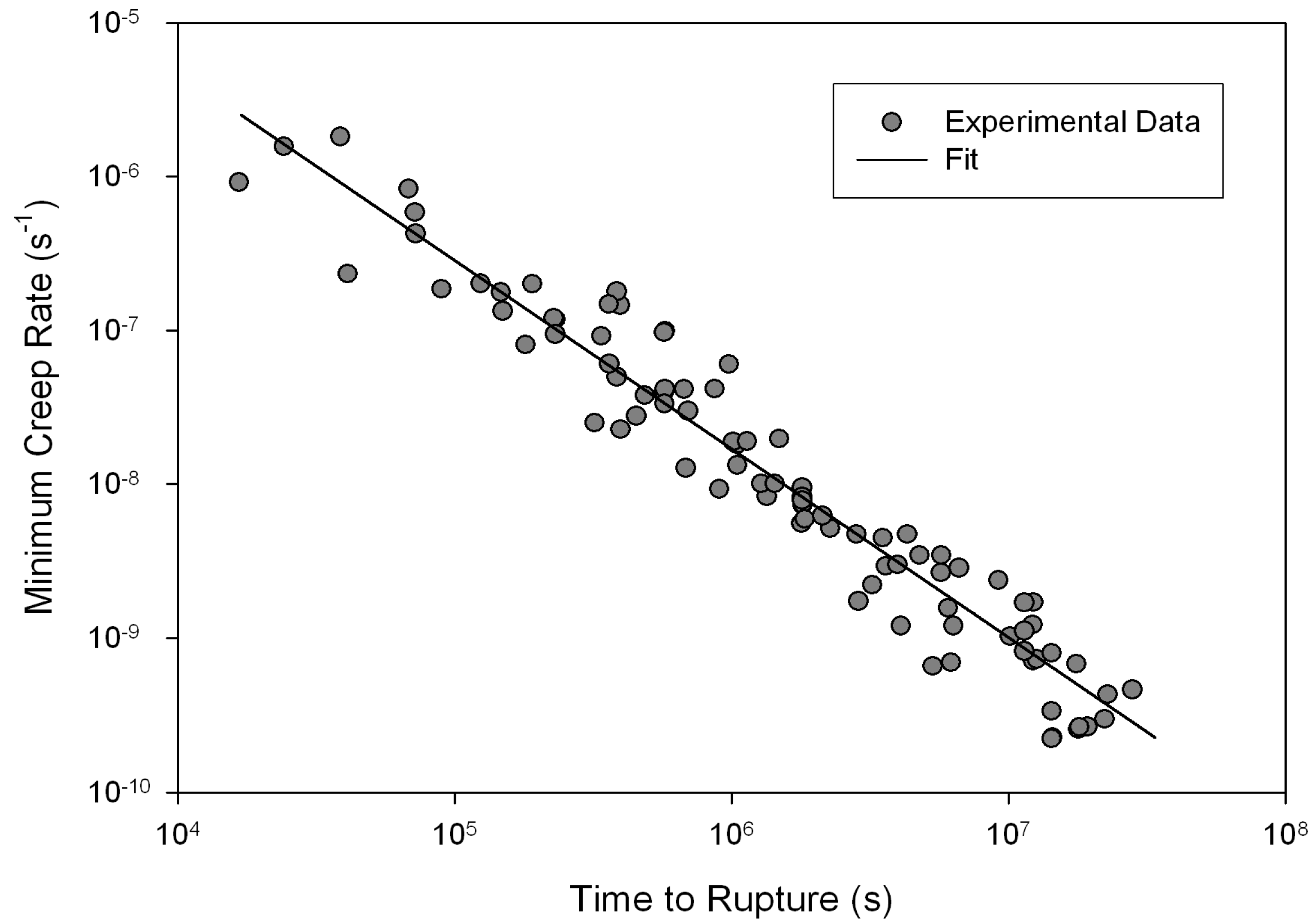

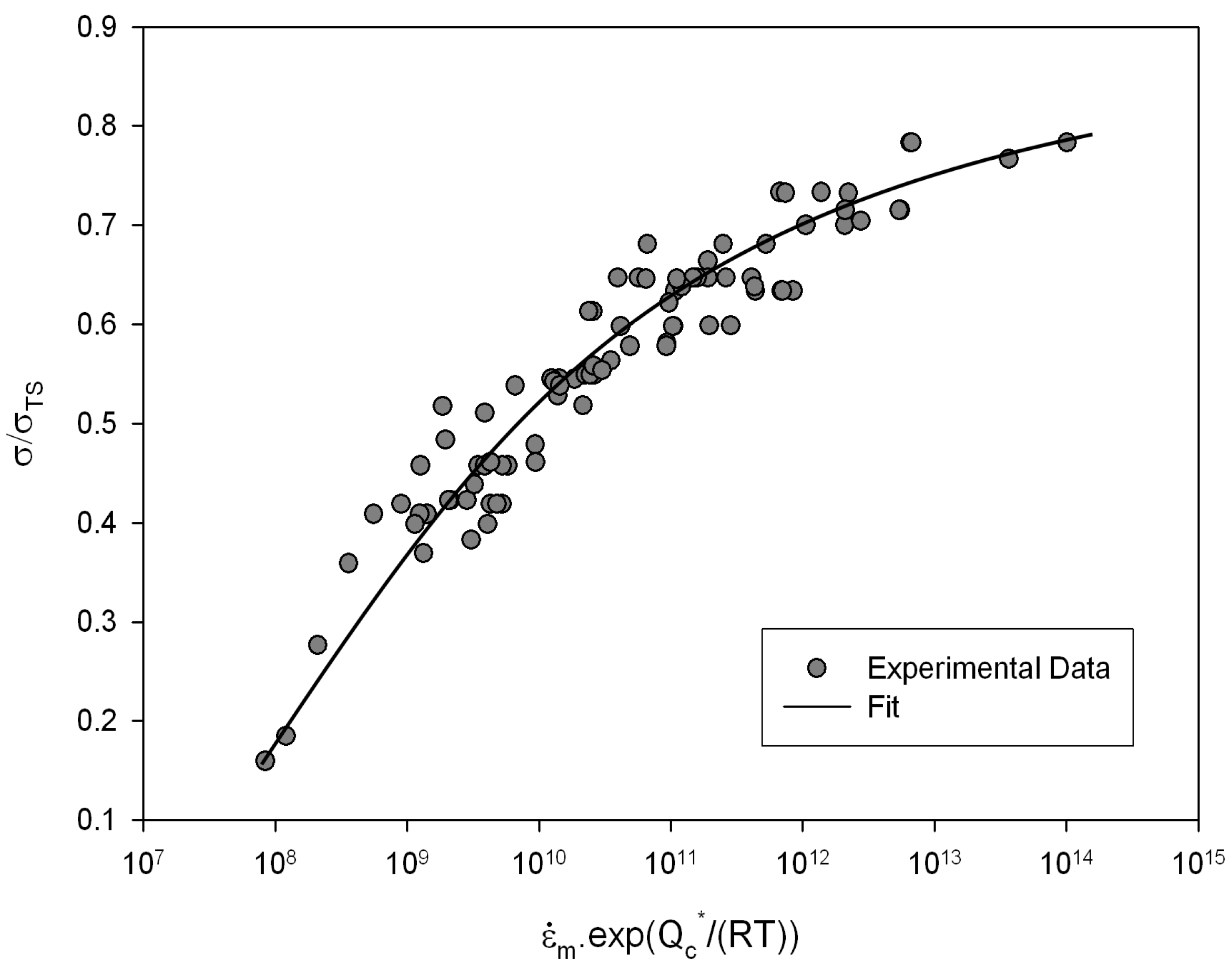

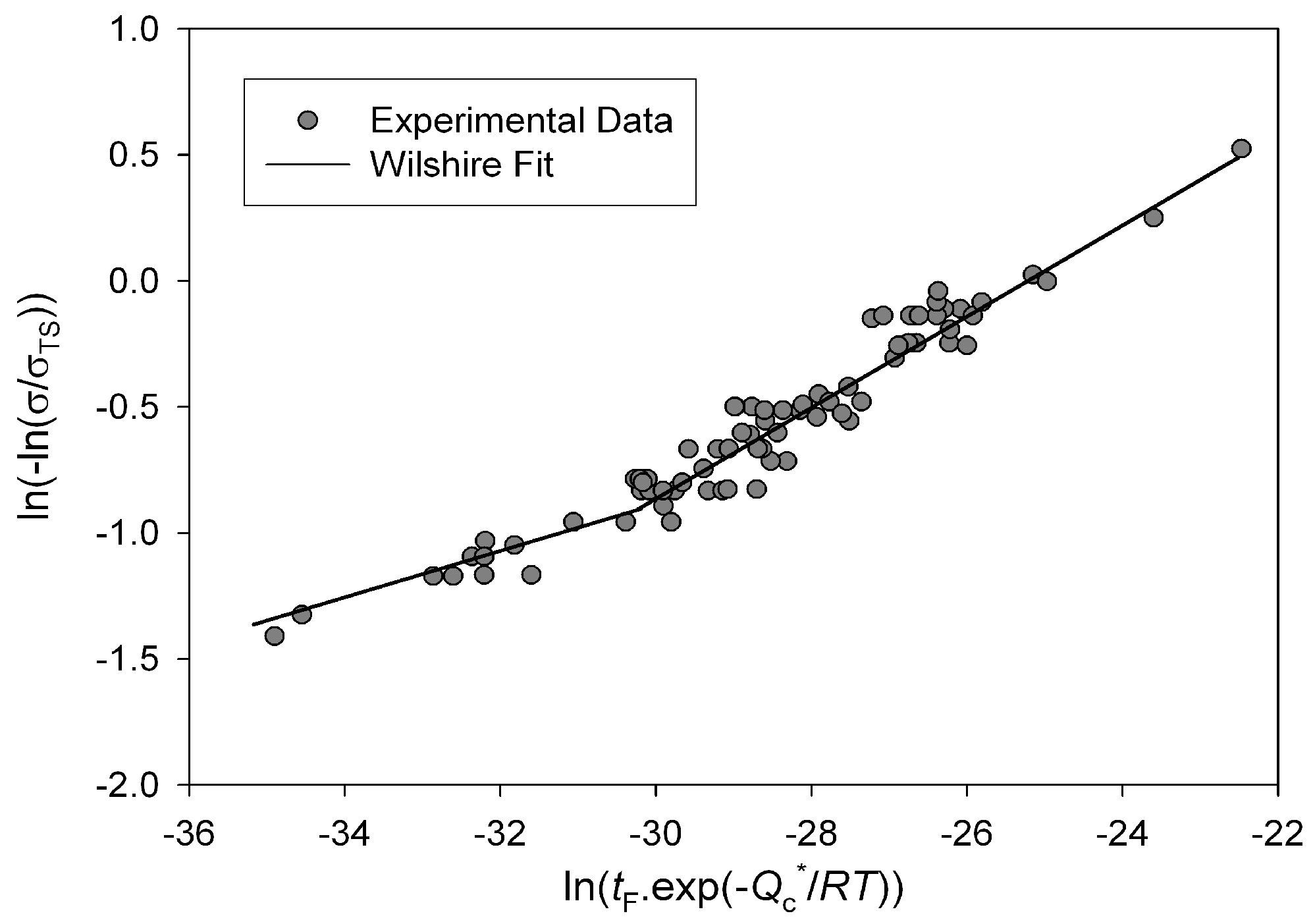

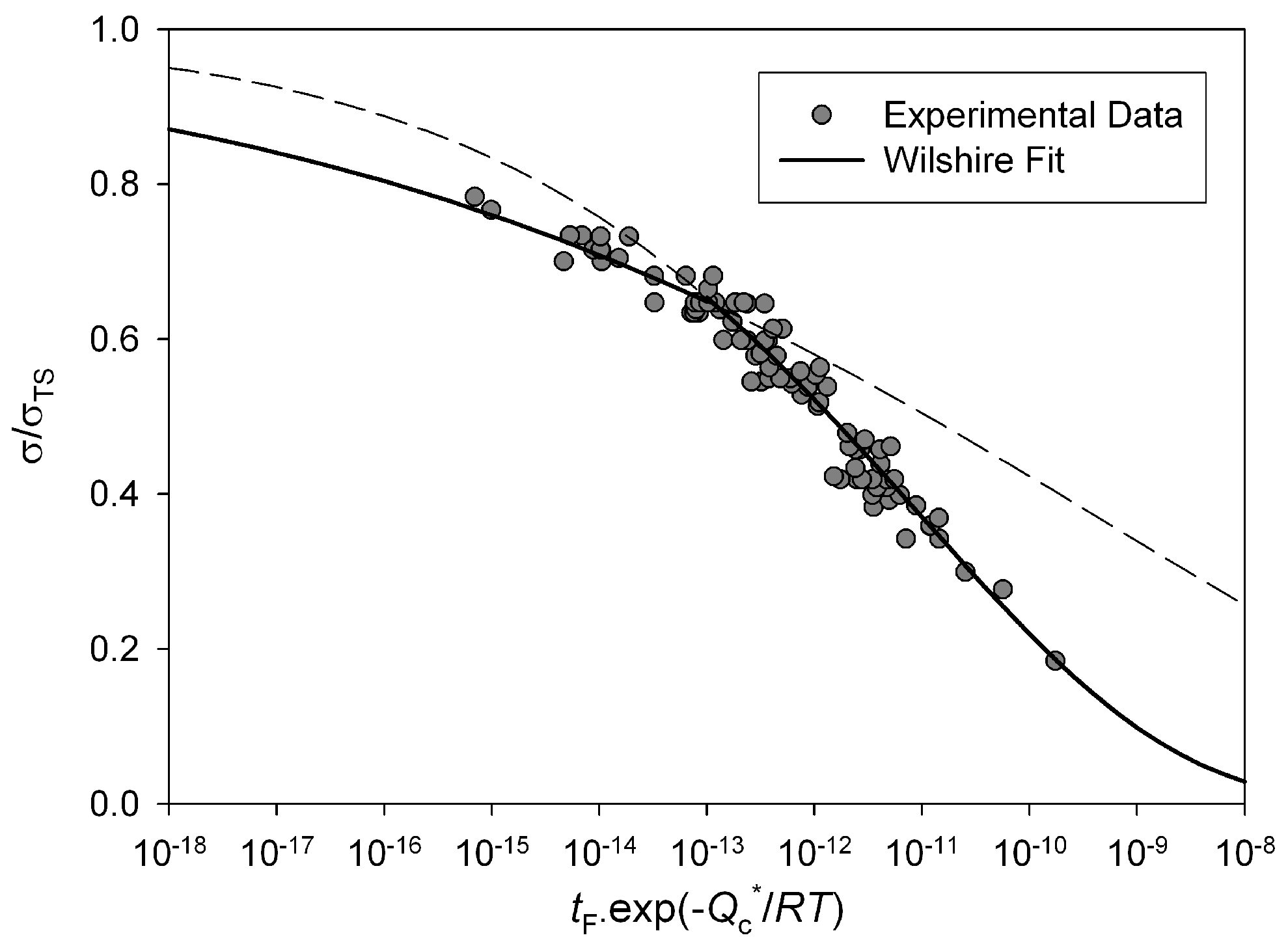

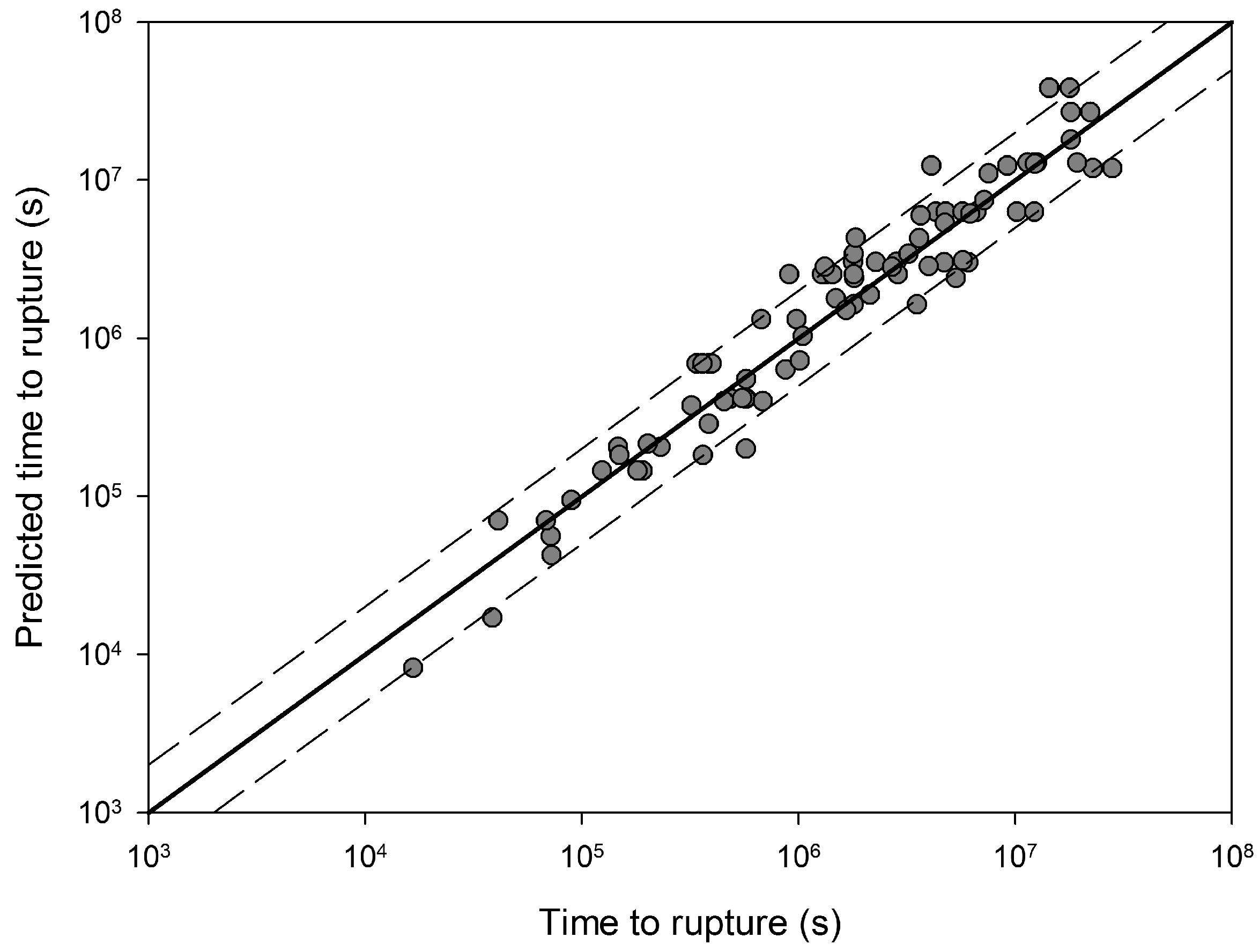

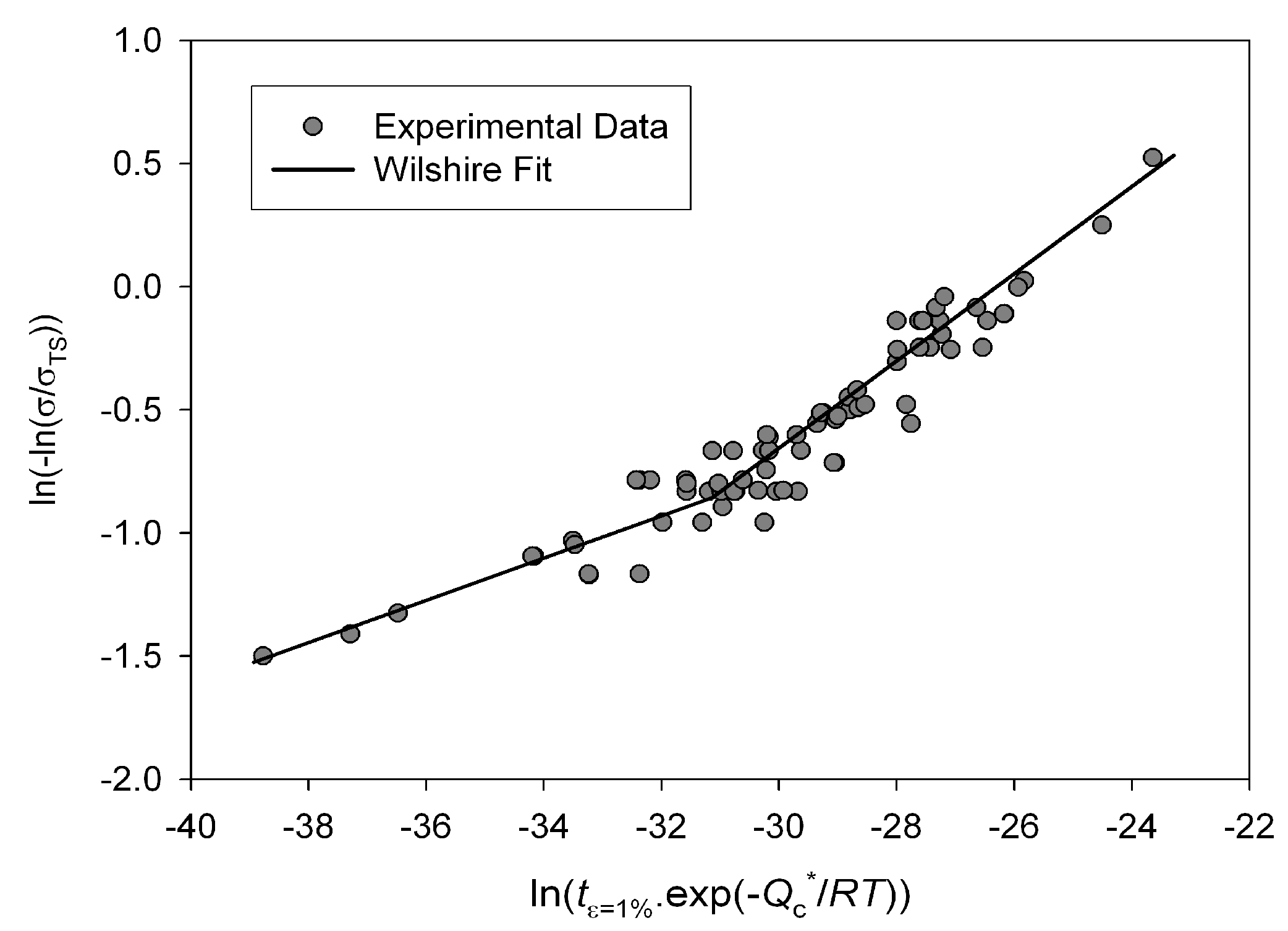

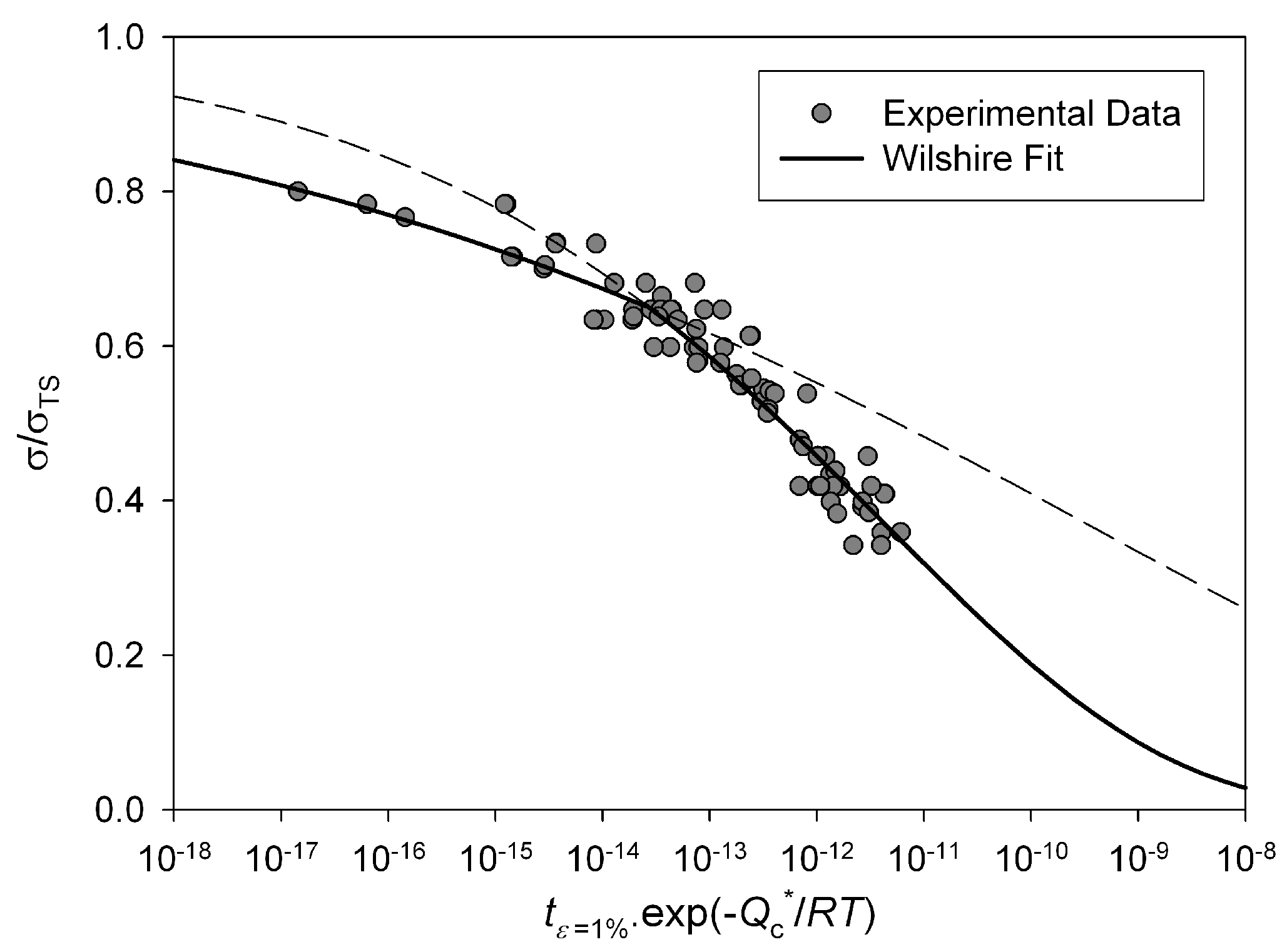

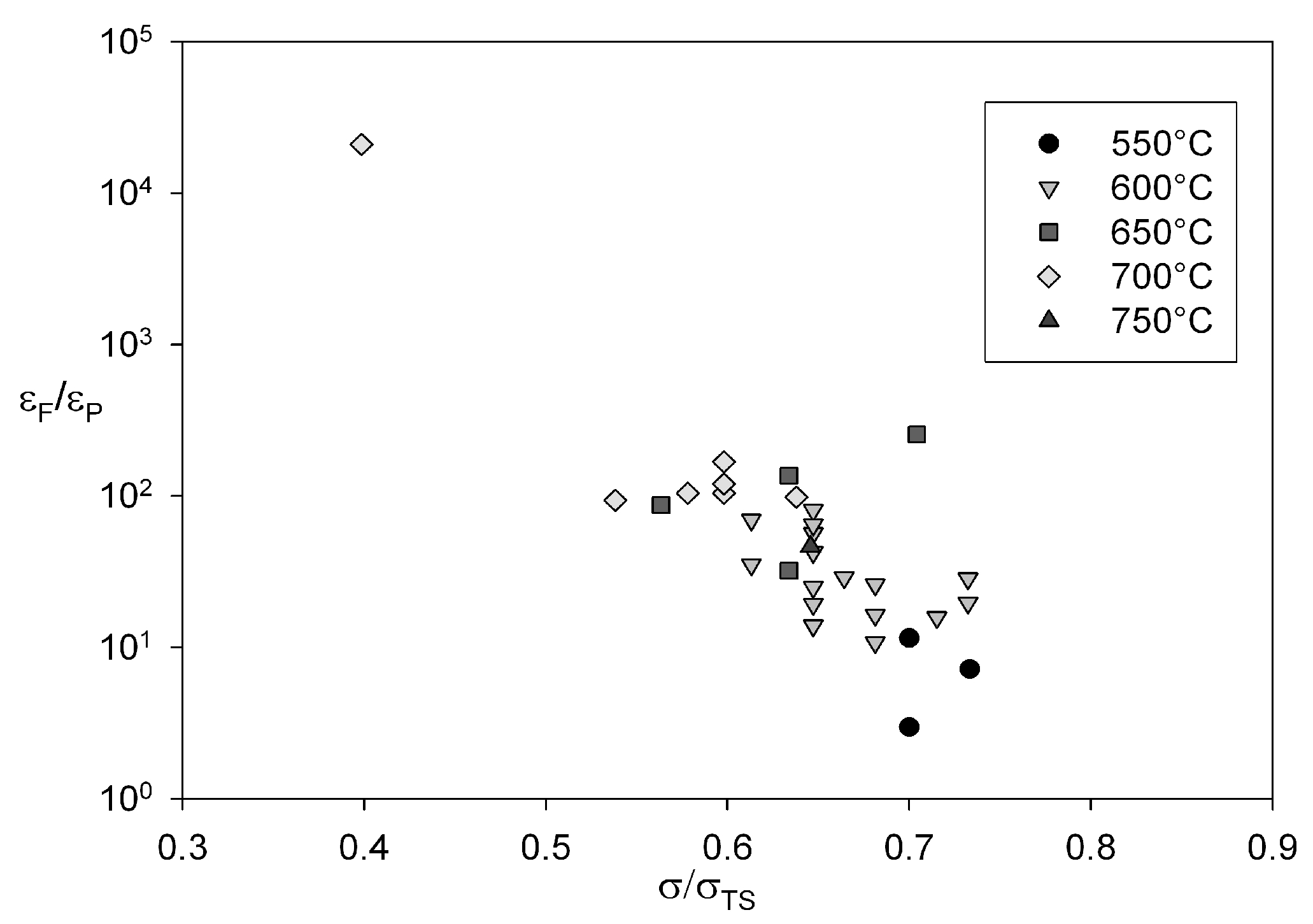

3.1. Extrapolation of Creep Data

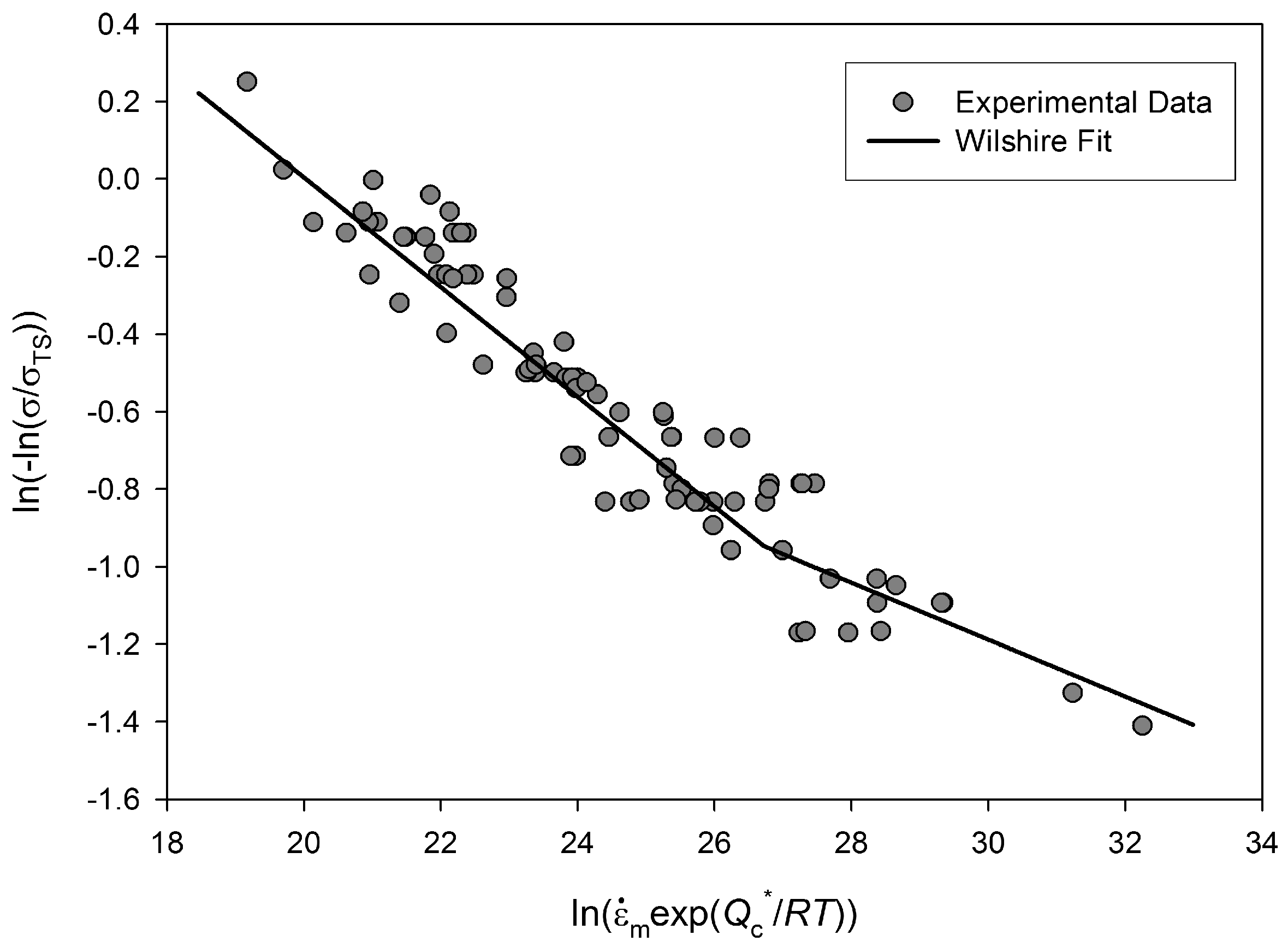

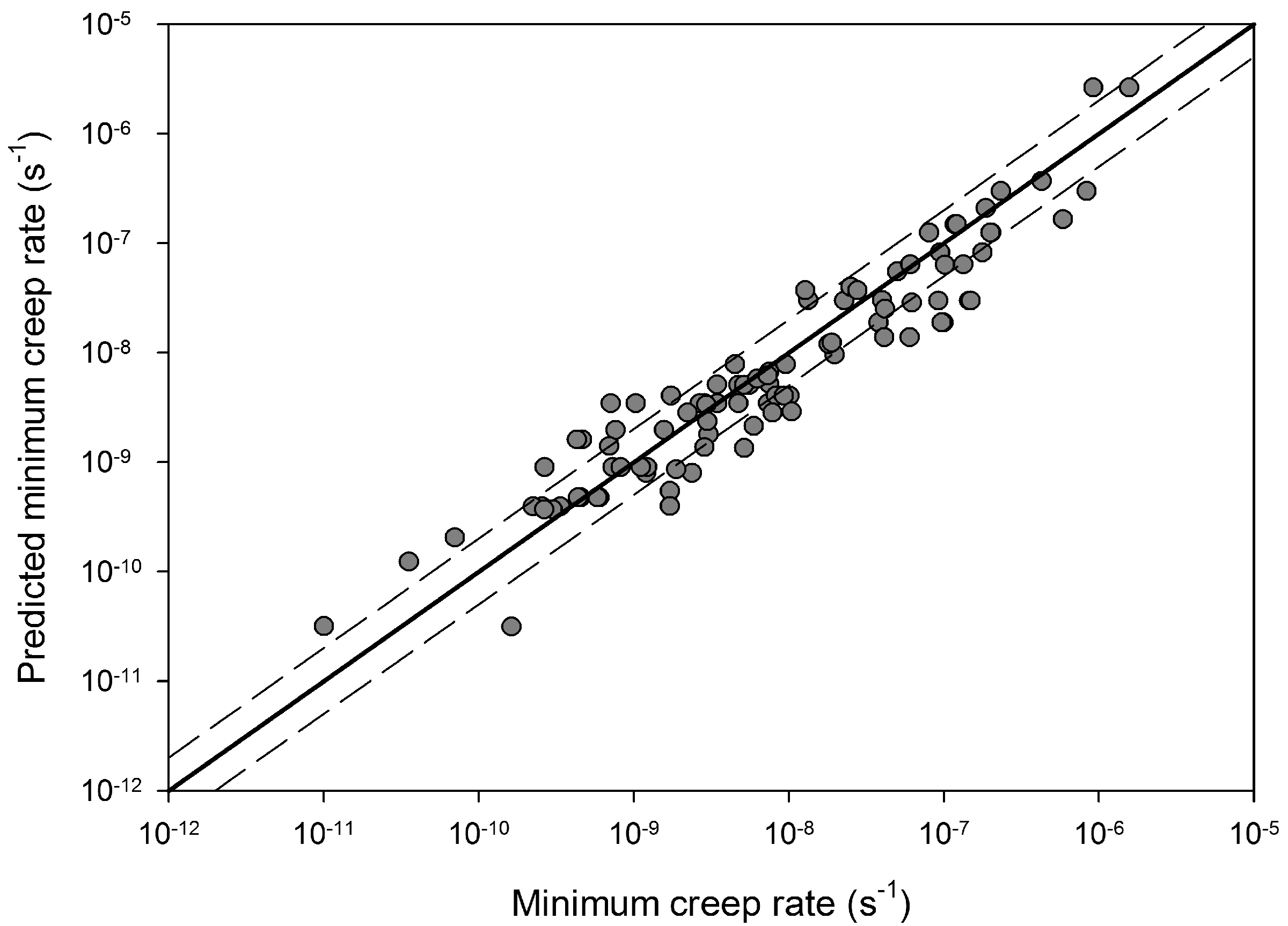

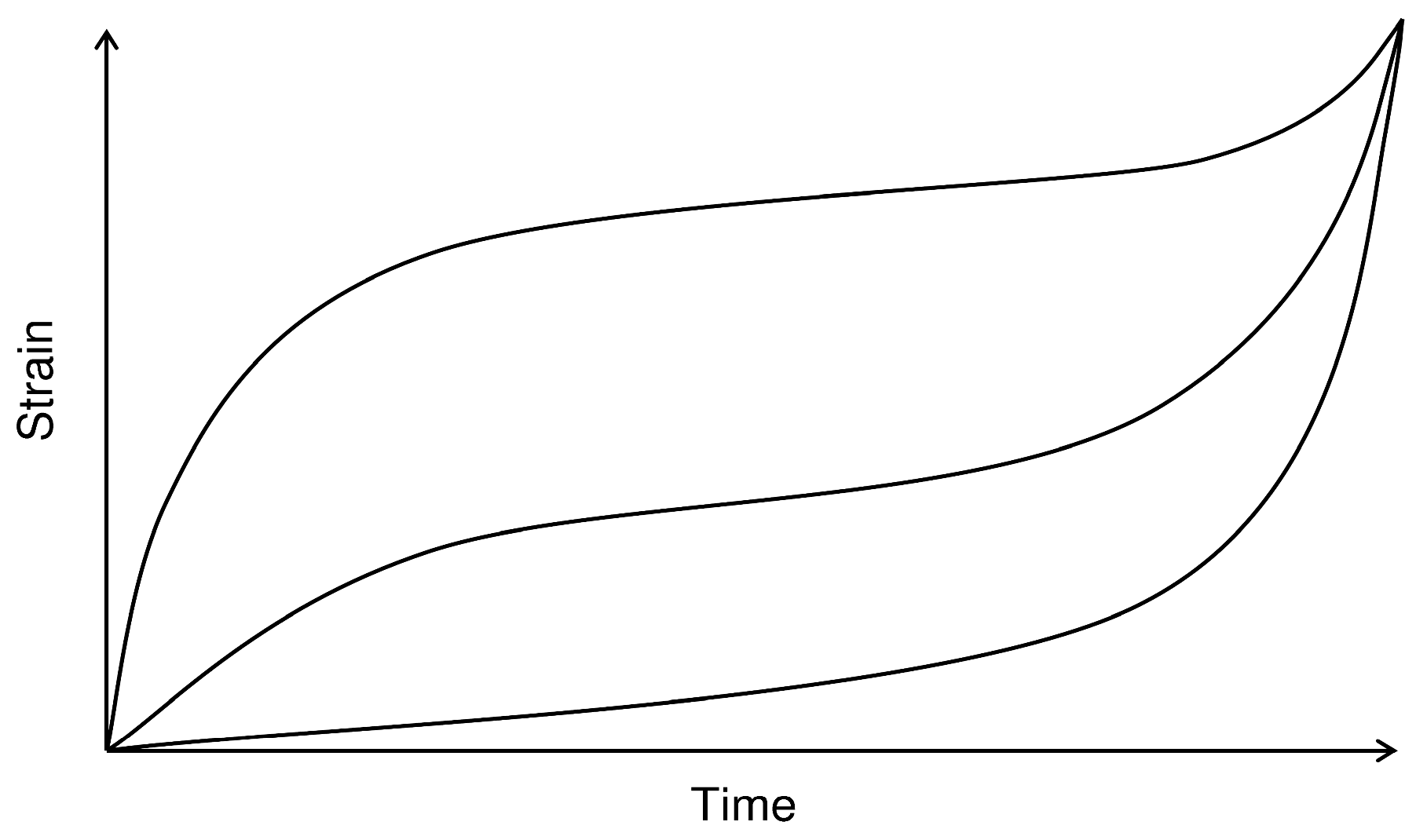

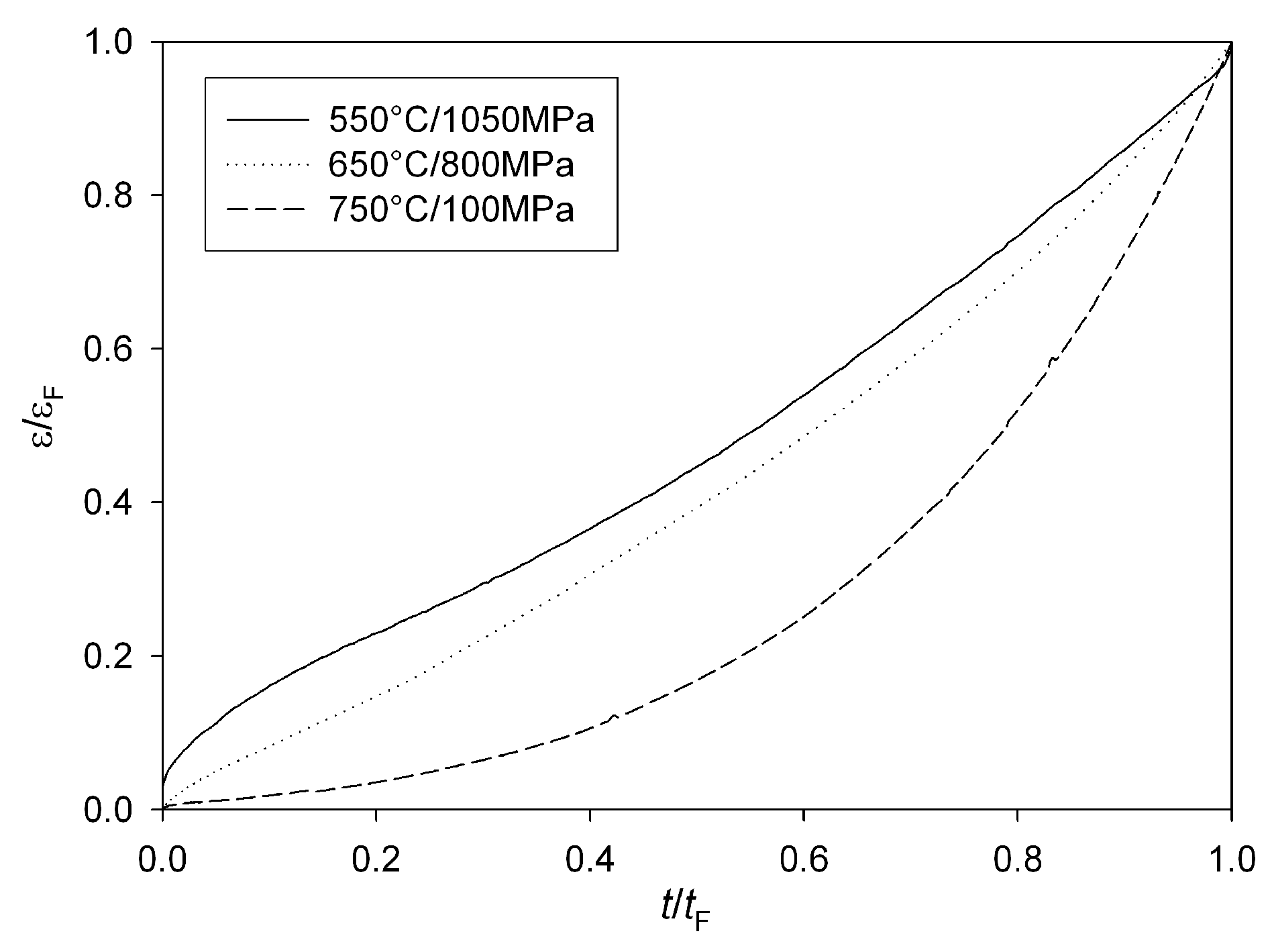

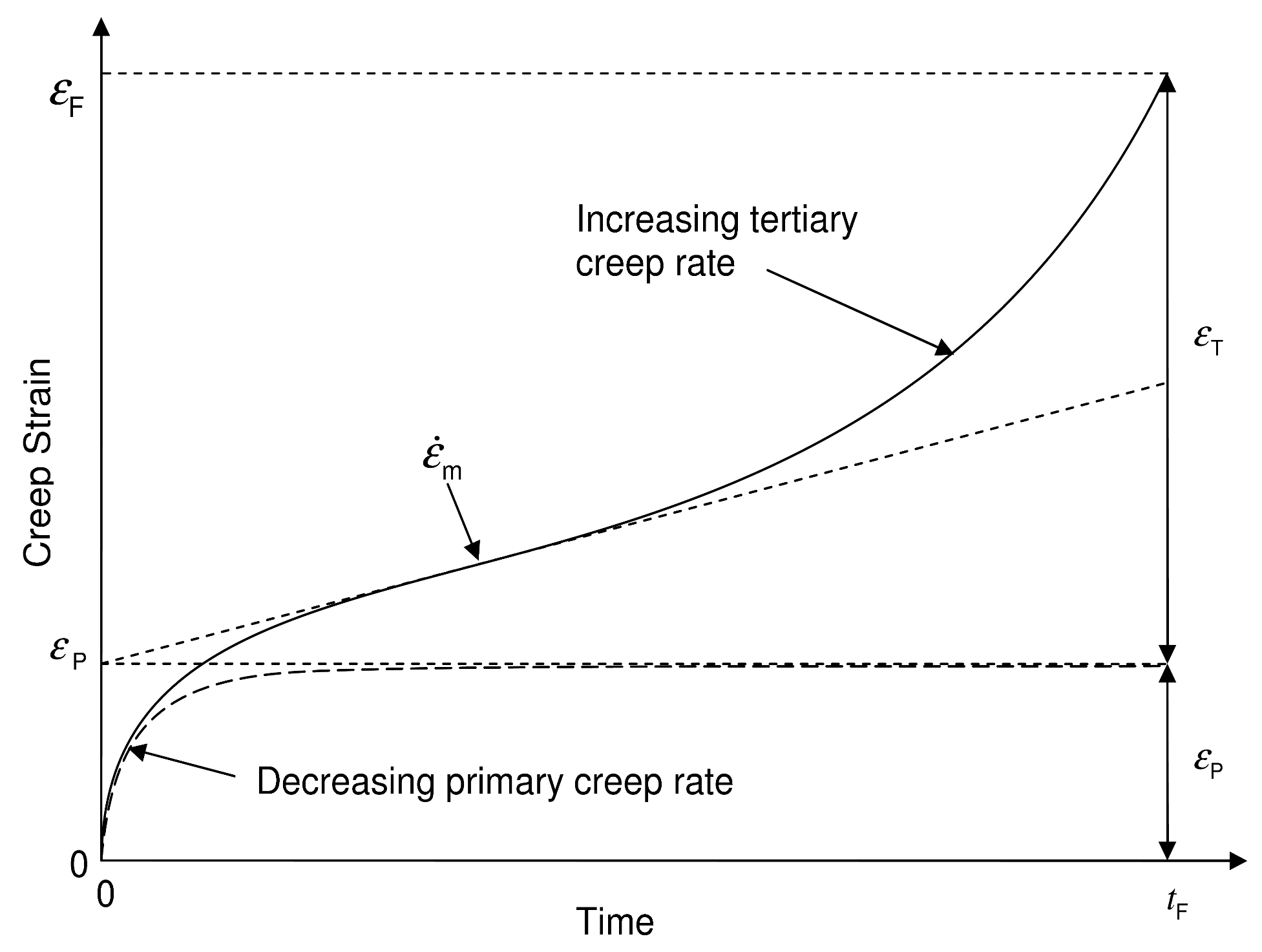

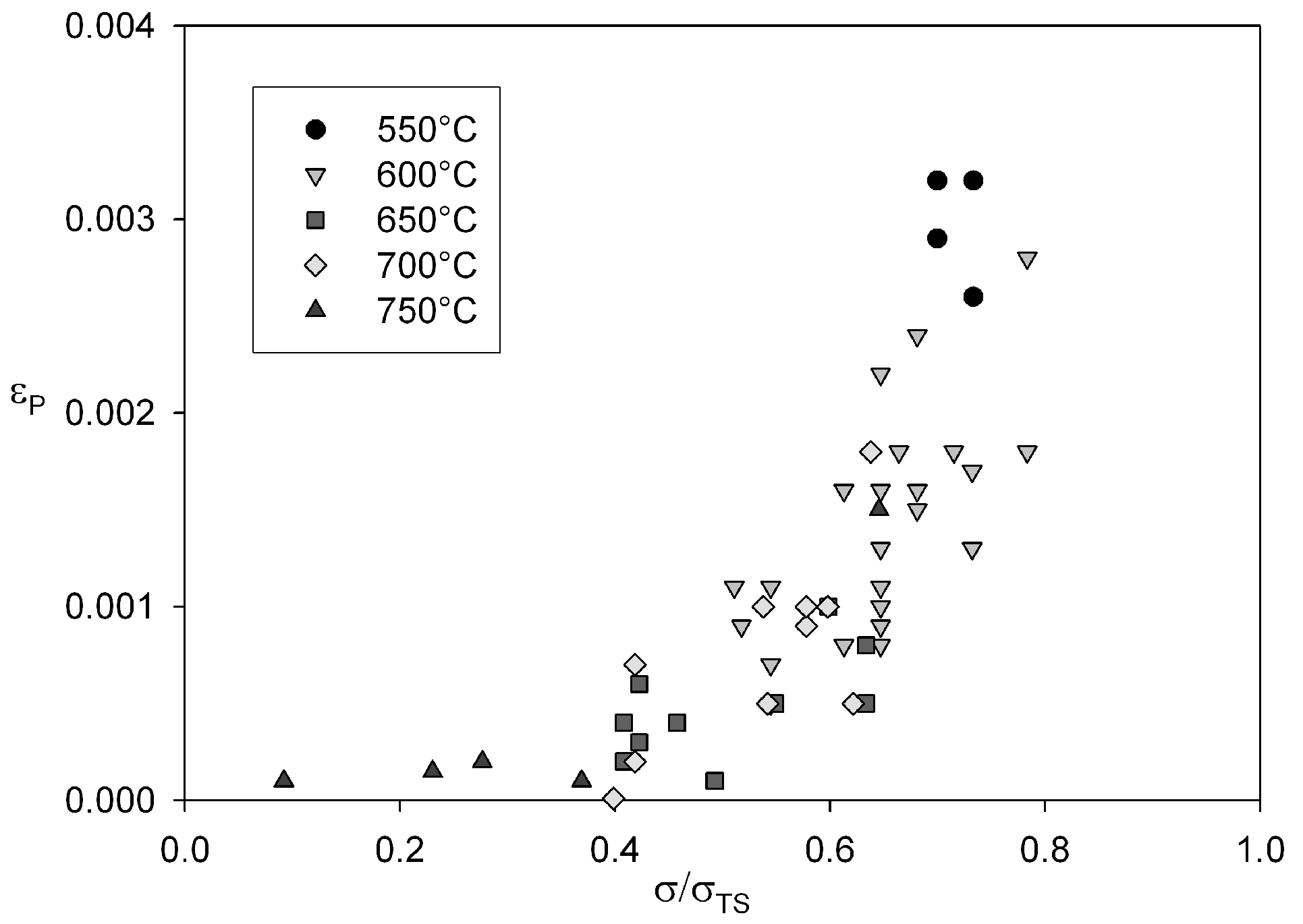

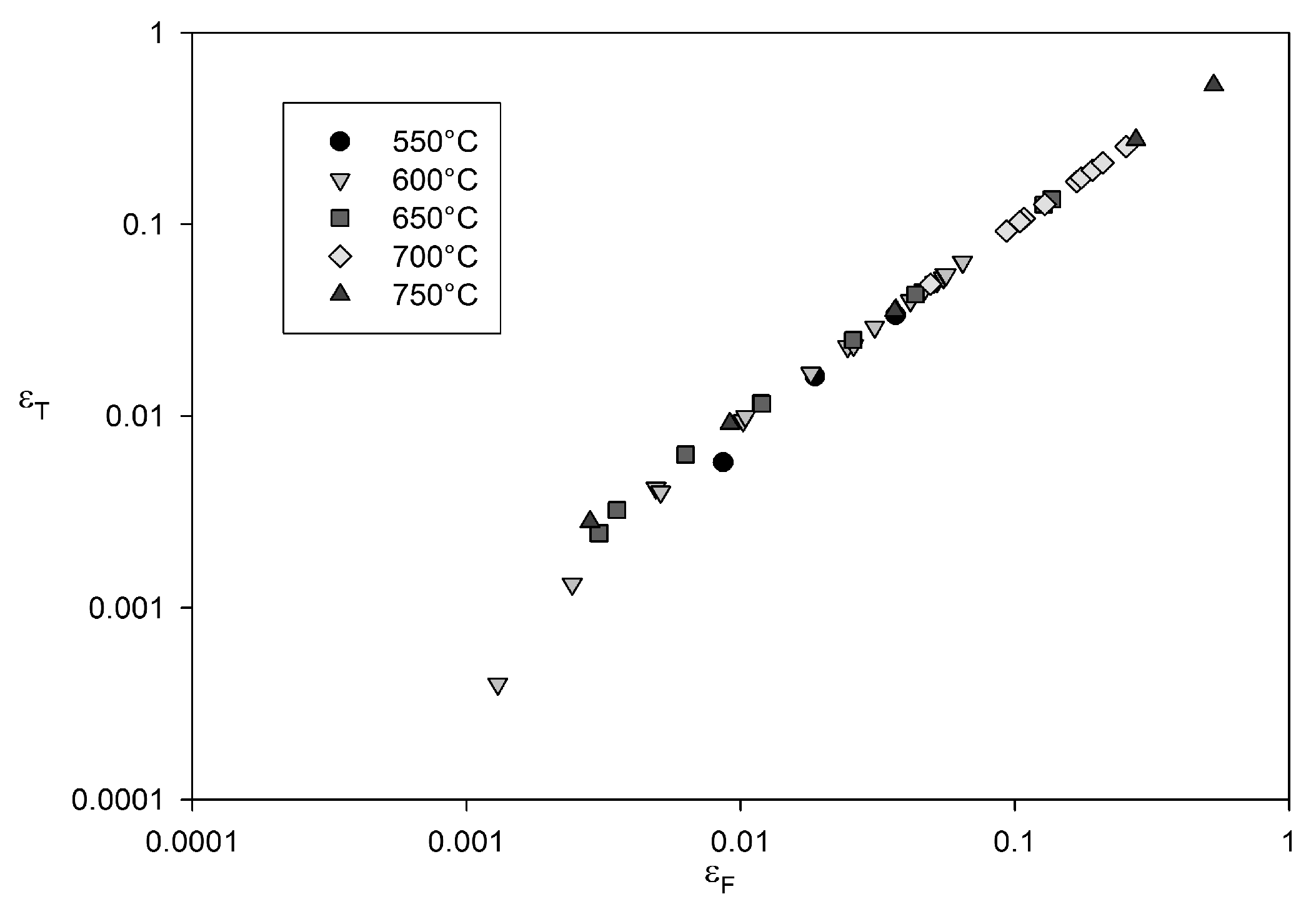

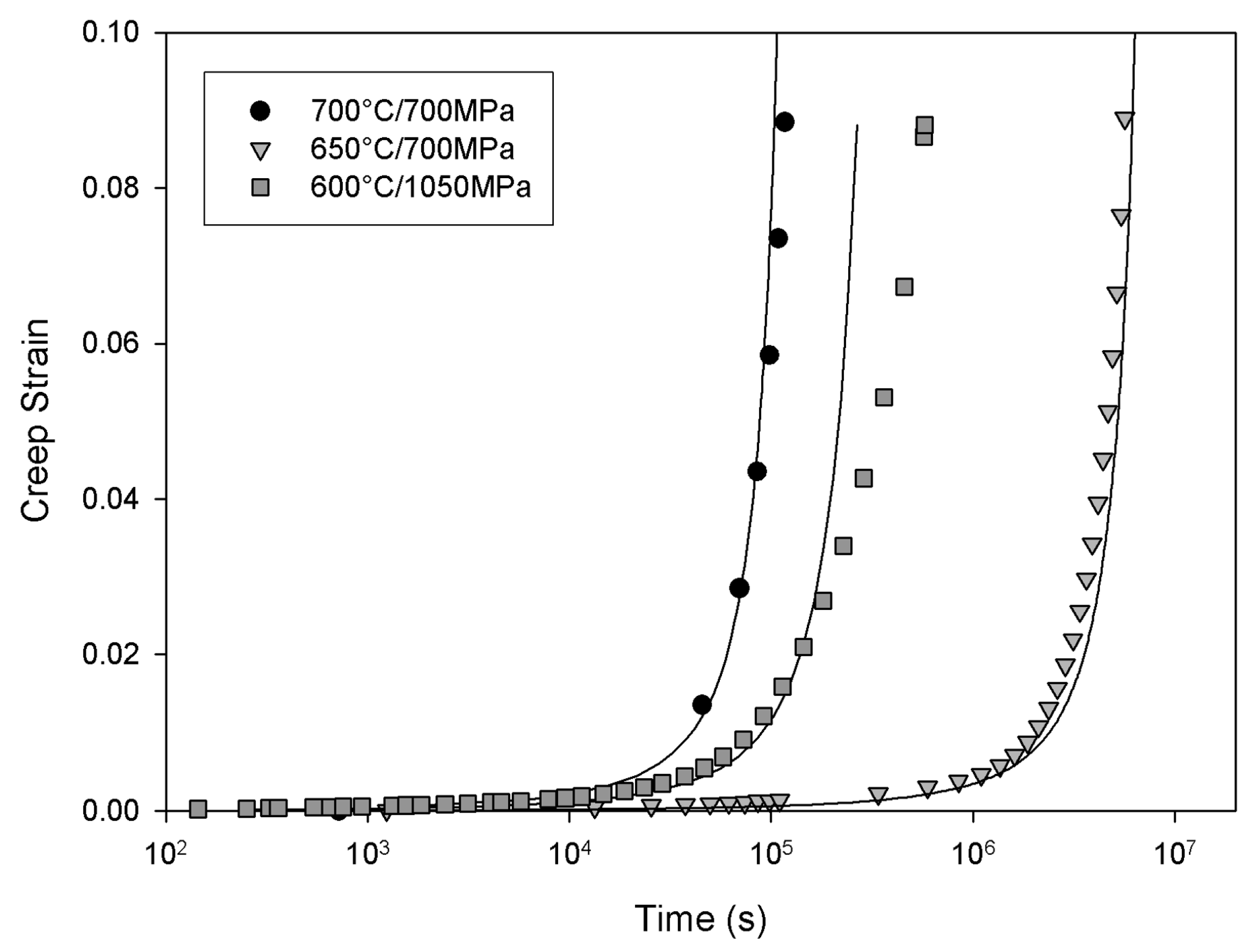

3.2. Creep Deformation

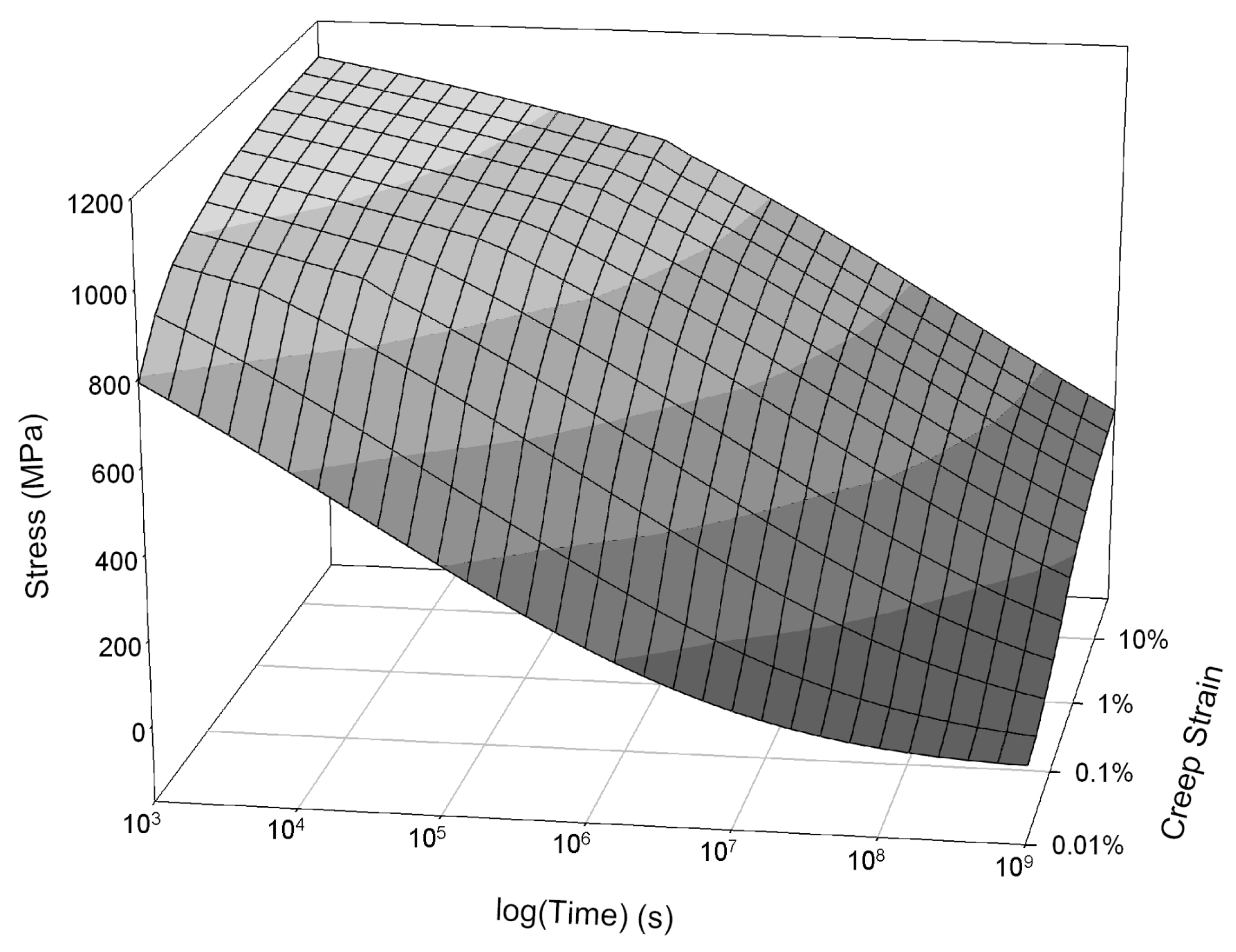

3.3. Extrapolation of Creep Curves

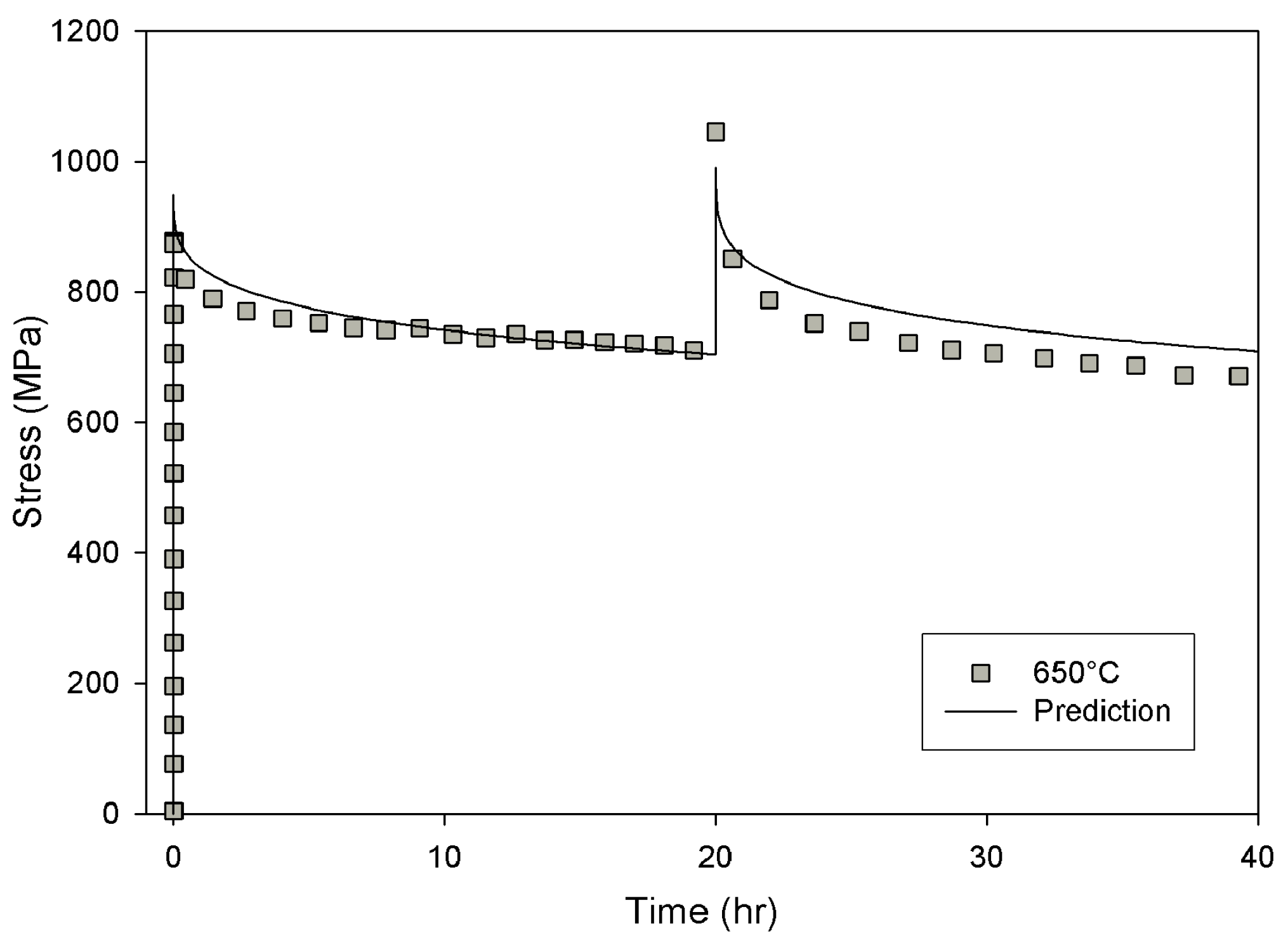

3.4. Stress Relaxation

4. Discussion

5. Conclusions

Acknowledgments

References

- Larson, F.R.; Miller, E.J. Time-Temperature relationship for rupture and creep stresses. Trans. ASME 1952, 74, 765–775. [Google Scholar]

- Evans, R.W.; Parker, J.D.; Wilshire, B. An extrapolation procedure for long-term creep strain and creep life prediction with special reference to 0.5Cr0.5Mo0.25V ferritic steels. In Proceedings of Recent Advances in Creep and Fracture of Engineering Materials and Structures, Swansea, UK, 24–27 March, 1981; Pineridge Press: Swansea, UK, 1982; pp. 135–184. [Google Scholar]

- Evans, R.W.; Beden, I.; Wilshire, B. Creep life prediction for 0.5Cr0.5Mo0.25V ferritic steel. In Proceedings of the 2nd International Conference on Creep and Fracture of Engineering Materials and Structures, Swansea, UK, 1-6 April 1984; Pineridge Press: Swansea, UK, 1984; pp. 1277–1296. [Google Scholar]

- McVetty, P.G. Creep of metals at elevated temperatures—The hyperbolic sine relation between stress and creep rate. Trans. ASME 1943, 65, 761–769. [Google Scholar]

- Wilshire, B.; Battenbough, A.J. Creep and creep fracture of polycrystalline copper. Mater. Sci. Eng. A 2007, 443, 156–166. [Google Scholar] [CrossRef]

- Wilshire, B.; Whittaker, M.T. The role of grain boundaries in creep strain accumulation. Acta Mater. 2009, 57, 4115–4124. [Google Scholar] [CrossRef]

- Wilshire, B.; Scharning, P.J. Long-Term creep life prediction for a high chromium steel. Scr. Mater. 2007, 56, 701–704. [Google Scholar] [CrossRef]

- Wilshire, B.; Scharning, P.J. Extrapolation of creep life data for 1Cr–0.5Mo steel. Int. J. Press. Vessel. Pip. 2008, 85, 739–743. [Google Scholar] [CrossRef]

- Evans, M. Prediction of long-term creep rupture data for 18Cr–12Ni–Mo steel. Int. J. Press. Vessel. Pip. 2011, 88, 449–451. [Google Scholar] [CrossRef]

- Wilshire, B.; Scharning, P.J. Prediction of long term creep data for forged 1Cr–1Mo–0.25V steel. Mat. Sci. Tech. 2008, 24, 1–9. [Google Scholar] [CrossRef]

- Abdallah, Z.; Perkins, K.; Williams, S. Advances in the Wilshire extrapolation technique—Full creep curve representation for the aerospace alloy Titanium 834. Mater. Sci. Eng. A 2012, 550, 176–182. [Google Scholar] [CrossRef]

- Bryant, D.J.; McIntosh, G. The Manufacture and evaluation of a large turbine disc in cast and wrought Alloy 720Li. In Proceedings of Superalloy 1996, Seven Springs, PA, USA, 22–26 September 1996; The Minerals, Metals & Materials Society: Warrendale, PA, USA, 1996; pp. 713–722. [Google Scholar]

- BSI (British Standards Institution). Tensile Stress Relaxation Testing, Procedure for Testing Machines; BS EN 10319-1:2003; BSI: London, UK, 2003. [Google Scholar]

- Monkman, F.C.; Grant, N.J. An empirical relationship between rupture life and minimum creep rate in creep-rupture tests. Proc. ASTM 1956, 56, 593–620. [Google Scholar]

- Gopinath, K.; Gogia, A.K.; Kamat, S.V.; Balamuralikrishnan, R.; Ramamurty, U. Tensile properties of Ni-Based Superalloy 720Li: Temperature and strain rate effects. Metal. Mater. Trans. A 2008, 39, 2340–2350. [Google Scholar] [CrossRef]

- Andrade, E.N. On the viscous flow in metals, and allied phenomena. Proc. Roy. Soc. Lond. A 1910, 84, 1–12. [Google Scholar] [CrossRef]

- Bailey, R.W. The utilization of creep test data in engineering design. Proc. Inst. Mech. Eng. 1935, 131, 209–284. [Google Scholar] [CrossRef]

- Garofalo, F. Fundamentals of Creep Rupture in Metals; Macmillan: London, UK, 1965. [Google Scholar]

- Evans, R.W. A constitutive model for the high-temperature creep of particle-hardened alloys based on the θ projection method. Proc. Roy. Soc. Lond. A 2000, 456, 835–868. [Google Scholar] [CrossRef]

- Kachanov, L.M. Time of the rupture process under creep conditions. Izv. Akad. Nauk. SSR Otd. Tech. Nauk. 1958, 8, 26–31. [Google Scholar]

- Rabotnov, Y.N. Creep Problems in Structural Members; North-Holland Publishing Company: North-Holland, the Netherlands, 1969. [Google Scholar]

- Othman, A.M.; Hayhurst, D.R. Multi-Axial creep rupture of a model structure using a two parameter material model. Int. J. Mech. Sci. 1990, 32, 35–48. [Google Scholar] [CrossRef]

- Sherby, O.D. Factors affecting the high temperature strength of polycrystalline solids. Acta Metal. 1962, 10, 135–147. [Google Scholar] [CrossRef]

- Wazzan, A.R. Lattice and grain boundary self-diffusion in nickel. J. Appl. Phys. 1965, 36, 3596–3599. [Google Scholar] [CrossRef]

- Whittaker, M.T.; Wilshire, B. Creep and creep fracture of 2.25Cr–1.6W steels (Grade 23). Mater. Sci. Eng. A 2010, 527, 4932–4938. [Google Scholar] [CrossRef]

- Whittaker, M.T.; Wilshire, B. Long term creep life prediction for Grade 22 (225Cr–1Mo) steels. Mater. Sci. Tech. 2011, 27, 642–647. [Google Scholar] [CrossRef]

- Whittaker, M.T.; Wilshire, B. Advanced procedures for long-term creep data prediction for 2.25 chromium steels. Metal. Mat. Trans. A 2013, 44, 136–153. [Google Scholar] [CrossRef]

- Manonukul, A.; Dunne, F.P.E. High- and low-cycle fatigue crack initiation using polycrystal plasticity. Proc. Roy. Soc. Lond. A 2004, 460, 1881–1903. [Google Scholar] [CrossRef]

- Goodall, I.W.; Leckie, F.A.; Ponter, A.R.S.; Townley, C. The development of high temperature design methods based on reference stresses and bounding theorems. J. Eng. Mater. Tech. Trans. ASME 1979, 101, 349–355. [Google Scholar] [CrossRef]

© 2013 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Harrison, W.; Whittaker, M.; Williams, S. Recent Advances in Creep Modelling of the Nickel Base Superalloy, Alloy 720Li. Materials 2013, 6, 1118-1137. https://doi.org/10.3390/ma6031118

Harrison W, Whittaker M, Williams S. Recent Advances in Creep Modelling of the Nickel Base Superalloy, Alloy 720Li. Materials. 2013; 6(3):1118-1137. https://doi.org/10.3390/ma6031118

Chicago/Turabian StyleHarrison, William, Mark Whittaker, and Steve Williams. 2013. "Recent Advances in Creep Modelling of the Nickel Base Superalloy, Alloy 720Li" Materials 6, no. 3: 1118-1137. https://doi.org/10.3390/ma6031118

APA StyleHarrison, W., Whittaker, M., & Williams, S. (2013). Recent Advances in Creep Modelling of the Nickel Base Superalloy, Alloy 720Li. Materials, 6(3), 1118-1137. https://doi.org/10.3390/ma6031118