Optimizing Wood–Hemp–Sodium Silicate Composites for Strength, Extrudability, and Cost in Additive Manufacturing Applications

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Design of Experiments

2.3. Particle Size Analysis and Bulk Density

2.4. Rheology

2.5. Extrusion

2.6. Specimen Density, Flexural, and Compression Strength Testing

2.7. Cost Analysis

2.8. Microscopy

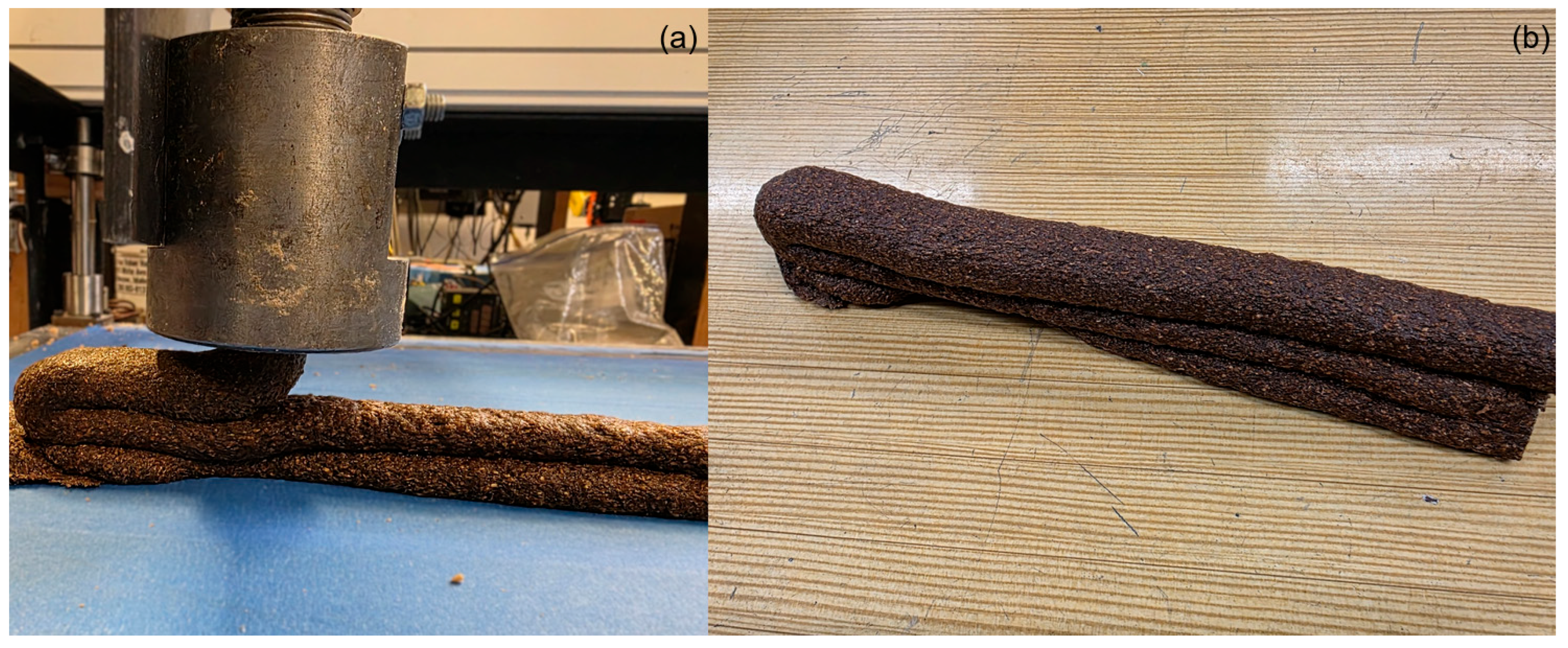

2.9. Additive Manufacturing

3. Results

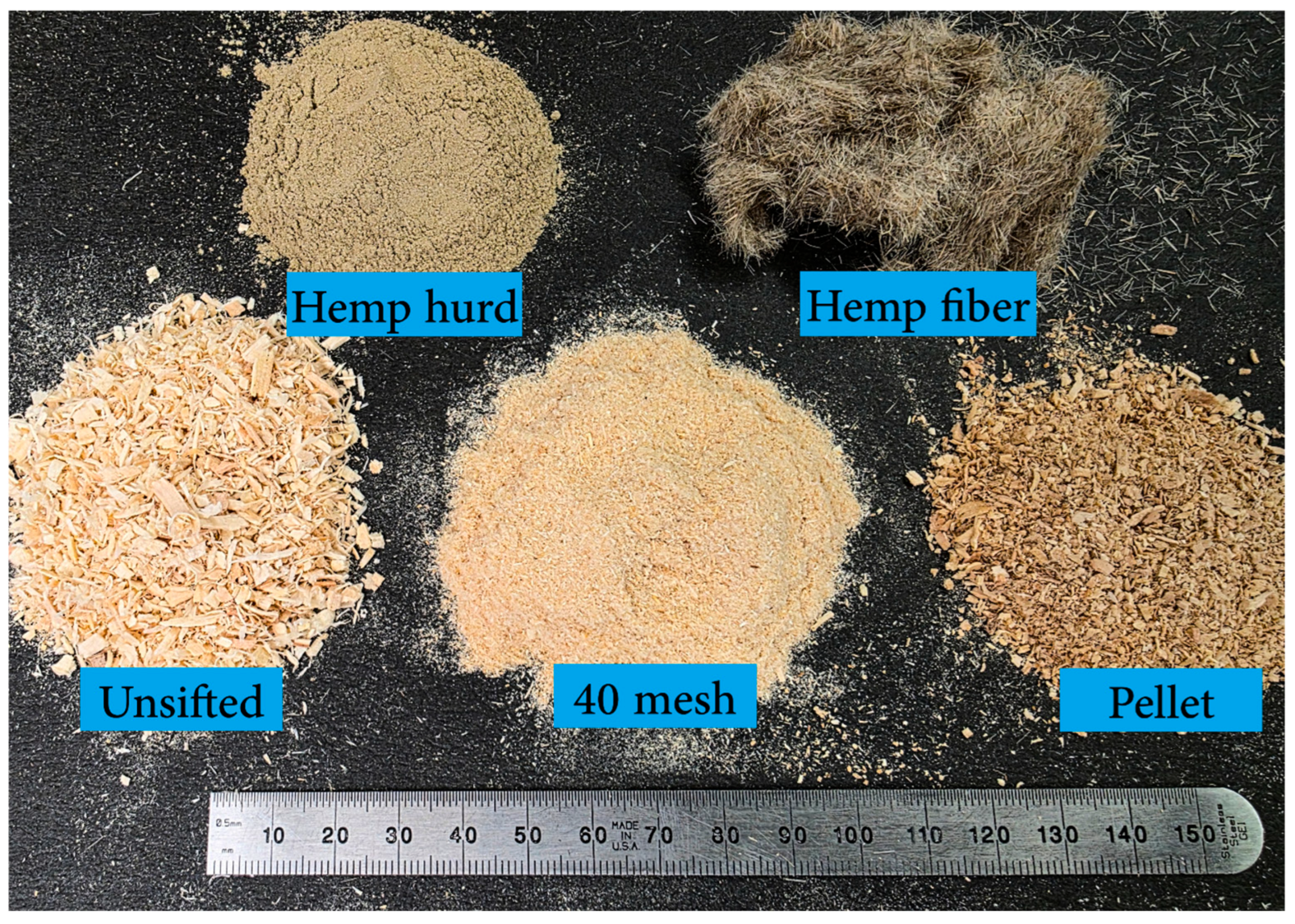

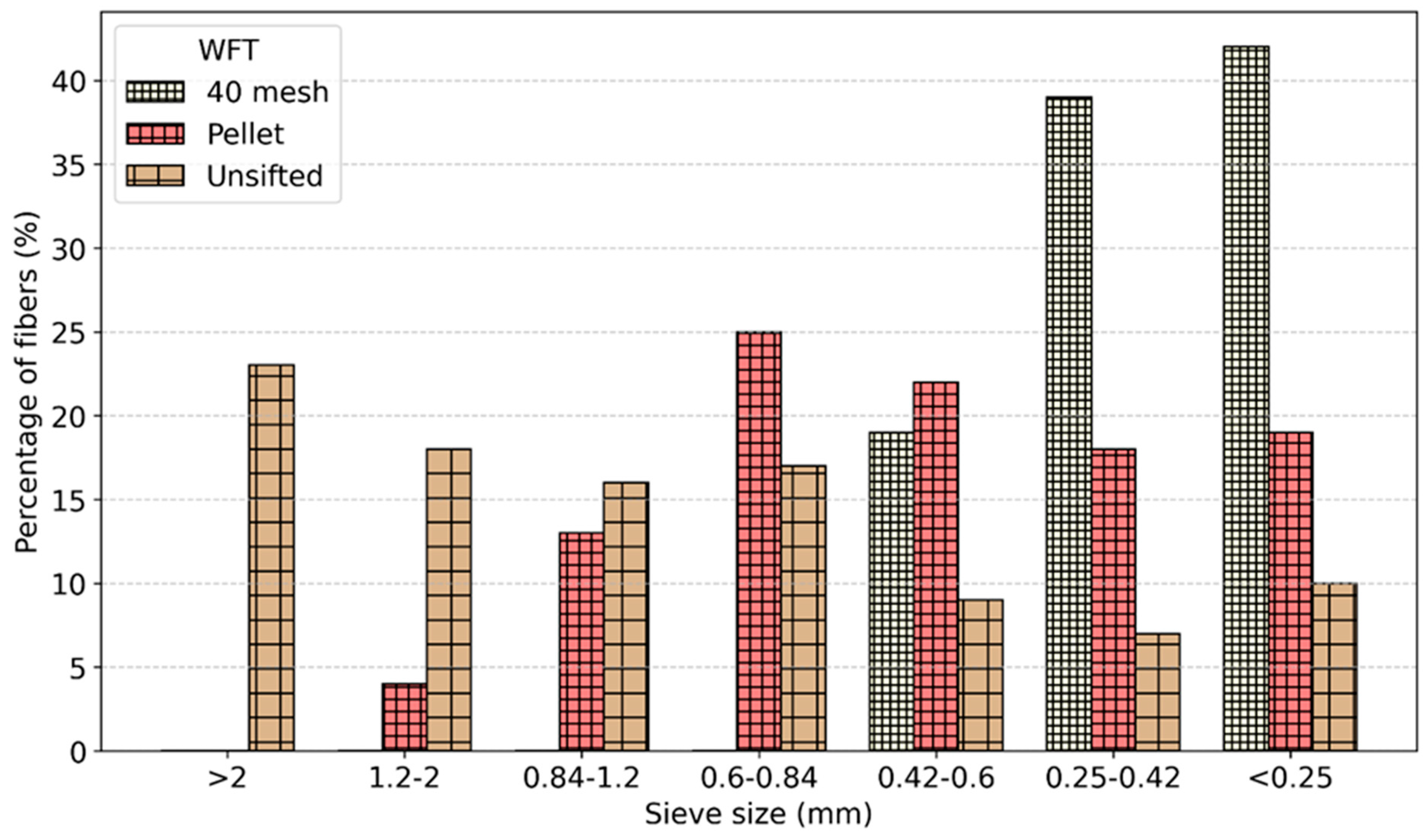

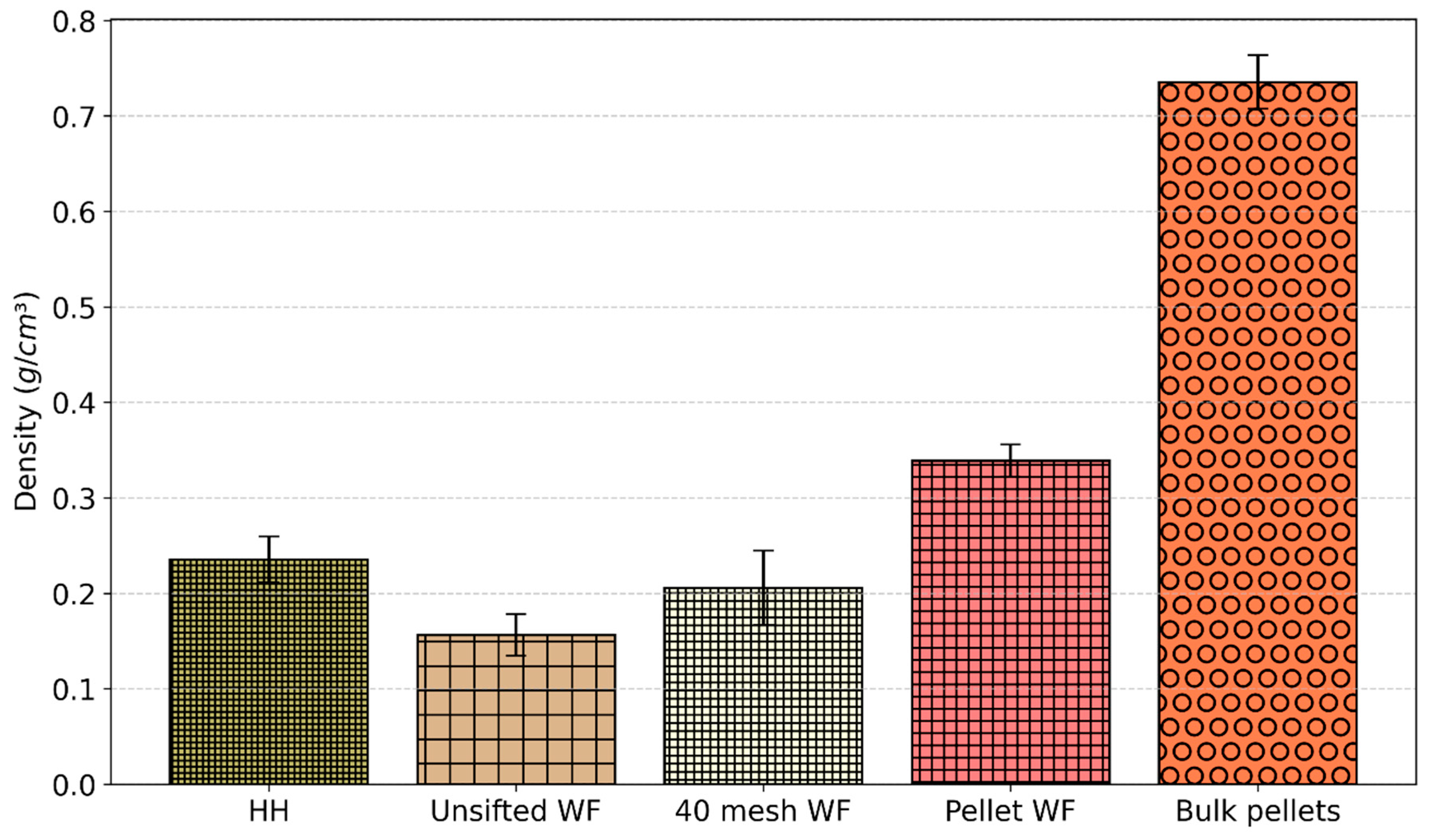

3.1. Particle Size Analysis and Bulk Density of Constituent Materials

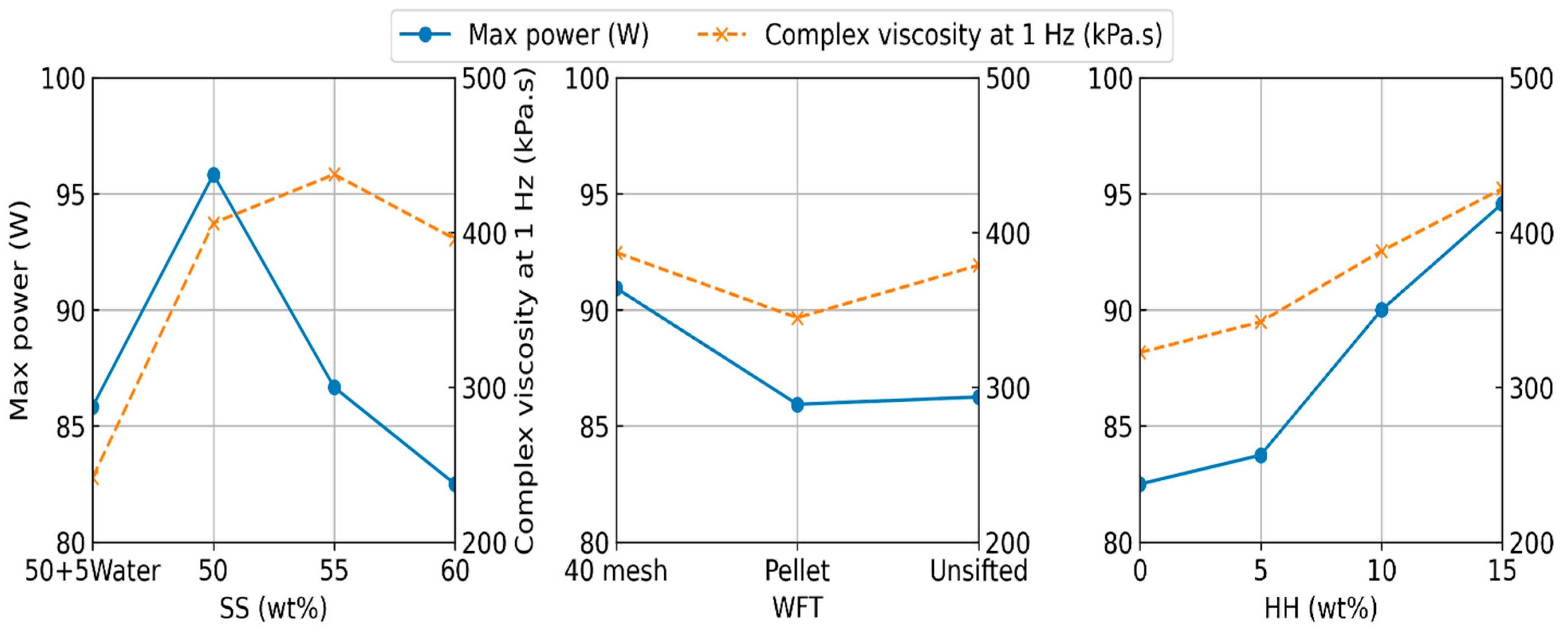

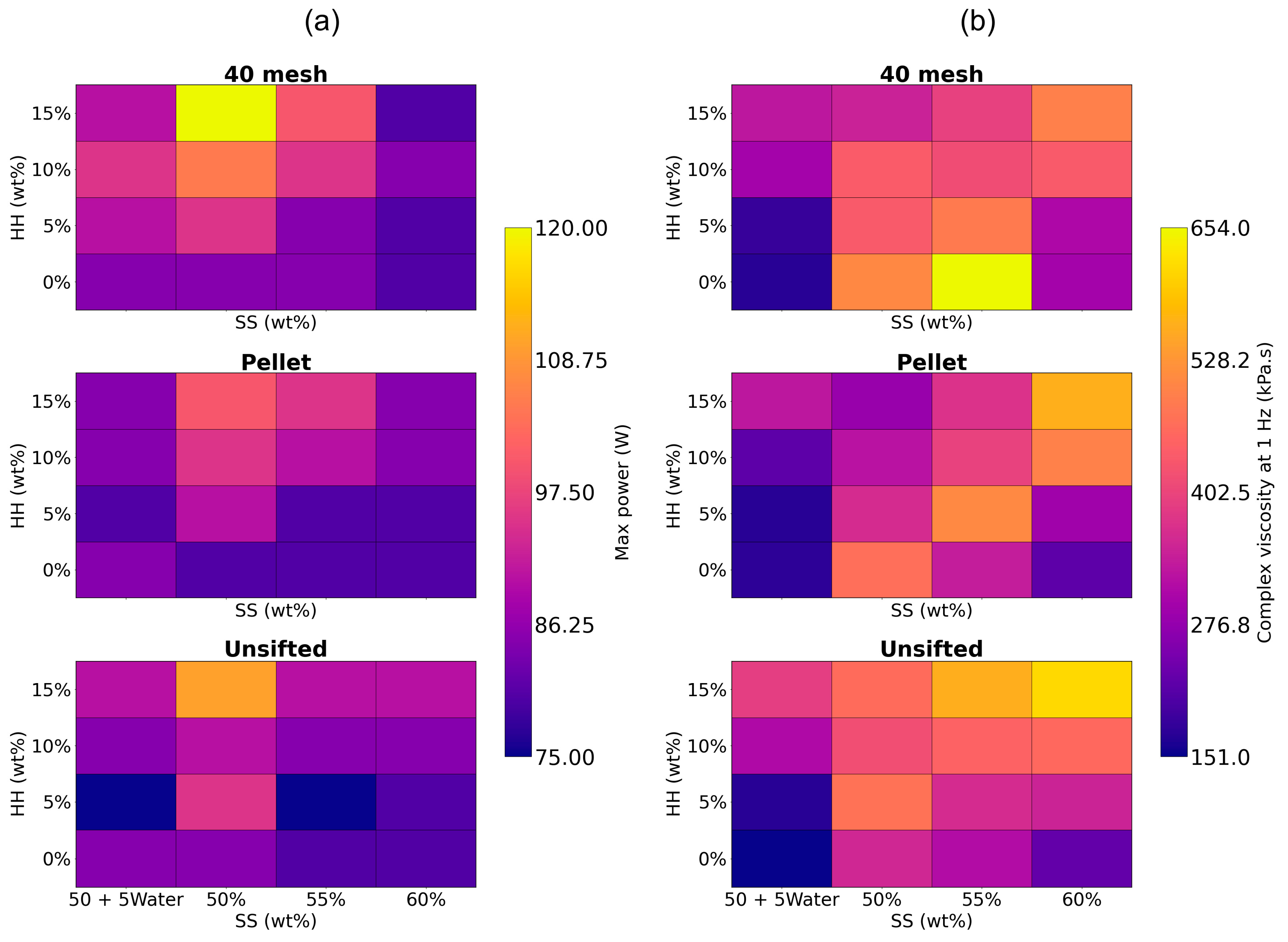

3.2. Rheology and Extrusion

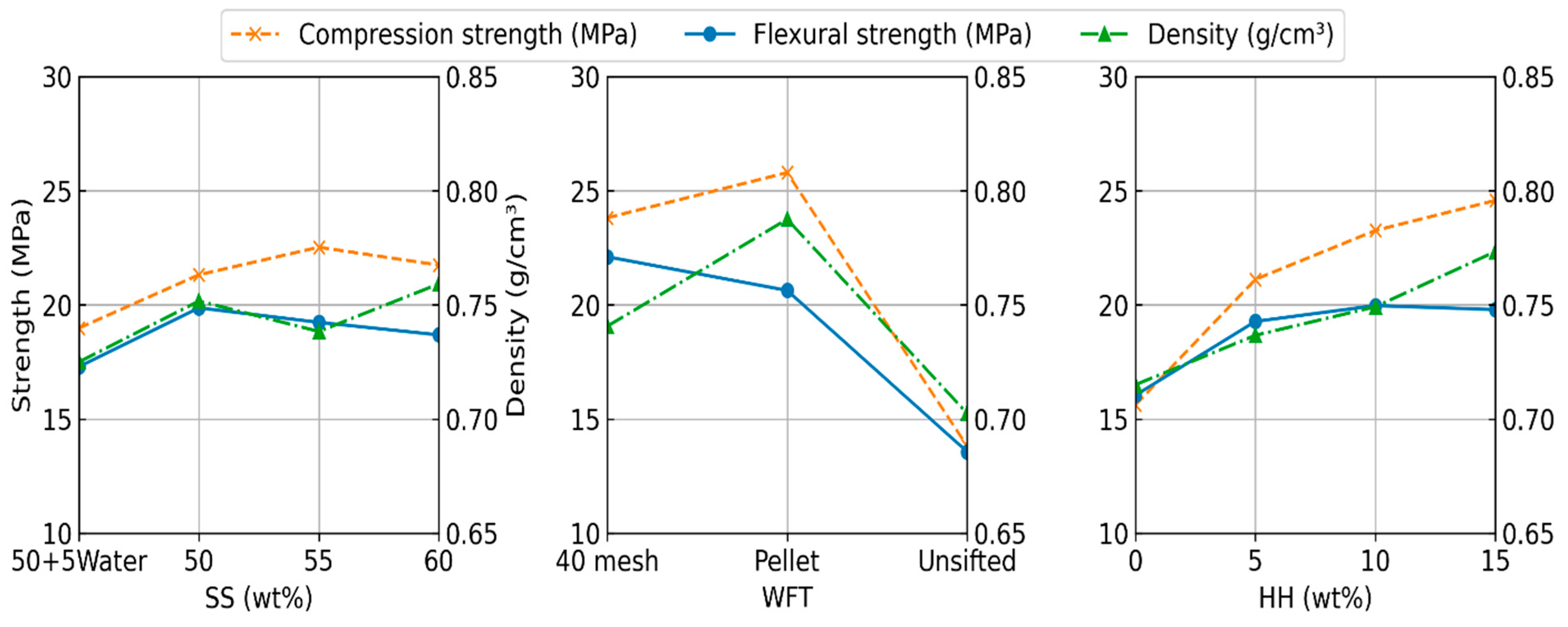

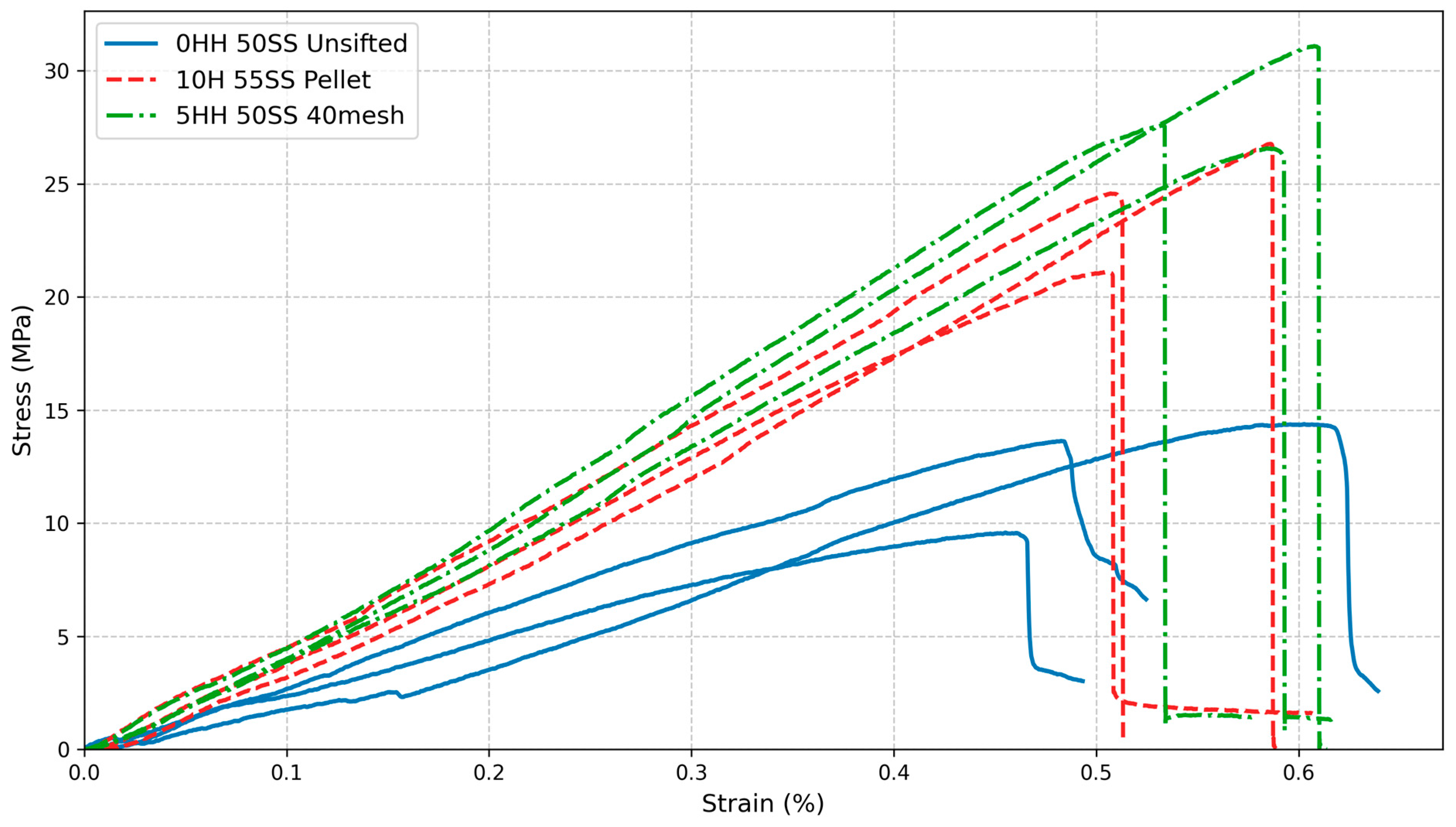

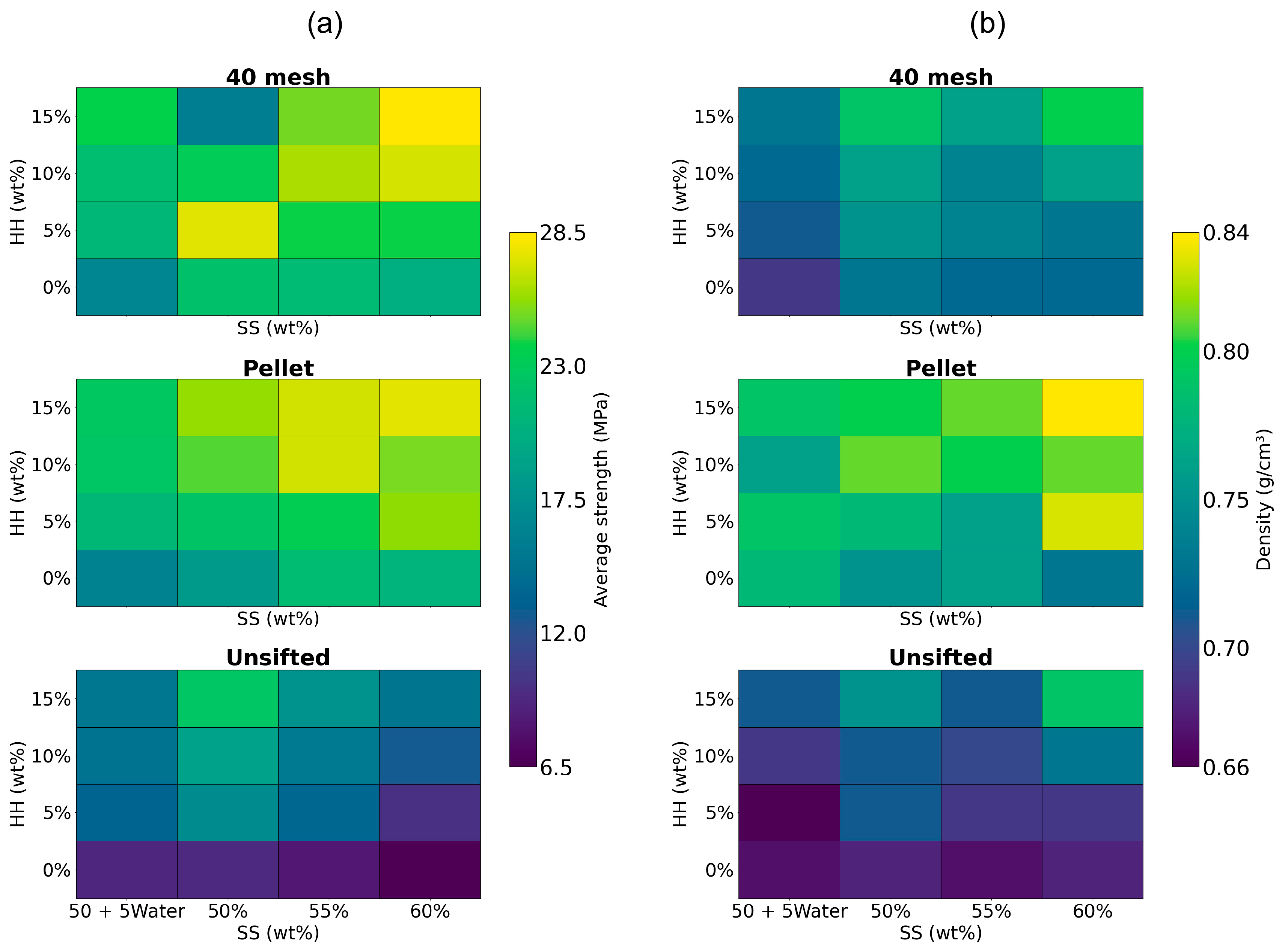

3.3. Specimen Density, Flexural and Compression Strength Testing

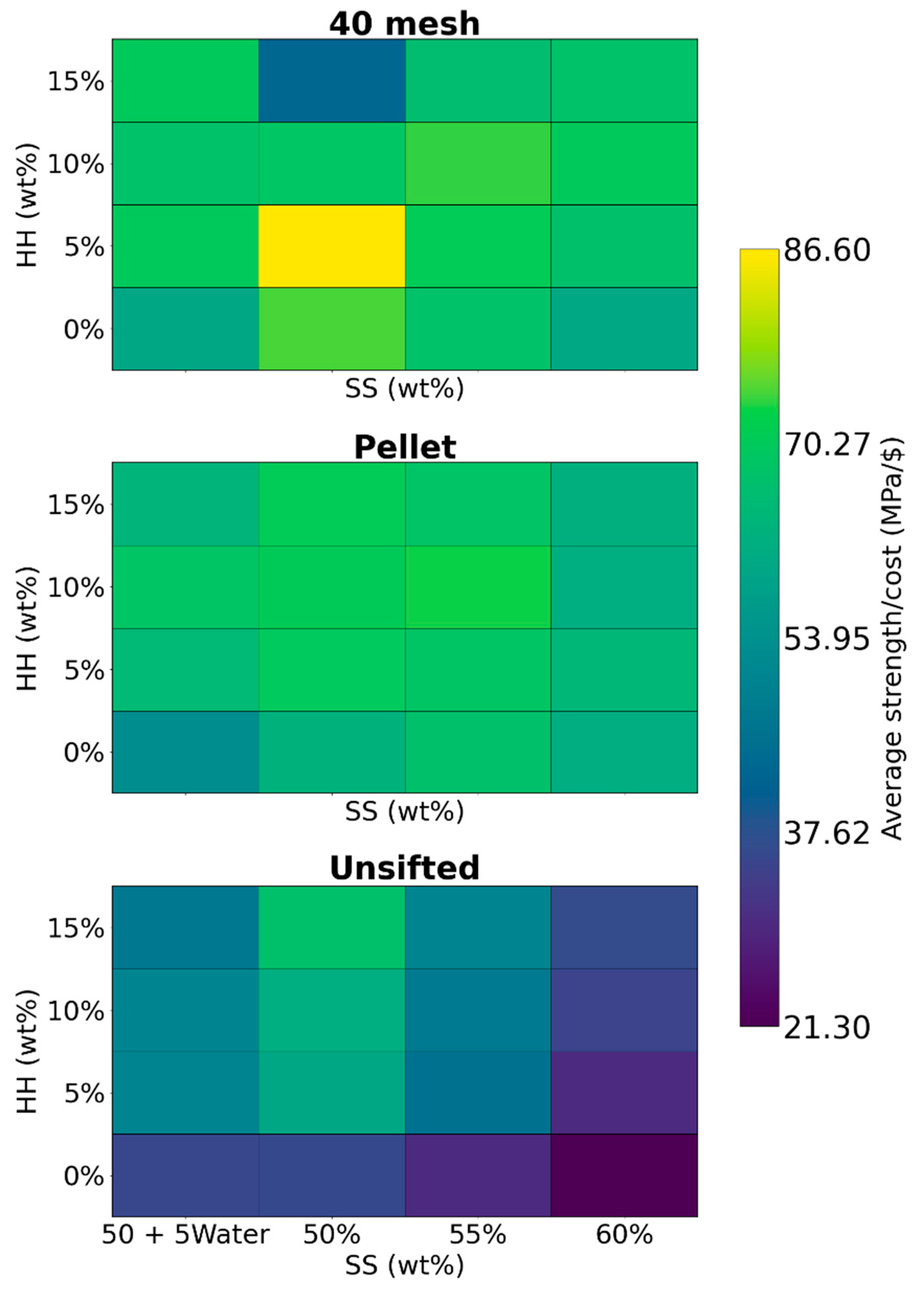

3.4. Cost Analysis

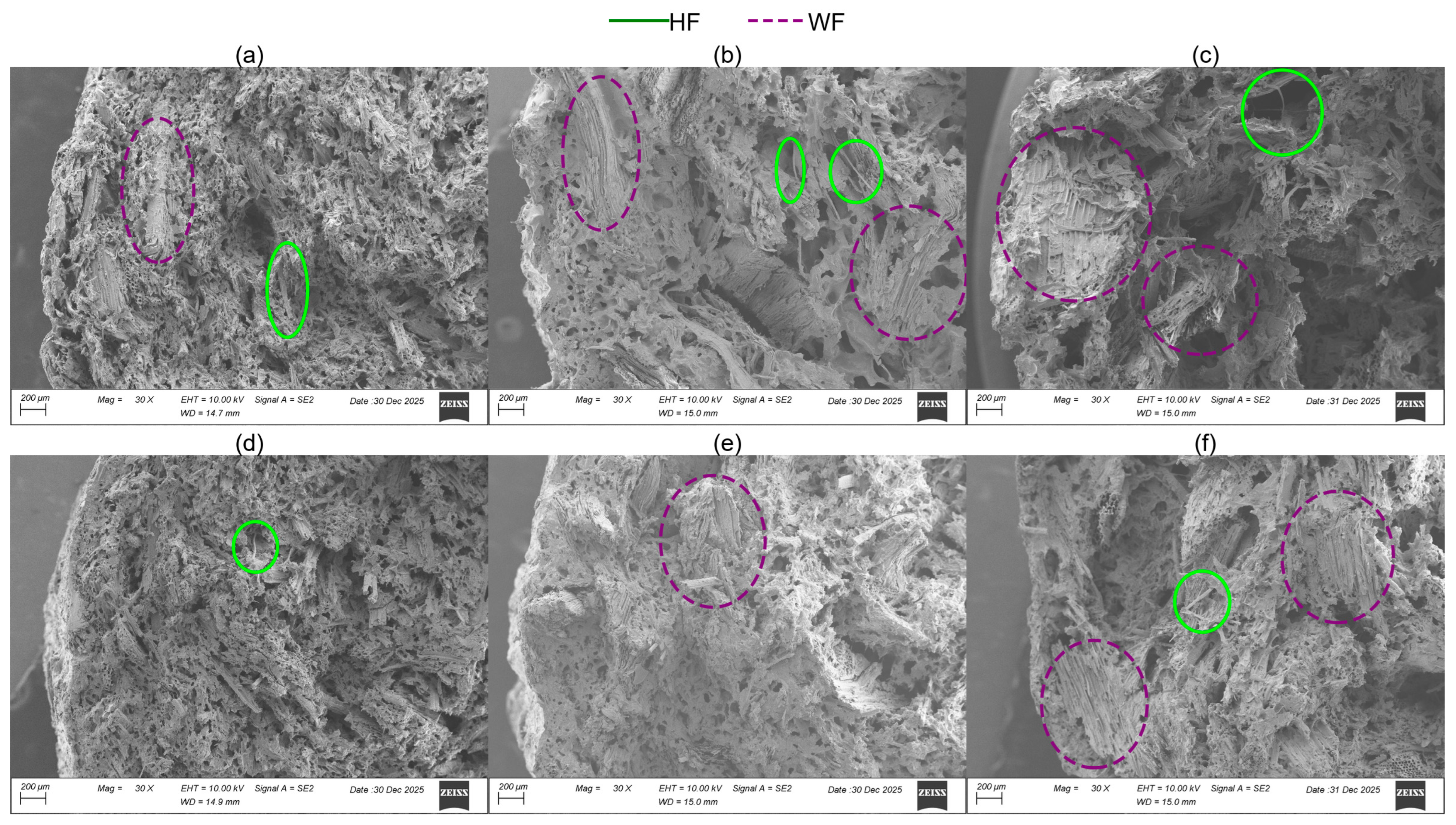

3.5. Scanning Electron Microscopy

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Food and Agriculture Organization of the United Nation. Global Forest Products Facts and Figures 2023; FAO: Rome, Italy, 2024. [Google Scholar] [CrossRef]

- Khoaele, K.K.; Gbadeyan, O.J.; Chunilall, V.; Sithole, B. A review on waste wood reinforced polymer composites and their processing for construction materials. Int. J. Sustain. Eng. 2023, 16, 104–116. [Google Scholar] [CrossRef]

- Abdoli, M.A.; Golzary, A.; Hosseini, A.; Sadeghi, P. Wood Pellet as a Renewable Source of Energy; Springer International Publishing: Cham, Switzerland, 2018. [Google Scholar] [CrossRef]

- Pa, A.; Bi, X.T.; Sokhansanj, S. Evaluation of wood pellet application for residential heating in British Columbia based on a streamlined life cycle analysis. Biomass Bioenergy 2013, 49, 109–122. [Google Scholar] [CrossRef]

- Thomson, H.; Liddell, C. The suitability of wood pellet heating for domestic households: A review of literature. Renew. Sustain. Energy Rev. 2015, 42, 1362–1369. [Google Scholar] [CrossRef]

- Carne, R.H.; Alade, A.A.; Orji, B.O.; Ibrahim, A.; McDonald, A.G.; Maughan, M.R. A screw extrusion-based system for additive manufacturing of wood: Sodium silicate thermoset composites. Adv. Mech. Eng. 2023, 15, 16878132231210373. [Google Scholar] [CrossRef]

- Orji, B.O.; Thie, C.; Baker, K.; Maughan, M.R.; McDonald, A.G. Wood fiber-sodium silicate mixtures for additive manufacturing of composite materials. Eur. J. Wood Wood Prod. 2023, 81, 45–58. [Google Scholar] [CrossRef]

- Tanikella, N.G.; Lehman-Chong, A.M.; McDonald, A.G.; Maughan, M.R. Extrudability and Mechanical Properties of Wood–Sodium Silicate Composites with Hemp Fiber Reinforcement for Additive Manufacturing. Polymers 2025, 17, 2478. [Google Scholar] [CrossRef] [PubMed]

- Adapa, S.K.; Jagadish. Prospects of Natural Fiber-Reinforced Polymer Composites for Additive Manufacturing Applications: A Review. JOM 2023, 75, 920–940. [Google Scholar] [CrossRef]

- Pokhrel, G.; Kizha, A.R.; Gardner, D.J. Transportation cost analysis on alternative wood feedstocks for manufacturing wood-plastic composites. BioResources 2021, 17, 634–651. [Google Scholar] [CrossRef]

- Pokhrel, G.; Gu, H.; Gardner, D.J.; O’Neill, S. Life Cycle Assessment (LCA) of Wood Flour and Pellets for Manufacturing Wood-Plastic Composites (WPCs). Recent Prog. Mater. 2022, 4, 003. [Google Scholar] [CrossRef]

- Pokhrel, G.; Gardner, D.J.; Han, Y. Properties of Wood–Plastic Composites Manufactured from Two Different Wood Feedstocks: Wood Flour and Wood Pellets. Polymers 2021, 13, 2769. [Google Scholar] [CrossRef]

- Billings, C.; Siddique, R.; Sherwood, B.; Hall, J.; Liu, Y. Additive Manufacturing and Characterization of Sustainable Wood Fiber-Reinforced Green Composites. J. Compos. Sci. 2023, 7, 489. [Google Scholar] [CrossRef]

- Siddiqui, V.U.; Yusuf, J.; Sapuan, S.M.; Hasan, M.Z.; Bistari, M.M.M.; Mohammadsalih, Z.G. Mechanical Properties and Flammability Analysis of Wood Fiber Filled Polylactic Acid (PLA) Composites Using Additive Manufacturing. J. Nat. Fibers 2024, 21, 2409868. [Google Scholar] [CrossRef]

- Maraveas, C. Production of Sustainable Construction Materials Using Agro-Wastes. Materials 2020, 13, 262. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Olaiya, B.C.; Lawan, M.M.; Olonade, K.A. Utilization of sawdust composites in construction—A review. SN Appl. Sci. 2023, 5, 140. [Google Scholar] [CrossRef]

- Kumbasaroglu, H.; Kumbasaroglu, A. Applicability of Agro-Waste Materials in Structural Systems for Building Construction: A Scoping Review. Appl. Sci. 2025, 15, 71. [Google Scholar] [CrossRef]

- Jena, M.; Mishra, S.; Moharana, H. Application of 3D printing across various fields to enhance sustainable manufacturing. Sustain. Soc. Dev. 2024, 2, 2864. [Google Scholar] [CrossRef]

- Ceylan, İ.; Alp, N.Ç.; Aytaç, A. Sustainable 3D printing with alkali-treated hemp fiber-reinforced polycarbonate composites. Cellulose 2024, 31, 4477–4495. [Google Scholar] [CrossRef]

- Ciolacu, F.; Măluțan, T.; Lisa, G.; Ichim, M. Influence of Lignin Type on the Properties of Hemp Fiber-Reinforced Polypropylene Composites. Polymers 2024, 16, 3442. [Google Scholar] [CrossRef] [PubMed]

- Hanson, M.; Yang, C.-H. Characterization of Polylactic Acid Filament with Biodegradable Hemp Fiber Infused During Additive Manufacturing Process. In Proceedings of the ASME 2022 17th International Manufacturing Science and Engineering Conference, West Lafayette, IN, USA, 27 June–1 July 2022. [Google Scholar] [CrossRef]

- Huzaifa, M.; Akhtar, N.; Zahoor, S.; Abdullah, M.H.; Arslan, M.; Niazi, A.K. Hemp fibers as sustainable reinforcement in natural fiber composites: A comprehensive review. World J. Biol. Biotechnol. 2024, 9, 1–8. [Google Scholar] [CrossRef]

- Islam, S.; Hasan, B.; Kodrić, M.; Motaleb, K.Z.M.A.; Karim, F.; Islam, R. Mechanical properties of hemp fiber-reinforced thermoset and thermoplastic polymer composites: A comprehensive review. SPE Polym. 2025, 6, e10173. [Google Scholar] [CrossRef]

- Koushki, P.; Kwok, T.-H.; Hof, L.; Wuthrich, R. Reinforcing silicone with hemp fiber for additive manufacturing. Compos. Sci. Technol. 2020, 194, 108139. [Google Scholar] [CrossRef]

- Sultan, R.; Skrifvars, M.; Khalili, P. 3D printing of polypropylene reinforced with hemp fibers: Mechanical, water absorption and morphological properties. Heliyon 2024, 10, e26617. [Google Scholar] [CrossRef]

- Hamou, K.B.; Kaddami, H.; Elisabete, F.; Erchiqui, F. Synergistic association of wood /hemp fibers reinforcements on mechanical, physical and thermal properties of polypropylene-based hybrid composites. Ind. Crops Prod. 2023, 192, 116052. [Google Scholar] [CrossRef]

- Hernandez-Estrada, A.; Müssig, J.; Hughes, M. The impact of fibre processing on the mechanical properties of epoxy matrix composites and wood-based particleboard reinforced with hemp (Cannabis sativa L.) fibre. J. Mater. Sci. 2022, 57, 1738–1754. [Google Scholar] [CrossRef]

- Beg, M.D.H.; Pickering, K.L.; Akindoyo, J.O.; Gauss, C. Recyclable hemp hurd fibre-reinforced PLA composites for 3D printing. J. Mater. Res. Technol. 2024, 33, 4439–4447. [Google Scholar] [CrossRef]

- Jubinville, D.; Chen, G.; Mekonnen, T.H. Simulated thermo-mechanical recycling of high-density polyethylene for the fabrication of hemp hurd plastic composites. Polym. Degrad. Stab. 2023, 211, 110342. [Google Scholar] [CrossRef]

- Sam-Brew, S.; Smith, G.D. Flax and Hemp fiber-reinforced particleboard. Ind. Crops Prod. 2015, 77, 940–948. [Google Scholar] [CrossRef]

- Xiao, X.; Chevali, V.S.; Song, P.; Yu, B.; Feng, J.; Loh, T.W.; Wang, H. Mechanical properties and microstructure of hemp hurd reinforced polylactide biocomposites for 3D printing. Polym. Compos. 2025, 46, 4927–4937. [Google Scholar] [CrossRef]

- Chen, J.J.; Kwan, A.K.H. Superfine cement for improving packing density, rheology and strength of cement paste. Cem. Concr. Compos. 2012, 34, 1–10. [Google Scholar] [CrossRef]

- Kwan, A.K.H.; Ng, P.L.; Huen, K.Y. Effects of fines content on packing density of fine aggregate in concrete. Constr. Build. Mater. 2014, 61, 270–277. [Google Scholar] [CrossRef]

- Cheng, Y.-H.; Zhu, B.-L.; Yang, S.-H.; Tong, B.-Q. Design of Concrete Mix Proportion Based on Particle Packing Voidage and Test Research on Compressive Strength and Elastic Modulus of Concrete. Materials 2021, 14, 623. [Google Scholar] [CrossRef]

- Wood Pellets Super Premium, North Ida. Energy Logs. Available online: https://northidahoenergylogs.com/wood-pellets/ (accessed on 29 September 2025).

- Hot & Cold Webbing Tape Cutting Machine 280W Automatic Textile Ribbon Cutter, eBay (n.d.). Available online: https://www.ebay.com/itm/404820935425 (accessed on 24 October 2025).

- De Coninck, E.; Marchesini, F.H.; Vanhoorne, V.; De Beer, T.; Vervaet, C. Viscosity of API/fatty acid suspensions: Pitfalls during analysis. Int. J. Pharm. 2020, 584, 119447. [Google Scholar] [CrossRef]

- Ferraris, C.F.; Geiker, M.; Martys, N.S.; Muzzatti, N. Parallel-plate Rheometer Calibration Using Oil and Computer Simulation. J. Adv. Concr. Technol. 2007, 5, 363–371. [Google Scholar] [CrossRef]

- ASTM D790-15; Standard Test Method for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM D6109-24; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastic Lumber and Related Products. ASTM International: West Conshohocken, PA, USA, 2024.

- ASTM D695-23; Standard Test Method for Compressive Properties of Rigid Plastics. ASTM International: West Conshohocken, PA, USA, 2023.

- Guo, M.; Song, W.; Buhain, J. Bioenergy and biofuels: History, status, and perspective. Renew. Sustain. Energy Rev. 2015, 42, 712–725. [Google Scholar] [CrossRef]

- Nasri, K.; Loranger, É.; Toubal, L. Effect of cellulose and lignin content on the mechanical properties and drop-weight impact damage of injection-molded polypropylene-flax and -pine fiber composites. J. Compos. Mater. 2023, 57, 3347–3364. [Google Scholar] [CrossRef]

- Komisarz, K.; Majka, T.M.; Pielichowski, K. Chemical and Physical Modification of Lignin for Green Polymeric Composite Materials. Materials 2022, 16, 16. [Google Scholar] [CrossRef]

- Shojaeiarani, J.; Bajwa, D.S.; Ryan, C.; Kane, S. Enhancing UV-shielding and mechanical properties of polylactic acid nanocomposites by adding lignin coated cellulose nanocrystals. Ind. Crops Prod. 2022, 183, 114904. [Google Scholar] [CrossRef]

- Zha, H.; Fu, H.; Chen, C.; Yang, J.; Wang, H.; Zhu, X.; Yuan, D.; Jia, C. The use of eco-friendly lignin as a cementitious material to improve the engineering properties of disintegrated carbonaceous mudstone. Constr. Build. Mater. 2022, 359, 129456. [Google Scholar] [CrossRef]

- Malkin, A.Y.; Patlazhan, S.A. Wall slip for complex liquids–Phenomenon and its causes. Adv. Colloid Interface Sci. 2018, 257, 42–57. [Google Scholar] [CrossRef] [PubMed]

- Wilms, P.; Wieringa, J.; Blijdenstein, T.; van Malssen, K.; Hinrichs, J.; Kohlus, R. On the difficulty of determining the apparent wall slip of highly concentrated suspensions in pressure driven flows: The accuracy of indirect methods and best practice. J. Non-Newton. Fluid Mech. 2022, 299, 104694. [Google Scholar] [CrossRef]

- Gao, G.; Xu, F.; Xu, J.; Liu, Z. Study of Material Color Influences on Mechanical Characteristics of Fused Deposition Modeling Parts. Materials 2022, 15, 7039. [Google Scholar] [CrossRef] [PubMed]

- Amazon.com: HATCHBOX 1.75mm Purple PLA 3D Printer Filament, 1 KG Spool, Dimensional Accuracy +/− 0.03 mm, 3D Printing Filament: Industrial & Scientific. Available online: https://www.amazon.com/HATCHBOX-3D-Filament-Dimensional-Accuracy/dp/B00MEZDRPO/?th=1 (accessed on 21 October 2025).

- LX175 PLA. Filabot. Available online: https://www.filabot.com/products/lx175-pla (accessed on 21 October 2025).

| Factor | Levels/Values |

|---|---|

| WFT | Unsifted, 40 mesh, pellet |

| SS fraction (wt%) | 50, 55, 60, 50 + 5Water |

| HH fraction (wt%) | 0, 5, 10, 15 |

| HF fraction (wt%) | Fixed at 5 (3 mm length) |

| WF fraction (wt%) | Balance to 100% |

| Variables | Metric | Responses | ||||

|---|---|---|---|---|---|---|

| Power | Viscosity | Density | Flexural Strength | Compression Strength | ||

| SS | p-Value | 0 | 0 | 0 | 0.026 | 0.008 |

| % Contribution | 32.9 | 38.9 | 8.2 | 4.0 | 3.5 | |

| HH | p-Value | 0 | 0 | 0 | 0 | 0 |

| % Contribution | 29.5 | 11.2 | 21.1 | 8.1 | 21.2 | |

| WFT | p-Value | 0.003 | 0.073 | 0 | 0 | 0 |

| % Contribution | 6.1 | 2.3 | 57.9 | 62.6 | 55.3 | |

| SS × HH | p-Value | 0 | 0 | 0.003 | 0.506 | 0.304 |

| % Contribution | 12.0 | 24.0 | 4.1 | 0.9 | 0.9 | |

| SS × WFT | p-Value | 0.054 | 0.45 | 0.234 | 0.101 | 0 |

| % Contribution | 4.9 | 2.4 | 1.9 | 4.5 | 8.9 | |

| HH × WFT | p-Value | 0.657 | 0 | 0.603 | 0.002 | 0.171 |

| % Contribution | 0.4 | 9.7 | 0.2 | 5.7 | 0.9 | |

| Material | Cost in USD ($/kg) |

|---|---|

| Unsifted WF | 0.11 |

| Pellet WF | 0.32 |

| 40 mesh WF | 0.85 |

| HH | 6.61 |

| HF | 6.61 |

| SS | 3.79 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Tanikella, N.G.; McDonald, A.G.; Maughan, M.R. Optimizing Wood–Hemp–Sodium Silicate Composites for Strength, Extrudability, and Cost in Additive Manufacturing Applications. Materials 2026, 19, 357. https://doi.org/10.3390/ma19020357

Tanikella NG, McDonald AG, Maughan MR. Optimizing Wood–Hemp–Sodium Silicate Composites for Strength, Extrudability, and Cost in Additive Manufacturing Applications. Materials. 2026; 19(2):357. https://doi.org/10.3390/ma19020357

Chicago/Turabian StyleTanikella, Nagendra G., Armando G. McDonald, and Michael R. Maughan. 2026. "Optimizing Wood–Hemp–Sodium Silicate Composites for Strength, Extrudability, and Cost in Additive Manufacturing Applications" Materials 19, no. 2: 357. https://doi.org/10.3390/ma19020357

APA StyleTanikella, N. G., McDonald, A. G., & Maughan, M. R. (2026). Optimizing Wood–Hemp–Sodium Silicate Composites for Strength, Extrudability, and Cost in Additive Manufacturing Applications. Materials, 19(2), 357. https://doi.org/10.3390/ma19020357