Relationship Between Hardness and Impact Strength of Epoxy–Glass Composites Modified with Carbonisate from MDF Pyrolysis

Abstract

1. Introduction

2. Materials and Methods

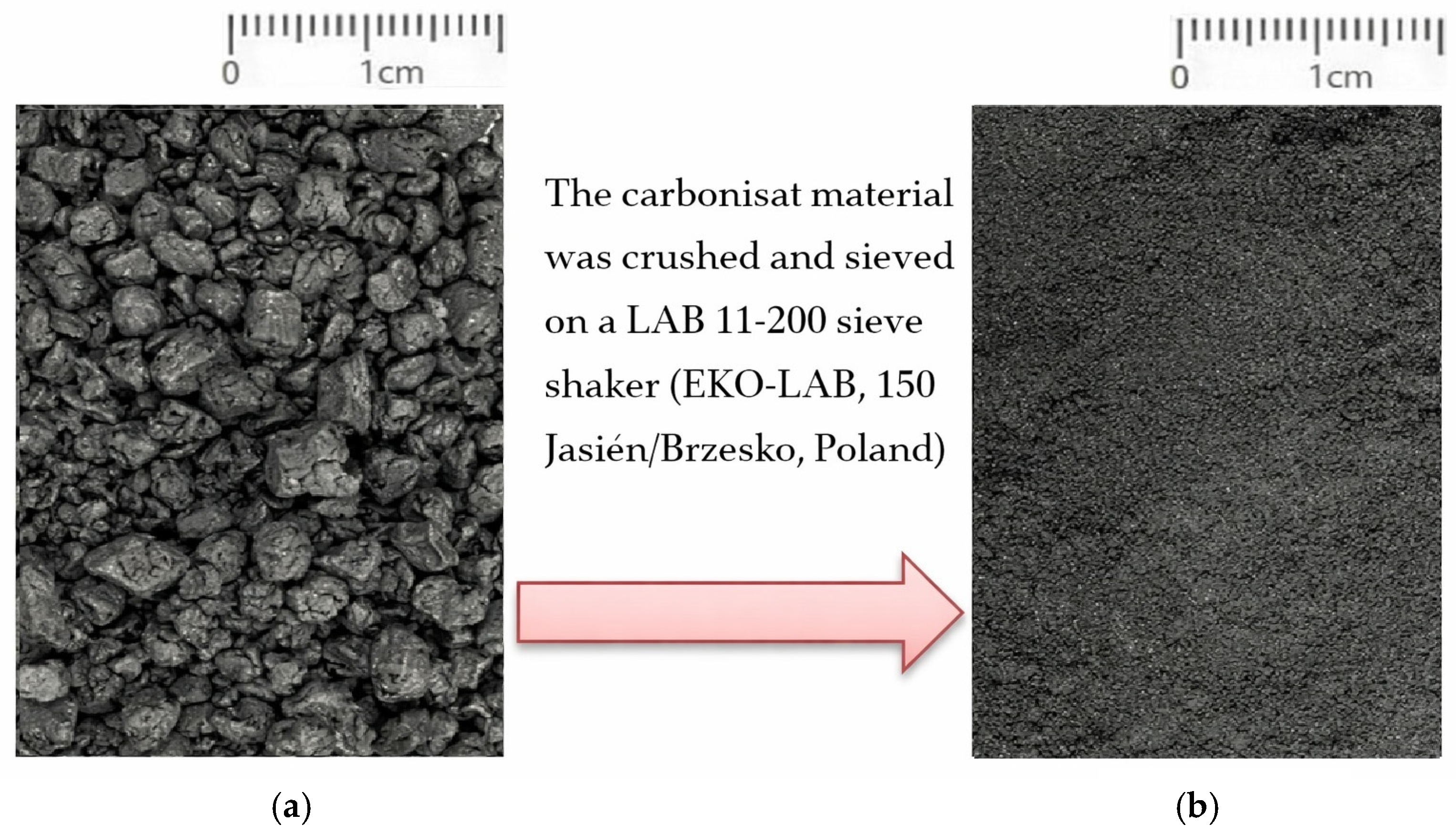

- Preparation of carbonisate: a fraction with particle size < 500 µm was obtained by grinding and sieving on a LAB 11-200 sieve shaker (EKO-LAB, Jasień/Brzesko, Poland), Figure 1.

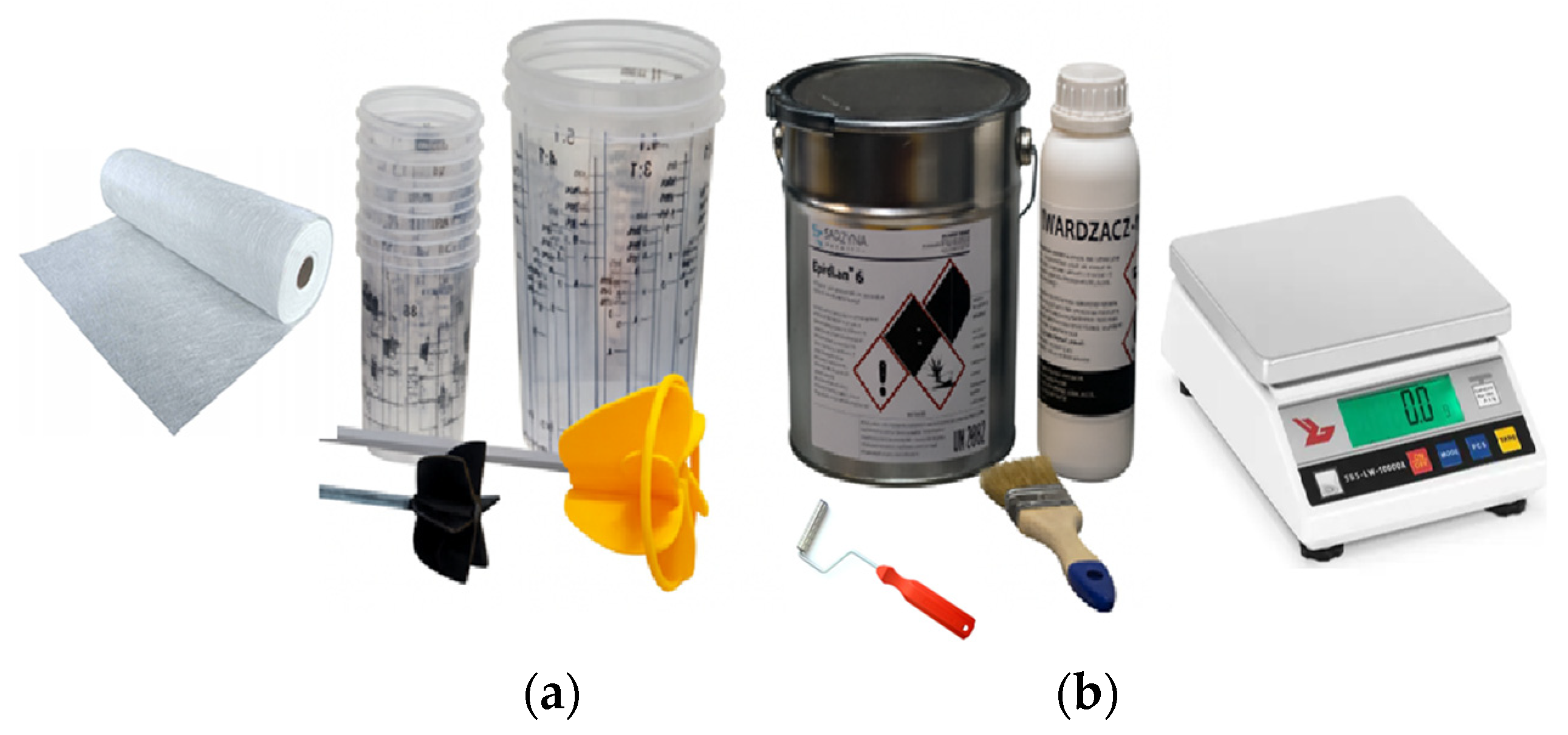

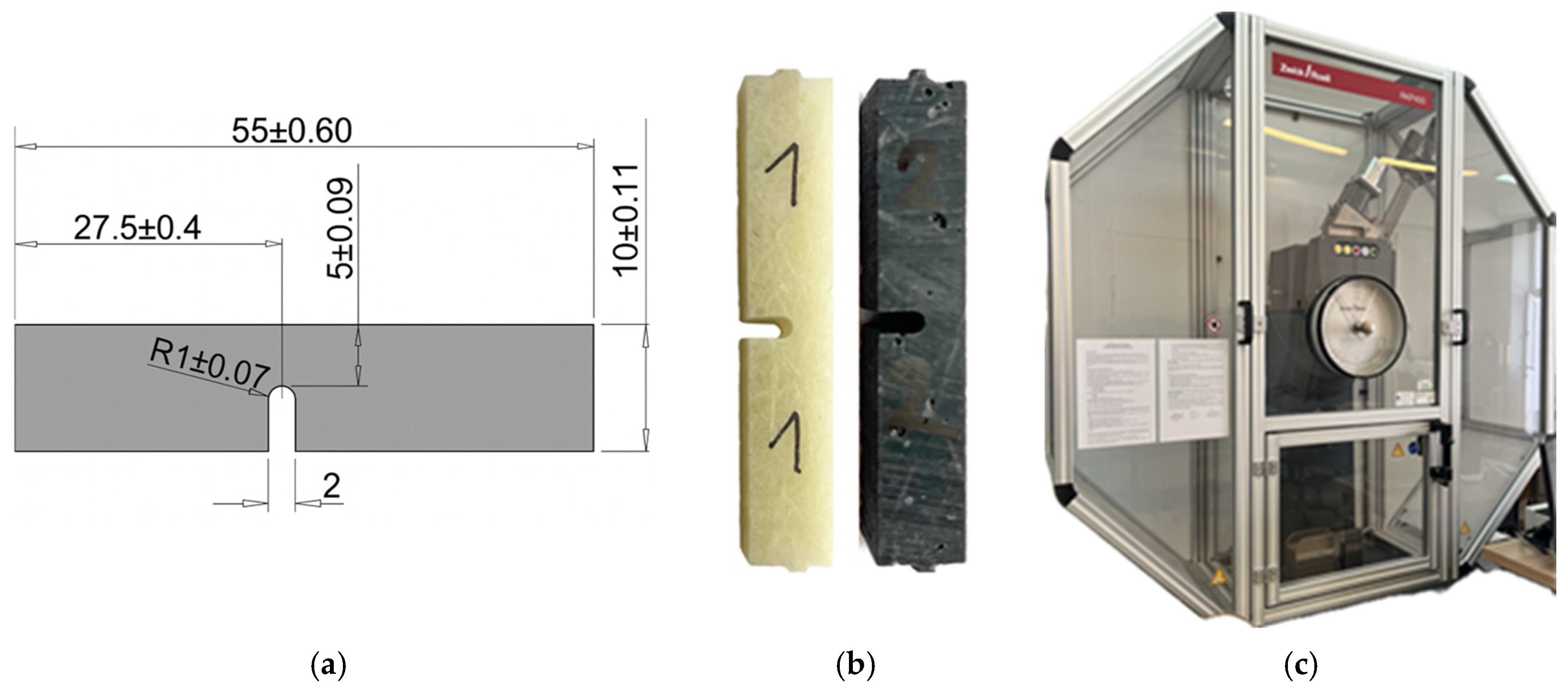

- Preparation of reinforcement: 10 layers of EM 1002/450/125 emulsion-bound glass mat with a randomly oriented fibre structure were incorporated into the laminate, Figure 2.

- Preparation of the matrix: Epidian 6 epoxy resin (CIECH Sarzyna S.A., Nowa Sarzyna, Poland) combined with the aliphatic-amine hardener Z-1, added at 13 g per 100 g of resin in accordance with the manufacturer’s recommendations. Figure 2.

- Preparation of the composite comprising epoxy resin (matrix), reinforcement (mat) and carbonisate material (filler). The carbonisate material was added in portions to the resin, mixing mechanically at low speed (approx. 200 rpm) for several minutes. Additional manual mixing allowed the filler to be dispersed and a homogeneous suspension to be obtained before impregnating the mat.

3. Results

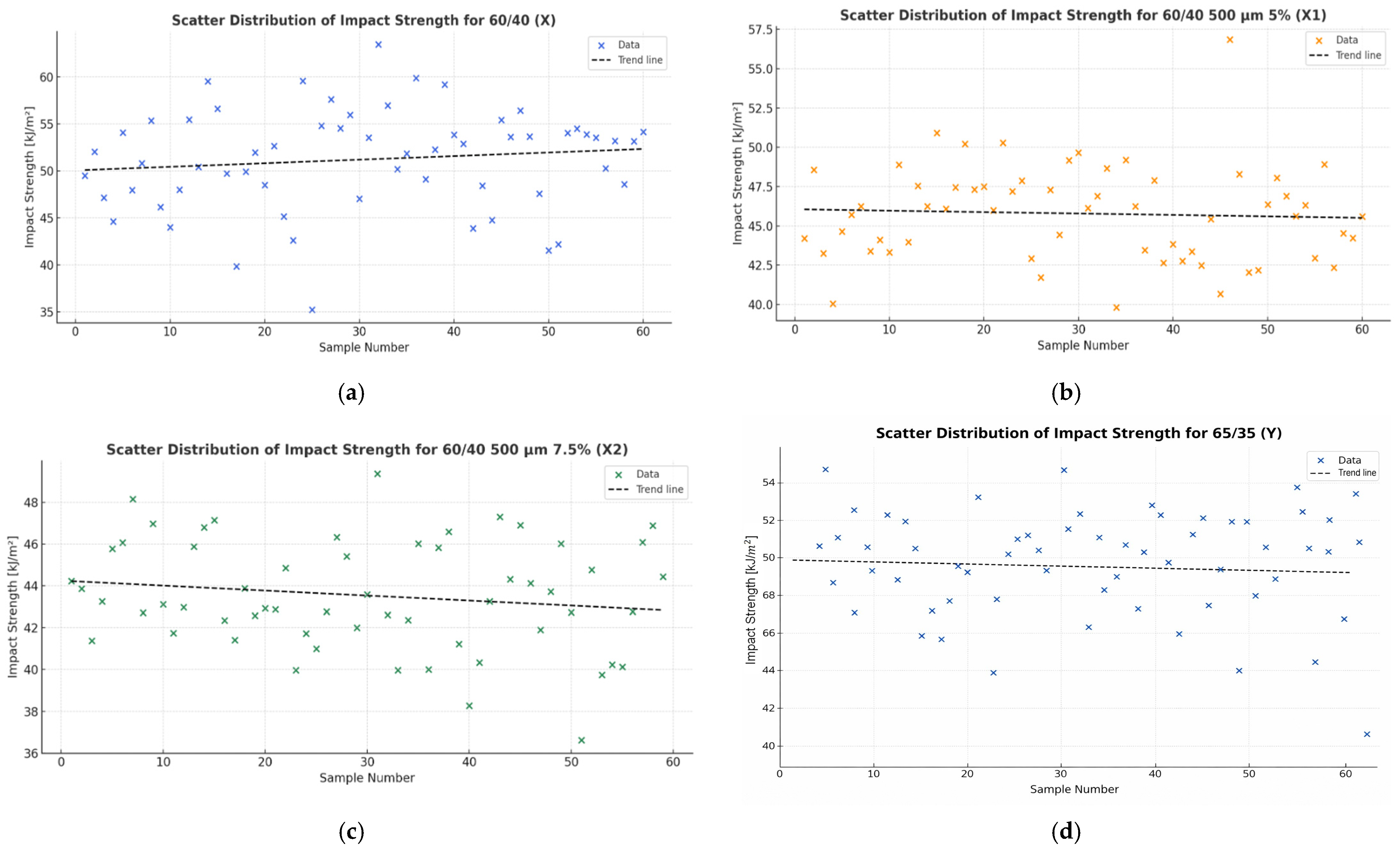

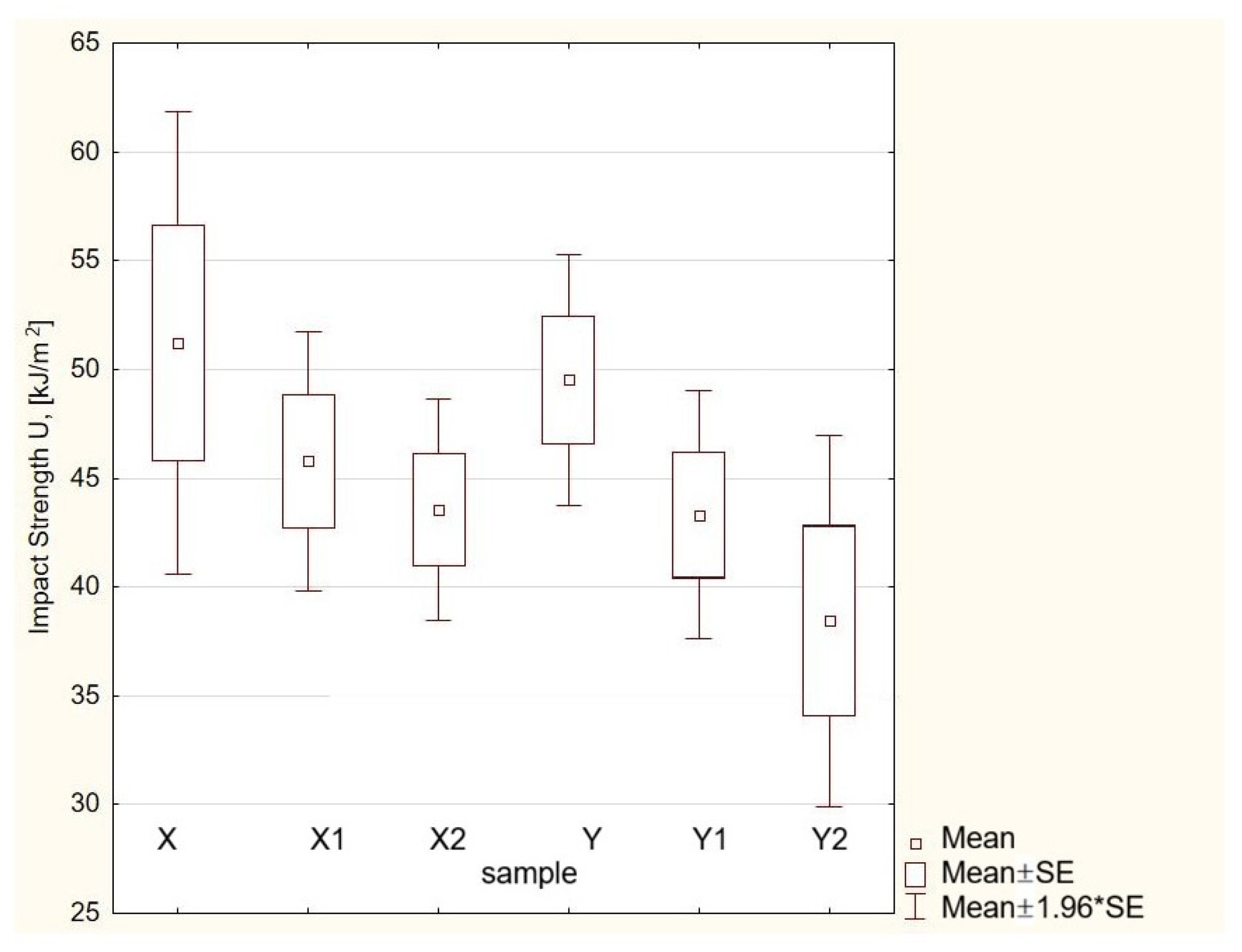

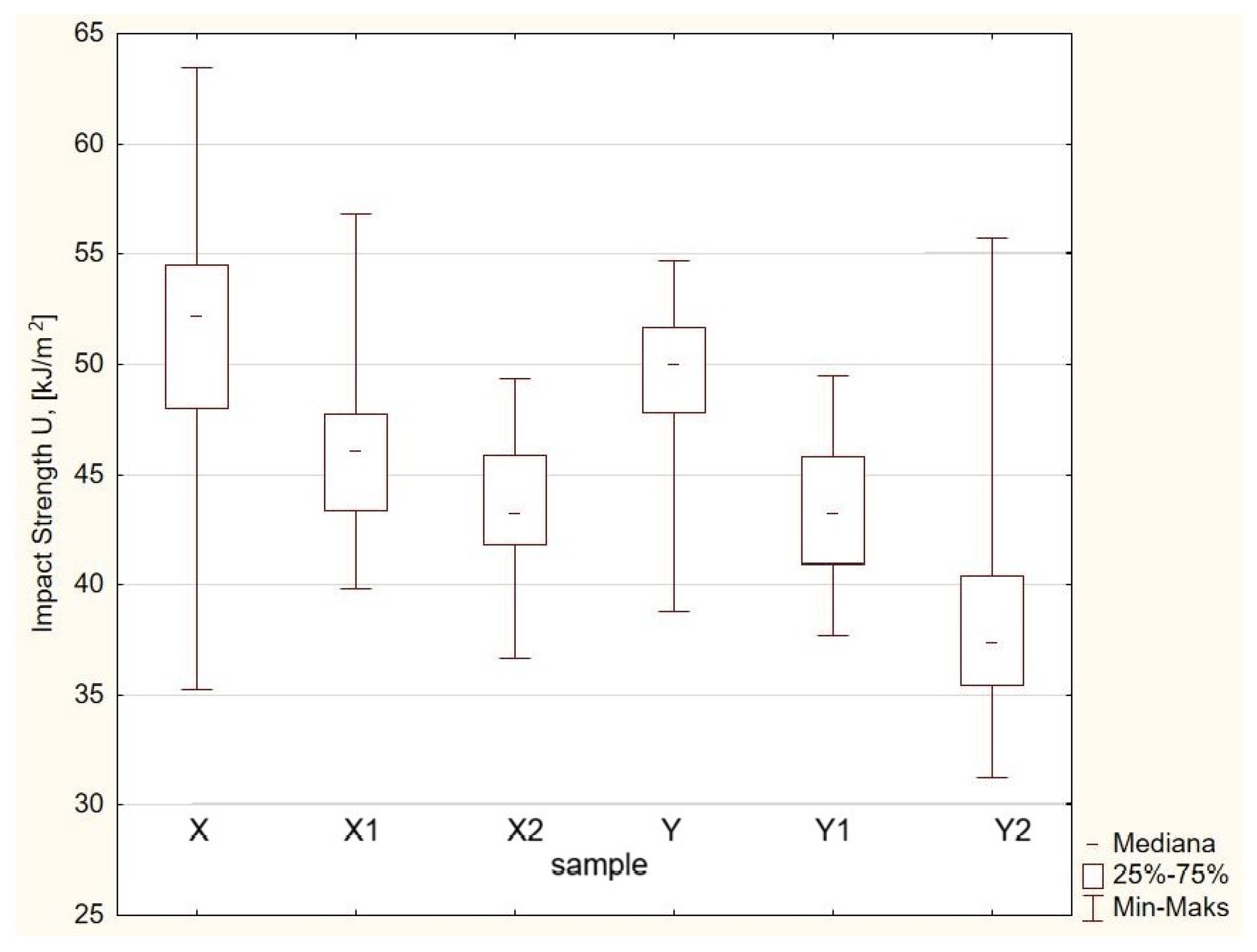

3.1. Impact Strength Results

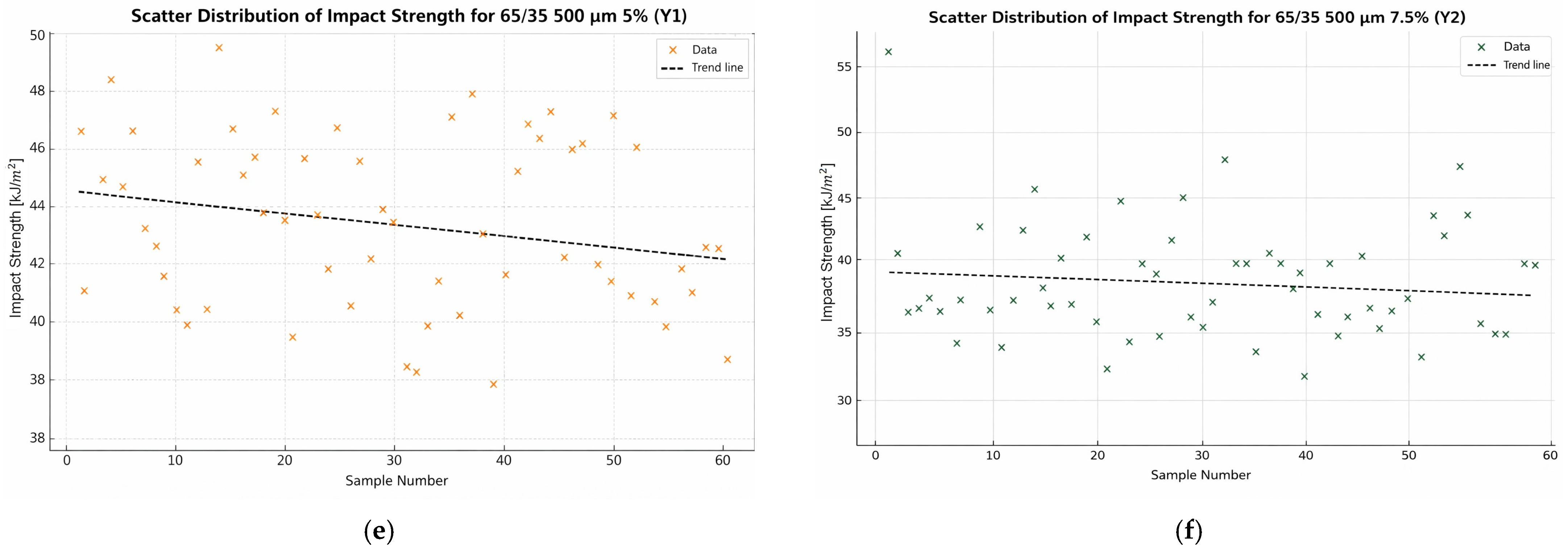

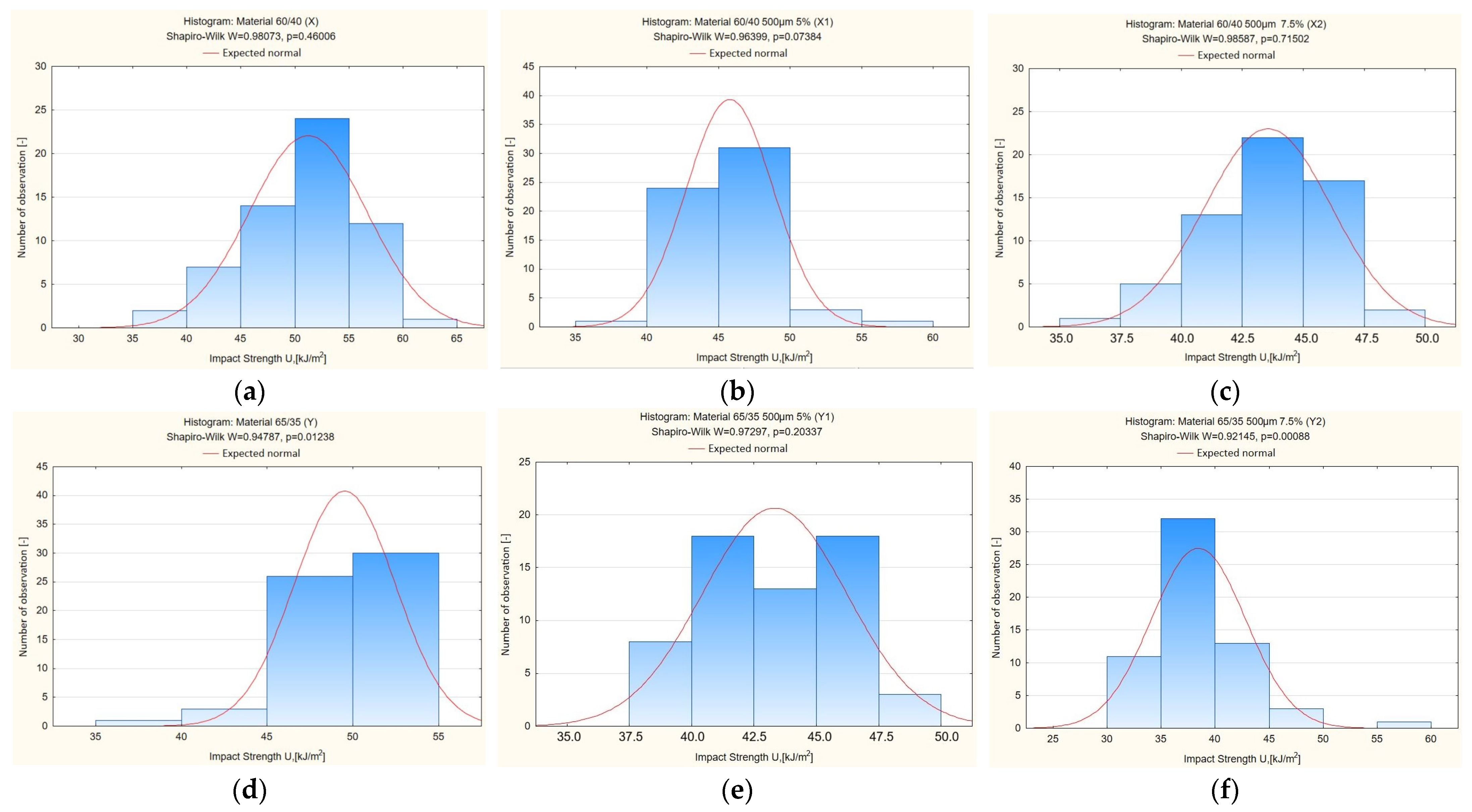

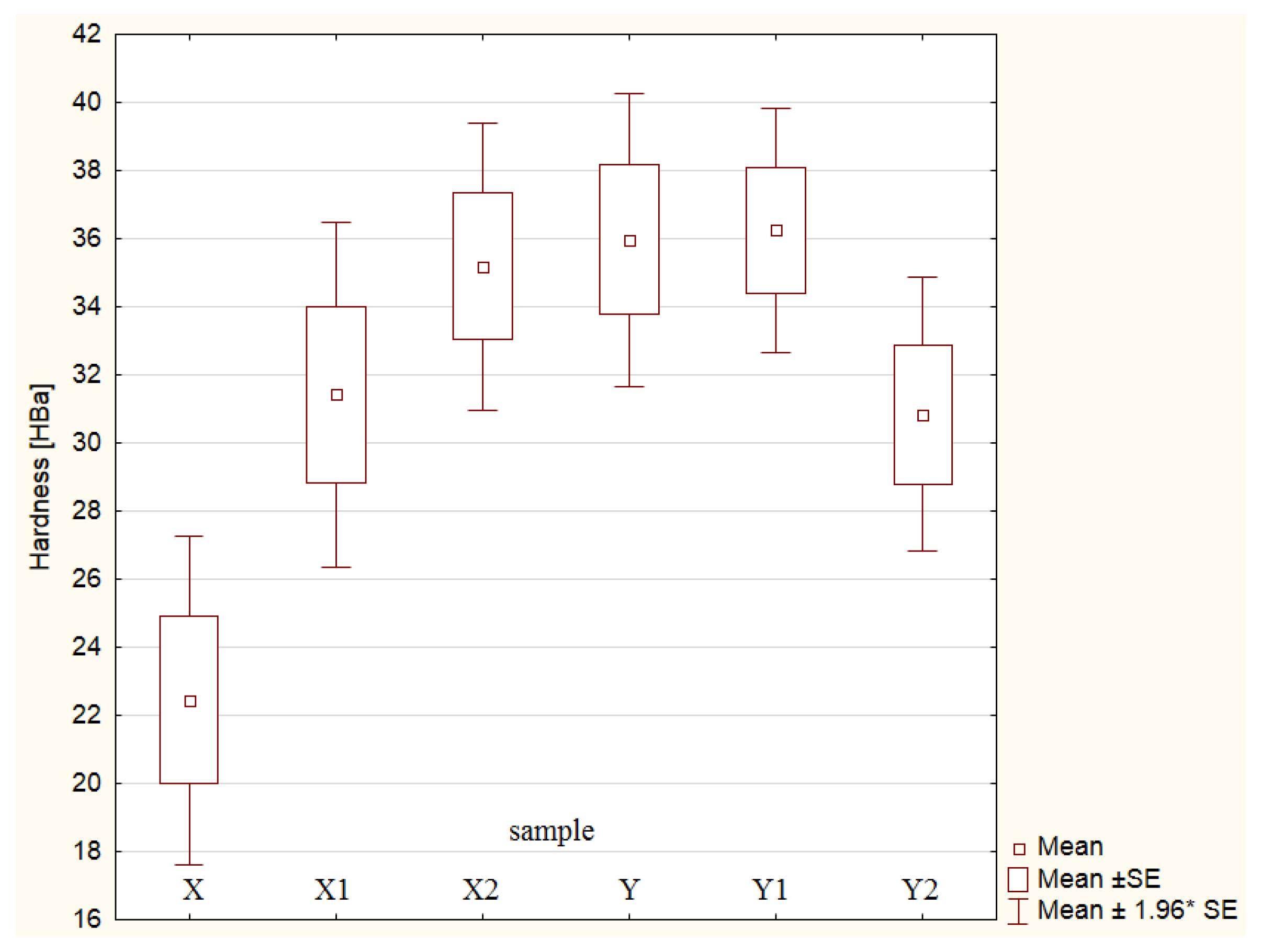

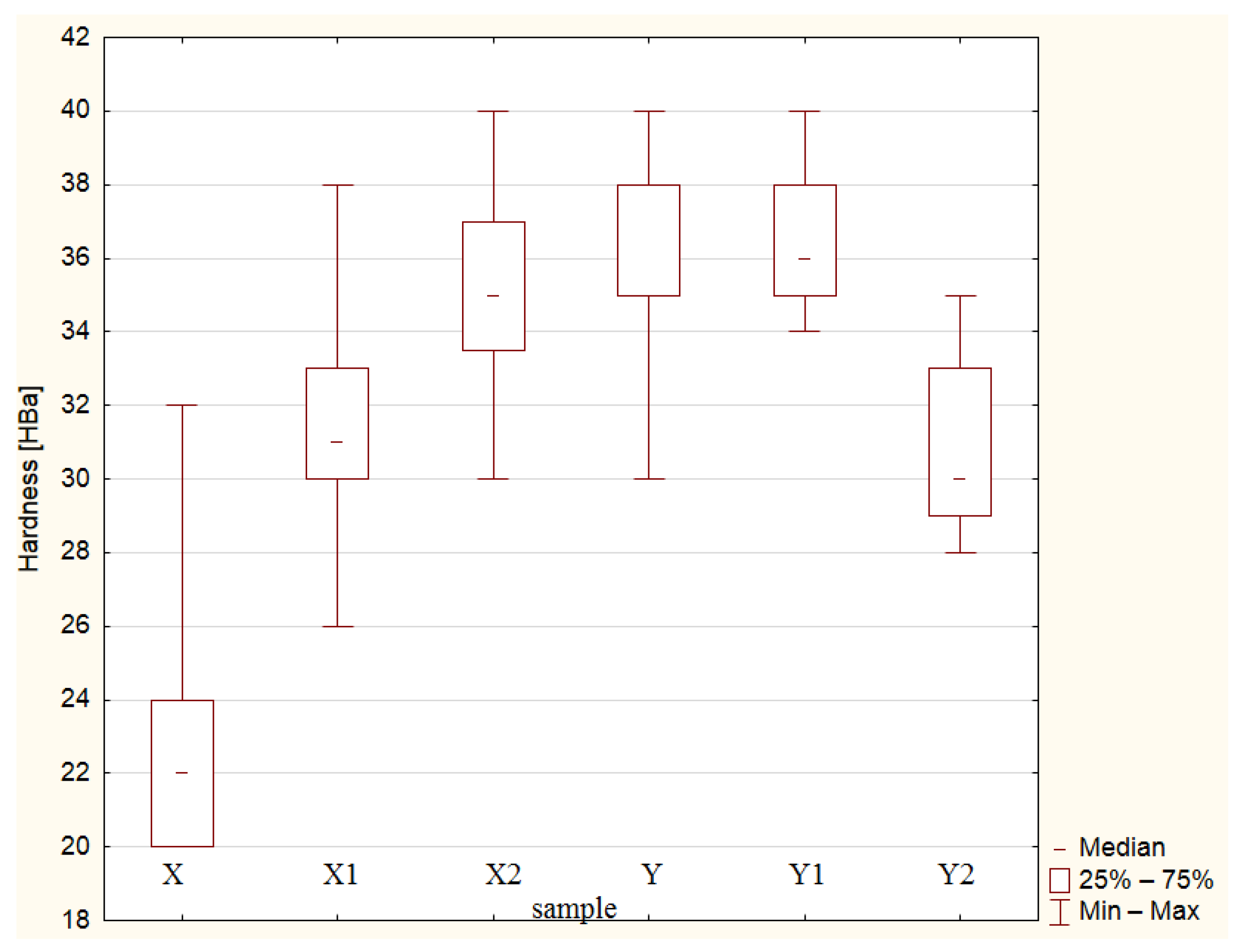

3.2. Barcol Hardness Results

3.3. Determination of the Number of Specimens for Impact Toughness and Hardness Testing

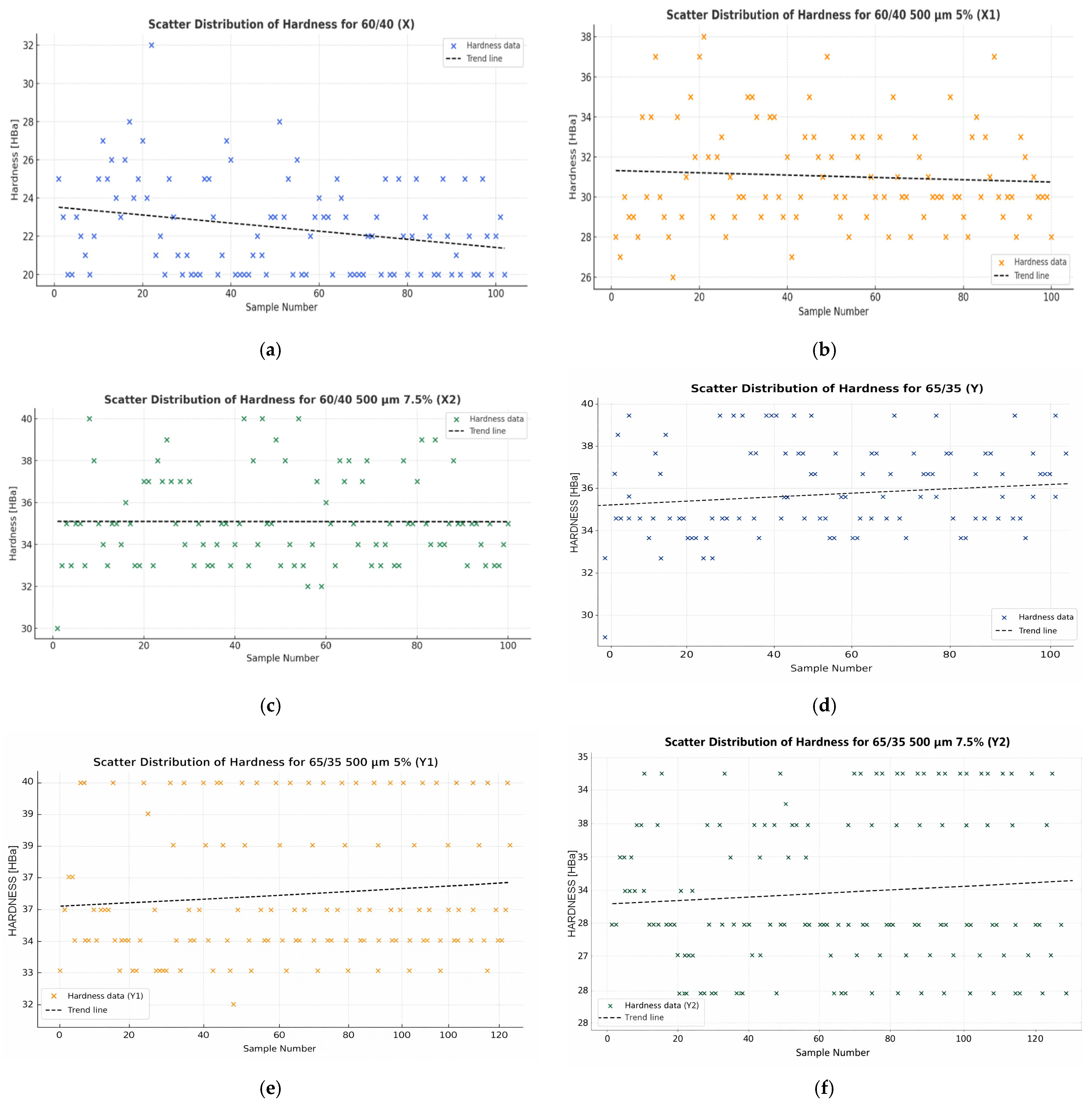

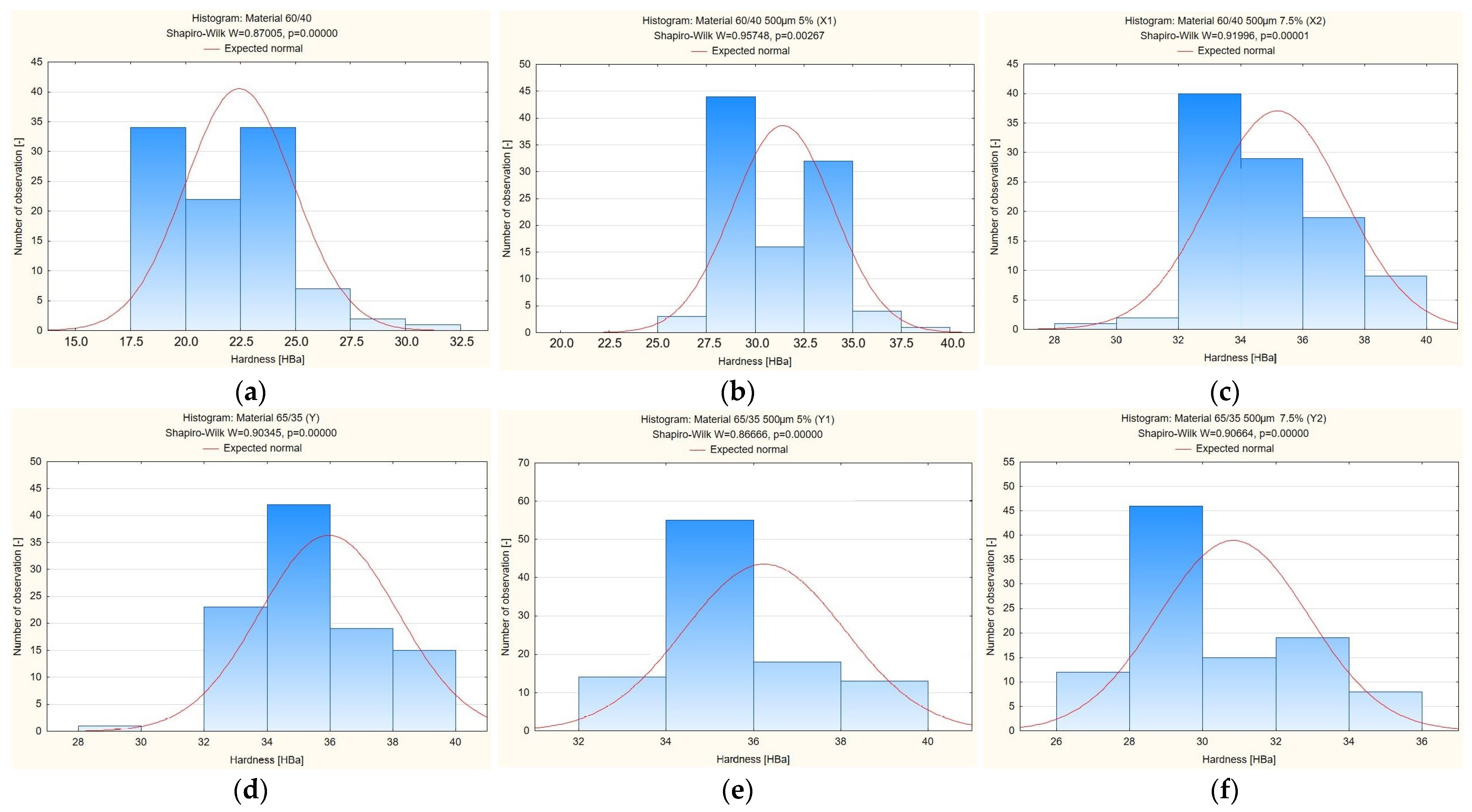

3.4. Evaluation of Distribution Normality for Mechanical Test Results

- -

- According to the Shapiro–Wilk test results summarised in Table 5 and Figure 8, all p-values for materials X, X1, X2 and Y1 exceed the 0.05 threshold, supporting the acceptance of the null hypothesis. Hence, the impact strength variables for these composites exhibit normal distribution characteristics.

- -

3.5. Analysis of Impact Strength and Hardness Differences Using Non-Parametric Tests

- -

- The analyses showed that samples X and Y, X1 and X2, as well as Y1 and X2, do not differ significantly. With p-values greater than 0.05, the data do not provide evidence to reject the null hypothesis.

- -

- For the other tested combinations—namely X and X1; X and X2; X and Y1; X and Y2; X1 and X2; X1 and Y1; X1 and Y2; X2 and Y; X2 and Y2; Y and Y1; Y and Y2; and Y1 and Y2—the p-values were less than 0.05. This provides grounds to reject the null hypothesis, demonstrating that these samples differ significantly.

- -

- The comparisons involving X2 and Y, X2 and Y1, Y1 and Y, as well as X1 and Y2 resulted in p-values above the 0.05 threshold. Consequently, the null hypothesis remains valid, meaning that these sample groups do not differ significantly.

- -

- For the other tested combinations—namely, X and X1; X and X2; X and Y; X and Y1; X and Y2; X1 and X2; X1 and Y; X1 and Y1; X2 and Y2; Y and Y2 and Y1 and Y2—the p-values were less than 0.05. This provides grounds to reject the null hypothesis, demonstrating that these samples differ significantly.

- <26%—low volatility,

- (26–45%)—average volatility,

- (46–100%)—high volatility,

- >100%—very high volatility.

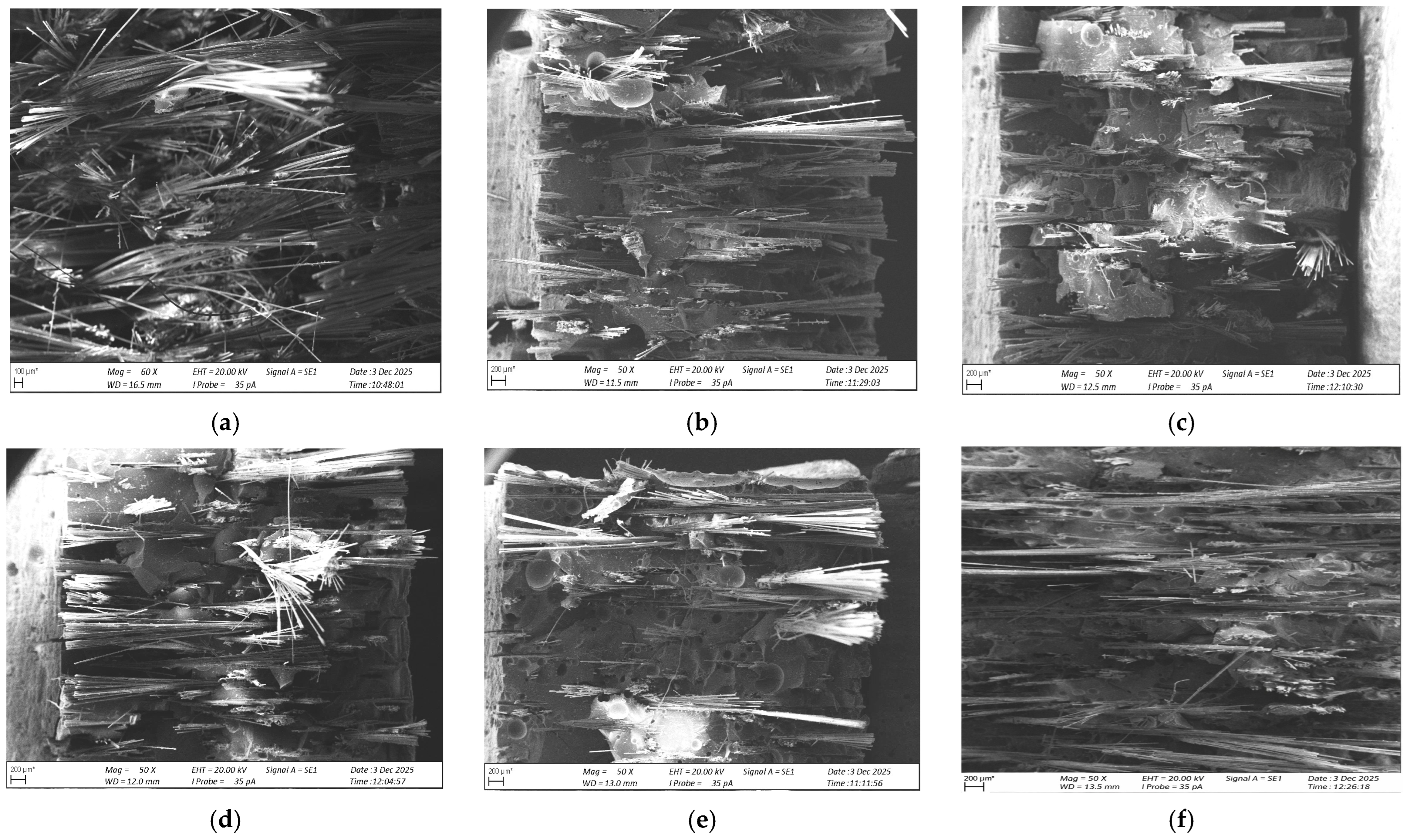

3.6. Microstructure Analysis (SEM)

4. Analysis of Results and Relationships Between Hardness and Impact Strength

4.1. Comparison of Hardness and Impact Strength Values

4.2. The Nature of the Relationship Between Hardness and Impact Strength

4.3. Assessment of the Significance of Differences

4.4. Summary of the Analysis

- As the amount of carbonisate rises, the composites exhibit increased surface hardness accompanied by a reduction in impact strength.

- The most favourable mechanical properties were obtained for composite X2 (60/40 + 7.5% carbonisate material), which is characterised by high hardness, good homogeneity and an acceptable level of impact strength.

- The relationship between hardness and impact strength is negative, confirming the existence of a trade-off between stiffness and fracture resistance.

- The use of non-parametric methods in data analysis was fully justified and allowed for a reliable assessment of the significance of differences between the studied groups.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Matykiewicz, D.; Barczewski, M.; Mousa, M.S.; Sanjay, M.R.; Siengchin, S. Impact Strength of Hybrid Epoxy–Basalt Composites Modified with Mineral and Natural Fillers. ChemEngineering 2021, 5, 56. [Google Scholar] [CrossRef]

- Dias, J.O.; Siqueira, R.D.; Coelho, B.F.; Conceição, A.O. Analysis of the Mechanical Properties of Polymer Composites Reinforced with Charcoal Particulate. Materials 2025, 18, 2746. [Google Scholar] [CrossRef] [PubMed]

- Kıstak, C.; Yanen, C.; Aydoğmuş, E. Advanced Sustainable Epoxy Composites from Biogenic Fillers: Mechanical and Thermal Characterization of Seashell Reinforced Composites. Appl. Sci. 2025, 15, 8498. [Google Scholar] [CrossRef]

- Kuciel, S.; Rusin-Żurek, K.; Kurańska, M. The Influence of Filler Particle Size on the Strength Properties and Mechanical Energy Dissipation Capacity of Biopoly(Ethylene Terephthalate) BioPET/Eggshell Biocomposites. Recycling 2024, 9, 88. [Google Scholar] [CrossRef]

- Rodríguez Sandoval, P.; Rubiano-Navarrete, A.F.; Gómez-Pachón, E.Y.; Vera-Graziano, R. Evaluation of Mechanical Properties of Composite Material with a Thermoplastic Matrix Reinforced with Cellulose Acetate Microfibers. Polymers 2024, 16, 2557. [Google Scholar] [CrossRef]

- Zhang, T.; Chao, X.; Liang, J.; Wang, B.; Sun, M. Enhanced Mechanical Properties of Epoxy Composites Reinforced with Silane Modified Al2O3 Nanoparticles: An Experimental Study. J. Compos. Sci. 2025, 9, 252. [Google Scholar] [CrossRef]

- Jen, Y.-M.; Chen, Y.-J.; Yu, T.-H. Improving the Impact Resistance and Post-Impact Tensile Fatigue Damage Tolerance of Carbon Fiber Reinforced Epoxy Composites by Embedding the Carbon Nanoparticles in Matrix. Polymers 2024, 16, 3589. [Google Scholar] [CrossRef]

- Fabijański, M. Properties of Composites Based on Polylactide Filled with Cork Filler. J. Compos. Sci. 2024, 8, 185. [Google Scholar] [CrossRef]

- Thimmegowda, D.Y.; Hindi, J.; Markunti, G.B.; Kakunje, M. Enhancement of Mechanical Properties of Natural Fiber Reinforced Polymer Composites Using Different Approaches—A Review. J. Compos. Sci. 2025, 9, 220. [Google Scholar] [CrossRef]

- Jelic, A.; Sekulic, M.; Travica, M.; Gržetic, J.; Ugrinovic, V.; Marinkovic, A.D.; Božic, A.; Stamenovic, M.; Putic, S. Determination of Mechanical Properties of Epoxy Composite Materials Reinforced with Silicate Nanofillers Using Digital Image Correlation (DIC). Polymers 2022, 14, 1255. [Google Scholar] [CrossRef]

- Laqsum, S.A.; Zhu, H.; Haruna, S.I.; Ibrahim, Y.E.; Al-shawafi, A. Mechanical and Impact Strength Properties of Polymer-Modified Concrete Supported with Machine Learning Method: Microstructure Analysis (SEM) Coupled with EDS. J. Compos. Sci. 2025, 9, 101. [Google Scholar] [CrossRef]

- K, B.; M, P.P.; M, S.; C G, R.; B H, M.P.; B, K.K. The Effect of Metal Filler on the Mechanical Performance of Epoxy Resin Composites. Eng. Proc. 2023, 59, 200. [Google Scholar] [CrossRef]

- Ramesh, V.; Karthik, K.; Cep, R.; Elangovan, M. Influence of Stacking Sequence on Mechanical Properties of Basalt/Ramie Biodegradable Hybrid Polymer Composites. Polymers 2023, 15, 985. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Ahmadi Moghaddam, H.; Palacios Moreno, J.; Mertiny, P. Magnetic Filler Polymer Composites—Morphology Characterization and Experimental and Stochastic Finite Element Analyses of Mechanical Properties. Polymers 2023, 15, 2897. [Google Scholar] [CrossRef]

- Meireman, T.; Verboven, E.; Kersemans, M.; Van Paepegem, W.; DeClerck, K.; Daelemans, L. Low-Velocity Impact Resistance and Compression After Impact Strength of Thermoplastic Nanofiber Toughened Carbon/Epoxy Composites with Different Layups. Polymers 2024, 16, 3060. [Google Scholar] [CrossRef]

- Fayzullin, I.; Gorbachev, A.; Volfson, S.; Serikbayev, Y.; Nakyp, A.; Akylbekov, N. Composite Material Based on Polypropylene and Modified Natural Fillers. Polymers 2024, 16, 1703. [Google Scholar] [CrossRef]

- Shahabaz, S.M.; Mehrotra, P.; Kalita, H.; Sharma, S.; Naik, N.; Noronha, D.J.; Shetty, N. Effect of Al2O3 and SiC Nano-Fillers on the Mechanical Properties of Carbon Fiber-Reinforced Epoxy Hybrid Composites. J. Compos. Sci. 2023, 7, 133. [Google Scholar] [CrossRef]

- Fekiac, J.J.; Krbata, M.; Kohutiar, M.; Janík, R.; Kakošová, L.; Breznická, A.; Eckert, M.; Mikuš, P. Comprehensive Review: Optimization of Epoxy Composites, Mechanical Properties, & Technological Trends. Polymers 2025, 17, 271. [Google Scholar] [CrossRef]

- Atmakuri, A.; Kolli, L.; Palevicius, A.; Urbaite, S.; Janusas, G. Influence of Filler Materials on Wettability and Mechanical Properties of Basalt/E-Glass Woven Fabric–Reinforced Composites for Microfluidics. Micromachines 2022, 13, 1875. [Google Scholar] [CrossRef]

- Dochev, B.; Dimova, D.; Zagorski, M.; Ublekov, F.; Tomanov, N.; Valeva, D. Investigation of the Mechanical Properties of Thermosetting Polymers Reinforced with Carbon Particles. Eng. Proc. 2025, 100, 21. [Google Scholar] [CrossRef]

- Kula, Z.; Neves, C.B.; Dąbrowska, K.; Roque, J.C.; Klimek, L. Evaluation of the Impact of Various Functional Fillers on Key Properties of Dental Composites. Appl. Sci. 2025, 15, 4961. [Google Scholar] [CrossRef]

- Islam, M.S.; Nassar, M.; Elsayed, M.A.; Jameel, D.B.; Ahmad, T.T.; Rahman, M.M. In Vitro Optical and Physical Stability of Resin Composite Materials with Different Filler Characteristics. Polymers 2023, 15, 2121. [Google Scholar] [CrossRef] [PubMed]

- Alshammari, B.A.; Alenad, A.M.; Al-Mubaddel, F.S.; Alharbi, A.G.; Al-shehri, A.S.; Albalwi, H.A.; Alsuabie, F.M.; Fouad, H.; Mourad, A.-H.I. Impact of Hybrid Fillers on the Properties of High Density Polyethylene Based Composites. Polymers 2022, 14, 3427. [Google Scholar] [CrossRef] [PubMed]

- Wieczorska, A.; Drewing, S. Statistical Methods in the Analysis of the Effect of Carbonisate on the Hardness of Epoxy-Resin-Based Composites. Materials 2024, 17, 5916. [Google Scholar] [CrossRef]

- Zuk, D.; Abramczyk, N.; Charchalis, A. Analysis of the Impact of Rubber Recyclate Addition to the Matrix on the Strength Properties of Epoxy–Glass Composites. Polymers 2023, 15, 3374. [Google Scholar] [CrossRef]

- Wieczorska, A.; Hajdukiewicz, G. Analysis of the Tensile Properties of Composite Material Added Carbonisate Based on the Change of Strain Dynamics. Materials 2024, 17, 6219. [Google Scholar] [CrossRef]

- Wieczorska, A.; Hajdukiewicz, G. Application of Kolmogorov–Sinai Metric Entropy to Determine the Exploitation Parameters of Epoxy–Glass Composites with Carbonisate. Materials 2025, 18, 4858. [Google Scholar] [CrossRef]

- PN-EN 1097-3:2000; Badania Mechanicznych i Fizycznych Właściwości Kruszyw—Oznaczanie Gęstości Nasypowej i Jamistości. Polish Committee for Standardization: Warszawa, Poland, 2013.

- PN-EN 15402:2011; Stałe Paliwa Wtórne—Oznaczenie Zawartości Części Lotnych. Polish Committee for Standardization: Warszawa, Poland, 2013.

- CEN/TS 15414-2:2010; Solid Recovered Fuels—Determination of Moisture Content Using the Oven Dry Method. European Committee for Standardization (CEN): Brussels, Belgium, 2010.

- PN-EN 15400:2011; Stałe Paliwa Wtórne—Oznaczenie Wartości Opałowej. Polish Committee for Standardization: Warszawa, Poland, 2011.

- GB/T 3854-2005; Plastics—Determination of Indentation Hardness by Means of a Barcol Hardness Tester. Standardization Administration of China: Beijing, China, 2005.

- PN-EN ISO 179-1:2010E; Plastics—Determination of Charpy Impact Properties—Part 1: Non-Instrumented Impact Test. Polish Committee for Standardization: Warsaw, Poland, 2010.

- Szydłowski, H. Teoria Pomiarów; Wydawnictwo Naukowe PWN: Warsaw, Poland, 1978. [Google Scholar]

- Szapiro, S.S.; Wilk, M.B. Analiza testu wariancji dla normalności (kompletne próby). Biometrika 1965, 52, 591–611. [Google Scholar]

- Ramachandran, K.M.; Tsokos, C.P. Rozdział 12—Testy nieparametryczne. In Statystyka Matematyczna z Zastosowaniami w R, 2nd ed.; Wydawnictwo Naukowe: Cambridge, MA, USA, 2015; pp. 589–637. [Google Scholar]

| No. | Layers of Mats | wt% Resin Ratio | wt% Content Glass Mats | wt% Carbonisate Ratio | Carbonisate Grain Size [μm] | Sample Designation |

|---|---|---|---|---|---|---|

| 1 | 10 | 60 | 40 | 0 | - | X |

| 2 | 10 | 60 | 35 | 5 | <500 | X1 |

| 3 | 10 | 60 | 32.5 | 7.5 | <500 | X2 |

| 4 | 10 | 65 | 35 | 0 | - | Y |

| 5 | 10 | 65 | 30 | 5 | <500 | Y1 |

| 6 | 10 | 65 | 27.5 | 7.5 | <500 | Y2 |

| Sample Designation | Impact Strength U, [kJ/m2] |

|---|---|

| X | 51.23 |

| X1 | 45.78 |

| X2 | 43.56 |

| Y | 49.52 |

| Y1 | 43.32 |

| Y2 | 38.46 |

| Sample Designation | Barcol Hardness HBa |

|---|---|

| X | 22.45 |

| X1 | 31.43 |

| X2 | 35.17 |

| Y | 35.97 |

| Y1 | 36.25 |

| Y2 | 30.84 |

| Sample Designation | Number n (Impact) | Number n (Hardness) |

|---|---|---|

| Material 60/40 (X) | 60 | 92 |

| Material 60/40 (X1) | 19 | 100 |

| Material 60/40 (X2) | 14 | 70 |

| Material 65/35 (Y) | 18 | 73 |

| Material 65/35 (Y1) | 18 | 51 |

| Material 65/35 (Y2) | 39 | 64 |

| Specimen ID | p Statistic Shapiro-Wilka |

|---|---|

| X | 0.46006 |

| X1 | 0.07384 |

| X2 | 0.71502 |

| Y | 0.01238 |

| Y1 | 0.20337 |

| Y2 | 0.00088 |

| Specimen ID | p Statistic Shapiro-Wilka |

|---|---|

| X | 0.00000 |

| X1 | 0.00267 |

| X2 | 0.00001 |

| Y | 0.00000 |

| Y1 | 0.00000 |

| Y2 | 0.00000 |

| Sample Designation | Independent Variable (Grouping) Impact Strength; p-Value for Multiple Comparisons (Two-Tailed); Kruskala-Wallisa Test: H (5, N = 360) = 207.7443 p = 0.000 | |||||

|---|---|---|---|---|---|---|

| X | X1 | X2 | Y | Y1 | Y2 | |

| X | 0.000041 | 0.000000 | 1.000000 | 0.000000 | 0.000000 | |

| X1 | 0.000041 | 0.102511 | 0.000397 | 0.045222 | 0.000000 | |

| X2 | 0.000000 | 0.102511 | 0.000000 | 1.000000 | 0.000155 | |

| Y | 1.000000 | 0.000397 | 0.000000 | 0.000000 | 0.000000 | |

| Y1 | 0.000000 | 0.045222 | 1.000000 | 0.000000 | 0.000503 | |

| Y2 | 0.000000 | 0.000000 | 0.000155 | 0.000000 | 0.000503 | |

| Sample Designation | Independent Variable (Grouping) Hardness; p-Value for Multiple Comparisons (Two-Tailed); Kruskala-Wallisa Test: H (5, N = 600) = 440.8020 p = 0.000 | |||||

|---|---|---|---|---|---|---|

| X | X1 | X2 | Y | Y1 | Y2 | |

| X | 0.000000 | 0.000000 | 0.000000 | 0.000000 | 0.000000 | |

| X1 | 0.000000 | 0.000000 | 0.000000 | 0.000000 | 1.000000 | |

| X2 | 0.000000 | 0.000000 | 1.000000 | 0.140833 | 0.000000 | |

| Y | 0.000000 | 0.000000 | 1.000000 | 1.000000 | 0.000000 | |

| Y1 | 0.000000 | 0.000000 | 0.140833 | 1.000000 | 0.000000 | |

| Y2 | 0.000000 | 1.000000 | 0.000000 | 0.000000 | 0.000000 | |

| Indicators | Sample Designation | |||||

|---|---|---|---|---|---|---|

| X | X1 | X2 | Y | Y1 | Y2 | |

| Mean | 51.23 | 45.78 | 43.56 | 49.52 | 43.32 | 38.46 |

| Median | 52.16 | 46.04 | 43.25 | 50.01 | 43.23 | 37.39 |

| Standard deviation | 5.43 | 3.04 | 2.60 | 2.94 | 2.90 | 4.35 |

| Variance | 29.44 | 9.26 | 6.77 | 8.62 | 8.40 | 18.95 |

| Minimum | 35.25 | 39.83 | 36.63 | 38.78 | 37.72 | 31.27 |

| Maximum | 63.47 | 56.85 | 49.36 | 54.70 | 49.50 | 55.70 |

| Q1 First quartile (25%) | 48.00 | 43.38 | 41.86 | 47.85 | 40.90 | 35.49 |

| Q3Third quartile (75%) | 54.53 | 47.63 | 45.84 | 51.50 | 45.79 | 40.37 |

| Vs | 10.59 | 6.65 | 5.97 | 5.93 | 6.69 | 11.32 |

| VQ | 6.27 | 4.61 | 4.59 | 3.65 | 5.65 | 6.53 |

| Indicators | Sample Designation | |||||

|---|---|---|---|---|---|---|

| X | X1 | X2 | Y | Y1 | Y2 | |

| Mean | 22.45 | 31.43 | 35.19 | 35.97 | 36.25 | 30.84 |

| Median | 22.00 | 31.00 | 35.00 | 35.00 | 36.00 | 30.00 |

| Standard deviation | 2.46 | 2.58 | 2.15 | 2.19 | 1.83 | 2.05 |

| Variance | 6.05 | 6.67 | 4.64 | 4.82 | 3.36 | 4.20 |

| Minimum | 20.00 | 26.00 | 30.00 | 30.00 | 34.00 | 28.00 |

| Maximum | 32.00 | 38.00 | 40.00 | 40.00 | 40.00 | 35.00 |

| Q1 First quartile (25%) | 20.00 | 30.00 | 33.75 | 35.00 | 35.00 | 29.00 |

| Q3Third quartile (75%) | 24.00 | 33.00 | 37.00 | 38.00 | 38.00 | 33.00 |

| Vs | 10.95 | 8.22 | 6.12 | 6.10 | 5.06 | 6.64 |

| VQ | 9.09 | 4.84 | 4.64 | 4.29 | 4.17 | 6.67 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Wieczorska, A.; Drewing, S. Relationship Between Hardness and Impact Strength of Epoxy–Glass Composites Modified with Carbonisate from MDF Pyrolysis. Materials 2026, 19, 42. https://doi.org/10.3390/ma19010042

Wieczorska A, Drewing S. Relationship Between Hardness and Impact Strength of Epoxy–Glass Composites Modified with Carbonisate from MDF Pyrolysis. Materials. 2026; 19(1):42. https://doi.org/10.3390/ma19010042

Chicago/Turabian StyleWieczorska, Agata, and Sebastian Drewing. 2026. "Relationship Between Hardness and Impact Strength of Epoxy–Glass Composites Modified with Carbonisate from MDF Pyrolysis" Materials 19, no. 1: 42. https://doi.org/10.3390/ma19010042

APA StyleWieczorska, A., & Drewing, S. (2026). Relationship Between Hardness and Impact Strength of Epoxy–Glass Composites Modified with Carbonisate from MDF Pyrolysis. Materials, 19(1), 42. https://doi.org/10.3390/ma19010042