Influence of Coupled Activated Recycled Fine Powder on the Performance of Ultra-High-Performance Concrete

Abstract

1. Introduction

2. Materials and Methods

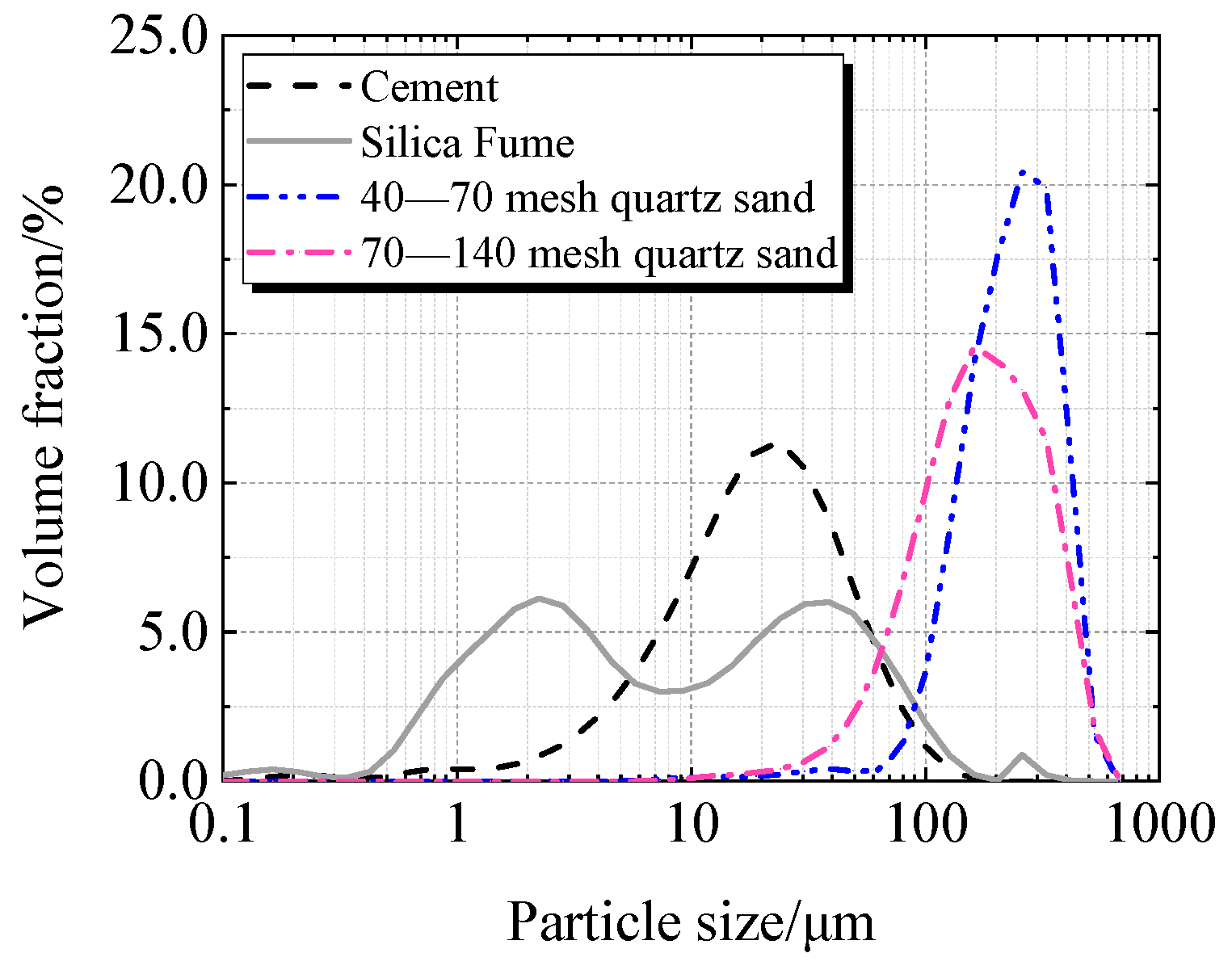

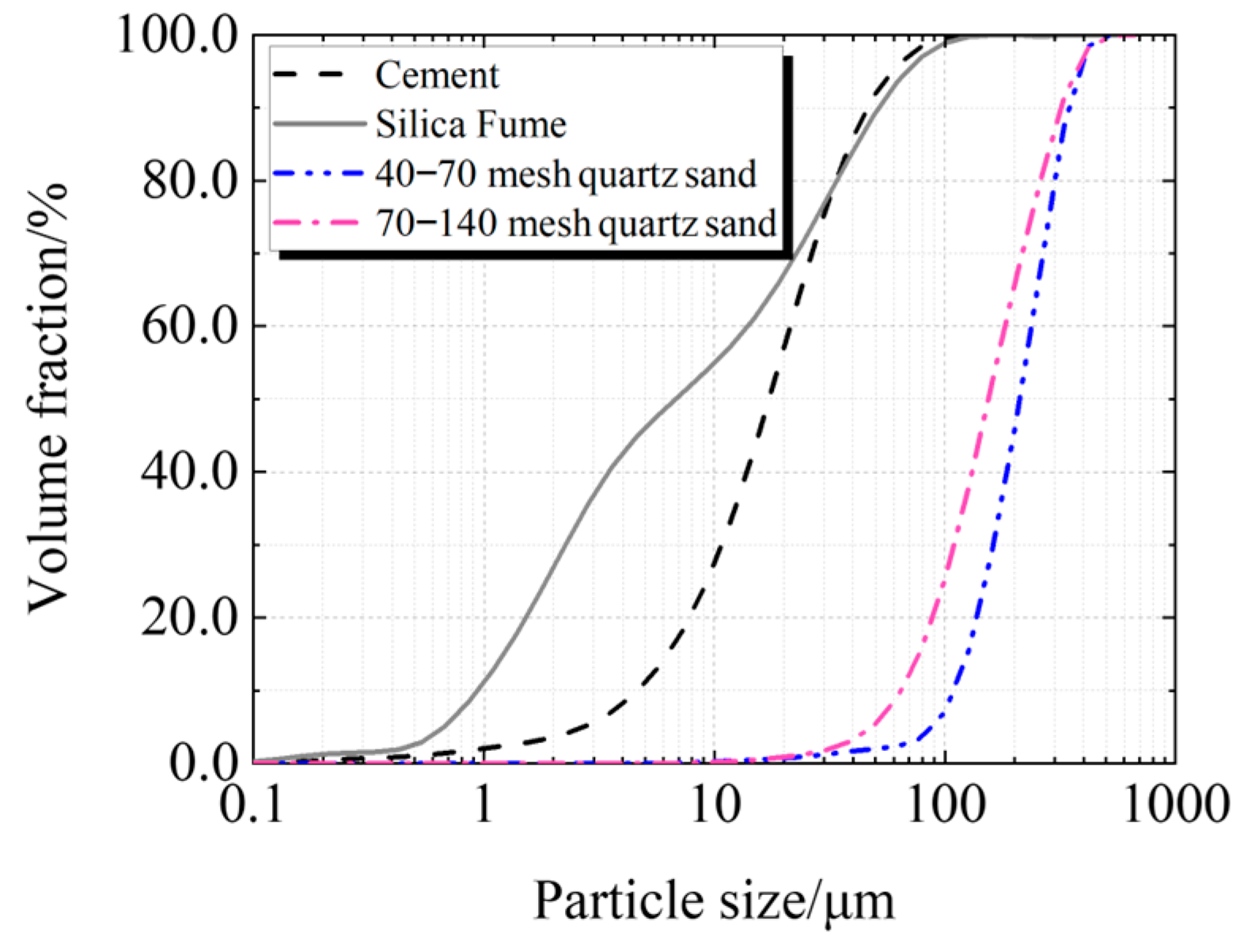

2.1. Materials

2.2. Mix Proportion and Preparation Process

2.3. Test Methods

3. Results and Discussion

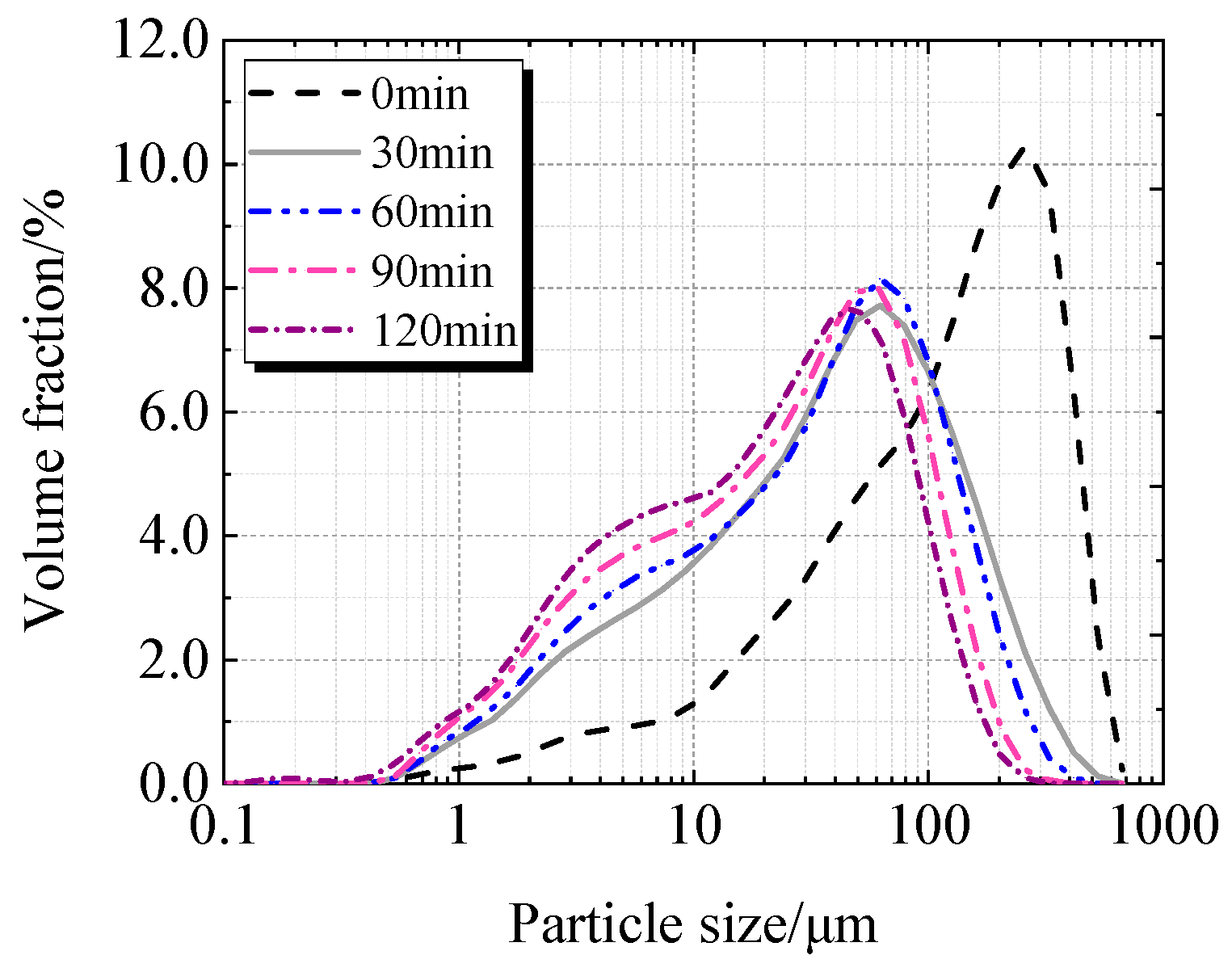

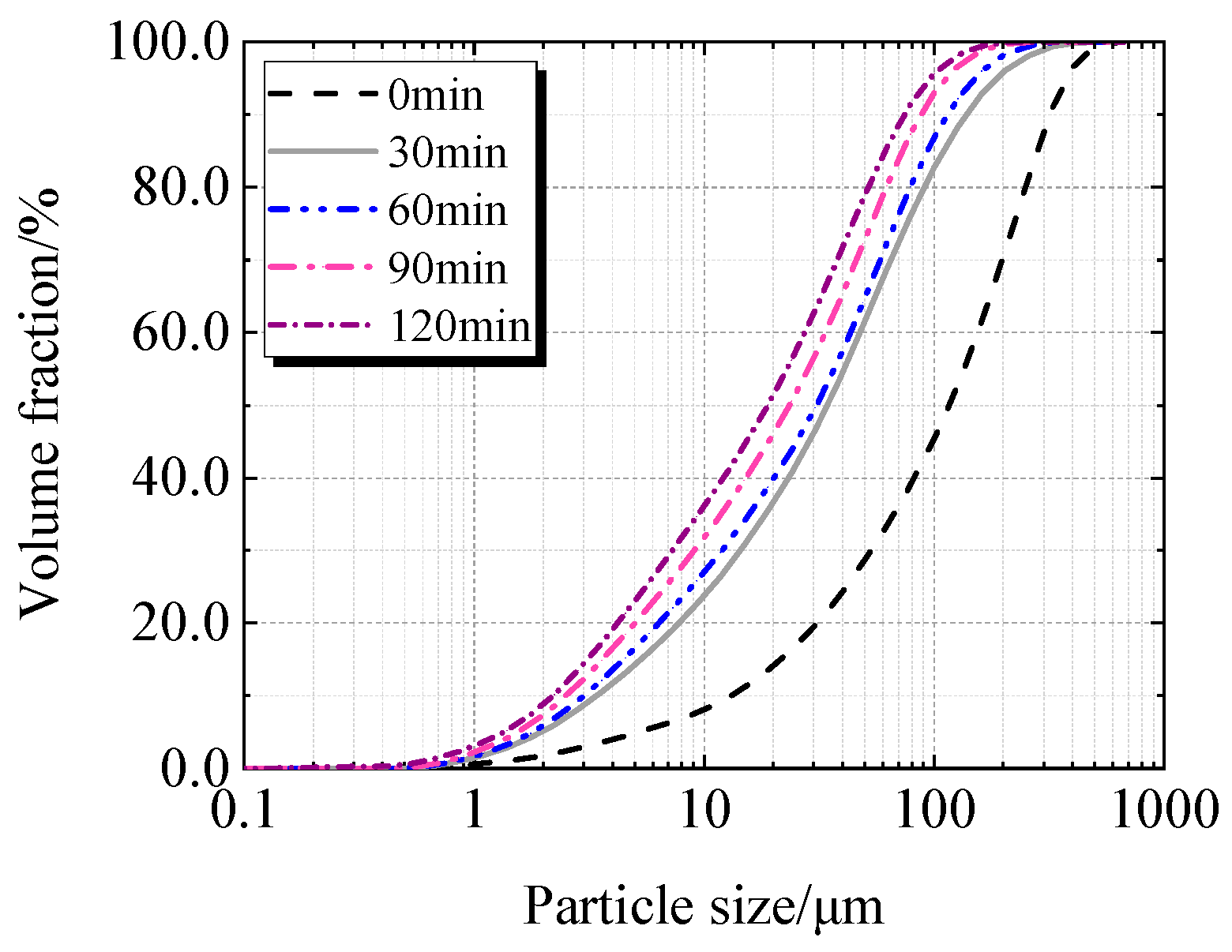

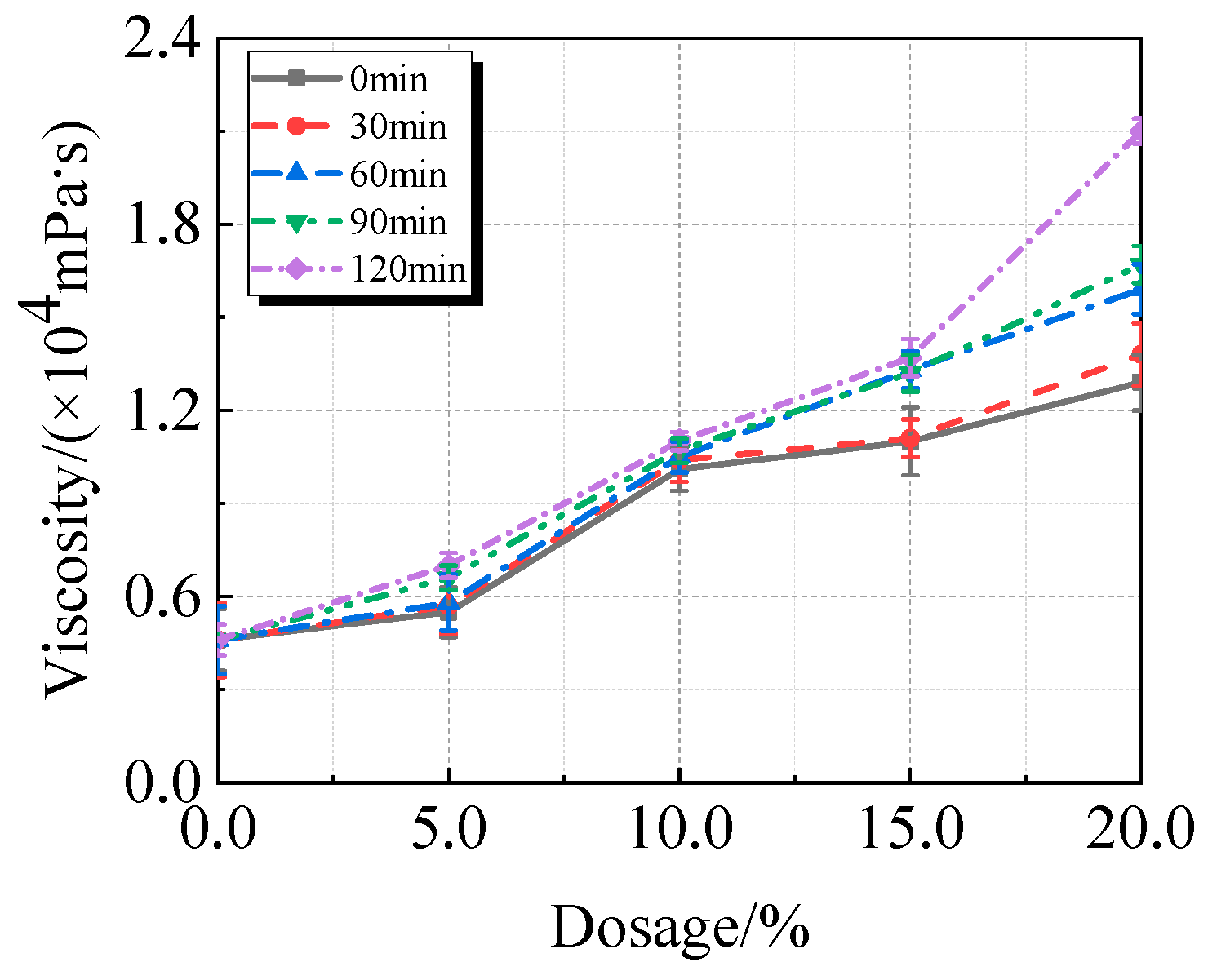

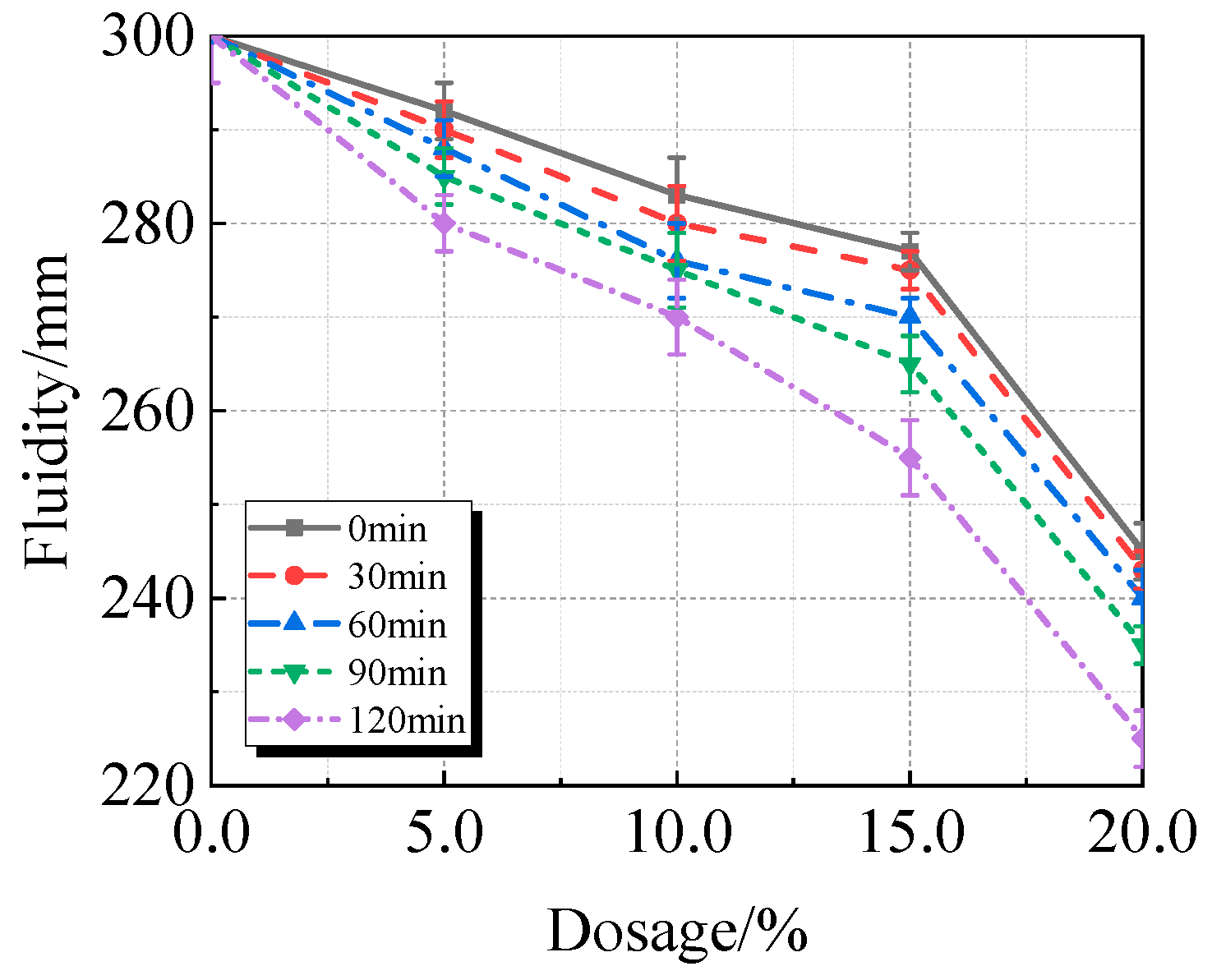

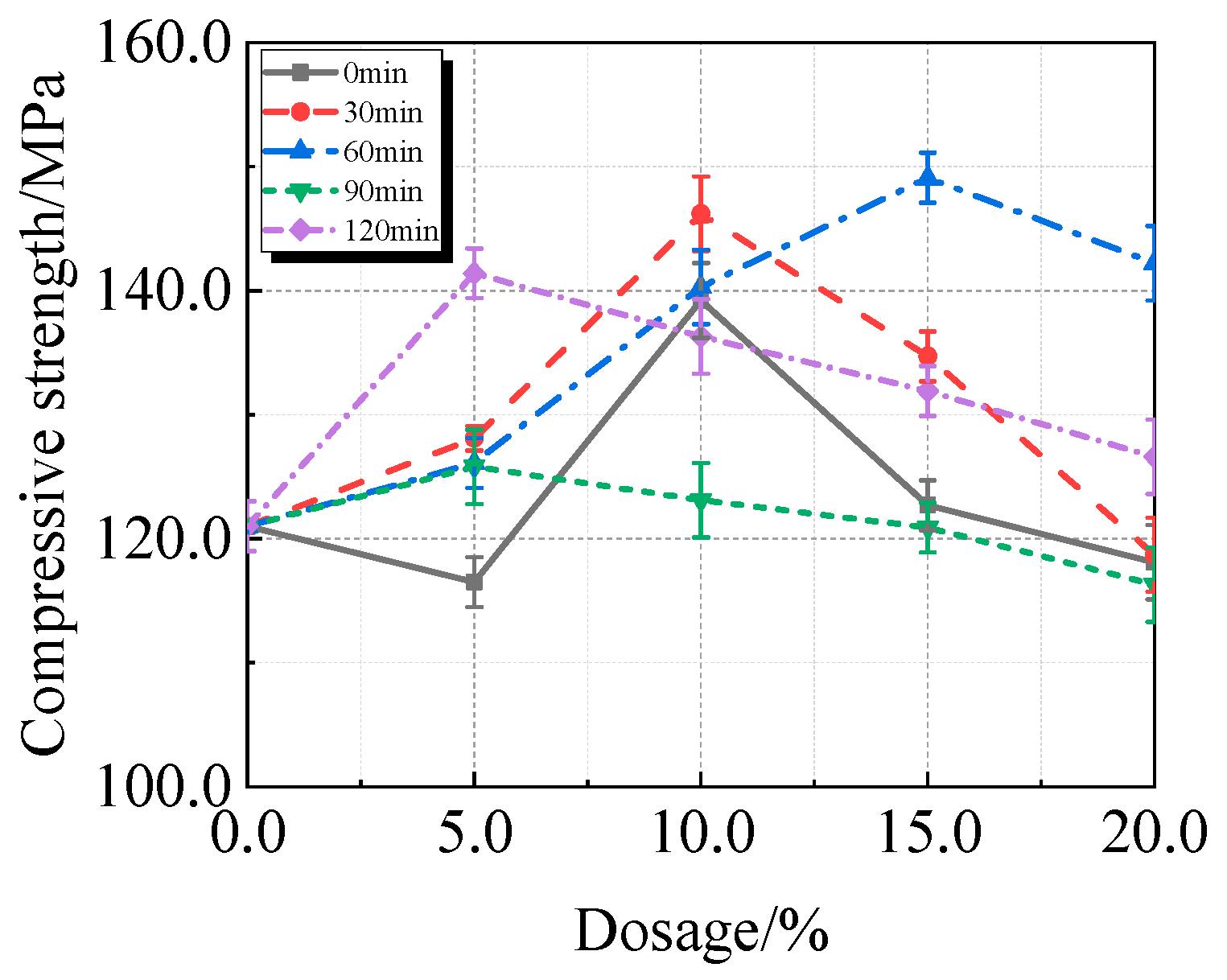

3.1. Effect of Grinding Time on Properties of UHPC Mixed Recycled Fine Powder

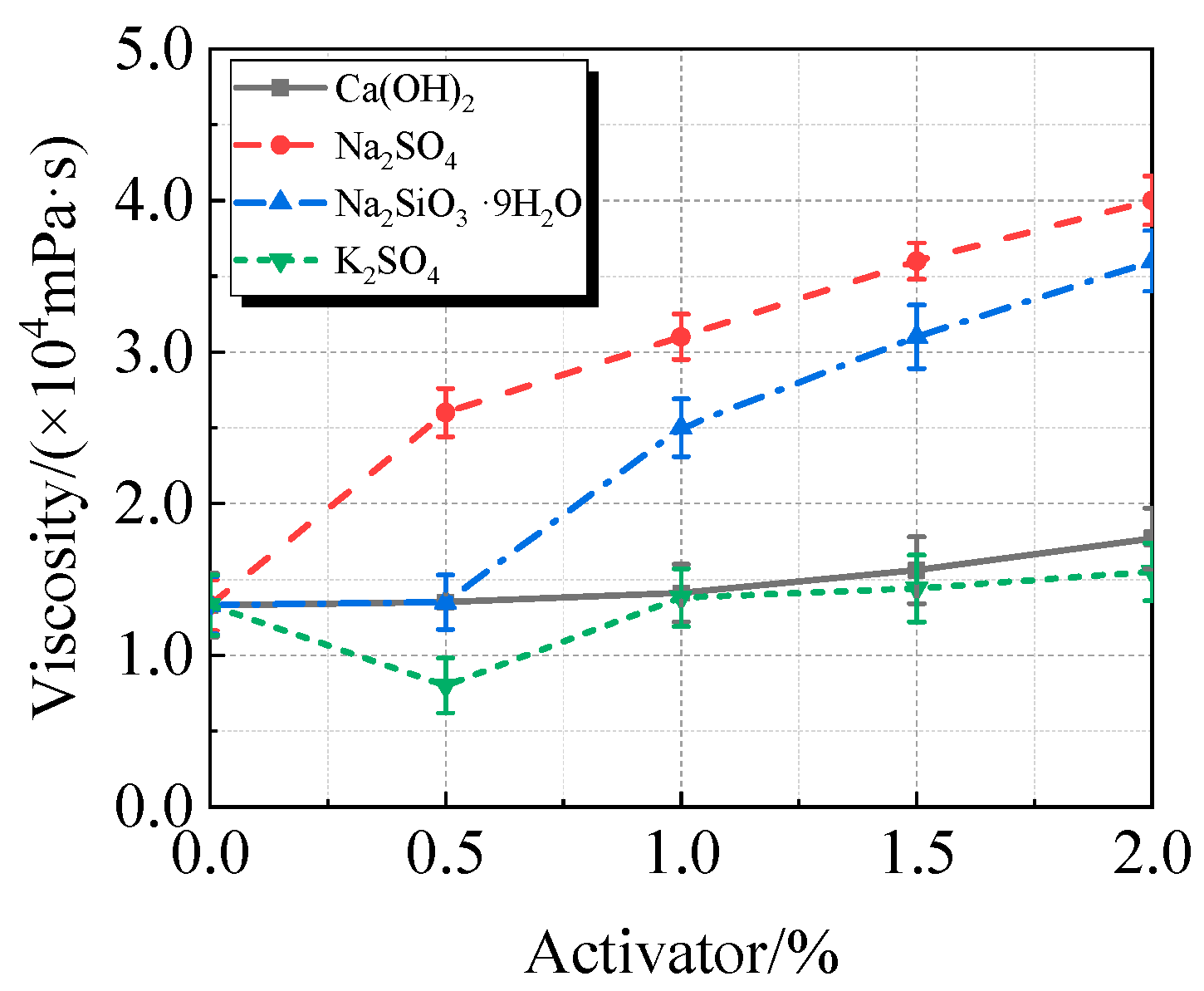

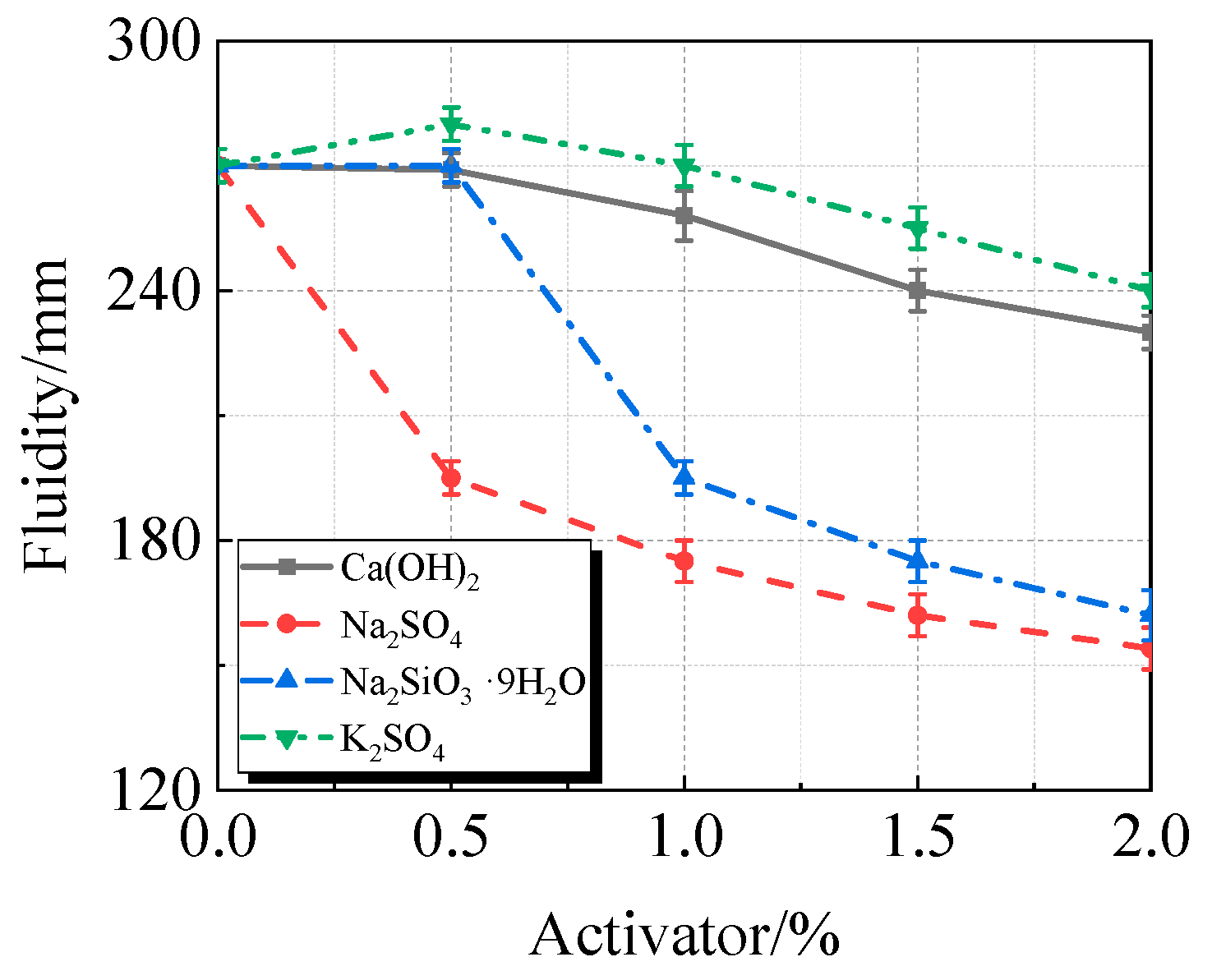

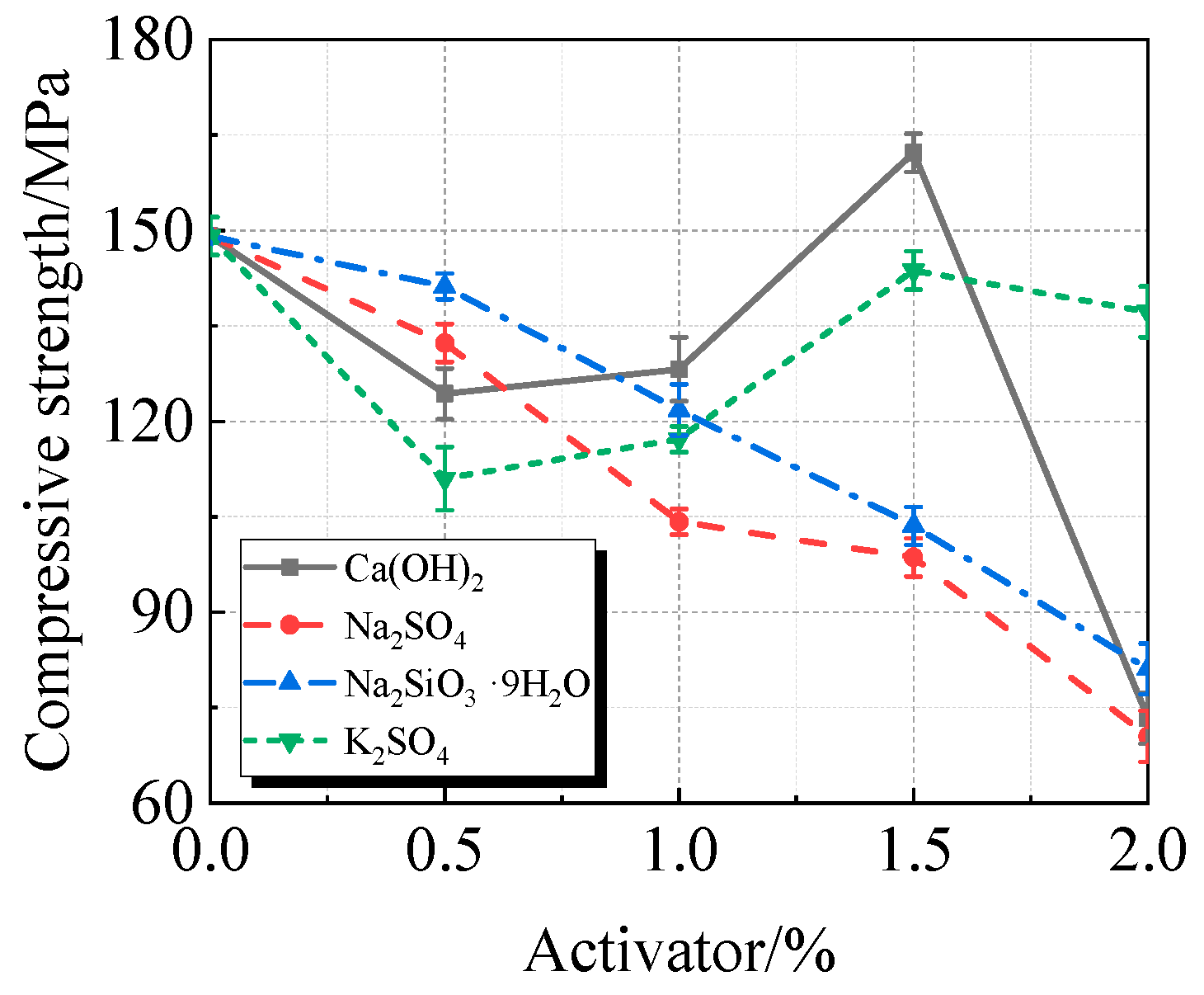

3.2. Effect of Activators on Properties of UHPC Mixed with Recycled Fine Powder

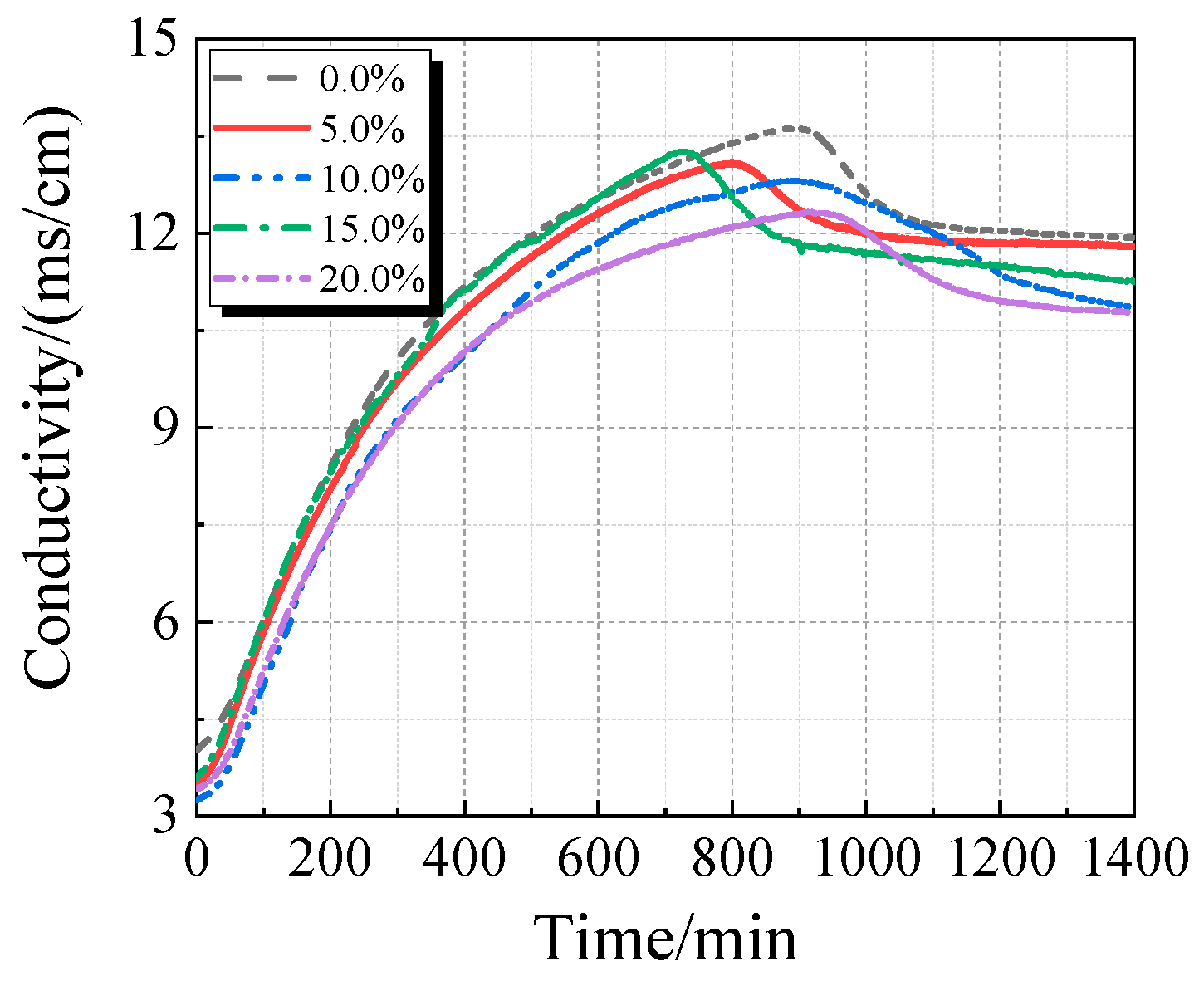

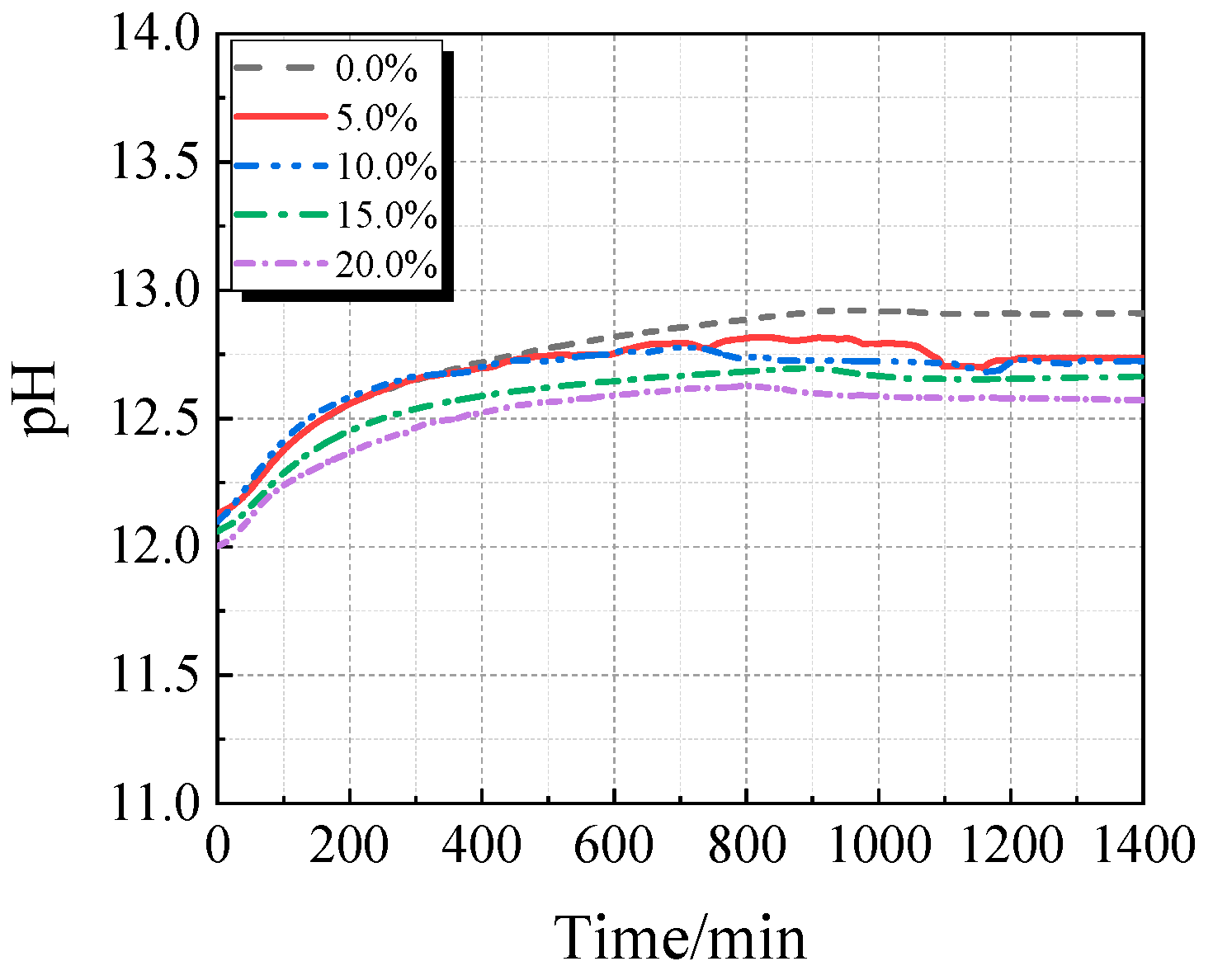

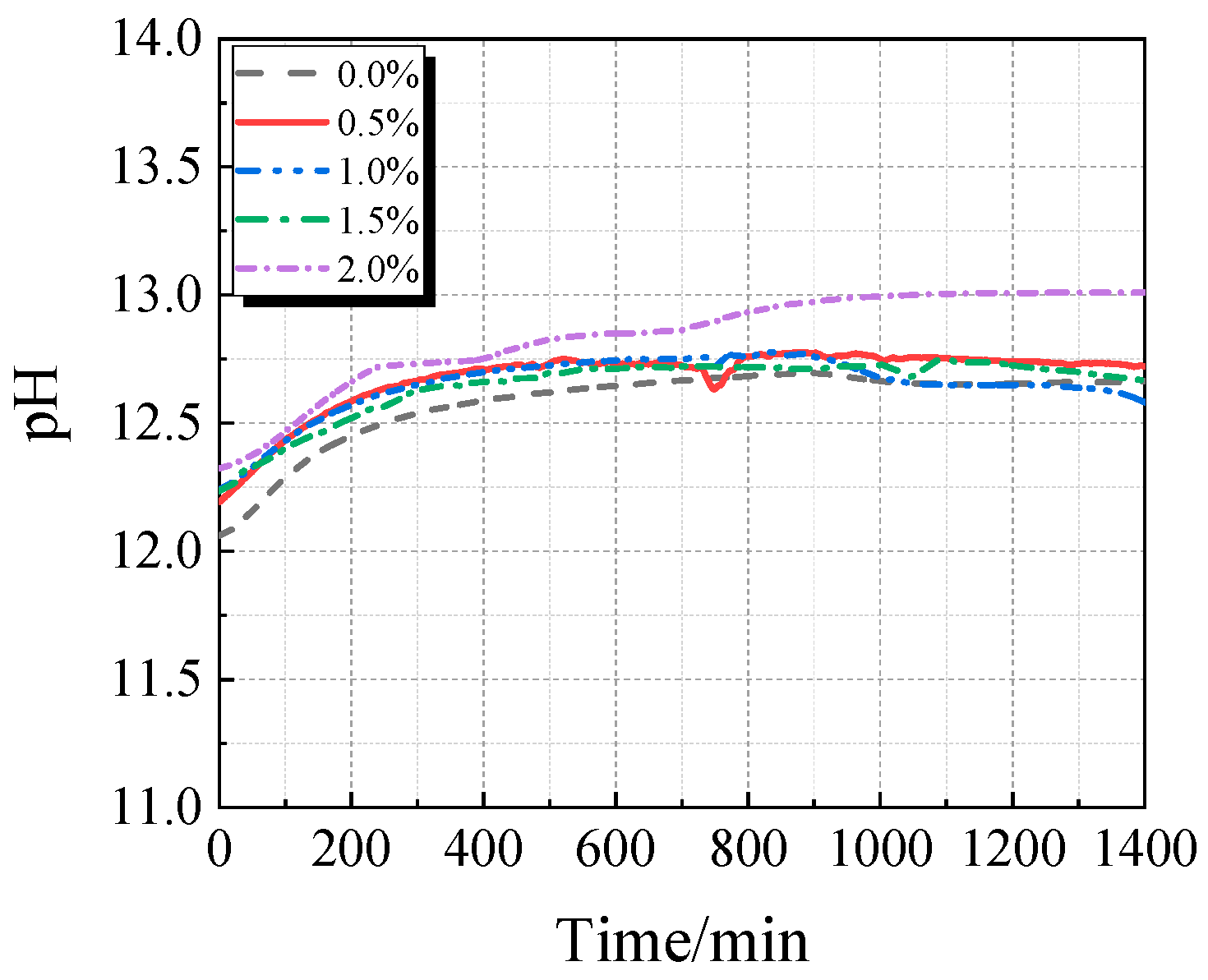

3.3. Electrical Conductivity and pH Value

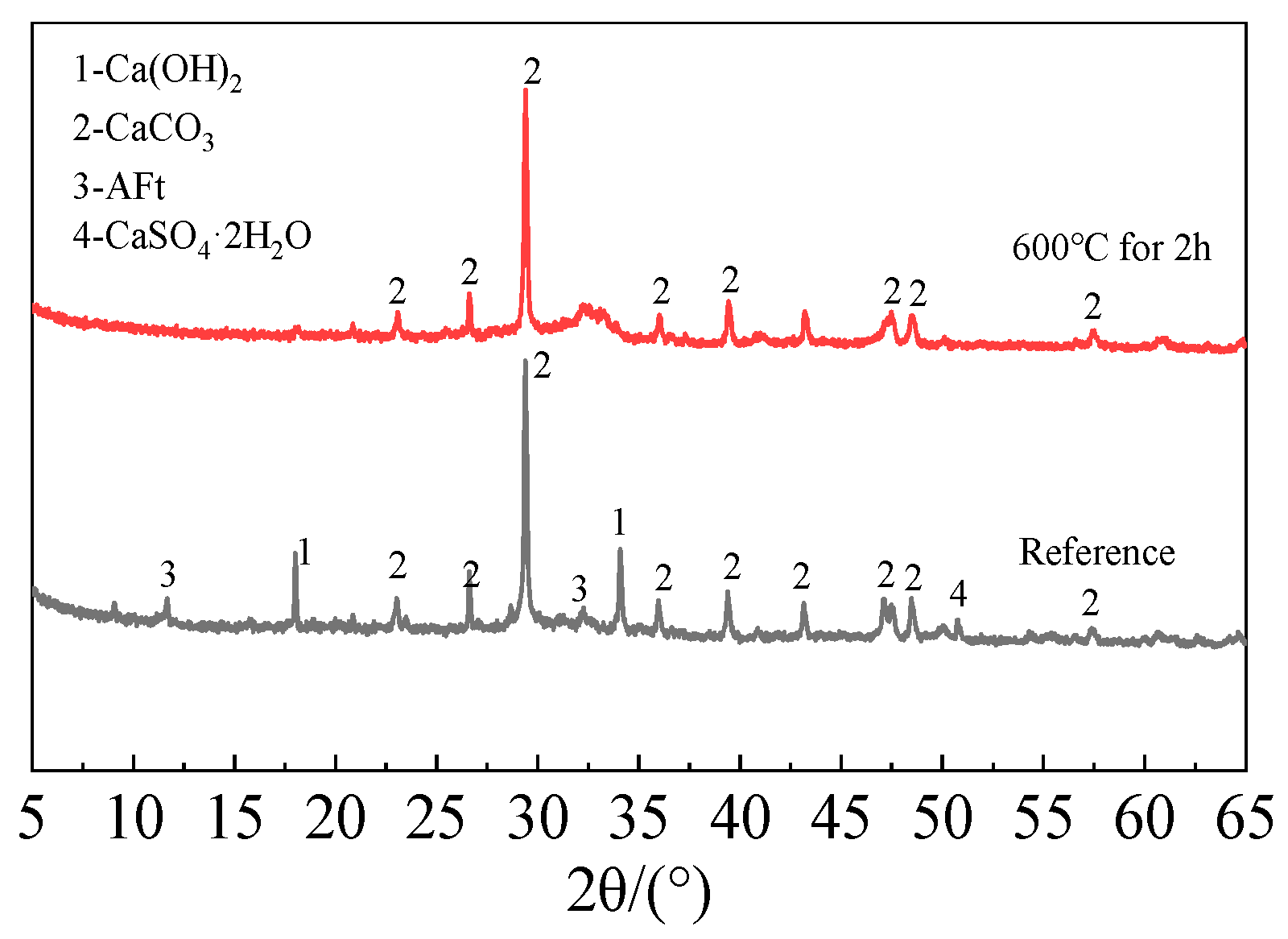

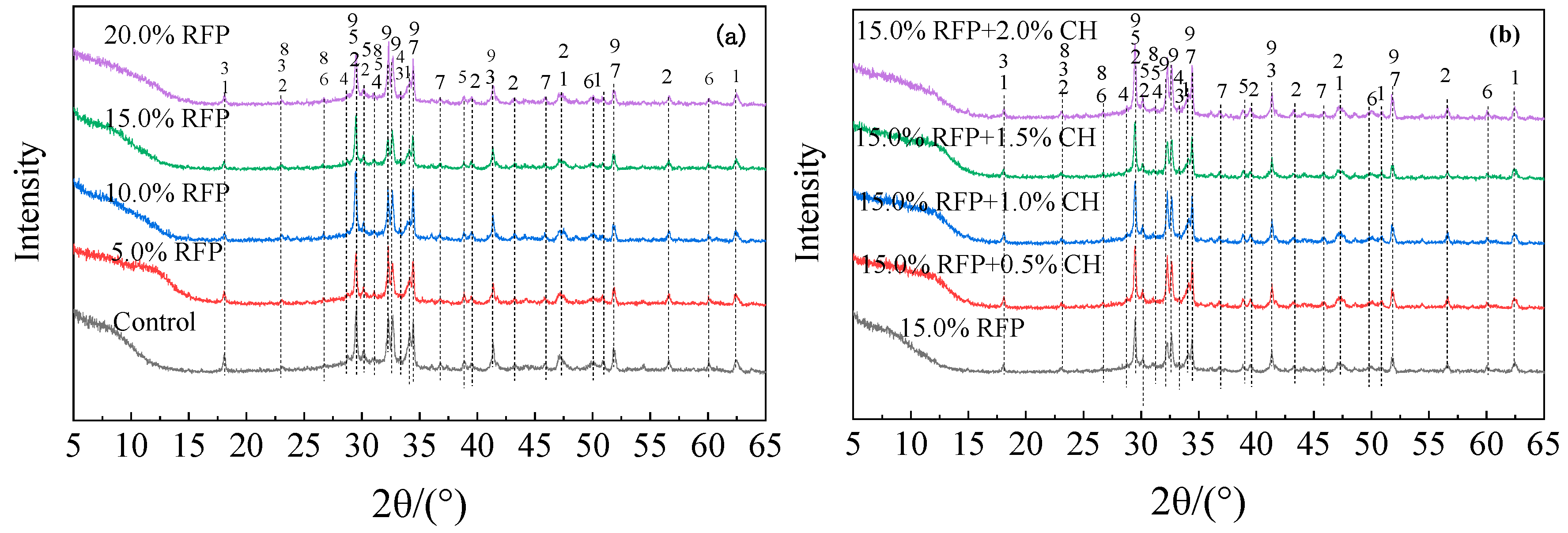

3.4. XRD Analysis

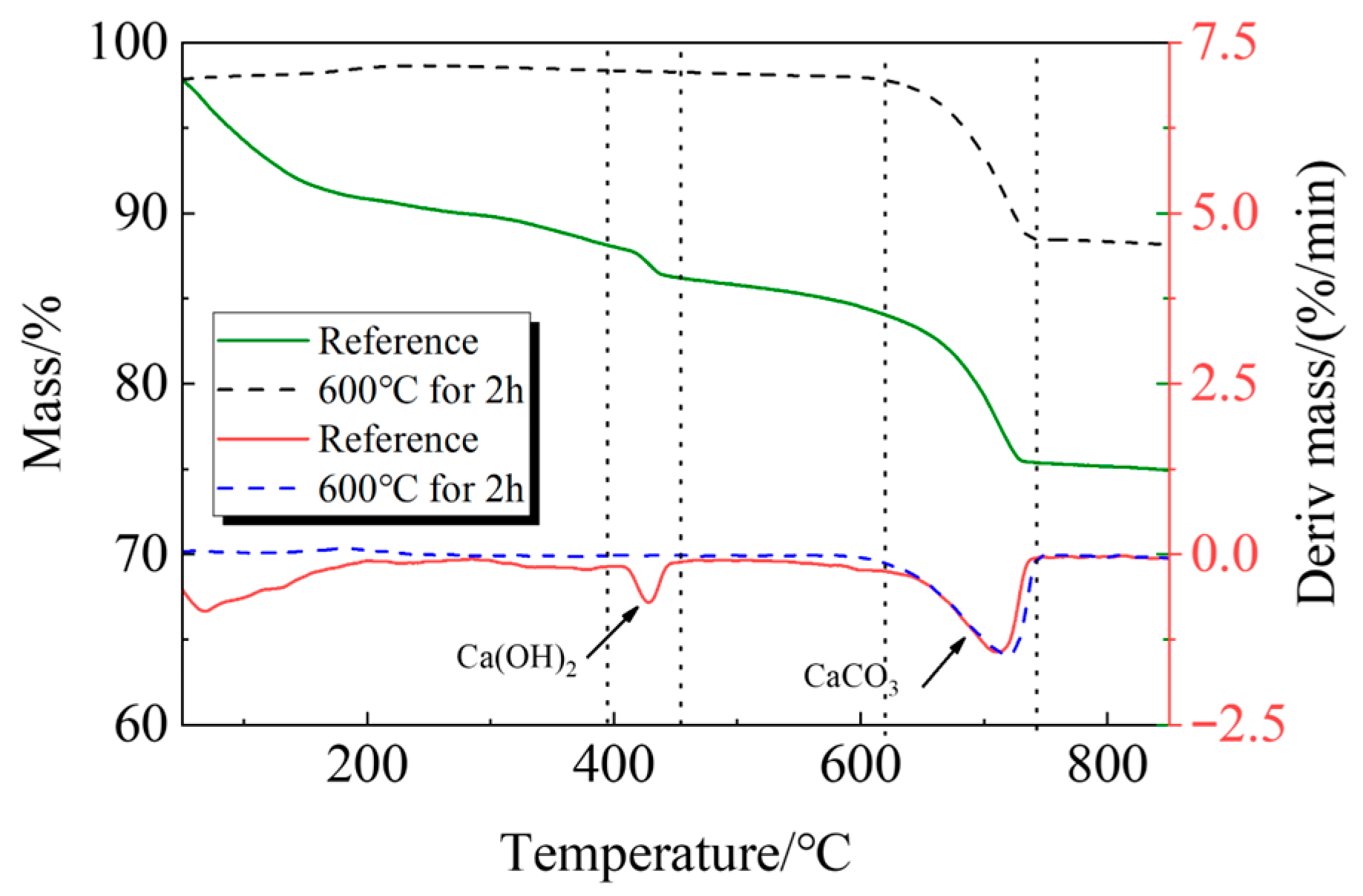

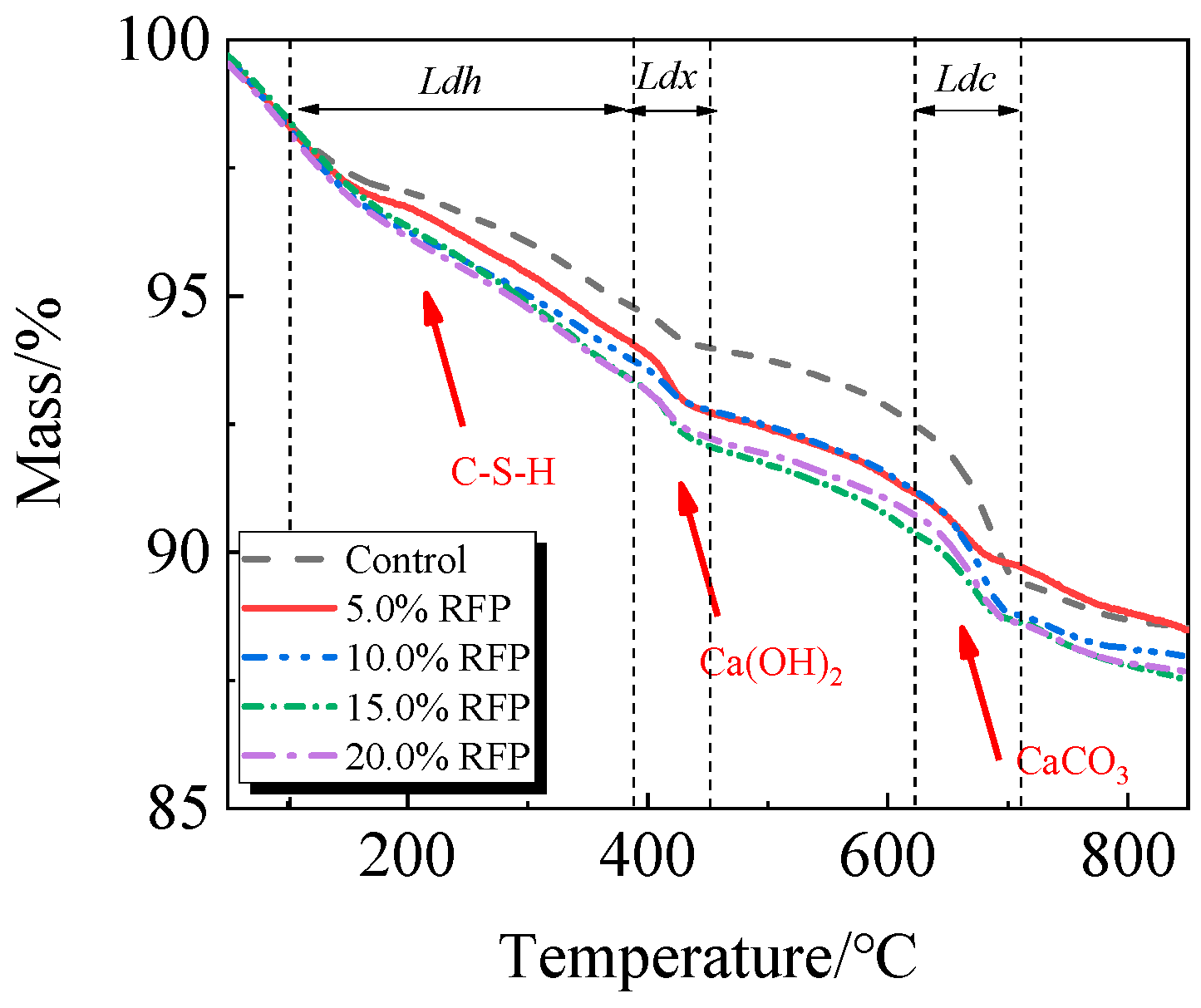

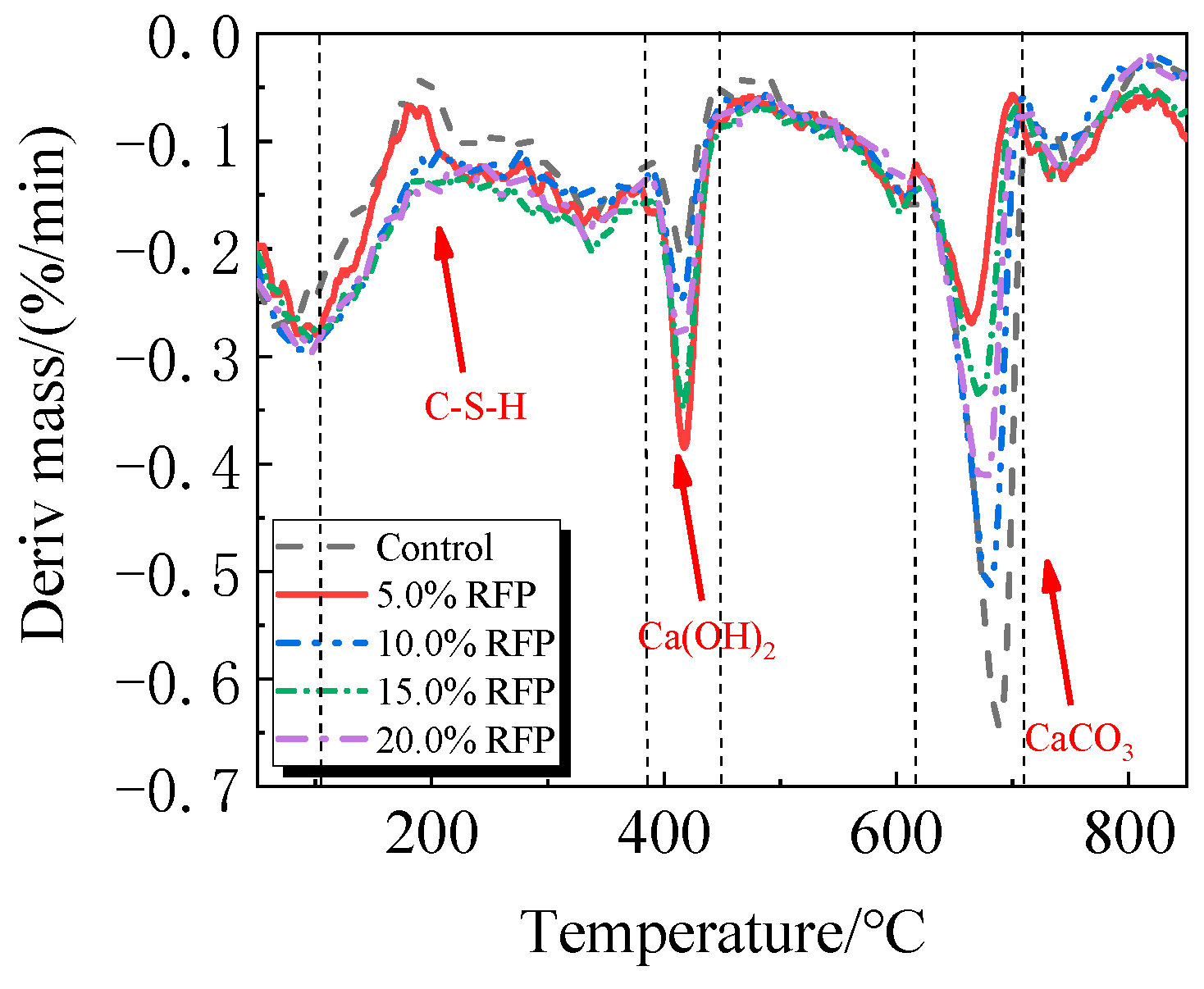

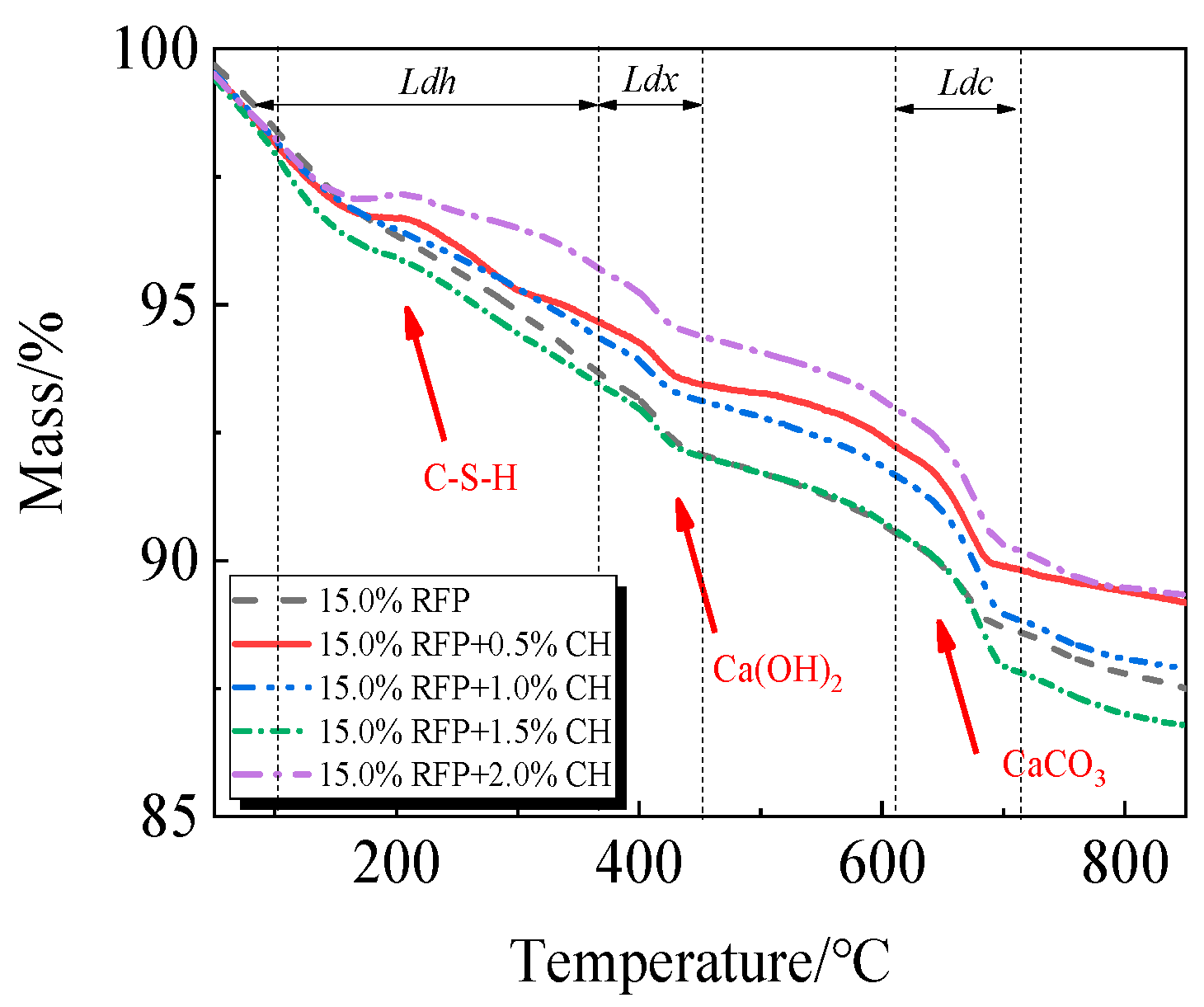

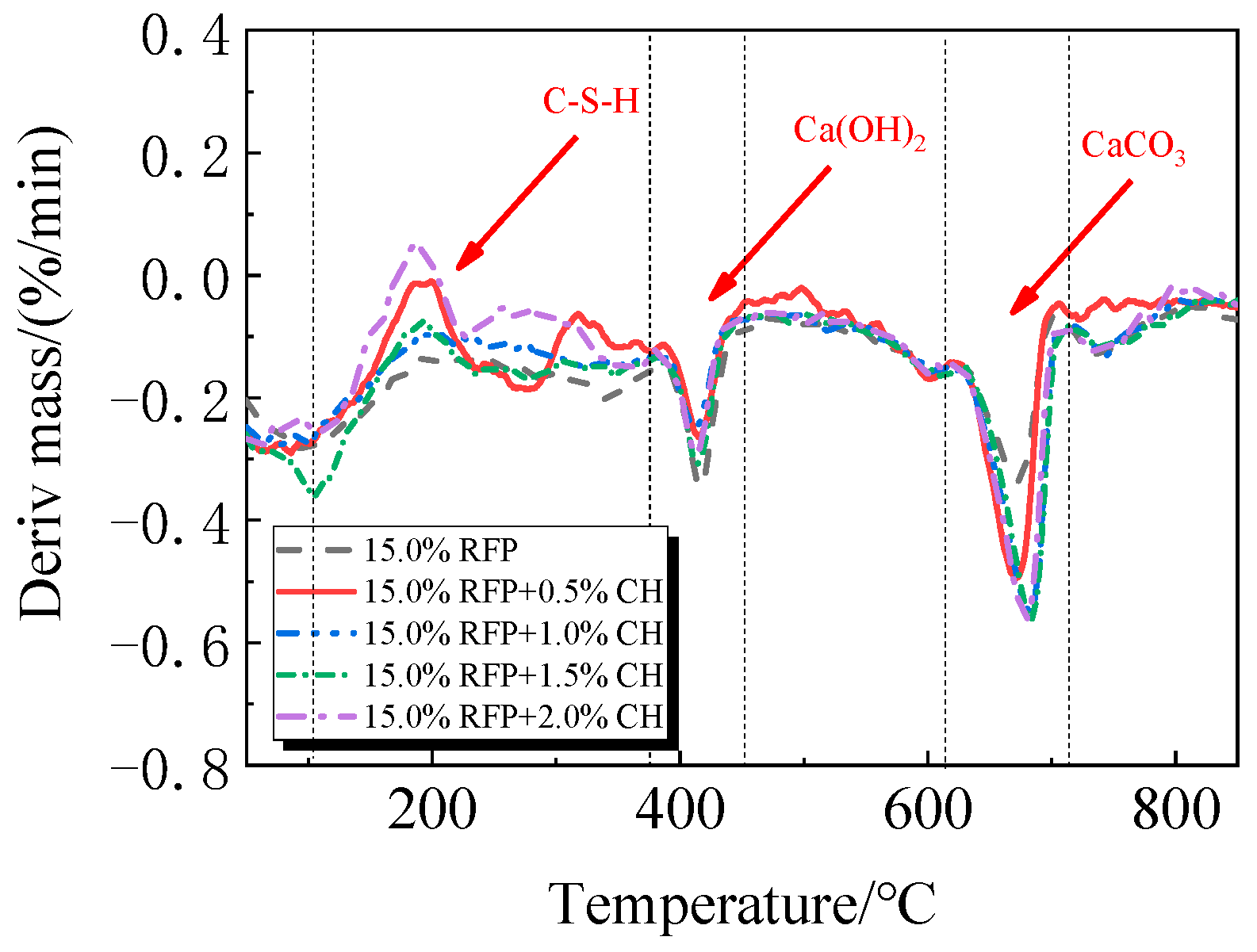

3.5. TG-DTG Analysis

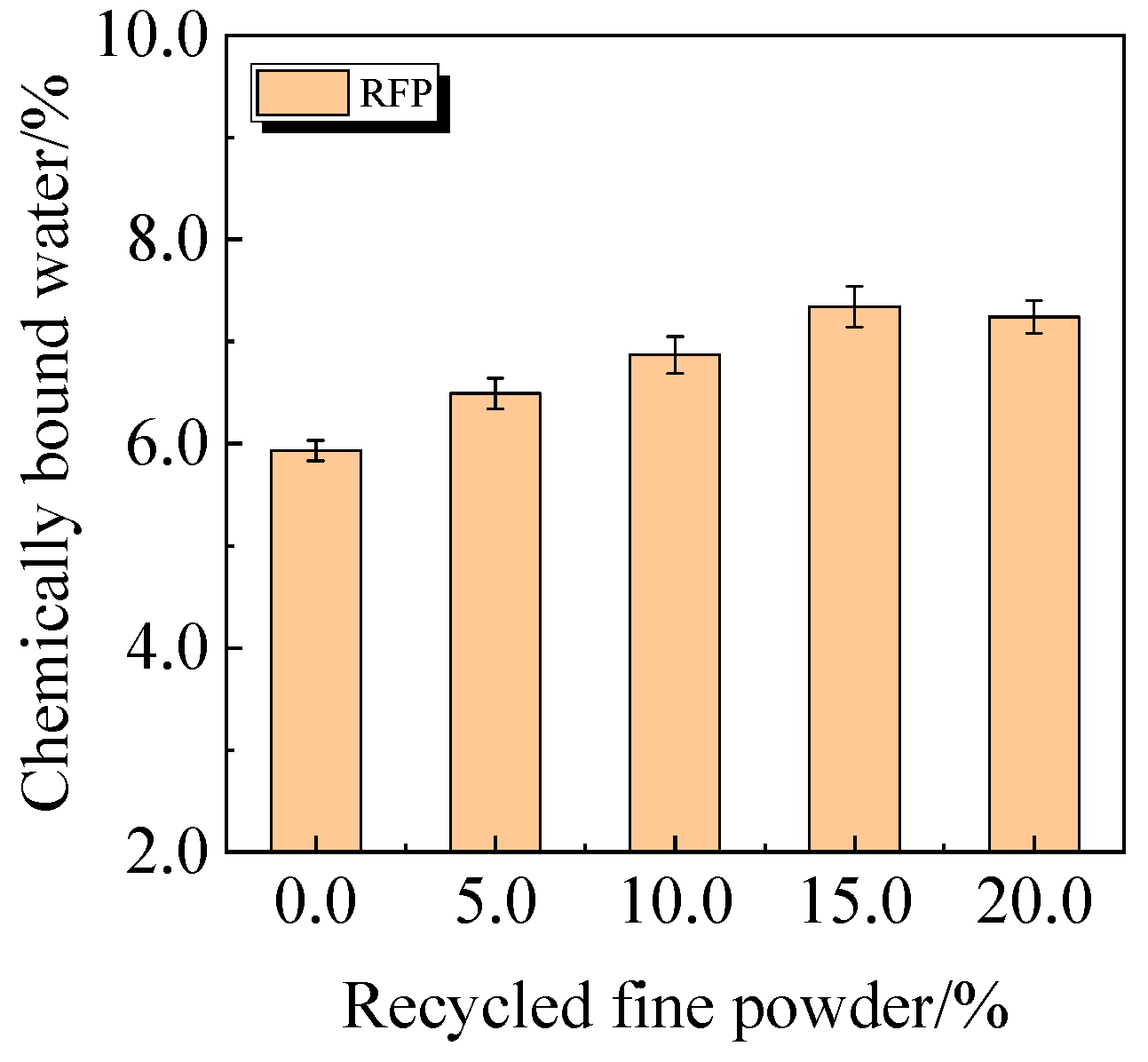

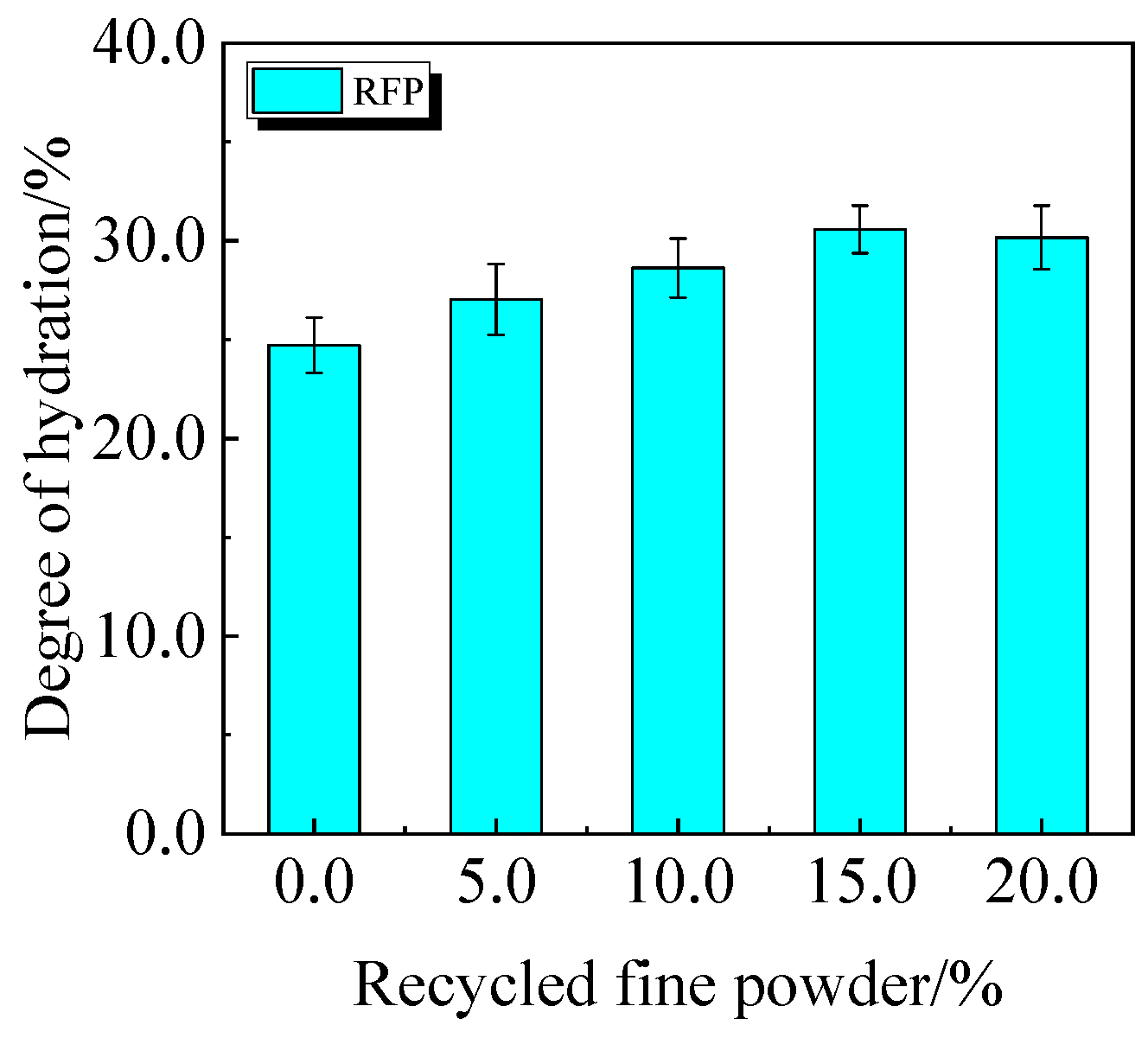

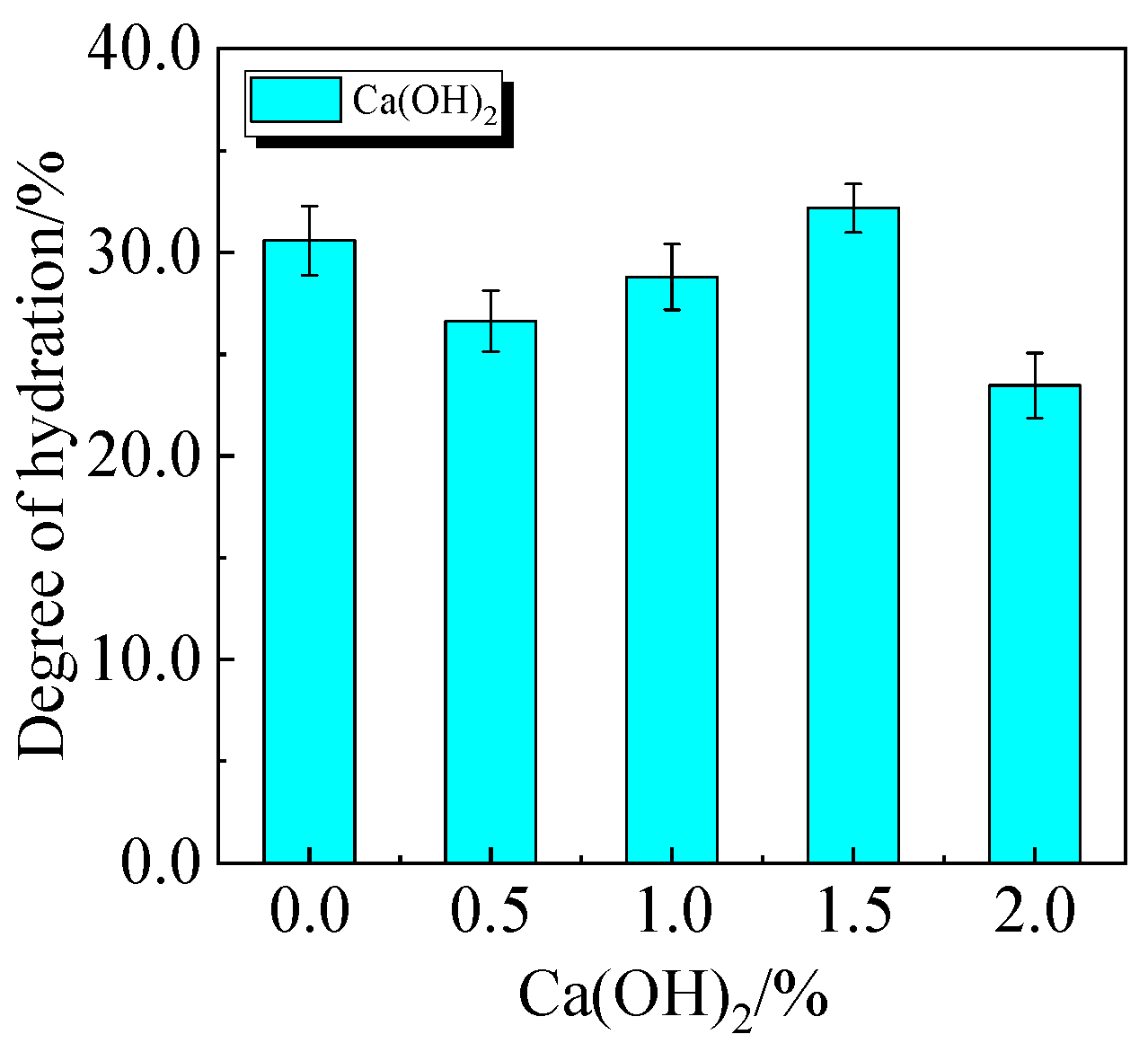

3.6. Degree of Hydration Analysis

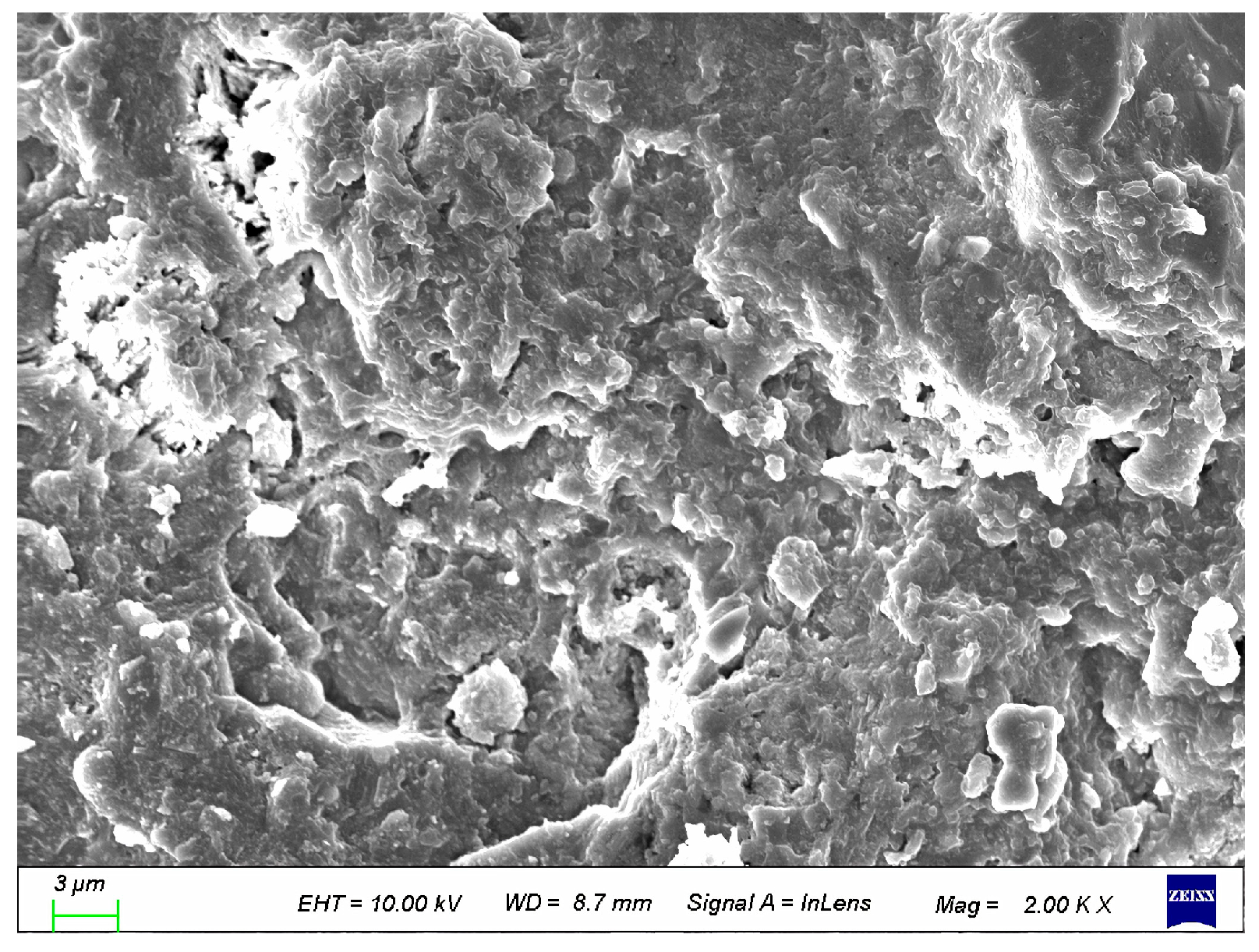

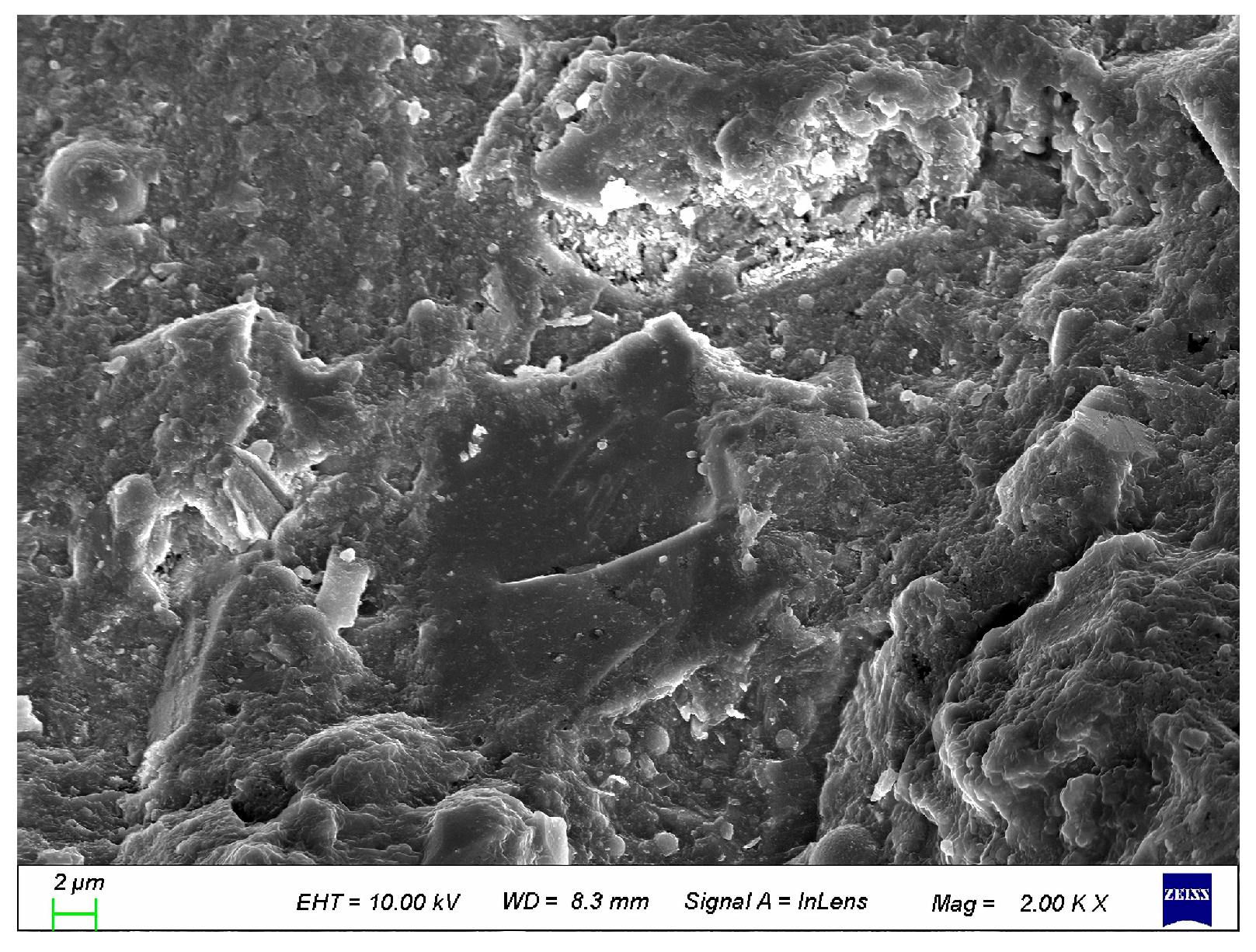

3.7. SEM Analysis

3.8. Carbon Emission of UHPC Mixed Calcined Recycled Fine Powder

4. Conclusions

- (1)

- The best qualities are shown by the recycled fine powder that was calcined at 600 °C for two hours and then milled for sixty minutes. UHPC shows a decrease in fluidity and an increase in viscosity when the dosage of the calcined recycled fine powder increases. UHPC reaches its maximum compressive strength at the ideal dosage of 15.0%, which is a 23.2% improvement over the reference UHPC without any recycled fine powder [40].

- (2)

- The activators Ca(OH)2, Na2SO4, Na2SiO3·9H2O, and K2SO4 cause the UHPC containing calcined recycled fine powder to become more viscous and less fluid. Of them, Na2SO4 has the strongest effect and K2SO4 the least; the effects of Ca(OH)2 and Na2SiO3·9H2O are between those of K2SO4 and Na2SO4. Ca(OH)2 can efficiently boost the strength of UHPC; at a dosage of 1.5%, the maximum strength is reached, leading to an 8.8% increase in compressive strength above reference UHPC.

- (3)

- UHPC hydration is enhanced by calcined recycled fine powder; nevertheless, the degree of hydration decreases when the dosage is above 15.0% [41]; The UHPC with 1.5% Ca(OH)2 shows the greatest amount of hydration products at the 15.0% dosage of calcined recycled fine powder; nevertheless, hydration is negatively impacted by dosages over 1.5% Ca(OH)2. Moreover, the carbon emissions linked to cement usage are successfully decreased by partially substituting calcined recycled fine powder for cement.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ma, S.L.; Yin, J.L.; Wu, W.D.; Zeng, Q.L.; Zhao, Y.H. A review of alkali-activated cementitious materials based on construction and demolition waste-derived recycled fine powder. Concrete 2023, 11, 170–174+180. [Google Scholar]

- Likes, L.; Markandeya, A.; Haider, M.M.; Bollinger, D.; McCloy, J.S.; Nassiri, S. Recycled concrete and brick powders as supplements to Portland cement for more sustainable concrete. J. Clean. Prod. 2022, 364, 132651. [Google Scholar] [CrossRef]

- Ortega, J.M.; Letelier, V.; Solas, C.; Moriconi, G.; Climent, M.Á.; Sánchez, I. Long-term effects of waste brick powder addition in the microstructure and service properties of mortars. Constr. Build. Mater. 2018, 182, 691–702. [Google Scholar] [CrossRef]

- Yuan, C.F.; Chen, Y.; Wang, S.B. Study on the influence and mechanism of activation methods on the activity of recycled brick powder. J. Zhengzhou Univ. (Eng. Sci. Ed.) 2022, 43, 97–103+110. [Google Scholar] [CrossRef]

- Li, Z.; Bian, Y.; Zhao, J.; Wang, Y.; Yuan, Z. Recycled concrete fine powder (RFP) as cement partial replacement: Influences on the physical properties, hydration characteristics, and microstructure of blended cement. J. Build. Eng. 2022, 62, 105326. [Google Scholar] [CrossRef]

- Tang, Y.; Xiao, J.; Liu, Q.; Xia, B.; Singh, A.; Lv, Z.; Song, W. Natural gravel-recycled aggregate concrete applied in rural highway pavement: Material properties and life cycle assessment. J. Clean. Prod. 2022, 334, 130219. [Google Scholar] [CrossRef]

- Tian, Q.; Qu, M.J.; Yao, T.S. The coupling of chemical excitation and heat treatment excites the reactive excitation of recycled powders. Bull. Chin. Ceram. Soc. 2023, 42, 1400–1408. [Google Scholar] [CrossRef]

- Tang, X.M.; Li, Y.; Fan, Y.H. Study on the effects of different excitation methods on the properties of recycled powder. Bull. Chin. Ceram. Soc. 2019, 38, 1135–1139. [Google Scholar] [CrossRef]

- Liu, Y.N.; Wu, X.R.; Wang, G.; Zhao, M.Y.; Tong, Y. Effect of roasting process on microstructure and activity index of recycled powder. China Powder Sci. Technol. 2024, 30, 113–120. [Google Scholar] [CrossRef]

- Xiong, K.X.; Zhan, B.G.; Wang, C. Study on physicochemical joint activation of waste concrete recycled powder. J. Hefei Univ. Technol. (Nat. Sci. Ed.) 2024, 47, 1275–1280+1287. [Google Scholar]

- Zheng, Q.; Wu, D.; Zhang, M.; Yu, J.; Wang, X.P. Design and performance studies of red mud-based ultra-high performance concrete. J. Qingdao Univ. Technol. 2024, 45, 1–7+15. [Google Scholar]

- Liu, C.J. Research on the performance and application of a low-carbon waste cement. Cement 2023, 5, 10–15. [Google Scholar] [CrossRef]

- Wu, N.; Ji, T.; Huang, P.; Fu, T.; Zheng, X.; Xu, Q. Use of sugar cane bagasse ash in ultra-high performance concrete (UHPC) as cement replacement. Constr. Build. Mater. 2022, 317, 125881. [Google Scholar] [CrossRef]

- Ding, M.; Yu, R.; Feng, Y.; Wang, S.; Zhou, F.; Shui, Z.; Gao, X.; He, Y.; Chen, L. Possibility and advantages of producing an ultra-high performance concrete (UHPC) with ultra-low cement content. Constr. Build. Mater. 2021, 273, 122023. [Google Scholar] [CrossRef]

- Wei, J.; Cen, K. Empirical assessing cement CO2 emissions based on China’s economic and social development during 2001–2030. Sci. Total Environ. 2019, 653, 200–211. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Lin, X.; Liu, H.W.; Hu, T.F. Effect of aeolian sand and recycled composite powder on mechanical properties of ultra-high performance concrete. Acta Mater. Compos. Sin. 2022, 39, 5415–5422. [Google Scholar] [CrossRef]

- Sun, D.; Hu, H.; Ma, R.; Hu, X.; Ding, Y.; Wang, A.; Liu, K. Preparation and hydration of low-carbon UHPC with high fraction of activated tuff and recycled fine powders. J. Build. Eng. 2024, 90, 109396. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Fan, M.X.; Zhou, Y.X.; Ji, D.D.; Li, J.H.; Yu, R. Development of a sustainable alkali activated ultra-high performance concrete (A-UHPC) incorporating recycled concrete fines. J. Build. Eng. 2023, 67, 105986. [Google Scholar] [CrossRef]

- Tong, D.B.; Chen, M.; Feng, L.; Lu, C.; Li, W.P.; Guo, J.; Zhang, M. Experimental study on recycled pervious concrete for ecological revetment engineering in small and medium-sized rivers. J. Water Resour. Archit. Eng. 2024, 22, 181–189. [Google Scholar]

- Zhang, C.; Chen, Z.T.; Li, F.Y. Preparation and Performance Regulation of Green Recycled Micro-UHPC. J. Wuhan Univ. Technol. 2025, 47, 7–13. [Google Scholar]

- GB/T 2419-2005; National Technical Committee for Cement Standardization. Method for Determining the Flowability of Cement Mortar. China Standards Press: Beijing, China, 2005.

- GB/T 17671-2021; National Building Materials Industry Bureau. Method for Testing Mortar Strength of Cement (ISO Method). China Standards Press: Beijing, China, 2021.

- Mao, X.; Yang, D.Y.; Cao, Z.L.; Zhao, J.; Chen, L.X.; Wang, T.Z. Research on the performance improvement of self-compacting ultra-high-performance concrete based on image method. Bull. Chin. Ceram. Soc. 2024, 43, 1398–1409. [Google Scholar] [CrossRef]

- Xu, B.; Zhang, Q.S.; Zhao, Y.Z. Effects of Aluminium Salts on the Properties and Hydration of Potassium Magnesium Phosphate Cement. J. Chin. Ceram. Soc. 2025, 53, 1205–1213. [Google Scholar] [CrossRef]

- Zhang, B.; Feng, Y.; Xie, J.; Chen, W.; Xue, Z.; Zhao, G.; Li, Y.; Li, J.; Yang, J. Compressive behaviour and microstructures of concrete incorporating pretreated recycled powder/aggregates:The coupling effects of calcination and carbonization. J. Build. Eng. 2023, 68, 106158. [Google Scholar] [CrossRef]

- Li, J.; Feng, Y.; Zhong, H.; Zhang, B.; Wang, J.; Zhang, B.; Xie, J. Effect of the Pretreatment on the Properties of Cement-Based Recycled Powder. Coatings 2024, 14, 107. [Google Scholar] [CrossRef]

- Li, X.; Liang, L. Research on the activation and properties of recycled concrete powder. Concrete 2023, 11, 105–108+113. [Google Scholar]

- Marvila, M.T.; de Azevedo, A.R.; de Matos, P.R.; Monteiro, S.N.; Vieira, C.M. Materials for Production of High and Ultra-High Performance Concrete: Review and Perspective of Possible Novel Materials. Materials 2021, 14, 4304. [Google Scholar] [CrossRef]

- Chen, J.S.; Qiao, M.; Wu, Q.Y. Effect and mechanism of different chemical activators on the activity of regenerated powder. Bull. Chin. Ceram. Soc. 2023, 42, 1409–1417. [Google Scholar] [CrossRef]

- Chen, T.; Gao, X.; Ren, M. Effects of Autoclave Curing and Fly Ash on Mechanical Properties of Ultra-High Performance Concrete. Constr. Build. Mater. 2018, 158, 864–872. [Google Scholar] [CrossRef]

- Zhang, X.L. Research on Grinding Characteristics and Powder Properties Evaluation of Limestone Coarse Aggregate Waste Concrete. Master’s Thesis, Guangxi University, Nanning, China, 2016; pp. 39–41. [Google Scholar]

- Fang, J.L.; Lu, W.X.; Xu, C.X. Research progress on the activation technology and mechanism of fly ash activity. J. Shanghai Univ. (Nat. Sci. Ed.) 2002, 3, 255–260. [Google Scholar]

- Deboucha, W.; Leklou, N.; Khelidj, A.; Oudjit, M.N. Hydration development of mineral additives blended cement using thermogravimetric analysis (TGA): Methodology of calculating the degree of hydration. Constr. Build. Mater. 2017, 146, 687–701. [Google Scholar] [CrossRef]

- Luo, X.; Jiang, X.; Chen, Q.; Huang, Z. An assessment method of hydration degree of Rice husk ash blended cement considering temperature effect. Constr. Build. Mater. 2021, 304, 124534. [Google Scholar] [CrossRef]

- Chen, L.; Wei, M.; Lei, N.; Li, H. Effect of chemical–thermal activation on the properties of recycled fine powder cementitious materials. Case Stud. Constr. Mater. 2024, 20, e02956. [Google Scholar] [CrossRef]

- Chen, L.; Li, Y.; Chen, W. Effects of Recycled Micro Powder and Mineral Admixtures on the Mechanical Properties and Microstructure of Concrete. Mater. Rev. 2024, 38, 182–187. [Google Scholar]

- Xia, C.C.; Xu, H.; Zhou, Z.; Zhai, W.Q.; He, Z.H. Performance and carbon emission analysis of recycled fine powder self-leveling mortar. Bull. Chin. Ceram. Soc. 2025, 44, 1477–1485. [Google Scholar] [CrossRef]

- Shi, J.; Li, J.; Hai, Y. Research on carbon source analysis and carbon emission accounting of cement industry. Cement 2023, 11, 20–23. [Google Scholar] [CrossRef]

- Yu, X.H.; Li, X.L.; Ma, R.; Shun, H.D.; Su, Z.P. Research on carbon emissions of prefabricated high-ductility recycled micronized concrete structures based on LCA theory. Mater. Rev. 2024, 38, 89–95. [Google Scholar]

- Yang, F.; Ma, Y.; Li, L.; Liu, S.; Hai, R.; Zhu, Z. Early-Age Behaviour of Portland Cement Incorporating Ultrafine Recycled Powder: Insights into Hydration, Setting, and Chemical Shrinkage. Materials 2024, 17, 5551. [Google Scholar] [CrossRef]

- Deng, M.; Xie, X.; Zhuo, J.; He, Y.; Wang, K. Experimental Study on the Strength and Hydration Products of Cement Mortar with Hybrid Recycled Powders Based Industrial-Construction Residue Cement Stabilization of Crushed Aggregate. Materials 2023, 16, 4233. [Google Scholar] [CrossRef]

| Material | Cement | Silica Fume | Quartz Sand | Water | Superplasticizer | |

|---|---|---|---|---|---|---|

| 425–212 μm | 212–106 μm | |||||

| Mix proportion/(kg·m−3) | 1330.8 | 190.1 | 456.3 | 456.3 | 273.8 | 16.7 |

| No. | Calcination Temperature/°C | Calcination Time/h | Grinding Time/min | D10/μm | D50/μm | D90/μm |

|---|---|---|---|---|---|---|

| 1 | 600 | 2 | 0 | 16.64 | 148.00 | 403.70 |

| 2 | 600 | 2 | 30 | 4.33 | 43.64 | 174.10 |

| 3 | 600 | 2 | 60 | 3.81 | 39.22 | 144.50 |

| 4 | 600 | 2 | 90 | 3.19 | 29.83 | 110.80 |

| 5 | 600 | 2 | 120 | 2.80 | 24.02 | 93.86 |

| Material | Cement | Silica Fume | Quartz Sand | Recycled Fine Powder |

|---|---|---|---|---|

| Carbon emission factors/(kg·kg−1) | 0.7590 | 0.0240 | 0.0102 | 0.0190 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Lu, C.; Zhang, M.; Shrestha, N.; Yang, D.; Yu, C. Influence of Coupled Activated Recycled Fine Powder on the Performance of Ultra-High-Performance Concrete. Materials 2026, 19, 201. https://doi.org/10.3390/ma19010201

Lu C, Zhang M, Shrestha N, Yang D, Yu C. Influence of Coupled Activated Recycled Fine Powder on the Performance of Ultra-High-Performance Concrete. Materials. 2026; 19(1):201. https://doi.org/10.3390/ma19010201

Chicago/Turabian StyleLu, Chun, Ming Zhang, Nirmal Shrestha, Dongdong Yang, and Chengxiao Yu. 2026. "Influence of Coupled Activated Recycled Fine Powder on the Performance of Ultra-High-Performance Concrete" Materials 19, no. 1: 201. https://doi.org/10.3390/ma19010201

APA StyleLu, C., Zhang, M., Shrestha, N., Yang, D., & Yu, C. (2026). Influence of Coupled Activated Recycled Fine Powder on the Performance of Ultra-High-Performance Concrete. Materials, 19(1), 201. https://doi.org/10.3390/ma19010201