A Study on the Effect of Different Cementitious Materials on the Mechanical Properties and Microscopic Characteristics of Alkali-Activated Green Ultra-High Performance Concrete (GUHPC)

Abstract

1. Introduction

2. Materials and Methods

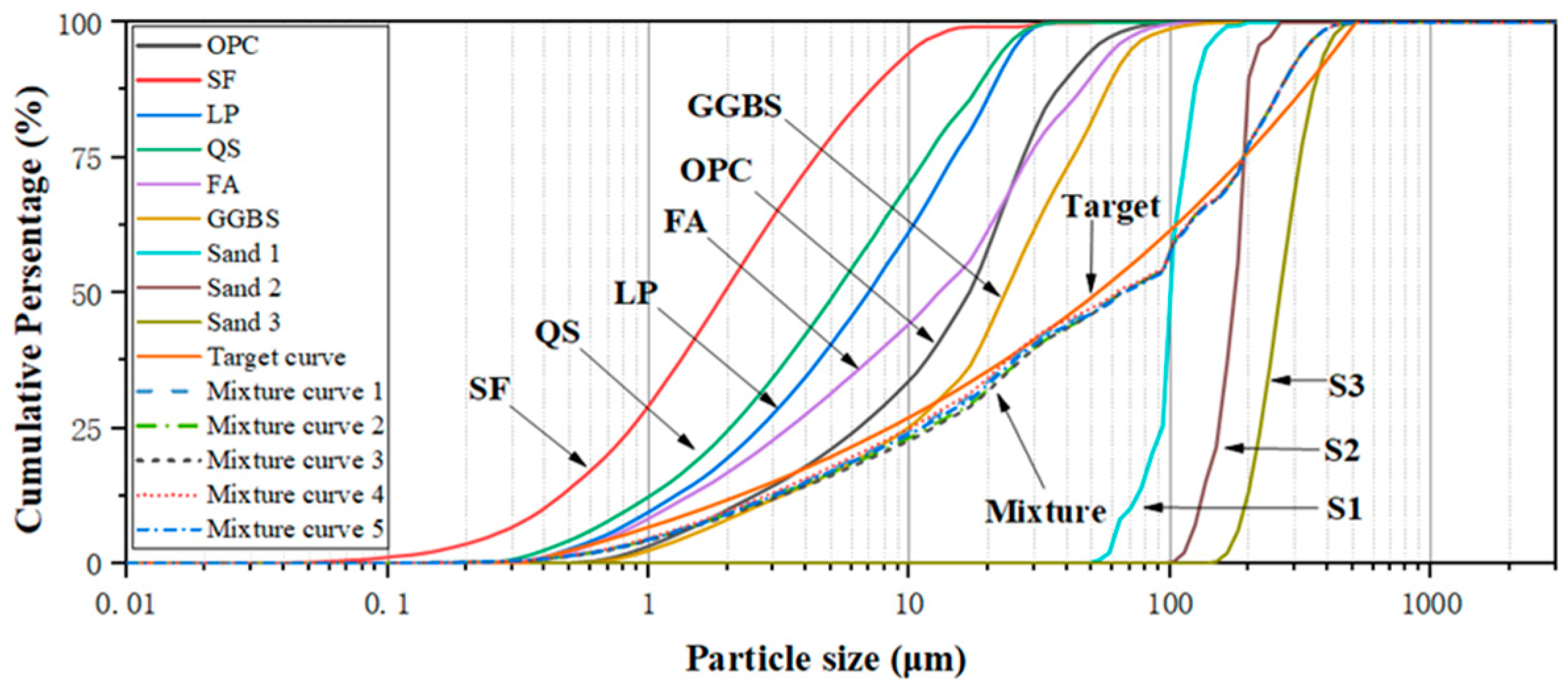

2.1. Raw Materials

2.2. Mix Proportions

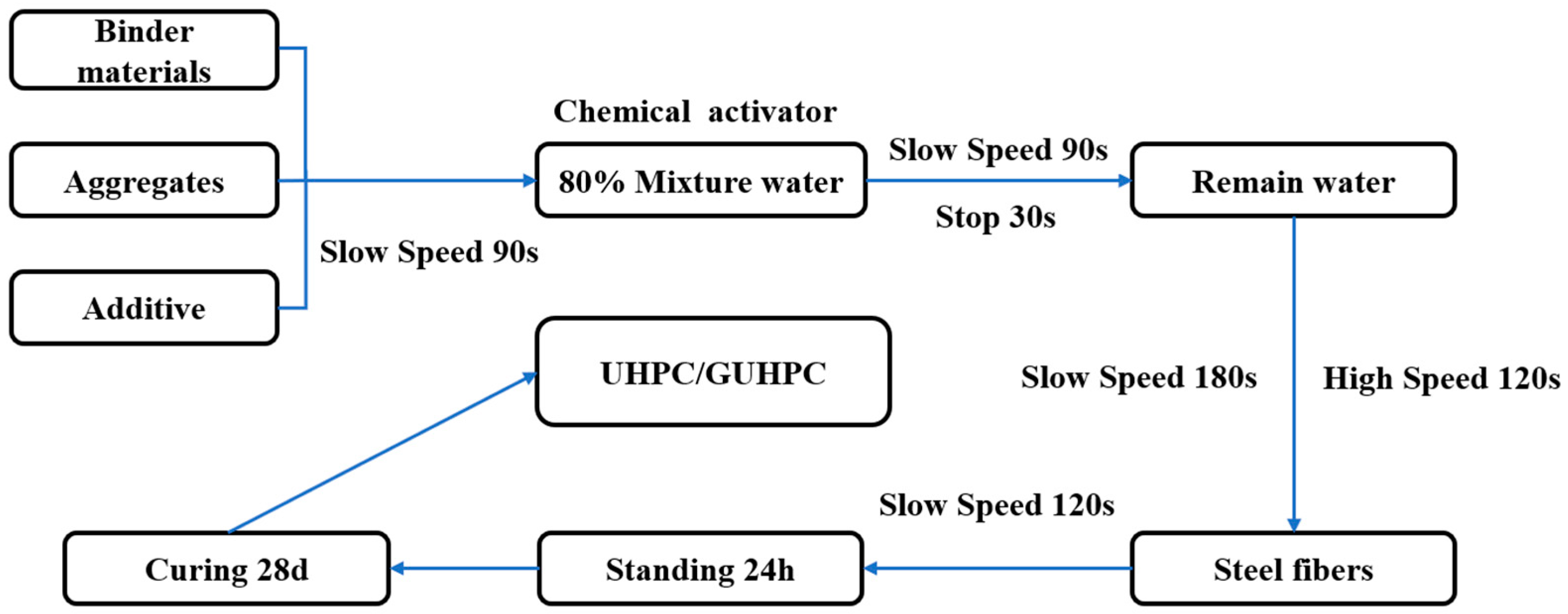

2.3. Specimen Preparation and Curing

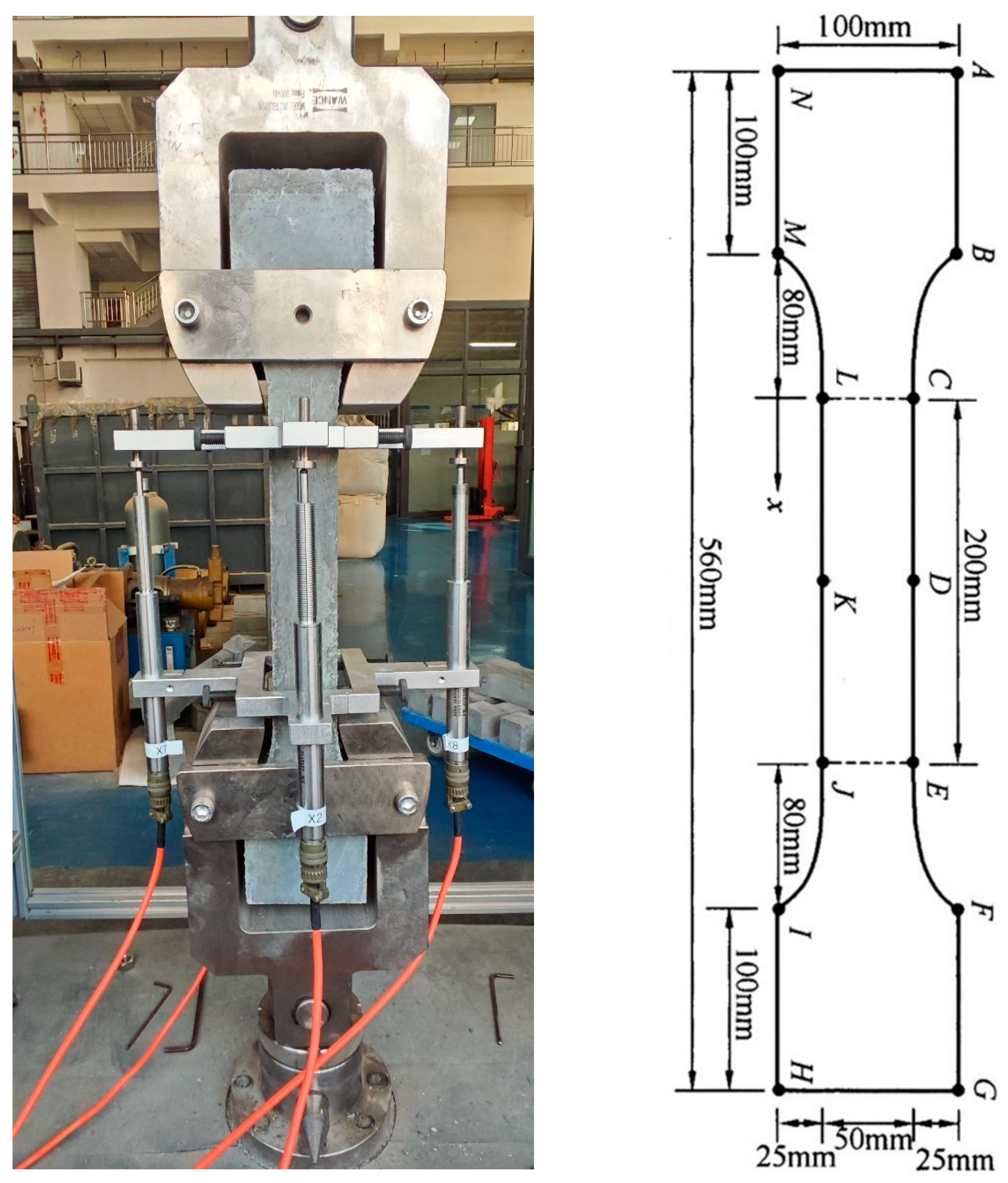

2.4. Testing Methods

2.4.1. Mechanical Property Test

2.4.2. Chloride Permeability Test

2.4.3. Freeze-Thaw Cycle Test

- ∆fc: Compressive strength loss rate of concrete after N freeze-thaw cycles (%), accurate to 0.1%.

- fc0: Compressive strength of reference concrete specimens (MPa), accurate to 0.1 MPa.

- Fcn: Compressive strength of concrete specimens after N freeze-thaw cycles, accurate to 0.1 MPa.

- ΔW: Mass loss rate of concrete after N freeze-thaw cycles (%), accurate to 0.1%.

- W0: Initial mass of concrete specimens before freeze-thaw cycling (g).

- Wn: Mass of concrete specimens after N freeze-thaw cycles (g).

2.4.4. X-Ray Diffraction Analysis

2.4.5. SEM Morphology Analysis

2.4.6. Mercury Intrusion Porosimetry

3. Results and Discussion

3.1. Mechanical Properties

3.1.1. Compressive Strength

3.1.2. Tensile Strength

3.2. Chloride Permeation Analysis

3.3. Frost Resistance Analysis

3.4. XRD

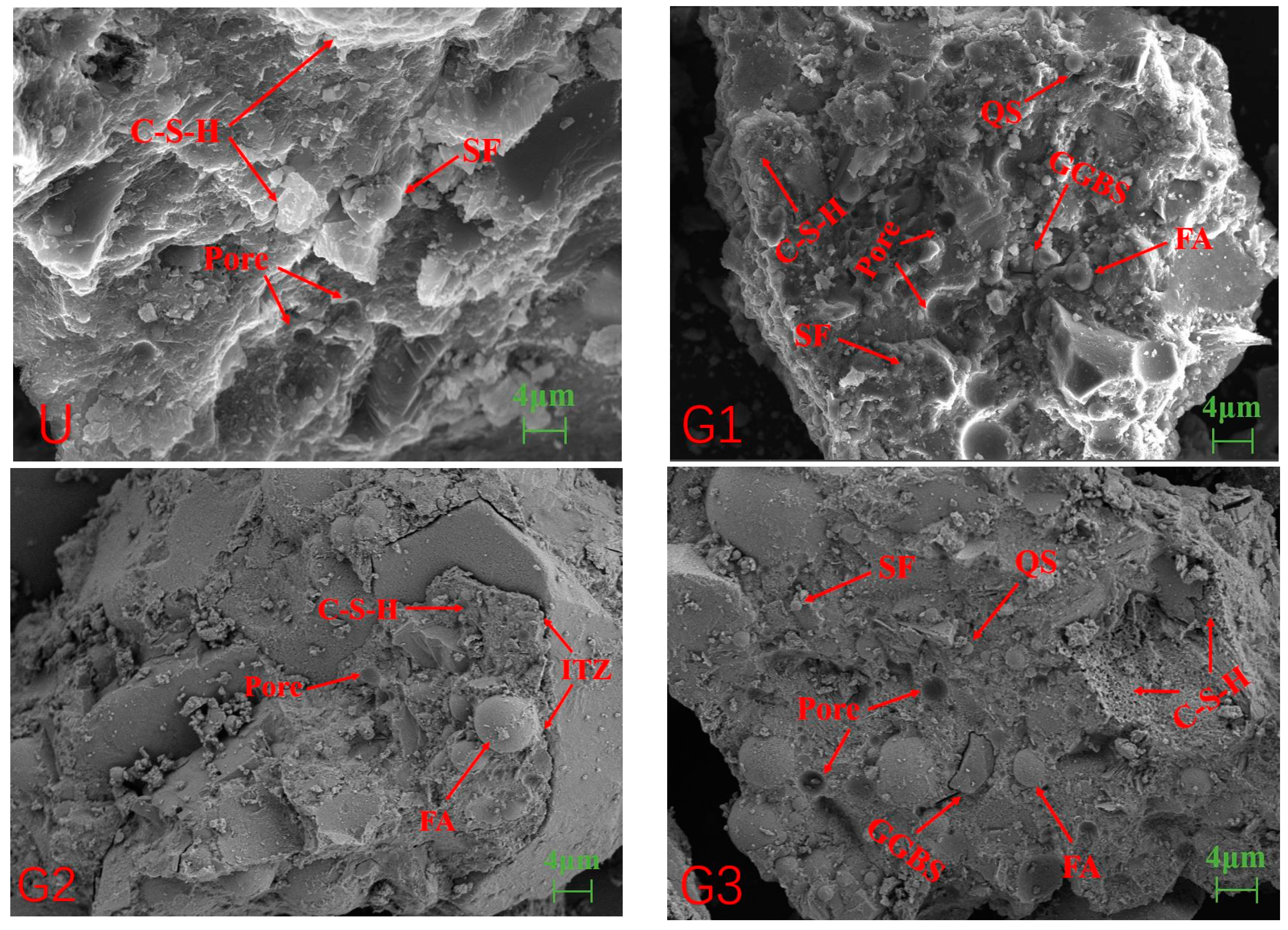

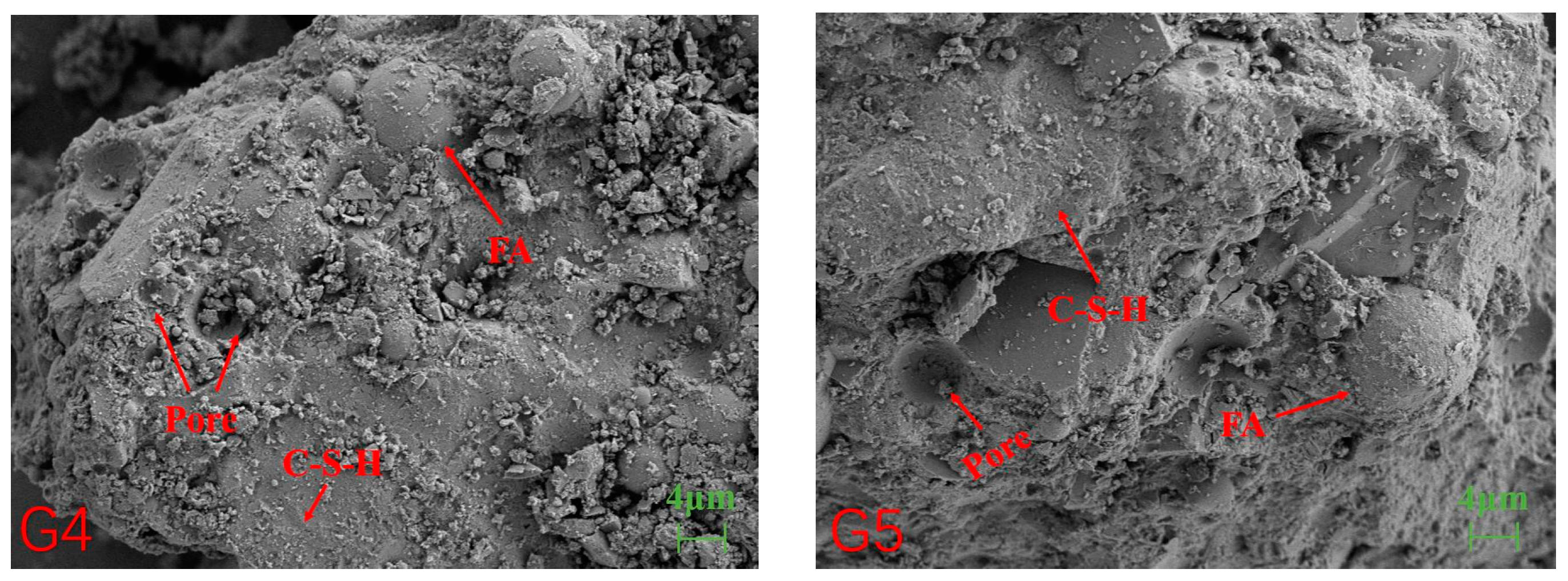

3.5. SEM

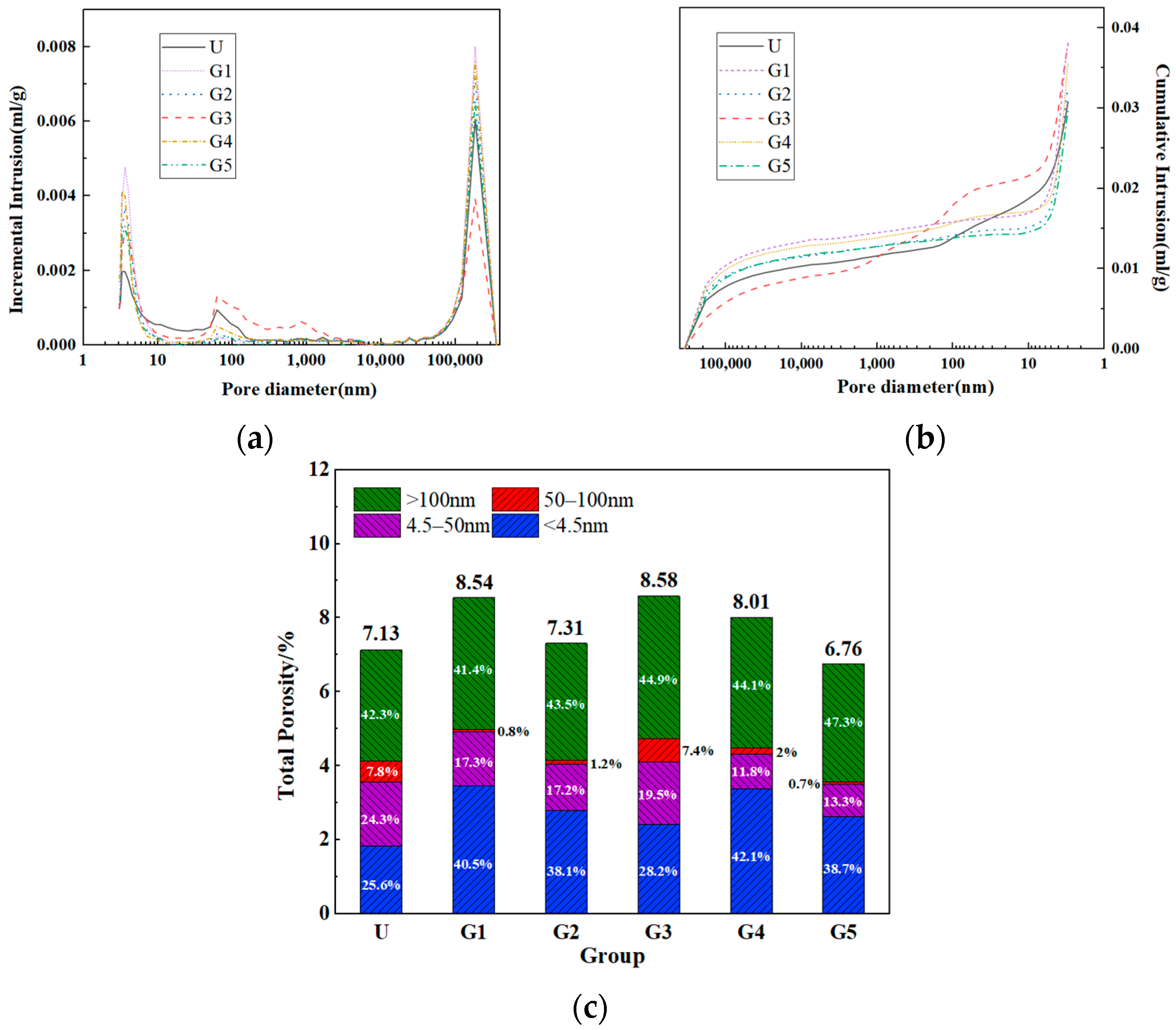

3.6. Pore Structure

4. Discussion

4.1. Optimization and Validation of Binder Replacement Strategy

4.2. New Insights into Microstructural Densification Mechanisms

4.3. Enhanced Durability and Mechanistic Advancements

4.4. Quantifiable Advancements in Low-Carbon Performance

4.5. Innovations

5. Conclusions

- (1)

- GUHPC with ≤264 kg/m3 cement content can achieve excellent compressive and tensile strengths of 165.3 MPa and 7.8 MPa, respectively, using 40% slag powder and 28% fly ash as replacements;

- (2)

- The multi-component cementitious system formed by slag and fly ash compensates for insufficient hydration products caused by cement reduction through physical filling, producing GUHPC with denser microstructure, lower porosity (6.76%), and enhanced durability;

- (3)

- Under alkali activation, slag powder exhibits superior hydration reactivity compared to fly ash, generating greater quantities of hydration products (e.g., C-S-H gels) to improve mechanical strength, while increased fly ash content extends the strain hardening phase of GUHPC;

- (4)

- Quartz and limestone powders function as inert fillers in the alkali-activated GUHPC system, physically occupying pore spaces without participating in hydration reactions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shi, C.; Wu, Z.; Xiao, J. A review on ultra high performance concrete: Part I. Raw materials and mixture design. Constr. Build. Mater. 2015, 101, 741–751. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Banthia, N. Mechanical properties of ultra-high-performance fiber-reinforced concrete: A review. Cem. Concr. Compos. 2016, 73, 267–280. [Google Scholar] [CrossRef]

- Lu, J.X.; Ali, H.A.; Jiang, Y. A novel high-performance lightweight concrete prepared with glass-UHPC and lightweight microspheres: Towards energy conservation in buildings. Compos. Part B Eng. 2022, 247, 110295. [Google Scholar] [CrossRef]

- Fan, D.; Zhu, J.; Fan, M.; Lu, J. Intelligent design and manufacturing of ultra-high performance concrete (UHPC)—A review. Constr. Build. Mater. 2023, 385, 131495. [Google Scholar] [CrossRef]

- Liu, K.; Yu, R.; Shui, Z. Optimization of autogenous shrinkage and microstructure for Ultra-High Performance Concrete (UHPC) based on appropriate application of porous pumice. Constr. Build. Mater. 2019, 214, 369–381. [Google Scholar] [CrossRef]

- Soliman, A.M.; Nehdi, M.L. Effect of drying conditions on autogenous shrinkage in ultra-high performance concrete at early-age. Mater. Struct. 2011, 44, 879–899. [Google Scholar] [CrossRef]

- Korpa, A.; Kowald, T.; Trettin, R. Phase development in normal and ultra high performance cementitious systems by quantitative X-ray analysis and thermoanalytical methods. Cem. Concr. Res. 2009, 39, 69–76. [Google Scholar] [CrossRef]

- Kazemi-Kamyab, H.; Muller, A.C.A.; Denarié, E. Kinetics of mixing-water repartition in UHPFRC paste and its effect on hydration and microstructural development. Cem. Concr. Res. 2019, 124, 105784. [Google Scholar] [CrossRef]

- Xu, D.; Cui, Y.; Li, H. On the future of Chinese cement industry. Cem. Concr. Res. 2015, 78, 2–13. [Google Scholar] [CrossRef]

- Graybeal, B.A. Material Property Characterization of Ultra-High Performance Concrete; National Academy of Sciences: Washington, DC, USA, 2006. [Google Scholar]

- Rashad, A.M.; Sadek, D.M.; Hassan, H.A. An investigation on blast-furnace stag as fine aggregate in alkali-activated slag mortars subjected to elevated temperatures. J. Clean. Prod. 2016, 112, 1086–1096. [Google Scholar] [CrossRef]

- Abdulkareem, O.M.; Ben Fraj, A.; Bouasker, M. Mixture design and early age investigations of more sustainable UHPC. Constr. Build. Mater. 2018, 163, 235–246. [Google Scholar] [CrossRef]

- Shi, Y.; Long, G.; Zeng, X. Green ultra-high performance concrete with very low cement content. Constr. Build. Mater. 2021, 303, 124482. [Google Scholar] [CrossRef]

- Ding, M.; Yu, R.; Feng, Y. Possibility and advantages of producing an ultra-high performance concrete (UHPC) with ultra-low cement content. Constr. Build. Mater. 2021, 273, 122023. [Google Scholar] [CrossRef]

- Guo, D.; Guo, M.; Xing, F. Using limestone calcined clay cement and recycled fine aggregate to make ultra-high-performance concrete: Properties and environmental impact. Constr. Build. Mater. 2023, 394, 132026. [Google Scholar] [CrossRef]

- Du, J.; Liu, Z.; Christodoulatos, C. Utilization of off-specification fly ash in preparing ultra-high-performance concrete (UHPC): Mixture design, characterization, and life-cycle assessment. Resour. Conserv. Recycl. 2022, 180, 106136. [Google Scholar] [CrossRef]

- Soliman, N.A.; Tagnit-Hamou, A. Development of ultra-high-performance concrete using glass powder—Towards ecofriendly concrete. Constr. Build. Mater. 2016, 125, 600–612. [Google Scholar] [CrossRef]

- Huang, W.; Kazemi-Kamyab, H.; Sun, W. Effect of cement substitution by limestone on the hydration and microstructural development of ultra-high performance concrete (UHPC). Cem. Concr. Compos. 2017, 77, 86–101. [Google Scholar] [CrossRef]

- Yu, R.; Spiesz, P.; Brouwers, H.J.H. Mix design and properties assessment of Ultra-High Performance Fibre Reinforced Concrete (UHPFRC). Cem. Concr. Res. 2014, 56, 29–39. [Google Scholar] [CrossRef]

- Yang, R.; Yu, R.; Shui, Z. Low carbon design of an Ultra-High Performance Concrete (UHPC) incorporating phosphorous slag. J. Clean. Prod. 2019, 240, 118157. [Google Scholar] [CrossRef]

- GB/T17671-1999; Method of Testing Cements-Determination of Strength. Standardization Administration of China: Beijing, China, 1999. (In Chinese)

- T/CECS10107-2020; Technical Requirements for Ultra High Performance Concrete. Standardization Administration of China: Beijing, China, 2020. (In Chinese)

- Yin, T.; Liu, K.; Fan, D. Derivation and verification of multilevel particle packing model for Ultra-High Performance Concrete (UHPC): Modelling and experiments. Cem. Concr. Compos. 2023, 136, 104889. [Google Scholar] [CrossRef]

- Chirkin, A.V.; Gajum, N.R.; Shaban, A.I.B. Metallographic determination of the depth of deformed layers resulting from the machining of zirconium casts. J. Nucl. Mater. 1986, 139, 287–290. [Google Scholar] [CrossRef]

- Yu, R.; Spiesz, P.; Brouwers, H.J.H. Development of an eco-friendly Ultra-High Performance Concrete (UHPC) with efficient cement and mineral admixtures uses. Cem. Concr. Compos. 2015, 55, 383–394. [Google Scholar] [CrossRef]

- Lao, J.C.; Xu, L.Y.; Huang, B.T. Strain-hardening Ultra-High-Performance Geopolymer Concrete (UHPGC): Matrix design and effect of steel fibers. Compos. Commun. 2022, 30, 101081. [Google Scholar] [CrossRef]

- Wang, D.; Shi, C.; Farzadnia, N. A review on effects of limestone powder on the properties of concrete. Constr. Build. Mater. 2018, 192, 153–166. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Banthia, N.; You, I. Recent advances in cementless ultra-high-performance concrete using alkali-activated materials and industrial byproducts: A review. Cem. Concr. Compos. 2024, 148, 105470. [Google Scholar] [CrossRef]

- Fan, J.; Zhang, B. Repair of ordinary Portland cement concrete using alkali activated slag/fly ash: Freeze-thaw resistance and pore size evolution of adhesive interface. Constr. Build. Mater. 2021, 300, 124334. [Google Scholar] [CrossRef]

- Quan, X.; Wang, S.; Liu, K. The corrosion resistance of engineered cementitious composite (ECC) containing high-volume fly ash and low-volume bentonite against the combined action of sulfate attack and dry-wet cycles. Constr. Build. Mater. 2021, 303, 124599. [Google Scholar] [CrossRef]

- Kang, S.H.; Jeong, Y.; Tan, K.H. The use of limestone to replace physical filler of quartz powder in UHPFRC. Cem. Concr. Compos. 2018, 94, 238–247. [Google Scholar] [CrossRef]

- Kang, S.H.; Jeong, Y.; Tan, K.H. High-volume use of limestone in ultra-high performance fiber-reinforced concrete for reducing cement content and autogenous shrinkage. Constr. Build. Mater. 2019, 213, 292–305. [Google Scholar] [CrossRef]

| Raw Materials | %Content by Weight | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | K2O | TiO2 | LOI | |

| Cement | 19.41 | 5.97 | 4.32 | 61.12 | 2.83 | 3.27 | 0.86 | 0.17 | 1.42 |

| FA | 47.60 | 33.20 | 5.20 | 4.20 | 1.50 | 1.28 | 0.52 | 1.15 | 5.12 |

| SF | 98.1 | ---- | 0.03 | 0.11 | 0.14 | 0.02 | 0.04 | ---- | 1.48 |

| GGBS | 34.50 | 17.70 | 2.03 | 34.00 | 1.01 | 1.64 | ---- | ---- | 0.84 |

| LP | 0.05 | ---- | 0.13 | 55.41 | 0.10 | 0.15 | ---- | ---- | 42.54 |

| UHPC (kg/m3) | G1 (kg/m3) | G2 (kg/m3) | G3 (kg/m3) | G4 (kg/m3) | G5 (kg/m3) | |

|---|---|---|---|---|---|---|

| Cement | 820 | 264 | 264 | 264 | 264 | 264 |

| SF | 111 | 111 | 111 | 111 | 111 | 111 |

| LP | 111 | 111 | ---- | 111 | 111 | 111 |

| QS | 111 | 111 | 111 | ---- | 111 | 111 |

| GGBS | ---- | 275 | 330.5 | 330.5 | 219.5 | 330.5 |

| FA | ---- | 275 | 330.5 | 330.5 | 330.5 | 219.5 |

| Sand1 | 550 | 550 | 550 | 550 | 550 | 550 |

| Sand2 | 220 | 220 | 220 | 220 | 220 | 220 |

| Sand3 | 330 | 330 | 330 | 330 | 330 | 330 |

| Fiber | 156 | 156 | 156 | 156 | 156 | 156 |

| KOH | ---- | 3.3 | 3.3 | 3.3 | 3.3 | 3.3 |

| SP | 5.8 | 5.6 | 5.6 | 5.6 | 5.6 | 5.6 |

| EA | 0.2 | 0.16 | 0.16 | 0.16 | 0.16 | 0.16 |

| DF | 1.7 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Water | 187 | 170 | 170 | 170 | 170 | 170 |

| Mixture | U | G1 | G2 | G3 | G4 | G5 |

|---|---|---|---|---|---|---|

| DRCM (10−12) | 0.093 | 0.175 | 0.114 | 0.182 | 0.156 | 0.078 |

| Mixture | U | G1 | G2 | G3 | G4 | G5 | C50 |

|---|---|---|---|---|---|---|---|

| (MPa) | 170.1 | 155.2 | 159.6 | 151.4 | 154.3 | 165.3 | 52.9 |

| (MPa) | 167.3 | 149.6 | 154.4 | 134.7 | 150.5 | 163.9 | 33.2 |

| (g) | 647 | 639 | 638 | 625 | 639 | 641 | 586 |

| (g) | 646 | 637 | 637 | 622 | 638 | 641 | 574 |

| (%) | 1.6 | 3.6 | 3.3 | 11 | 2.5 | 0.85 | 37.2 |

| (%) | 0.2 | 0.3 | 0.16 | 0.48 | 0.16 | 0 | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liao, Z.; Xue, W.; Liao, L.; Hao, R.; Shen, L.; Cui, D. A Study on the Effect of Different Cementitious Materials on the Mechanical Properties and Microscopic Characteristics of Alkali-Activated Green Ultra-High Performance Concrete (GUHPC). Materials 2025, 18, 2163. https://doi.org/10.3390/ma18092163

Liao Z, Xue W, Liao L, Hao R, Shen L, Cui D. A Study on the Effect of Different Cementitious Materials on the Mechanical Properties and Microscopic Characteristics of Alkali-Activated Green Ultra-High Performance Concrete (GUHPC). Materials. 2025; 18(9):2163. https://doi.org/10.3390/ma18092163

Chicago/Turabian StyleLiao, Zhiling, Wanwen Xue, Lin Liao, Ruiqing Hao, Litao Shen, and Dongxia Cui. 2025. "A Study on the Effect of Different Cementitious Materials on the Mechanical Properties and Microscopic Characteristics of Alkali-Activated Green Ultra-High Performance Concrete (GUHPC)" Materials 18, no. 9: 2163. https://doi.org/10.3390/ma18092163

APA StyleLiao, Z., Xue, W., Liao, L., Hao, R., Shen, L., & Cui, D. (2025). A Study on the Effect of Different Cementitious Materials on the Mechanical Properties and Microscopic Characteristics of Alkali-Activated Green Ultra-High Performance Concrete (GUHPC). Materials, 18(9), 2163. https://doi.org/10.3390/ma18092163