Effects of Complex Environmental Conditions on Fatigue Self-Healing Properties of Fast-Melting SBS-Modified Asphalt

Abstract

1. Introduction

2. Materials and Methods

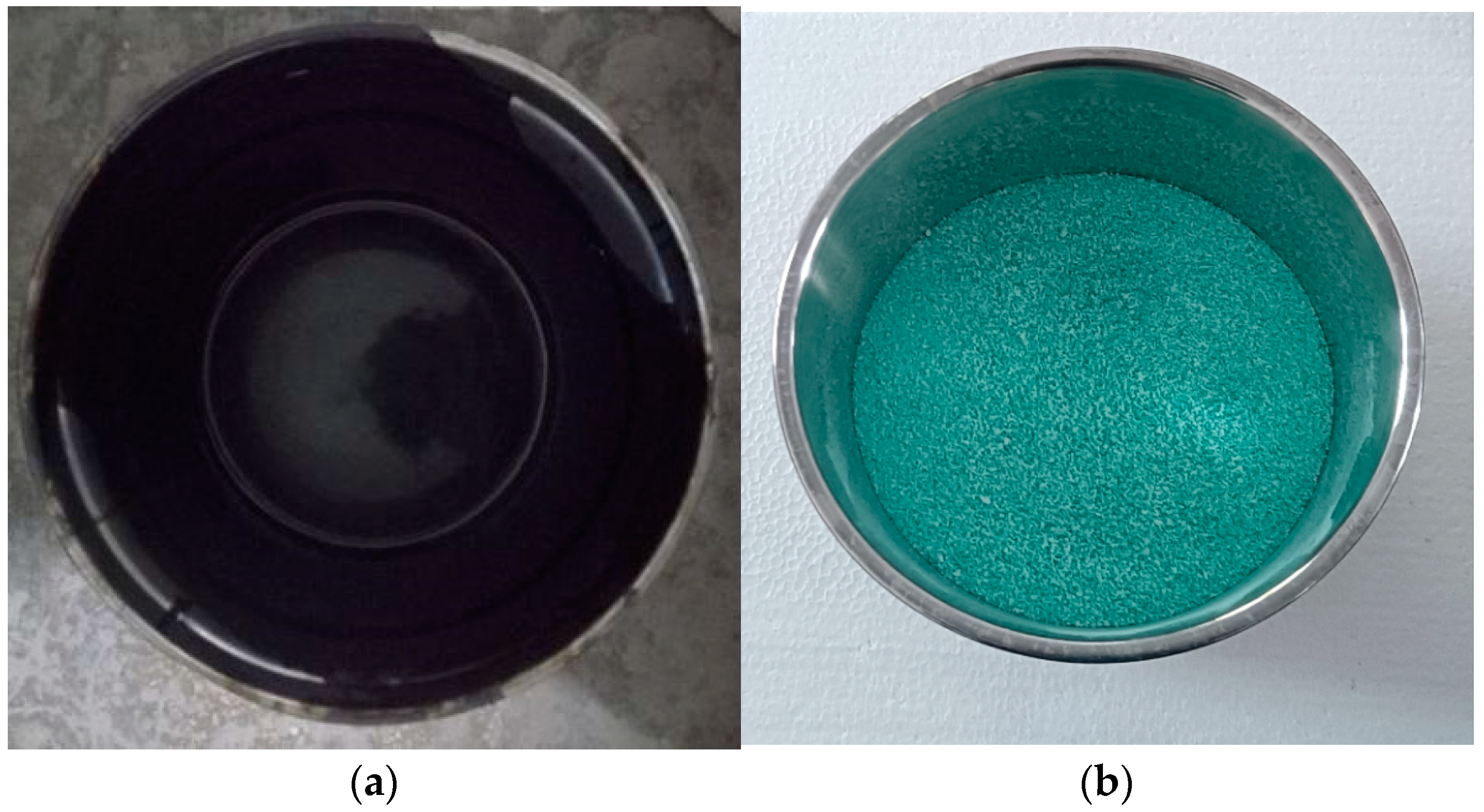

2.1. Materials

2.2. Preparation of Fast-Melting SBS-Modified Asphalt

2.3. Preparation of Salt Solutions

2.4. Aging Process Simulation Tests

2.4.1. UV–Pressure Aging Test

2.4.2. UV–Salt Solution Aging Test

2.4.3. UV–Pressure–Salt Solution Aging Test

2.5. Experimental Protocols

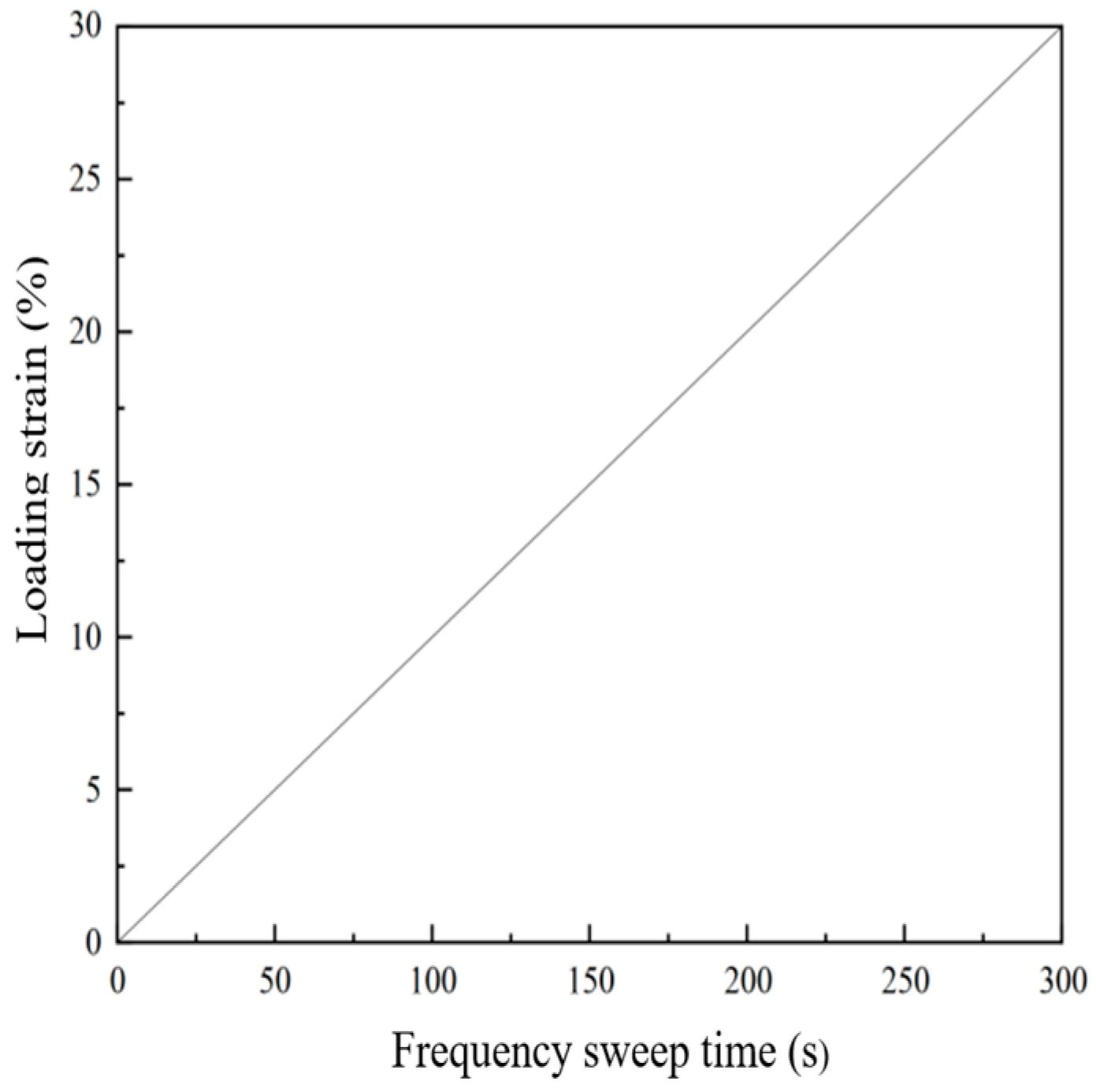

2.5.1. Frequency Sweep Test

2.5.2. Linear Amplitude Sweep (LAS) Test

2.5.3. Fatigue–Healing–Fatigue Test

3. Results and Discussion

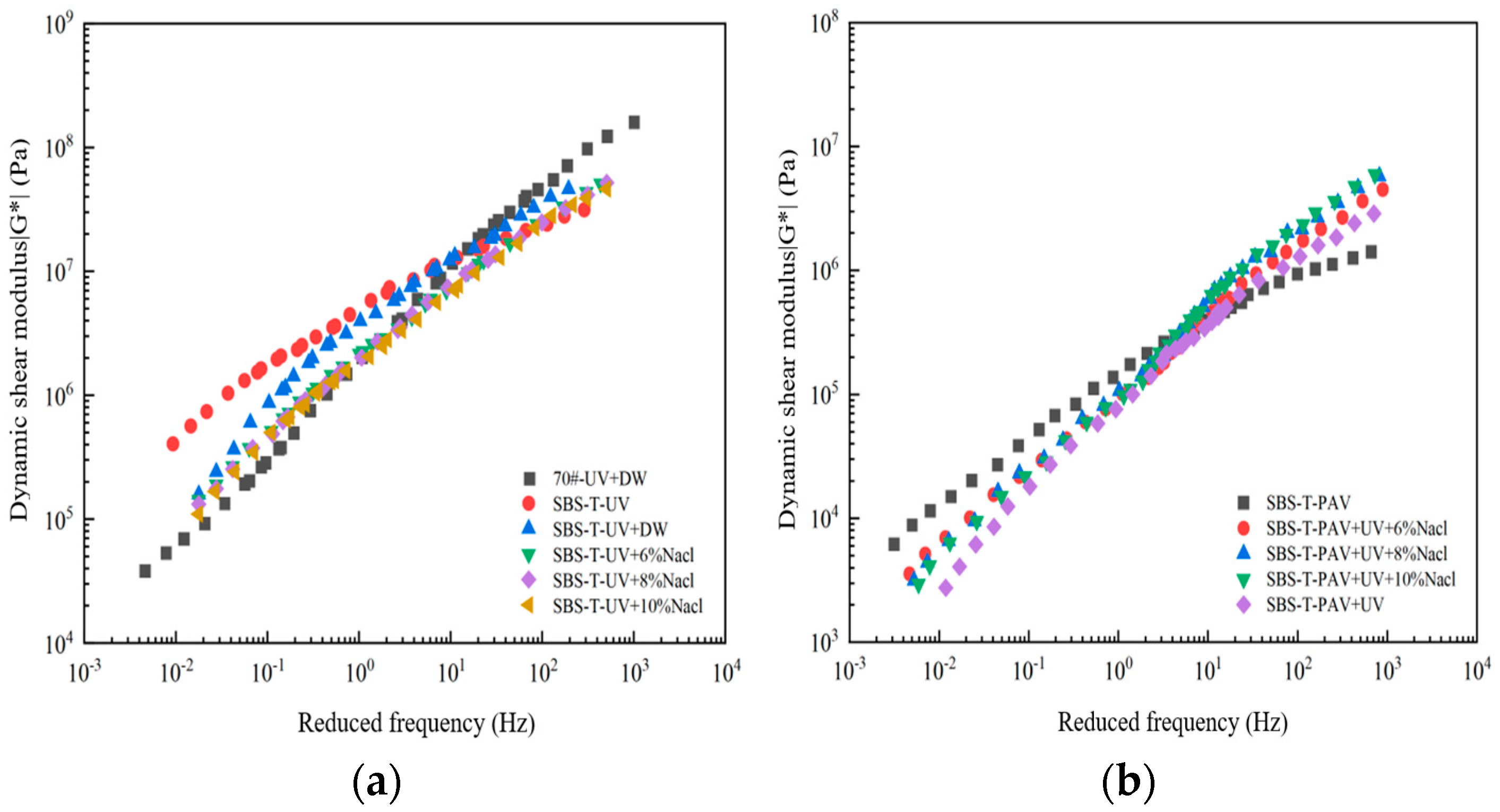

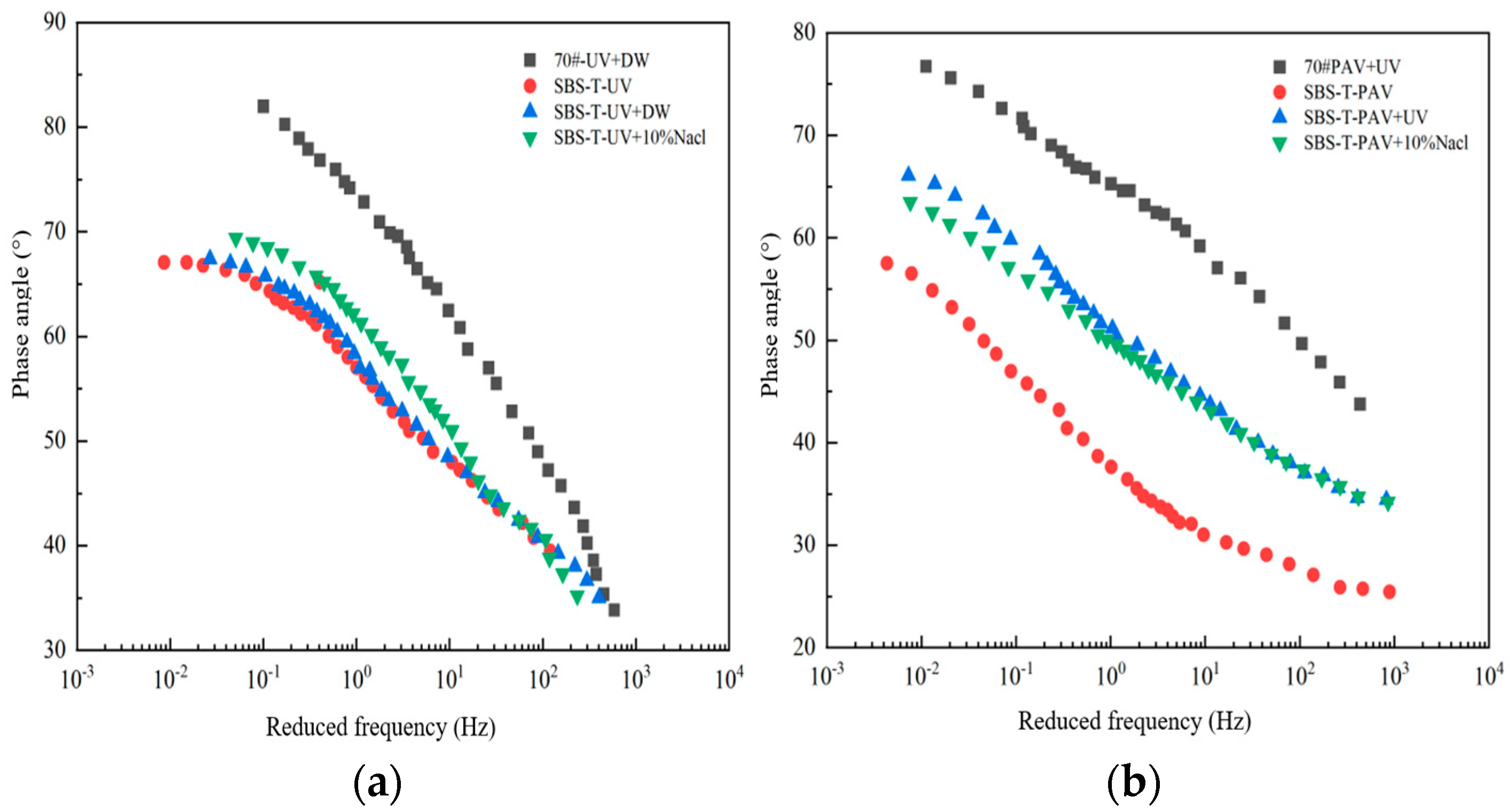

3.1. Linear Viscoelastic Analysis (Continued)

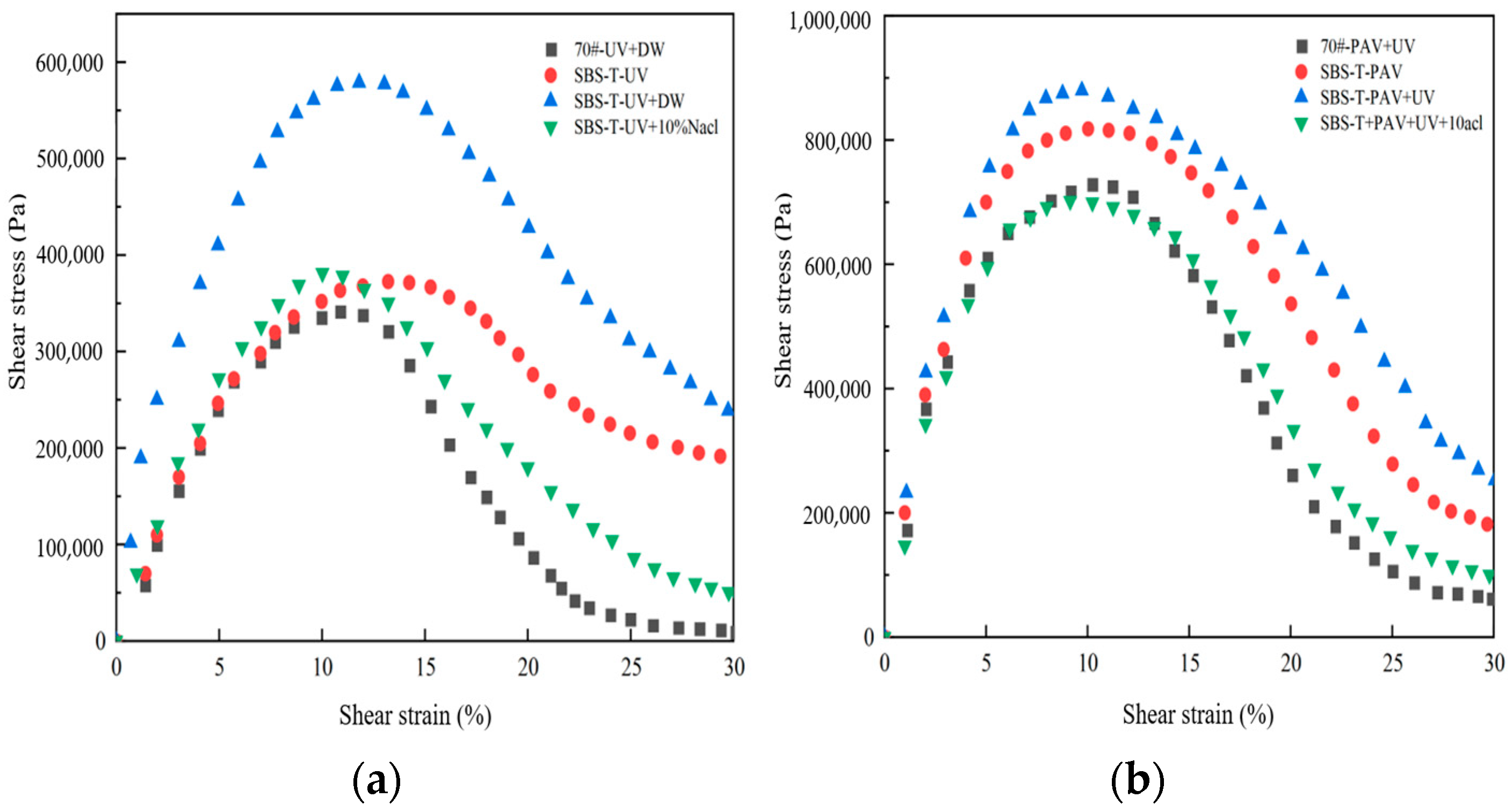

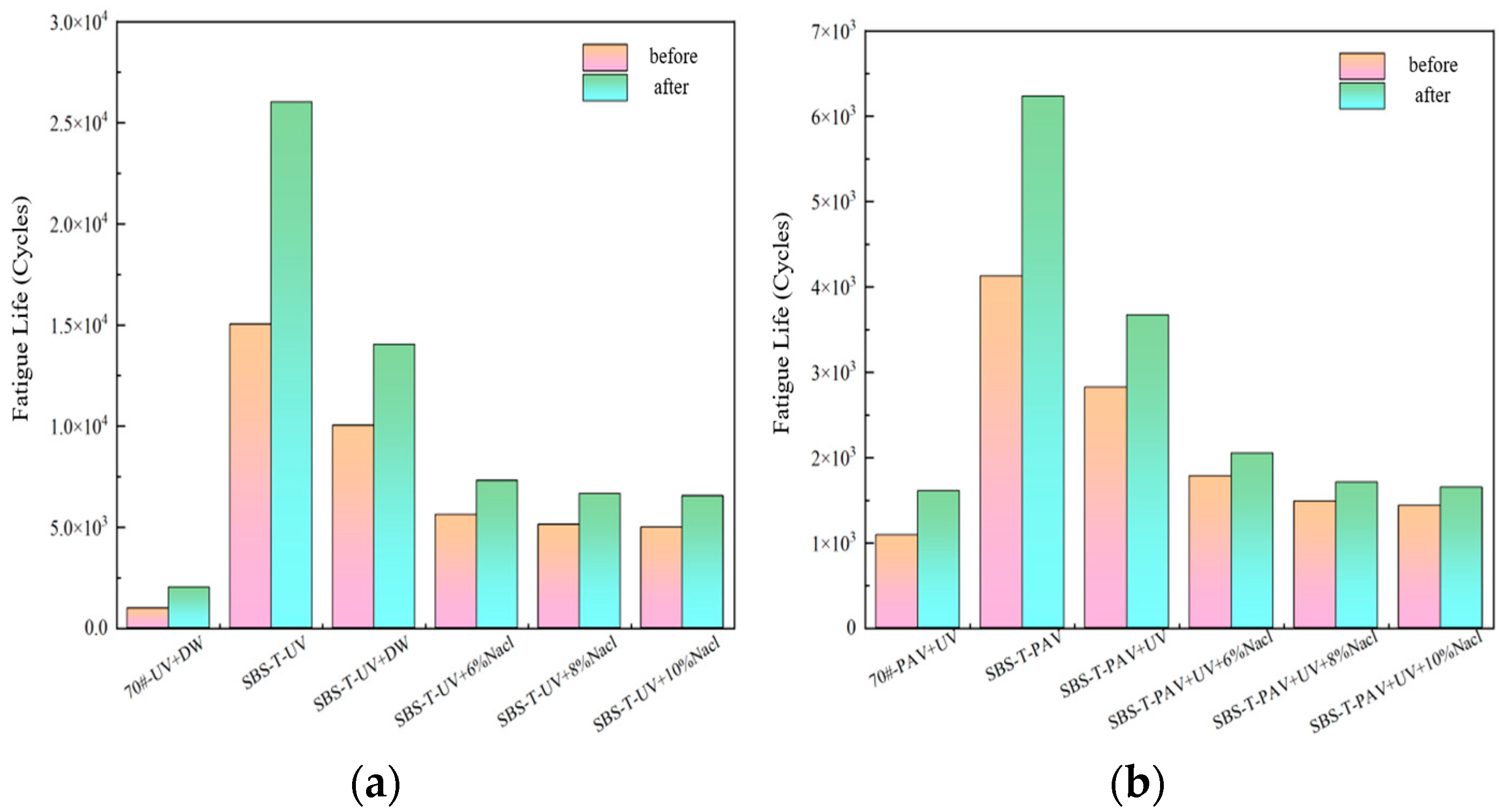

3.2. Fatigue Performance Analysis

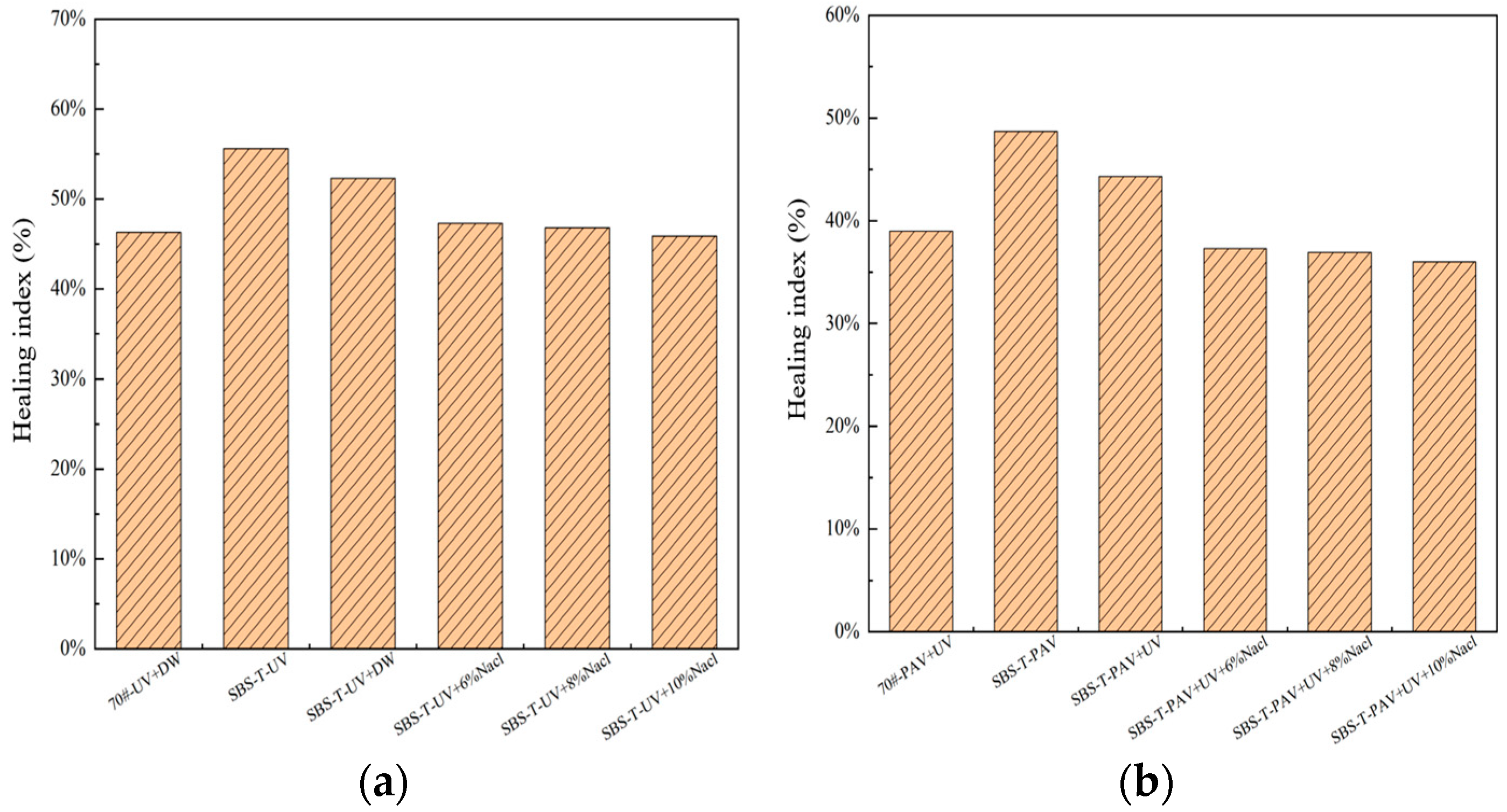

3.3. Self-Healing Performance Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhuang, Y.; Yue, J.; Men, B.; Tang, G.; Wang, R. Experimental Study on Mechanism, Aging and Fatigue Performance of Warm Mixing Speed Melting SBS Modified Asphalt Binders. Coatings 2023, 13, 0311. [Google Scholar] [CrossRef]

- Xu, Y. Study on Influencing Factors and Correlation of Asphalt Fatigue and Self-Healing Properties. Master’s Thesis, Wuhan University of Technology, Wuhan, China, 2018. [Google Scholar]

- Zhang, R.; Yu, H. Influence of Different Aging Environments on Rheological Behavior and Structural Properties of Rubber Asphalt. Materials 2020, 13, 33–43. [Google Scholar] [CrossRef] [PubMed]

- Sun, S.; Wang, Y. Application of Ultraviolet Absorbers in Asphalt Mixtures. Highw. Eng. 2012, 37, 109–114. [Google Scholar]

- Wang, J. Study on Ageing Mechanism and Rheologic Behavior of Asphalt Under Simulated Ultraviolet Environment. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, 2008. [Google Scholar]

- Zhou, Z.; Jiang, T.; Jiang, W. Evaluation of Water Damage Resistance of Asphalt Mixtures in High-Temperature and Humid Regions. J. Chang. Univ. Sci. Technol. (Nat. Sci.) 2013, 10, 8–14. [Google Scholar]

- Xiong, R.; Chu, C.; Qiao, N.; Wang, L.; Yang, F.; Sheng, Y.; Guan, B.; Niu, D.; Geng, J.; Chen, H. Performance Evaluation of Asphalt Mixture Exposed to Dynamic Water and Chlorine Salt Erosion. Constr. Build. Mater. 2019, 201, 121–126. [Google Scholar] [CrossRef]

- Zhang, Q.; Huang, Z. Investigation of the Microcharacteristics of Asphalt Mastics under Dry-Wet and Freeze-Thaw Cycles in a Coastal Salt Environment. Materials 2019, 12, 2627. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.Y.; Sha, A.M.; Jiang, W.; Wang, Y. Effect and Mechanism of Salt Erosion on Performance of Bitumen and Asphalt Mixtures. J. Chang’an Univ. (Nat. Sci. Ed.) 2017, 33–38, 46. [Google Scholar] [CrossRef]

- Zhang, Q.; Wu, D.; Zhang, X.; Chang, K.; Wang, Y. Effect of Organic Deicing Agents on Asphalt Rheology and Analysis of the Mechanism. Constr. Build. Mater. 2021, 284, 122649. [Google Scholar] [CrossRef]

- Polacco, G.; Stastna, J.; Biondi, L. Relation between Polymer Architecture and Nonlinear Viscoelastic Behavior of Modified Asphalt. Eur. Polym. J. 2006, 42, 446–457. [Google Scholar] [CrossRef]

- Xia, X.; Tang, D.; Wang, P.; Zhao, Y. Synergistic effect of polymer-modified rejuvenator and fresh asphalt on road performance of hot in-place recycling styrene–butadiene–styrene-modified asphalt mixtures. Polym Int. 2025. [Google Scholar] [CrossRef]

- Zhuang, H.; Zhong, H.; Wang, J.; Xian, L.; Li, D. Comparative Analysis of High-Temperature Performance of SBS-Modified Asphalt and Its Mixtures. Highw. Eng. 2023, 48, 116–122. [Google Scholar]

- Mao, S.; Xiong, L.; Lin, X.; Yang, K. Study on Evaluation Indexes of Storage Stability of SBS-Modified Asphalt. Pet. Asph. 2012, 26, 11–15. [Google Scholar]

- Sun, D.; Lü, W. Study on Thermal Storage Stability of SBS-Modified Asphalt. J. Build. Mater. 2006, 9, 671–674. [Google Scholar]

- Wang, H. Directly Added SBS Modifier and Its Preparation Method. CN103509358A, 15 January 2014. [Google Scholar]

- Wang, Z.; Liu, C.; Zhao, Y.; Wen, L.; Li, K.; Liu, B.; Hu, F. Study on Road Performance of Directly Added SBS Modifier. J. Highw. Transp. Res. Dev. (Appl. Technol. Ed.) 2016, 12, 90–92. [Google Scholar]

- Li, R.; Wang, Y.; Zhu, W.; Chen, Y.; Yue, J. Research on the Rheological Performance of Fast-Melting SBS-Modified Asphalt under Complex Environmental Factors. Coatings 2024, 14, 1241. [Google Scholar] [CrossRef]

- Wang, Y. Application of Dry-Process SBS-Modified Asphalt in Municipal Roads. Build. Superv. Test. Cost 2022, 15, 9–12, 20. [Google Scholar]

- Feng, Z.; Yu, J.; Zhang, H.; Kuang, D.; Xue, L. Effect of Ultraviolet Aging on Rheology, Chemistry, and Morphology of Ultraviolet Absorber-Modified Bitumen. Mater. Struct. 2013, 46, 1123–1132. [Google Scholar] [CrossRef]

- Zhang, C.; Yu, J.; Feng, K.; Xue, L.; Xie, D. Synthesis and Characterization of Triethoxyvinylsilane Surface-Modified Layered Double Hydroxides and Application in Improving UV Aging Resistance of Bitumen. Appl. Clay Sci. 2016, 120, 1–8. [Google Scholar] [CrossRef]

- Dong, Y.; Tang, G.; Hou, Y.; Wang, H.; Tian, J.; Wei, Y. Study on aging kinetics of dry-modified asphalt based on complex modulus. Hunan J. Transp. Sci. Technol. 2022, 48, 20–22. [Google Scholar]

- Schwarzl, F.R.; Staverman, A.J. Time-Temperature Dependence of Linear Viscoelastic Behavior. J. Appl. Phys. 1952, 23, 838–843. [Google Scholar] [CrossRef]

- Findley, W.N.; Lai, J. A Modified Superposition Principle Applied to Creep of Nonlinear Viscoelastic Material under Abrupt Changes in State of Combined Stress. Trans. Soc. Rheol. 1967, 11, 361–380. [Google Scholar] [CrossRef]

- Tan, Y.; Shao, X.; Zhang, X. Research on Evaluation Method of Low-Temperature Performance of Asphalt Based on Low-Temperature Rheological Properties. China J. Highw. Transp. 2002, 3–7. [Google Scholar] [CrossRef]

- Yue, M.; Yue, J.; Wang, R.; Xiong, Y. Evaluating the fatigue characteristics and healing potential of asphalt binder modified with Sasobit (R) and polymers using linear amplitude sweep test. Constr. Build. Mater. 2021, 289, 123054. [Google Scholar] [CrossRef]

- Kang, X.; Wang, R.; Yue, J.; An, X.; Tang, G. Investigation of the adhesion characteristics of a novel fast-melting SBS-based modifier to asphalt-aggregate systems based on a multiscale approach. J. Mater. Civ. Eng. (ASCE) 2023, 35, 04023435. [Google Scholar] [CrossRef]

- Zhou, S.; Shi, J.; Zhang, R.; Zhang, X.; Yuan, Y. Evaluation of Asphalt Fatigue Performance Based on Linear Amplitude Sweep Test. Pet. Asph. 2018, 32, 27–33. [Google Scholar]

- Xie, W.; Castorena, C.; Wang, C.; Kim, Y.R. A Framework to Characterize the Healing Potential of Asphalt Binder Using the Linear Amplitude Sweep Test. Constr. Build. Mater. 2017, 154, 771–779. [Google Scholar] [CrossRef]

- Wang, R.; Xiong, Y.; Yue, M.; Hao, M.; Yue, J. Investigating the Effectiveness of Carbon Nanomaterials on Asphalt Binders from Hot Storage Stability, Thermodynamics, and Mechanism Perspectives. J. Clean. Prod. 2020, 276, 124180. [Google Scholar] [CrossRef]

- Wang, C. Rheological Study on Road Performance of Asphalt Binder. Ph.D. Thesis, Beijing University of Technology, Beijing, China, 2015. [Google Scholar]

| Property | Value |

|---|---|

| Ductility (25 °C, cm) | >100 |

| Penetration (25 °C, 0.1 mm) | 72 |

| Dynamic viscosity (135 °C, Pa·s) | 0.68 |

| Softening point (°C) | 50.5 |

| Indexes | Results |

|---|---|

| Mass of a single particle (g) | 0.25 |

| Styrene percentage (%) | 30~32 |

| Ash (%) | 0.25 |

| Dispersion of dry mixing | No particle residue |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yue, J.; Fu, J.; Wang, Y.; Ming, Y.; Tang, G.; Li, R. Effects of Complex Environmental Conditions on Fatigue Self-Healing Properties of Fast-Melting SBS-Modified Asphalt. Materials 2025, 18, 2157. https://doi.org/10.3390/ma18092157

Yue J, Fu J, Wang Y, Ming Y, Tang G, Li R. Effects of Complex Environmental Conditions on Fatigue Self-Healing Properties of Fast-Melting SBS-Modified Asphalt. Materials. 2025; 18(9):2157. https://doi.org/10.3390/ma18092157

Chicago/Turabian StyleYue, Jinchao, Jiahao Fu, Yihan Wang, Yang Ming, Guoqi Tang, and Ruixia Li. 2025. "Effects of Complex Environmental Conditions on Fatigue Self-Healing Properties of Fast-Melting SBS-Modified Asphalt" Materials 18, no. 9: 2157. https://doi.org/10.3390/ma18092157

APA StyleYue, J., Fu, J., Wang, Y., Ming, Y., Tang, G., & Li, R. (2025). Effects of Complex Environmental Conditions on Fatigue Self-Healing Properties of Fast-Melting SBS-Modified Asphalt. Materials, 18(9), 2157. https://doi.org/10.3390/ma18092157