Mechanical Strength of Waste Materials: A Cone Penetration Testing-Based Geotechnical Assessment for the Reclamation of Landfills

Abstract

:1. Introduction

1.1. Geotechnical Challenges and Reclamation of MSW Landfills

1.2. Heterogeneity of Waste and Safety of Landfill Body

1.3. Evaluating the Mechanical Behavior of Aged Waste Using Cone Penetration Tests

2. Materials and Methods

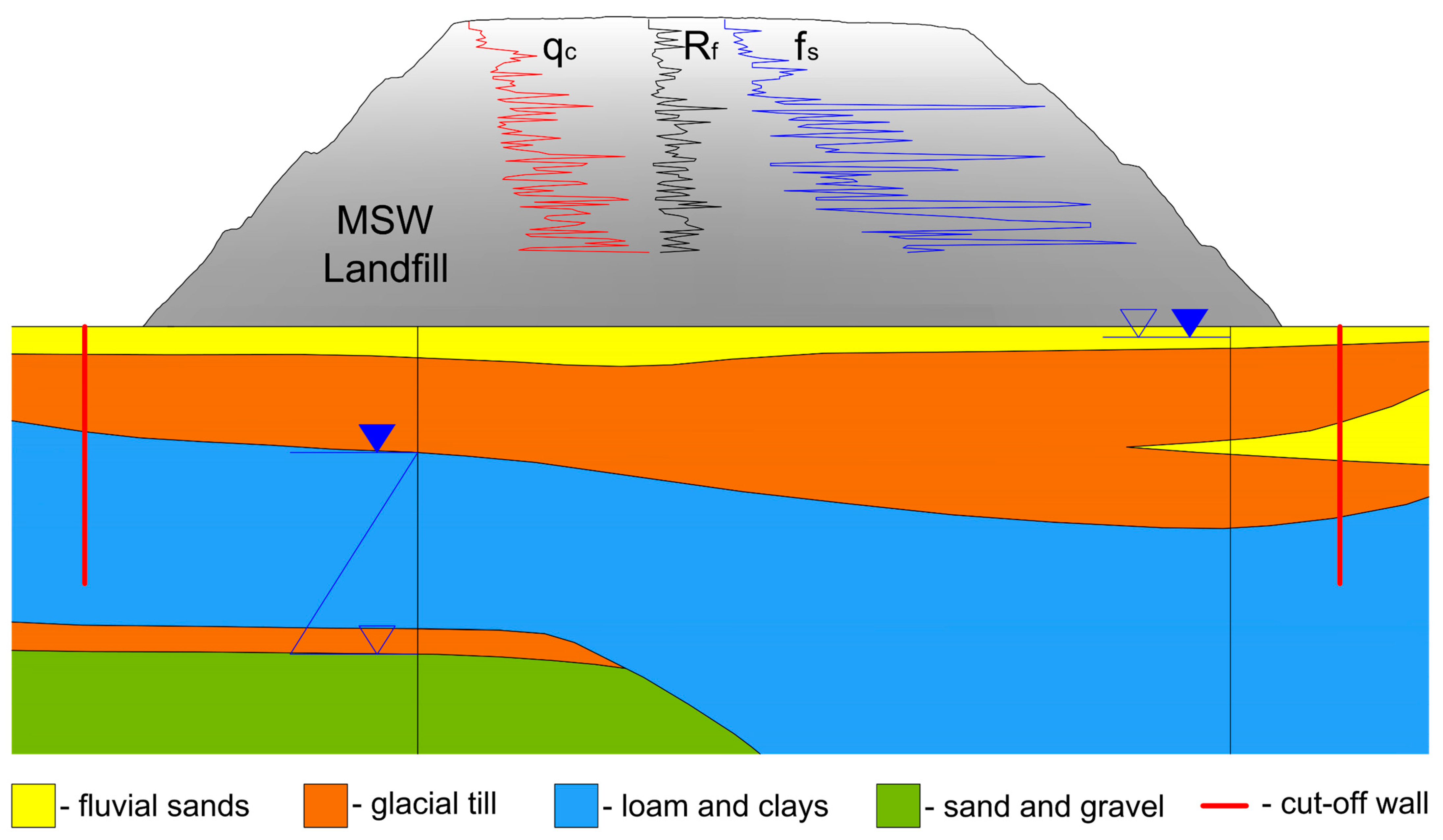

2.1. Study Sites

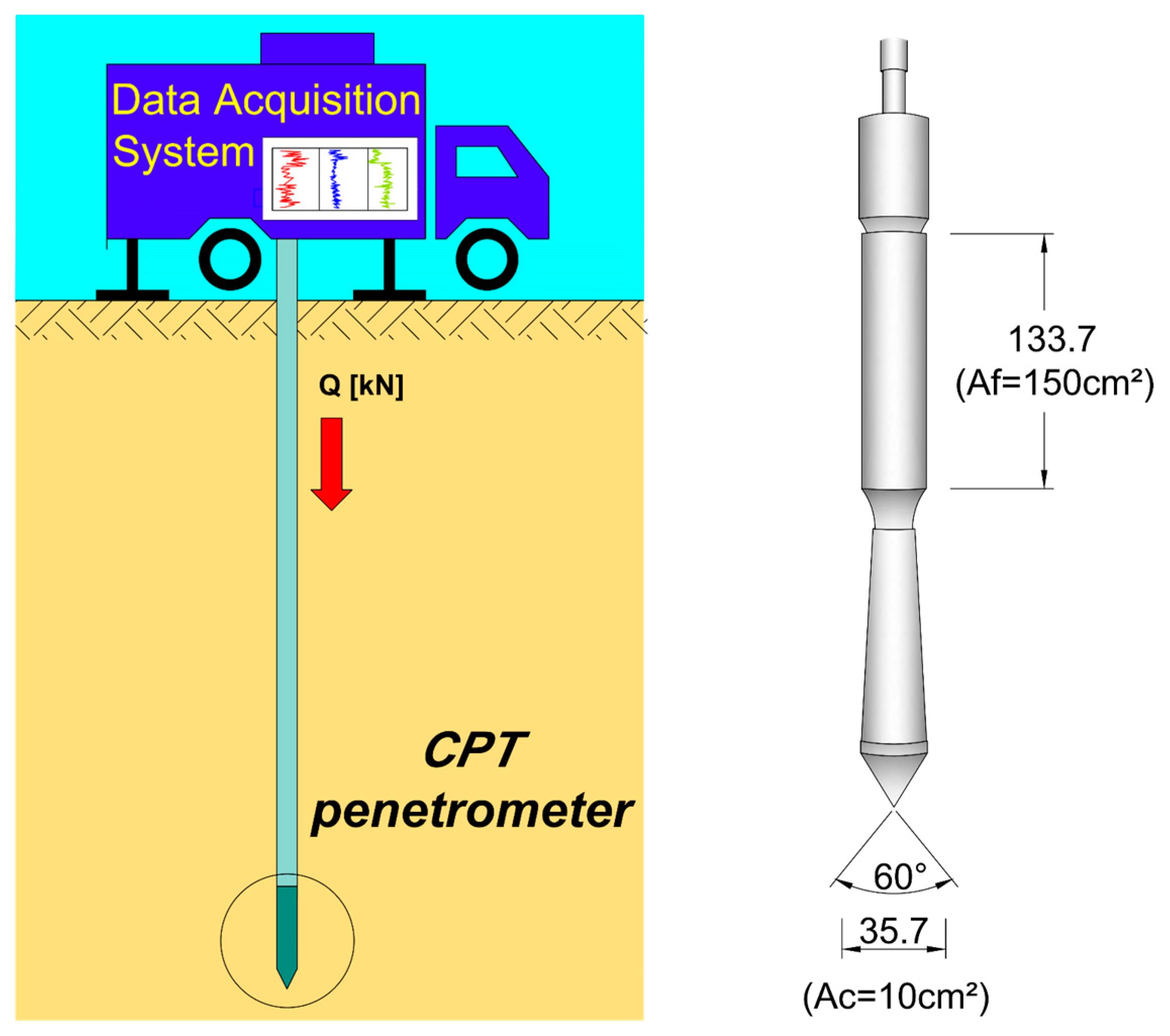

2.2. Site Investigation Methods Used in Study for Determination of Mechanical Parameters of MSW

3. Results and Discussion

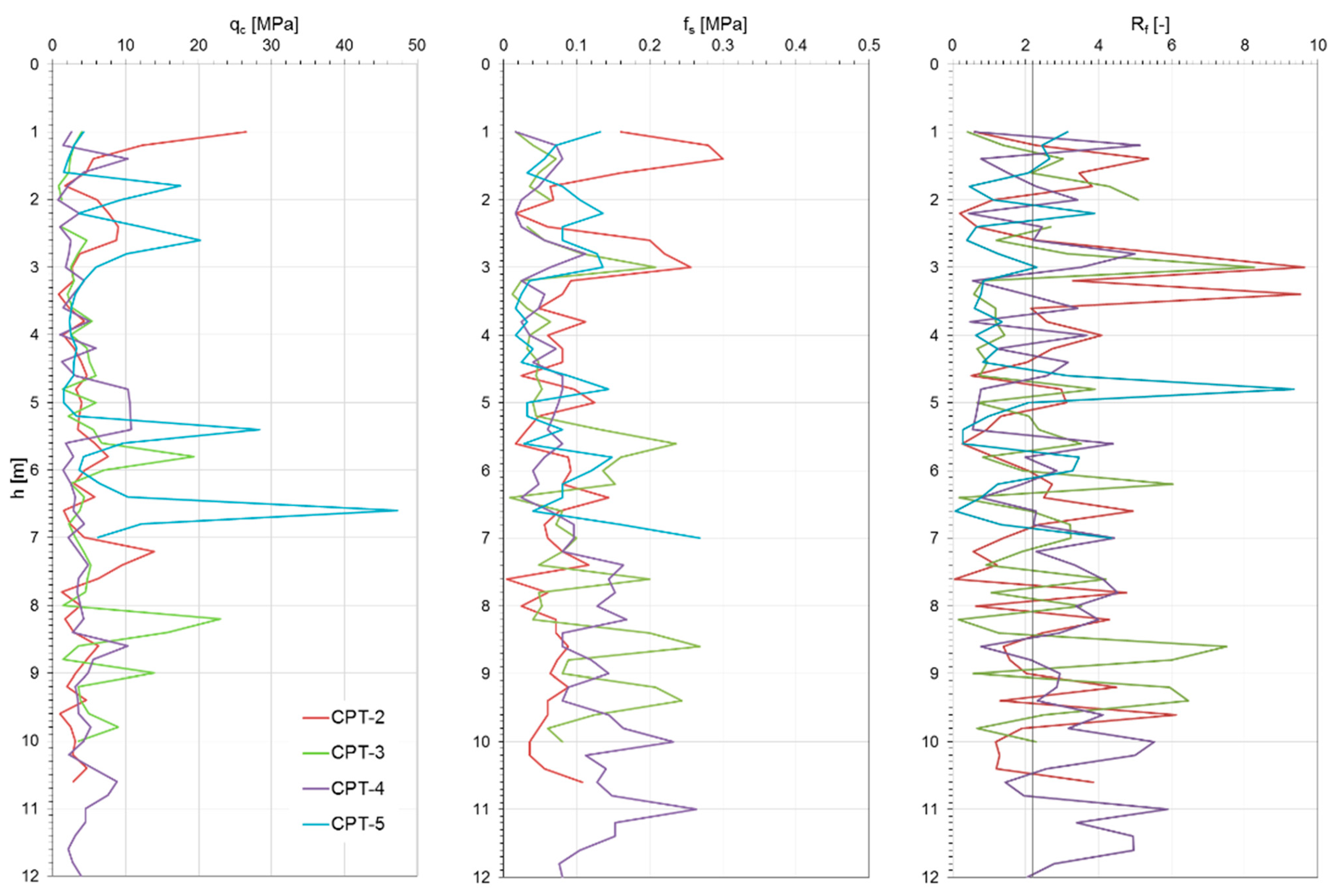

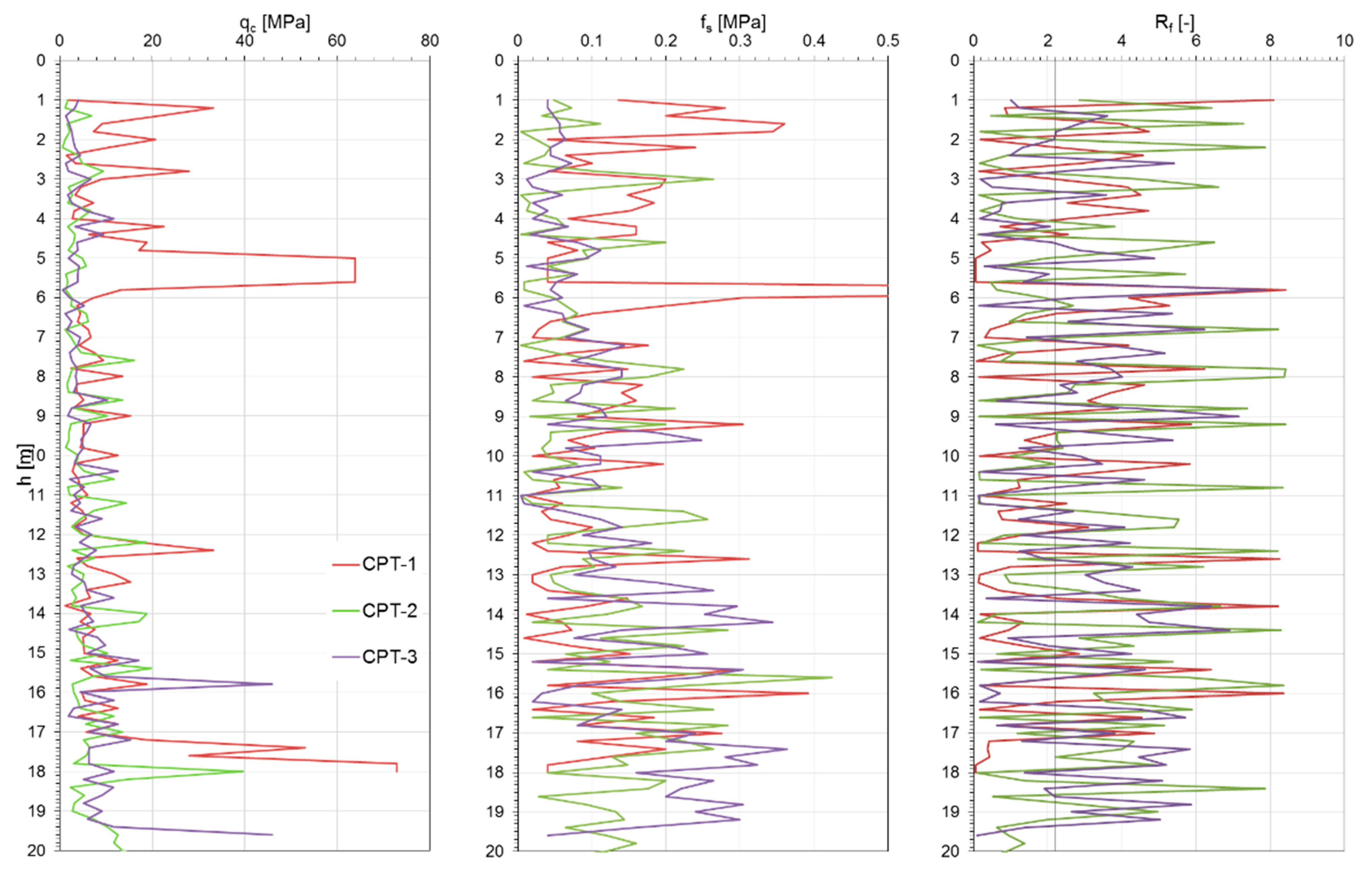

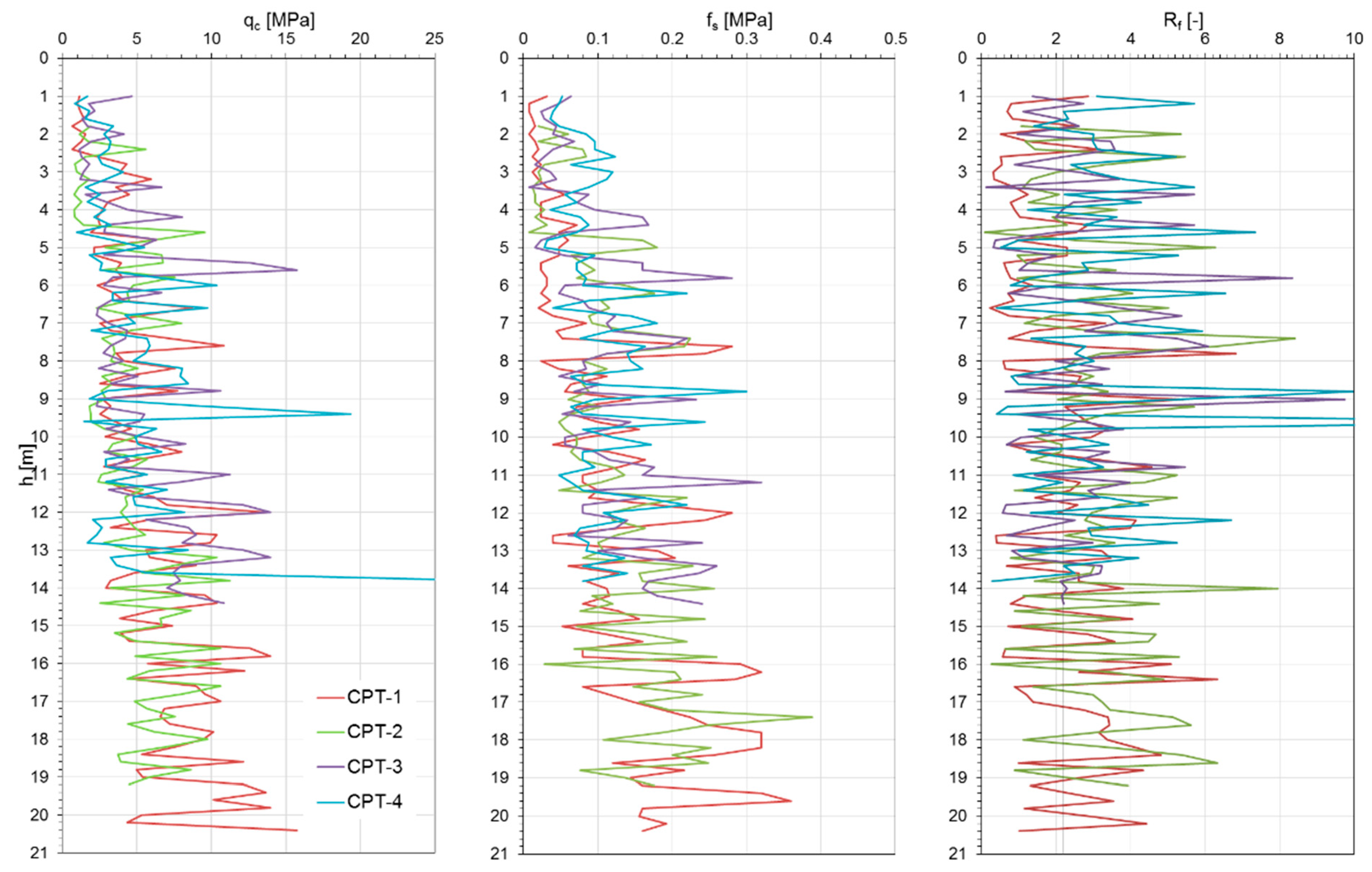

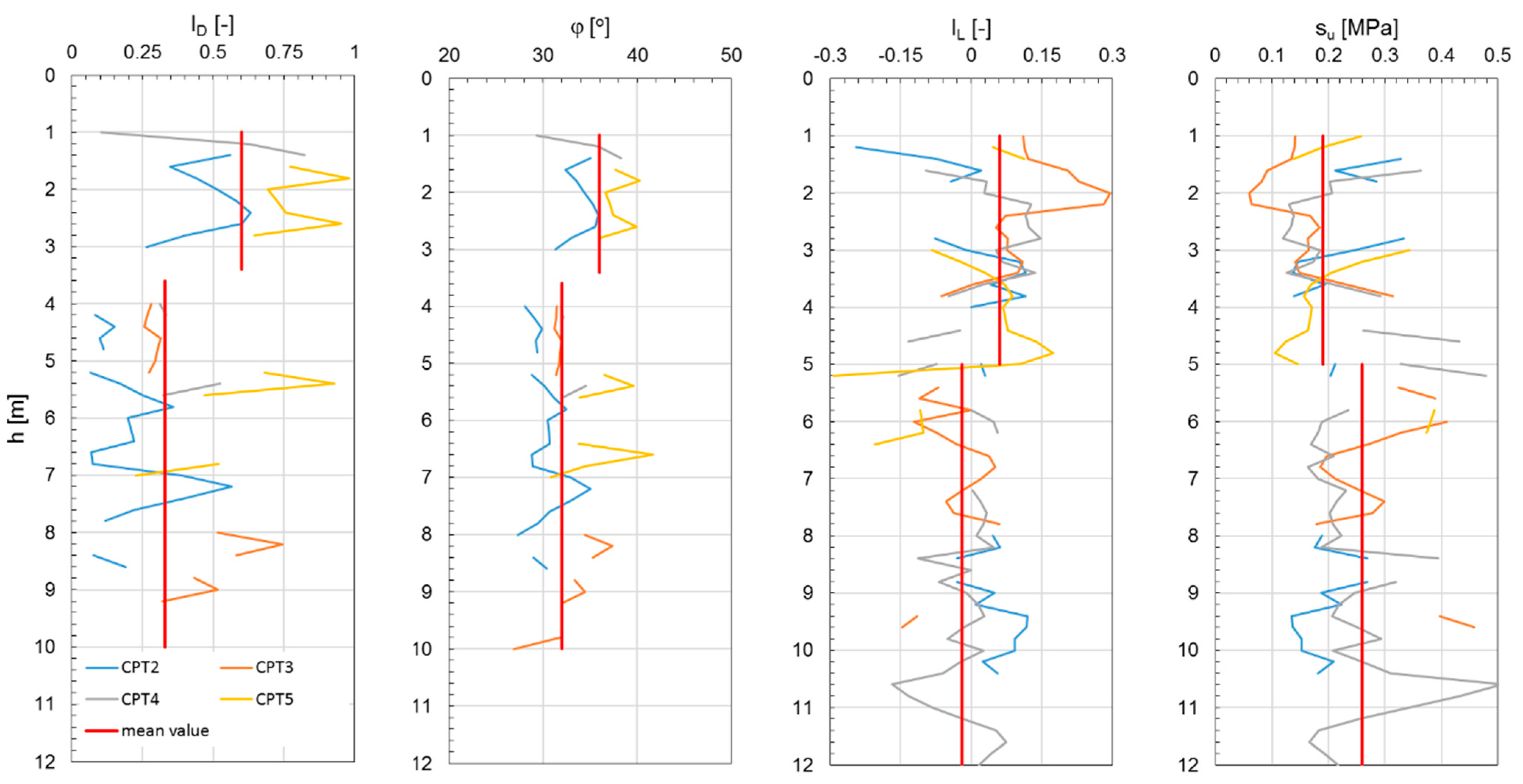

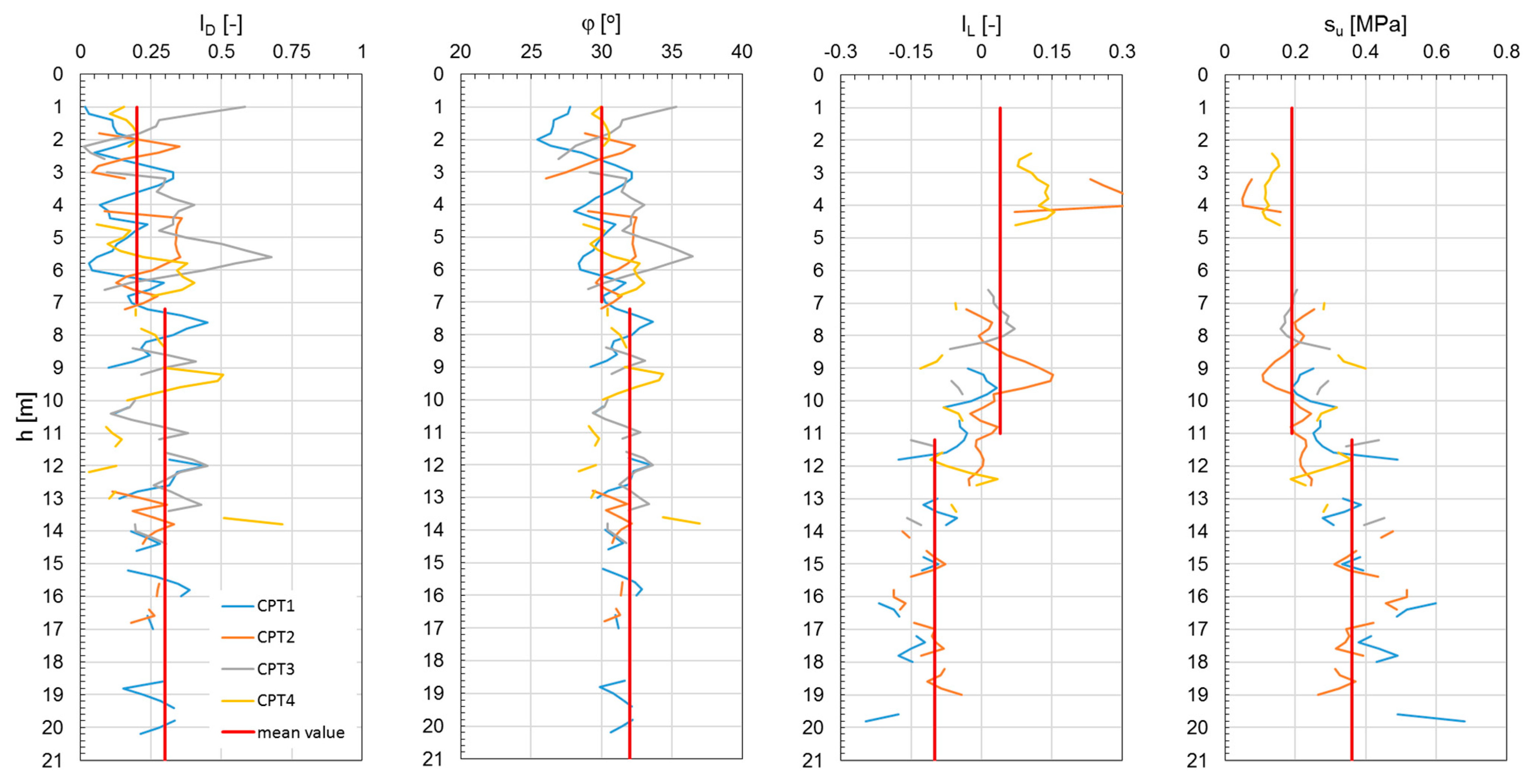

3.1. Mechanical Parameters of MSW Based on CPT Profiles

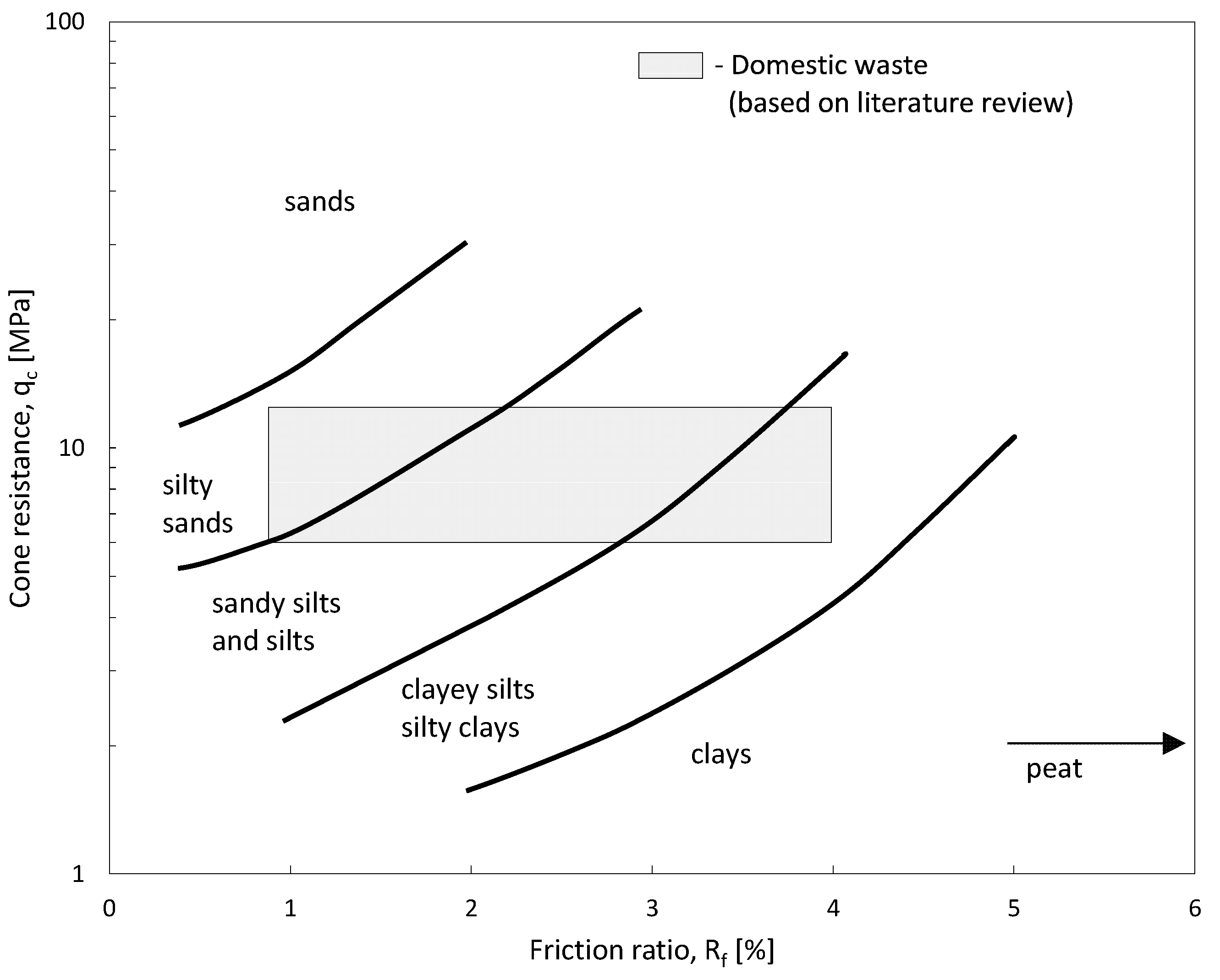

3.2. Classification of Waste Materials Based on Cone Resistance and Friction Ratio Results

3.3. Discussion on the Interpretation of the Obtained Research Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- ISWA: International Solid Waste Association. Global Waste Management Outlook 2024: Beyond an Age of Waste, Turning Rubbish into a Resource; ISWA: Rotterdam, The Netherlands, 2024. [Google Scholar]

- Bano, A. A Summary of Solid Waste Generation and Management Strategy. In Waste-to-Energy; Elsevier: Amsterdam, The Netherlands, 2025; pp. 3–29. [Google Scholar]

- EN-1997; Eurocode 7: Geotechnical Design—Part 1: General Rules. European Committee for Standardization: Brussels, Belgium, 2004.

- EN-1997; Eurocode 7: Geotechnical Design—Part 2: Ground Investigation and Testing. European Committee for Standardization: Brussels, Belgium, 2004.

- Juarez, M.B.; Mondelli, G.; Giacheti, H.L. An overview of in situ testing and geophysical methods to investigate municipal solid waste landfills. Environ. Sci. Pollut. Res. 2023, 30, 24779–24789. [Google Scholar] [CrossRef] [PubMed]

- Dixon, N.; Jones, D.R.V. Engineering properties of municipal solid waste. Geotext. Geomembr. 2005, 23, 205–233. [Google Scholar] [CrossRef]

- Lunne, T.; Eidsmoen, T.; Gillespie, D.; Howland, J.D. Laboratory and field evaluation on cone penetrometers. In Proceedings of the Use of In Situ Tests in Geotechnical Engineering, Blacksburg, VA, USA, 23–25 June 1986; ASCE: Reston, VA, USA; pp. 714–729. [Google Scholar]

- Jessberger, H.L.; Kockel, R. Mechanical properties of waste materials. In Proceedings of the XV Ciclo di Conference di Geotecnica di Torino, Torino, Italy, 19–21 November 1991. [Google Scholar]

- Ramaiah, B.J.; Ramana, G.V.; Datta, M. Mechanical characterization of municipal solid waste from two waste dumps at Delhi, India. Waste Manag. 2017, 68, 275–291. [Google Scholar] [CrossRef] [PubMed]

- Sarmah, P.; Katsumi, T.; Yamawaki, A.; Takai, A.; Omine, K.; Ishiguro, T.; Doi, Y.; Nakase, Y.; Ideguchi, S. Physical and mechanical properties of waste ground at inert waste landfills. Waste Manag. 2021, 132, 1–11. [Google Scholar] [CrossRef]

- Manassero, M.; Pasqualini, E. Surveying and construction in urban, suburban, and polluted areas. In Proceedings of the International Conference on The Environment and Geotechnics, Paris, France, 8–15 March 1993. [Google Scholar]

- Lunne, T.; Robertson, P.K.; Powell, J.J.M. Cone Penetration Testing in Geotechnical Practice; Blackie Academic and Professional: London, UK, 1997. [Google Scholar]

- Koda, E.; Kiersnowska, A.; Kawalec, J.; Osiński, P. Landfill slope stability improvement incorporating reinforcements in the reclamation process applying observational method. Appl. Sci. 2020, 10, 1572. [Google Scholar] [CrossRef]

- Gabr, M.A.; Valero, S.N. Geotechnical properties of municipal solid waste. Geotech. Test. J. 1995, 18, 241–251. [Google Scholar] [CrossRef]

- Zekkos, D.; Athanasopoulos, G.A.; Bray, J.D.; Grizi, A.; Theodoratos, A. Large-scale direct shear testing of municipal solid waste. Waste Manag. 2010, 30, 1544–1555. [Google Scholar] [CrossRef]

- Reddy, K.R.; Hettiarachchi, H.; Gangathulasi, J.; Bogner, J.E. Geotechnical properties of municipal solid waste at different phases of biodegradation. Waste Manag. 2011, 31, 2275–2286. [Google Scholar] [CrossRef]

- Zhao, Y.R.; Xie, Q.; Wang, G.L.; Zhang, Y.J.; Zhang, Y.X.; Su, W. A study of shear strength properties of municipal solid waste in Chongqing landfill, China. Environ. Sci. Pollut. Res. 2014, 21, 12605–12615. [Google Scholar] [CrossRef]

- Feng, S.J.; Gao, K.W.; Chen, Y.X.; Li, Y.; Zhang, L.M.; Chen, H.X. Geotechnical properties of municipal solid waste at Laogang Landfill, China. Waste Manag. 2017, 63, 354–365. [Google Scholar] [CrossRef]

- Fei, X.; Zekkos, D. Comparison of direct shear and simple shear responses of municipal solid waste in USA. Environ. Geotech. 2017, 5, 158–167. [Google Scholar] [CrossRef]

- Kumar, G.; Reddy, K.R. Comprehensive Coupled Thermo-Hydro-Bio-Mechanical Model for Holistic Performance Assessment of Municipal Solid Waste Landfills. Comput. Geotech. 2021, 132, 103920. [Google Scholar] [CrossRef]

- Jakimiuk, A.; Koda, E.; Goli, V.S.N.S.; Podlasek, A.; Winkler, J.; Singh, Y.; Vaverková, M.D. COVID-19 pandemic-induced medical waste in the Anthropocene: Generation, management, and environmental impact. Anthr. Rev. 2025, 20530196251315452. [Google Scholar] [CrossRef]

- Slatinek, T.; Slapnik, J. Upcycling of SARS-CoV-2 rapid antigen test cassettes into flame retardant plastics. Materials 2024, 17, 2384. [Google Scholar] [CrossRef]

- Idrees, M.; Akbar, A.; Mohamed, A.M.; Fathi, D.; Saeed, F. Recycling of waste facial masks as a construction material, a step towards sustainability. Materials 2022, 15, 1810. [Google Scholar] [CrossRef]

- Castellote, M.; Jiménez-Relinque, E.; Grande, M.; Rubiano, F.J.; Castillo, Á. Face mask wastes as cementitious materials: A possible solution to a big concern. Materials 2022, 15, 1371. [Google Scholar] [CrossRef]

- Khan, A.H.; López-Maldonado, E.A.; Khan, N.A.; Villarreal-Gómez, L.J.; Munshi, F.M.; Alsabhan, A.H.; Perveen, K. Current solid waste management strategies and energy recovery in developing countries—State of the art review. Chemosphere 2022, 291, 133088. [Google Scholar] [CrossRef]

- Mondelli, G.; Juarez, M.B.; Jacinto, C.; de Oliveira, M.A.; Coelho, L.H.G.; Biancardi, C.B.; de Castro Faria, J.L. Geo-environmental and geotechnical characterization of municipal solid waste from the selective collection in São Paulo city, Brazil. Environ. Sci. Pollut. Res. 2022, 29, 19898–19912. [Google Scholar] [CrossRef]

- Lino, F.A.; Ismail, K.A.; Castañeda-Ayarza, J.A. Municipal solid waste treatment in Brazil: A comprehensive review. Energy Nexus. 2023, 11, 100232. [Google Scholar] [CrossRef]

- Li, K.; Li, X.; Du, C.; Xue, H.; Sun, Q.; Liu, L. Experimental study on microstructure and erosion mechanisms of solid waste cemented paste backfill under the combined action of dry–wet cycles and sulphate erosion. Materials 2022, 15, 1484. [Google Scholar] [CrossRef]

- Koda, E.; Osiński, P.; Podlasek, A.; Markiewicz, A.; Winkler, J.; Vaverková, M.D. Geoenvironmental approaches in an old municipal waste landfill reclamation process: Expectations vs reality. Soils Found 2023, 63, 101273. [Google Scholar] [CrossRef]

- Koda, E. Stability conditions improvement of the old sanitary landfills. In Proceedings of the 3th Internatonal Congress on Environment Geotechnics, Lisboa, Portugal, 7–11 September 1998; pp. 223–228. [Google Scholar]

- Robertson, P.K.; Campanella, R.G.; Wightman, A. SPT-CPT correlations. J. Geotech. Eng. 1983, 109, 1449–1459. [Google Scholar] [CrossRef]

- McKnight, T.; Cho, Y.M.; Townsend, T.G.; Choate, A. Cone penetration testing for characterizing landfilled municipal solid waste. J. Geotech. Geoenviron. Eng. 2015, 141, 06014018. [Google Scholar] [CrossRef]

- Falamaki, A.; Ghareh, S.; Homaee, M.; Hamtaeipour Shirazifard, A.; Abedpour, S.; Kiani, S.; Mousavi, N.; Rezaei, M.; Taghizadeh Motlagh, M.; Dehbozorgi, M.; et al. Laboratory shear strength measurements of municipal solid waste at room and simulated in situ landfill temperature, Barmshoor Landfill, Iran. Int. J. Civ. Eng. 2020, 18, 185–197. [Google Scholar] [CrossRef]

- Fang, H.Y. Engineering behaviour of urban refuse, compaction control and slope stability analysis of landfill. In Proceedings of the General Report GREEN’93, International Symposium on Geotechnics Related to the Environment, Bolton, UK, 1–6 June 1993. [Google Scholar]

- Gomes, C.; Lopes, M.L.; Oliveira, P.J.V. Municipal solid waste shear strength parameters defined through laboratorial and in situ tests. J. Air Waste Manag. Assoc. 2013, 63, 1352–1368. [Google Scholar] [CrossRef]

- Schmertmann, J.H. Guidelines for Cone Penetration Tests Performance and Design; Federal Highways Administration: Washington, DC, USA, 1978; FHWA-TS-78-209.

- Stoltz, G.; Tinet, A.J.; Staub, M.J.; Oxarango, L.; Gourc, J.P. Moisture retention properties of municipal solid waste in relation to compression. J. Geotech. Geoenviron. Eng. 2012, 138, 535–543. [Google Scholar] [CrossRef]

- Wang, Z.Z.; Jiang, S.H. Characterizing geotechnical site investigation data: A comparative study using a novel distribution model. Acta Geotech. 2023, 18, 1821–1839. [Google Scholar] [CrossRef]

- Fernandes, I.; Chaminé, H.I. In situ geotechnical investigations. In Advances on Testing and Experimentation in Civil Engineering: Geotechnics, Transportation, Hydraulics and Natural Resources; Springer Nature: Berlin/Heidelberg, Germany, 2022; Volume 1, pp. 29–54. [Google Scholar]

- Keramati, M.; Shahedifar, M.; Aminfar, M.H.; Alagipuor, H. Evaluating the shear strength behavior of aged MSW using large-scale in situ direct shear test: A case of Tabriz Landfill. Int. J. Civ. Eng. 2020, 18, 717–733. [Google Scholar] [CrossRef]

- Manassero, M.; Van Impe, W.F.; Bouazza, A. Waste disposal and containment. In Proceedings of the 2nd International Congress on Geotechnical Environmental Engineering, Osaka, Japan, 5–8 November 1996; Volume 3, pp. 1425–1474. [Google Scholar]

- Mohammad, A.; Osiński, P.; Koda, E.; Singh, D.N. A Case Study on Establishing the State of Decomposition of Municipal Solid Waste in a Bioreactor Landfill in India. Waste Manag. Res. J. A Sust. Circ. Econo. 2021, 39, 1375–1388. [Google Scholar] [CrossRef]

- Rabarijoely, S.; Lech, M.; Bajda, M. Determination of Relative Density and Degree of Saturation in Mineral Soils Based on In Situ Tests. Materials 2021, 14, 6963. [Google Scholar] [CrossRef]

| Landfill | Description | Density Index ID [-] | Liquidity Index IL [-] | Angle of Friction φ [°] | Shear Strength Su [kPa] |

|---|---|---|---|---|---|

| Zakroczym | “cohesive” waste | - | <0 | - | 250–350 |

| - | 0.05–0.15 | - | 100–200 | ||

| - | 0.25–0.35 | - | 50–80 | ||

| “non-cohesive” waste | 0.70–0.80 | - | 37–39 | - | |

| 0.40–0.60 | - | 34–36 | - | ||

| 0.10–0.30 | - | 28–31 | - | ||

| Łubna | “cohesive” waste | - | <0 | - | 250–350 |

| - | 0.05–0.15 | - | 100–200 | ||

| - | 0.25–0.35 | - | 50–80 | ||

| “non-cohesive” waste | 0.70–0.90 | - | 37–40 | - | |

| 0.40–0.60 | - | 34–36 | - | ||

| 0.10–0.30 | - | 28–31 | - | ||

| Radiowo | “cohesive” waste | - | <0 | - | 200–400 |

| - | 0.00–0.14 | - | 100–150 | ||

| “non-cohesive” waste | 0.89–1.00 | - | 40–45 | - | |

| 0.69–0.80 | - | 37–39 | - | ||

| 0.35–0.65 | - | 33–36 | - | ||

| 0.10–0.30 | - | 28–32 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bajda, M.; Lech, M.; Markowska-Lech, K.; Osiński, P.; Koda, E. Mechanical Strength of Waste Materials: A Cone Penetration Testing-Based Geotechnical Assessment for the Reclamation of Landfills. Materials 2025, 18, 2130. https://doi.org/10.3390/ma18092130

Bajda M, Lech M, Markowska-Lech K, Osiński P, Koda E. Mechanical Strength of Waste Materials: A Cone Penetration Testing-Based Geotechnical Assessment for the Reclamation of Landfills. Materials. 2025; 18(9):2130. https://doi.org/10.3390/ma18092130

Chicago/Turabian StyleBajda, Marek, Mariusz Lech, Katarzyna Markowska-Lech, Piotr Osiński, and Eugeniusz Koda. 2025. "Mechanical Strength of Waste Materials: A Cone Penetration Testing-Based Geotechnical Assessment for the Reclamation of Landfills" Materials 18, no. 9: 2130. https://doi.org/10.3390/ma18092130

APA StyleBajda, M., Lech, M., Markowska-Lech, K., Osiński, P., & Koda, E. (2025). Mechanical Strength of Waste Materials: A Cone Penetration Testing-Based Geotechnical Assessment for the Reclamation of Landfills. Materials, 18(9), 2130. https://doi.org/10.3390/ma18092130