Carpathian Diatomites and Their Applications in Phase-Change Composites

Abstract

1. Introduction

1.1. Directions of Use of Diatomite Rocks

1.2. Use of Mineral Raw Materials with PCM

2. Materials and Methods

2.1. Materials

- The organic PCM is a mixture of saturated hydrocarbons. The mixture is characterized by a melting/freezing point of 28 °C and a phase-change enthalpy of 190 J/g. PCM RT28HC was produced by Rubitherm GmbH, Berlin, Germany.

- Carpathian diatomite is a porous, brittle rock with a light cream color. It is characterized by a low bulk density in the range of 1.28–1.38 g/cm3. Material with a fraction of 0–2 mm was used in the tests. The material for the tests was prepared in the appropriate proportions of 50% PCM and 50% diatomite, and 40% PCM and 60% diatomite. Diatomite rock samples were collected in Krosno, Poland.

2.2. Methods

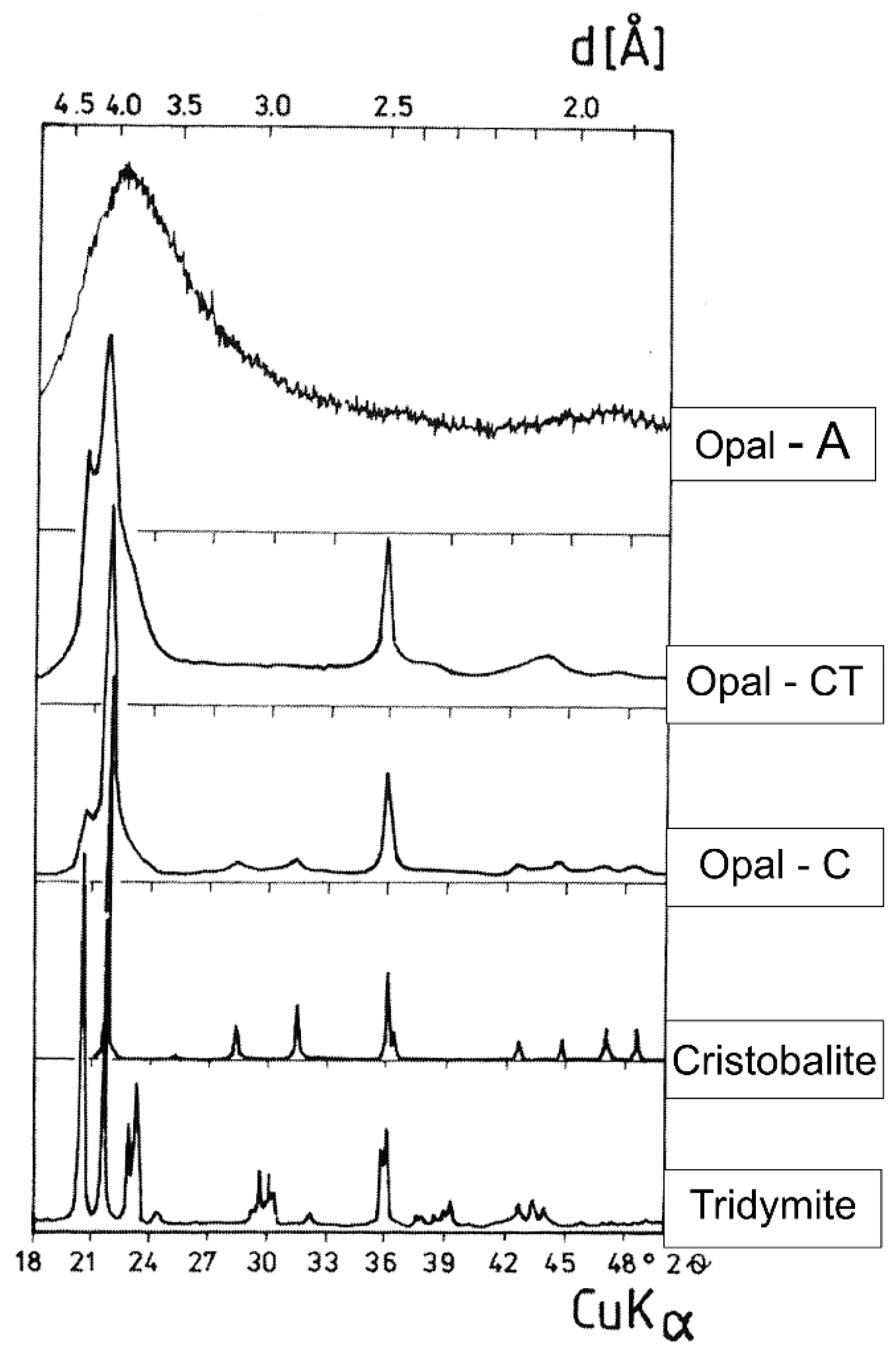

2.2.1. Mineralogical Research

2.2.2. Differential Scanning Calorimetry Tests

3. Results and Discussion

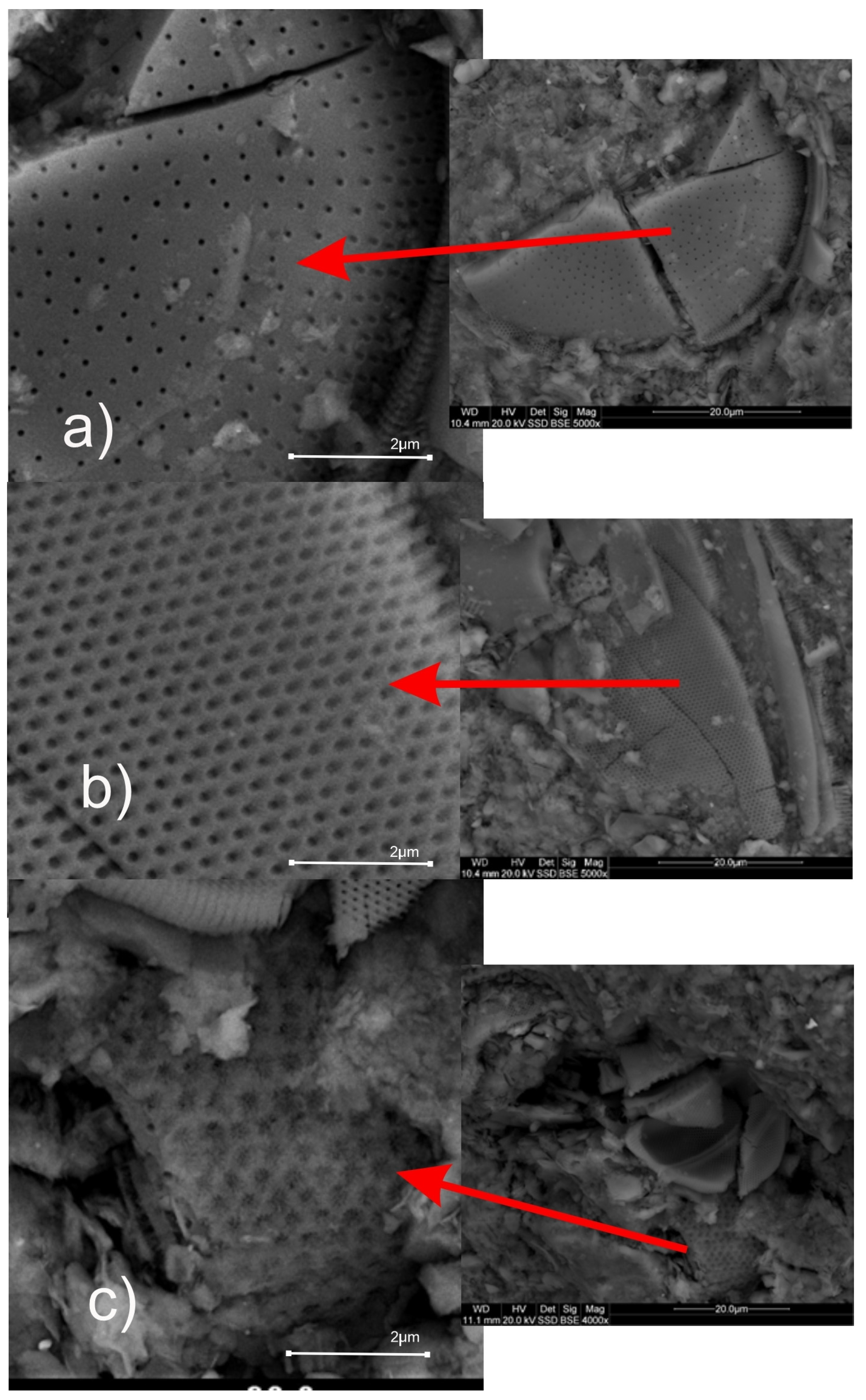

3.1. Mineralogical and Petrographic Studies of Diatomites

3.2. Experimental Studies

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kotlarczyk, J.; Krawczyk, A.J.; Leśniak, T. Diatomite Horizon from Futoma in the Polish Flysch Carpathians; Institute of Geology and Mineral Resources AGH: Cracow, Poland, 1991. (In Polish) [Google Scholar]

- Kotlarczyk, J.; Krawczyk, A.J.; Słomka, T. Diatomite deposit in Futoma near Błażowa (Polish Flysch Carpathians). In Mineral Resources Management; Polisch Geological Institute: Warsaw, Poland, 1996; Volume 12/3. (In Polish) [Google Scholar]

- Malata, T.; Poprawa, P. Evolution of the Skole subbasin. In Paleotectonic Development of the Outer Carpathian Basins and the Pieniny Klippen Belt; Oszczypko, N., Uchman, A., Malata, E., Eds.; Institute of Geological Sciences of the Jagiellonian University: Cracow, Poland, 2006; pp. 103–110. (In Polish) [Google Scholar]

- Oszczypko, N. Outher Carpathians in Poland. In The Geology of Central Europe: Mesozoic and Cenozoic; McCann, T., Ed.; Geological Society: London, UK, 2008; Volume 2, pp. 1078–1081. [Google Scholar]

- Szydło, A.; Garecka, M.; Jankowski, L.; Malata, T. Paleogene microfossils from the submarine debris flows in the Skole Basin (Polish and Ukraine Outer Carpathians). Geol. Geophys. Environ. 2014, 40, 49–65. [Google Scholar] [CrossRef][Green Version]

- Figarska-Warchoł, B.; Stańczak, G.; Rembiś, M.; Toboła, T. Diatomaceous rocks of the Jawornik deposit (the Polish Outer Carpathians): Petrophysical and petrographical evaluation. Geol. Geophys. Environ. 2015, 41, 311–331. [Google Scholar] [CrossRef]

- Noraini, M.S.N.N.; Sethupathi, S.; Chung, L.L.; Ahmad, W. Carbon dioxide adsorption by raw and modified diatomite. AIP Conf. Proc. 2019, 2157, 020049. [Google Scholar] [CrossRef]

- Vinaches, P.; Schwanke, A.J.; Lopes, C.W.; Villarroel-Rocha, J.; Sapag, K.; Pergher, S.B.C. Incorporation of Brazilian Diatomite in the Synthesis of An MFI Zeolite. Molecules 2019, 24, 1980. [Google Scholar] [CrossRef]

- Nikjoo, D.; Perrot, V.; Akhtar, F. Laminated porous diatomite monoliths for adsorption of dyes from water: Diatomite monoliths for adsorption of dyes. Environ. Prog. Sustain. Energy 2018, 38, 1. [Google Scholar] [CrossRef]

- Wu, W.; Cong, S. Modified diatomite forms in the rubber nanocomposites. J. Thermoplast. Compos. Mater. 2018, 33, 5. [Google Scholar] [CrossRef]

- Akduman, C. Fabrication and Characterization of Diatomite Functionalized Cellulose Acetate Nanofibers. AATCC J. Res. 2019, 6, 28. [Google Scholar] [CrossRef]

- Suwanan, T.; Lertcumfu, N.; Rujijanagul, G. The Effects of Replacement Metakaolin with Diatomite in Geopolymer. Key Eng. Mater. 2019, 798, 267. Available online: https://www.scientific.net/KEM.798.267 (accessed on 29 April 2025).

- Hassan, N.A.; Jaya, R.P.J.; Hainin, M.R.; Abdullah, E. Physical properties of bitumen containing diatomite and waste engine oil MJFAS. Malaysjan J. Fundam. Appl. Sci. 2019, 15, 4. [Google Scholar] [CrossRef]

- Dong, K.; Gu, X.; Peng, L.; Liu, P.; Jiang, S.; Bian, L. Recent advancements in typical mineral-encapsulated form-stable phase change materials for thermal energy storage. J. Energy Storage 2022, 52 Pt B, 104931. [Google Scholar] [CrossRef]

- Karaman, S.; Karaipekli, A.; Sarı, A.; Biç, A. Polyethylene glycol (PEG)/diatomite composite as a novel form-stable phase change material for thermal energy storage. Sol. Energy Mater. Sol. Cells 2011, 95, 1647. [Google Scholar] [CrossRef]

- Costa, J.A.C.; Martinelli, A.E.; do Nascimento, R.M.; Mendes, A.M. Microstructural design and thermal characterization of composite diatomite-vermiculite paraffin-based form-stable PCM for cementitious mortars. Constr. Build. Mater. 2020, 232, 117167. [Google Scholar] [CrossRef]

- Jeong, S.G.; Jeon, J.; Lee, J.H.; Kim, S. Optimal preparation of PCM/diatomite composites for enhancing thermal properties. Int. J. Heat Mass Transf. 2013, 62, 711–717. [Google Scholar] [CrossRef]

- Jian, D.; Chen, P.; Liu, J.; Xu, Y. Preparation and performance study of modified diatomite based PCM for construction. Green Mater. 2024, 12, 1–13. [Google Scholar] [CrossRef]

- Ren, M.; Gao, X.; Tian, W.; Chen, S. Graphene modified octadecane/diatomite composite phase change materials for developing high-performance thermal energy storage concrete. J. Energy Storage 2025, 115, 115956. [Google Scholar] [CrossRef]

- Yang, Y.; Shen, Z.; Wu, W.; Zhang, H.; Ren, Y.; Yang, Q. Preparation of a novel diatomite-based PCM gypsum board for temperature-humidity control of buildings. Build. Environ. 2022, 226, 109732. [Google Scholar] [CrossRef]

- Musiał, M.; Lichołai, L.; Katunsky, D. Modern Thermal Energy Storage Systems Dedicated to Autonomous Buildings. Energies 2023, 16, 4442. [Google Scholar] [CrossRef]

- Musiał, M.; Lichołai, L.; Pękala, A. Analysis of the thermal performance of isothermal composite heat accumulators containing organic phase change material. Energies 2023, 16, 1409. [Google Scholar] [CrossRef]

- Musiał, M.; Pękala, A. Functioning of Heat Accumulating Composites of Carbon Recyclate and Phase Change Material. Materials 2022, 15, 2331. [Google Scholar] [CrossRef]

- Yu, H.; Li, C.; Zhang, K.; Tang, Y.; Song, Y.; Wang, M. Preparation and thermophysical performance of diatomite-based composite PCM wallboard for thermal energy storage in buildings. J. Build. Eng. 2020, 32, 101753. [Google Scholar] [CrossRef]

- Flörke, O.W.; Graetsch, H.; Martin, B.; Röller, K.; Wirth, R. Nomenclature of micro- and non-crystalline silica minerals, based on structure and microstructure. Neues Jahrb. Für Mineralogie. Abhandlungen 1991, 163, 19. [Google Scholar]

- Figarska-Warchoł, B.; Rembiś, M.; Stańczak, G. The impact of calcination on changes in the physical and mechanical properties of the diatomites of the Leszczawka Member (the Outer Carpathians, Poland). Geol. Geophys. Environ. 2019, 45, 4. [Google Scholar] [CrossRef]

- Maeda, H.; Aoyama, M.; Kasuga, T. Potential of diatoms as phase change materials. Mater. Lett. 2021, 282, 128673. [Google Scholar] [CrossRef]

| Chemical Component | Content [% by Weight] | ||

|---|---|---|---|

| Minimal | Maximum | Average Value (N = 5) | |

| SiO2 | 62.13 | 85.71 | 77.45 |

| Al2O3 | 5.7 | 10.39 | 8.52 |

| Fe2O3 | 1.12 | 12.95 | 3.25 |

| MnO | 0.007 | 1.191 | 0.013 |

| MgO | 0.39 | 0.74 | 0.63 |

| CaO | 0.2 | 0.4 | 0.29 |

| Na2O | 0.18 | 0.51 | 0.2 |

| K2O | 0.89 | 1.79 | 1.41 |

| TiO2 | 0.212 | 0.50 | 0.26 |

| P2O5 | 0.02 | 0.22 | 0.02 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pękala, A.; Musiał, M.; Lichołai, L. Carpathian Diatomites and Their Applications in Phase-Change Composites. Materials 2025, 18, 2097. https://doi.org/10.3390/ma18092097

Pękala A, Musiał M, Lichołai L. Carpathian Diatomites and Their Applications in Phase-Change Composites. Materials. 2025; 18(9):2097. https://doi.org/10.3390/ma18092097

Chicago/Turabian StylePękala, Agnieszka, Michał Musiał, and Lech Lichołai. 2025. "Carpathian Diatomites and Their Applications in Phase-Change Composites" Materials 18, no. 9: 2097. https://doi.org/10.3390/ma18092097

APA StylePękala, A., Musiał, M., & Lichołai, L. (2025). Carpathian Diatomites and Their Applications in Phase-Change Composites. Materials, 18(9), 2097. https://doi.org/10.3390/ma18092097