Study of Properties of Composite Cementitious Materials with Sulfoaluminate Cement and Solid Waste Based on Compaction Forming Process

Abstract

:1. Introduction

2. Materials and Methods

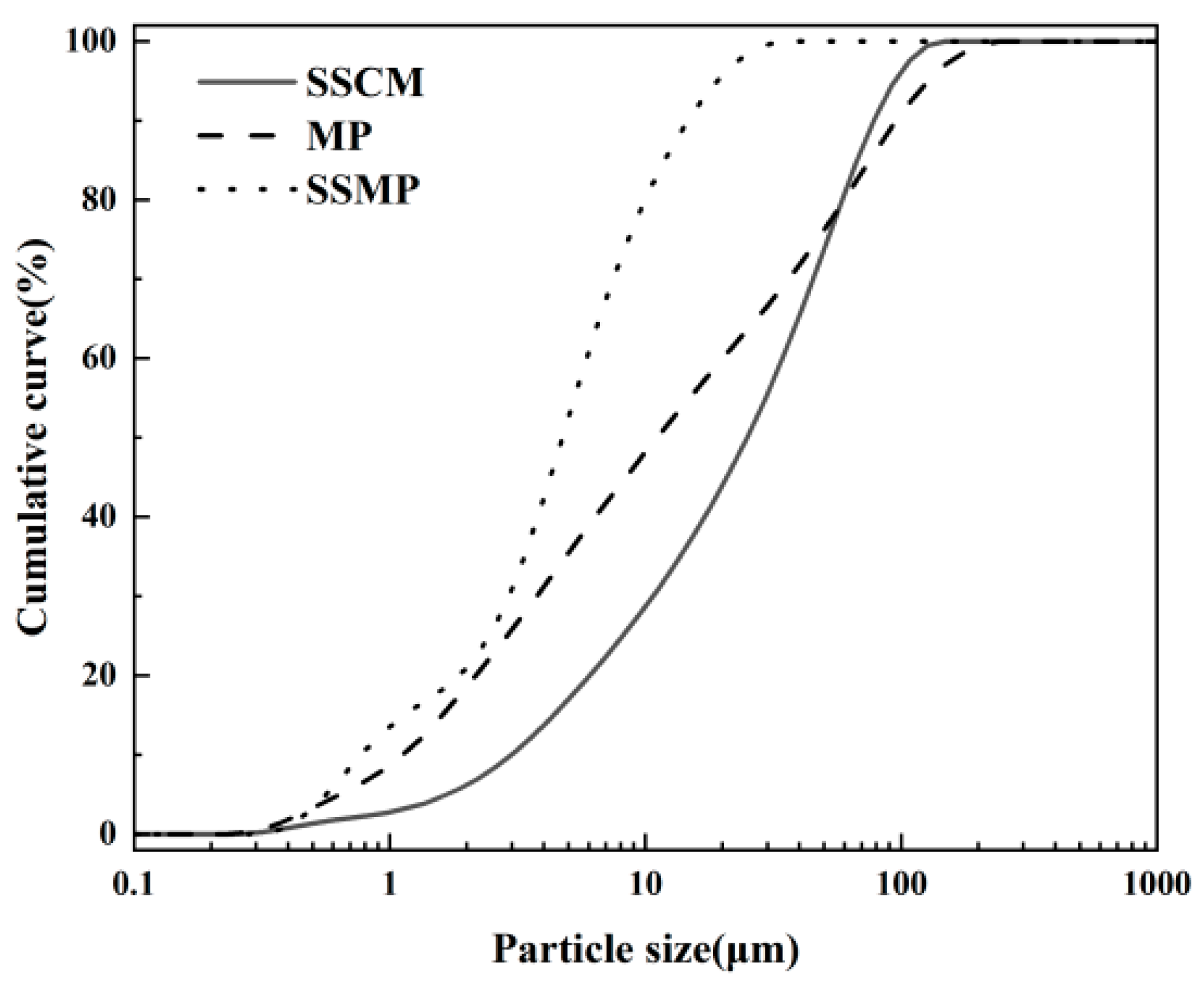

2.1. Materials

2.2. Experimental Program

2.3. Methods

3. Results and Discussion

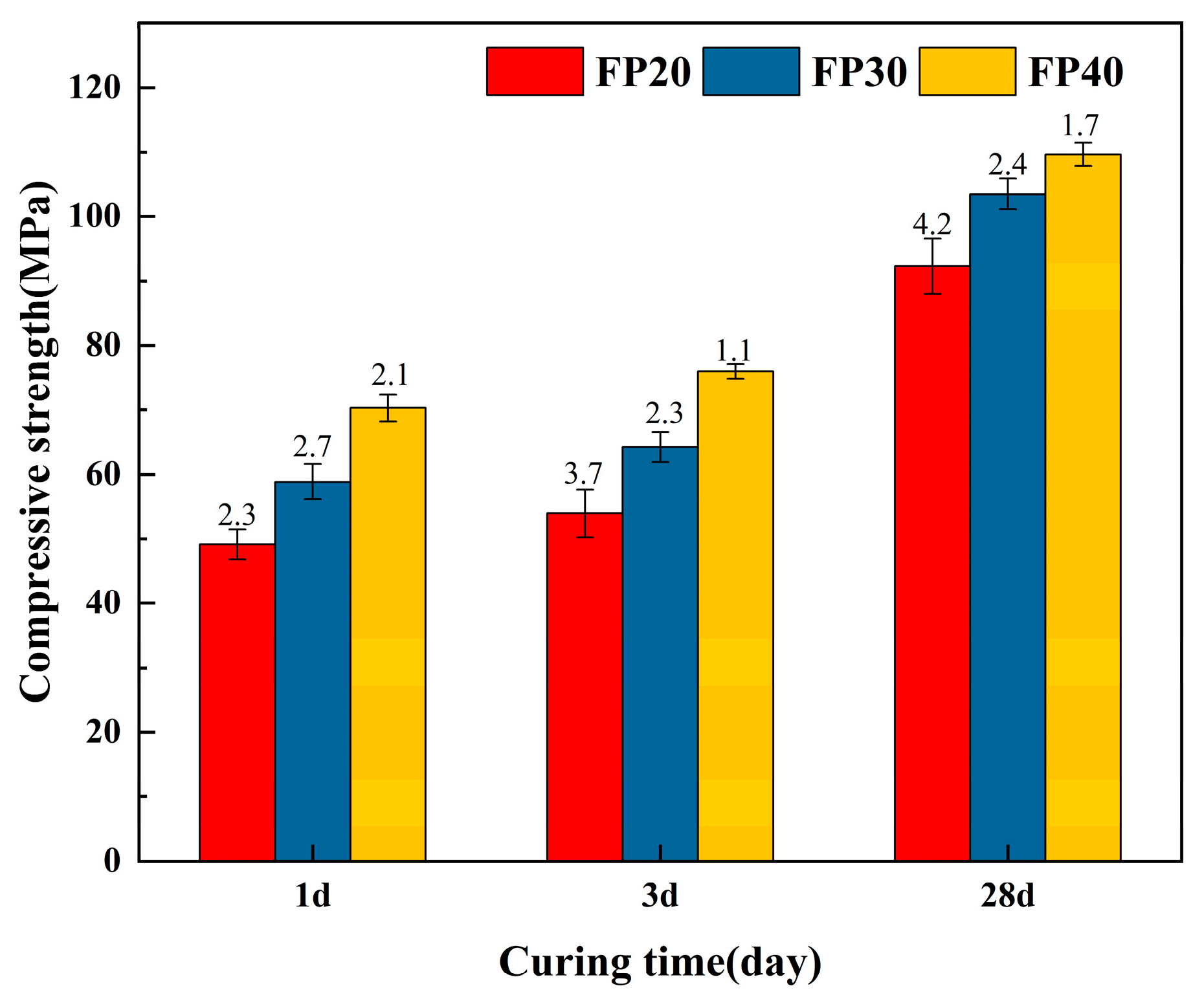

3.1. Effect of Forming Pressure on the Strength of SSCM

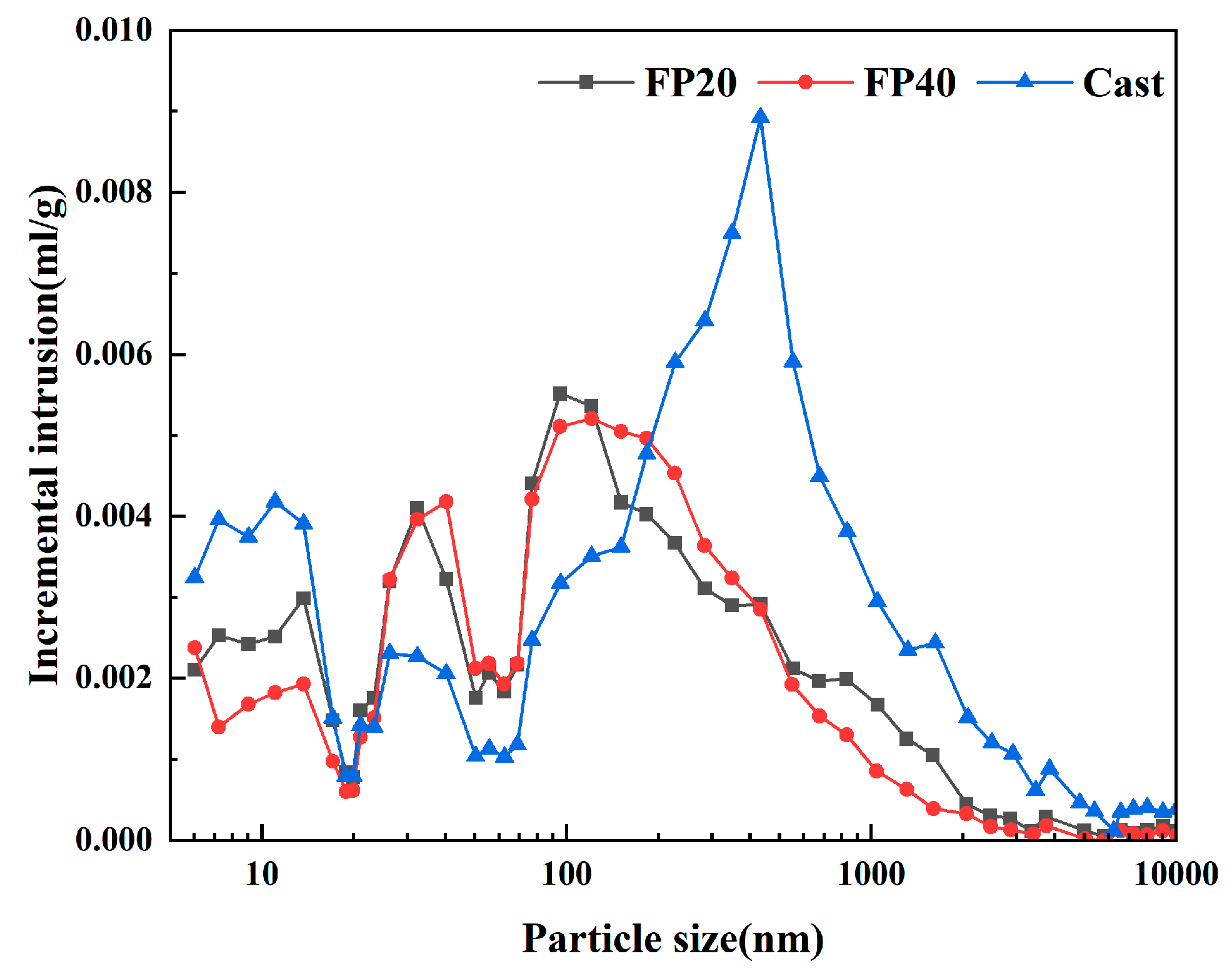

3.2. Effect of Forming Pressure on the Pore Structure of SSCM

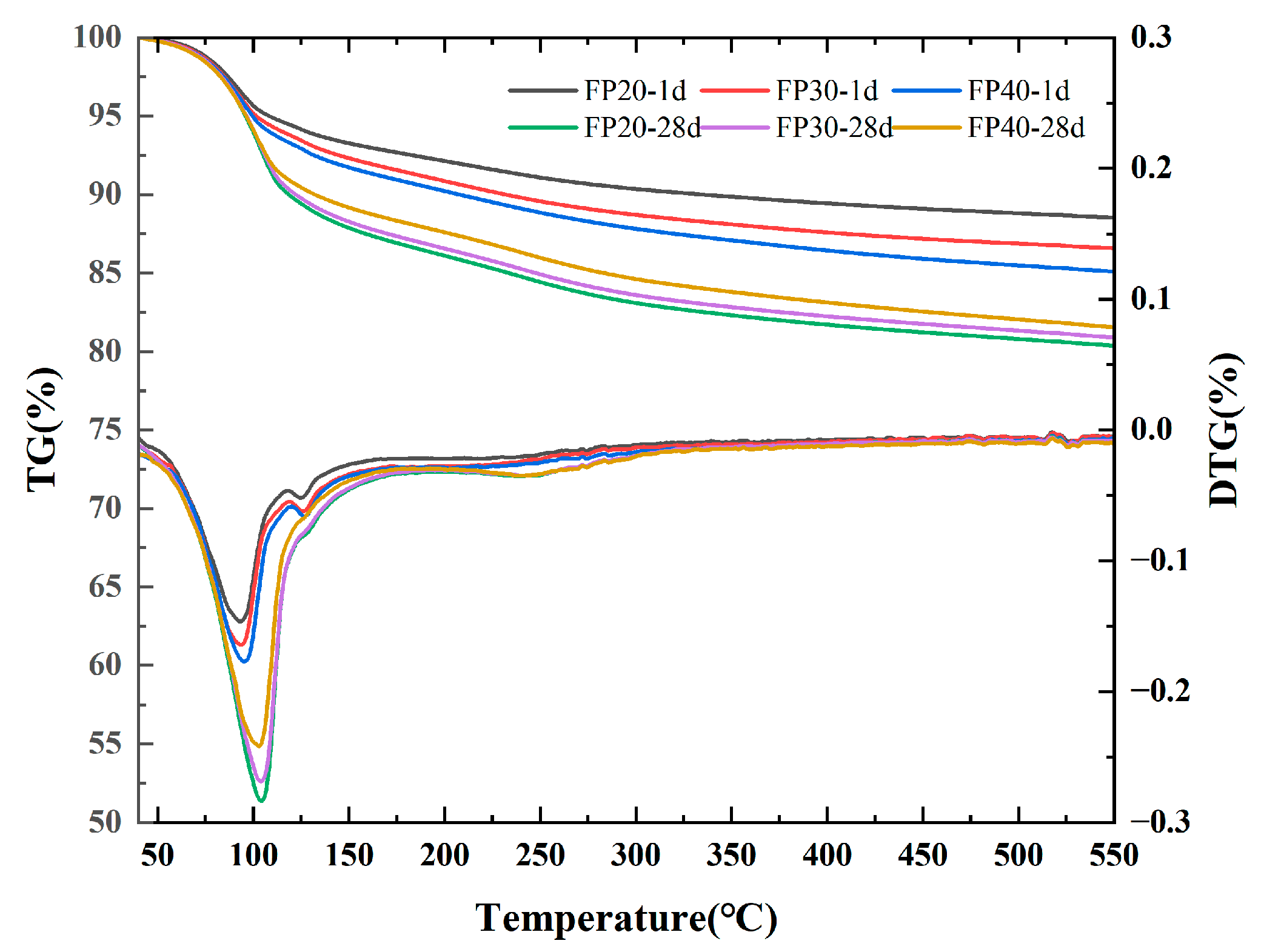

3.3. Effect of Forming Pressure on the Hydration Process of SSCM

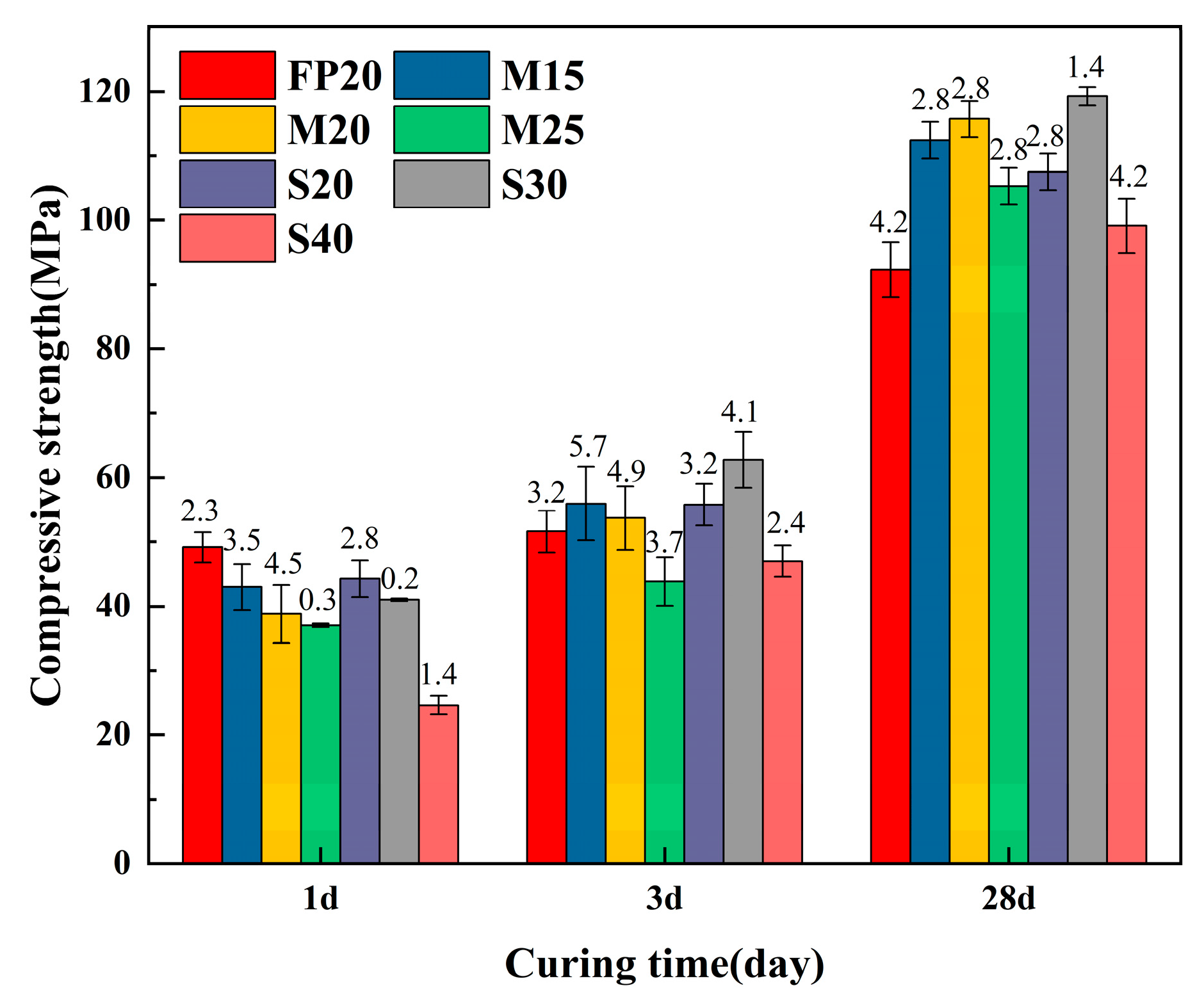

3.4. Effect of MP and SSMP Content on the Strength of SSCM

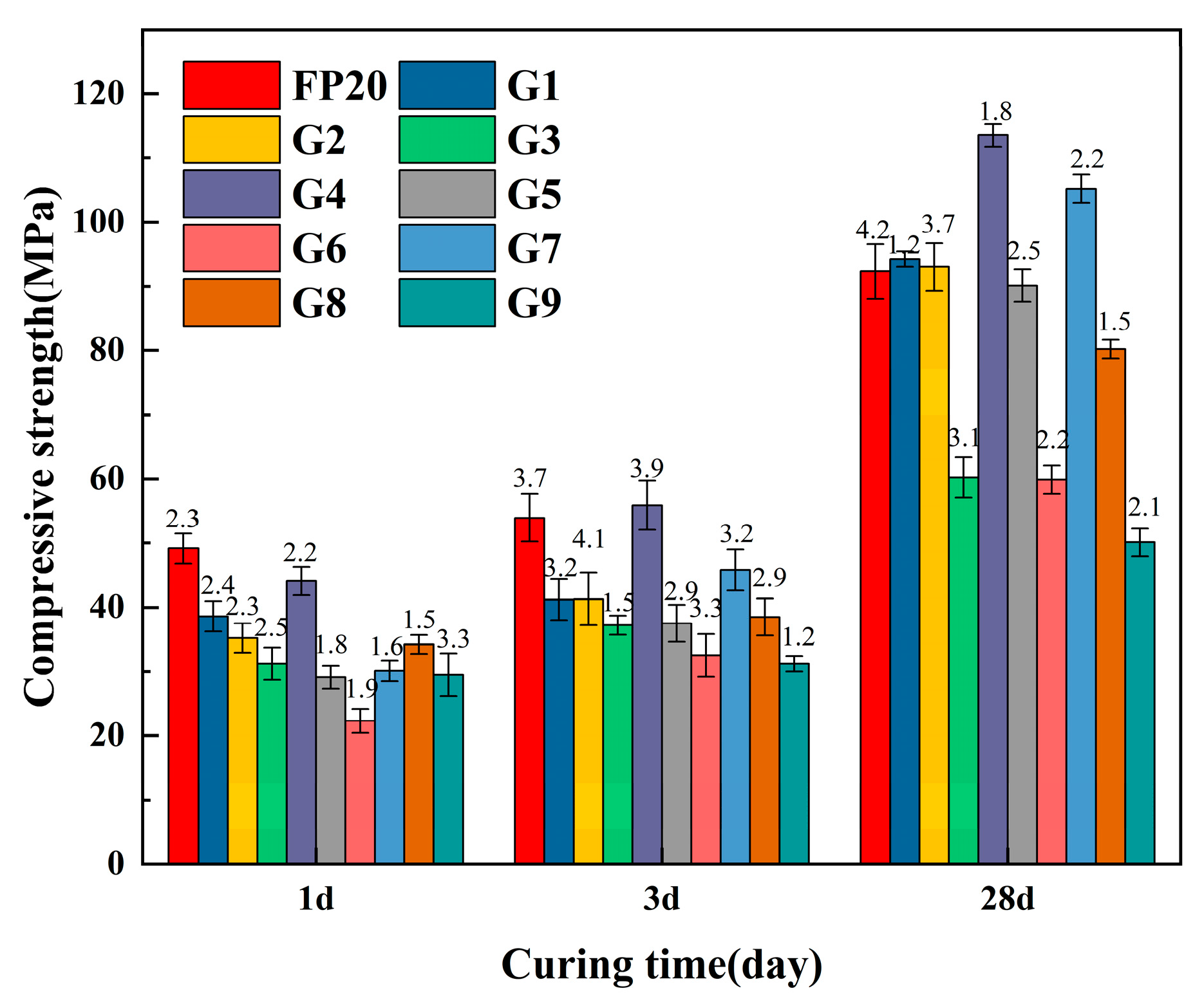

3.5. Process Optimization of Materials Under Compaction Forming Technology

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| <10 nm | 10–100 nm | 100–1000 nm | 1000–3000 nm | >3000 nm | |

|---|---|---|---|---|---|

| Cast | 3.38 | 2.7 | 9.19 | 1.82 | 14.94 |

| FP20 | 2.95 | 5.34 | 7.50 | 1.00 | 2.17 |

| FP40 | 2.22 | 5.64 | 8.10 | 0.51 | 1.79 |

References

- Kokubu, K.; Cabrera, J.G.; Ueno, A. Compaction properties of roller compacted concrete. Cem. Concr. Compos. 1996, 18, 109–117. [Google Scholar] [CrossRef]

- Roy, D.M.; Gouda, G.R.; Bobrowsky, A. Very high strength cement pastes prepared by hot pressing and other high pressure techniques. Cem. Concr. Res. 1972, 2, 349–366. [Google Scholar] [CrossRef]

- Ying-Kit, C.; Groom, J.L. RCC Mix Design—Soils Approach. J. Mater. Civ. Eng. 2001, 13, 71. [Google Scholar]

- Nematollahzade, M.; Tajadini, A.; Afshoon, I.; Aslani, F. Influence of different curing conditions and water to cement ratio on properties of self-compacting concretes. Constr. Build. Mater. 2020, 237, 117570. [Google Scholar] [CrossRef]

- Du, J.; Liu, Z.; Christodoulatos, C.; Conway, M.; Bao, Y.; Meng, W. Utilization of off-specification fly ash in preparing ultra-high-performance concrete (UHPC): Mixture design, characterization, and life-cycle assessment. Resour. Conserv. Recycl. 2022, 180, 106136. [Google Scholar] [CrossRef]

- Yoon, H.N.; Seo, J.; Kim, S.; Lee, H.K.; Park, S. Hydration of calcium sulfoaluminate cement blended with blast-furnace slag. Constr. Build. Mater. 2021, 268, 121214. [Google Scholar] [CrossRef]

- Shi, C.; Qu, B.; Provis, J.L. Recent progress in low-carbon binders. Cem. Concr. Res. 2019, 122, 227–250. [Google Scholar] [CrossRef]

- Gartner, E.; Hirao, H. A review of alternative approaches to the reduction of CO2 emissions associated with the manufacture of the binder phase in concrete. Cem. Concr. Res. 2015, 78, 126–142. [Google Scholar] [CrossRef]

- Shi, C.; Jiménez, A.F.; Palomo, A. New cements for the 21st century: The pursuit of an alternative to Portland cement. Cem. Concr. Res. 2011, 41, 750–763. [Google Scholar] [CrossRef]

- Hargis, C.W.; Telesca, A.; Monteiro, P.J.M. Calcium sulfoaluminate (Ye’elimite) hydration in the presence of gypsum, calcite, and vaterite. Cem. Concr. Res. 2014, 65, 15–20. [Google Scholar] [CrossRef]

- Péra, J.; Ambroise, J. New applications of calcium sulfoaluminate cement. Cem. Concr. Res. 2004, 34, 671–676. [Google Scholar] [CrossRef]

- Ren, C.; Wang, W.; Li, G. Preparation of high-performance cementitious materials from industrial solid waste. Constr. Build. Mater. 2017, 152, 39–47. [Google Scholar] [CrossRef]

- Julphunthong, P. Synthesizing of calcium sulfoaluminate-belite (CSAB) cements from industrial waste materials. Mater. Today Proc. 2018, 5, 14933–14938. [Google Scholar] [CrossRef]

- Yao, Y.; Wang, W.; Ge, Z.; Ren, C.; Yao, X.; Wu, S. Hydration study and characteristic analysis of a sulfoaluminate high-performance cementitious material made with industrial solid wastes. Cem. Concr. Compos. 2020, 112, 103687. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, Z.; Li, J.; Wang, W.; Mao, Y.; Song, Z. Quantification of CO2 emission from the preparation and utilization of solid waste-based sulphoaluminate cementitious materials. J. Clean. Prod. 2022, 376, 134054. [Google Scholar] [CrossRef]

- Wang, X.; Wang, K.; Li, J.; Wang, W.; Mao, Y.; Wu, S.; Yang, S. Heavy metals migration during the preparation and hydration of an eco-friendly steel slag-based cementitious material. J. Clean. Prod. 2021, 329, 129715. [Google Scholar] [CrossRef]

- Gopalakrishnan, R.; Sounthararajan, V.M.; Mohan, A.; Tholkapiyan, M. The strength and durability of fly ash and quarry dust light weight foam concrete. Mater. Today Proc. 2020, 22, 1117–1124. [Google Scholar] [CrossRef]

- Liu, S.; Pan, C.; Zhang, H.; Yao, S.; Shen, P.; Guan, X.; Shi, C.; Li, H. Development of novel mineral admixtures for sulphoaluminate cement clinker: The effects of wet carbonation activated red mud. J. Build. Eng. 2023, 67, 105920. [Google Scholar] [CrossRef]

- Zhang, W.; Shi, F.; Zhao, L.; Duan, X.; Feng, C.; Su, F. Effect of biomineralization on the early mechanical properties and microstructure of fly-ash cement-based materials. Constr. Build. Mater. 2022, 359, 129422. [Google Scholar] [CrossRef]

- Martin, L.H.J.; Winnefeld, F.; Tschopp, E.; Müller, C.J.; Lothenbach, B. Influence of fly ash on the hydration of calcium sulfoaluminate cement. Cem. Concr. Res. 2017, 95, 152–163. [Google Scholar] [CrossRef]

- Liu, C.; Luo, J.; Li, Q.; Gao, S.; Zhang, J.; Zhang, P. Effect of Fly Ash on Bonding and Shrinking Behaviors of High-Belite Sulphoaluminate Cement–Based Foam Concrete. J. Mater. Civ. Eng. 2021, 33, 04021329. [Google Scholar] [CrossRef]

- Saraya, M.E.-S.I. Study physico-chemical properties of blended cements containing fixed amount of silica fume, blast furnace slag, basalt and limestone, a comparative study. Constr. Build. Mater. 2014, 72, 104–112. [Google Scholar] [CrossRef]

- Ma, J.; Wang, T.; Shi, H.; Yu, Z.; Shen, X. Effects of Limestone Powder on the Early Hydration Behavior of Ye’elimite: Experimental Research and Thermodynamic Modelling. Materials 2022, 15, 6645. [Google Scholar] [CrossRef]

- Jeong, Y.; Hargis, C.W.; Chun, S.; Moon, J. Effect of Calcium Carbonate Fineness on Calcium Sulfoaluminate-Belite Cement. Materials 2017, 10, 900. [Google Scholar] [CrossRef] [PubMed]

- Cui, K.; Lau, D.; Zhang, Y.; Chang, J. Mechanical properties and mechanism of nano-CaCO3 enhanced sulphoaluminate cement-based reactive powder concrete. Constr. Build. Mater. 2021, 309, 125099. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, Z.; Zhu, Z.; Chen, Y.; Wu, K.; Huang, H.; Anvarovna, K.G.; Xu, L. Influence of metakaolin and calcined montmorillonite on the hydration of calcium sulphoaluminate cement. Case Stud. Constr. Mater. 2022, 16, e01104. [Google Scholar] [CrossRef]

- Gou, M.; Zhao, M.; Zhou, L.; Zhao, J.; Hou, W.; Ma, W.; Hou, Z. Hydration and mechanical properties of FGD gypsum-cement-mineral powder composites. J. Build. Eng. 2023, 69, 106288. [Google Scholar] [CrossRef]

- Wei, H.; Wan, H.; Yuan, S.; Liu, G.; Teng, J.; Shi, N.; Liu, Z. A new gelling material: Properties of recycled aggregate concrete under conditions of complete cement replacement using steel slag, ore slag, and fly ash. Constr. Build. Mater. 2025, 464, 140180. [Google Scholar] [CrossRef]

- Dai, J.; Gong, C.; Wang, Y.; Huo, L.; Lu, L. Effect of nano-silica on structure and properties of high sulfate resistant Portland cement mixed with mineral powder or fly ash. J. Build. Eng. 2023, 66, 105843. [Google Scholar] [CrossRef]

- Wang, K.; Guo, S.; Yuan, H.; Ren, J.; Chen, P.; Zhang, Q. Influence of cement particle size, ultra-fine fly ash, and ultra-fine silica fume on the physical and microscopic properties of slurry. Case Stud. Constr. Mater. 2025, 22, e04337. [Google Scholar] [CrossRef]

- Wei, Y.; Li, L.; Li, Z.; Liu, S. Preparation of vegetative concrete with recycled aggregate: Mix proportion orthogonal test, curing methods, and microstructure. Constr. Build. Mater. 2025, 460, 139892. [Google Scholar] [CrossRef]

- Lang, L.; Chen, B.; Pan, Y. Engineering properties evaluation of unfired sludge bricks solidified by cement-fly ash-lime admixed nano-SiO2 under compaction forming technology. Constr. Build. Mater. 2020, 259, 119879. [Google Scholar] [CrossRef]

- Zhao, X.; Liu, C.; Zuo, L.; Zhu, Q.; Ma, W.; Liu, Y. Preparation and characterization of press-formed fly ash cement incorporating soda residue. Mater. Lett. 2020, 259, 126852. [Google Scholar] [CrossRef]

- Shuang, L.; Ming-Zhi, G.; Fang-Ping, Z.; Tung, P.B.; Hongbin, L.; Tung-Chai, L. Role of interaction between molding pressure and CO2 pressure in carbonating cement block. J. Build. Eng. 2023, 78, 107579. [Google Scholar]

- Roy, D.M.; Gouda, G.R. High strength generation in cement pastes. Cem. Concr. Res. 1973, 3, 807–820. [Google Scholar] [CrossRef]

- Liska, M.; Al-Tabbaa, A. Performance of magnesia cements in pressed masonry units with natural aggregates: Production parameters optimisation. Constr. Build. Mater. 2008, 22, 1789–1797. [Google Scholar] [CrossRef]

- Hlobil, M.; Šmilauer, V.; Chanvillard, G. Micromechanical multiscale fracture model for compressive strength of blended cement pastes. Cem. Concr. Res. 2016, 83, 188–202. [Google Scholar] [CrossRef]

- Shaowen, D. Liquid Drainage in the Compaction Process of Asphalt Emulsion Mixtures with Cement. J. Mater. Civ. Eng. 2024, 36, 04024361. [Google Scholar]

- Živica, V.; Križma, M. Dependence of efficiency of pressure compaction on the cement type used. Constr. Build. Mater. 2011, 25, 3073–3077. [Google Scholar] [CrossRef]

- Živica, V. Effects of the very low water/cement ratio. Constr. Build. Mater. 2009, 23, 3579–3582. [Google Scholar] [CrossRef]

- Chang, L.; Liu, H.; Wang, J.; Liu, H.; Song, L.; Wang, Y.; Cui, S. Effect of chelation via ethanol-diisopropanolamine on hydration of pure steel slag. Constr. Build. Mater. 2022, 357, 129372. [Google Scholar] [CrossRef]

- Zhang, L.; Zhou, J. Fractal characteristics of pore structure of hardened cement paste prepared by pressurized compact molding. Constr. Build. Mater. 2020, 259, 119856. [Google Scholar] [CrossRef]

- Tikkanen, J.; Cwirzen, A.; Penttala, V. Effects of mineral powders on hydration process and hydration products in normal strength concrete. Constr. Build. Mater. 2014, 72, 7–14. [Google Scholar] [CrossRef]

- Tambara, L.U.D.; Cheriaf, M.; Rocha, J.C.; Palomo, A.; Fernández-Jiménez, A. Effect of alkalis content on calcium sulfoaluminate (CSA) cement hydration. Cem. Concr. Res. 2020, 128, 105953. [Google Scholar] [CrossRef]

| Density (g/cm3) | Setting Time (min) | Compressive Strength (MPa) | Flexural Strength (MPa) | |||||

|---|---|---|---|---|---|---|---|---|

| 2.83 | Initial setting | Final setting | 1 d | 3 d | 28 d | 1 d | 3 d | 28 d |

| 25 | 42 | 36.5 | 45.3 | 66.2 | 6.2 | 6.7 | 7.6 | |

| Material | CaO | SiO2 | Al2O3 | Fe2O3 | SO3 | MgO | Loss on Ignition |

|---|---|---|---|---|---|---|---|

| SSCM | 43.27 | 7.69 | 22.28 | 7.09 | 17.87 | 1.79 | 1.5 |

| MP | 48.23 | 17.75 | 5.43 | 28.03 | 0.38 | 0.19 | 0.9 |

| SSMP | 31.52 | 23.37 | 13.57 | 17.85 | 2.95 | 10.75 | 0.4 |

| Series | Group | Forming Pressure (MPa) | SSCM (%) | MP (%) | SSMP (%) |

|---|---|---|---|---|---|

| I | FP20 | 20 | 100 | 0 | 0 |

| FP30 | 30 | 100 | 0 | 0 | |

| FP40 | 40 | 100 | 0 | 0 | |

| II | M15 | 20 | 85 | 15 | 0 |

| M20 | 20 | 80 | 20 | 0 | |

| M25 | 20 | 75 | 25 | 0 | |

| S20 | 20 | 80 | 0 | 20 | |

| S30 | 20 | 70 | 0 | 30 | |

| S40 | 20 | 60 | 0 | 40 | |

| III | G1 | 20 | 65 | 15 | 20 |

| G2 | 20 | 55 | 15 | 30 | |

| G3 | 20 | 45 | 15 | 40 | |

| G4 | 20 | 60 | 20 | 20 | |

| G5 | 20 | 50 | 20 | 30 | |

| G6 | 20 | 40 | 20 | 40 | |

| G7 | 20 | 55 | 25 | 20 | |

| G8 | 20 | 45 | 25 | 30 | |

| G9 | 20 | 35 | 25 | 40 |

| Levels | Factors | ||

|---|---|---|---|

| A (%) | B (%) | C (MPa) | |

| 1 | 15 | 1 | 15 |

| 2 | 20 | 2 | 20 |

| 3 | 25 | 3 | 25 |

| Number | A | B | C | Compressive Strength (MPa) |

|---|---|---|---|---|

| P1 | 1 | 1 | 1 | 95.34 |

| P2 | 1 | 2 | 2 | 105.43 |

| P3 | 1 | 3 | 3 | 101.52 |

| P4 | 2 | 1 | 2 | 119.85 |

| P5 | 2 | 2 | 3 | 123.07 |

| P6 | 2 | 3 | 1 | 60.25 |

| P7 | 3 | 1 | 3 | 106.46 |

| P8 | 3 | 2 | 1 | 74.95 |

| P9 | 3 | 3 | 2 | 54.77 |

| Mean A | 100.76 | 107.21 | 76.85 | 95.34 |

| Mean B | 101.05 | 101.15 | 93.35 | 105.43 |

| Mean C | 78.73 | 72.18 | 110.35 | 101.52 |

| Range | 22.33 | 35.03 | 33.51 | 119.85 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, Z.; Wang, X.; Yu, M.; Chen, S.; Liu, J.; Li, J.; Wang, J.; Sun, H.; Mao, Y.; Hu, Z.; et al. Study of Properties of Composite Cementitious Materials with Sulfoaluminate Cement and Solid Waste Based on Compaction Forming Process. Materials 2025, 18, 2076. https://doi.org/10.3390/ma18092076

Ma Z, Wang X, Yu M, Chen S, Liu J, Li J, Wang J, Sun H, Mao Y, Hu Z, et al. Study of Properties of Composite Cementitious Materials with Sulfoaluminate Cement and Solid Waste Based on Compaction Forming Process. Materials. 2025; 18(9):2076. https://doi.org/10.3390/ma18092076

Chicago/Turabian StyleMa, Zhiyao, Xujiang Wang, Mushen Yu, Shouyan Chen, Jiwen Liu, Jingwei Li, Jianyong Wang, Hao Sun, Yanpeng Mao, Zhijuan Hu, and et al. 2025. "Study of Properties of Composite Cementitious Materials with Sulfoaluminate Cement and Solid Waste Based on Compaction Forming Process" Materials 18, no. 9: 2076. https://doi.org/10.3390/ma18092076

APA StyleMa, Z., Wang, X., Yu, M., Chen, S., Liu, J., Li, J., Wang, J., Sun, H., Mao, Y., Hu, Z., & Wang, W. (2025). Study of Properties of Composite Cementitious Materials with Sulfoaluminate Cement and Solid Waste Based on Compaction Forming Process. Materials, 18(9), 2076. https://doi.org/10.3390/ma18092076