The cemented sand and gravel (CSG) dam is a new type of dam whose performance lies between that of the concrete gravity dam and face rockfill dam [

1,

2,

3,

4]. Due to its material-saving properties, rapid construction speed, adaptability to soft foundations, excellent seismic performance, economic efficiency, and environmental protection, among others, it is widely used in various hydraulic structures. A CSG dam’s construction begins with foundation preparation, where the ground is leveled, compacted, and reinforced with grouting if necessary. Thereafter, a simple mix of local sand/gravel, cement, and water is blended in a batching plant to form the CSG material. This mixture is placed in 30–50 cm thick layers, with each layer compacted by vibratory rollers to achieve optimal density. Between layers, the surface (construction interface) is roughened or coated with mortar to ensure strong bonding [

5,

6]. If the construction interface cannot be properly handled, weak interface will be formed between the layers. Therefore, to ensure the safety of the CSG dam, it is crucial to analyze its mechanical performance considering the influence of the construction interface.

Up until now, studies on the mechanical properties of CSG materials have attracted great attention, and various constitutive models, including the linear elastic model [

7], equivalent linear elastic model [

8], modified Duncan–Chang model [

1], improved Saenz’s model [

9], elastic–plastic model [

10,

11,

12], damage hypo-plasticity constitutive model [

13], and multi-linear ideal softening model [

14], have been proposed, laying the foundation for the analysis of CSG dams. The mechanical behaviors of CSG dams were analyzed using a multi-linear ideal softening model based on the finite difference method by Huang and Zhang [

14], and the results showed that the failure mode of the dam was plastic yielding. To consider material non-uniformity, the static working behavior of CSG dams was studied by Huang et al. [

15] through the elastic random field model. The stress, strain, deformation, and failure mode of the Naheng Reservoir CSG dam were analyzed and discussed using the elastoplastic D-P model in [

16]. The Lattice Discrete Particle Model (LDPM) was first used by Chen et al. [

17] to model experimental tests of CSG materials, and the behavior of the prototype CSG dam under various loading conditions was also simulated using a multiscale technique in combination with LDPM. The seismic performance of a cemented sand and gravel (CSG) dam was assessed by accounting for two failure modes: tension cracking and base joint sliding [

18]. It is noted that the concrete damage plasticity (CDP) model and Mohr–Coulomb friction law were utilized to model the mechanical behaviors of CSG materials and dam–foundation interface, respectively. Based on the improved Saenz’s model, the load-bearing capacity of the CSG dam was evaluated by Zhao et al. [

9] using the strength-reduction method and the overload method. A nonlinear finite element program was programmed based on the proposed elastic–plastic model by Wang et al. [

10], and numerical simulations of high concrete-faced sand–gravel dams were conducted. Based on the design theories of concrete dams and earth-rock dams, profile design criteria for 100-m CSG dams with different cementing material content under different foundation conditions were proposed by Guo et al. [

2]. It is noted that the influence of the construction interface on the global mechanical behaviors of the CSG dams was usually omitted in the above studies.

To incorporate the effect of the construction interfaces of CSG dams, a continuum equivalent model was proposed to simulate the stratified structure of a CSG dam in [

8,

19], and its stress stability in the static state was analyzed. However, the effect of the construction interface on load-bearing capacity was neglected. For other types of dams, the influence of construction interfaces on their global behaviors was also concerned. The influence of construction interfaces on the dynamic characteristics of roller-compacted concrete (RCC) dams was analyzed by Gu et al. [

6], and the results showed that the combination quality of the RCC layers should be ensured to avoid fractures along the construction interfaces. To consider the effect of the construction interface and its seepage, a multipoint hybrid model for RCC arch dam displacement health monitoring was proposed by Liu et al. [

20], and the results showed that the displacement field of the dam changed due to the interface.

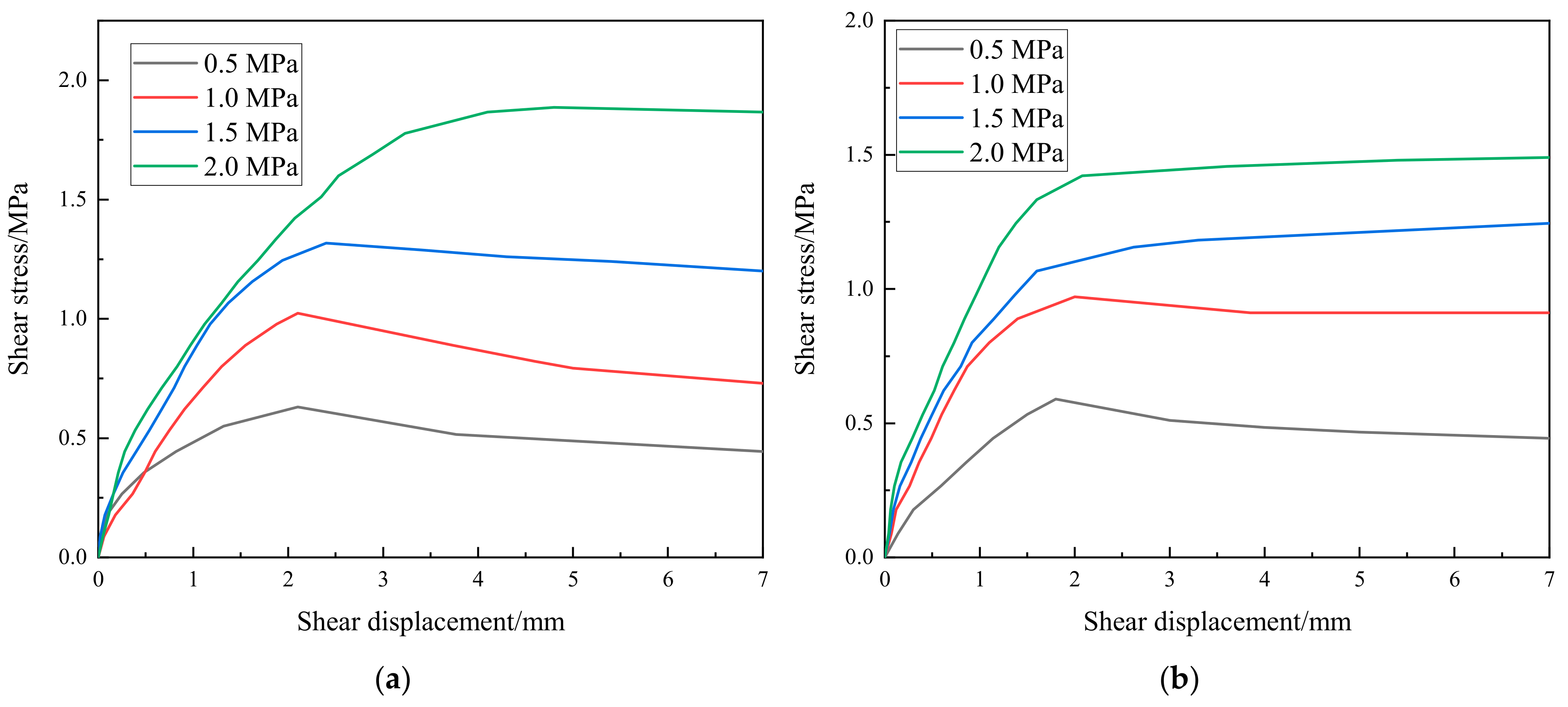

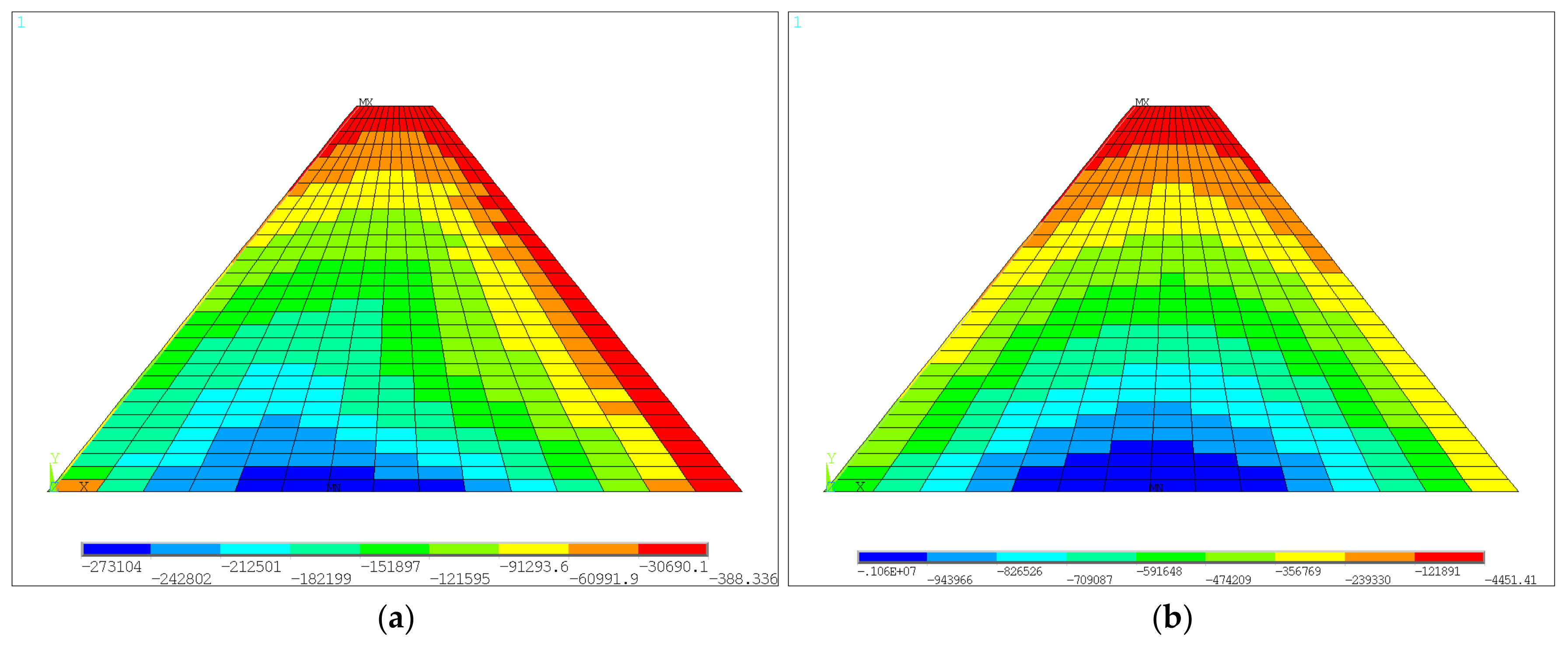

In summary, although a few studies on the influence of construction interfaces have been explored, their coverage of effects on the global mechanical behaviors of CSG dams are scarce. In this paper, direct shear tests of construction interfaces with roughening and laying mortar under four different normal pressures are first conducted to obtain interface parameters (cohesive stress and friction coefficient) for finite element modeling. Then, a modified Duncan–Zhang model for the CSG material is introduced. Thereafter, finite element models of the middle-low dam and 100-m dam are developed to analyze the effects of construction interfaces on horizontal and vertical displacements, first and third principal stresses, anti-sliding stability, and ultimate load-bearing capacity of the medium-low and 100-m CSG dams after the construction and service periods.